R & D SOLUTIONS

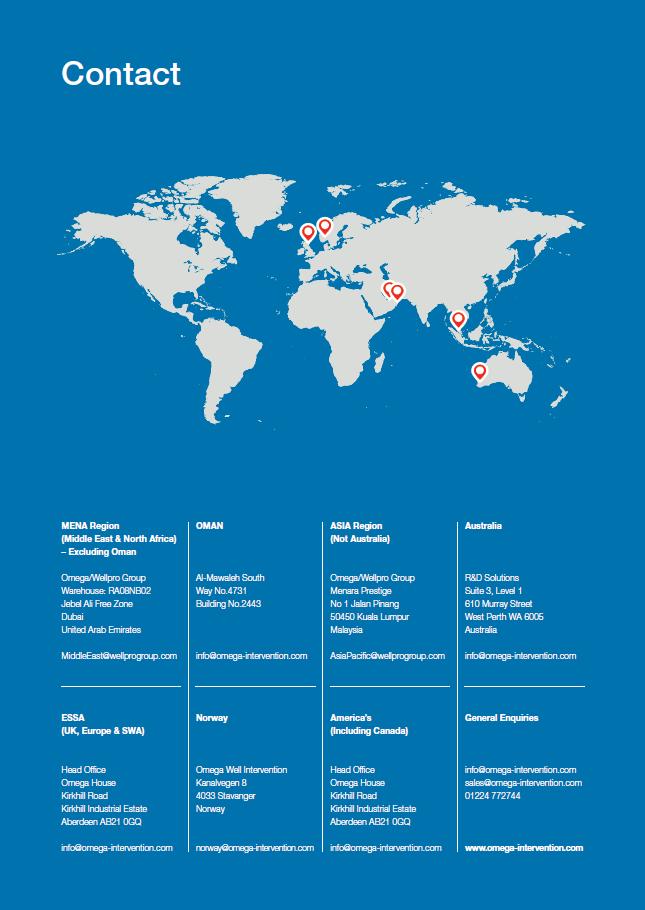

R&D Solutions is a privately owned oil, gas, and renewable energies equipment and services provider.

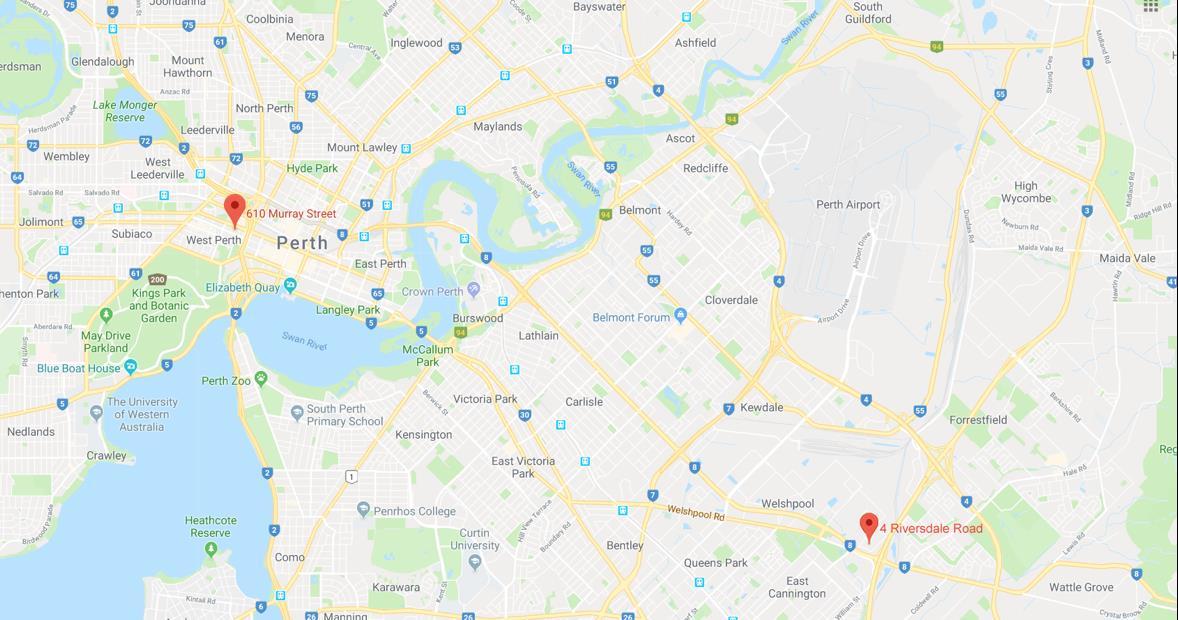

Based in Perth Western Australia, R&D Solutions prides itself on providing a broad spectrum of equipment and technology solutions. From the remote outback of Australia to offshore Asia and Europe.

We are available around the clock to assist service and support your operations.

We are the representative agents for a range of suppliers of proven drilling, completion and monitoring technology. Whether your requirements are for geothermal renewable energies, or traditional oil and gas, locally and internationally, our track record proves we will deliver on time and to budget.

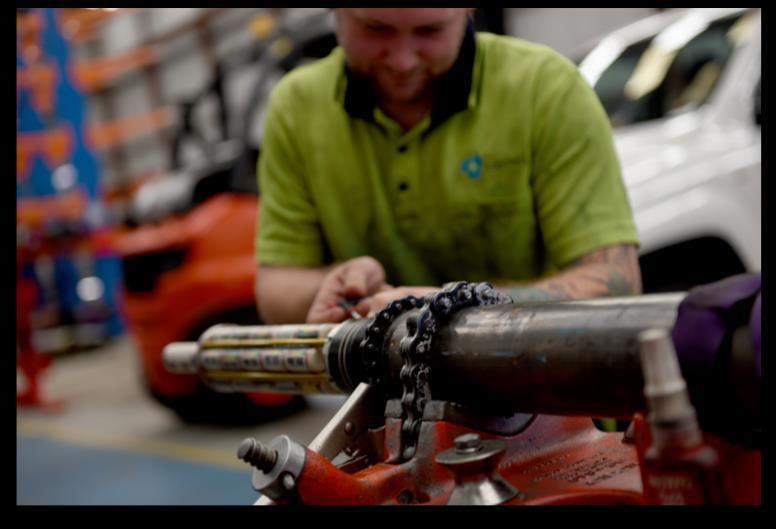

In addition to product supply our locally based engineering group is well positioned to assist you with one off tool requirements that may arise during operations.

We also facilitate heavy industry machine repairs of damaged equipment or refurbishment.

R&D Solutions prides itself on being able to take on special build items and turn these round in a timely manner from concept to delivery.

In alliance with independent training providers, R&D Solutions provides industry training on all of the following:

• Slickline Operations

• Well Completion

• Basic Completions

• Overall production & exploration overviews

• Induction type courses for new hires

• Slickline course for supervisory personnel

Our customers engage us for our proven history of delivering responsive and cost competitive solutions. R&D Solutions’ Directors bring significant local and international experience. Russell Furner is formerly of BBL Bits and Doug Gillespie is exWeatherford Completions.

Our history of continued repeat business from our client base of major oil and gas companies is testament to our commitment to outstanding service, including Apache Energy, Chevron, Esso Exxon, Hess, Horizon Energy, Inpex, Santos, Shell, Vermilion Oil and Gas, Weatherford and Woodside.

Local highlights since establishment include the award of the Chevron Wheatstone contract for the supply of drill pipe protectors and service, the Shell prelude contract for the supply of Matrix Low Friction centralisers, drill pipe protectors and service and a Master Services agreement with Santos to provide Packers Plus technology and services.

The bigger, new R&D Solutions warehouse is conveniently located at Welshpool near Perth City airport to provide accountable Equipment Storage and Inventory Management with prompt receipt and delivery to and from customer’s mobilisation point or workshop.

4 Riversdale Road Welshpool Western Australia 6106

• Full service Office with access 24/7

• 2000m² fully enclosed, high truss, air conditioned warehouse and workshop

• Double overhead cranes

• 2000m² outside hardstand

• 30 minute drive from Perth CBD. 15 minutes from Perth airport.

• Fully equipped workshop with hand tools

• Total Inventory management

• All good stored under cover

• Fully fenced, secure yard with parking and lay down area

• Monitored alarm and security cameras

• Forklifts and qualified staff to conduct equipment load outs and receivals

For small shipments R&D Solutions can deliver to customer’s facilities at short notice. For larger goods R&D Solutions use local transport and shipping specialists to ensure quality service at a competitive cost.

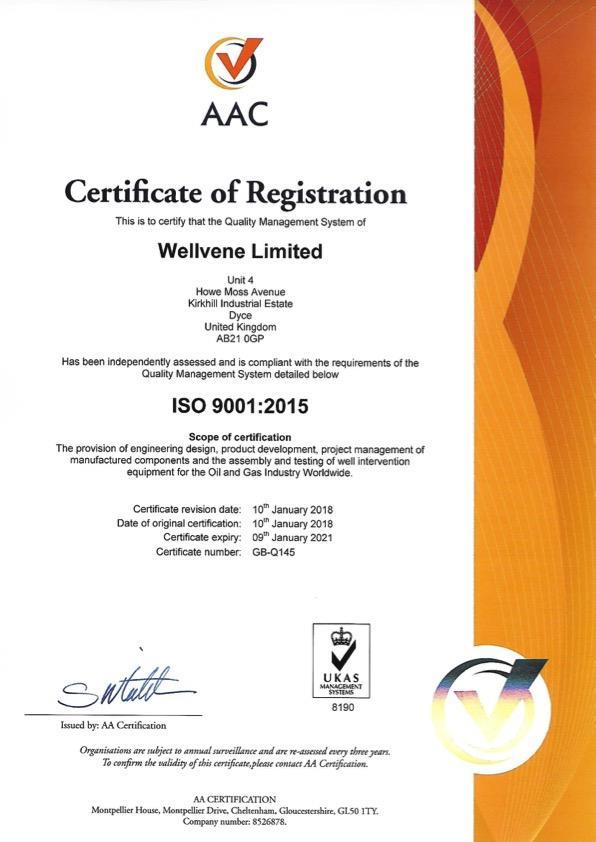

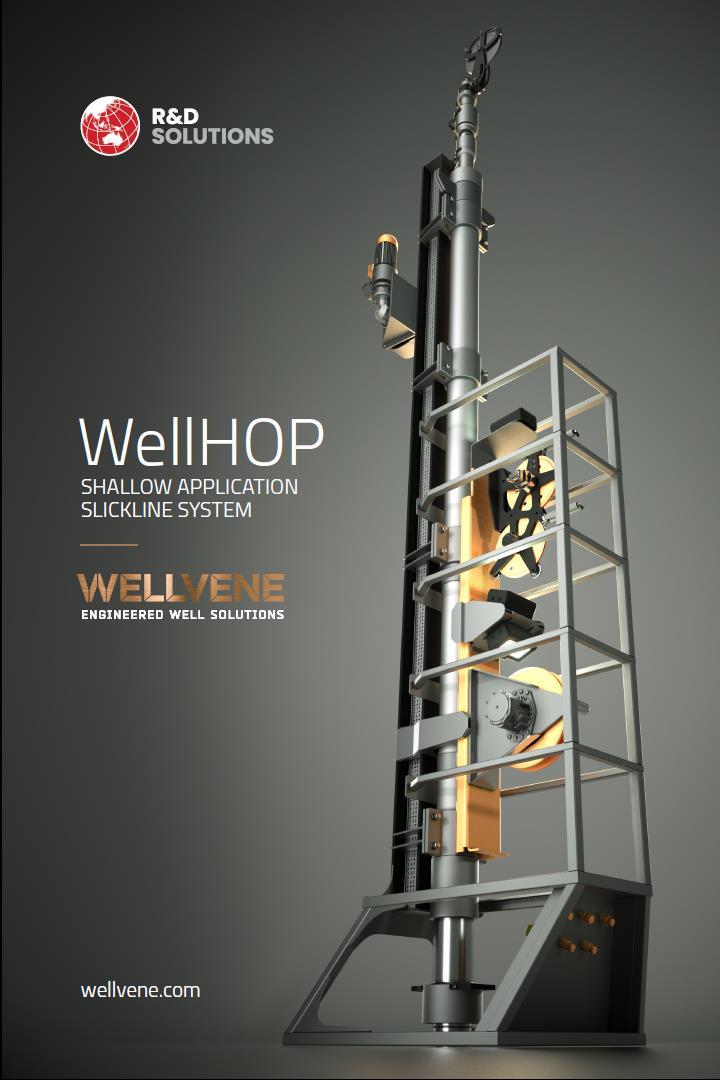

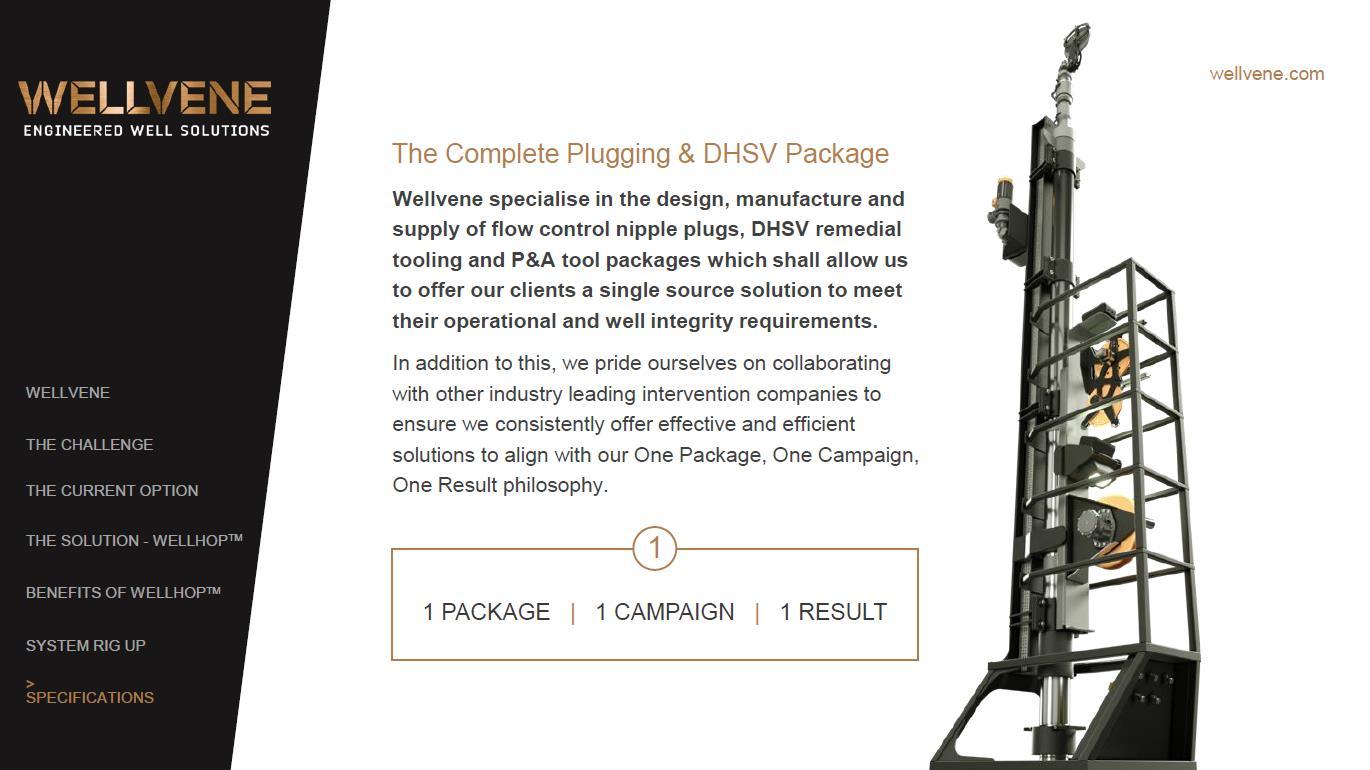

Based in Aberdeen, Wellvene’s goal is to ensure the highest level of customer service through providing responsive, cost effective solutions for design engineering and manufacturing of specialised intervention tooling.

With their cross-industry background, extensive knowledge and experience in completion, intervention and integrity operations, coupled with expertise in design engineering and manufacturing, Wellvene are positioned to understand and evaluate customer requirements. This ensures they deliver quality assured products to meet your operational demands.

Wellvene Limited was formed by Bronson Larkins and Stephen Crossan to support the well intervention industry’s increasing demand for custom design, engineered tooling solutions and quick turnaround manufacturing services.

Whether a standard or specialised engineering requirement, the goal at Wellvene is to provide the customer with a service that allows for prompt understanding and evaluation of the challenges encountered with intervention operations

With the design engineering and in-house manufacturing capability, Wellvene can rapidly take a design from concept to completion, ensuring it meets the time frame and expectations associated with planned or ongoing operational requirements

The team offer a cross industry background with extensive knowledge and experience in completion, intervention and integrity operations. This coupled with our expertise in design engineering and manufacturing, allows us to deliver a quality assured product ready to meet the most demanding of challenges.

From concept through to completion, we offer 3D conceptual modelling for each project. This allows for in-depth conceptual feasibility reviews to be completed prior to committing to the manufacture of a prototype or finished product. We have the capability of designing, manufacturing, testing and qualifying all technology and products in house to ensure the highest level of quality assurance.

With all products, Wellvene offer onsite training, in-depth technical manuals and tool assembly / disassembly videos. This ensures personnel product competency for every tool that has been designed, manufactured and supplied.

Wellvene is an innovative design engineering and manufacturing company. Formed to specialise in providing bespoke engineering services to support the global oil and gas well completion, intervention and integrity industry.

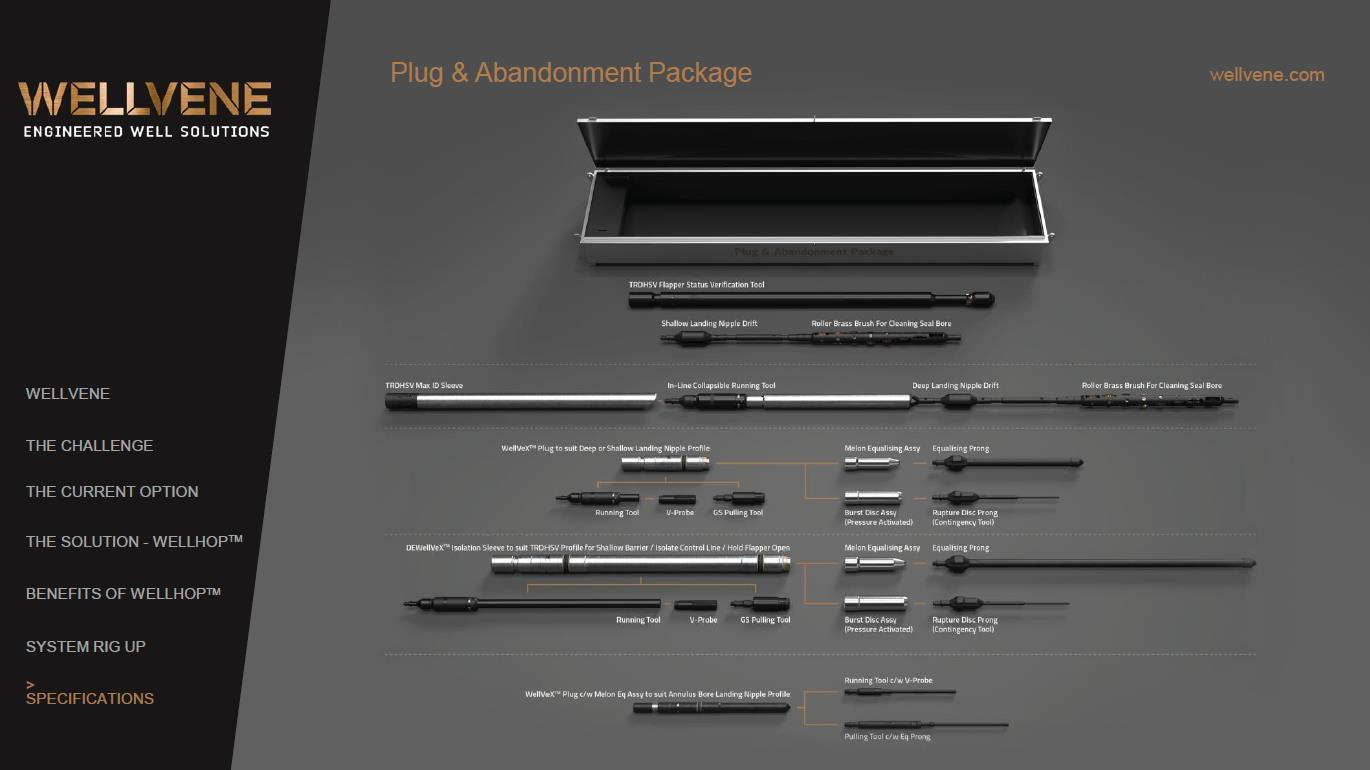

P&AOPERATIONS/

DoesyourInterventionoperationrequire thesettingof aDHSVSleeveandMedium ExpansionBridgePlugorCompositePlug?

If so,theWellvene4.244” MaxIDDHSVHoldOpen ProtectionSleevemayoffer asimpleyet veryeffective solutiontoreduceyour operational risk,timeandcost byreducingthenumber of wirelinerunsinhole.

Most DHSVHoldOpenProtectionSleevesinstalledwithin a5.500” TRDHSVofferathroughboreIDof approximately 3.900”.ThisIDissuitableformost interventionoperations, howeverincaseswherebyadeepset MediumExpansionBridge PlugorCompositePlug(ODtypicallygreaterthan4.000”)is required,accessthroughthesesleevescannot beachieved.

Assuch,thismaydictatethesequenceof operationalrunsand limit optionsforinterventiontoolselection.Incaseswhereby thewellhasaninoperableTRDHSVFlapperValvethiscan potentiallyturnastandardoperationintoacomplexoperation.

TheWellveneMaxIDSleevewithit’sthroughboreIDof 4.244” allowsforMediumExpansionBridgePlugsandComposite PlugswithanODupto4.200” tobesafelyrunandretrieved throughthesleevewhilst ensuringsufficient clearance.

TheSleevecomescompletewithtwoWellveneSpecialised RunningTooloptions.TheStandardRunningToolwhich setsthesleeveandisthenretrievedtosurfaceforchange out tothenext toolstringortheInlineCollapsibleRunning Toolthat setsthesleeveandcontinuesinhole.

WhenrunontheInlineCollapsibleRunningToolc/w 4.200” ODExtension,thisbecomesasimulateddrift forbridgeplugs/ compositeplugs.TheDrift canberun tothetarget settingdepthtoconfirmaccesspriorto runningandsettingyourpreferredplugoption.

Fora4.500”TRDHSVour4.500”MaxIDSleeveallowsfor thestandard3.125”sleeveIDtobeincreasedupto3.494”

Ò RunandretrieveonstandardGSPullingTool

Ò InlineRunningTool/ PullingTool

InternalLift Suballowssleevetobesetandretrieved duringsinglerun

Ò CollapsibleRunningTool

Allowssleevetobeset,T/SruntoTDandretrieved backthroughsleeve

Ò Designedtosuit anynippleprofilesizeandtype

Ò SnapinCollet Fingerstosecurelyholdinposition

Ò Savetimeandriskbyreducingrunsinhole

Ò Designedtoprotect sealboresandholdflapper valveinopenposition

Ò Suppliedwithliftingclamp

Ò SecureLockCollet Fingerstosecurelyholdin position

Ò RunandretrievedonastandardGSc/w check pull,Set VerificationSub(SVS)

Ò Designedtosuit anynippleprofilesizeandtype

Ò Designedtoprotect sealboresandholdflapper valveinopenposition

Ò Suppliedwithliftingclamp

Ò RunandretrievedonStandardorCollapsible RunningTool

Ò Designedtosuit anynippleprofilesizeandtype

Ò SnapinCollet Fingerstosecurelyholdinposition

Ò Savetimeandriskbyreducingrunsinhole

Ò Designedtoprotect sealboresandholdflapper valveinopenposition

Ò Suppliedwithliftingclamp

Ò Maximumthroughborea owsaccessfor4200” ODBridgePlug/ CompositePlug INLINECOLLAPSIBLERUNNINGTOOL

Ò P&AOperations- reducerisk,timeandcost by reducingrunsinwell

Ò TheCollapsibleRunningTooloptionallows ortheDHSVSleevetobeset and the4200” ODRunningToolExtension

Ò RunandretrievedonE-Line

Ò Designedtosuit anynippleprofilesizeandtype

Ò Eliminatesrequirement for Slicklinerigupto set sleeve

Ò Mechanicallyset andretrieved

Ò SnapinCollet Fingerstosecurelyholdinposition

Ò Savetimeandriskbyreducingrunsinhole

Ò Designedtoprotect sealboresandholdflapper valveinopenposition

Ò Suppliedwithliftingclamp

Ò RunonspecialisedRunningTool / RetrievedwithstandardGS

Ò Designedtosuit anynipple profilesizeandtype

Ò Availablewitharangeof seals tosuit sealborerequirements

(V-Packings,D-Seals, Swellables)

Ò Manufacturedinarangeof materialstosuit wellconditions

Ò Pressureratingtosuit operationalrequirements

Ò ThroughboreIDtosuit operationalrequirements

Ò Availablefor DHSVor Injection ValvePack-Off

Ò Runandretrievedonastandard GSc/w Set VerificationSub (SVS)

Ò Designedtosuit anynipple profilesizeandtype

Ò Availablewitharangeof seals tosuit sealborerequirements (V-Packings,D-Seals, Swellables)

Ò Manufacturedinarangeof materialstosuit wellconditions

Ò Pressureratingtosuit operationalrequirements

Ò ThroughboreIDtosuit operationalrequirements

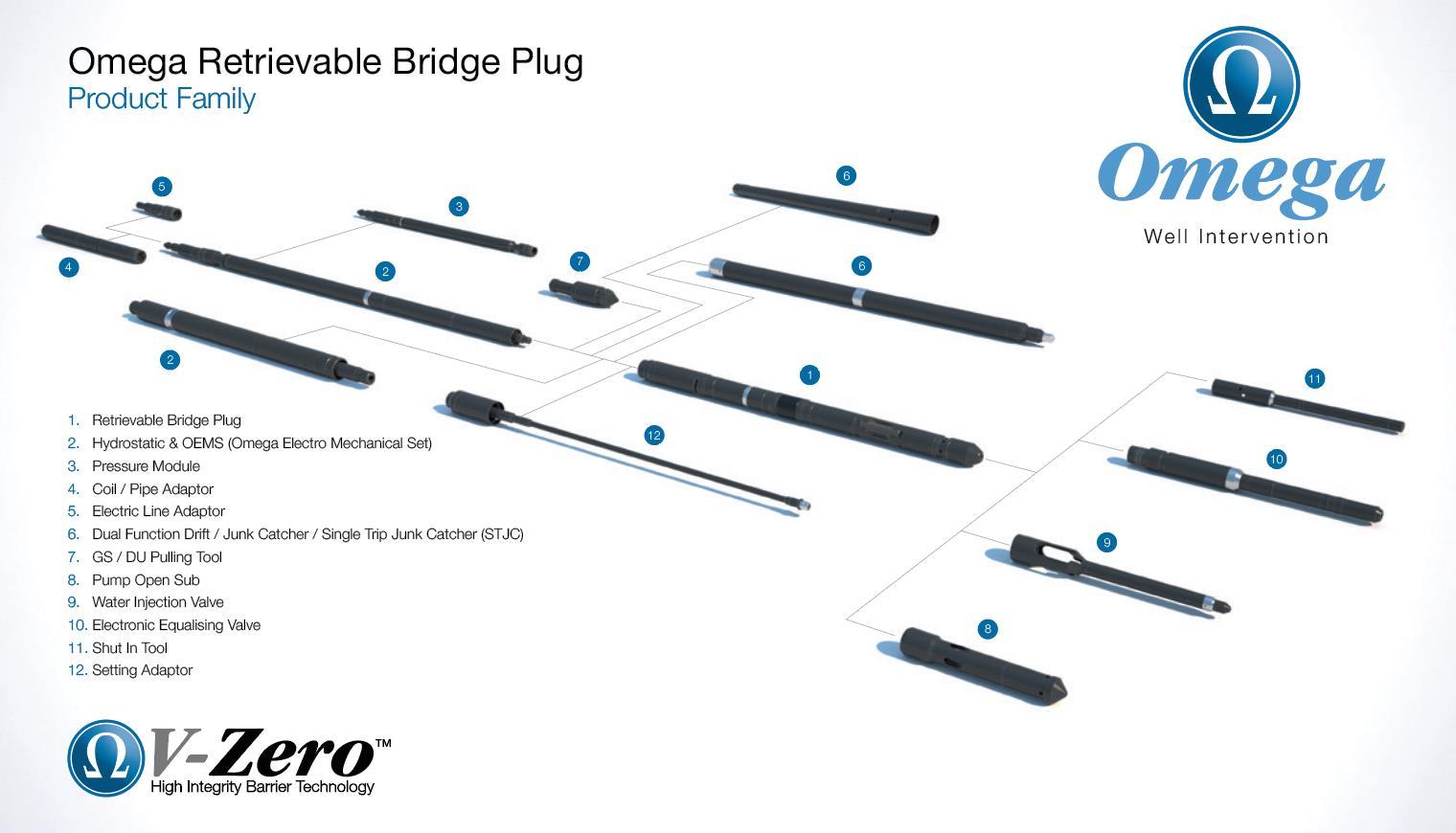

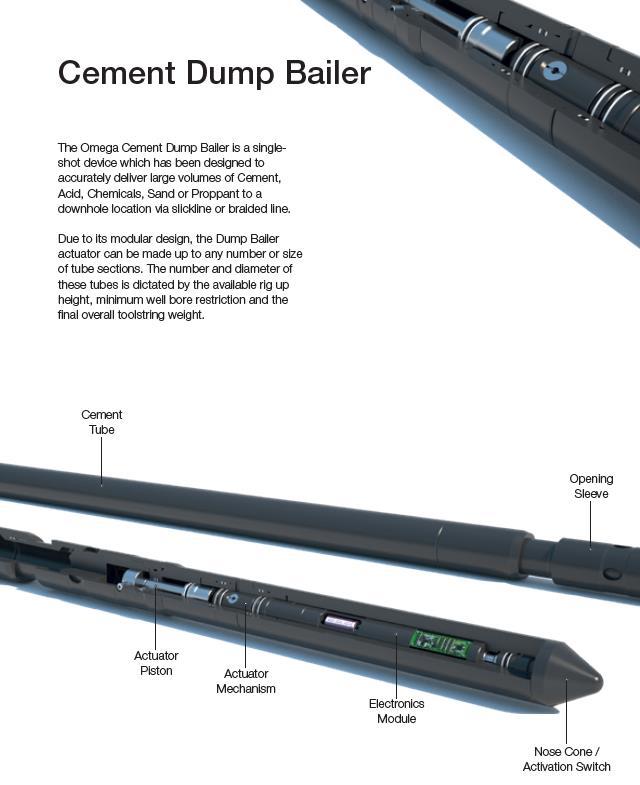

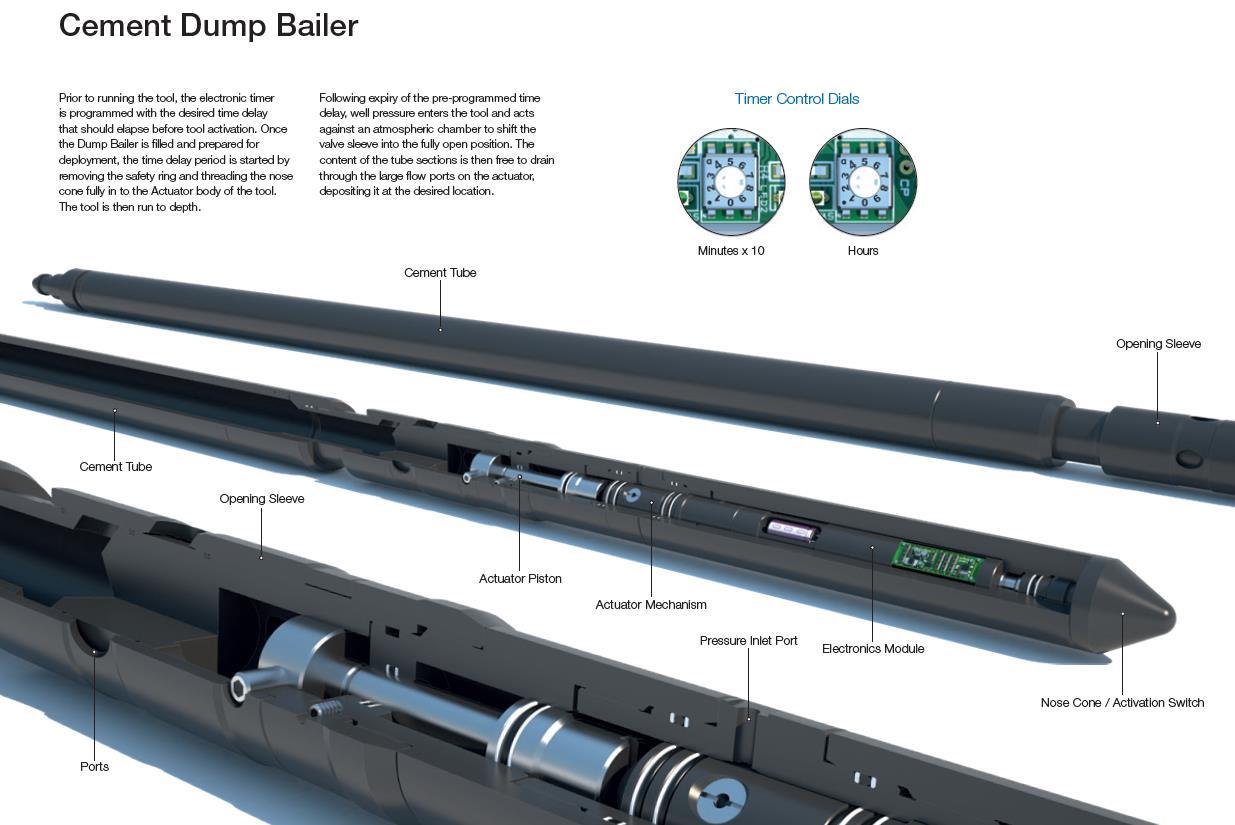

Omega Well Intervention is an innovative technology developer who design, engineer and manufacture downhole well Intervention tools for the global Oil and Gas industry. We offer quality assured products to help support our clients with their most demanding challenges.

As well as operational design, we offer 24/7 office and field support to run and deploy our well intervention technology.

With our extensive knowledge and experience in intervention, Omega can provide our clients with solutions to meet their operational requirements and challenges. Along with our alliance partner Wellpro, we have the capability to service clients through the use of a wide range of innovative market leading solutions in downhole intervention products - covering portfolios of Well Isolation, Well Abandonment, Well Surveillance and Monitoring, and Wireline products.

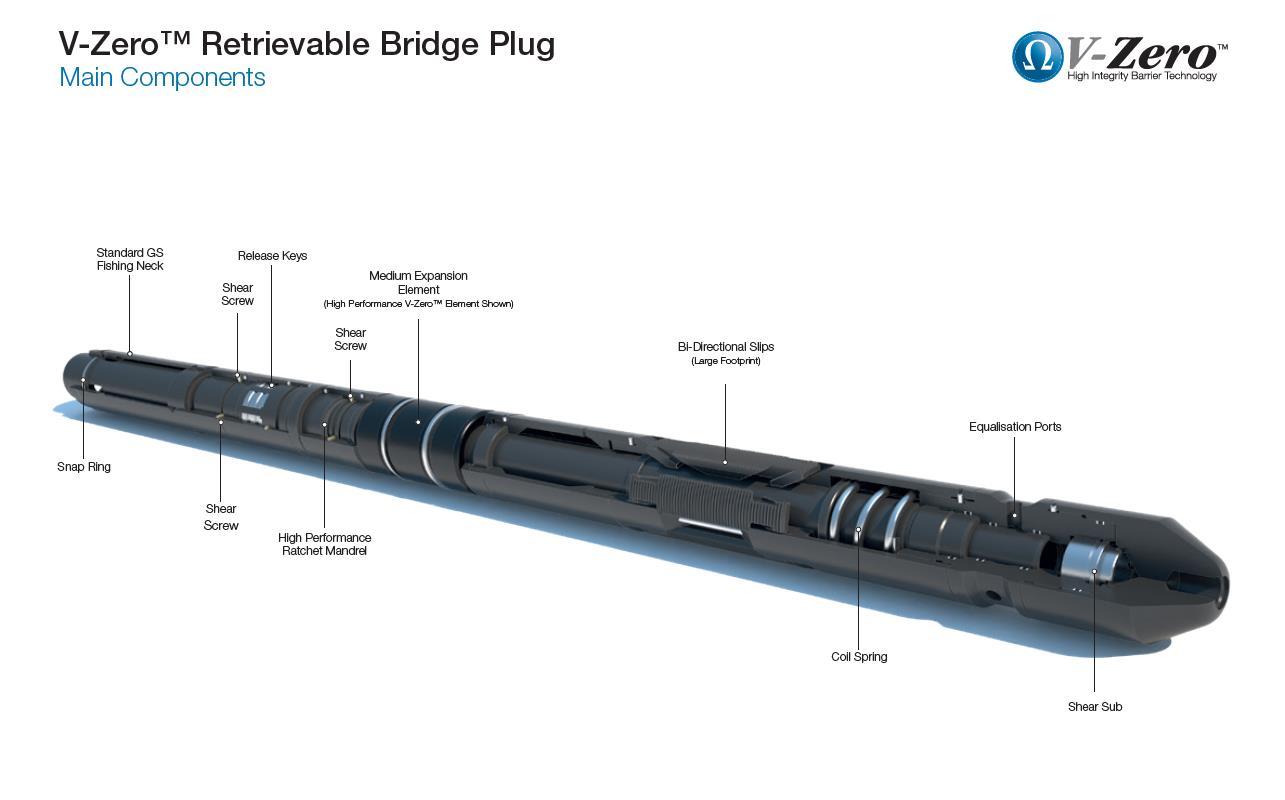

The V-Zero Retrievable Bridge Plug is a high performance monobore plugging device which can be set at any required depth in the tubing or casing.

The plug is deployed, equalised and retrieved using conventional well intervention methods.

Deployment is achieved in one run, as is the subsequent equalisation and retrieval of the plug. This enables a reduction in both well intervention risk and operational cost.

The plug features bi-directional slips which anchor it to the well casing before the element is packed-off to form the pressure seal. This multistage setting sequence makes it ideal for cross flow applications.

The large ‘through bore’ design ensures full equalisation occurs prior to retrieval. This also means that accessory equipment can be attached below the plug such as Omega’s remotely activated equalising valves.

Omega’s plug portfolio has undergone an extensive testing program qualifying them to the highest relevant industry standard.

Omega qualifies the V-Zero Retrievable Bridge Plug range to 5,000 psi @ 150ºC - 4ºC as per the requirements of API 11D1. Contact your Omega representative for more specific and updated testing information.

• High integrity barrier qualified elastomers.

• Medium expansion rate.

• Equalised and retrieved in a single run.

• Bi-directional mechanical slips.

• Large slip footprint maximises slip/casing contact area.

• Overall length minimized for restricted access deployment.

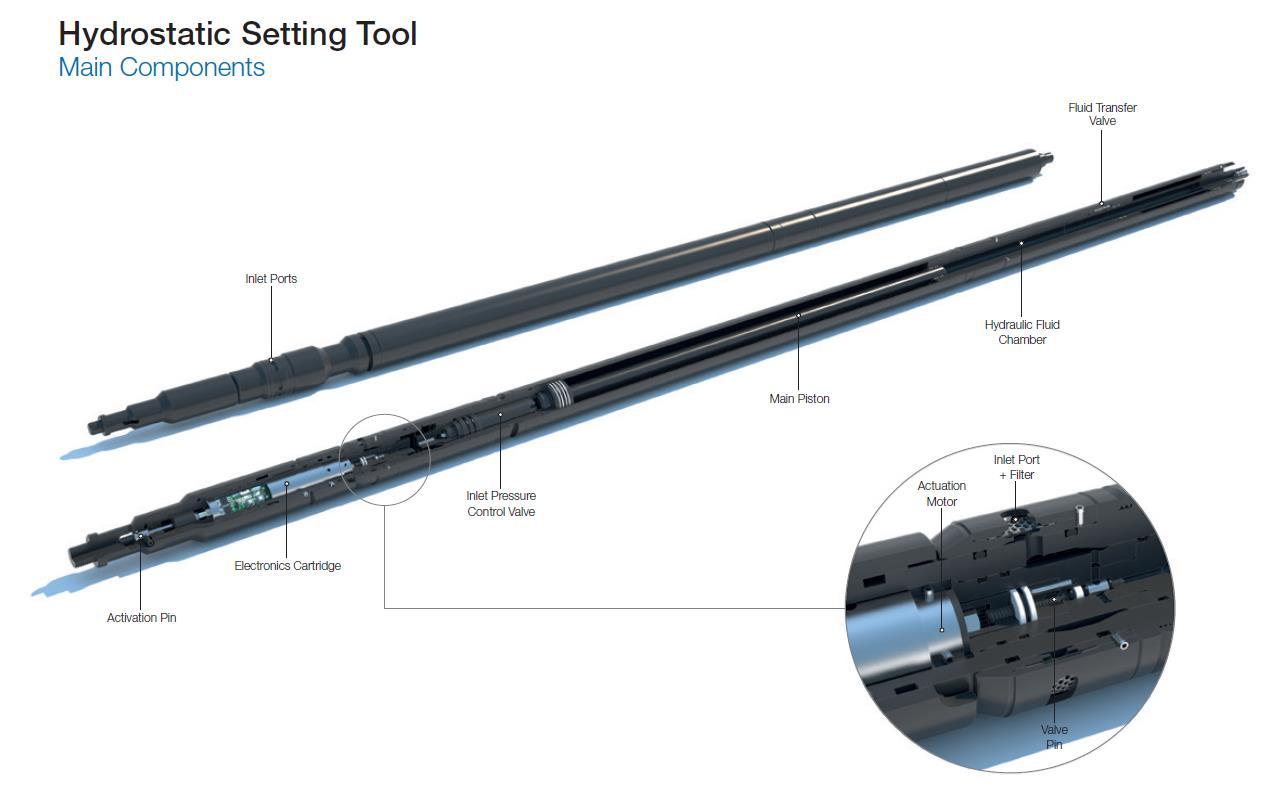

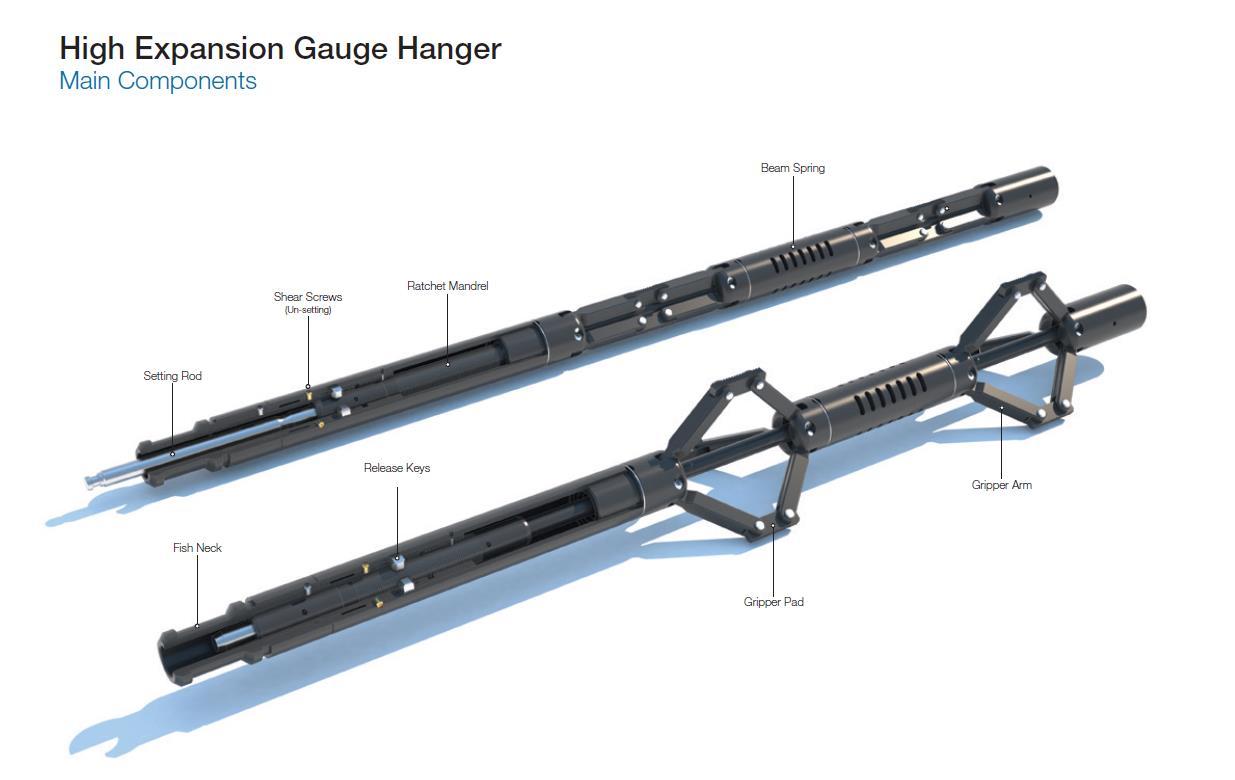

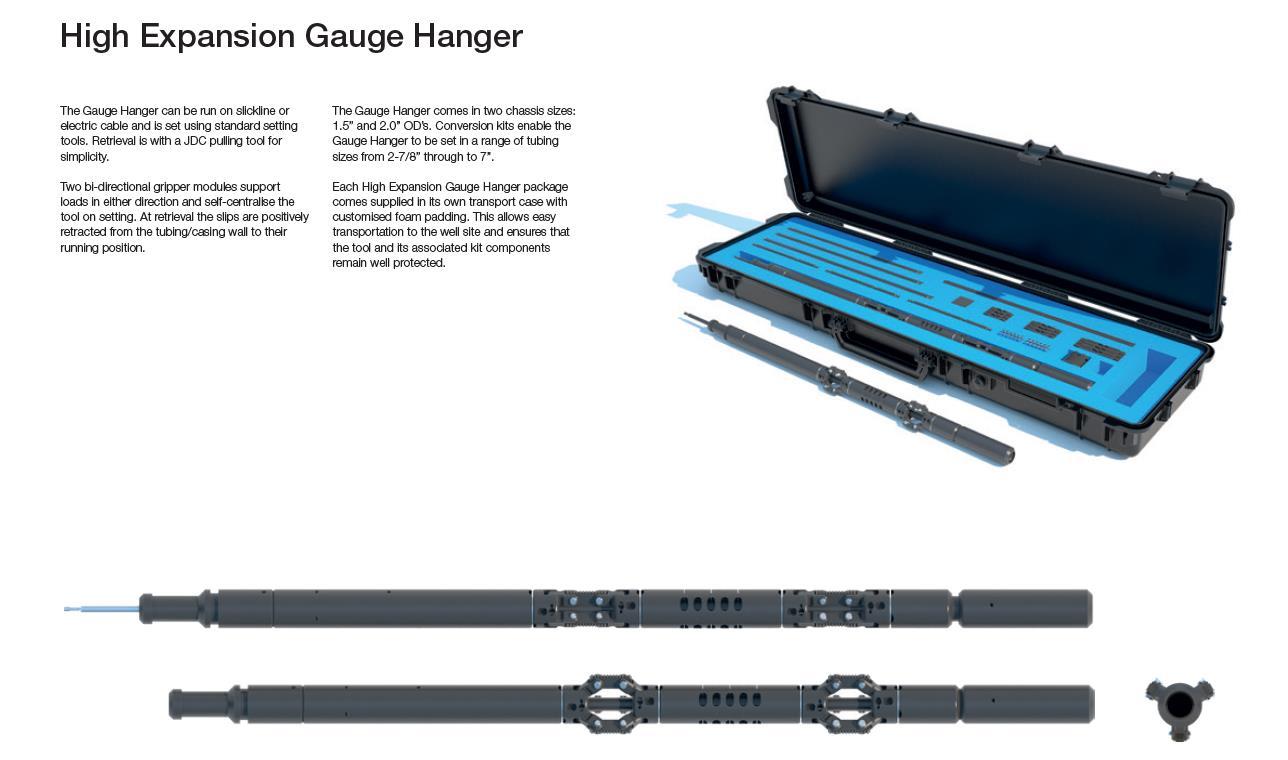

The Omega Hydrostatic Setting Tool (HST) provides the industry with a highly reliable, nonpyrotechnic setting device for the installation of downhole tools such as Bridge Plugs, High Expansion Gauge Hangers and Straddles.

The setting tool converts the hydrostatic pressure at the tool into an axial force. The short overall length of the HST has been achieved by incorporating a highly efficient pressure multiplier within the design. This combines with a unique regulating device to maximize the available output force whilst safely controlling the pressure entering the tool.

The tool can be deployed on slickline, wireline, coiled tubing and drillpipe. The lower end of the setting tool will make up to industry-standard wireline adapter kits. When run on slickline, a switch at the top of the tool is used to activate the timer prior to picking up the toolstring.

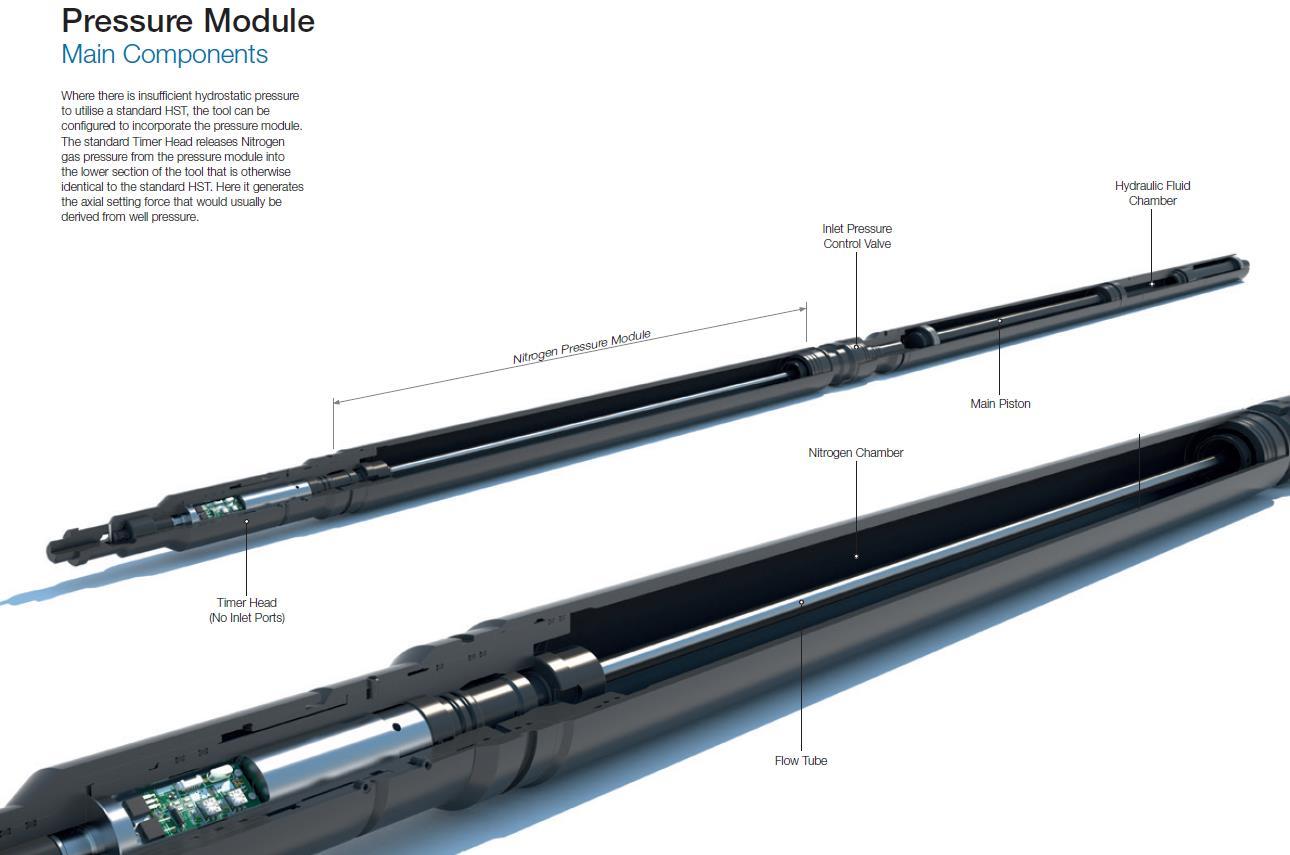

In applications where insufficient hydrostatic well pressure is available, a Pressure Module can be integrated into the HST. With no requirements for explosives, the Omega Hydrostatic Setting Tool negates the issues commonly associated with the handling, transportation, storage, importing and exporting of hazardous materials.

• Accurate time delay mechanism.

• Large output forces generated.

• High Pressure / High Temperature HST’s available.

• Large “Stroke” capability.

• Extensive track record.

The OEMS has a non-hazardous design, utilizing alkaline battery power instead of pyrotechnic or hydraulic pressure in the motive force provision of the setting cycle.

The OEMS is electronically controlled and can be used in both real-time and memory mode, providing multiple methods of activation along with the option of real-time command and control.

Once the setting cycle is commanded the tool provides a slow, controlled axial movement which aids in the centralization of the wellbore device.

The OEMS has onboard logging with the option to store the captured data on flash memory for analysis post-run, or transmit it in real-time to the surface. Once back at surface, the OEMS requires only the replacement of the combined power/control module to ready it for another run. This allows for faster turnaround times, reduced risk of operator error, and no need for specialist technician training.

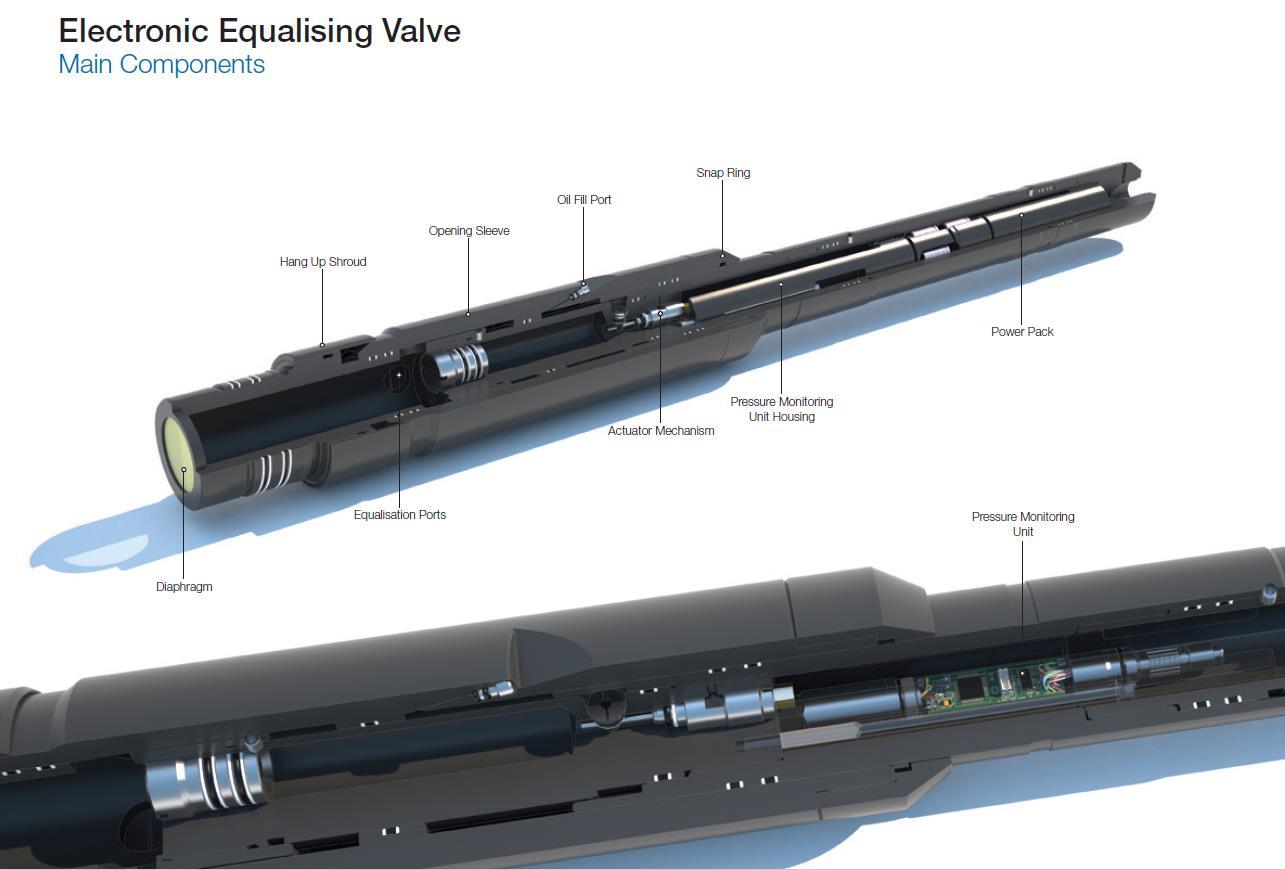

The Equalising Valve is an electronically-actuated valve that allows plugged wells to be equalised or brought onto production without the need for intervention.

The field-proven onboard electronics require no connection to surface as the valve is functioned with a ‘Command’ remote pressure signal. The unique command pressure signature can be selected based on operational requirements to avoid the possibility of communicating to other well bore devices accidently.

The pressure signature can be easily programmed at the wellsite using a laptop computer.

The valve can be installed below any lock or plug and can be used as a shallow or deep set barrier.

The Equalising Valve has successfully delivered a zero bubble, gas tight seal using the rigorous requirements set down by the ISO standard ISO 14310.

• Shallow set barrier for tree testing, maintenance and change outs.

• Deep set barrier for packer setting and tubing testing.

• Rapid resumption of production without the need for Intervention access.

• Isolation and opening of Multi-Lateral legs.

• Barrier for Work Overs.

Although the Omega Water Injection Valve is typically used in water injectors, it is also ideal for use where oil producers are being converted to injectors due to failed safety valves.

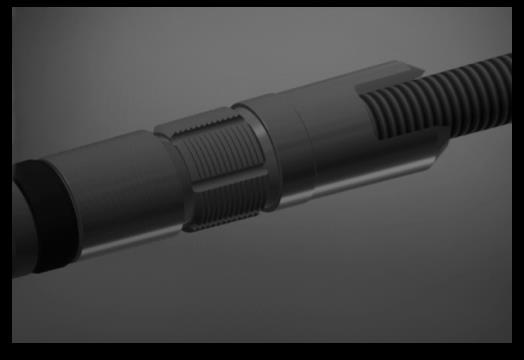

The Injection Valve acts as a fluid barrier and in certain scenarios it can prevent the ingress of sand to the well when injection is stopped.

The valve is unique within the market place, incorporating a hydraulic dampening system to deal with flow-induced vibration. The dampening system also allows the valve to ‘softclose’ preventing any damage to the seal faces when injection ceases. Anti-rotation locking rings secure each of the threaded connections within the tool ensuring there is no potential for backout during flowing conditions.

The Injection Valve is spring-biased into the closed position and opens when injection fluid is pumped down the tubing. The large annular flow ports maximise available flow area through the valve whilst minimising the pressure drop across it.

When pumping is stopped the spring forces the plunger upward to seat on the seal face, preventing any fluid from below the valve flowing back into the tubing above.

• Hydraulic dampening system to prevent unwanted vibration.

• Soft closure feature to extend plunger seal life cycle.

• Debris tolerant seal system.

• Anti rotation connections.

• Large annular flow ports.

• Metal To Metal Seal increases durability

The Omega Dual Function Drift Junk Catcher can be quickly and easily configured to fulfil either of two roles based on operational requirements.

Drift The overall length of the drift assembly can be configured to mimic the OD dimensions of Bridge Plugs, Straddles, Locks and any other flow control device to be installed in the well. It is then run to the required depth and retrieved ensuring that the tools can be run and set without hanging-up within the well bore.

Junk Catcher As a Junk Catcher the assembly can be run to depth on a GS running tool and landed off in the fishing neck profile of the equipment already installed in the well bore. The Junk Catcher is left in position to capture debris which may build up above the well bore device. The Junk Catcher may then be removed at a later date using a GS pulling tool.

The Omega Dual Function Drift Junkcatcher is easily converted from one mode to the other, by simply changing the orientation of the conversion sleeve within the tool. To use as a Junk catcher, the Conversion Sleeve covers the flow ports in the Ported Sub. To use as a drift the sleeve is reversed leaving the ports open for fluid bypass.

• Fully adjustable drift length and junk capacity.

• Standard GS running/pulling profile.

• Bull nose supplied with standard sucker rod connection.

• Increased latching area for improved jarring impact.

The Omega Single Trip Junk Catcher is designed to be run in conjunction with the Omega Retrievable Plug range.

Deployed on the Omega Hydrostatic Setting Tool, the Junk Catcher remains located above the Bridge Plug, preventing debris from entering the plug, where it could compromise the flow path or the subsequent plug retrieval.

The Single Trip Junk Catcher benefits from a flapper system that will close upon setting of the Bridge Plug, isolating and protecting the plug.

Generously sized ports allow fluid bypass should the Bridge Plug be run with a hydraulic equalisation device such as the Omega Equalising Valve or Pump Open Sub.

The Single Trip Junk Catcher is retrieved on Slickline with an appropriate GS Pulling tool.

• Standard GS running / pulling profile.

• Isolation Flapper.

• Large Bypass Ports.

The Pump Open Sub can be attached beneath a packer or lock to provide an equalising facility prior to the retrieval of the equipment.

The Pump Open Sub is run in hole in the closed position. Pressure can be applied to the tubing to perform a pressure test or set completion equipment above the tool.

Opening is achieved in one of two ways. Applying pressure to the tubing will shear the shear screws, allowing the sleeve to move until it is locked in the open position.

Alternatively, the shear screws can be sheared and the sleeve mechanically pushed off seat using a prong. Once the sleeve reaches the bottom of the tool it is locked in the open position.

The Pump Open Sub has successfully delivered a zero bubble, gas tight seal using the rigorous requirements set down by the ISO standard ISO 14310.

• Primary hydraulic equalising function is achieved by applying pressure from surface.

• Secondary mechanical equalisation method by using prong.

• Fully adjustable shear load activation.

• Once equalized the device is retained in the open position.

• All shear screws are retained within the tool.

The Omega Presssure Activated Shut-In Tool is a singleshot closing device designed to be run below a Bridge Plug or Lock Mandrel.

It closes after a pre-programmed time delay or after reaching a pressure threshold.

It is primarily intended for use in basic well testing situations where a flowing well is shut-in downhole and the resulting pressure build up is monitored by memory gauges.

A predetermined delay period and trigger pressure is programmed at surface prior to running in hole. When the monitoring unit scans the required hydrostatic pressure, the delay countdown is initiated and the tool is remotely closed.

The tool can also be used in new completions together with pre-installed plugs. This allows the tubing to be auto-filled prior to closing the tool. With the required barriers in place the Production Packer can be set and pressure tested prior to installing the xmas tree.

The tool contains two independent sets of electronics, two pilot valve mechanisms for 100% redundancy and once closed the valve is mechanically locked in the closed position.

• Provides pressure build up monitoring.

• Deployed below Lock or Bridge Plug.

• Allows auto-filling in new completions.

• Large flow area through tool.

• Two independent operating mechanisms.

• Field proven, 100% Activation Success.

4 Riversdale Road, Welshpool, Perth, WA 6106 Australia

Website: www.randd-solutions.com

Welshpool & Canning Vale Australia

Mobile: +61 450 663 908

Office: +61 8 9486 8350

allan.paterson@randd-solutions.com