R & D SOLUTIONS

R&D Solutions is a privately owned oil, gas, and renewable energies equipment and services provider.

Based in Perth Western Australia, R&D Solutions prides itself on providing a broad spectrum of equipment and technology solutions. From the remote outback of Australia to offshore Asia and Europe.

We are available around the clock to assist service and support your operations.

We are the representative agents for a range of suppliers of proven drilling, completion and monitoring technology. Whether your requirements are for geothermal renewable energies, or traditional oil and gas, locally and internationally, our track record proves we will deliver on time and to budget.

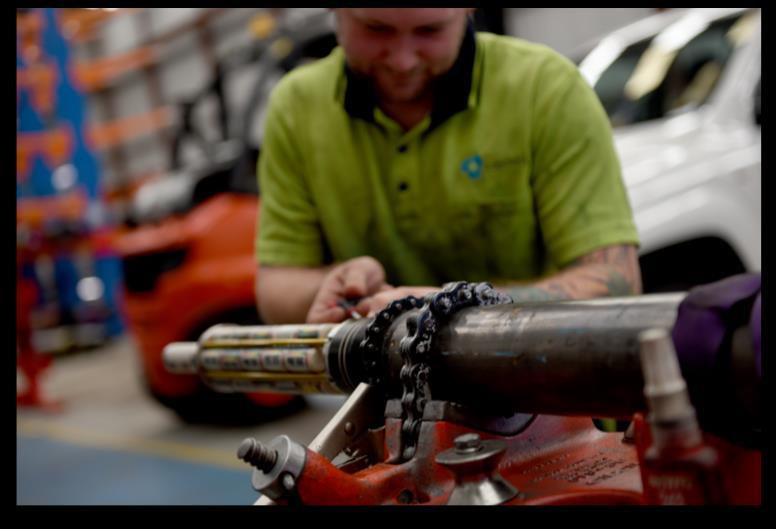

In addition to product supply our locally based engineering group is well positioned to assist you with one off tool requirements that may arise during operations.

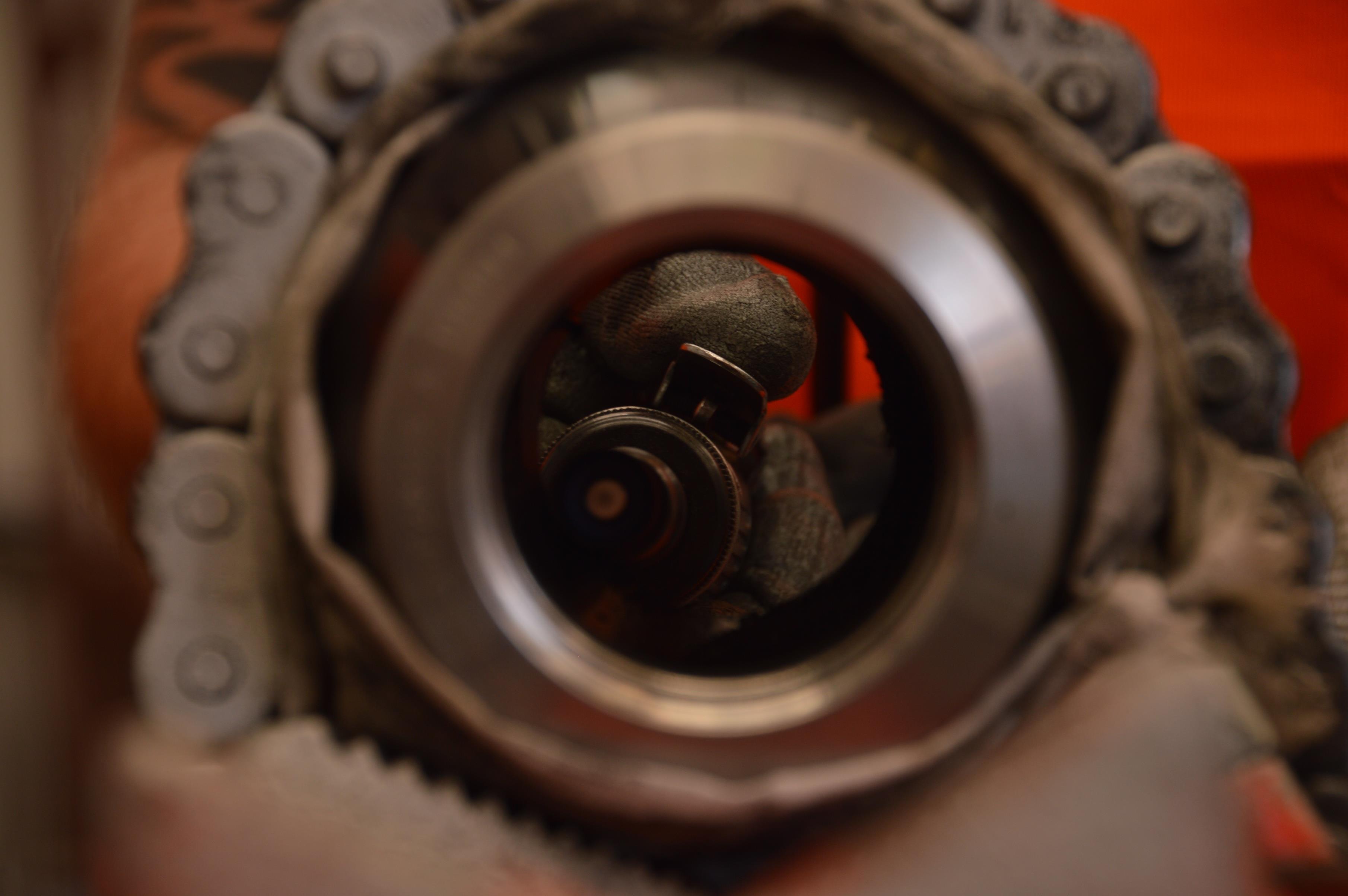

We also facilitate heavy industry machine repairs of damaged equipment or refurbishment.

R&D Solutions prides itself on being able to take on special build items and turn these round in a timely manner from concept to delivery.

In alliance with independent training providers, R&D Solutions provides industry training on all of the following:

• Slickline Operations

• Well Completion

• Basic Completions

• Overall production & exploration overviews

• Induction type courses for new hires

• Slickline course for supervisory personnel

Our customers engage us for our proven history of delivering responsive and cost competitive solutions. R&D Solutions’ Directors bring significant local and international experience. Russell Furner is formerly of BBL Bits and Doug Gillespie is exWeatherford Completions.

Our history of continued repeat business from our client base of major oil and gas companies is testament to our commitment to outstanding service, including Apache Energy, Chevron, Esso Exxon, Hess, Horizon Energy, Inpex, Santos, Shell, Vermilion Oil and Gas, Weatherford and Woodside.

Local highlights since establishment include the award of the Chevron Wheatstone contract for the supply of drill pipe protectors and service, the Shell prelude contract for the supply of Matrix Low Friction centralisers, drill pipe protectors and service and a Master Services agreement with Santos to provide Packers Plus technology and services.

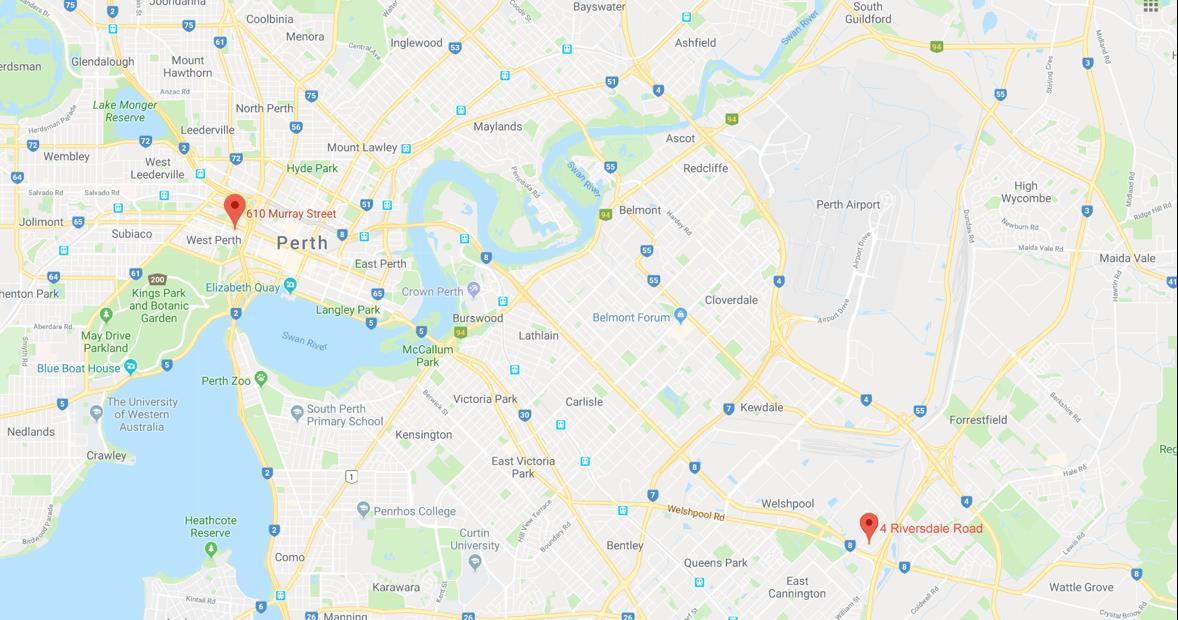

The bigger, new R&D Solutions warehouse is conveniently located at Welshpool near Perth City airport to provide accountable Equipment Storage and Inventory Management with prompt receipt and delivery to and from customer’s mobilisation point or workshop.

4 Riversdale Road Welshpool Western Australia 6106

• Full service Office with access 24/7

• 2000m² fully enclosed, high truss, air conditioned warehouse and workshop

• Double overhead cranes

• 2000m² outside hardstand

• 30 minute drive from Perth CBD. 15 minutes from Perth airport.

• Fully equipped workshop with hand tools

• Total Inventory management

• All good stored under cover

• Fully fenced, secure yard with parking and lay down area

• Monitored alarm and security cameras

• Forklifts and qualified staff to conduct equipment load outs and receivals

For small shipments R&D Solutions can deliver to customer’s facilities at short notice. For larger goods R&D Solutions use local transport and shipping specialists to ensure quality service at a competitive cost.

https://youtu.be/y-yhu5sUNvc

CORETRAX

DELPHIAN BALLISTICS

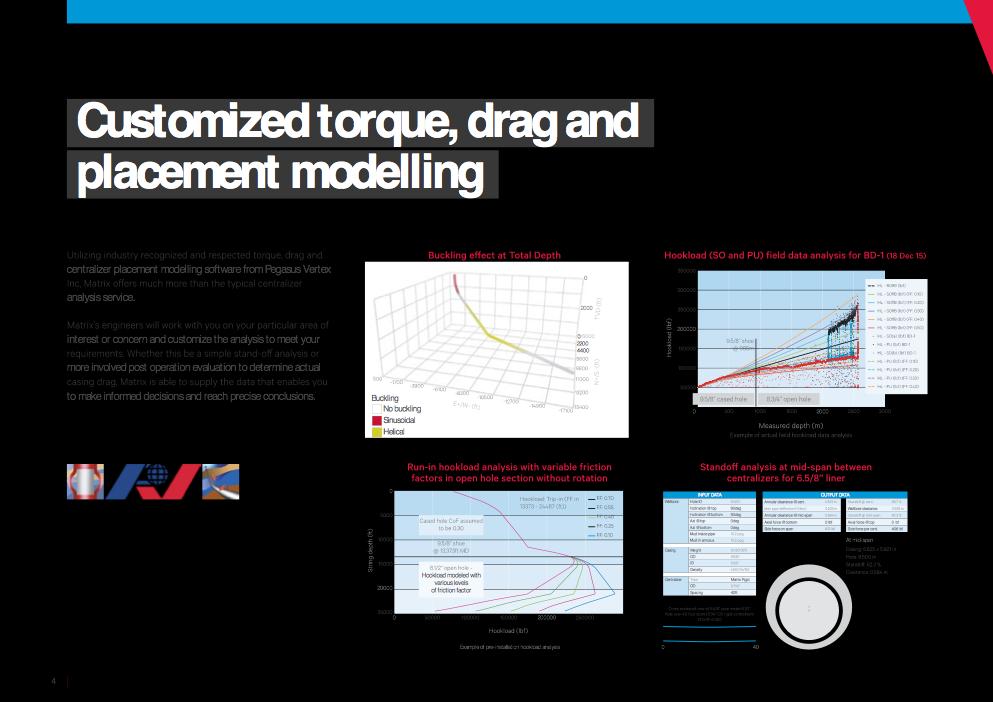

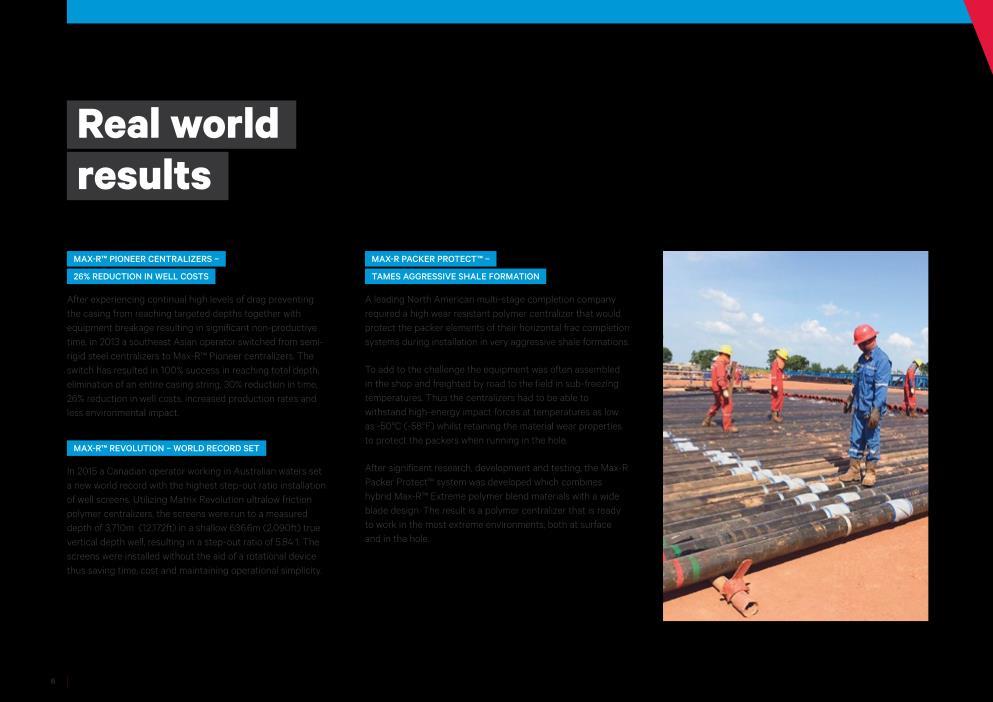

Matrix Composites & Engineering is an ASX listed company that provides solutions consisting of engineered products and integrated services to the global oil and gas industry. Using innovative manufacturing and advanced composite and polymer materials technology, Matrix is the global market leader in the manufacture of subsea buoyancy systems.

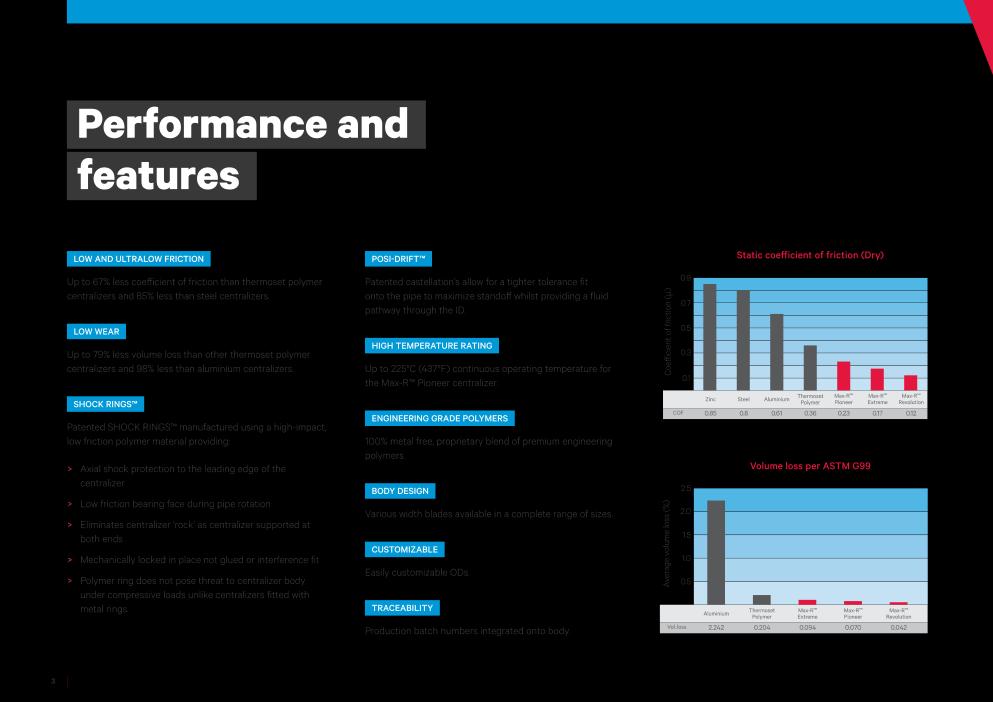

As well as supplying the traditional industry standard steel and aluminium centraliser, Matrix designs and manufactures a large range of patented low friction composite drilling and completions centralisers that are designed to convey well screens, completion tool strings and typical casing and tubing strings into highly deviated and challenging horizontal wellbores.

Matrix advanced polymer centralisers are light weight, highly durable and exhibit ultra low friction factors. They are made from proprietary composite material formulations designed by Matrix's in-house technology team.

• Reduce total well construction costs - eliminate the need for expensive casing couplings

• Enables casing or screen deployment in longer reach wells - industry leading low friction factors reduce torque and drag, enabling the user to reach total depth

• Zero corrosion - totally non-metallic material removes the contamination risk to carbon, or expensive hi- chrome content steel tubulars and completion equipment

• Low wear and material loss - low friction factors and advanced material formulations result in low wear

• High impact and side load resistance - longer lasting

• Light weight - the size to weight ratio is significantly lower than metallic centralisers which reduces freight and handling costs

• Specific OD's can be accommodatedcomposite material can be machined down to meet requirements.

The advanced polymer centralisers have the following design features:

• Spiral blade configuration - provides for optimal stand- off and assists turbulent flow during cementing operations

• Zero porosity construction

• Suit casing ranges from 4.5 to 10.75 inches

• Manufactured to strict ISO 9001-2000 quality standards

• Tested to API 10TR5.

Matrix uses integral Kevlar / Fibre Glass combination in its composite products. This provides extra reinforcement to high impact and strain areas. Every Matrix product goes through rigorous QA/QC & manufacturing controls to prevent product failure.

In 2011, Matrix opened the largest composites syntactic manufacturing plant in the world, located in Henderson, Western Australia.

The plant has double the production capacity of the company’s previous facilities and uses superior technologies to produce a high quality and more expansive range of products

The new plant has resulted in multiple operational efficiencies enabling greater output, shorter production times and superior product quality and consistency for the benefit of clients.

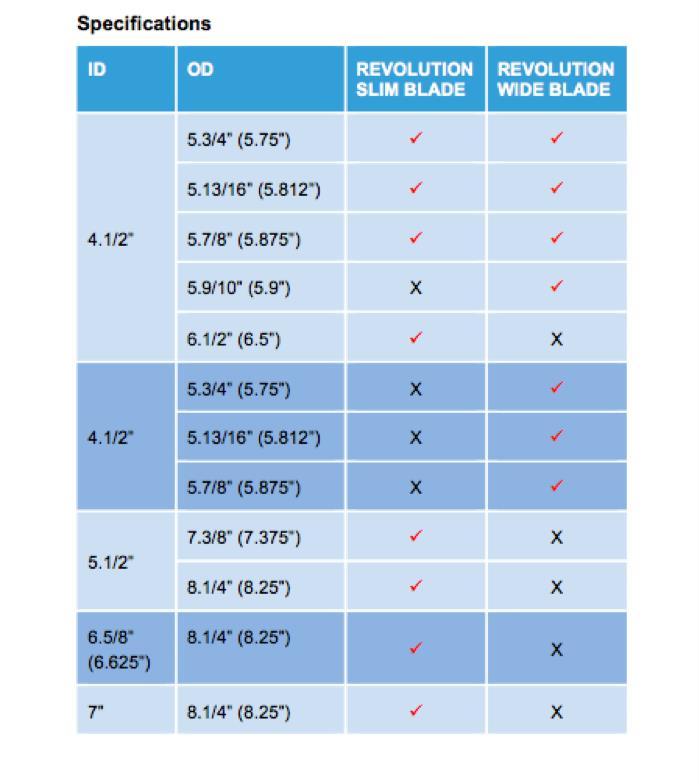

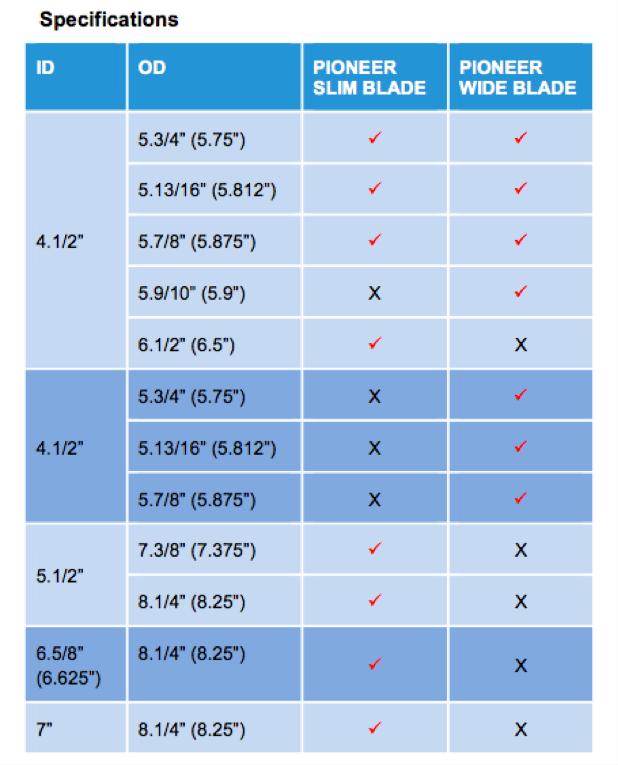

Ultra low friction centraliser. Designed specifically for extremely challenging, longer deviated wells and assists in achieving total depth, with low friction factors decreasing drag and torque, which reduces well construction costs.

• Reduces need for high torque, expensive casing couplings

• Reduces rig time by decreasing drag and reaching total depth quicker

• Allows for use of less expensive water based muds

• Light weight which reduces freight and handling costs

• Zero corrosion and contamination due to non-metallic material

• Highly durable, longer lasting

Ultra low friction centraliser. Designed specifically for extremely challenging, longer deviated wells and assists in achieving total depth, with low friction factors decreasing drag and torque, which reduces well construction costs.

• Reduces need for high torque, expensive couplings

• Reduces rig time by decreasing drag and reaching total depth quicker

• Allows for use of less expensive water based muds

• Light weight which reduces handling costs

• Zero corrosion and contamination due to non- metallic material

• Highly durable, longer lasting

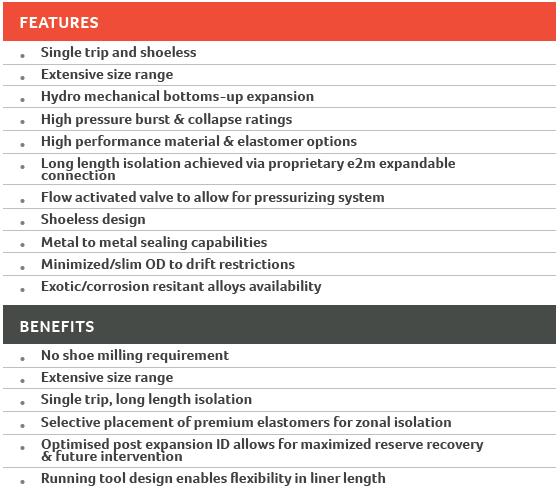

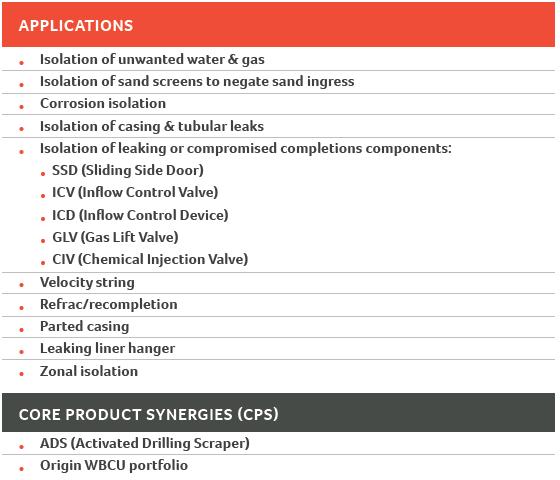

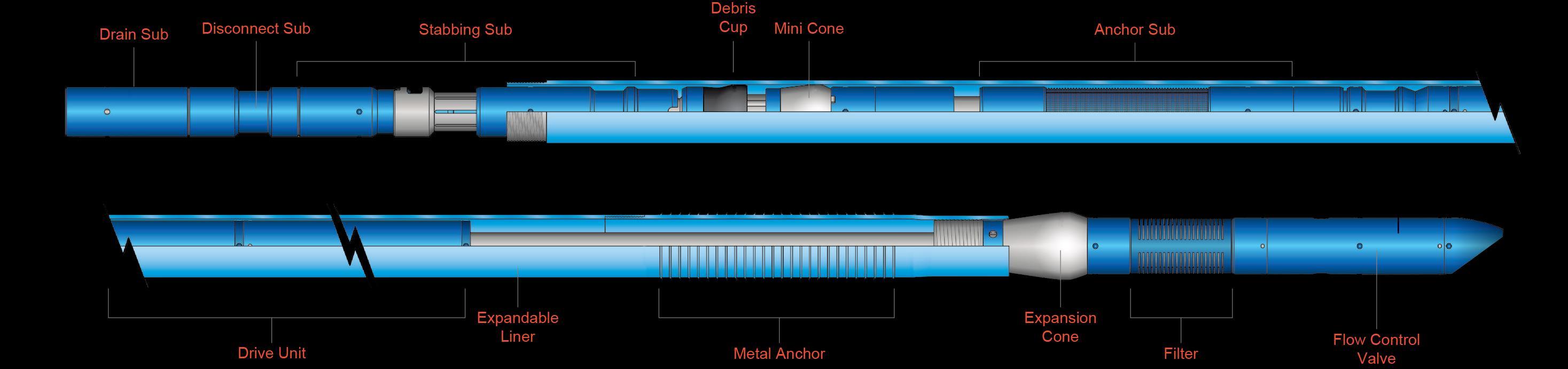

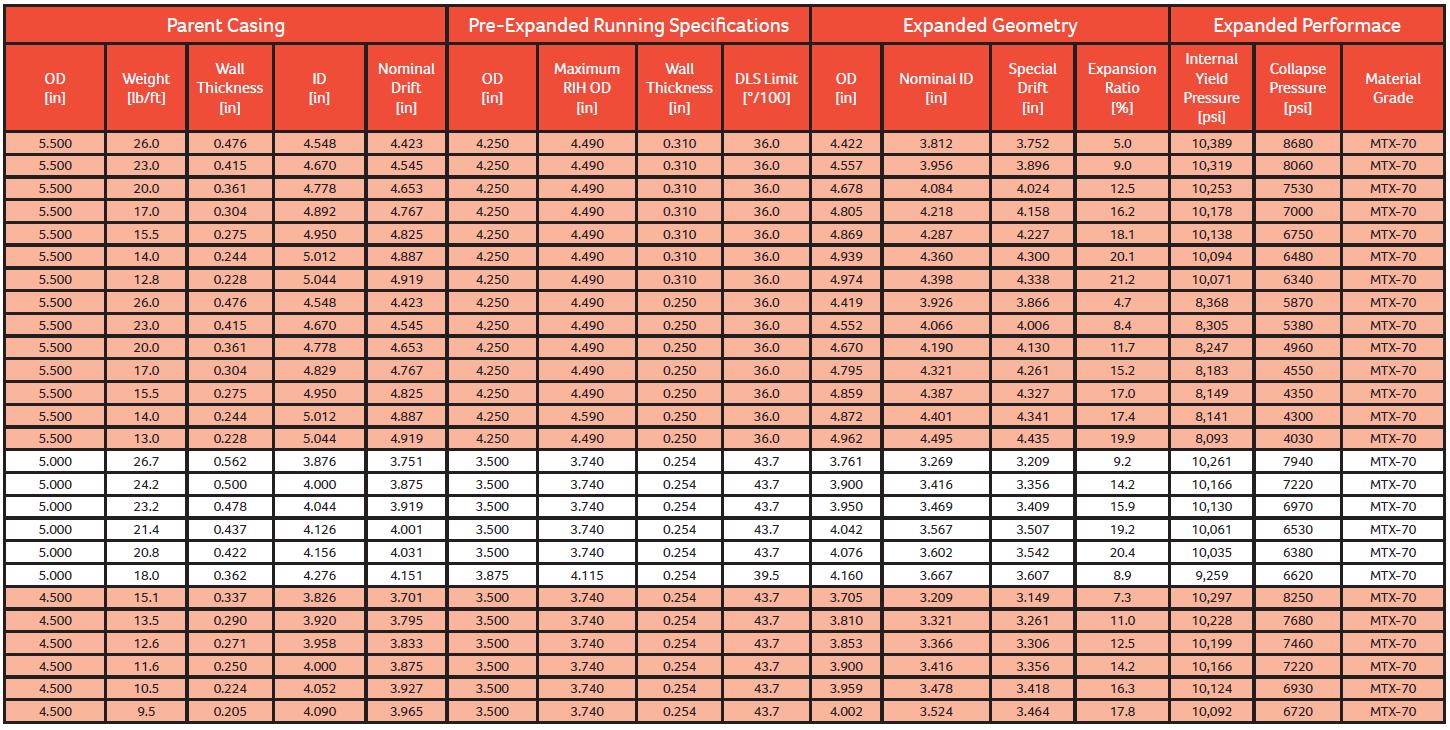

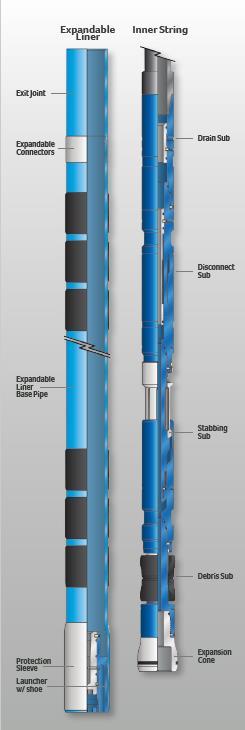

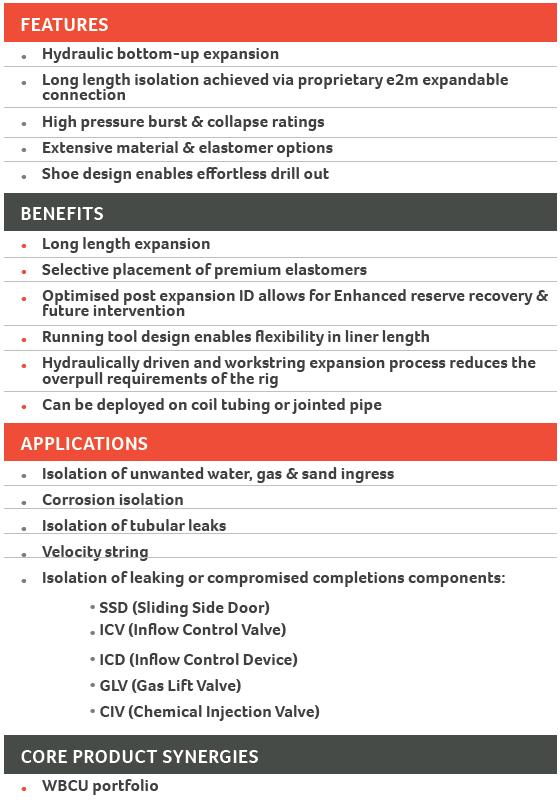

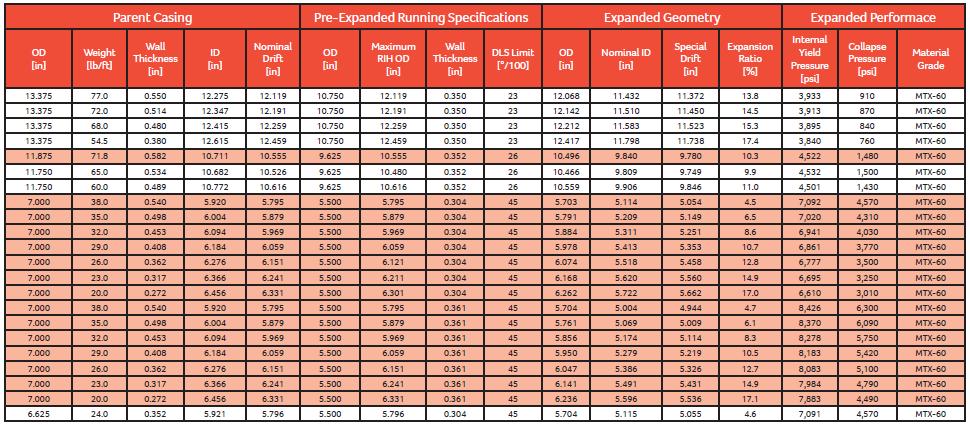

Our flagship reline MNS system provides a single trip isolation solution with significant added value of no shoe milling, enabling the relining and isolation of various casing integrity concerns.

Once installed the ReLine MNS provides minimal loss of inner diameter (ID), whilst providing high burst and collapse ratings.

The MNS cased hole system is designed for deployment primarily on jointed pipe but can be adapted in certain applications to be deployed on coil tubing, providing the ability to cover both long and short intervals.

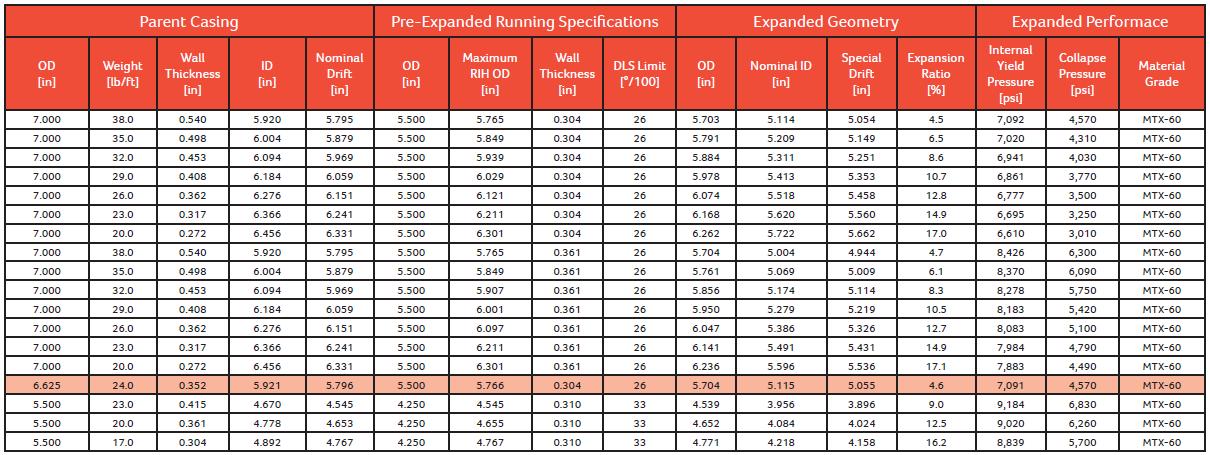

1. All values calculated at ambient temperature unless otherwise noted. 2. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

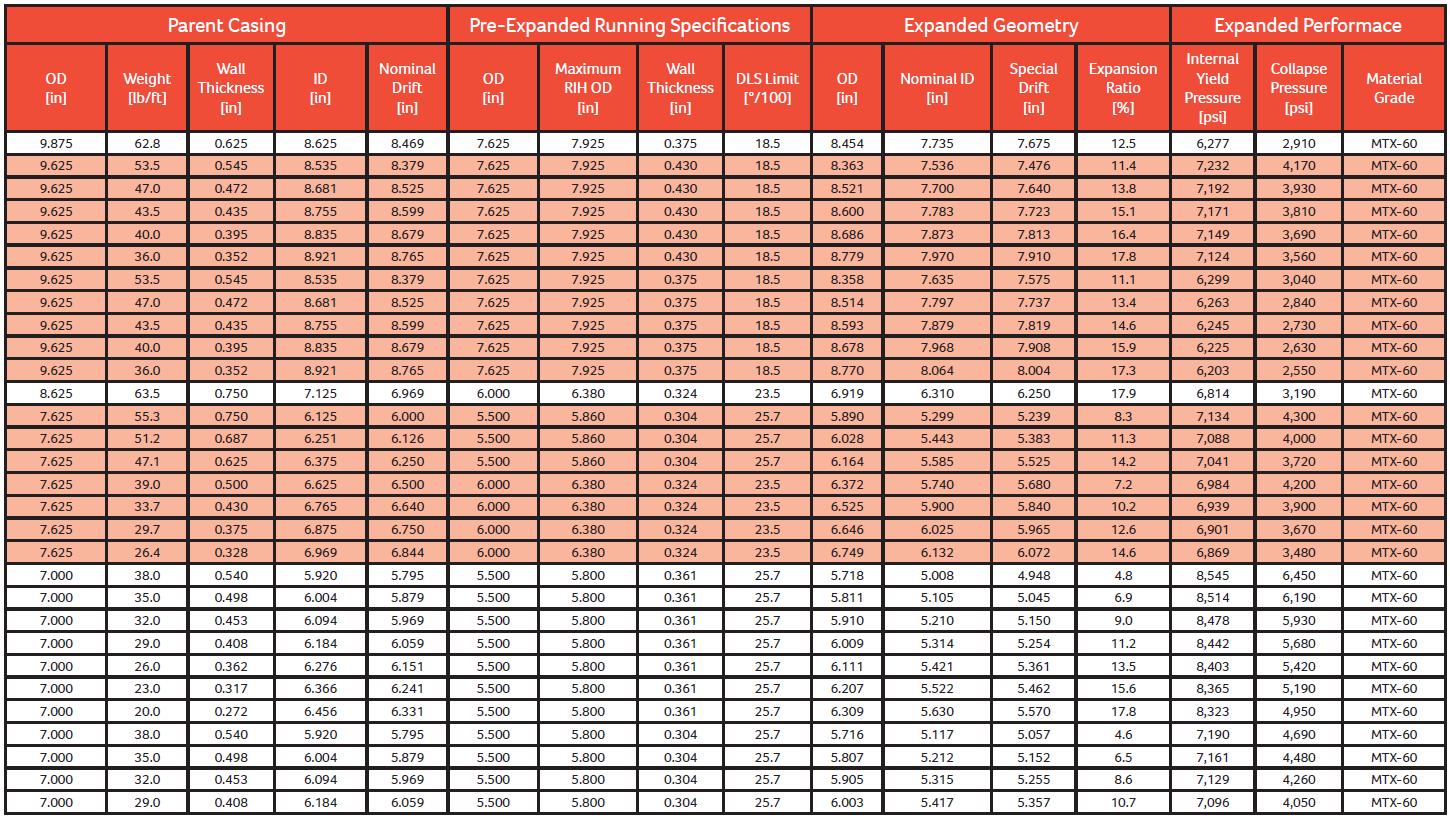

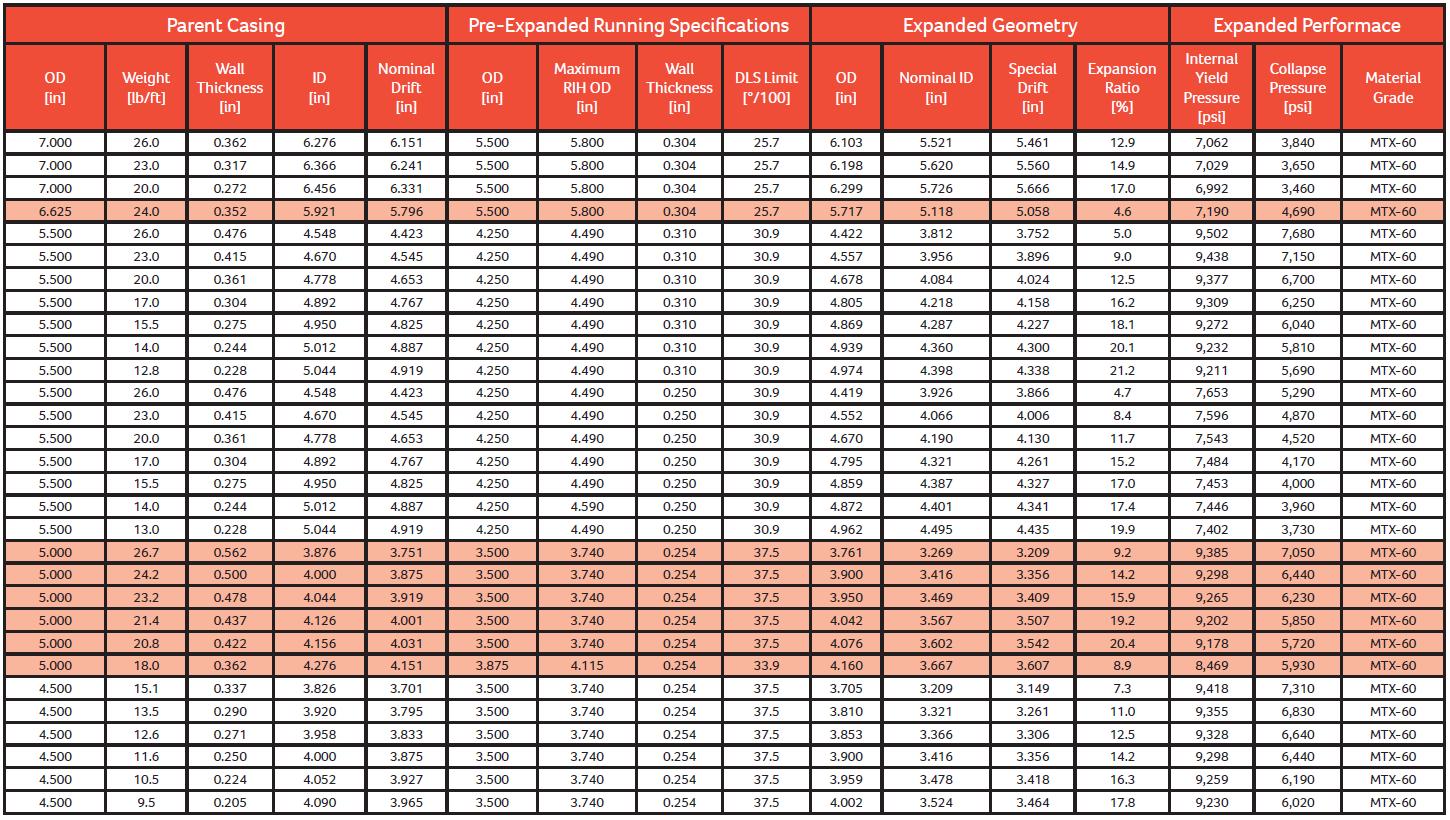

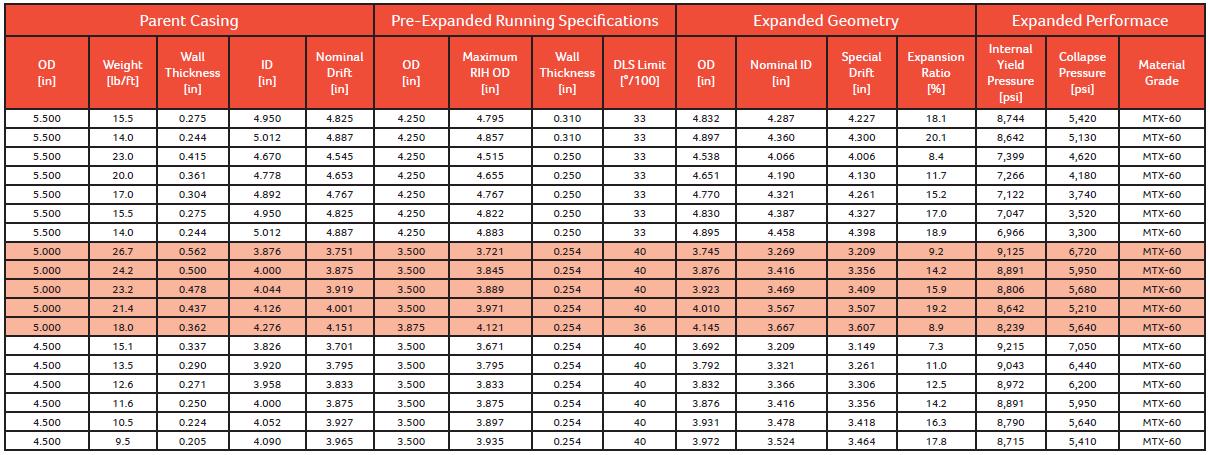

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

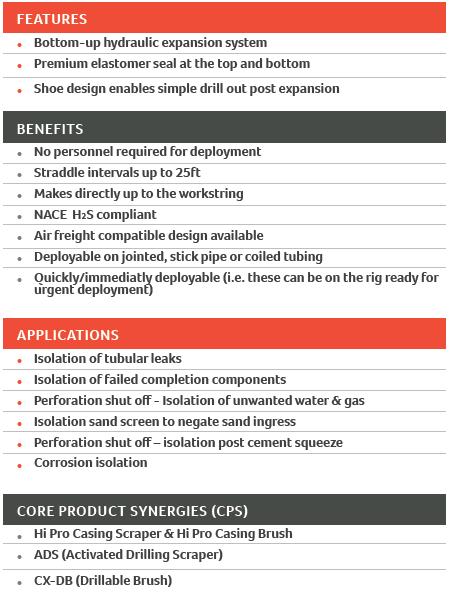

During the life of a well, tubulars or components may suffer a loss of integrity, damage, or corrosion.

ReLine HYD expandable tubular solution provides both short & long length isolation solutions for these issues with minimal loss of inner diameter, whilst providing high burst and collapse ratings.

The expansion system uses hydraulic pressure to pump the expansion cone from the bottom of the liner to the top.

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled. 4. For application sizes above 7”parent casing - please refer to ReLine DL table on next page

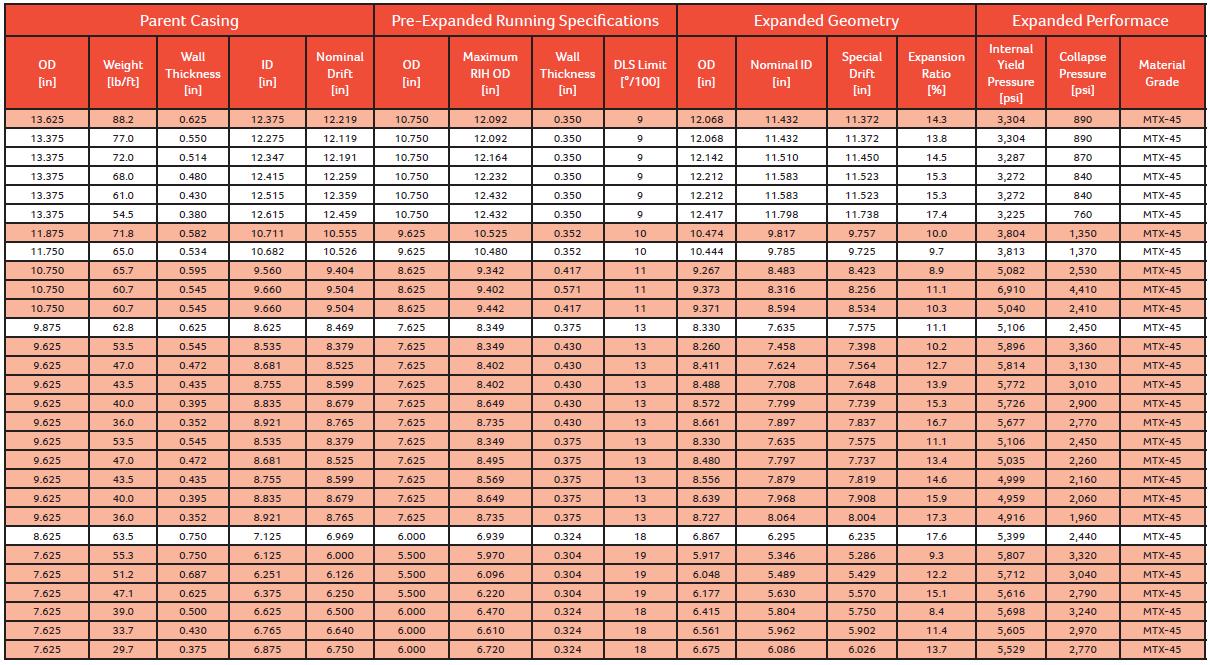

1. All values are based on MTX-45 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

Our onepatch is a rig ready solution to isolate various casing integrity issues. Its compact design and simple operation enable repairs to be made efficiently, significantly reducing operational expenditure. The tool can seal perforations or repair leaking casing while providing a large production conduit to bring the well back online. The device can be snubbed on a live well so there is no requirement to cease production before deployment.

With its robust construction, it is designed to last the life of the well.

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled.

1. All values are based on MTX-60 material grade. Other material grades are available on request.

2. All values calculated at ambient temperature unless otherwise noted.

3. Coretrax makes no warranties, guarantees, or representations, express or implied, as to the accuracy of the data, calculations and or values contained herein. In no event shall Coretrax be liable for incidental, indirect, punitive, or consequential damages arising out of the use of any products, materials, data, calculations and or values herein. Values subject to change without notice. Hard copies are considered uncontrolled

Formed in 1997 in Norway relocated to Dubai in 2006

Privately owned

Engineering design Manufacturing for well completion technology

Headquartered in Jebel Ali, Dubai UAE

- Design

- R&D

- Product Assembly

- Testing Facility

- Service Facility

Global client base

Extensive raw material range and supplier base

Focus on Quality - API Certification

Products are designed in house using the latest version of 3D Design Software (SolidWorks)

Our 3D Computer Aided Design (CAD) software incorporates Product modelling, Computer Aided Machining (CAM) capability, and it is complemented by a Product Data Management (PDM) system for traceability and control

Our engineers are from different background and expertise that allow us to develop the best solutions to our clients

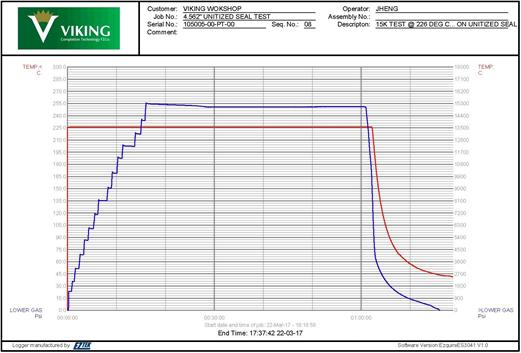

Our Testing Facility capability

- 250°C [480°F] temperature

- Hydraulic ram systems press capable loads in excess of 500,000lbs

- 30,000 psi Hydraulic pumps Gas testing capability up 20,000 psi with Nitrogen Gas

- Data acquisition system with eight independent channel (Temperature/Pressure).

In-house testing performed is for API 11D1 (V6-V0), API 19AC (V0) and API 14A (V3) product qualification

API Q1-1791 - Design, Assembly, Service & Maintenance of Well Completion, Intervention & Wire Line Equipment

API 11D1-0082 - Packers at V6, V5, V4, V3, V2, V1, V0

API 14A-0072 - Subsurface Safety Valves

API 14L-0074 - Landing Nipples at V3, V2; Lock Mandrels at V3, V2, V1

API 19AC-0021 - Completion Accessories - Pressure Containing and Non-Pressure Containing

ISO 9001:2015-1928 - Design, Assembly, Service Maintenance of Well Completion, Intervention & Wire Line Equipment ISO 14001-2015-EMS 693625 - Environmental Management System ISO 45001-2018 OHS 693626 - Occupational Health & Safety Management System

Viking Completions has a global record of supplying equipment in the following countries:

Australia / Asia Pacific

- Australia

- China

- India

- Indonesia

- Malaysia

- New Zealand

- Thailand

Russia and CIS

- Georgia

- Russia

- Turkmenistan

-Uzbekistan Africa

- Algeria

- Congo

- Egypt

- Gabon

- Mozambique

- Sudan

- Tanzania

- Tunisia

Middle East

- Iraq

- Kurdistan

- Kuwait

- Oman

- Qatar

- Saudi Arabia

- UAE

- Yemen Europe

- Greece

- Italy - Norway

- Romania

- UK Americas

- Ecuador

- Mexico

- USA

Retrievable (Straight-Pull, Cut-to-Release, Shift to Release), Permanent Packers, Feed-Through Packers, ESP Packers, Sealbore Packers, Velocity String Packers, Hi-Flo Packers, DST Packers

Seal Stinger Anchor Latch Assemblies, Sealbore Extensions, Back-off Subs, Running/Pulling Tools, Polished Bore Receptables

- To suit Casing Sizes: 4-/12", 5", 5-1/2", 6-5/8", 6-3/4", 7", 7-3/4", 8-5/8", 9-5/8", 9-7/8", 10-3/4", 11-3/4", 13-3/8", 13-5/8", 14“

- Pressure Ratings: 2,000psi, 3,000psi, 5,000psi, 7,500 psi, 8,000 psi, 10,000 psi, 12,000psi & 15,000psi

- Temperature Ranges: 20-226 deg C

- Feedthrough Line sizes: 1/4", 3/8", 1/2" & 3/4" w/ proprietary premium or NPT-type connections

- API 11D1 Validation Grades: V6 - V0

Compact design, minimum metal to metal body connections to reduce leak paths, available in equalizing and non equalizing.

Flow tube with exercise profile, wireline insert valve and full suite of accessory tools available.

- To suit Tubing Sizes: 3-1/2", 4-/12", 5-1/2", 7"

- Curved flapper design

- Pressure Ratings: 5,000psi (all sizes), 10,000psi (3-1/2" size)

- Temperature Ranges: 20 - 150deg C

- API 14A Validation Grades V3, V2, V1

Chemical Injection Assemblies (dual MTM check valves, Rupture Disc)

Tubing Expansion Joints and PBA’s (2ft-40ft)

Sliding Side Doors (Mechanical or Hydraulic)

Adjustable Unions & Swivel Subs

Landing Nipples

Entry Guides & Mule Shoes

Pump-out/open plugs and ceramic discs

- To suit Tubing Sizes: 2-3/8", 2-7/8", 4", 4-/12", 5", 5-1/2", 6-5/8", 6-3/4", 7"

- Pressure Ratings: 5,000psi, 7,500psi, 10,000psi, 15,000psi

- Temperature Ranges: 20-226deg C

- Control Line sizes: 1/4", 3/8", 1/2" & 3/4"

- API 19AC Validation

Integrating pumping solutions with completion equipment that allow our customers to focus on their reservoirs in extended well life cycles

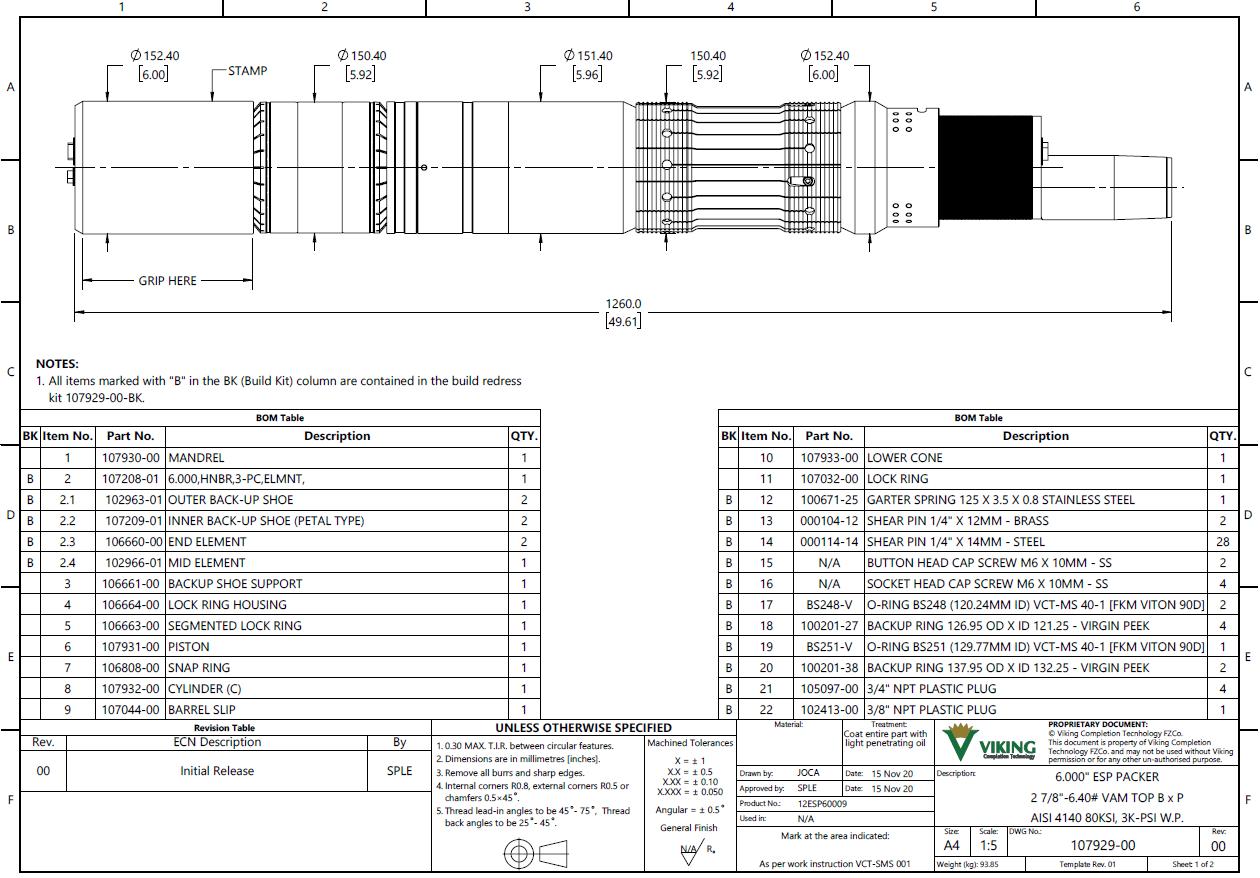

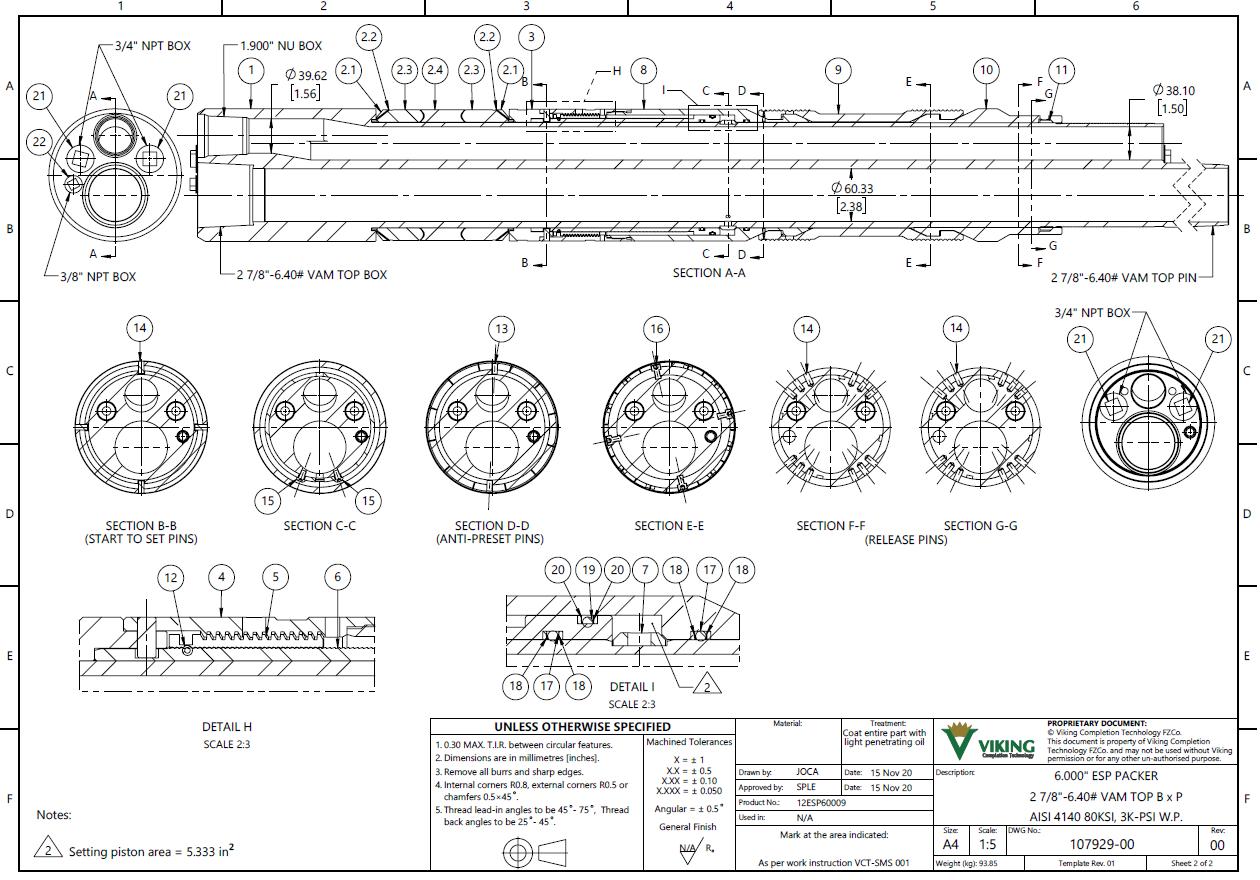

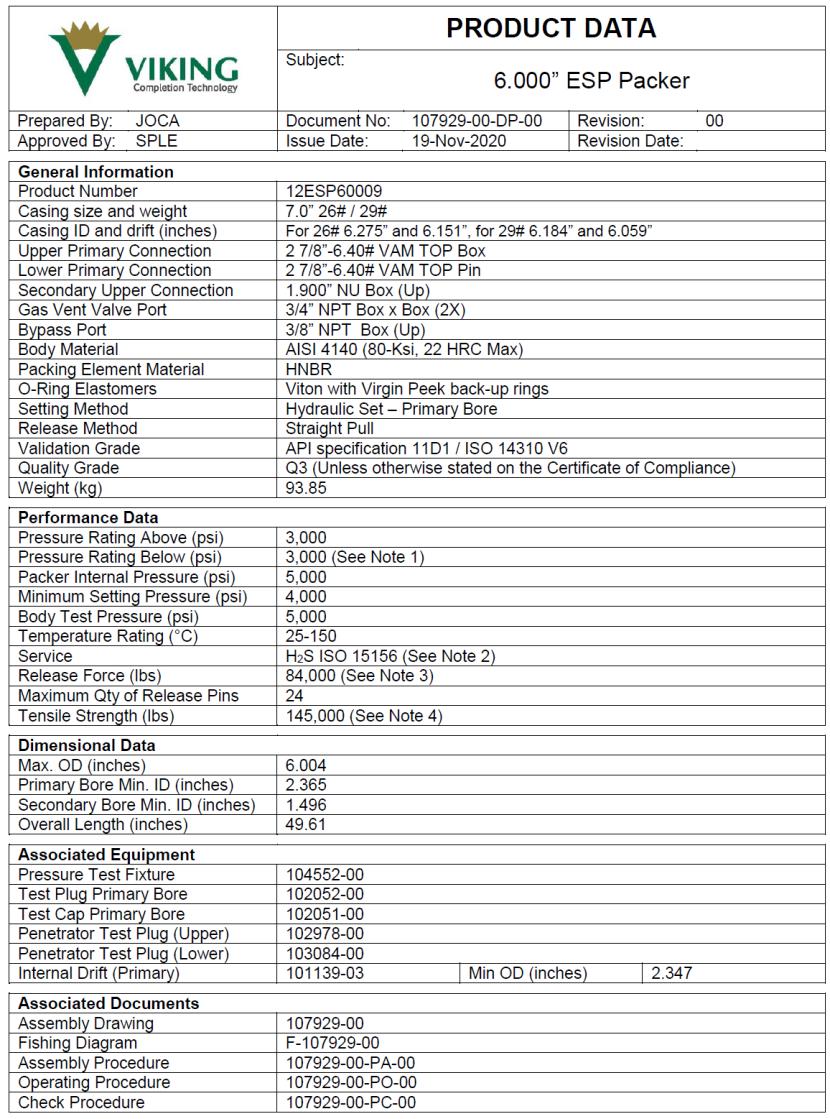

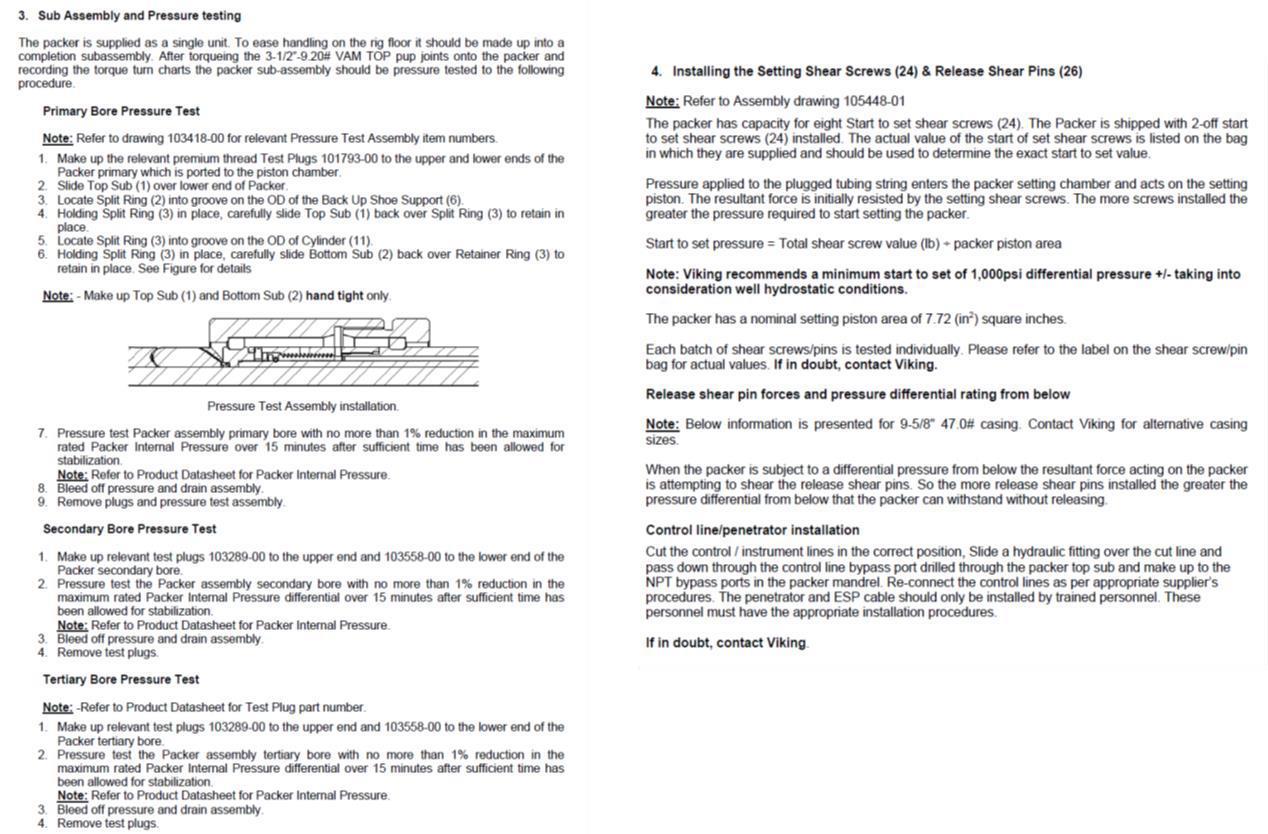

- ESP packers: customisable to suit any cable penetrator configuration (5,000psi, 25-177deg C, Vented, Feedthrough, Low Release)

- Mechanical Formation Isolation Valve (5kpsi, 9-5/8" x 5-1/2") w/ mechanical shifting tool

- Adjustable Unions

- Swivel Subs

- Chemical Injection Assemblies

- Gas Vent Valves

- Cable Pack-offs

Extensive experience designing, manufacturing and installing velocity strings in both, oil and gas wells (over 350 wells to date)

Equipment w/ range of pressures and temperatures in tubing sizes up to 5-1/2" in diameter and pressure ratings up to 7,500psiCustomizable

Designed in mind with intent to simplify operations and extend well life, base products are adaptable to a variety of well parameters and can be customized to suit specific well restrictions and parameters.

Our velocity string product range includes:

- Wireline, CT & hydraulic set packers and their accessories

- Seal assemblies and latches

- Landing and seating nipples

- Sliding sleeves

- Pump-out plugs ceramic discs

- Related intervention and deployment tools

Mechanical Formation Isolation Valve w/ mechanical shifting tool

- For reservoir isolation during ESP or upper completion changeouts

- 5kpsi, 9-5/8" x 5-1/2"

Wireline run water injection valves

- 5kpsi

- To suit 3-1/2" and 4-1/2" tubing

Hydraulic Controlled Surface Annular VR Safety Valve

- Creates a surface 5kpsi or 10kpsi controlled secondary barrier within the wellhead

- Allows safe shut in of the well in emergencies (annulus cement or casing leak or unplanned annular pressure)

- Facilitates gas injection and controls gas venting to optimize production

- Minimizes wellhead arrangement space & set in the existing VR profile

Field proven high-pressure and high temperature completion equipment is designed to handle the most hostile well environments.

Our 15,000psi and 450deg F range of completion equipment includes:

- Permanent production and injection packers

- Chemical injection valves

- Polished bore receptacles and stinger seal units

- Completion accessories

All our HPHT equipment are designed in-house and incorporates specialised seal technologies, ranging from elastomeric, and metalto-metal, to high temperature thermoplastic sealing material.

Our solutions are rigorously analysed and tested to the operating pressure and temperature to simulate downhole performance using our own test facilities.

Our operations team focuses on the delivery timeline to meet operational needs, as well as unplanned and urgent delivery requirements.

Quick access to a variety of raw material including CRA material.

Access to a most premium thread licenses in the area.

All our product solutions are complemented by our in-house testing and validation ability.

Our track record includes providing numerous built-to-order packer products in as little as two weeks from request and safety valves within a four-week timeline; significantly shorter lead times than industry norms.

Operations support extends to preparing service tools and wellsite supervision.

4 Riversdale Road, Welshpool, Perth, WA 6106 Australia

Website: www.randd-solutions.com

Welshpool & Canning Vale Australia

Mobile: +61 450 663 908

Office: +61 8 9486 8350

allan.paterson@randd-solutions.com