R & D SOLUTIONS

R&D Solutions is a privately owned oil, gas, and renewable energies equipment and services provider.

Based in Perth Western Australia, R&D Solutions prides itself on providing a broad spectrum of equipment and technology solutions. From the remote outback of Australia to offshore Asia and Europe.

We are available around the clock to assist service and support your operations.

We are the representative agents for a range of suppliers of proven drilling, completion and monitoring technology. Whether your requirements are for geothermal renewable energies, or traditional oil and gas, locally and internationally, our track record proves we will deliver on time and to budget.

In addition to product supply our locally based engineering group is well positioned to assist you with one off tool requirements that may arise during operations.

We also facilitate heavy industry machine repairs of damaged equipment or refurbishment. R&D Solutions prides itself on being able to take on special build items and turn these round in a timely manner from concept to delivery.

In alliance with independent training providers, R&D Solutions provides industry training on all of the following:

• Slickline Operations

• Well Completion

• Basic Completions

• Overall production & exploration overviews

• Induction type courses for new hires

• Slickline course for supervisory personnel

Our customers engage us for our proven history of delivering responsive and cost competitive solutions. R&D Solutions’ Directors bring significant local and international experience. Russell Furner is formerly of BBL Bits and Doug Gillespie is exWeatherford Completions.

Our history of continued repeat business from our client base of major oil and gas companies is testament to our commitment to outstanding service, including Apache Energy, Chevron, Esso Exxon, Hess, Horizon Energy, Inpex, Santos, Shell, Vermilion Oil and Gas, Weatherford and Woodside.

Local highlights since establishment include the award of the Chevron Wheatstone contract for the supply of drill pipe protectors and service, the Shell prelude contract for the supply of Matrix Low Friction centralisers, drill pipe protectors and service and a Master Services agreement with Santos to provide Packers Plus technology and services.

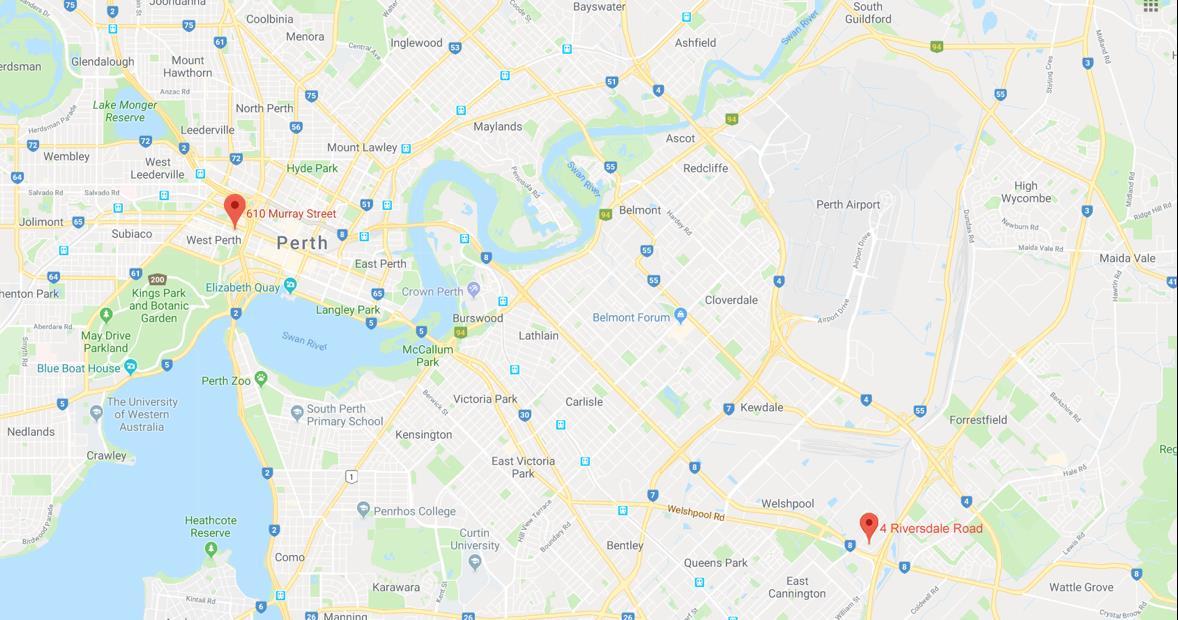

The bigger, new R&D Solutions warehouse is conveniently located at Welshpool near Perth City airport to provide accountable Equipment Storage and Inventory Management with prompt receipt and delivery to and from customer’s mobilisation point or workshop.

4 Riversdale Road Welshpool Western Australia 6106

• Full service Office with access 24/7

• 2000m² fully enclosed, high truss, air conditioned warehouse and workshop

• Double overhead cranes

• 2000m² outside hardstand

• 30 minute drive from Perth CBD. 15 minutes from Perth airport.

• Fully equipped workshop with hand tools

• Total Inventory management

• All good stored under cover

• Fully fenced, secure yard with parking and lay down area

• Monitored alarm and security cameras

• Forklifts and qualified staff to conduct equipment load outs and receivals

For small shipments R&D Solutions can deliver to customer’s facilities at short notice. For larger goods R&D Solutions use local transport and shipping specialists to ensure quality service at a competitive cost.

LEE ENERGY SYSTEMS

WATERCUT AUSTRALIA

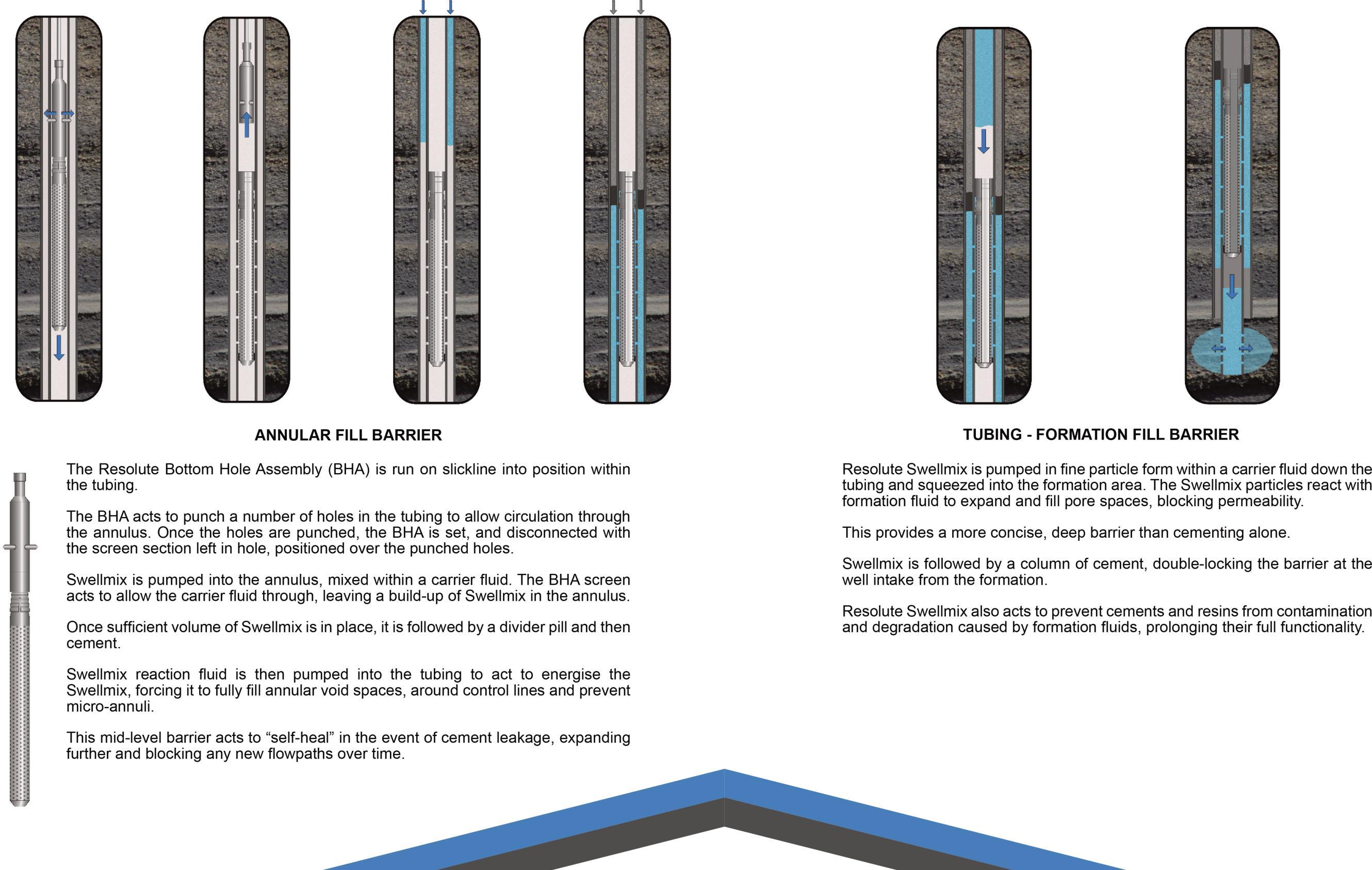

RESOLUTE

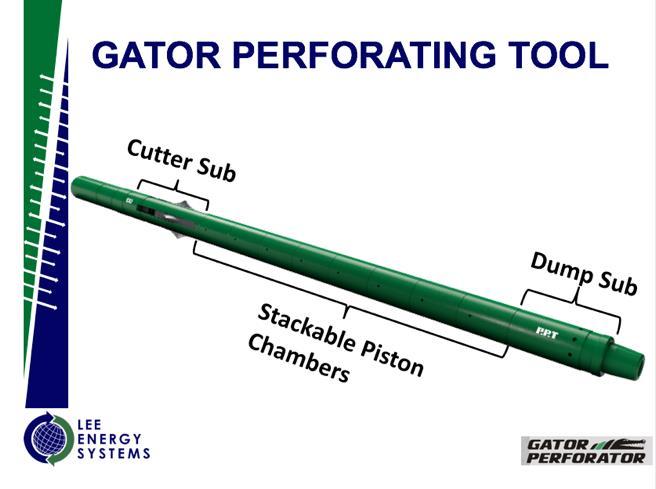

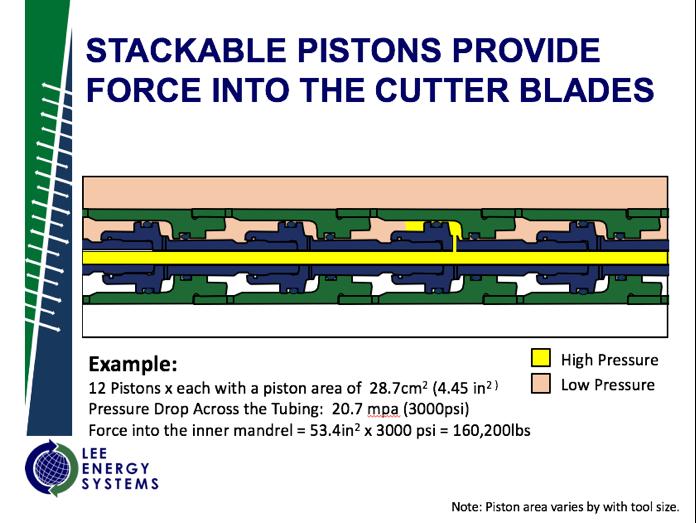

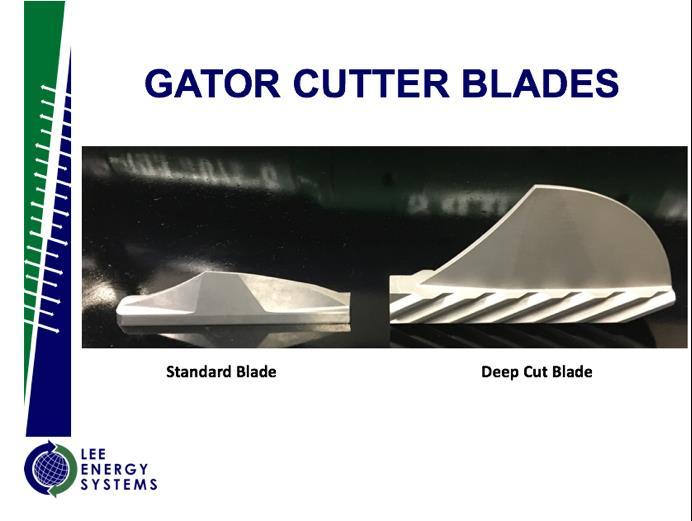

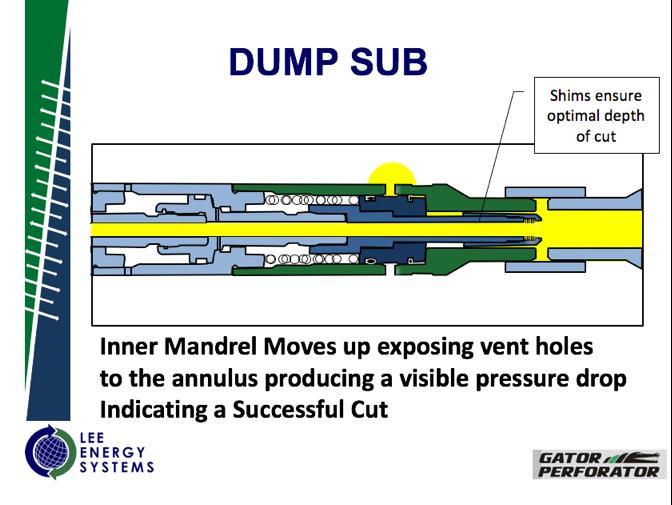

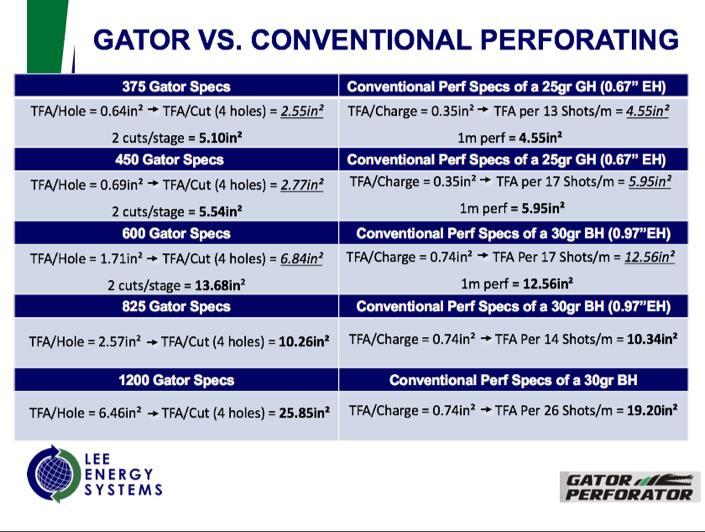

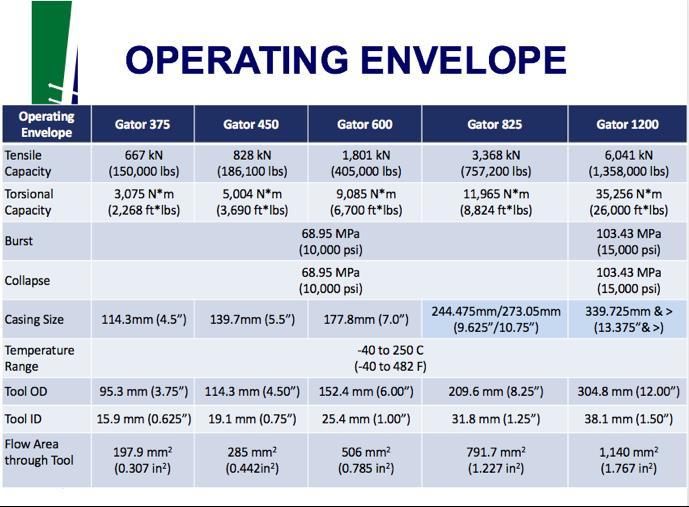

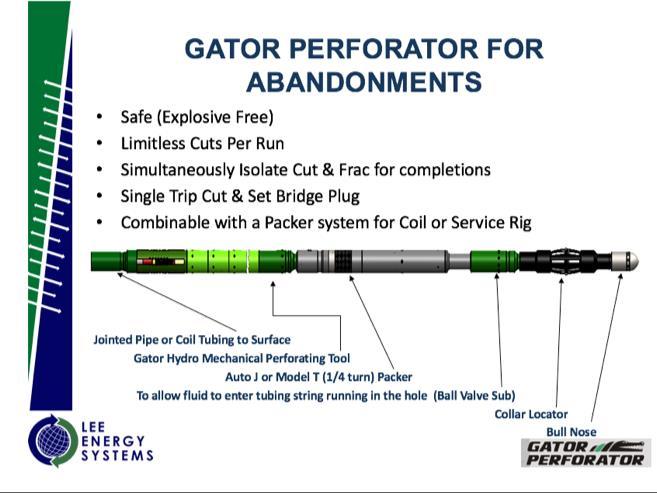

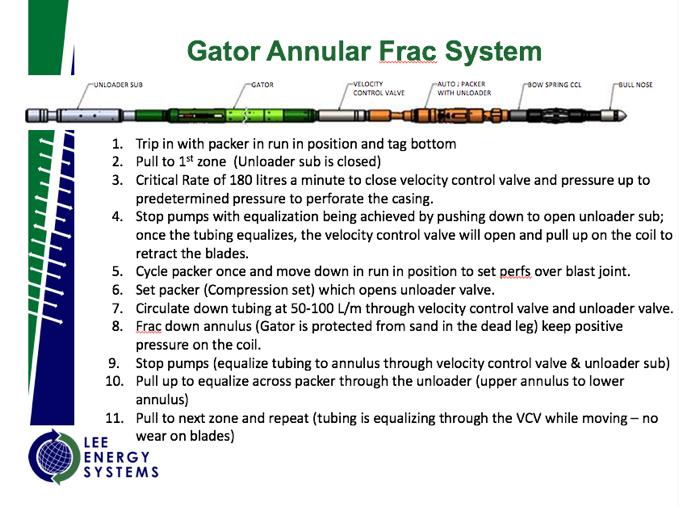

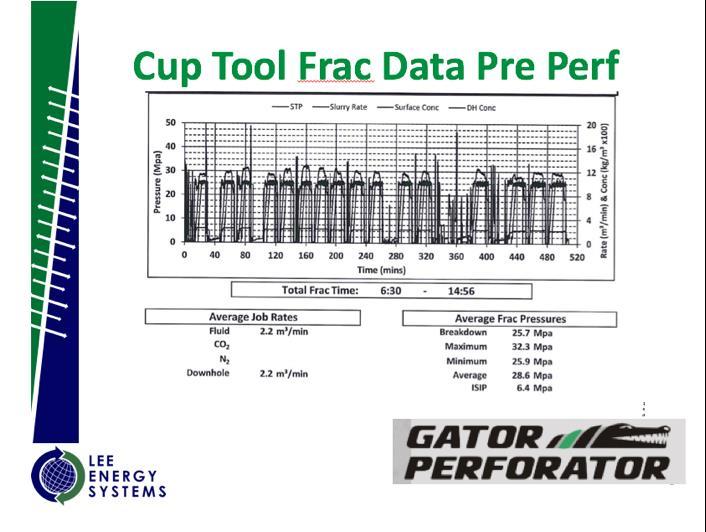

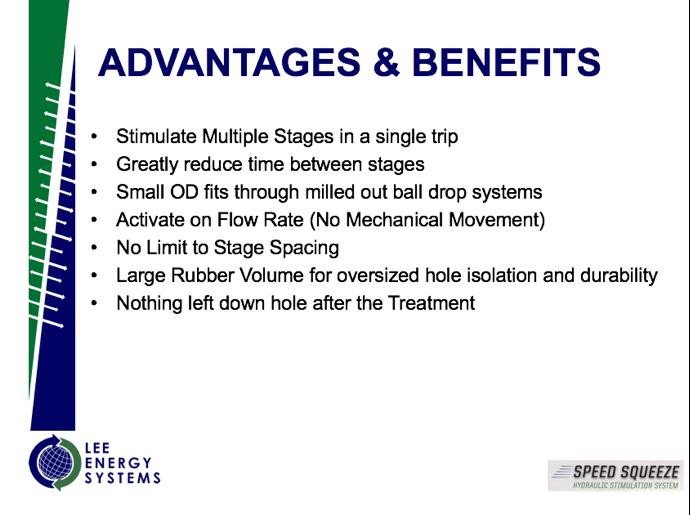

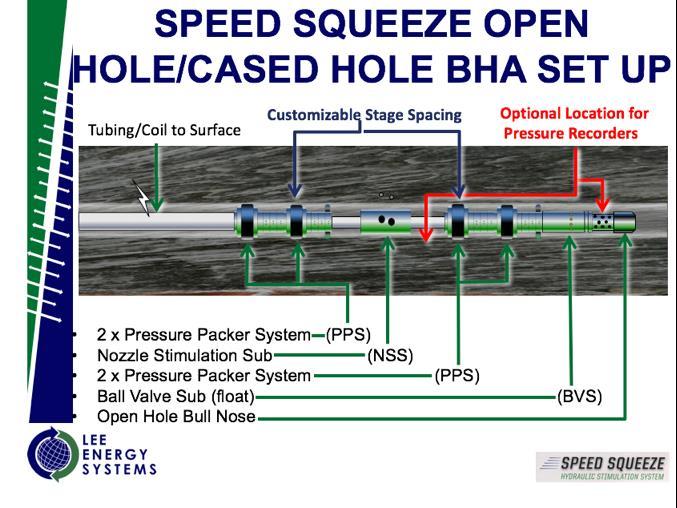

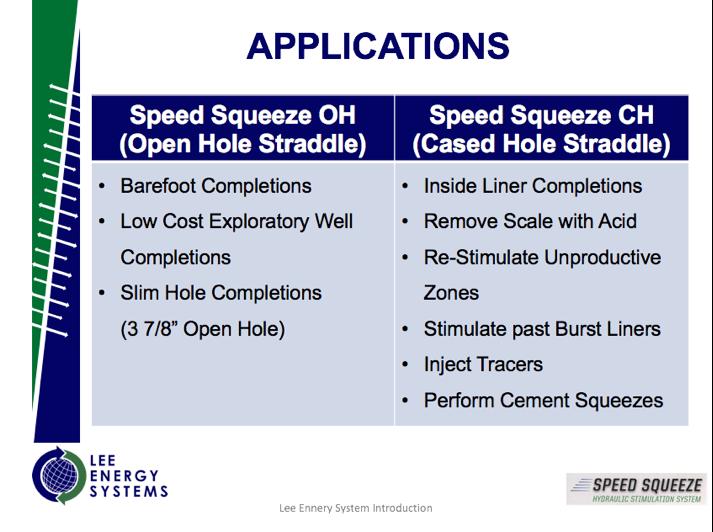

LEE ENERGY SYSTEMS is committed to developing new and unique petroleum upstream service systems to the ever changing demands of this exciting industry.

LEE ENERGY SYSTEMS is focussed on providing solutions to Oil and Gas Operators in all phases of their well bore completion.

The Leadership team has over 100 years of experience in Canada, US and International markets, both from a service company and operator perspective.

Click to Play

Click to Play

Watercut Australia (formerly known as UHP) was awarded the 2007 Director’s EHS Award for Best Health and Safety Project or Innovation from Santos Oils Australia. The award was won for its development and utilisation of abrasive water jet technology for field work in the Cooper basin South Australia.

Watercut Australia prides itself on the ability to find solutions for complicated problems.

Watercut Australia (formerly known as UHP Solutions) specialises in abrasive water jet technology Its field operations are fast becoming recognised for their ability to provide solutions to a number of different clients such as Chevron Australia and Santos Oils Australia PTTEP

An abrasive water jet entrainment system mixes the abrasive with the water jet in a mixing chamber just after the nozzle In most systems being built today, a venturi effect is utilised to pull the abrasive into the water jet The abrasive particles are accelerated into the stream and then with the stream out the focusing tube

Water Cut Australia has been in operation for over 20 years, with a combined 52 years experience for both on and offshore work, possessing an impressive 100% safety record.

Regardless of how remote the location, from the remote outback to an unmanned monopod or rig, this fully selfcontained unit is able to work in any area.

Utilising an inert form of cutting with only water and garnet as the medium, minimises risks of explosion or fire.

Being remotely operated ensures minimal personnel in the immediate area of operation, providing a safe work environment.

Watercut Australia with R&D

Solutions offer a full wellhead, casing and structure removal capability which is safe and easy to use, quick to deploy, and both environmentally and personnel responsible.

Total solutions with a minimal footprint.

Click to Play

It is agreed in the industry that one of the most dangerous aspects of a well’s life can be decommissioning, if not handled correctly.

This can lead to unplanned events or even harm to personnel and the environment, particularly when removing wellheads, redundant gas flow lines or oil and gas storage vessels.

R&D Solutions uses custom built Ultra High Pressure (UHP) Inert jet cutting technology to precision cut and remove wellheads and flow-lines, removing the need for old fashioned techniques and burning equipment. An example of a typical set up and the resulting clean cut wellhead ready for disposal is shown adjacent.

UHP technology has a successful 11-year track record of use by major oil and gas companies on and offshore.

Advantages of using UHP technology include:

• Inert cutting using high pressure water and garnet, no naked flame

• Safe to use with no one in close proximity to the cutting head

• Minimal environmental footprint

• Unit self contained

• Staff trained to cutting industry standards

• 4 x 4 driver trained

• IVMS installed

• Remote area permit trained.

Mobile: +61 433 332 365 Office: +61 8 9486 8350

doug.gillespie@randd-solutions.com

Mobile: +61 433 606 555

Office: +61 8 9486 8350

russell.furner@randd-solutions.com

4 Riversdale Road, Welshpool, Perth, WA 6106 Australia

Website: www.randd-solutions.com

R&D Solutions

Welshpool & Canning Vale Australia

Mobile: +61 450 663 908

Office: +61 8 9486 8350

allan.paterson@randd-solutions.com