EDGE BANDING MACHINE

The edge banding machine from RADEK’s premium series is equipped with numerous functions to achieve a perfect finish on every produced piece. It is ideal for industries looking to improve production and increase edge banding capacity up to a speed of 23 meters per minute. A large touchscreen display allows for automatic panel thickness adjustment. Its robust construction ensures stability and reliability during operation. An additional unit with press wheels has been added to eliminate the possibility of panel movement during processing.

UNIT

Allows the application of adhesive residue remover on the panel.

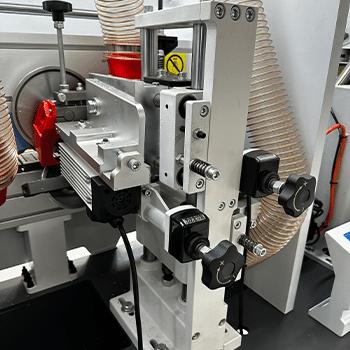

PRE-MILLING UNIT

Designed to eliminate cutting damage and guarantee a flat surface ideal for gluing. Made with diamond cutters and additional blowers to remove residue from the work piece for quality tape adhesion. Control of two pre-freesers is done with high-quality pneumatic cylinders.

Preheats the panels, essential for high-quality edge banding, particularly important in winter.

ROUGH TRIMMING UNIT

Precise processing of the upper and lower part of the panel with two flat routers and high spindle speeds (12,000 RPM).

Panel width

Panel thickness

Edge band thickness

Processing speed

Operating pressure

Pre-milling power

End cutting power

APPLICATION

The canister is designed for adhesive granules, with a 4-liter capacity, enabling precise adjustment of adhesive quantity to avoid over or under application.

FINE TRIMMING UNIT

Precision treatment of the upper and lower part of the panels with two radius routers (R1, R2, R3) and high spindle speeds (12,000 RPM).

CORNER ROUNDING UNIT

Precise corner finishing on both sides of the panel with two radius routers (R1, R2, R3) and high spindle speeds (18,000 RPM).

minimum 80mm 10-60mm

0.4-3mm

2.2kW (x2) 0.37kW (x2)

RADIUS SCRAPING UNIT

Scrapers with a radius for edge finishing to ensure smoothness.

Six pneumatic rollers (4 identical, 1 larger diameter and 1 with rubber material) ensure pressure for excellent tape adhesion.

END SPRAYING UNIT

Allows the application of adhesive residue cleaning agents on the panel.

Fine trimming power

Corner rounding power

Polishing power

Conveyor power

Total power

Machine dimensions

Packing dimensions

BUFFING UNIT

Final panel finishing by polishing for an even smoother surface.

0.75kW (x2)

0.37kW (x2) 0.37kW (x2)

4kW

16.5kW

6600x1000x1600mm

6800x970x1800mm

Rough trimming power

(x2)

Weight

2450kg

SPRAYING

ADHESIVE

PNEUMATIC ROLLERS

Precise cutting of panel edges with two saw blades and high spindle speeds (12,000 RPM).

END CUTTING