R & D SOLUTIONS

R&D Solutions is a privately owned oil, gas, and renewable energies equipment and services provider.

Based in Perth Western Australia, R&D Solutions prides itself on providing a broad spectrum of equipment and technology solutions. From the remote outback of Australia to offshore Asia and Europe.

We are available around the clock to assist service and support your operations.

We are the representative agents for a range of suppliers of proven drilling, completion and monitoring technology. Whether your requirements are for geothermal renewable energies, or traditional oil and gas, locally and internationally, our track record proves we will deliver on time and to budget.

In addition to product supply our locally based engineering group is well positioned to assist you with one off tool requirements that may arise during operations.

We also facilitate heavy industry machine repairs of damaged equipment or refurbishment. R&D Solutions prides itself on being able to take on special build items and turn these round in a timely manner from concept to delivery.

In alliance with independent training providers, R&D Solutions provides industry training on all of the following:

• Slickline Operations

• Well Completion

• Basic Completions

• Overall production & exploration overviews

• Induction type courses for new hires

• Slickline course for supervisory personnel

Our customers engage us for our proven history of delivering responsive and cost competitive solutions. R&D Solutions’ Directors bring significant local and international experience. Russell Furner is formerly of BBL Bits and Doug Gillespie is exWeatherford Completions.

Our history of continued repeat business from our client base of major oil and gas companies is testament to our commitment to outstanding service, including Apache Energy, Chevron, Esso Exxon, Hess, Horizon Energy, Inpex, Santos, Shell, Vermilion Oil and Gas, Weatherford and Woodside.

Local highlights since establishment include the award of the Chevron Wheatstone contract for the supply of drill pipe protectors and service, the Shell prelude contract for the supply of Matrix Low Friction centralisers, drill pipe protectors and service and a Master Services agreement with Santos to provide Packers Plus technology and services.

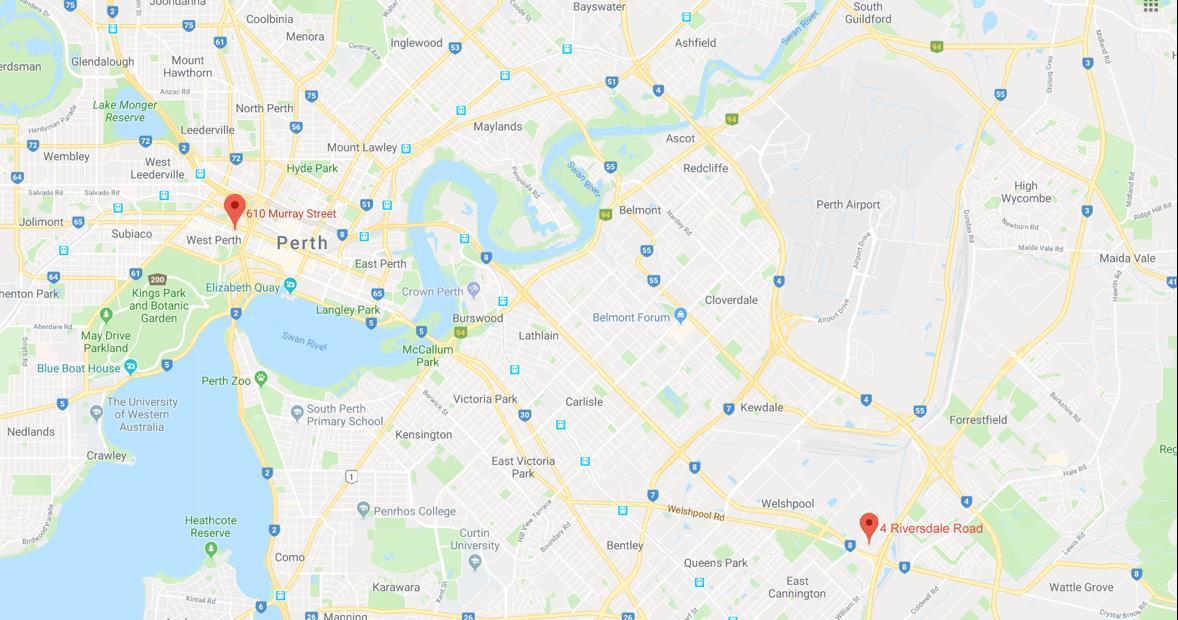

The bigger, new R&D Solutions warehouse is conveniently located at Welshpool near Perth City airport to provide accountable Equipment Storage and Inventory Management with prompt receipt and delivery to and from customer’s mobilisation point or workshop.

4 Riversdale Road Welshpool Western Australia 6106

• Full service Office with access 24/7

• 2000m² fully enclosed, high truss, air conditioned warehouse and workshop

• Double overhead cranes

• 2000m² outside hardstand

• 30 minute drive from Perth CBD. 15 minutes from Perth airport.

• Fully equipped workshop with hand tools

• Total Inventory management

• All good stored under cover

• Fully fenced, secure yard with parking and lay down area

• Monitored alarm and security cameras

• Forklifts and qualified staff to conduct equipment load outs and receivals

For small shipments R&D Solutions can deliver to customer’s facilities at short notice. For larger goods R&D Solutions use local transport and shipping specialists to ensure quality service at a competitive cost.

KCI was established in 2002 to respond to the unique and challenging specialist requirements of brownfield and greenfield developments.

KCI offers a range of unique products and services specifically designed to reduce costs and minimise downtime, whilst maintaining or increasing production across:

• Sub sea

• Surface

• Refinery

• Down hole

• Topside

• Pipeline

• Other applications

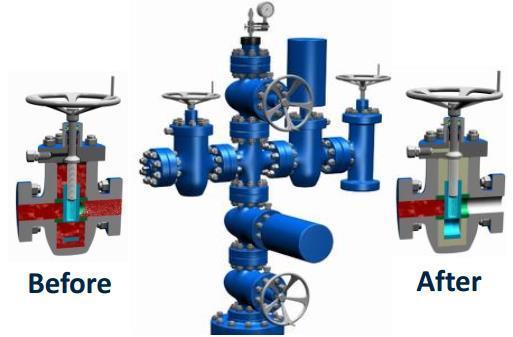

❑ KCI were requestedbya major Oil andGas Operator in the UK to provide isolations for Christmas Tree Valves on a Water InjectionWellwhere all three inline Gate Valves have failed.

❑ The Isolations are requiredto breakcontainment to enable the installation of a secondarySwab Valve. This wouldallowWell InterventionandWellAbandonment operations to continue.

❑ With all inline Gate Valves closed theyhada recordedleakrate of 10 Litres per minute of fluid& a PBU (Pressure BuildUp) of 540psi.The Valves had been greasedwith Clare 601 & 701 but still leaked at 10 Litres per/ min.

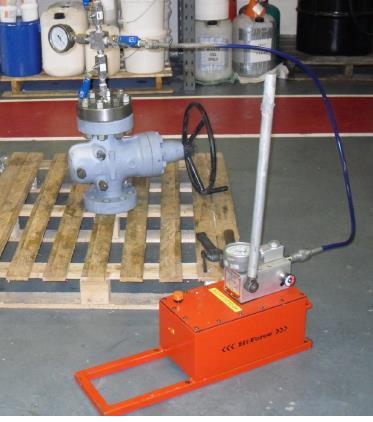

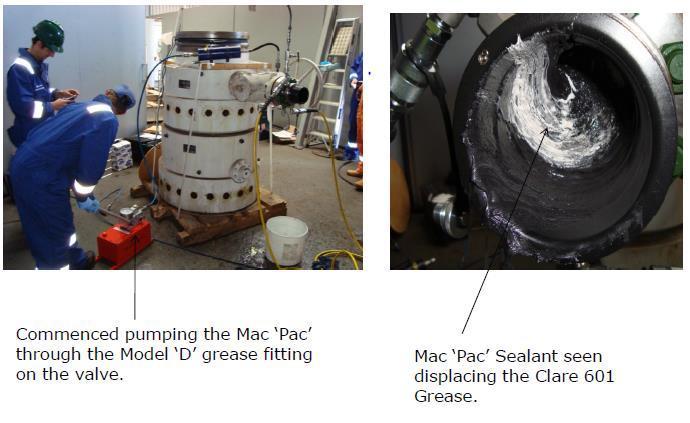

❑ DeployKCI’s Mac-Pac Sealant throughthe standardGrease fittingon the Bonnet. Displace the existing Grease from the Valve cavities andreplace it with Mac-Pac to provide an effective andrepeatable Valve isolation.

❑ Allowthe Well to be preparedfor future safe Intervention Operations.

Kinetics Controls & Innovation Ltd

Established in 2002

Office, Workshop and Manufacturing facility in Dyce, Aberdeen, UK

Specialising in Well Integrity Engineered Leak Solutions

❑ Connect KCI deployment toolingto the SWAB Valve. Inject 1.5 Litres of Mac-Pac andwitnesseda PBU. FunctionedValve and tested. ZeroPBU or leakrate above.

❑ Connect KCI deployment toolingto the LMV. Inject 5.5Ltrs of Mac-Pac andwitnesseda PBU. Functioned Valve andtested. Zero PBU above however, a verysmallfluidleakage was witnessedat the vent point. An extendedPBU test was carried out overnight and a goodresult was confirmed.

❑ The HMV’s Actuator Springwas brokenso the Valve could not be functioned.

❑ The well will remainsafelyclosedin until the planned interventionworkbegins.

* Objective Achieved*

Our customer was extremelysatisfiedwithour Safe, Effective & Efficient Isolationof the Well. This Value Adding, Rigless Isolation Operationsavedthe Well owner from a potentially time consumingandcostlyWellKill or Freeze operation.

Wellhead, Christmas Tree Valve & Topside Valve Isolations

Annulus & Downhole Isolations

Subsea Well Isolations

Production & Pipeline Applications

Well Decommissioning & Abandonments

Wellhead Isolations Gate Valve Isolations

Subsea Applications Well Abandonment Downhole Isolations

Mac-Seal:

A variety of “Time Activated” viscosity compounds

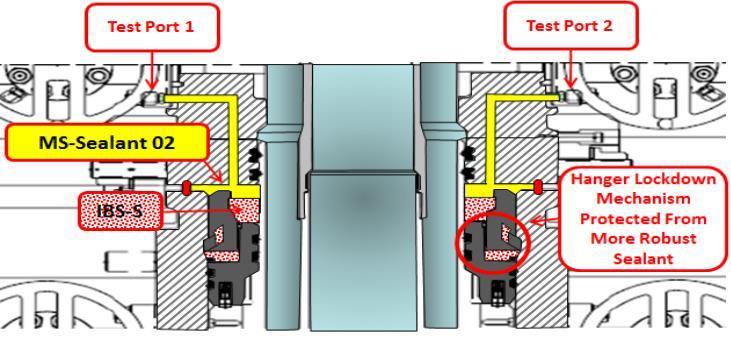

MS-Sealant:

A variety of “Time Activated” viscosity compounds

Isolation Barrier System (IBS)

Time Activated Compound and Breaker

Mac-Pac:

Non-Activated Sealant Compound

Leak Sealing Solutions High Pressure

Leak Sealing Solutions

Medium to High Pressure

Flexible non-porous gel with high compression load limits

High Viscosity Sealing & Lubricating Compound

MHS-Protect:

Paint on Anti-Corrosion Product

Corrosion & Erosion

Protective Coatings

Seals, Wellhead Voids & Pack Offs

Wellhead Seals, Tubing & Casing Hanger

Wellhead Seals, Tubing & Casing Hanger

Seals, Wellhead Voids & Pack Offs

Formulated for Hotter Climates & Regions

Isolation Solutions including:-

Production Pipelines, Ball Valves & Hybrid solutions

Downhole Annulus Isolation of Packers & Casing Shoes

Ideal for leaking Gate Valve Isolations

Energise Wellhead Seals as a more stable replacement for Plastic Packing

Protect Injection Fittings, Nuts, Bolts,

Threaded Equipment & Splash Zones etc.

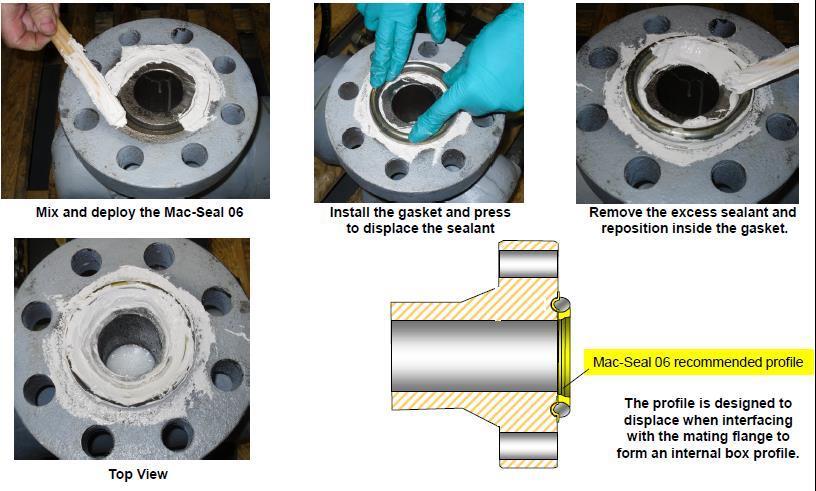

Mac-Seal & MS-Sealant provide a static seal between existing damaged sealing areas. Deployed as a time activated viscous fluid, Mac-Seal & MS-Sealant convert to a resilient self-bonding, pressure energised, solid but flexible material to re-establish a pressure retaining barrier without shrinkage.

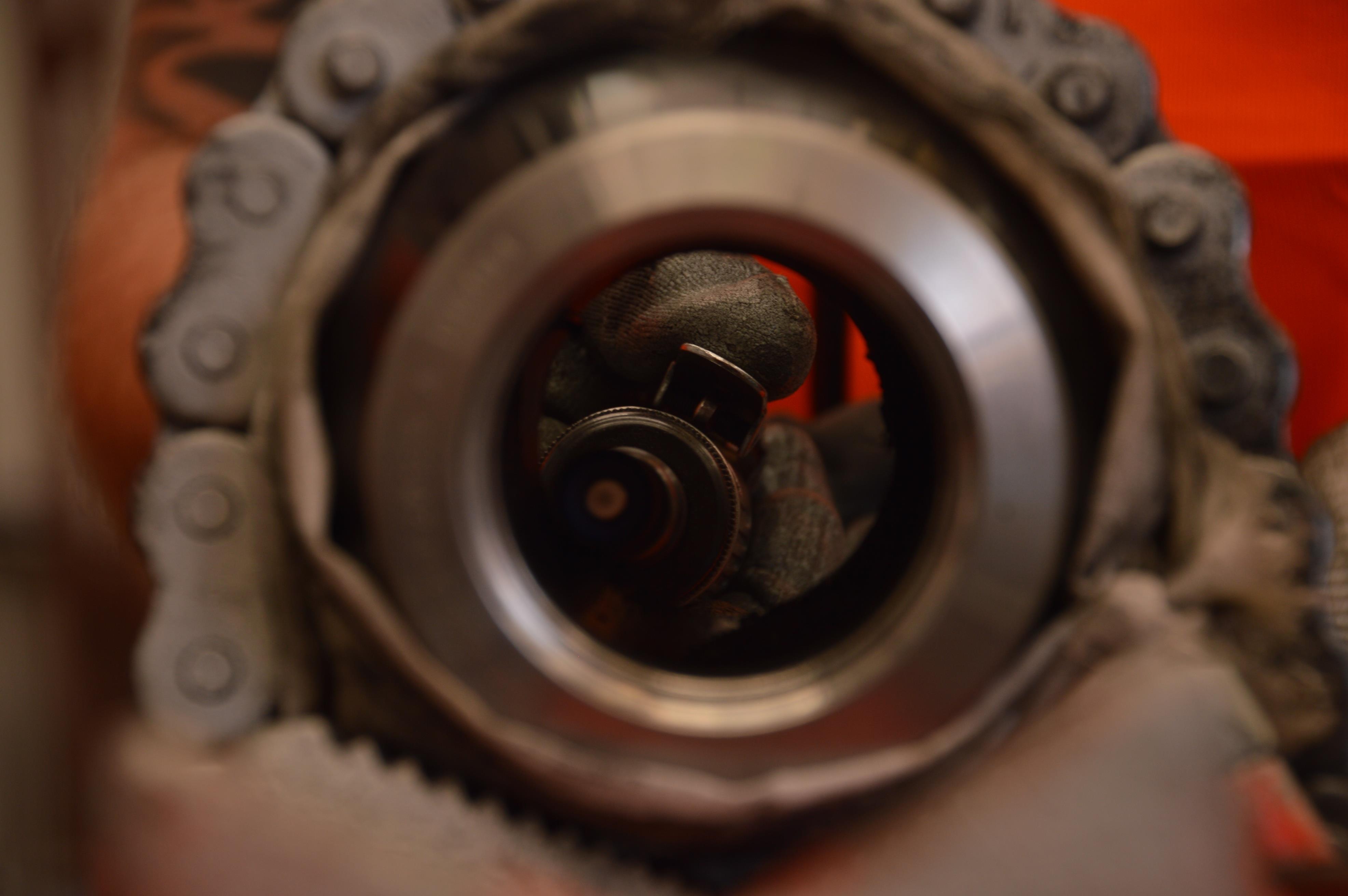

Sealing face very badly damaged by Grinder

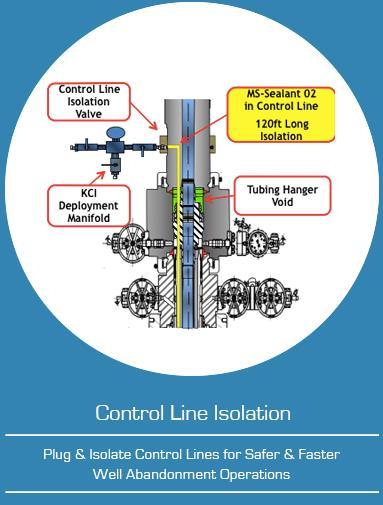

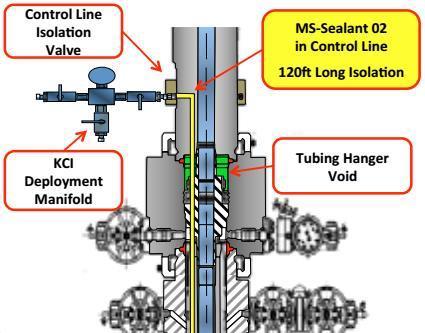

Mac-Seal or MS-Sealant is used to permanently Plug & Isolate DHSV Control Lines, Chemical Injection Lines, Capillary Strings etc.

Used when well pressure is witnessed at surface in the Control Line, Workover or Abandonment. This would indicate that the well is down to one barrier from the reservoir pressure.

Control Line Isolation

Valve

KCI

Deployment Manifold

MS-Sealant 02 in Control Line

120ft Long Isolation

Tubing Hanger Void

• Can regain Well Integrity if in-line Check Valves or Control Line structure fails.

• Safer, Faster & more Economical compared with Traditional Intervention operations.

• Negates the need to set a Straddle Plug in the DHSV nipple for an isolation.

• The cured isolation can be Pressure tested & Leak-Off tested.

• Just 500mls of Sealant required to fill a ¼” Control Line to a depth of 120ft.

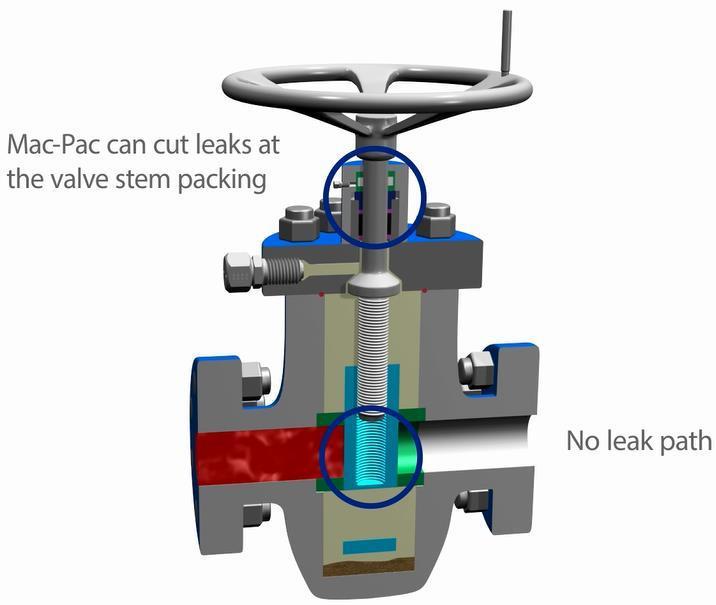

Mac-Pac is a dynamic product that sits within the valve and reacts to any leaks.

Ideal for isolating leaking Stem Seals

Mac-Pac coats scored

Gate Valve internals

It is a repeatable solution

NOT just a one time isolation

Mac-Pac is easily pumped

Will displace grease and plastic packing An alternative to plastic packing due to stable structure at Low & High Temperatures

Mac-Pac seals leaking Gate

Mac-Pac is a Sealant + High Temp Lubricant which remains in the valve pocket much longer than grease

Commenced pumping Mac-Pac through “Model D” grease injection fitting on valve

Mac-Pac has displaced the Clare 601 grease from the valve cavity

Kinetics Controls & Innovation Ltd

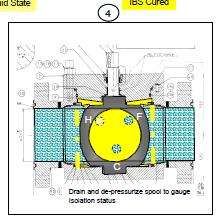

Deployed as a fluid and transforms to a gel to provide a seal / barrier directly into or between leaking production ball or gate valves, on surface or subsea.

IBS can be converted back into a fluid and dispersed within the system or pigged out as solid.

Valve

Gas Manifold

Mac-Pac

Inject IBS into the Spool by directional isolation

Mac-Pac

Short or Long Term

Temperatures: +5 to +120°C

Ideal for:

• Gate Valves

• Ball Valves

• Production Pipelines

• Surface or Subsea

Direct access Isolation When Possible

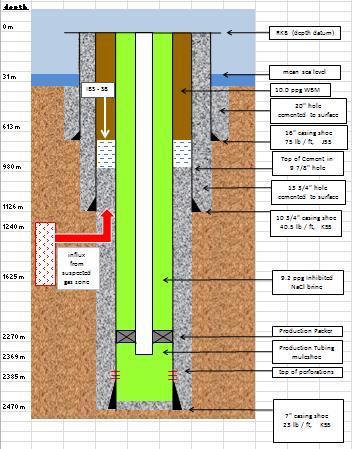

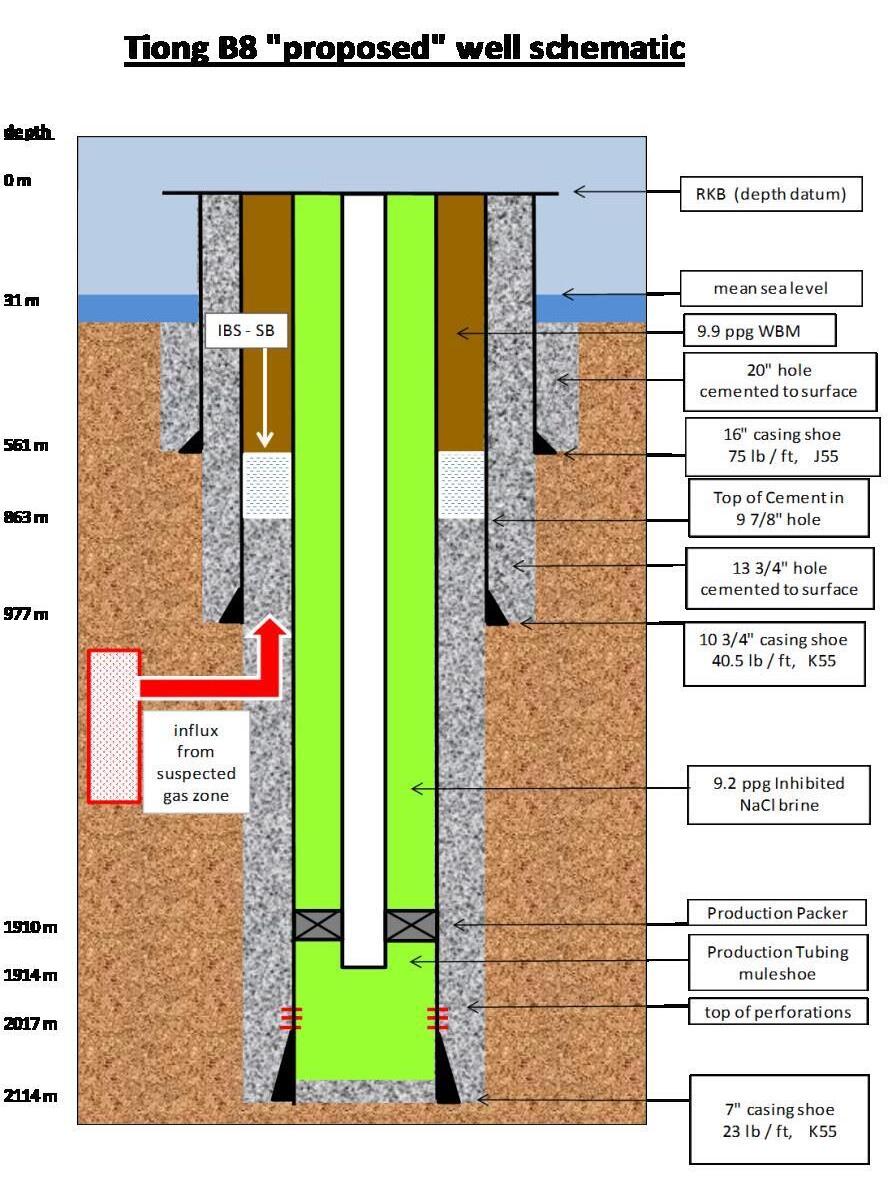

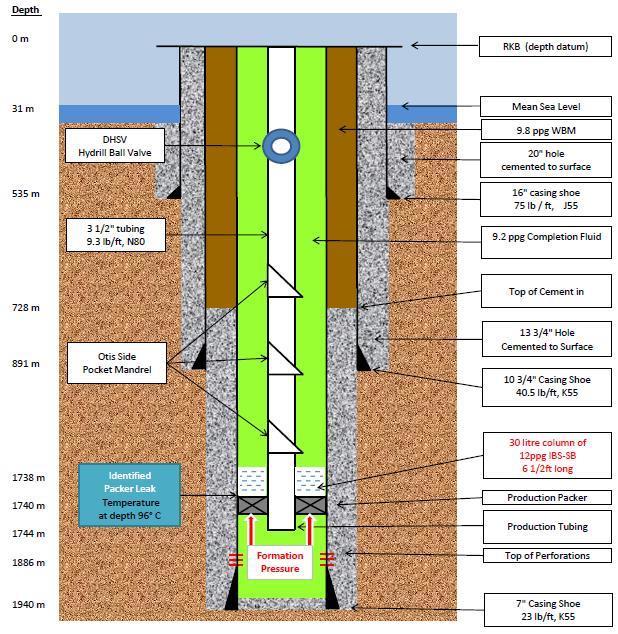

Deployed from surface as a fluid, transforms to a solid flexible membrane when it reaches the target depth to provide a seal directly at the problem area - Packer Element, Casing Shoe or Casing Hanger.

Ideal for: Rigless Low Cost Well Intervention – Behind Pipe, Micro Annuli, Cement Porosity & Hanger Seal Issues

Heavier than Oil, Seawater and most Brines

Layers from top down:

IBS-SX

Oil

IBS-S

Seawater

IBS-SB

Dry sand & cement mix

Leaking Packer Element

/ Well Fluids Brine

Nipple WEG

IBS-SX Being deployed

IBS-SX Floats on Oil

Flush Line with water Leak Reduced

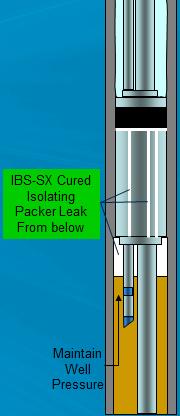

IBS-SX Cured Isolating Packer Leak From below Maintain Well Pressure

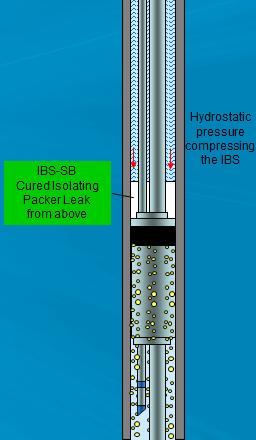

Deployment of IBS-SB Fluid State

Packer

Element

Leak

Top up with heavy fluid or apply fluid pressure and hold until IBS is cured

IBS-SB Cured Isolating Packer Leak from above

Hydrostatic pressure compressing the IBS

• Maintains balanced pressure in the annulus

• Protects wellhead from harmful well fluids and gasses

• Protects wellhead seal structures from constant exposure to well pressure

• Prevents gas escape to atmosphere

• Sealant can be broken back to fluid state when required (surface only)

• Allows monitoring of annulus pressure

• Allows venting of annulus pressure when required

Tubing Perforations

Micro

Porosity Issues

Position the IBS-SX below the Hanger to protect the casing hanger seals with communication to the tubing

VR hose mandrel to allow annulus pressure monitoring

Cement Treatment of IBS-SB Heavy Fluids Seawater

to Play

4 Riversdale Road, Welshpool, Perth, WA 6106 Australia

Website: www.randd-solutions.com

Welshpool & Canning Vale Australia

Mobile: +61 450 663 908

Office: +61 8 9486 8350

allan.paterson@randd-solutions.com