At RADEK, we are not just a supplier of machines – we are partners to every business aiming to grow, advance and thrive. Behind our brand stands a clear vision: to assist both new and established manufacturing companies in making the right, strategic decisions when investing in equipment. Our role goes beyond simply selling machines, we provide comprehensive support in developing production capacities – from small woodworking workshops to large-scale industrial operations.

Our mission is to provide each client with a technologically optimal and financially justified solution. We offer carefully selected machines, focusing on quality, efficiency and long-term cost-effectiveness.

RADEK exists to simplify every step in the process of establishing or expanding production –from equipment selection and consultation to technical support and training. Our team views manufacturing as a continuous process, not merely as individual machine purchases.

What sets us apart is not just our products, but our approach. We pay attention to every detail – from the first contact to the final stages of installation and support. Every collaboration is built on respect, fairness and true professionalism.

Allow us to introduce ourselves and we promise that you will find in us a reliable and trustworthy business partner, because quality is our top priority!

GOOGLE MAPS

RADEK WOODWORKING MACHINES

Address: Jadranska Magistrala 71b, Skopje

Showroom with over 40 different machine models. RADEK offers professional demonstrations and machine testing so that you can personally experience the quality and functionality of the machines.

MACHINE OPERATOR TRAINING

PRODUCTION LINES SOLUTIONS

MACHINE SELECTION SUPPORT TECHNICAL SUPPORT

Over 1,000 spare parts in stock… If needed, we manufacture metal and plastic parts in our service center.

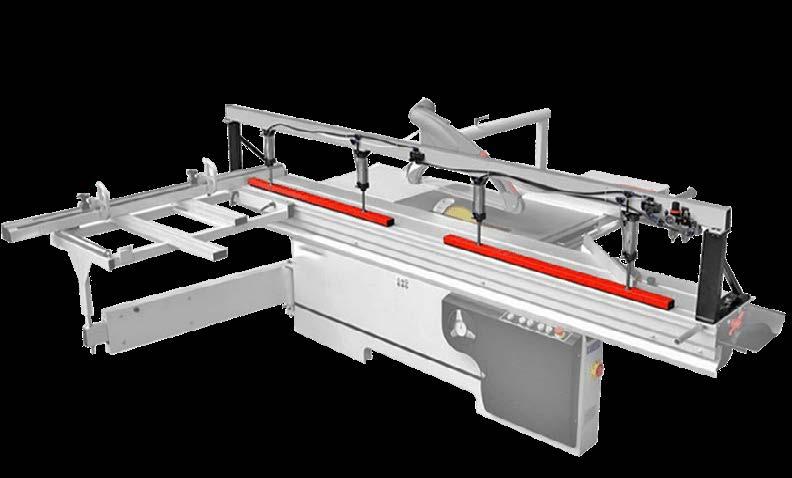

Sliding table length 3200mm

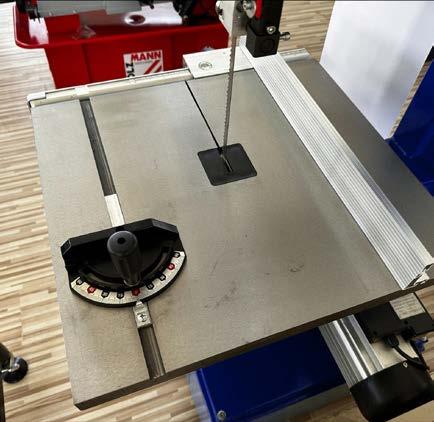

A professional series PANEL SAW MACHINE with a scoring unit designed for longitudinal, cross and angular cutting of panel materials (MDF, particle board, plywood, plastics…) as well as solid wood. It is an essential machine in all small, medium and industrial productions. It is equipped with manual tilt and height adjustment, scoring unit adjustment, an extendable front fence, a dust cover and an auxiliary fence with a protractor.

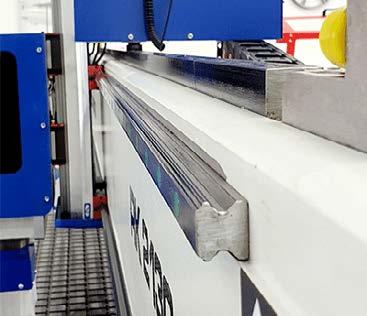

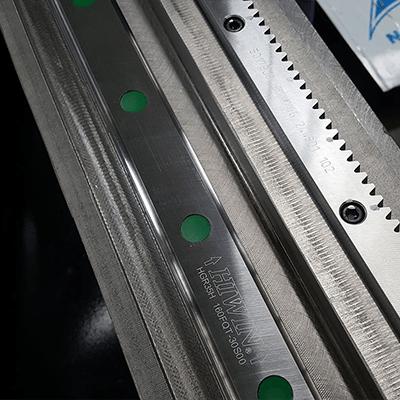

Premium sliding table system ensuring ultra-smooth movements with high precision, without lubrication or special maintenance.

Widely recognized as the top choice for high-end format saws.

Main motor power

Scoring saw power

Sliding table dimensions

Main blade diameter

Main motor speed

Scoring saw diameter

Scoring saw speed

Main blade shaft diameter

Scoring saw shaft diameter

Distance from blade to rear fence

Main blade and

Machine dimensions

Packing dimensions

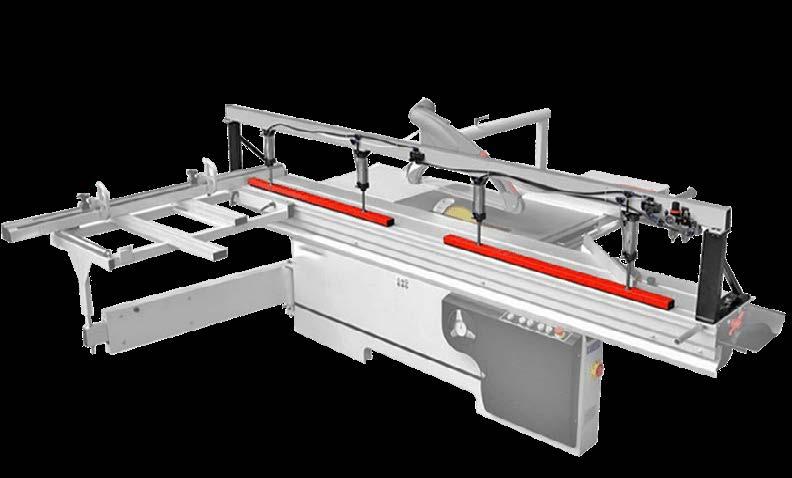

Sliding table length 3200mm

A PANEL SAW MACHINE from the industrial series with premium equipment, designed for longitudinal, cross and angular cutting of panel materials (MDF, particle board, plywood, plastic…) as well as solid wood. It is an essential machine in all small, medium and industrial productions. It is equipped with motorized tilt and height adjustment, precise scoring unit adjustment, an extendable front fence, a digital angle gauge, a premium dust cover, an auxiliary fence with a protractor, a rear fence with precise adjustment, a lubrication system, auxiliary tables larger than standard cutting tables and a sliding table locking system in multiple positions.

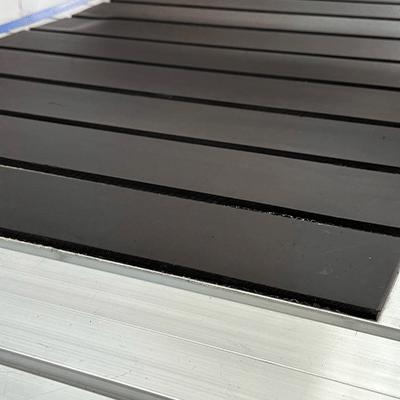

sliding table is made of aluminum, with a width of 430mm. It features the most reliable and durable sliding system, ensuring ultra-precise and smooth movements with high accuracy, without the need for lubrication or special maintenance.

Main motor power

Scoring saw power

Sliding table dimensions

Main blade diameter

Main motor speed

Scoring saw diameter

Scoring saw speed

Main blade shaft diameter

Scoring saw shaft diameter

Distance from blade to rear fence

Main blade and scoring saw tilt

Machine dimensions

Packing dimensions

Weight

Sliding table length

1600mm

Main motor power

Scoring saw power

A professional series PANEL SAW MACHINE with a scoring unit designed for longitudinal, cross and angular cutting of panel materials (MDF, particle board, plywood, plastics…) as well as solid wood. It is an essential machine in all small, medium and industrial productions. It is equipped with manual tilt and height adjustment, scoring unit adjustment, an extendable front fence, a dust cover and an auxiliary fence with a protractor.

Premium sliding table system ensuring ultra-smooth movements with high precision, without lubrication or special maintenance.

Widely recognized as the top choice for high-end format saws.

Main motor power

Scoring saw power

Sliding table dimensions

Main blade diameter

Main motor speed

Scoring saw diameter

Scoring saw speed

The powerful, high-quality motors with a working power of 4kW and 0.75kW, deliver exceptional performance.

The reliable, robust construction eliminates vibrations, ensuring stable operation and longevity. It is built to high standards of quality and durability.

The sliding table measuring 1600mm in length, combined with an ergonomic design, makes this panel saw the perfect pick for operations requiring high-precision cutting.

Two stops equipped with magnifiers and clamps allow for precise adjustments to the preferred dimensions.

Main blade shaft diameter

Scoring saw shaft diameter

Distance from blade to rear fence

Main blade and scoring saw tilt

Machine dimensions

Packing dimensions Weight

1120x1250x980mm / 430x1830x260mm 450kg

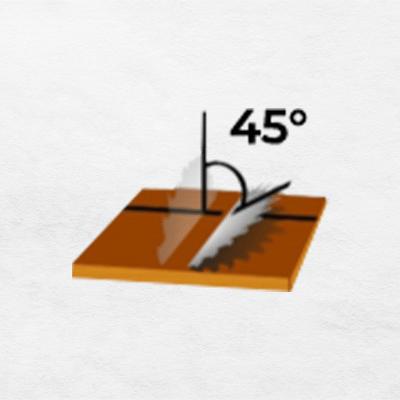

Machine features height and tilt adjustment for precise angle cutting.

OPTIONAL

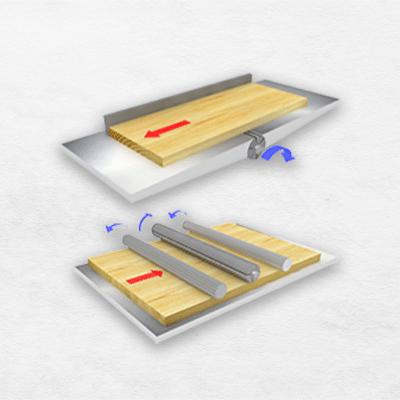

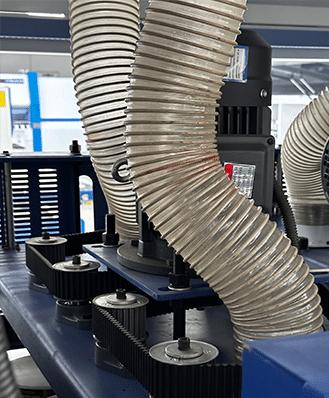

The return conveyor is an intelligent solution that significantly increases productivity and reduces the need for labor. Compatible with the RK-5ALL-PREMIUM edgebander, this conveyor automatically returns the processed workpiece to the operator, allowing full operation by a single person—without any additional assistance.

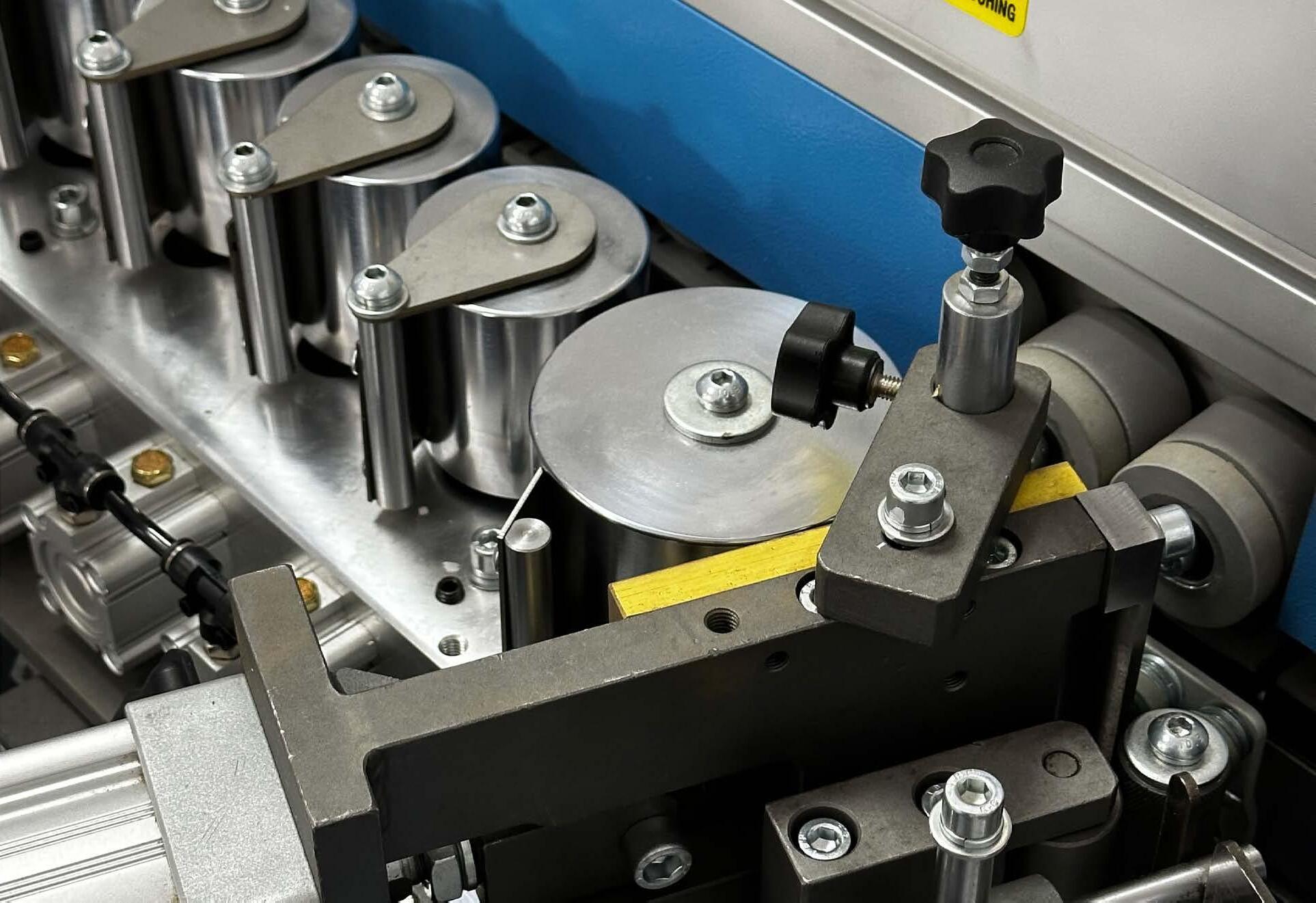

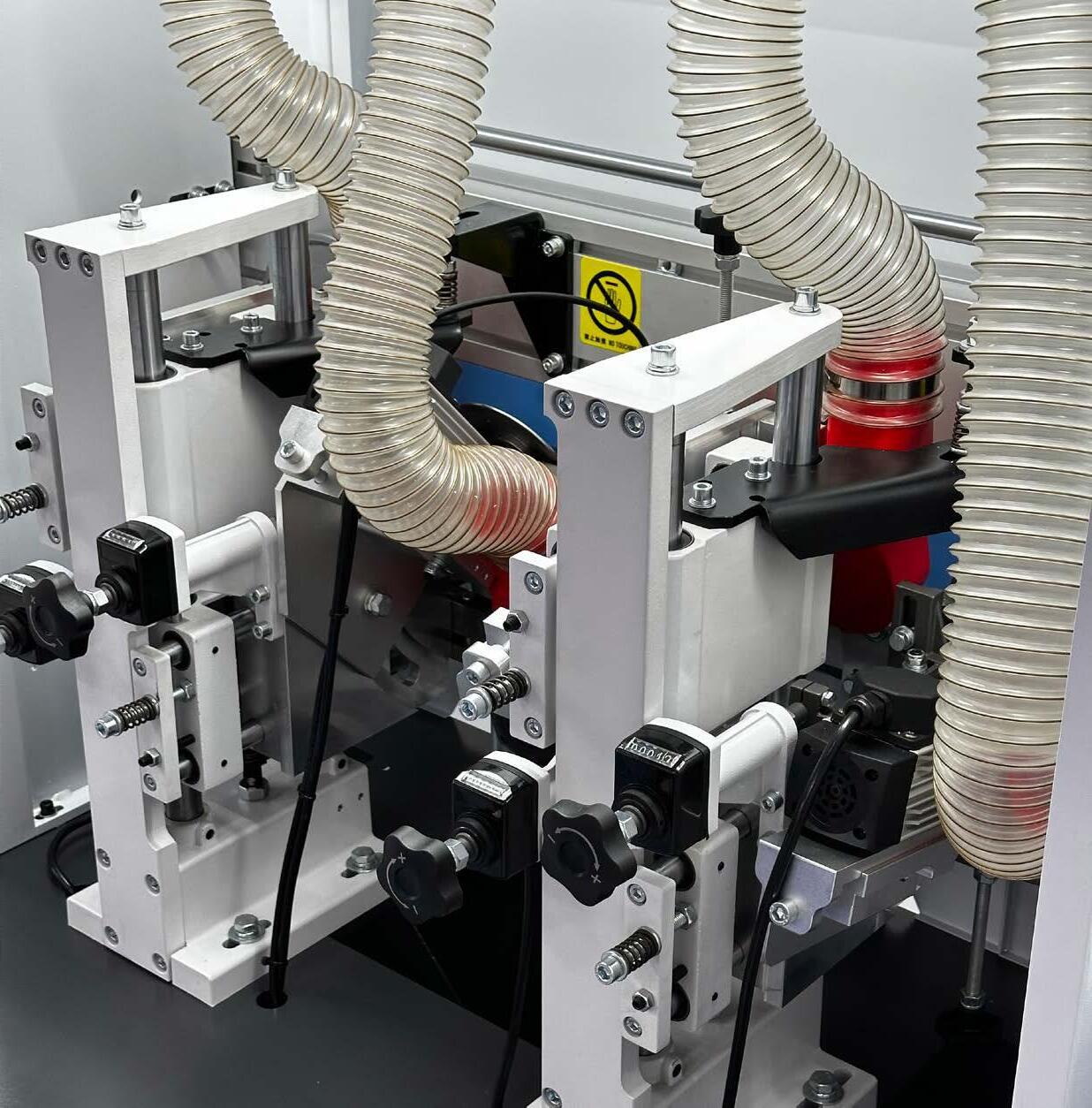

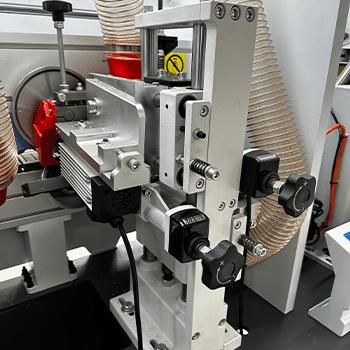

The edge banding machine from RADEK’s premium series is equipped with numerous functions to achieve a perfect finish on every produced piece. It is ideal for industries looking to improve production and increase edge banding capacity up to a speed of 23 meters per minute. . A large touchscreen display allows for automatic panel thickness adjustment. Its robust construction ensures stability and reliability during operation.

Allows the application of adhesive residue remover on the panel.

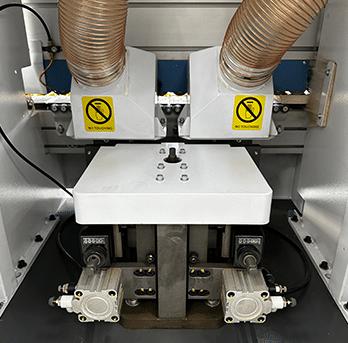

Precise processing of the upper and lower part of the panel with two flat routers and high spindle speeds (12,000 RPM).

Panel width

Panel thickness

Edge band thickness

Processing speed

Operating pressure

Pre-milling power

End cutting power

Designed to eliminate cutting damage and guarantee a flat surface ideal for gluing. Made with diamond cutters and additional blowers to remove residue from the work piece for quality tape adhesion.

Precision treatment of the upper and lower part of the panels with two radius routers (R1, R2, R3) and high spindle speeds (12,000 RPM).

Preheats the panels, essential for high-quality edge banding, particularly important in winter.

Precise corner finishing on both sides of the panel with two radius routers (R1, R2, R3) and high spindle speeds (18,000 RPM).

Rough trimming power minimum 80mm 10-60mm 0.4-3mm 15-23m/min 6 bar 2.2kW (x2)

(x2) 0.75kW (x2)

The canister is designed for adhesive granules, with a 4-liter capacity, enabling precise adjustment of adhesive quantity to avoid over or under application.

Scrapers with a radius for edge finishing to ensure smoothness.

Six pneumatic rollers (4 identical, 1 larger diameter and 1 with rubber material) ensure pressure for excellent tape adhesion.

and high spindle

(12,000 RPM).

Allows the application of adhesive residue cleaning agents on the panel.

Fine trimming power

Corner rounding power

Polishing power

Conveyor power

Total power

Machine dimensions

Packing dimensions

Weight

ishing for an even smoother surface.

Panel thickness 10-50mm

Processing speed 7m/min

Total power 6.15kW

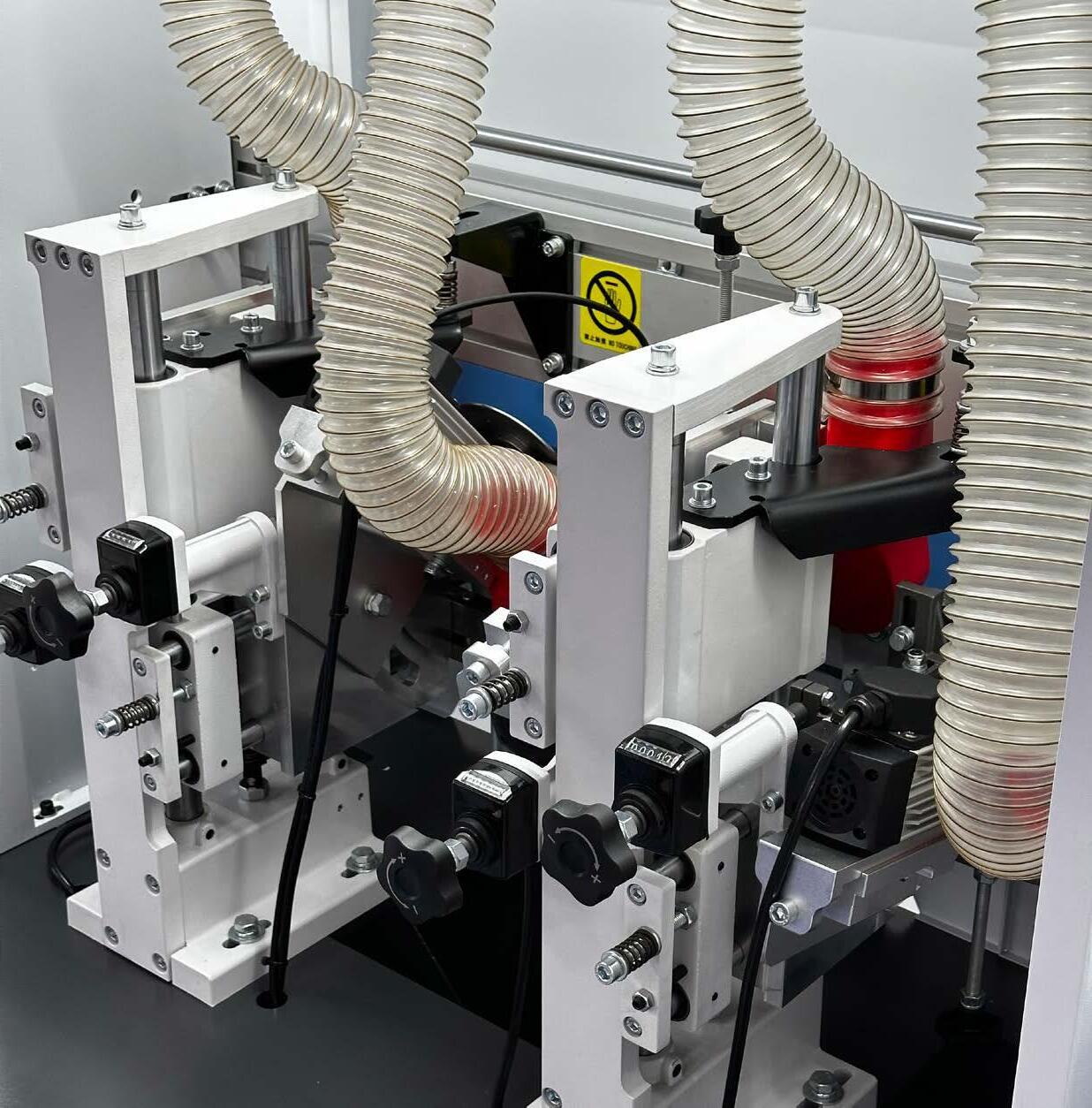

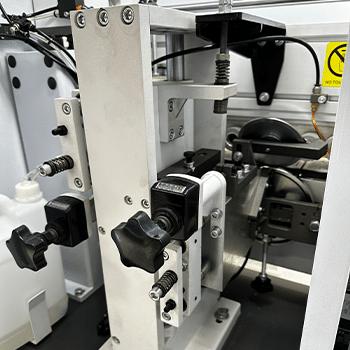

A compact edge banding machine with a perfect assembly of individual components to ensure flawless finishing. All machine parts are manufactured with absolute precision on high-end Japanese machines and inspected by expert engineers under strict quality control. A large touchscreen display detects errors and provides a quick resolution guide whenever a problem arises. It is ideal for small, medium and industrial-scale production.

PRE-MILLING UNIT

Designed to eliminate cutting damage and guarantee a flat surface ideal for gluing. Made with diamond cutters that rotate in different directions.

ADHESIVE APPLICATION

The canister is coated with Teflon and features a quick-detach system. It is designed for adhesive granules that require just 15 minutes to heat up.

PNEUMATIC ROLLERS

Two pneumatic rollers apply pressure to the tape with adjustable regulators.

Precise cutting of panel edges with two saw blades and high spindle speeds (12,000 RPM).

TRIMMING UNIT

Precise processing of the upper and lower panel parts with two radius routers (R1, R2, R3) and high spindle speeds (12,000 RPM).

Panel width

Panel thickness

Edge band thickness

Panel length

Processing speed

Operating pressure

Total power

Machine dimensions

Packing dimensions

Weight

minimum 80mm 10-50mm

0.4-3mm

minimum 70mm

7m/min

6 bar

6.15kW

2730x1080x1230mm

2422x645x1245mm

780kg

Scrapers with a radius for edge finishing to ensure smoothness.

Allows the application of adhesive residue cleaning agents on the panel.

Final panel finishing by polishing for an even smoother surface.

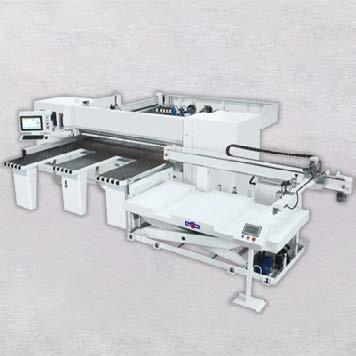

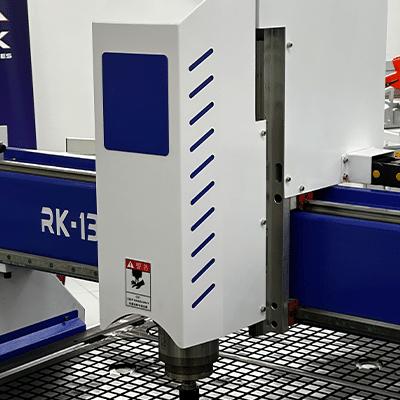

Designed for high-quality cutting with maximum performance and precision. This machine stands out from other CNC cutters on the market due to its massive structure, power, high-end components and consistent cutting quality. Manufactured under strict quality and durability standards, it is an excellent long-term investment for boosting your company’s production and efficiency. It meets every requirement with outstanding performance, precision and capacity.

Made of high-quality iron with significantly more weight than other CNC cutters on the market, effectively eliminating vibrations during operation, ensuring perfect cuts at all times.

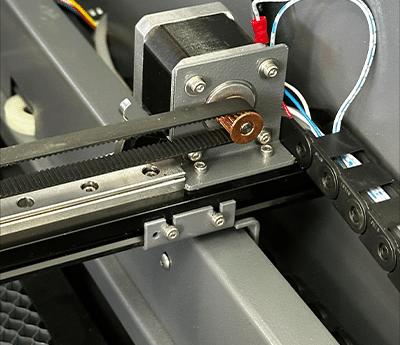

The saw unit moves along two rails controlled by high-performance servo motors, ensuring maximum speed up to 120 meters per minute.

The interface is equipped with an industrial computer and has the simplest, most intuitive design, allowing operators to easily create layouts or import from optimization software. Well-defined functions for full work overview and easy adjustments.

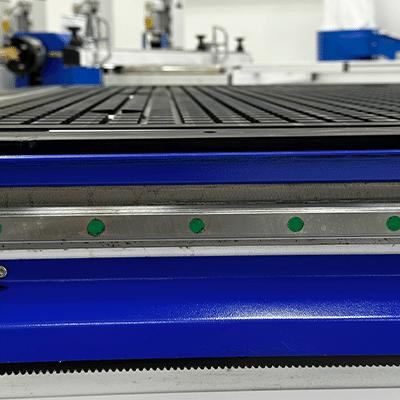

Air tables with round bearings provide efficient and easy panel movement. Additional air tables are also located in the cutting zone, facilitating work with small pieces and protecting them from damage.

Pneumatic double-support clamps ensure stable fixation of panels without slipping. Controlled by precise servo motors without deviation or errors.

Scoring saw power

Air table motor power

Speed of main motor

Pre-cutter speed

Maximum cutting length

Maximum cutting width

Main blade diameter

Scoring saw diameter

Main blade shaft diameter

Scoring saw shaft diameter

Processing speed

Movement speed

Operating pressure

Machine dimensions

Packing dimensions

Weight 3200x3200 /4200x4200 2.2kW 4kW 4100rpm 6100rpm 3200mm (optional 4300mm) 3200mm (optional 4300mm)

6-8 bar

5600x6800x1900mm

5500x1330x1900mm / 4050x600x1650mm

5800kg / 7200kg

Stable and reliable PLC from the reputable DELTA brand, featuring large memory capacity and speed.

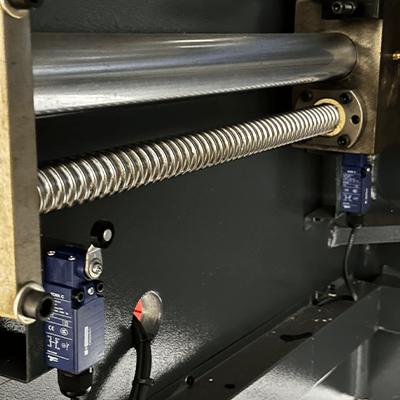

PRECISE LINEAR GUIDES

German-made SLM linear guides, offering quiet operation, high precision, smooth movement and long lifespan.

Included with the machine is a labeling machine for printing details on workpieces.

ELECTRICAL COMPONENTS

Electrical components from the renowned Schneider brand.

Possibility for an upgrade with a device for automatic material loading, aimed at saving time and personnel. The device consists of a lift table that automatically adjusts into position and a pusher that efficiently moves the panels without damaging them.

High-performance INVT servo motors for quick and precise execution of control commands, ensuring high-quality cutting.

Additional support with side rollers for precise workpiece positioning. SIDE ROLLERS

CAPABILITIES

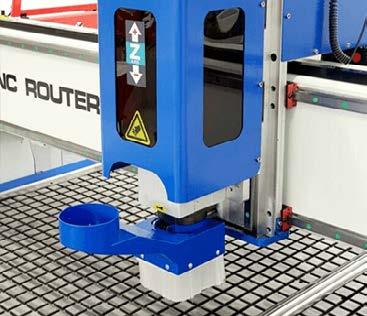

This CNC router offers endless possibilities in processing various materials such as wood, MDF, plywood, acrylic, foreks, particleboard and more. It’s an excellent opportunity for starting or expanding a business, commonly used in industries like furniture making, decorative elements, icons, logo creation and board flattening.

EXCELLENT INVESTMENT

CNC routers are essential machines in any production facility, enhancing efficiency and reducing human error. They significantly increase processing capacity, offering constant and unchanging work quality.

Take your woodworking and panel processing projects to the next level. This CNC machine is designed for cutting, drilling and engraving, bringing your ideas to life. With top-tier performance, quality and stability, this CNC router is a reliable and long-term investment. It comes equipped with a vacuum table, a vacuum pump, a tool calibration sensor, an automatic lubrication system, a dust collector with two bags, a flexible dust extraction hose, vacuum table seals, a set of tool holders and cutters, leveling feet, a flexible hose holder, a dust cover, a set of manual clamps and a Richauto controller.

The machine features a massive structure, ensuring a high level of stiffness and resistance to both static and dynamic loads. The structure is made using high-precision CNC machining centers for metal, guaranteeing precision, quality and durability.

Working area

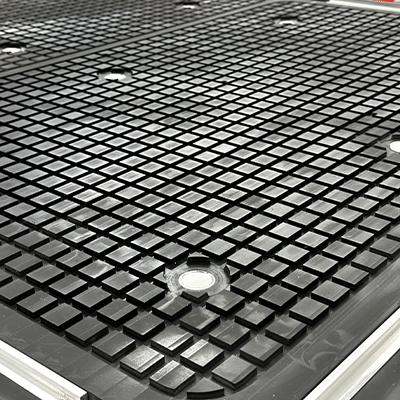

The machine’s working table is made from wear-resistant special plastic and designed for use with a vacuum pump. It includes integrated aluminum “T” rails for manually securing pieces using clamps. WORKING TABLE

INDUSTRIAL VACUUM PUMP

Equipped with a powerful 7.5 kW air-cooled vacuum pump with a capacity of 530 m³ per hour, ensuring high absorption of workpieces.

Built from rectangular steel profiles, structurally improved, and reinforced inside, the bridge guarantees high strength, durability and precision, offering a significantly better quality than other market alternatives.

HYBRID HIGH-PRECISION STEP MOTORS

Ensures precise positioning of the bridge and spindle without deviations or errors and allows high-speed movement up to 20 meters per minute.

Optional working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor model

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

2100x3000x200mm

2100x4000x200mm 6kW

18.000rpm

Air-cooled

Hybrid stepper motors

86BHH114-500A-32E

Vacuum table + aluminum rails

7.5kW

530m³/h

Air-cooled x8

Richauto 0-20m/min

ER32

2-25mm

3650x2900x2450 1650kg

The movement of the axes is through linear guides (20mm) and toothed rack, from the highly renowned brand HIWIN from Taiwan, proven to be the best and most usable movement system for most cnc machines. It enables smooth operation, low noise and a significant reduction of all additional loads, thus increasing their durability and durability.

RICHAUTO CONTROLLER

The Richauto controller simplifies machine operation and parameter adjustments compared to standard computer operating systems.

The Z axis is considered the most loaded and therefore a 25mm threaded spindle has been implemented, which enables exceptional precision, low friction of the elements, maximum protection against rapid wear, as well as prevention of heating of the elements that rub during machine operation.

LICENSED UCANCAM SOFTWARE

A sophisticated software with numerous options for quick and efficient design and drawing simulation previews.

Schneider electronics, Yako drivers, Folinn inverters, HQD main motors, CW hybrid step motors, Hiwin rails, TBI spindles, etc. COMPONENTS

The RADEK Premium Series 4-axis CNC router is specialized for complex products and door processing, offering cutting, vertical and horizontal drilling, carving and engraving—all in a single machine.

Known for high precision, speed, productivity and flexibility, this machine is ideal for various woodworking applications. Equipped with a vacuum table, 7.5kW vacuum pump, pneumatic positioners, automatic tool changer, tool calibration sensor, magazine for 12 tools, automatic lubrication system, dust extractor with two bags (5.5kW), flexible dust extraction hose, set of vacuum table seals, lifting molds for workpieces and a set of bushings and cutters.The machine’s construction is steel and fully welded, made from rectangular steel profiles that provide a high degree of rigidity and excellent resistance to static and dynamic loads. The machine body is manufactured on highly precise CNC metalworking centers, ensuring precision, quality and durability.

The motor has 24,000 RPM and air cooling, enabling flawless processing of all types and thicknesses of materials.

Similar to the previous machine, this working table is designed with special wear-resistant plastic for vacuum pump usage, along with integrated “T” aluminum rails for manual securing.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Tool magazine

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

Equipped with two 7.5 kW air-cooled vacuum pumps, each with a capacity of 550m³ per hour, ensuring high absorption even for small panels. The vacuum absorption is further enhanced with pneumatic rollers pressing the panel.

1300x2500x500mm 9kW

24.000rpm

Air-cooled

Servo motors

1.5kW

Vacuum table + aluminum rails 7.5kW 550m³/h Air-cooled

These motors guarantee precise positioning of the bridge and spindle, offering high-speed movement up to 30 meters per minute and exceptional quality and stability in demanding industrial conditions.

a

for exceptional precision, low friction, maximum protection from wear and prevention of overheating of friction elements during machine operation.

The movement is facilitated by linear guides (30mm and 25mm) and a rack and pinion system by the renowned HIWIN brand, ensuring smooth operation, low noise and long-lasting durability.

Features the LNC operating system from a renowned Taiwanese brand, allowing organized and easy access to all machine functions.

CAPABILITIES

Endless possibilities for processing materials such as wood, MDF, plywood, plexiglass, foreks, lesonit and alubond.

A great opportunity to start or expand a business, widely used in industries such as furniture manufacturing, decorative elements, icons, panel leveling and logo creation.

The construction ensures a high level of rigidity and excellent resistance to loads.

CNC routers are increasingly used in various industries as they are one of the most important machines in any production facility. They significantly increase processing capacity and eliminate human error, ensuring consistent and unchanging work quality.

Take your woodworking and panel processing projects to the next level. This CNC machine is designed for cutting, drilling and engraving, turning your ideas into reality. Equipped with an aluminum T-slot table or optional vacuum table, a vacuum pump (optional), a lubrication system, a water-cooled spindle motor, a set of vacuum table seals (optional), tool holders and cutters, leveling feet, a set of manual clamps and an NC Studio operating system.

A powerful 3.2kW motor with 24,000 RPM and water cooling.

WORKING TABLE

Optionally, an aluminum table with T-slots or a vacuum table designed for use with a vacuum pump made from wear-resistant plastic. It also features integrated “T” aluminum rails for manual piece fixation using clamps.

Equipped with a powerful 7.5kW vacuum pump with air cooling. The vacuum pump capacity is 530m³ per hour, allowing high absorption of workpieces.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor model

Worktable

Worktable (optional)

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

86BHH-400B-35

Aluminum table with T-slots

SOLID BRIDGE

The bridge structure ensures high rigidity, durability and precision.

HIGH-PRECISION STEP MOTORS

Ensure precise positioning of the bridge and spindle with high-speed movement of up to 15 meters per minute. Excellent quality and stability in operations.

Movement of the axes is achieved via linear guides and rack-and-pinion, providing smooth operation, low noise and significantly reduced additional loads, increasing durability.

The Z-axis is equipped with a ball screw, ensuring exceptional precision, low friction, maximum protection from rapid wear and preventing overheating of elements during operation.

CAPABILITIES

Endless possibilities for processing various materials such as wood, MDF, chipboard, plexiglass, forex, hardboard, plywood, alubond and others. A great opportunity for starting a new business or expanding an existing one.

EXCELLENT INVESTMENT

CNC routers are increasingly used across various industries as they are among the most important machines in any production facility. They are essential for improving and facilitating work. They significantly increase processing capacity and eliminate errors caused by human factors.

Constructed to provide excellent structural integrity and load-bearing capacity

Take your woodworking and panel processing projects to the next level. This CNC machine is designed for cutting, drilling and engraving, turning your ideas into reality. Equipped with an aluminum T-slot table, set of manual clamps, water-cooled motor, water circulation cooling pump, stepper motors for movement, set of tool holders and milling cutters and NC Studio operating system.

A powerful 1.5kW motor with 24,000 RPM and water cooling.

Optional aluminum table with T-slots or a vacuum table designed for use with a vacuum pump, made of special wear-resistant plastic. Additionally, it features integrated “T” aluminum rails that allow for manual piece fixation using clamps.

The gantry construction provides a high degree of rigidity, durability and high precision.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor model

Worktable

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

600x900x100mm 1.5kW

24.000rpm

Water-cooled

Stepper motors

86BHH-400B-35

Aluminum table with T-slots

NC studio 0-3m/min

ER11

1-7mm

1304x1100x1500mm

250kg

Ensure precise positioning of the gantry and spindle, with a high movement speed of up to 3 meters per minute. Excellent quality and stability in operation.

The Z-axis is considered the most heavily loaded, so a ball screw system is implemented, providing exceptional precision, low friction, maximum protection against rapid wear and prevention of overheating of frictional components during machine operation.

Axis movement occurs via linear guides and a rack-and-pinion system, which is proven to be the best and most commonly used movement system in most CNC machines. This ensures smooth operation, low noise levels and significant reduction of additional loads, thereby increasing durability and longevity.

NC STUDIO

NC Studio operating system enables easy and organized access to all machine functions.

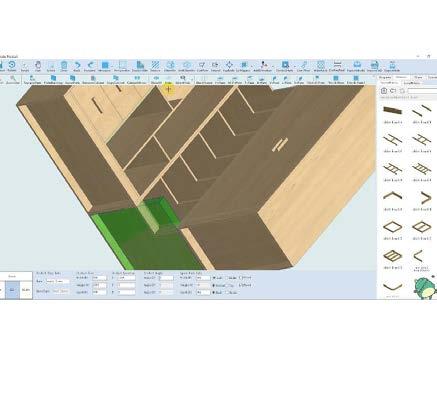

Sophisticated software enabling fast and efficient design and production optimization, 3D preview, and instant quotation generation with detailed pricing. Compatible with RADEK CNC drilling machines.

UPGRADE CAPABILITY

Automatic panel loading with vacuum foot devices located on the bridge for material pickup from a lifting table. Automatic unloading with a device on the bridge for transferring processed pieces to a special conveyor belt.

With the CNC nesting machine, you get the best value for your budget. It is renowned for high precision, speed, productivity and flexibility when cutting, engraving and drilling. It also offers the option to upgrade with an automatic panel loading and unloading system for additional automation.

The motor’s manufacturing, design and accompanying parts are 100% identical in quality to world-renowned brands. It operates at 24,000 RPM with air cooling, allowing seamless processing of all types and thicknesses of materials.

MASSIVE GANTRY CONSTRUCTION

Made of rectangular steel profiles, structurally enhanced and additionally reinforced internally. This type of gantry construction ensures a high degree of rigidity, durability and guarantees high precision. The quality is significantly superior to other gantries on the market.

Specially designed for high demands and performance in combination with a reducer from a highly renowned Japanese brand. Guaranteed precise positioning of the bridge and spindle without deviation and error and with a high speed of movement up to 30 meters per minute. Proven quality and stability in operation and in difficult industrial conditions.

The machine is equipped with two 7.5kW vacuum pumps with air cooling. Each pump has a capacity of 550m³ per hour, providing high absorption even for small panels, enhanced with pneumatic rollers pressing the panels.

The working table is made of special wear-resistant plastic for use with the vacuum pump. Additionally, it features integrated “T” aluminum rails that allow for manual piece fixation using clamps.

Axis movement occurs via linear guides (30mm and 25mm) and a rack-and-pinion system from the highly reputable HIWIN brand from Taiwan. This is proven to be the best and most efficient movement system in most CNC machines, ensuring smooth operation, low noise levels, and significantly reducing additional loads, thereby increasing durability and longevity.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

Equipped with a ball screw on the Z-axis for exceptional precision, low friction, maximum protection from rapid wear, and preventing overheating of elements

LNC operating system from a highly reputable Taiwanese brand. Allows easy and organized access to all

Sophisticated software enabling fast and efficient design and production optimization, 3D preview and instant quotation generation with detailed pricing. Compatible with RADEK CNC drilling machines.

UPGRADE OPTIONS

Automatic Panel Loading: Vacuum suction device on the gantry, enabling material pickup from a lifting table. Automatic Panel Unloading: A mechanism on the gantry that moves processed pieces onto a special conveyor belt for further handling.

With a CNC nesting machine you get the most for your budget, it is known for its high precision, speed, productivity, flexible use in cutting, engraving and drilling, as well as the possibility of upgrading with a panel loading and unloading device for additional machine automation.

The motor’s manufacturing, design and accompanying parts are 100% identical in quality to world-renowned brands. It operates at 24,000 RPM and air cooling, ensuring seamless processing of all material types and thicknesses.

Made of high-strength rectangular steel profiles, structurally improved and reinforced internally for superior precision and durability. MASSIVE GANTRY CONSTRUCTION

SERVO MOTORS

Designed for high performance, combined with a high-quality reducer from a leading Japanese brand, ensuring precision without deviations, with speeds up to 30 meters per minute.

The working table is made of special wear-resistant plastic for use with the vacuum pump. Additionally, it features integrated “T” aluminum rails that allow for manual piece fixation using clamps.

Axis movement occurs via linear guides (30mm and 25mm) and a rack-and-pinion system from the highly reputable HIWIN brand from Taiwan. This is proven to be the best and most efficient movement system in most CNC machines, ensuring smooth operation, low noise levels and significantly reducing additional loads, thereby increasing durability and longevity.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Packing dimensions

Weight

AXIS MOVEMENT

A ball screw system ensures exceptional precision, low friction and maximum durability, reducing wear and heat buildup.

LNC operating system, ensuring user-friendly machine control.

The production process employs advanced technology, including robotic welding, thermal treatment of the structure, an industrial CNC metalworking machining center and the latest, most reliable quality control inspections.

The machine features a sizable construction weight of 4,200kg, fully welded as opposed to other models. This specific trait provides a dependable degree of strength and excellent resistance to static and dynamic loads.

An innovative machine technology for precise and fast six-sided drilling and simultaneous processing of two workpieces. It is mainly used for drilling and grooving panel materials and can produce various types of furniture joints, as well as drilling for hinges, dowels, eccentric connectors, perforations, back panel slots and more. The machine can automatically identify workpiece codes via wireless barcode scanning. Automatic workpiece positioning and unloading is enabled via a rear conveyor table.

High-performance servomotors execute control commands quickly and accurately, ensuring accurate, fast and high-quality drilling.

X-axis movement

Y-axis movement

Z-axis movement

X-axis speed

Y-axis speed

Z-axis speed

UPPER DRILLING BLOCK

Equipped with 12 vertical drill bits and 8 horizontal drill bits. It also features a dedicated 6kW motor for cutting and engraving.

Equipped with 9 vertical drill bits, along with an additional 3.5kW motor for cutting and engraving.

The machine includes a wireless barcode reader for workpiece codes, capable of scanning codes in batches and automatically waiting for the next workpiece in line.

INTEGRATED CAM SOFTWARE

The system includes specialized CAM software with a graphical interface, providing high stability and suitability for automated production lines across industrial capacities.

Air tables with round bearings efficiently facilitate the movement of workpieces.

Minimum processing dimensions

Total power

Upper drilling block

Lower drilling block

Type of movement motor

Additional upper motor

Additional lower motor

Operating air pressure

Control system

Machine dimensions

Packing dimensions

Weight

High-performance bearings with double support ensure the secure holding of both small and large pieces, guaranteeing stable fixation of the workpiece without slipping. They are controlled by precise servomotors, ensuring accuracy and error-free operation.

An additional support with a side pressure mechanism for accurate and stable machine work without causing damage.

The machine is equipped with a conveyor belt for the processed piece, which allows the material to be transported to the end of the belt using a signal sensor. This improves both the functionality and the working speed.

Working area 1200x2440mm

Movement speed

Main motor power 3.5kW

A high-precision CNC drilling machine designed for horizontal drilling, capable of automatically identifying workpiece codes via wireless barcode scanning. Workpieces can be placed in three zones and the machine will automatically scan and process them.

CONSTRUCTION

Robust construction ensures high rigidity and excellent resistance to static and dynamic loads. Manufactured using high-precision CNC machining centers for metal, guaranteeing precision, quality and machine longevity.

Working area

Movement range

Movement speed

Barcode reader

Main motor power

Main motor speed

SERVO MOTORS AND DRIVERS

High-performance servo motors quickly and accurately execute control commands for precise, fast and high-quality drilling.

Axis movement occurs via linear guides and a rack-and-pinion system, ensuring smooth operation, low noise and increased durability. MOVEMENT

1200x2440mm

2450x50mm

60m/min

Included 3.5kW

18.000rpm

Number of drilling motors

Number of pneumatic presses

Machine dimensions

Packing dimensions

Weight

x1 (optional x2)

х9 (3 positions x3)

3600x1500x1600mm

3500x1200x1500mm

800kg

Made of special wear-resistant plastic for durability.

Three clamping zones with three clamps each ensure efficient and stable workpiece fixation without slipping.

FIRST-CLASS PERFORMANCE!

APPLICATION

The CNC plasma cutter is ideal for cutting steel, stainless steel and non-ferrous metals up to 30mm thick (120A). It is used in various industries such as fence manufacturing, decorative elements, construction, urban equipment, machine parts, ventilation and more.

A robust construction design ensures stability under heavy loads, guaranteeing the quality and precision of processed pieces.

Plasma cutting is a process that uses a jet of high-temperature ionized gas to conduct electrical energy, heating and melting the material. The machine is equipped with licensed software, an automatic height control sensor, a high-performance operating system, a 120-amp plasma power source (optional 100A, 160A, 200A) and a lubrication system.

Controller for automatic height regulation of the plasma torch relative to the material, maintaining a high level of cutting quality.

The movement of the axes is carried out through linear guides and a rack-andpinion system, which is the most commonly used and proven system in CNC machines.

Guarantee precise positioning of the bridge and spindle without deviations or errors, ensuring highspeed movement. Proven quality and operational stability.

Uses IGBT inverter technology for high efficiency and operational stability. It is widely used in various industries with proven quality. Allows stepwise amperage adjustment for cutting different thicknesses while ensuring high quality.

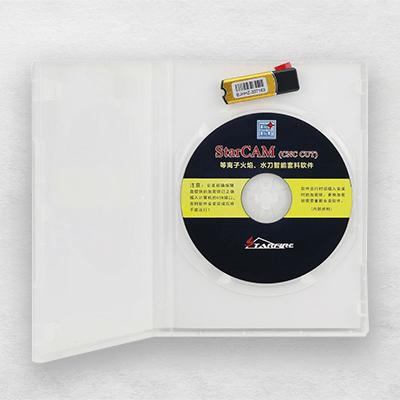

The operating system includes a library with 24 different industry-standard parts, allowing direct dimension changes. Fully compatible with STARCAM and FASTCAM software.

Working area

Optional working area

Plasma type

Plasma cooling type (100-120A)

Plasma cooling type (160-200A)

Processing speed

Total plasma power (120A)

Movement motor type

Plasma power

Maximum cutting thickness (fine)

Maximum cutting thickness (rough)

Licensed software

Operating system

Working air pressure

Height controller

Plasma dimensions

Machine dimensions

Packing dimensions

Weight

1500х3000x130mm

2000х4000x130mm

Huayuan LGK-120IGBT

Air-cooled

Water-cooled

0-50m/min

17.9kW

Hybrid step motors

120A (optional 160А, 200А)

0.4-25mm (120А)

45mm Starcam Starfire

4-6 bar

HYDTHC (included)

675x320x605mm

3800x2300x1600mm

3800x2200x1650mm

1300kg

Unlike other CNC cutting machines, the CNC plasma cutter does not use gas, making it significantly more economical and safer.

supports importing finished drawings in various formats such as

and processing them efficiently.

APPLICATION

The fiber laser is ideal for cutting steel, stainless steel, aluminum, copper, brass and more. It is used in industries such as fence manufacturing, decorative elements, construction, urban equipment, machine parts, ventilation and others.

The CNC fiber laser represents the fastest and most advanced technology for cutting metal without additional processing. The cutting speed is incomparably higher compared to other cutting technologies which significantly increases efficiency. It is equipped with a MAX laser source, RAYTOOLS laser head, CYPCUT control system, FUJI servo motors, an industrial chiller for cooling, a ventilation system and a voltage stabilizer. The best configuration for the best results and highest quality!

brand laser

with automatic focusing, a leading name in quality, durability and precision.

Working area

Optional working area

Laser power

Optional laser power

Movement motor type

Y-axis motor power

X-axis motor power

Z-axis motor power

Laser source type

Laser head type

Positioning accuracy

SOURCE

MAKS brand laser source with 100,000 operating hours, proven to be the most durable and long-lasting compared to other brands.

The movement of the axes is carried out through linear guides and a rack-andpinion system, which is the most commonly used and proven system in CNC machines.

1500x3000mm

2000x4000mm

1500W

3000W, 4000W, 6000W Servo motors 850W

Repeat positioning accuracy

Processing speed

Travel speed

Maximum load capacity

Operating system

Ventilation

Cooling chiller

Voltage stabilizer

Machine dimensions

Packing dimensions

Weight

±0.05mm/m ±0.02mm

0-30m/min 0-100m/min

700kg

4600x2450x1700mm

4580x2250x1800mm

Specially designed for high demands and performance. Ensure precise positioning of the bridge without deviations or errors and enable high-speed movement.

Available laser power options: 1500W, 3000W, 4000W and 6000W.

The industrial chiller cools the liquid heated during laser operation, maintaining a constant temperature and ensuring protection and uninterrupted laser operation.

A massive structure providing a high level of rigidity and excellent resistance to static and dynamic loads. Manufactured using high-precision CNC machining centers for metal, ensuring precision, quality and machine durability.

Maximum cutting thickness 1500W

Maximum cutting thickness 3000W

Maximum cutting thickness 4000W

Maximum cutting thickness 6000W 12-16mm 16-20mm 18-22mm 20-25mm

OVER 4,000 WOOD AND MACHINES SOLD IN THE

CO2 lasers are among the greatest technological advancements, offering superior quality in processing various materials. Due to their operational safety and extremely low maintenance costs, CO2 lasers positively impact business economics.

CO2 lasers present an excellent opportunity for starting a new business or expanding an existing one, thanks to their versatility in processing numerous materials and their application in various industries and projects.

Unlike standard CO2 lasers, RADEK lasers are fully equipped at the highest level with features such as an industrial cooling chiller, motorized movable platform (Z-axis), automatic focus, red dot pointer for positioning, honeycomb working table, a powerful compressor and a fan with a flexible hose.

Working area (X and Y axis)

Working area (Z axis)

Laser power

Engraving speed

Cutting speed

Positioning

Cooling system

Worktable

Linear guides

Movement motor

Software

Controller

Air compressor

Ventilation

Cutting thickness

Positioning accuracy

Rotary axis

Machine dimensions

Packing dimensions

Weight

High-quality CO2 cylinder that allows you to process materials up to 20mm thick.

The industrial chiller functions to cool the liquid that heats up during laser operation. It maintains a constant liquid temperature, ensuring protection and smooth operation of the laser.

400x400mm

150mm

50W

1-400mm/s

1-400mm/s

Red dot (RED DOT)

Industrial chiller CW3000

Movable platform with Honeycomb 15mm (X and Y axis)

Step motor 42

Rdworks Ruida 6445

Included Built-in 38W

1-20mm (depending on material)

≤0.01mm

Optional

900x750x420mm

1020x880x610mm

70kg

600x400mm

250mm

60W / 80W

1-1000mm/s

1-500mm/s

Automatic focus + red dot

Industrial chiller CW5000

Movable platform with Honeycomb 15mm (X and Y axis)

Step motor 57

Rdworks Ruida 6445

Included 550W

1-20mm (depending on material)

≤0.01mm

Optional

1200x780x980mm

1370x900x850mm

128kg

The laser beam, guided by mirrors and lenses, efficiently transmits and focuses the beam for successful engraving and cutting of materials such as wood, MDF, plywood, HDF, acrylic, leather, cardboard, rubber, marble, mirrors, coated metals and more. They are widely used across various industries, including manufacturing, small and large enterprises, crafts, packaging, printing, leather processing, clothing, automotive, musical instruments, architecture, label production, medical industries and many others.

Highly precise linear guides guarantee stable and smooth movement during operation.

Industrial RUIDA 6445 controller with numerous options and a large display.

The laser includes doors that allow positioning of materials larger than the working area of the laser.

Rotary axis for engraving cylindrical products.

600x900mm

250mm

80W / 100W / 130W

1-1000mm/s

1-500mm/s

Automatic focus + red dot

Industrial chiller CW5000

Movable platform with Honeycomb

15mm (X and Y axis)

Step motor 57

Rdworks Ruida 6445

Included

550W

1-20mm (depending on material)

≤0.01mm

Optional

1400x980x980mm

1620x1100x850mm

190kg

1300x1000mm

350mm

100W / 130W / 150W

1-1000mm/s

1-500mm/s

Automatic focus + red dot

Industrial chiller CW5200

Movable platform with Honeycomb 15mm (X and Y axis)

Step motor 57

Rdworks Ruida 6445

Included 550W

1-20mm (depending on material)

≤0.01mm

Optional

1850x1390x990mm

2130x1510x860mm

360kg

1600x1000mm

350mm

130W / 150W

1-1000mm/s

1-500mm/s

Automatic focus + red dot

Industrial chiller CW5200

Movable platform with Honeycomb 15mm (X and Y axis)

Step motor 57

Rdworks Ruida 6445

Included 550W

1-20mm (depending on material)

≤0.01mm

Optional

2150x1530x1130mm

2280x1620x1290mm

476kg

Manufactured according to strict quality and durability standards, making it a longterm investment.

The INDUSTRIAL ABRIGHTER RBS-600-PREMIUM is an industrial planer from the RADEK premium series, featuring a spiral shaft that guarantees superior smooth finishes compared to standard shaft types. Additional benefits of the spiral shaft include easily replaceable blades (used on all 4 sides), quieter and more stable operation and in case of blade damage, only the damaged blade needs to be replaced. It also performs much better when dealing with knots in wood and more... Heavy-duty, solid construction capable of handling large workloads while maintaining top-quality performance.

With the RBS-600-PREMIUM jointer, you will achieve outstanding results on every workpiece, regardless of the type and hardness of the wood. EXCELLENT

Industrial design with compact dimensions for increased functionality.

Maximum processing width

Maximum processing thickness

Rotational speed

Number of blades

Table dimensions

Table tilt

Shaft diameter

Motor power

Total worktable length

Machine dimensions

Packing dimensions

Weight

LONG-TERM INVESTMENT

Manufactured according to strict quality and durability standards, making it a long-term investment.

MASSIVE CONSTRUCTION

Heavy-duty construction capable of handling large workloads while maintaining top-quality performance.

The INDUSTRIAL THICKNESSER RBS-630-PREMIUM is an industrial planer from the RADEK premium series, featuring a spiral shaft that guarantees superior smooth finishes compared to standard shaft types. Additional benefits of the spiral shaft include easily replaceable blades (used on all 4 sides), quieter and more stable operation and in case of blade damage, only the damaged blade needs to be replaced. It also performs much better when dealing with knots in wood and more...

Maximum

Maximum processing thickness

Minimum processing length

Minimum processing thickness

Maximum working thickness per pass

Processing speed

Rotational speed

Number of blades

Shaft diameter

Power

Packing

Solid working tables for absolute precision and stability during operation. STURDY

With the RBS-630-PREMIUM planer, you will achieve outstanding results on every workpiece, regardless of the type and hardness of the wood. EXCELLENT RESULTS

EXCELLENT PERFORMANCE!

Maximum working width

The THICKNESSER RK-1050-PRO is a thickness planer machine from the professional series, offering excellent performance and top-quality results with every piece produced, regardless of wood type. It is an essential machine in all woodworking shops.

Two additional work tables at the front and rear of the machine provide extra support for larger workpieces.

Maximum working width

Maximum working thickness

Minimum working length

Minimum working thickness

Maximum working depth

Processing speed

Rotation speed

Number of blades

Shaft diameter

Power

Total worktable length

Machine dimensions

Packing dimensions

Weight

A gear roller at the front and a rubber roller at the rear ensure smooth and stable material movement.

Manufactured according to industrial standards, with a solid structure resistant to vibrations and deformations, fixed in four positions.

A strong and stable transmission ensures safety during operation and a long service life.

Maximum working width 310mm

RK-31-PRO is a combined surface planer and thicknesser machine designed for perfect working results. It is designed for both soft and hardwood with a robust construction that eliminates vibrations and ensures stable operation. Easy to adjust and with compact dimensions, it is ideal for small to medium-sized workshops.

Maximum working width

Maximum working thickness

Minimum working length

Thickness range (planing)

Processing speed

Rotation speed

Number of blades

Table dimensions

Table tilt

Shaft diameter

Motor power

Machine dimensions

Packing dimensions

Weight

pieces

Max. cutting thickness 200mm

The Wood planer, or band saw, is an essential machine in every woodworking shop. It allows for straight and circular cutting of wood and sheet materials. The mobile design is equipped with LED lighting and a tool drawer for added convenience.

Durable working table with an auxiliary fence and measuring scale for efficient cutting of workpieces.

Maximum processing width

Maximum processing thickness

Blade speed

Blade dimensions

Worktable dimensions

Worktable tilt

Wheel diameter

Wheel width

Motor power

Machine dimensions

Packing dimensions

Weight

2685x13mm

500x450x32mm

0° - 45°

0.75kW

640x440x1630mm

1600x650x860mm 145kg

Max. cutting thickness 370mm

The Wood Planer features a stable and compact construction, allowing for straight, circular and angular cutting of wood and sheet materials. An essential machine in every woodworking shop.

Solid working table with an auxiliary fence and measuring scale for efficient cutting of workpieces.

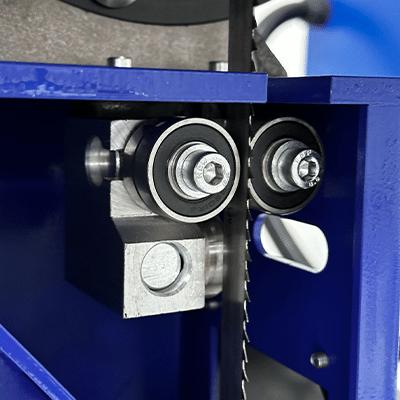

Located above and below the table, ensuring stability and precision of the saw blade during cutting.

wheels with a diameter of 500mm and a width of 35mm, fitted with a saw blade of dimensions 4020x16mm.

Maximum cutting width

Maximum cutting thickness

Blade speed

Blade dimensions

Worktable dimensions

Worktable tilt

Wheel diameter

Wheel width

Motor power

Machine dimensions

Packing dimensions

Weight

4020x16mm

630x525x55mm

0° - 45°

3kW

760x920x1900mm

1950x650x1050mm

278kg

Heavy-duty working table measuring 1000x660mm.

Comes with a

to which you can attach

tools of your choice.

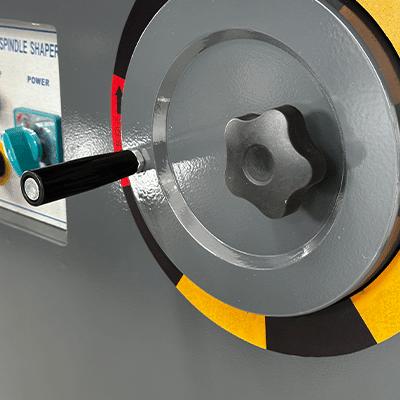

A milling machine with the option to install a conventional conveyor, designed for processing all types of wood and sheet materials. It comes with a protective cover made of adjustable aluminum firuns. The machine features excellent robust construction that eliminates vibrations and ensures long-lasting durability.

Table size

Processing thickness

Rotational speed

Conveyor

dimensions

Designed for installation with professional series milling machines like the RBS-350-PRO model. This modern and sturdy design features 8 speeds and 4 wear-resistant rubber rollers for smooth movement of workpieces. It is adjustable in different positions according to the workpiece.

ADJUSTABLE WHEEL WITH HANDLE

A wheel with a handle used to

ROLLERS

Equipped with 4 rollers that enable firm and smooth movement of the workpiece.

Various work positions that can be quickly and easily adjusted.

Processing width 18-120mm

Processing thickness 8-100mm Total power 12.47kW

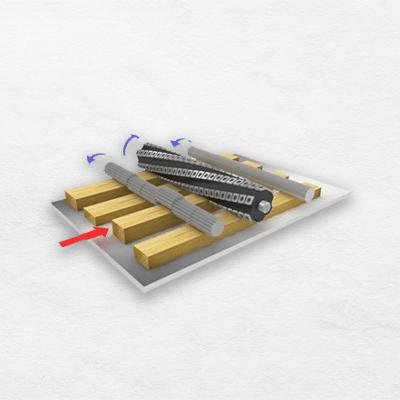

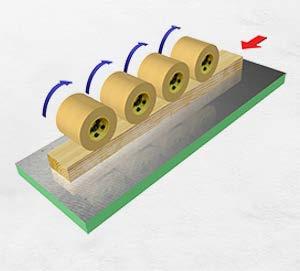

Designed for four-sided processing of workpieces. It is commonly used for precise planing, grooving, or shaping according to your choice, with speeds up to 20 meters per minute. Three features make it an excellent choice: compact dimensions that save space, economical power consumption, and ease of use and maintenance. The machine comes with 4 heads that allow you to attach knives (blades) in any desired shape.

ECONOMICAL AND SIMPLE! SEPARATE MOTORS

TRANSPORT ROLLERS

One

Processing speed

Number of miling cutters

Rotational speed

Shaft diameter

Bottom cutter diameter

Top cutter diameter

Right cutter diameter

Left cutter diameter

Bottom motor power

Top motor power

Right motor power

Left motor power

Conveyor power

Height regulator power

Machine dimensions

Packing dimensions

Weight

Driven by a cardan shaft for firm and smooth movement of the workpiece. Transport is done using toothed metal rollers at the front and smooth rubber rollers at the back to prevent potential damage to the workpiece.

ADDITIONAL SUPPORT

Horizontal and vertical rollers are placed in the work zone for maximum support during the transport of the workpiece.

ROLLER ADJUSTMENT

The pressure of the transport rollers is automatically adjusted via the control panel.

The position of the planer is mechanically adjusted using handles placed at the front of the machine.

Ø110-140mm Ø110-140mm

With the brush machine, you gain numerous processing options such as sanding raw MDF, sanding MDF with a base coat (primer), sanding panels of irregular shapes, 2D and 3D shapes and sanding solid wood products.

The automatic brushing machine is one of the most popular machines on the market due to its ease of use, lack of human error and ability to increase your sanding capacity by up to 10 times. This machine will return your investment in record time. It consists of 3 independent zones that can be adjusted by height, rotation speed and oscillation.

Grinding is a painstaking process and a stage in the work that no worker wants, that’s why this machine is necessary in all industries that will allow you to increase the capacity and reduce the human factor in the processing process.

Material movement is enabled by a high-quality rubber belt and rubber rollers that stabilize the workpiece in two positions, ensuring smooth movement of the material without damage.

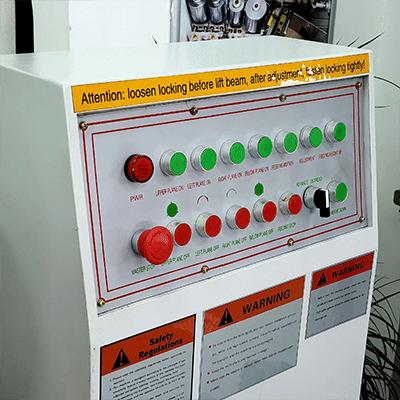

The control panel allows for the regulation of each zone separately, including turning on, adjusting speed and regulating oscillations. Additionally, it controls the activation of the conveyor belt and the processing height.

The sanding belts are divided into three zones: 7 horizontal brushes in the first zone, 9 circular brushes in the second zone and 2 long brushes in the third (final) zone. The most compatible grit for various materials like MDF and wood is: in the first zone 240, in the second zone 320 and in the third zone 400.

Six F100 dust extraction openings are placed at the top of the machine for efficient dust extraction. The machine also comes with internal flexible hose installations for dust extraction.

Maximum working width

Maximum working lenght

Maximum working thickness

Motor power (horizontal brushes)

Motor power (circular brushes)

Motor power (long rollers)

Motor power (oscillation of horizontal brushes)

Motor power (oscillation of circular brushes)

Motor power (oscillation of long brushes)

Motor power (conveyor)

Reducer power

Total power

Roller diameter for horizontal brushes

Number of circular rollers

Roller diameter for circular brushes

Number of long rollers

Roller diameter for long brushes

Processing speed

Number of sanding strips on horizontal roller

Number of sanding strips on circular rollers

Number of sanding strips on long rollers

Conveyor belt dimensions

Machine dimensions

Packing dimensions

Weight

It consists of 3 zones with horizontal, circular and long brushes, each of which is independently adjusted according to the type of material being processed. Each zone has two rows of brushes with different rotations, left and right. All these advantages ensure top-notch processing and flawless finishing of every detail of the workpiece. PREMIUM

9

2

Massive construction made of high-quality iron ensures durability and stability while working in tough conditions during multiple shifts.

A sanding machine designed for calibration, sanding, fine polishing and leveling. It consists of two separate sanding zones with different grits and oscillations to improve processing quality. Tested for intensive work in multi-shift operations.

The machine is equipped with a photo sensor for oscillations of the sanding belt. When the belt crosses the light beam, the oscillation system is activated and the belt moves in the opposite direction. Additionally, it has an emergency stop sensor in case the sanding belt separates.

Separate high-power industrial motors 18.5kW in the first zone and 15kW in the second zone that guarantee stable operation even in difficult conditions, motor rotations are interrupted by the use of special brake pads.

Maximum worktable width

Minimum worktable lenght

Processing power

First motor power

Second motor power

Conveyor power

Motor power for height adjustment

Total power

First roller diameter

Second roller diameter

Sanding belt dimensions

Working pressure

Processing speed

Machine dimensions

Packing dimensions

Weight

Coarse and fine sanding in one process, choose the required sanding belt granulation according to the type of material and you will get an ideal smooth surface in one process.

The first zone is equipped with one metal roller with a rubber coating, efficiently calibrating the workpiece to its dimensions.

The second zone has two metal rollers, one with a rubber coating for fine sanding and one with a smooth metal surface for leveling.

The control panel includes: machine power, turning on the first or second sanding zone, turning on the conveyor belt, adjusting the processing height with a digital gauge, emergency stop button and voltmeter.

The sanding belt tension is regulated by a pneumatic system, ensuring stability and preventing the sanding belts from tearing.

Easy replacement of the sanding belt in two steps: removing the rubber limiter and pulling out the worn sanding belt or brush.

The machine is equipped with a speed controller, allowing you to adjust the rotation of the sanding belts according to the material you are processing.

CONSTRUCTION

Well-built construction that eliminates vibrations and ensures stability during operation.

for larger workpieces, adjustable as needed.

Designed for processing solid wood in various shapes and sheet materials, most commonly MDF. It is equipped with two motors, one for the sanding belt roller and the other for oscillations, significantly improving sanding quality. The work table has two adjustable stops based on the required pressure for processing.

Roller diameter

Roller height

First main motor power

Power of the first motor for oscillations

power

of sanding strips

of short brushes

The machine is equipped with a speed controller, allowing you to adjust the rotation of the sanding belts according to the material you are processing.

Easy replacement of the sanding belt in two steps: removing the rubber limiter and pulling out the worn sanding belt or brush.

A F100 dust extraction port is installed for connecting

for

Well-built construction that eliminates vibrations and ensures stability during operation.

Designed for processing solid wood in various shapes and sheet materials, most commonly MDF. It is equipped with three rollers, two of which are 300mm and one is 600mm, allowing two people to work simultaneously. Auxiliary tables are mounted on the middle roller for placing and moving the workpiece.

Roller diameter

Processing width of left roller

Processinf width or right roller

Processing width of middle roller

Motor power

Number of sanding strips (300mm)

Number of short brushes (300mm)

Number of long brushes (300mm)

Number of sanding strips (600mm)

Number of short brushes (600mm)

Number of long brushes (600mm)

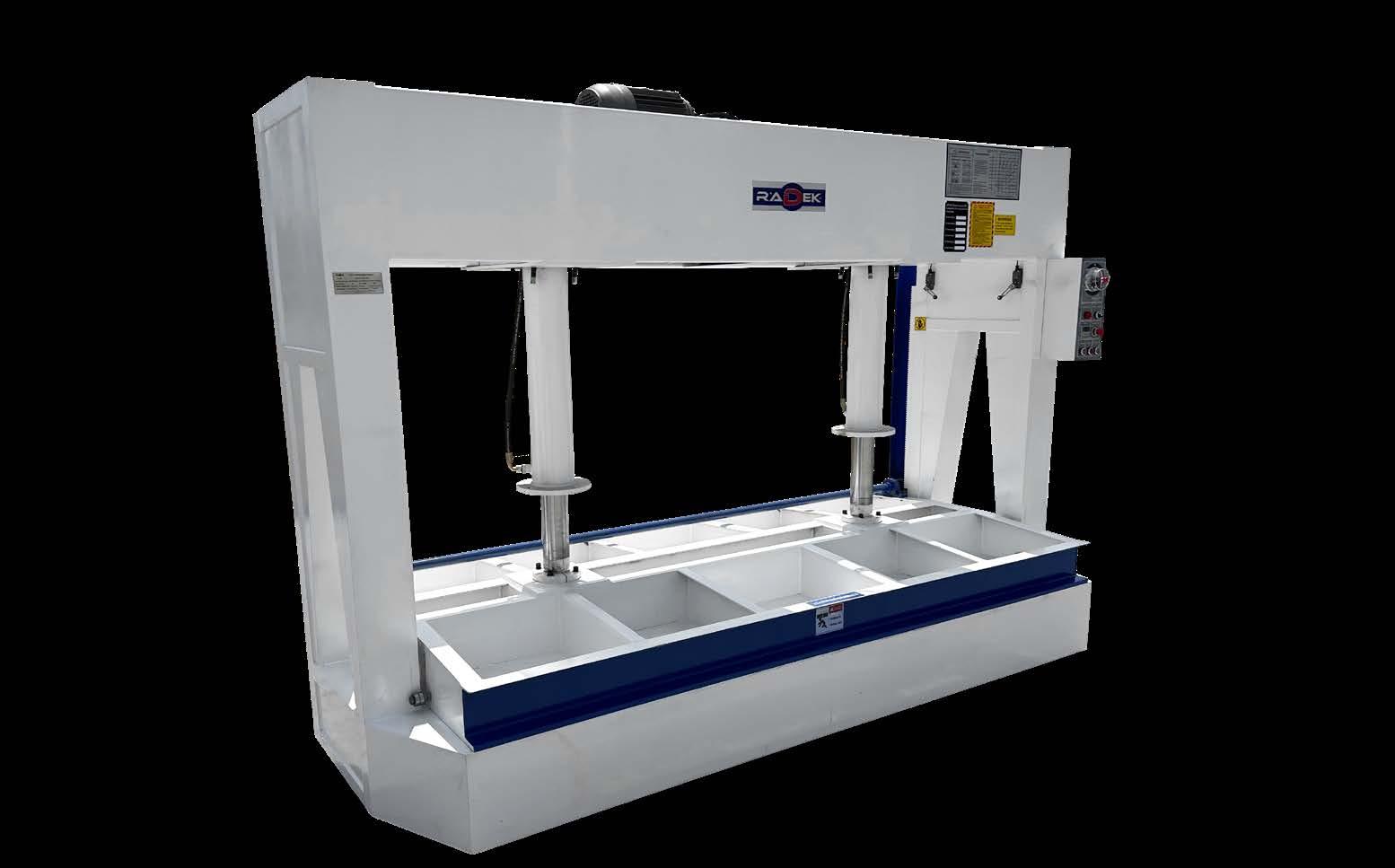

Available in various sizes and with different pressures

The cold press is a hydraulic machine essential for the production of doors, furniture, or multi-layer products. Compared to hot presses, it is much more economical and has a shorter reaction time. Easy to operate, with stable performance and consistent quality in operation. Available in different dimensions and pressure ratings depending on work requirements.

CONSTRUCTION

Massive construction that ensures a high degree of rigidity and excellent resistance to static and dynamic loads. Made on high-precision CNC machining centers for metal, ensuring precision, quality and durability of the machine.

Working surface

Maximum pressure

Hydraulic system pressure

Maximum opening

Cylinder diameter (large)

Cylinder diameter (small)

Number of cylinders (large)

Number of cylinders (small)

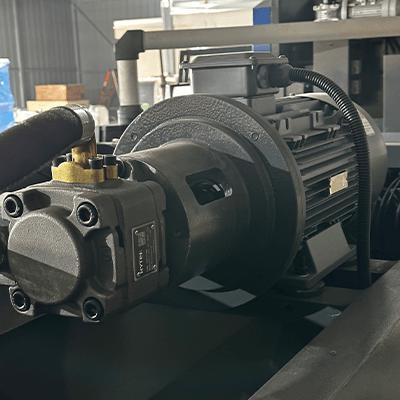

Hydraulic motor power

Machine dimensions

Packing dimensions

Weight

CYLINDERS

High-quality cylinders that guarantee long service life and consistent performance.

The control panel is located on the right side of the machine and allows you to control the pressure and processing time.

The maximum press opening is 1000mm, allowing pressure on multiple workpieces at the same time.

RK1225-CP50-PRO

1250x2500mm

50T (1.1kg/cm²)

210kg/cm²

3.7kW

2900x1250x2300mm

2950x1300x2350mm 2000kg

RK1530-CP50-PRO

1500x3000mm

50T (1.1kg/cm²)

210kg/cm²

1500x3500x2200mm

1500x3500x2200mm 3000kg

RK2030-CP50-PRO

2000x3000mm

50T (0.8kg/cm²)

210kg/cm² 1000mm 125mm 90mm x2 x2

4kW

2000x3500x2200mm

2000x3500x2200mm

3500kg

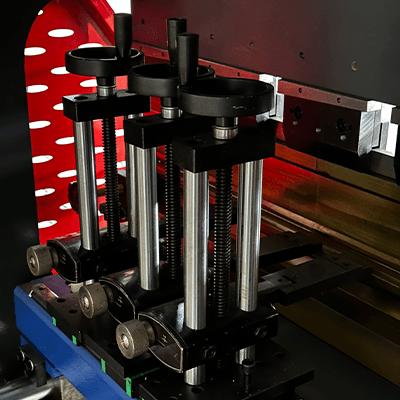

Hydraulic press brake for bending steel, stainless steel and other materials, used in various industries such as manufacturing decorative elements, construction, urban equipment, shelving, ventilation and much more. Available with different pressure options depending on the thickness and bending length. Top quality with a 1-year factory warranty. Equipped with components from trusted and renowned brands in the market.

RK100T-400-PRO

RK135T-250-PRO

Pressing / bending force

Max. bending thickness of steel

Bending thickness of stainless steel

Maximum bending length

Distance between columns

Throat depth

Stroke distance

Maximum opening height

Pressing speed

Back gauge speed

Working speed

Maximum back gauge distance

Bending angle accuracy

Main motor power

Control system

Machine

Packing

ERGONOMIC CONTROLLER

Equipped with the ESTUN E21 controller, offering numerous options such as programming the bending angle in degrees, axis control, a memory library for 30 programs and more.

The standard prism is included in the set with numerous bending angles.

ADDITIONAL EQUIPMENT

Adjustable Z-stops, solid iron cylinders, a system for easy and precise tool adjustment and front auxiliary supports.

Laser for protective barriers and “Crowning” system to eliminate the “banana” effect.

Massive construction that ensures a high degree of rigidity and excellent resistance to static and dynamic loads. Made on high-precision CNC machining centers for metal, ensuring precision, quality and durability of the machine.

The motor is made under Siemens license, Vickers valves, Sunny hydraulic pump, LS inverter made under LG license, Schneider electronics, Hawe pneumatics and others. BRANDS

Rear station with a threaded spindle that provides exceptional precision and low friction of the elements. Additionally, Z-stops are installed for easy and precise adjustment.

RK200T-320-PRO

200T RK200T-400-PRO 8mm

RK250T-250-PRO 15mm 8mm

250T

RK250T-400-PRO

RK300T-320-PRO

Hydraulic shears for cutting steel, stainless steel and other materials with high precision. They are used in various industries such as the production of decorative elements, construction, urban equipment, shelving, ventilation and much more. Available with different pressures depending on the thickness and length of the cut. Premium quality with a 1-year factory warranty. They are equipped with components from proven, reputable brands.

RK4-250-PRO

RK4-400-PRO

RK6-250-PRO

RK6-320-PRO

RK6-400-PRO

RK8-250-PRO

RK8-320-PRO

Maxi. steel cutting thickness

Maximum cutting length

Throat depth

Cutting angle

Cutting speed

Cutting blade dimensions

Cutting blade (quantity) 1100x3mm 3(top) + 3(bottom) 1025x4mm 4(top) + 4(bottom) 1300x2mm 2(top) + 2(bottom) 1100x3mm 3(top) + 3(bottom) 1025x4mm 4(top) + 4(bottom)

2(top) + 2(bottom)

Back gauge travel

Back gauge speed

Back gauge accuracy

Front arm length

Front arms (quantity)

Main

Machine dimensions

Packing dimensions –

1300x2mm 2(top) + 2(bottom) 1100x3mm 3(top) + 3(bottom)

ERGONOMIC CONTROLLER

Equipped with the ESTUN E21C controller, offering numerous options such as intelligent positioning, axis control, a memory library for 30 programs and more.

Massive construction that ensures a high degree of rigidity and excellent resistance to static and dynamic loads. Made on high-precision CNC machining centers for metal, ensuring precision, quality and durability of the machine.

BRANDS

The motor is made under Siemens license, Rexroth valves, Sunny hydraulic pump, LS inverter made under LG license, Schneider electronics, Hawe pneumatics and others.

ADVANTAGES

High precision and cutting speed with large capacity, top-quality cutting and massive construction make it a real long-term investment.

RK16-250-PRO

200mm 1°30’ ≥8 times per minute 16mm

RK16-320-PRO 3200mm 200mm 1°30’ ≥7 times per minute 16mm

RK16-400-PRO

1025x4mm 4(top) + 4(bottom)

1300x2mm 2(top) + 2(bottom) 1100x3mm 3(top) + 3(bottom)

20-600mm 10.8m/min

±0.02mm 800mm 2 19 7.5kW E21S 4600mm 20-600mm 10.8m/min ±0.02mm 800mm

1025x4mm 4(top) + 4(bottom)

1300x2mm 2(top) + 2(bottom)

1100x3mm 3(top) + 3(bottom)

1025x4mm 4(top) + 4(bottom)

1300x2mm 2(top) + 2(bottom) 1100x3mm 3(top) + 3(bottom)

200mm 1°30’ ≥5 times per minute

1025x4mm 4(top) + 4(bottom)

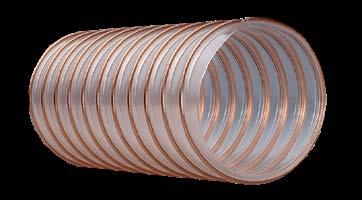

Widely used in various industries, these machines provide a clean, efficient and comfortable working environment while protecting the operator’s health. They are available in various dimensions, power levels and bag capacities depending on the machine’s requirements. It also includes a reducer with multiple openings that enables the connection of several machines.

Unlike other dust collectors with a plastic fan, this model is equipped with a metal fan, which is crucial for better dust extraction and longevity.

Power

Capacity

Inlet diameter

Bag diameter

Fan type

Flexible Hose

Machine dimensions

Packing dimensions

Weight

Mounted on a base with 4 wheels for easy transportation.

2.2kW

2350m³/hr

Ø100mm x3

Ø480mm x4

Metal

Optional

940x530x2000mm

970x560x530mm

52kg

The dust collector comes with a reducer with multiple openings that allow connection to multiple machines simultaneously.

Optionally, you can purchase flexible hoses of various diameters and lengths, reducers with different diameters and replacement bags.

3kW

3150m³/hr

Ø100mm x3

Ø480mm x4

Metal

Optional 1170x530x2000mm 1200x560x530mm

70kg

4kW

4450m³/hr

Ø100mm x3

Ø630mm x4

Metal

Optional 1800x700x2200mm 1470x690x690mm

77kg

5.5kW

5500m³/hr

Ø100mm x6

Ø630mm x4

Metal

Optional 1800x700x2200mm 1450x730x710mm

94kg

7.5kW

9000m³/hr

Ø100mm x6

Ø650mm x8

Metal

Optional 1800x700x2200mm 1460x1460x400mm

138kg

DUST BAG FOR DUST COLLECTOR