CNC ROUTER

The RADEK Premium Series 4-axis CNC router is specialized for complex products and door processing, offering cutting, vertical and horizontal drilling, carving and engraving—all in a single machine. Known for high precision, speed, productivity and flexibility, this machine is ideal for various woodworking applications.

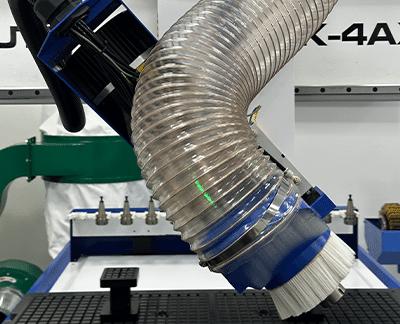

INDUSTRIAL MOTOR 9KW

The motor has 24,000 RPM and air cooling, enabling flawless processing of all types and thicknesses of materials.

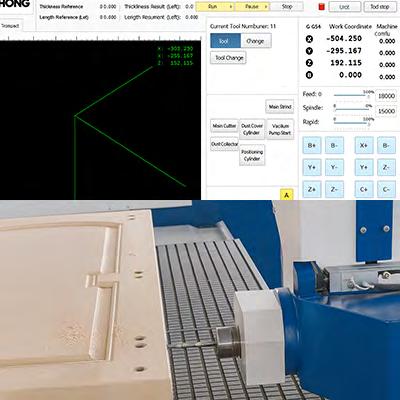

WORKING TABLE

Similar to the previous machine, this working table is designed with special wear-resistant plastic for vacuum pump usage, along with integrated “T” aluminum rails for manual securing.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Tool magazine

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

Z

for exceptional precision, low friction, maximum protection from wear and prevention of overheating of friction elements during machine operation.

Equipped with two 7.5kW aircooled vacuum pumps, each with a capacity of 550m³ per hour, ensuring high absorption even for small panels. The vacuum absorption is further enhanced with pneumatic rollers pressing the panel.

The movement is facilitated by linear guides (30mm and 25mm) and a rack and pinion system by the renowned HIWIN brand, ensuring smooth operation, low noise and long-lasting durability.

Specialized CNC software for fast and precise door machining. It offers real-time visualization, automatic measurements, and intelligent control of all operations — from hinges and locks to frames and grooves — ensuring stable, automated operation with minimal operator intervention.

HIGH-PRECISION SERVO MOTORS

These motors guarantee precise positioning of the bridge and spindle, offering high-speed movement up to 30 meters per minute and exceptional quality and stability in demanding industrial conditions.

The main motor can rotate, allowing for the processing of complex products. Enables machining of irregular shapes, ideal for modeling complex designs and 2D–3D surfaces.

4TH AXIS

INDUSTRIAL VACUUM PUMP

X AND Y AXIS MOVEMENT

The

axis uses a ball screw

Z AXIS MOVEMENT