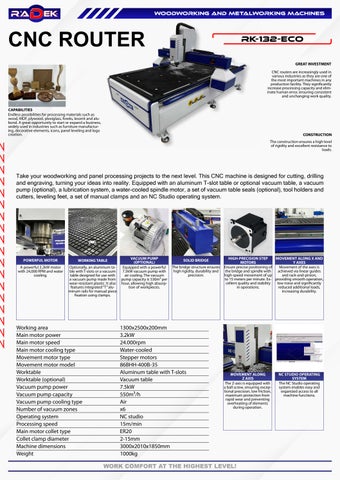

CNC ROUTER

CAPABILITIES

Endless possibilities for processing materials such as wood, MDF, plywood, plexiglass, foreks, lesonit and alubond. A great opportunity to start or expand a business, widely used in industries such as furniture manufacturing, decorative elements, icons, panel leveling and logo creation.

CNC routers are increasingly used in various industries as they are one of the most important machines in any production facility. They significantly increase processing capacity and eliminate human error, ensuring consistent and unchanging work quality. GREAT INVESTMENT

CONSTRUCTION

The construction ensures a high level of rigidity and excellent resistance to loads.

Take your woodworking and panel processing projects to the next level. This CNC machine is designed for cutting, drilling and engraving, turning your ideas into reality. Equipped with an aluminum T-slot table or optional vacuum table, a vacuum pump (optional), a lubrication system, a water-cooled spindle motor, a set of vacuum table seals (optional), tool holders and cutters, leveling feet, a set of manual clamps and an NC Studio operating system.

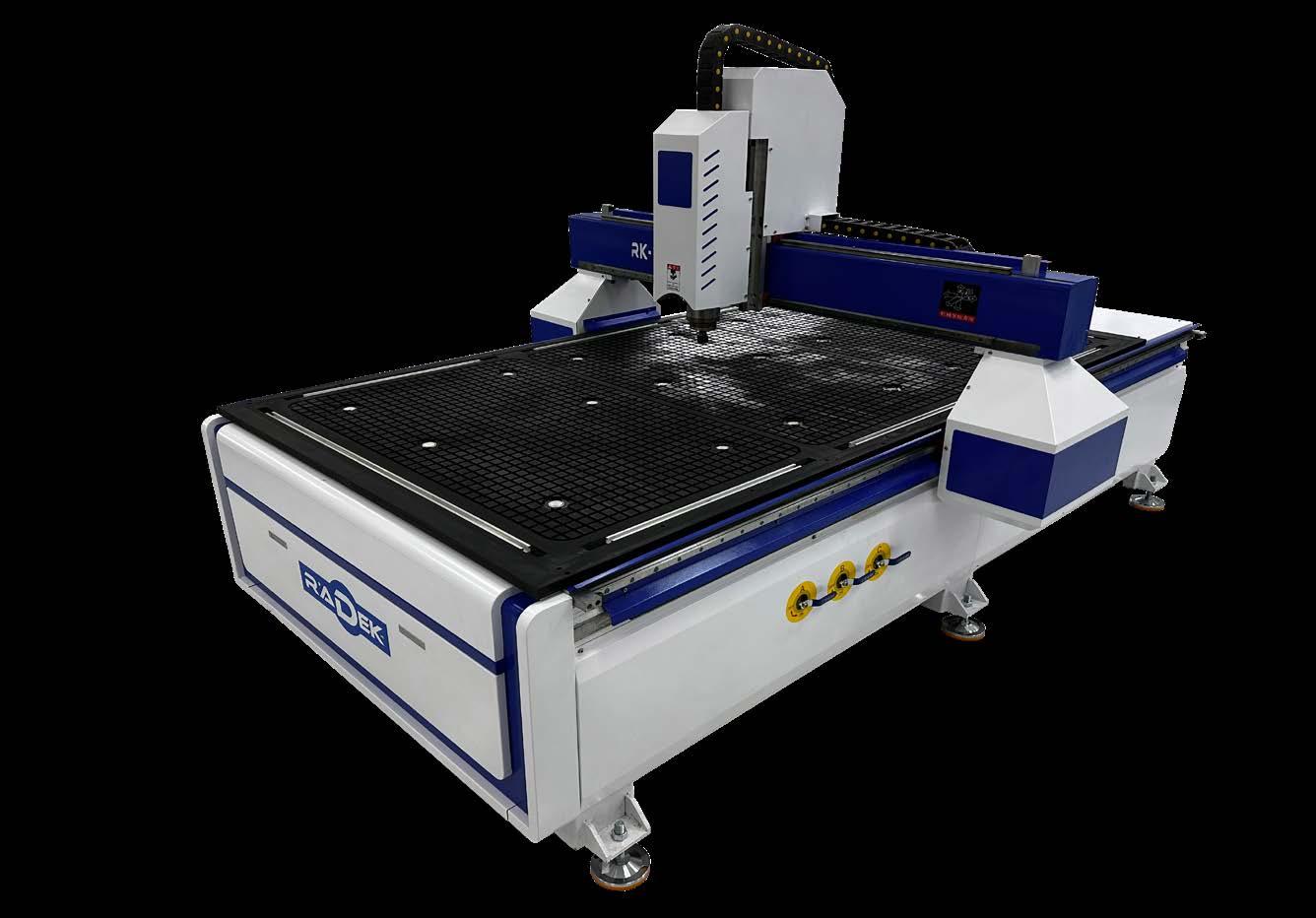

Optionally, an aluminum table with T-slots or a vacuum table designed for use with a vacuum pump made from wear-resistant plastic. It also features integrated “T” aluminum rails for manual piece fixation using clamps.

Equipped with a powerful 7.5kW vacuum pump with air cooling. The vacuum pump capacity is 530m³ per hour, allowing high absorption of workpieces.

HIGH-PRECISION STEP MOTORS

precision.

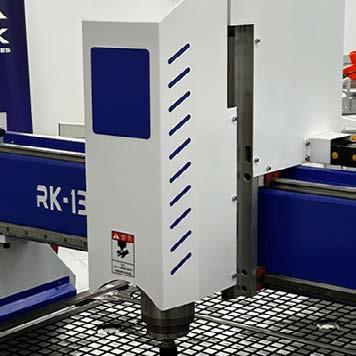

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor model

Worktable

Worktable (optional)

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

1300x2500x200mm

3.2kW 24.000rpm

Water-cooled

Stepper motors

86BHH-400B-35

Aluminum table with T-slots

Vacuum table

7.5kW

550m³/h

Air x6

NC studio 15m/min

ER20 2-15mm

3000x2010x1850mm 1000kg

Ensure precise positioning of the bridge and spindle with high-speed movement of up to 15 meters per minute. Excellent quality and stability in operations.

MOVEMENT ALONG X AND Y AXES

Movement of the axes is achieved via linear guides and rack-and-pinion, providing smooth operation, low noise and significantly reduced additional loads, increasing durability.

MOVEMENT ALONG Z AXIS

The Z-axis is equipped with a ball screw, ensuring exceptional precision, low friction, maximum protection from rapid wear and preventing overheating of elements during operation.

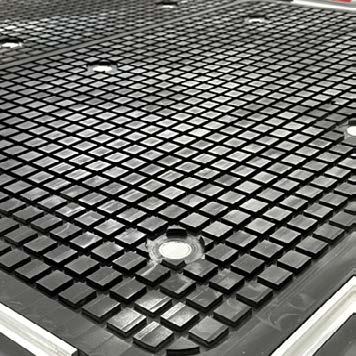

A powerful 3.2kW motor with 24,000 RPM and water cooling.

POWERFUL MOTOR

WORKING TABLE

VACUUM PUMP (OPTIONAL)

The NC Studio operating system enables easy and organized access to all machine functions.

NC STUDIO OPERATING SYSTEM

The bridge structure ensures high rigidity, durability and

SOLID BRIDGE