5

5

NCB300 NCB500 NCB700 LCB700

From high-performance combi technology with cutting-edge ON AI smart controls, to the UK’s first A+ energy-rated oil boilers, find out about the full Navien range today.

navien.co.uk

The new government is big on ambition. In the energy sector, as in other sectors of the economy, it has pledged change and regeneration.

The broad-brush picture is upbeat: it wants to double onshore wind, triple solar power and quadruple offshore wind. It says it will invest in carbon capture and storage and hydrogen, as well as long-term energy storage. And it’s targeting a zero-carbon grid by 2030.

One of its first steps will be to set up Great British Energy, a publicly-owned clean power company, paid for by windfall taxes on oil and gas giants. A new Energy Independence Act will set the framework for energy and climate policies. There’s no doubt that the government’s hands are very full. A lot of money is being pledged elsewhere, propping up the NHS and dealing with water companies, railways and prisons, among others.

While the industry has broadly welcomed the new government and its plans (see page 16), the honeymoon period won’t last forever. Many want to see the detail: will the cost of electricity be rebalanced more favourable compared with gas, encouraging households to see low-carbon heating as a real alternative? Will the Clean Heat Market Mechanism actually kick in next year? And what does the future hold for gas boilers?

Nicki Shearer, editor

Are you ready for Gas Safety Week? Will you join thousands of individuals and organisations to promote gas safety and raise national awareness? The free supporters’ toolkit has everything you need to get involved and show your support

Gas Safe Register, PO Box 631, DARLINGTON, DL1 9GD

Email: enquiries@gassaferegister.co.uk, register@gassaferegister. co.uk or technical@gassaferegister.co.uk

Managing editor: Sue Harker, sue.harker@gassaferegister.co.uk

Editor: Nicki Shearer, editorial@registeredgasengineer.co.uk

News: Jennie Ward, news@registeredgasengineer.co.uk

Publisher: Peter McCreary, publisher@registeredgasengineer.co.uk

Technical consultants: Rob Walkerdine, Carl Banister, Jonathan Palmer, Mike Cummings

Production: Mark Turpin

Advertising enquiries only: Ian Carter, ian@rgemagazine.co.uk

Additional print subscriptions £25 per year email: wgardiner@circdata.com, Tel 020 8149 9222

Registered Gas Engineer is written, designed and published by The Team on behalf of Gas Safe Register. 30 Park Street, London, SE1 9EQ

CIRCULATION: Jan-Dec 2023 78,987

The views expressed in this magazine are not necessarily those of Gas Safe Register. The publishers will accept an advertisement or other inserted material only on the condition that the advertiser warrants that such advertisement does not in any way infringe copyright or contravene the provisions of the Trade Descriptions Act. All copy is subject to the approval of the publisher, who reserves the right to refuse, amend, withdraw or otherwise deal with advertisements submitted to it at its absolute discretion and without explanation. All advertisements must comply with the British Code of Advertising Practice. ABC membership approved 19 March, 2009.

14

Why it’s important to keep your Gas Safe Register inspection appointment – and what could happen if you don’t

Illegal gas fitters and rogue traders brought to justice PLUS Tech Talk Episode 6 is now available on YouTube, looking at mobile catering and some of the questions that gas engineers ask

16

“Change begins now,” said the new Prime Minister. But what changes does the government plan in this sector?

18

The good, the bad and the ugly

21 Industry Standard Update 123

IGEM/G/11 Edition 2 with amendments July 2022 and June 2024: Gas Industry Unsafe Situations Procedure (GIUSP)

22 Technical Bulletin 055

Duties of landlords: Clarification on the requirements for landlords with regard to the Gas Safety (Installation and Use) Regulations 1998 (GSIUR)

32 Controls

Controls are a key area that the new government should prioritise; the best boiler control features to maximise energy efficiency; benefits of upgrading underfloor heating controls

The ventilation requirements for domestic meter banks 28 Boiler flues in high-rise buildings

What the Building (Amendment) Regulations 2018 – often referred to as the “high-rise combustibles ban” – mean for gas engineers

40 The Legislative, Normative and Informative Documents List

Cadent and Stay Energy Safe are teaming up to deter people from tampering with their gas meter and encourage the reporting of gas theft

38 Your business

How using automated software can speed up your work; The best way to buy a van

46 Towards net zero

What’s holding back heat pump installations? PLUS MCS reboot delayed until January 2025 49 Competition

We’ve teamed up with Monument Tools to give you the chance to win brand new plumbing tools

The latest launches from around the industry

A reception at the Houses of Parliament on 10 September will give prominence to Gas Safety Week and will welcome parliamentarians alongside gas safety champions. The event will include insightful speeches addressing gas safety and carbon monoxide awareness, as well as the pivotal role of registered engineers in gas safety.

Gas Safety Week is nearly here. From 9 until 15 September, the whole industry will come together with one common goal: to keep the nation gas safe.

The pan-industry campaign is now in its 14th year and this

year’s theme, “Checking— Every Check Counts”, emphasises the importance of regular gas safety checks and other simple checks that people can do to keep themselves gas safe.

Gas Safe Register has a new film that will encourage

people to think about their gas safety and the importance of checking gas appliances. It’s under wraps for now but we can tell you that we think you’ll recognise a familiar voice. The film will make its debut during the week itself.

Will you join thousands of individuals and organisations to promote gas safety and raise national awareness? It’s not too late to get involved: all the tools and materials you need to support the campaign are in the free Gas Safety Week 2024 toolkit, which you can still download at: www.gassafetyweek.co.uk

The toolkit includes a huge range of different materials to help you connect with your own customers and followers. And this year there are new and refreshed resources, including social media assets in Welsh.

You can use any or all of the images, logos and helpful content in the Gas Safety Week toolkit. It’s easy to use and can really help you stand out from your competitors, reach new customers and assure them of your professionalism and commitment to gas safety.

Not sure what to say? You can use the pre-written social media posts with a different daily gas safety focus. There’s a new video and social media images, as well as copy for all images. The video and social media images are available in English and Welsh. When you share social media posts, don’t forget to use #GSW24 and tag Gas Safety Week and Gas Safe Register, and they will share as many as they can.

2

Logos and images

Make your posts and messages really pop with a range of images, including general gas safety pictures, logos and the Safety Squad.

3 Leaflet and poster

You can download and print this year’s Gas Safety Week leaflet and poster. The leaflet includes a useful list of simple checks that your customers can tick off to ensure they and their loved ones are gas safe.

4 Articles and factsheets

If you’re looking for new content for your website, you’ll find copy tailored for consumers, landlords, tenants and the trade. There are also factsheets about carbon monoxide and advice for carers.

5 Press release kit

Here you’ll find templates and guidance on how to work with the media to reach out to your community.

5 million Logics and counting!

We have the UK’s widest range of underfloor heating systems. Combine this with our expert sales advisers, and you can see why Continal always provides the best solutions.

We design all our systems to work with any heat source, floor construction and covering. Whatever your project we have the solution.

Why it’s important to keep your Gas Safe Register inspection appointment – and what could happen if you don’t.

You can find out more about what to expect and how to prepare for your upcoming inspection at www.registered gasengineer. co.uk – search for ‘Inspection’.

When you are invited for your inspection, it’s important to keep your appointment: If you cancel or don’t attend, sanctions may be applied to your business, which could have an impact on you carrying out gas work legally.

Whether you’ve been invited to a standard work inspection, a virtual inspection event (VIE) or a more focused inspection that deals with applied competence or gas safety concerns raised by consumers, you’ll receive four to six weeks’ notice of the date and time.

You’ll usually be notified by email if that is your preferred communication method with the Register, and this will include details of the type of inspection.

Important: Check your email settings to make sure that communications from Gas Safe Register are not landing in your spam or junk folders.

Please keep your inspection appointment: cancellations are costly and cause inefficiencies for the Register. If you need to change your inspection appointment for a justified

Virtual Inspection Events are carried out online and hosted by a specially trained team of advisors and technical officers. They incorporate a pre-assessment briefing and an online knowledge-based technical assessment that is based on your registration work categories and unsafe situations.

Gas Safe Register operates a risk-based inspection programme using a range of factors to profile the risk applied to businesses and individuals and determine the frequency of inspection. These factors include but are not limited to:

• The certification/awarding bodies used for qualifications

• Engineer demographic

• Previous inspection history, including any unsafe gas work accredited to the registration

• Any gas safety concern history

• Business size (number of employed engineers)

• Location of the business’s registered address or regional depot

• Gas safety qualifications and resultant work categories

• Scope of gas work undertaken, eg, domestic, commercial, etc

• Any pre-existing registration history.

The frequency of inspection can vary depending on these factors but most businesses will be inspected every two to three years.

For all new (probationary) registrations, a work inspection is mandatory within three months of joining the Register. www.GasSafeRegister.co.uk/about-us/our-policies/

reason – such as sickness or a pre-booked holiday – please contact Gas Safe Register as soon as you can with your available dates.

Not allowing a work inspection without a justified reason is a breach of the Rules of Registration and will result in sanctions being applied to your business. Failure to attend a re-arranged appointment will result in sanctions being applied to your business.

Gas Safe Register will apply a sanction if you do not attend your inspection and didn’t contact them before this. n

Tech Talk Episode 6 is now live Episode 6 of Tech Talk is now available on Gas Safe Register’s YouTube Channel. This time, Rob and Jon from the Technical Team discuss the topic of mobile catering.

They answer some of your most frequently asked questions about qualifications, essential safety features, clearances, ventilation, pipework and cleaning products.

Tech Talk is a regular series that helps you stay up to date with the topics that matter to you and your work, and you can find them on Gas Safe Register’s You Tube playlists.

• You can read more about mobile catering in the July/August 2024 edition of this magazine.

A sole trader has been given a suspended prison sentence for taking payments for work he did not carry out and misleading customers that he was Gas Safe registered.

Jason Wornes, from Hampton Hill in South-west London, was prosecuted by London Borough of Hillingdon’s Trading Standards Service, which said customers had complained about him through the Citizens Advice consumer helpline and directly to the local authority.

London Borough of Hillingdon said Mr Wornes had carried out work in two London boroughs. In Harrow, one customer paid a deposit of £1,510 for a new boiler but Mr Wornes did not return.

Another customer paid £580 for two radiators but he did not come back to fit them.

In Hillingdon, he told customers he was Gas Safe registered when he was not. He also provided a business card with the name of a limited company that had been dissolved. He fitted a boiler badly and failed to provide cancellation rights.

At Uxbridge Magistrates Court, Jason Wornes pleaded guilty to breaches of The Consumer Protection from Unfair Trading Regulations 2008, namely:

• He contravened the requirements of due diligence, contrary to Regulation 8, by fitting a boiler incorrectly and displaying Gas Safe logo

on a business card;

• He misled customers by claiming to be a company that had dissolved, he falsely claimed to be Gas Safe Registered, and falsely stated that he would install new boilers and replace radiators, contravening Regulation 9;

• He failed to provide cancellation rights, breaching Regulation 10.

Mr Wornes was sentenced at Isleworth Crown Court, where he was given a four-month prison sentence, suspended for 12 months and ordered to carry out 80 hours of community service. He was also ordered to pay £1,000 in legal costs to the council, and compensation of £1,510 and £580 to two customers.

An illegal gas fitter who carried out dangerous work in a mobile park home has been given a suspended prison sentence.

Bristol Magistrates’ Court heard that Christian Davis from Bristol was self-employed and traded as BS1 Plumbing and Heating. He carried out gas work illegally as part of the renovation of a mobile park home in Hallen between June and July 2020. Some of the work included installing pipework, a boiler and gas hob.

The HSE, prosecuting, carried out the investigation and told the court that Mr Davis fitted an LPG boiler but there was no securing clamp on the chimney/ flue, leaving a clearly visible gap. The gas hob was found to be Immediately Dangerous and showing a yellow flame due to incomplete combustion. On the

pipework underneath, bubbles could be seen coming from the soldered joint.

Mr Davis falsely claimed he was Gas Safe registered but had been removed from the Register due to concerns about the standard of his work and his competence.

Christian Davis, of Callington Road, Brislington, Bristol, pleaded guilty to breaching Regulations 3(1), 3(3) and 3(7) of the Gas Safety (Installation and use) Regulations 1998. He was given a 48-week prison sentence, suspended for two years. He was ordered to pay £3,000 in compensation to the homeowner plus £5,000 costs.

The District Judge told him that he could have killed someone and that she was relieved to find out he no longer

holds himself as competent to carry out gas work. He now runs a burger restaurant and has no connection to the plumbing and gas industry.

An illegal fitter from County Down has been given a suspended prison sentence after carrying out gas work despite having been prohibited from doing so.

Newtownards Magistrates Court heard that Ian Campbell, trading as MGB Gas and Building Services, had replaced the gas boiler at a property in Bangor, County Down, in November 2022 although he was not registered. The installation was subsequently

classified At Risk.

The investigation by HSENI, prosecuting, also found that Mr Campbell was working on gas illegally despite having been prohibited from doing so by HSENI in February 2023.

He was charged with one breach of the Gas Safety (Installation and Use) Regulations (Northern Ireland) 2004 and two breaches of the Health and Safety at Work (Northern Ireland) Order 1978. He was sentenced to four

months in prison for each breach, suspended for three years.

Mr Campbell was ordered pay £1,750 in compensation to the homeowner of the Bangor property, and received additional one-month sentences, suspended for three years for two health and safety offences with which he was charged during a previous court hearing on 12 April 2022. The previous offences also related to unsafe gas work.

“Change begins now,” new Prime Minister Sir Kier Starmer said following Labour’s landslide election victory. But what changes does the new government plan in this sector?

The government got off to a quick start with the appointment of Ed Miliband as the Secretary for Energy Security and Net Zero: he was in charge of the Department for Energy and Climate Change, as it was known then, back in 2008-2010.

Mr Miliband said: “Our department will be at the heart of the new government’s agenda, leading one of the Prime Minister’s five national missions, to make Britain a clean energy superpower with zero-carbon electricity by 2030, and accelerating our journey to net zero.”

The government has pledged to end the former administration’s chopping and changing on energy policies and says its Green Prosperity Plan will be a partnership between the public and private

sectors, aiming to create 650,000 jobs by 2030, boosting energy security and investing in insulating homes.

On low-carbon energy, it says: “Labour will work with the private sector to double onshore wind, triple solar power, and quadruple offshore wind by 2030. We will invest in carbon capture and storage, hydrogen and marine energy, and ensure we have the long-term energy storage our country needs. A new Energy Independence Act will establish the framework for Labour’s energy and climate policies.”

At the heart of its energy policies is the creation of Great British Energy, a publicly owned company with its HQ in Scotland. The government will introduce a Bill to set up the company, which it says will own, manage and operate clean power

“We welcome the new government’s manifesto pledge of £6.6 billion into the Warm Homes Plan, which will aim to upgrade 5 million homes and cut bills for families through insulation and other measures, including heat pump installs. We look forward to details surrounding home upgrades, to be clarified in the coming weeks.

“Engaging consumers must be a priority for the new government: heat pumps are the lowest-carbon heating solution and therefore should reward homes with lower energy costs.”

Mark Wilkins, Technologies and Training director, Vaillant

“The announcement of the new GB Energy firm is an opportunity to fast-track the UK’s clean power goals, and ultimately deliver cost savings for households and businesses across the country.”

“While the beneficial effects of the clean power scheme are apparent, the government must simultaneously recognise the low-hanging fruit solutions already within reach to help cut energy bills fast, by focusing on providing energy efficiency. Lack of awareness around how to optimise heating systems, such as through hydraulic balancing or replacement of old circulator pumps, costs households and businesses £3.1 billion each year.”

Glynn Williams, UK managing director, Grundfos

projects all over the UK.

Great British Energy will invest in partnership with the private sector with capitalisation of £8.3 billion of ‘new money’ over the Parliament.

The government says: “The Bill builds on the immediate work by the Energy Secretary to deliver the government’s mission to achieve clean energy by 2030, including scrapping the ban on onshore windfarms and appointing Chris Stark to lead the Mission Control for 2030.”

On energy bills, it wants to toughen up regulation and reduce standing charges, as well as upgrading the national transmission infrastructure.

And for the UK’s homes, it says it will invest an extra £6.6 billion pounds over the next Parliament to upgrade 5 million homes. Its Warm Homes Plan “will offer grants and low-interest loans to support investment in insulation and other improvements such as solar panels, batteries and low-carbon heating to cut bills. We will partner with combined authorities, local and devolved governments to roll out this plan.

“Labour will also work with the private sector, including banks and building societies, to provide further private finance to accelerate home upgrades and low-carbon heating.” n

One of the Energy Secretary’s first moves was to appoint Chris Stark to head its new Mission Control, which will drive the UK’s shift to clean power by 2030. Mr Stark formerly headed the Climate Change Committee.

Mission Control will focus on accelerating the transition away from fossil fuels to clean power, says DESNZ, describing it as a “one-stop shop, bringing together a top team of industry experts and officials to troubleshoot, negotiate and clear the way for energy projects”.

It will work with energy companies and organisations including the regulator Ofgem, National Grid and the Electricity System Operator to remove obstacles and identify and resolve issues as they arise. It will target speeding up the connection of new power infrastructure to the grid, and cleaner, cheaper power.

Lawrence Slade, chief executive of Energy Networks Association (ENA) – which represents the UK's electricity network operators – said: “Delivering the clean power mission requires a staggering amount of coordination. Chris's expertise will be invaluable in this role.”

“Redistribution of policy costs from electricity bills and better representation of the generation mix in the unit cost build-up are some of the activities that need to be progressed. “To make heat pumps and electrically-driven systems a truly massmarket proposition, the running costs, compared to a gas boiler, need to be attractive and lower-carbon options should become the affordable, default choice.”

Jeff House, director of External Affairs and Policy, Baxi

“We urge the new government to pursue robust, clear regulatory changes and policy developments that remove unnecessary barriers to the widescale deployment of heat pumps, such as the implementation of the Future Homes Standard, changes to permitted development rights and provide clarity on the future of the Clean Heat Market Mechanism.”

Charlotte Lee, chief executive, the Heat Pump Association

“Ed Miliband’s remarks about moving away from a strict 2035 gas boiler ban and addressing concerns about prematurely replacing gas boilers show a practical and affordable approach to sustainable heating solutions.

“The agnostic stance on available technologies is a positive development. It suggests a willingness to explore various heating solutions rather than enforcing a one-size-fits-all policy, and indicates considerable effort in researching effective paths to meeting net-zero targets.

“While promising, the focus must be on practical implementation for success, benefiting installers, homeowners and the environment.”

Graham Parkes, commercial director, Navien UK

Registered Gas Engineer wants to see your pictures –whether you’ve come across some horrors or instances of really good work. Please email your stories and pictures to editorial@registeredgasengineer.co.uk

Paul’s customer had noticed an odd smell while they were cooking. Paul soon saw that the hob burner was melting the sockets above. He disconnected, made safe and advised on clearances.

FROM KEV BONNAR

Kev’s customers’ CO alarm had gone off and they had a headache. He advised them to contact the emergency gas supplier, who made safe. Kev found the flue had been disconnected accidentally after external decorating of the residential park home. It had not been secured or sealed.

Samuel’s customer had badly distorted pipework to their dual fuel gas hob. Sam replaced the pipework and fitted a new appliance in line with the manufacturer’s installation instructions.

Dan found a makeshift connection piece for a boiler’s inner flue hidden under some closure plate tape. The can dated from 2004.

This boiler was leaking because the pressure relief valve/condensate discharges were not connected, and the chimney/flue was not sealed. The installation was made safe and Jason quoted for it to be brought up to standard.

No access to the Emergency Control Valve (ECV) is one thing, but no access to the property because of the meter installation was a new one to Paul.

While Luke was removing a boiler, he noticed a huge gap between the chimney/flue and elbow that was hiding behind the collar.

Rob was replacing a gas fire with an electric fire. He removed the fire from a precast chimney/flue and noticed the bottom starter block had been knocked out – or never put in. Nothing was sealed, allowing fumes to enter the cavity. Up on the roof, the ridge vent/twin-wall outlet had been tiled over. The second photo highlights where the fireplace was.

We may share some of your pictures on social media, so remember to include your contact details so we can tag you (or let us know if you’d rather we didn’t).

Introducing new Hep2O Keyless – developed hand-in-hand with plumbers for an even easier and speedier fit. With two great Hep2O systems to choose from, to key or not to key is now the only question.

Smaller, streamlined design

Key-free: Twist and push for easy demounting

Optimised flow rate

Supplied locked for an even speedier fit

50-year guarantee

Industry Standard Update 123

IGEM/G/11 Edition 2 with amendments July 2022 and June 2024: Gas

Date issued: 18 July 2024

This Industry Standard Update provides an overview of the key areas of change arising from the revision of IGEM/G/11 Ed 2, the GIUSP, with amendments (July 2022 and June 2024).

Introduction

In June 2024, an updated version of IGEM/G/11 Edition 2 with amendments July 2022 and June 2024 Gas Industry Unsafe Situations Procedure(1) (GIUSP) communication 1887, was released. This revised procedure supersedes the IGEM/G/11 Edition 2 with amendments July 2022 Gas Industry Unsafe Situations Procedure(2) (GIUSP) communication 1866, which has been withdrawn.

The revision to this standard comes into effect immediately.

The guidance in this standard is relevant to all competent engineers and is based on the assessed risk when they encounter situations that have a potential or an immediate effect on safety.

The priority for gas engineers when dealing an unsafe situation is to safeguard life and property.

The standard covers all commissioned gas installations, equipment and appliances installed in all domestic and non-domestic premises.

The following is a brief overview of the amendments made in the update to IGEM/G/11.

The scope of GIUSP has been expanded to include natural gas, liquefied petroleum gas and hydrogen, as defined in Gas Safety (Installation and Use) Regulations 1998(3) (GSIUR).

Clause 3.1 clarifies that anyone working on gas installations is duty bound to comply with the law (particularly The Health and Safety at Work Act etc 1974(4) and GSIUR), and that IGEM/G/11 is a guidance document that provides an agreed industry approach on how those working on gas installations may comply with those requirements of law.

A note below Clause 3.3.2 clarifies that where non-metallic (eg, PE) service pipework is connected to metallic pipework within the building, the metallic pipework may not require equipotential earth bonding.

Table 1 gives examples of unsafe situations. However, the list is not exhaustive and engineers shall use their engineering judgement if their situation differs from Table 1.

There have only been two changes to Table 1 in this update, which are:

• Scenario 2.8 gives expanded guidance on dealing with a potential pathway for to gas to enter property from meter boxes (eg, damaged boxes). Where a damaged meter

box cannot be repaired or sealed, ensure the gas user/responsible person is advised and the gas supplier is informed where a pathway for gas into the property exists.

• 3.19 gives guidance for where equipotential bonding is not installed or inadequate but clarifies that this guidance is only for where bonding is required and refers back to clause 3.3.2.

Appendix 5 of IGEM/G/11 gives guidance on the procedure of a visual risk assessment of a gas appliance. This guidance has been changed to clarify that generally a visual risk assessment is for visually apparent defects only and does not require moving an appliance or any building infrastructure, unless the gas engineer has any concerns. It also now states that the expression ‘safe to use’ is not to be applied to a visual risk assessment, as this would imply that a full 26 (9) examination has been performed.

You can view IGEM/G/11 by logging in to your Gas Safe Register online account and visiting the technical information area at www.GasSafeRegister. co.uk/sign-in

It’s also available at www.igem.org.uk and search for G/11.

This Industry Standard Update is an overview of the information contained in the amended standard. Gas Safe registered engineers/businesses should be aware that they have a responsibility to ensure that they are fully apprised of all the requirements of the whole published standard and their practical application.

Bibliography

(1) IGEM/G/11 Ed 2 Gas Industry Unsafe Situations Procedure with amendments July 2022 and June 2024 (Communication 1887)

(2) IGEM/G/11 Ed 2 Gas Industry Unsafe Situations Procedure with amendments July 2022 (Communication 1866)

(3) GS(IU)R Gas Safety (Installation and Use) Regulations 1998 (amended)

(4) The Health and Safety at Work Act etc 1974

Date issued: 24 June 2024

Note: This version of Technical Bulletin (TB) 055 replaces the version published on 3 June 2021, which is now withdrawn. This version has been reviewed and revised where appropriate to ensure that it remains both current and relevant.

This Technical Bulletin provides clarification to Gas Safe registered businesses/engineers on certain requirements for landlords with regard to the Gas Safety (Installation and Use) Regulations 1998 (GSIUR).

Introduction

This Technical Bulletin (TB) has been written to provide registered gas businesses/ engineers working in Great Britain (GB) with greater clarity on Regulation 36 of the Gas Safety (Installation and Use) Regulations 1998 (GSIUR). For additional guidance, please see the HSE publication L56 Safety in the Installation and use of Gas Systems and Appliances(1), which is the Approved Code of Practice and guidance document that accompanies GSIUR.

Note 1: Similar requirements apply in other geographical areas covered by Gas Safe Register. For details of current health and safety legislation, gas safety legislation, building legislation and industry standards for the geographical areas covered by Gas Safe Register, see the Legislative, Normative & Informative Document List (LNIDL)(2) by logging in to your online account at: www. gassaferegister.co.uk/sign-in

Note 2: Although the following guidance applies particularly to GB, the health and safety enforcing authorities in all geographical areas covered by Gas Safe Register, ie, GB, Northern Ireland, Isle of Man

and Guernsey, regard the guidance in this TB as a best practice requirement and would expect all Gas Safe registered businesses/engineers to apply its requirements when and where appropriate circumstances/relevant installations are encountered.

Q1. Does Regulation 36 of GSIUR apply to hotel rooms used for residential purposes?

A1. Regulation 36 applies to any relevant gas fitting (appliance and pipework) that directly or indirectly serves hotel rooms. This duty extends to any chimney/flue that serves any relevant gas fitting.

Regulation 36 places two main related but distinct duties on hotels acting as a landlord:

• To maintain any relevant gas fitting (gas appliances and pipework supplying gas appliances) and associated chimneys/flues serving hotel rooms; and

• To undertake an annual gas safety check of all gas appliances and chimneys/ flues serving hotel rooms.

Hotels should display (in a prominent position for guests) a copy of the record of the annual safety check, often called the Landlord’s Gas Safety Record (LGSR), covering all relevant gas appliances and

chimneys/flues. This should include appliances indirectly serving hotel rooms such as boilers in a boiler house.

The LGSR does not need to record gas appliances, installation pipework or chimneys/flues exclusively used for non-residential parts of the hotel (eg, public bars).

Gas appliances, installation pipework or chimneys/flues exclusively used for nonresidential parts of a hotel are required to be maintained in a safe condition by Regulation 35 of GSIUR.

Q2. What equipment is covered by Regulation 36 of GSIUR (a landlord’s duties) in relation to tenanted properties?

A2. Regulation 36 applies to any relevant gas fittings (gas appliances and pipework supplying gas appliances) and any chimney/flue that serves the relevant gas fitting.

The definition of a relevant gas fitting set out in Regulation 36 excludes a tenant’s own gas appliance(s) (eg, gas cooker) – however, it covers the installation pipework supplying the gas appliance.

If, as part of an installation, a tenant supplies their own chimney/flue to serve their gas appliance (eg, serving a gas AGA), it falls outside the

landlord’s Regulation 36 duties. If the tenant moves out and leaves gas appliances and chimneys/flues in situ, these will be adopted by the landlord and fall under the landlord’s Regulation 36 duties for the next tenant.

Q3. What should I do when I find open-flued appliances in rooms used temporarily as sleeping accommodation, eg, by elderly people or those with disabilities?

A3. Legislation does not make any allowance for temporary use. Therefore, if the appliance(s) has a heat input greater than 12.7kW net (14kW gross) or less than 12.7kW but does not incorporate a safety control designed to shut down the appliance before a dangerous quantity of products of combustion builds up in the room, the installation does not comply with current requirements. As such it should be classified as At Risk (AR) in accordance with the current IGEM/G/11(3), Gas Industry Unsafe Situations Procedure (GIUSP), until the situation can be resolved.

Where tenants have altered their sleeping arrangements as described above, landlords have a duty of care under Section 3 of HSWA (4), to take reasonably practical steps to ensure the safety of their tenants. They could therefore consider:

• Replacing/removing the appliance(s)

• Re-housing the tenant into other suitable

accommodation.

In the event of an incident occurring in such premises, it would be for the landlord to show that they did all that was reasonably practical to avoid the incident occurring.

Q4. If I make a mistake completing the LGSR, can I make a change to the information I have recorded?

A4. For minor amendments, such as incorrect postcodes or telephone numbers, then it may be possible to change the record, but only within a reasonable period of time, eg, within one to two weeks of the check being undertaken. Changes would need to be made by the registered business that undertook the work and the change should be signed so that an audit trail can be maintained. The amended copy (showing the changes) of the record should be given to the landlord.

No changes should be made to any technical data or test results. If an error was made, the check would need to be redone and a new record issued.

Where the date on which the check was undertaken is found to be incorrect, the check would need to be redone and a new record issued.

Q5. Do I have to record all and any type of defect on a LGSR?

A5. Only safety-related defects, ie, ID or AR defects on “relevant gas fittings” are required to be recorded on the LGSR.

All safety defects must be addressed by the landlord, as required by Regulation 36(2) of GSIUR.

Q6. Do I have to record the tenant’s own gas appliance(s) on the LGSR?

A6. Tenant’s own appliances are not required by GSIUR to be recorded on the LGSR.

Q7. Where a contractual agreement dictates that a tenant’s own appliance(s) (appliances not owned by the landlord) is recorded on the LGSR, what is recorded in the ‘Safe To Use’ section on the paperwork or electronic device?

A7. Landlords/clients may require (through a contractual agreement) that a registered gas engineer records a tenant’s own appliance(s) on the LGSR. If this is the case, there is guidance in IGEM/G/11, the Gas Industry Unsafe Situation Procedure (GIUSP), which clearly guides the gas engineer through a visual risk assessment: “Generally, a visual risk assessment is for visually apparent defects only and does not require moving an appliance or any building infrastructure unless the engineer has concerns. The expression “Safe to Use” should not be applied to a visual only assessment as this expression implies a full 26(9) examination has been performed”.

For a tenant’s own appliance(s), a visual inspection only should be carried out and no further checks are required. >

Date issued: 24 June 2024

Where a visual inspection only is carried out on a tenant’s own appliance, it is advised that “N/A” is recorded in the “Safe To Use” section of the LGSR.

Visual checks alone cannot confirm an appliance or installation is safe to use. If the visual inspection identifies safety issues on the appliance, then “No” should be recorded in the “Safe To Use” section, and IGEM/G/11 should be followed.

Note 3: There can be difficulty changing some electronic recording devices which are a pre-set programme not allowing any variations: however, it is recommended over time these will be adjusted to deliver an industry-consistent message.

Q8. Do I have to record all and any types of defect on a tenant’s own appliance(s) on the LGSR?

A8. If the RGE has entered No in the “Safe To Use” section of the form covering a tenant’s own gas appliance, it is advised that the action taken in accordance with IGEM/G/11 (GIUSP) is recorded.

Q9. Is a safety check the only legally required duty on landlords to be completed within each 12 months on “relevant gas fittings”, ie, landlord’s gas appliances?

A9. Landlords are also required to maintain any relevant gas fitting (eg, gas appliances and pipework supplying gas appliances) and associated

chimneys/flues in a safe condition.

An example of effective maintenance would be a full service of the landlord’s appliances, along with a visual inspection of the rest of the installation and a gas tightness test.

Q10. Is there any leeway in the renewal date of the safety check?

A10. The renewal date is the date by which the next safety check must be carried out (within 12 months). There can be no overrun of this date.

Regulation 36A of GSIUR allows for “MOT-style” checks to be carried out up to two calendar months early while retaining the renewal date.

For example, a landlord’s gas safety check due for renewal on 12 April 2024 can be carried out between 12 February 2024 and 12 April 2024. The next 12-month period would run from 12 April 2024 and so the next renewal date would be 12 April 2025.

A landlord is required by GSIUR to retain the last two (years) LGSRs. If the landlord does not have complete records demonstrating compliance with Regulation 36 of GSIUR then the renewal date will be taken as 12 months from the date of the last gas safety check.

To conform to the requirements of Regulation 36(2) & 36(3) of GSIUR, a landlord needs to:

a) Ensure that appliances and

chimneys/flues to which the landlord’s duty extends are checked for gas safety at periods not exceeding 12 months.

b) Although installation pipework is not covered by the requirements of the annual safety check, there is a requirement for landlords to ensure that it is maintained in a safe condition. It is generally accepted that a test for tightness on the whole gas system, including installation pipework, together with visual examination (as far as is reasonably practicable) of the pipework, be made at the same time as the safety check.

Note 4: Newly installed gas appliances must be checked for gas safety within 12 months of installation. It is, however, recommended that at the date of the safety check, all installed appliances are checked for gas safety, so as to bring them in line with the date of the annual safety check (otherwise more than one visit would be required).

c) Ensure that a record in respect of any appliance or chimney so checked is made and retained until there have been two further checks of the appliance or chimney under this paragraph or, in respect of an appliance or chimney that is removed from the premises, for a period of two years from the date of the last check of that appliance or chimney. The record shall include the

following information:

(1) The date on which the appliance or chimney/flue was checked

(2) The address of the premises at which the appliance or chimney/flue is installed

(3) The name and address of the landlord of the premises (or, where appropriate, an agent) at which the appliance or chimney/flue is installed

(4) A description of and the location of each appliance or chimney/flue checked

(5) Any safety defect identified (6) Any remedial action taken (7) Confirmation that the check undertaken complies with but is not limited to, an examination of the requirements referred to in sub-paragraphs (a) to (d) of Regulation 26(9) of GSIUR; (8) The name and signature of the individual carrying out the check, and (9) The registration number with which the individual or their employer is registered with Gas Safe Register (for the purposes of Regulation 3(3) of GSIUR).

Note 5: Regulation 36(3)(c)(v) requires that safety defects, ie, ID or AR defects on “relevant gas fittings” are recorded on the LGSR.

Regulation 26(9) of GSIUR requires that after “work” has been undertaken on a gas appliance, RGEs need to undertake the necessary gas safety checks and tests to ensure that the appliance and any associated chimney/flue, is safe for continued use. They need to examine: (a) The effectiveness of any flue

(b) The supply of combustion air (c) Subject to paragraph (ca) (below), its operating pressure or heat input or, where necessary, both (ca) If it is not reasonably practicable to examine its operating pressure or heat input (or, where necessary, both), its combustion performance (d) Its operation so as to ensure safe functioning.

Note 6: Regulation 26(9) (d) would include any appliancespecific or manufacturerspecified safety checks, eg, combustion analysis.

The term “work” is defined in GSIUR and lists specific activities, which are:

• Maintaining, servicing, permanently adjusting, disconnecting, repairing, altering or renewing the fitting or purging it of air or gas

• Where the fitting is not readily movable, changing its position

• Removing the fitting. Where an annual gas safety check or other maintenance work involves an appliance incorporating a pre-mix burner and a zero-set pressure regulator, and the installation does not incorporate a gas meter (eg, many LPG installations), it will not be possible to check the heat input or burner pressure. This is a requirement of Regulation 26(9)(c) of GSIUR. In such circumstances, provided that the RGE is equipped with a suitable electronic combustion gas analyser (ECGA) that is both operating in current calibration

and capable of measuring a combustion ratio, then a satisfactory combustion ratio reading in accordance with the manufacturer’s published value or BS 7967(5) will be acceptable as an alternative check.

Measuring the gas inlet working pressure on a boiler fitted with an air/gas ratio valve would not fulfil the requirements of Regulation 26(9)(c).

Note 7: For further guidance on the use of an ECGA to confirm safe operation of a gas appliance, see TB 013(6) and TB 143(7)

Note 8: For guidance about the use of electronic records and signatures in relation to a landlord’s gas safety record check, refer to TB 076(8)

Note 9: For general information about the process behind the development of Gas Safe Register Technical Bulletins and the expectations for all stakeholders, see TB 1000(9)

For further guidance on the duties of landlords in GB, visit:

• www.hse.gov.uk/gas/ landlords/

• www.hse.gov.uk/gas/ domestic/faqtenant.htm

• www.hse.gov.uk/gas/ domestic/faqlandlord. htm

• www.hse.gov.uk/gas/ landlords/ gassaferecord. htm#standard

Bibliography

(1) HSE L56 – Safety in the installation and use of gas systems and appliances - Approved code of Practice and Guidance to the Gas Safety Installation and use) Regulations

(2) LNIDL – Gas Safe Register Legislative, Normative & Informative Document List

(3) IGEM/G/11 – The Gas Industry Unsafe Situations Procedure (4) HSWA –Health and Safety at Work etc Act 1974

(5) BS 7967: 2015 –Guide for the use of electronic portable combustion gas analysers for the measurement of carbon monoxide in dwellings and the combustion performance of domestic gas-fired appliances

(6) TB 013 – Air/Gas ratio valves

(7) TB 143 – CO and combustion ratio checks using an Electronic Combustion Gas Analyser (ECGA) when commissioning a condensing boiler incorporating air/gas ratio control valve technology.

(8) TB 076 – Electronic records and signatures - Information for landlords and gas installation businesses (9) TB 1000 – An introduction to Gas Safe Register Technical Bulletins

Gas Safe Register’s Technical Team receive a substantial number of queries about meter banks in buildings of multi-occupancy. Here, they take a closer look at domestic meter banks, focusing on the ventilation that is needed.

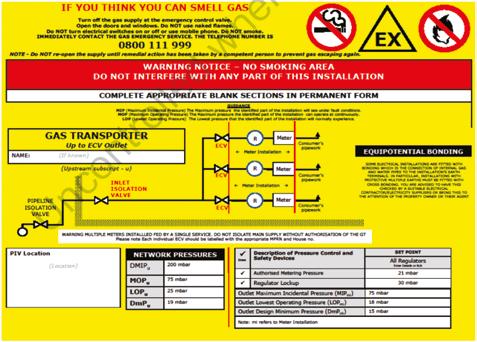

When working at buildings of multi occupancy, it can be common to find that the incoming gas supply and meters are located remotely to the dwelling they serve. Sometimes they are in individual external meter boxes and sometimes in a specific housing or enclosure. These multiple primary meter installations or “meter banks” have specific requirements when installed internally.

What is a meter bank?

When two or more domestic low-pressure gas meters are installed in a room, it is classed as a meter bank. They generally share one incoming gas supply and are fed from a manifold. Each meter will be labelled to indicate the flat or dwelling that it serves. These areas, whether classed as a compound, enclosure or meter house, require ventilation direct to outside air.

How much ventilation do they need?

From here, we can take guidance from IGEM/G/5 Edition 3 – Gas in multi-occupancy buildings with amendments April 2023. Section 8.3.2.1 states: “The total effective area (free area) shall be not less than the lower of 2 per cent of the internal floor area or its notional equivalent area. When ventilation is provided in one wall only, the minimum effective area shall be increased from 2 per cent to 3 per cent.”

The first step is to measure the wall, floor or ceiling –whichever has the greatest dimension – to calculate the ventilation required. The ventilation will then be distributed evenly to give us the high-level and low-level ventilation required.

The following example uses a small enclosure with a floor space of 2m x 1m, to be ventilated using more than one wall.

First, we measure the space 2m² x 1m² = 2m².

Then calculate 2 per cent of 2m² = 0.04²m (400cm²). This would be distributed evenly at high and low level on all external doors/walls.

Ventilating using one wall only would be 2m² x 1m² = 2m².

Then calculate 3 per cent of 2m² = 0.06m² (600cm²). This would be distributed at high and low level on the wall/door that is available to use.

In some cases, it may be difficult to calculate the room area. This can be due to abnormal room layouts, partitions or because the room is so large that using the wall/ floor space as a guide would give unrealistic ventilation requirements. In such cases, we can use its notional equivalent.

The notional equivalent floor area is the floor area of a typical

prefabricated housing for the particular size of gas meter installation. This calculation method would use the number of gas meters installed, as opposed to the floor area. The notional method would allocate an area of 0.5m² to each gas meter, as the following calculation (taken from IGEM/G/5) illustrates.

Note: The total effective ventilation area shall not be less than 2 per cent of the internal floor area or its notional equivalent area.

Using the 10 x gas meters ventilated to one wall example, this would be as follows: 10 gas meters @ 0.5m² per meter = 5m².

Calculate 3 per cent of 5m² = 0.15m² (1500cm²). This would be distributed evenly at high and low level.

Ventilation height

The low-level ventilators should be at least 150mm above the floor level. High-level ventilators should be as close as possible but not more than 10 per cent of the total height below the roof/ceiling level.

What if there is no outside wall?

The enclosure/space requires natural ventilation direct to outside, which may be ducted if required. Careful consideration should be given to fire resistance of any duct, unless fire-protection measures are not relevant.

Other considerations

• The room or enclosure must be designed so that any escaping gas will not pass into any habitable part of the building and must be compliant with fire regulations.

“Meter banks have specific requirements when installed internally.”

A typical example of what to display on a meter bank enclosure/ housing.

• The meter bank house door shall be self-closing and kept locked. However, the consumer/responsible person shall always have access to it. Keys shall be made readily available for reading the gas meter and in case of an emergency to access the Emergency Control Valve (ECV.) The room shall always be openable from the inside.

• Smoking and the use of naked flames are prohibited.

• A sign displaying where the keys can be found shall be displayed on the door. This is to help people such as meter readers and the Emergency Service Provider (ESP) to gain access. The sign displayed should list all the following details:

- Action to take in the event of a gas escape

- A diagram of the installation pipework

- An EX label indicating a hazardous area

- No smoking label

- Gas pressures

- Equipotential bonding information

- Security seals. ■

Gas Safe Register’s

Technical Team looks at what the Building (Amendment) Regulations

2018 – often referred to as the “high-rise combustibles ban” –mean for gas engineers.

In June 2018, the Ministry of Housing, Communities and Local Government (MHCLG) consulted on banning combustible materials within any space forming part of the external walls of relevant high-rise buildings – such as new blocks of flats, hospitals, residential care homes and student accommodation. This followed the Grenfell Tower fire in June 2017.

The subsequent amendment to Building Regulations for England and Wales 2010 was initially applicable only to buildings higher than 18 metres in England but similar restrictions are now in place in Scotland.

The following questions and answers highlight some key points to consider if you are carrying out work such as a boiler installation/replacement in this type of building.

How do the regulations affect buildings undergoing improvements such as a boiler replacement?

The requirement is that any new building work on such buildings that includes installation of a new or replacement boiler must be carried out so that only materials with a fire-resistance rating of A1 or A2-s1,d0 become part of an external wall or specified attachment, unless covered by one of the exemptions in the regulations.

This had an immediate impact for new condensing boilers being installed soon after the amendment was introduced. Boiler manufacturers have had to develop flues that had a metallic inner flue duct resistant to corrosion from the condensing products of combustion as an alternative to flues with inner ducts made from plastic polypropylene.

A relevant building is one with a storey (not including rooftop plant areas or any storey consisting exclusively of plant rooms) at least 18m above ground level and which:

• Contains one or more dwellings

• Contains an institution

• Contains a room for residential purposes (excluding any room in a hostel, hotel or boarding house).

“Above ground level” in relation to a storey means above ground level when measured from the lowest level adjoining the outside of a building to the top of the floor surface of the storey. This includes residential blocks of flats, student accommodation, care homes, sheltered housing, hospitals and dormitories in boarding schools, etc, with a storey above 18m in height, irrespective of the primary purpose of the building.

The regulations apply to the entire building if it includes even a single residential dwelling as well as other uses, such as offices or retail.

Regulations regarding fire spread over the external wall of a building must always be demonstrated. Consideration should be given to the choice of materials used for the external wall, or attachments to the wall, to reduce the risk of fire spread over the wall, including their extent and arrangement.

What exemptions apply to the installation of a flue?

The exemptions include membranes, seals, gaskets, fixings, sealants and backer rods (see Regulation 7(3)).

External flue weatherproofing collars are likely to be classified as a seal and so exempted under Regulation 7(3). These components are designed to help ensure compliance with other requirement of the Building Regulations, such as those addressing risk of re-entry of products of combustion considered in Approved Document J, and where it is impractical to make good the flue externally due to restrictions of working at height.

If it does not form part of the external wall, then this does not apply because it is not a specified attachment. The same applies to plume management kits.

Note: Compliance with Requirement B4 of Schedule 1

to the Regulations regarding fire spread over the external wall of a building must always be demonstrated. Consideration should be given to the choice of materials (including their extent and arrangement) used for the external wall, or attachments to the wall, to reduce the risk of fire spread over the wall.

You should confirm the use of a plume kit with the appliance manufacturer and/or local building control.

What if a building is being converted from an office to a relevant building?

If the works result in an existing building being converted to a “relevant building”, the materials in the existing wall must comply with the combustibility restrictions throughout the entire building. This will require a review of existing external walls and removal of materials, such as boilers with flues that do not comply.

Does the ban affect condensate discharge pipes?

Yes. A plastic condense pipe cannot pass through the wall for an external waste discharge point.

What about existing boiler flues?

Materials that are already part of the external wall or are existing specified attachments and are not being replaced are not covered by the ban.

Are older boilers with a flue using combustible material in a high-rise property At Risk?

When you are carrying out a service or gas safety check, you should still risk-assess the installation as usual for compliance with the gas safety regulations, manufacturer’s instructions and Normative documents, and follow IGEM/G/11, the Unsafe Situations Procedure, if you find defects.

The Building (Amendment) Regulations do not, on their own, mean that an existing installation is At Risk. n

Gas Safe Register recommends that you should read and fully understand the regulation requirements and consult your local building control office if you have any questions.

Cadent and Stay Energy Safe are teaming up to deter people from tampering with their gas meter and encourage the reporting of gas theft.

Meter tampering is an age-old issue. But over the past couple of years, Cadent has experienced more illegal gasrelated activities, which have resulted in injuries and fatalities.

Stay Energy Safe, the energy theft reporting service, provided by the charity Crimestoppers, has seen a 48 per cent increase in reports over the past two years, with an average of more than 900 reports a month in the past 10 months.

Cadent has set up a gas industry working group that includes the gas distribution networks and Gas Safe Register to see what could be done to combat gas theft and protect lives. Initial steps included canvassing eBay and other online marketplaces to take down the gas meter bypass kits.

But it’s important to make consumers aware, too, and this month will see a new campaign supported by Stay Energy Safe.

It’s aimed at bringing mass education to the public, reducing temptation, empowering people to be vigilant and encouraging those with suspicions of gas theft

to report it to Stay Energy Safe, with the peace of mind that they will stay completely anonymous.

As well as raising vital awareness, the campaign will highlight where those in fuel poverty can get support and advice.

A film features mum and dad and their two children, going about their lives at home, when dad starts to tamper with the gas meter. Dad, with all the best intentions, is trying to help keep the bills down by altering his gas meter. After some tugging and tinkering, there is

“The aim is to make gas theft socially unacceptable, regardless of circumstances or situation. Safety always comes first.”

a release of gas, resulting in an explosion that takes the lives of his whole family.

The message is clear: gas theft takes lives and it’s not worth it. If you suspect it, report it.

Cadent expects to see an uplift in reported cases over time, from more informed and knowledgeable communities who understand what to do if they suspect a neighbour, friend, family member – or anyone else – is attempting to steal gas. The ultimate goal is to reduce the threats to health and life associated with tampered gas meters.

The campaign goes live later this month in online ads across social channels including Facebook and YouTube, as well as radio ads nationally.

Other parts of the gas industry will share the messaging across their own networks to reach as many customers as possible. n

Theft of gas or an unregistered connection: what to do

Call the Stay Energy Safe service free on 0800 023 2777 or fill in the simple online form at www. stayenergysafe. co.uk. You will remain 100 per cent anonymous. They won’t ask who you are, can’t see your phone number and your IP address will be scrambled.

You can find out more about the signs of meter tampering –including photos of what it can look like – at www.registered gasengineer. co.uk and search for ‘theft of gas’.

With our newest revision of Vitodens boilers we’ve enhanced the commissioning flow across the 050-W and 100-W product ranges.

What’s new?

• More functionality

• Easy commissioning via the boiler panel

• Remote monitor and control with ViGuide app

10 year warranty as

12 year warranty as

Jeremy Palmer, general manager at Drayton, suggests some key areas that the new government should prioritise to help improve energy efficiency.

We can expect to see a refreshed approach to tackling energy and sustainability from the Labour government. We’ve already seen ambitious plans to make the country a clean energy superpower, including an £8.3 billion investment in generating renewable energy through the Great British Energy Bill.

Reducing carbon emissions remains a significant challenge but improving energy efficiency in existing buildings is a good starting point that the government could focus on, providing both sustainability and financial benefits to homeowners.

1. Continued ambitious targets for low-carbon heating systems

There are big targets when it comes to installing renewable technologies like heat pumps in our homes and funding is in place in the form of the Boiler Upgrade Scheme.

This push to renewables is something we hope remains in place, as it is a crucial piece of the puzzle in reducing our carbon emissions and reaching net zero. However, new targets could be introduced in the installation of smart heating controls.

Research from BEAMA found that simply upgrading from an outdated thermostat and programmer to a bestpractice thermostat can make energy savings of up to 12 per cent, with a further 6 per cent achievable if a smart control is installed.

2. Future Homes Standard Timelines for the Future Homes Standard, which sets out the requirement for new-build homes, remain uncertain but it’s likely to come into force in 2025. Part of the proposal is the move from SAP (Standard Assessment Procedures) ratings to a HEM (Home Energy Model) rating system. However, one key area that we hope to see improved is the rating given to smart heating controls. Smart controls can help to make savings of up to 30 per cent on energy bills. For example, a multi-zone smart heating system, which allows for room-to-room temperature control to avoid heating empty spaces, can save up to 19 per cent.

3. Implementation of the boiler standards and efficiencies consultation Drayton has been actively involved in the boiler standards

and efficiency consultation, which looks at implementing open protocols, as well as promoting the installation of TRVs and auto-balancing technology on all heating systems.

A well-balanced system is essential to the overall performance of a heating system. When not balanced, the radiators closest to the boiler receive a larger flow of hot water and heat up quickly, whereas the radiators farther

“Balance is essential to the performance of a heating system.”

away from the boiler – perhaps upstairs or in the far corner of the property – receive a lower flow of hot water. This leads to cold spots around the home and households using more energy as they crank up the thermostat to keep warm.

The consultation also proposed the mandatory installation of certain classes of controls and we hope to see the government implement these proposals. n www.draytoncontrols.co.uk

A 4-in-1 handheld digital tool designed to precisely measure water flow, pressure, temperature, and hardness.

Andrew Speake, product manager at Baxi, looks at the best boiler control features to maximise energy efficiency.

Households are still feeling the pinch and are monitoring their energy bills more closely than ever. And they want to use energy more efficiently – and that’s where you can help.

Most modern boilers work highly efficiently if installed, serviced and used correctly. But the latest advancements in controls can boost performance even further.

Dynamic range rating

Modulation is a common feature of most modern boilers but many people are not familiar with the concept of dynamic range rating. This enables the boiler to increase or decrease the heat output in a more gradual and controlled way, accurately matching the required heating load.

The benefit for homeowners is that less energy is wasted because the output of the boiler is matched to the heating requirements. The boiler automatically provides

only the minimum heat output necessary to meet the demand temperature, helping to cut energy usage and heating bills.

Weather compensation

Weather compensation is one of the recommended ways to comply with the Boiler Plus requirements. It automatically adjusts to weather conditions, so the right amount of

too. Adjusting to the outside temperature means that radiators are not always piping hot – something they sometimes misconstrue as a sign of malfunction or poor performance. Instead, the boiler is better managing its heating output to meet the desired comfortable temperature at a lower rate, all the while using less energy.

“The latest advancements in controls can boost the performance of boilers even further.”

energy is used to compensate for cold weather without needing to adjust the thermostat. However, many homeowners don’t know if they already have weather compensation as part of their heating system.

It’s worth explaining to homeowners how weather compensation behaves,

Load compensation

Load compensation is where the boiler lessens its output as it gets close to the target temperature and avoids wasting energy by overheating.

It matches the heat output to the room requirements, putting no more energy than required into the system to meet the desired temperature. This feature is increasingly being incorporated into standard and smart controls.

Smart controls

Smart controls mean that homeowners can customise the way their system works precisely to their needs. They can monitor how much energy they’re using and control the heating system remotely, with flexible scheduling options. n baxi.co.uk/products/ controls

Astagnant housing market has always been bad news for the heating industry. People tend to invest in upgrading their properties to get them ready to sell: then, after they have moved, they will often invest in new boilers, better heating systems and newer controls.

But the new Labour government has pledged to build 1.5 million new homes over the next five years – a welcome boost that will help kickstart the repair, maintenance and improvement (RMI) market. Falling inflation rates and a lower energy price cap are also expected to begin restoring consumer confidence.

Although we expect the market to begin to improve (albeit slowly) over the coming months, it’s likely there will still be some hesitancy from homeowners to spend significant amounts, and people will be looking for the most

cost-effective upgrades.

Investing in heating controls is a great way to renovate a property and make the existing heating system more efficient, helping to reduce future fuel bills and offering short payback periods, alongside the additional bonus of a warmer home.

Modern digital controls are smart enough to help people get all the comfort they want while using as little fuel as possible by only turning the system on when heat is actually needed. This gives underfloor heating engineers a great opportunity for add-on sales as people look for low-cost ways to lower their heating bills.

Smart heating controls can be retrofitted to existing systems easily and larger homes may benefit from being zoned and installing separate thermostats in bedrooms, living areas and home offices to

make sure that different areas in the property are kept warm only when they are actually in use. Home offices can be heated during working hours, and bedrooms only for a couple of hours in the evening and first thing in the morning, for example, rather than the whole system being on constantly during the day.

For multi-generational families, Continal’s Quantum range has a rotary dial thermostat that can also be connected to the Wi-Fi, which means users who prefer a simple-to-use dial can stick with manual heating control, while those who may prefer smart home controls can use the same thermostat remotely.

All these options give UFH engineers everything they need to maximise sales while the market continues to be challenging, and to help them grow their businesses. n

Continal supplies different UFH solutions and a wide range of controls products from digital to dial thermostats. The company is system-agnostic and technical advisers provide unbiased advice on the best system type, as well as full CAD designs and support at every stage of your project. www.continal. co.uk

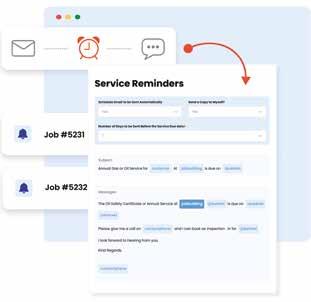

Arran Saunders from Gas Engineer Software walks through some of the ways you can speed up your work.

Running a successful heating business is all about using your time effectively. Jobs may bring in the money but a lot more goes on behind the scenes to keep everything ticking over.

There are areas where your workflow can be automated effectively using specialist software to help you claw back precious time.

Each job has a series of records attached to it: quotes, invoices, certificates and job sheets being the most common. Most of these records need to be kept for around six years.

Automating this process is far simpler than it sounds when you use an integrated job management package that handles each step of the workflow, from quote through to invoice. Creating each of these records using the same software means it can automatically categorise and file them away without you having to lift a finger.

They’ll be safe and secure

Gas Engineer Software is an all-inone software platform for heating and plumbing companies. The easy-to-use job management software helps more than 5,000 companies schedule jobs, build quotes, send invoices, issue certificates and get paid faster – all at the click of a button.

www.gasengineersoftware.co.uk

on the cloud, and you can sort through old records by date, customer name and property address. But, most importantly, it unlocks several other ways of automating work.

Most paperwork can be done at your own pace –except when you’re waiting for a customer to get back on a quote or invoice. These delays can have very real consequences for your business: not following up on quotes can mean lost jobs, and late payments are a huge issue.

Most businesses will happily send out a quick reminder but, without a proper system, sorting through and finding out which quotes and invoices need following up is timeconsuming and tedious.

Software can use your job records to detect which invoices or quotes you haven’t heard back from. It can then send out pre-written reminders at a specific time.

If you haven’t had time to send reminders, automating them can bring huge benefits to your business and save hours if you do regularly sit down and chase customers up.

When it comes to annual service reminders, software can contact your customers one month in advance by simply sorting through your records, filtering those done 11 months ago, and sending a quick message.

This all happens in the

background while you carry on with your day job and other important tasks. Automating these reminders creates a self-feeding model for your business through work for existing customers.

Good bookkeeping is essential but with so many income and expense streams it can quickly become a tedious process. Most businesses now use some kind of accounting software for easy bookkeeping and compliance. The trouble here is that you (or your accountant) have to manually enter all your data line by line. A platform that integrates with your accounting software system will automatically sync across customer info and all your earnings. This makes the whole process quicker, easier, and free of mistakes. n

Buying a van through your company can be a very tax-efficient option. Here, Which? Trusted Traders and Registered Gas Engineer set out what you need to know, from whether to hire your vehicle or buy it outright, to deciding between petrol, diesel or electric.

Whether you want to lease a vehicle or buy it, there are pros and cons to both.

When you lease a van, almost everything is wrapped into a monthly fee that includes things like insurance and maintenance.

You can’t claim for a leased car against your capital allowances because it’s not a company asset but you can treat your rental payments as tax-deductible expenses.

At the end of the lease, you can usually return the van, make a payment to own it outright, or sign a contract for a new one.

Buying a van means you can use it as you please. There are no restrictions on mileage, and even if you use a finance deal or bank loan for your purchase, you will own the vehicle at the end of the arrangement.

The tax advantages can make buying a company van a sensible financial option.

However, you’ll need to think about and budget for things like insurance and maintenance.

When choosing your van, you’ll need to consider whether you want electric, petrol or diesel.

If you’re choosing between diesel and petrol, you can use Which?’s fuel calculator1 to see what the price difference is likely to be based on your normal usage.

Electric vehicles cost more to buy, but they’re generally cheaper to run than petrol or diesel cars. Whether this will suit you depends on whether there is a charging point at or near your home or business and how far you typically drive.

There are also useful grants that can slash the cost of a company van by 35 per cent.

You can read the full details of the scheme at gov.uk2

Your business can claim back VAT on any fuel it pays for that is exclusively businessrelated.

If the company pays for fuel and you use the van for personal trips, this is classed as a benefit-in-kind and you’ll need to pay the Van Fuel Benefit Charge.

You don’t need to pay this tax if the vehicle is electric.

One of the main advantages of getting a van for your small business, rather than a car, is that you can claim 100 per cent of the cost of purchase against your capital allowance. That’s because vans are counted as plant and machinery for tax purposes.

Essentially, you can deduct the full price of the van from your company profits.

You can also claim the full VAT back from the cost of your van if your company is registered for VAT.

You may also be able to claim other costs for using your work van, such as vehicle insurance, fuel, repairs and servicing, parking, breakdown cover and vehicle licence fees3.

The tax situation is complex, so you should speak to your accountant. They will be able to tell you whether you should buy your van through your company and exactly how much relief you can claim.n

Get 50% off when you join Which?

Trusted Traders

Gas Safe registered engineers can get 50 per cent off their first six months of membership when they join Which? Trusted Traders. Find out more at: www.which. co.uk/tt-gassafe

1 www.which.co.uk/ petrol-calculator

2 www.gov.uk/plugin-vehicle-grants/ vans

3 www.which.co.uk/ tax-deductibleexpenses

Legislative, Normative & Informative

Date issued: 1 July 2024

Introduction

This document defines all documents recognised by Gas Safe Register as being Legislative, Normative (gas standards) and Informative reference documents.

Some documents may only be available as hard copy documents, but the majority are available to download, either via Gas Safe Register’s engineer website or from the organisation or body promoting the document. In some cases, the document is only available for purchase from the organisation or a recognised supplier.

In this document list, the hierarchy of documents within the following tables is defined in order of significance.

Detailed first are Statutory Acts or regulations that are legally enforceable. These are followed by a recognised list of documents known as ‘Second Tier’ documents. This series of documents provides practical guidance on ways to comply with the functional requirements of Regulations. This guidance is not law, but provides information that, if followed correctly, will ensure that legal obligations have been met.

Where someone chooses to depart from this guidance, they will need to ensure that the method chosen provides equivalent or better standards of safety than the relevant published guidance. The guidance provided within appropriate second-tier documents will be used to assess compliance.

The next tier of documents is gas industry standards that are aimed specifically at the installation, commissioning or maintenance of gas equipment (pipework, appliances, etc). These are known as Normative Documents and are referred to as ‘Gas Industry Standards’. These documents, in conjunction with any available manufacturer’s

instructions, will be used by Gas Safe Register to assess compliance.

Finally, the remaining listings provide details of links to other available information that is considered useful to help registered businesses comply with their obligations and assist them in carrying out their day-today activities. These are referred to as Informative Documents.

In this section, the listed documents are those brought to the Statute Book by an Act of Parliament and are referenced as Statutory Instruments (SI) or equivalent. These are the law in the respective countries as stated and must be followed. The SI Reference number (or equivalent) is preceded by the year of it being added to the Statute Book, ie, the Gas Safety (Installation and Use) Regulations 1998 has an SI Number of 1998:2451. Regulations are in general written in a format that provides high-level requirements.

Documents supporting legislation

These documents provide practical guidance on ways to comply with the functional requirements of the Regulations. For the Building Regulations, these are outlined in a series of Approved Documents (AD) published by the appropriate government department responsible for the Regulations.

The ADs that currently apply to gas work are:

• A Structure

• B Fire safety

• F Ventilation

• G3 Hot water storage

• J Heat producing appliances

• L Conservation of fuel and power

• M Access to and use of buildings

• P Electrical safety in dwellings.

Each document contains general guidance on the performance expected of

materials and building work to comply with each of the requirements of the Building Regulations; and practical examples and solutions on how to achieve compliance for some of the more common building situations.

2. Gas Industry Standards