CNC PLASMA

Plasma cutting is a process that uses a jet of high-temperature ionized gas to conduct electrical energy, heating and melting the material. The machine is equipped with licensed software, an automatic height control sensor, a high-performance operating system, a 120-amp plasma power source (optional 100A, 160A, 200A) and a lubrication system.

ECONOMICAL

and IGES, optimizing and processing them efficiently.

Working area

Optional working area

Plasma type

Plasma cooling type (100-120A)

Plasma cooling type (160-200A)

Processing speed

Total plasma power (120A)

Movement motor type

Plasma power

Maximum cutting thickness (fine)

Maximum cutting thickness (rough)

Licensed software

Operating system

Working air pressure

Height controller

Plasma dimensions

Machine dimensions

Packing dimensions

Weight

1500х3000x130mm

2000х4000x130mm

Huayuan LGK-120IGBT

Air-cooled

Water-cooled

0-50m/min

17.9kW

Hybrid step motors

120A (optional 160А, 200А)

0.4-25mm (120А)

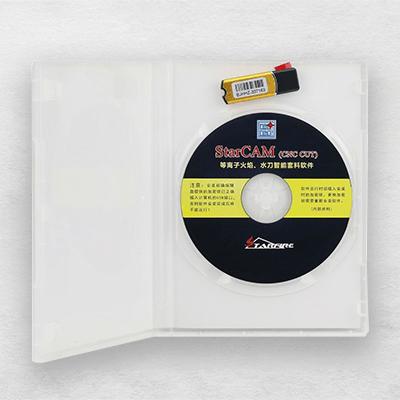

The operating system includes a library with 24 different industry-standard parts, allowing direct dimension changes. Fully compatible with STARCAM and FASTCAM software. Intuitive and easy-to-use interface for quick learning by operators. Perfectly defined functions for complete work control and easy adjustments.

HYDTHC (included)

675x320x605mm

3800x2300x1600mm

3800x2200x1650mm

1300kg

The movement of the axes is carried out through linear guides and a rack-and-pinion system, which is the most commonly used and proven system in CNC machines. It enables smooth operation, low noise levels and significantly reduces additional loads, increasing their lifespan and durability.

Uses IGBT inverter technology for high efficiency and operational stability. It is widely used in various industries with proven quality. Allows stepwise amperage adjustment for cutting different thicknesses while ensuring high quality and energy savings.

Controller for automatic height regulation of the plasma torch relative to the material, maintaining a high level of cutting quality.

HYDTHC CONTROLLER

X AND Y AXIS MOVEMENT

Guarantee precise positioning of the bridge and spindle without deviations or errors, ensuring high-speed movement. Proven quality and operational stability.

HIGH-PRECISION HYBRID STEP MOTORS

PLASMA INVERTER POWER SOURCE

The CNC plasma cutter is ideal for cutting steel, stainless steel and non-ferrous metals up to 30mm thick (120A). It is used in various industries such as fence manufacturing, decorative elements, construction, urban equipment, machine parts, ventilation and more. APPLICATION

A robust construction design ensures stability under heavy loads, guaranteeing the quality and precision of processed pieces.

DESIGN

Unlike other CNC cutting machines, the CNC plasma cutter does not use gas, making it significantly more economical and safer.

AND SAFE

Licensed STARCAM software supports importing finished drawings in various formats such as DXF, CAM, DWG,

LICENSED SOFTWARE