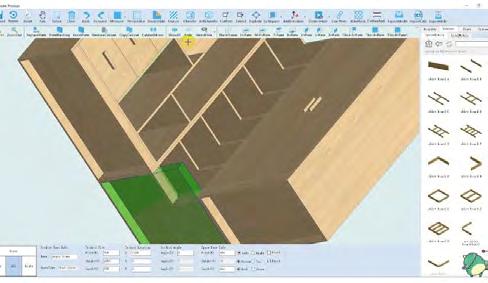

CNC NESTING

HAIXUN LICENSED SOFTWARE (OPCIONAL)

Sophisticated software enabling fast and efficient design and pro duction optimization, 3D preview and instant quotation generation with detailed pricing. Compatible with RADEK CNC drilling machines.

Automatic Panel Loading: Vacuum suction device on the gantry, enabling material pickup from a lifting table. Au tomatic Panel Unloading: A mechanism on the gantry that moves processed pieces onto a special conveyor belt for further handling UPGRADE OPTIONS

With a CNC nesting machine you get the most for your budget, it is known for its high precision, speed, productivity, flexible use in cutting, engraving and drilling, as well as the possibility of upgrading with a panel loading and unloading device for additional machine automation.

INDUSTRIAL 9KW MOTOR

The motor’s manufacturing, design and accompanying parts are 100% identical in quality to world-renowned brands. It operates at 24,000 RPM and air cooling, en suring seamless processing of all material types and thicknesses.

MASSIVE GANTRY CONSTRUCTION

Made of high-strength rectangular steel profiles, structurally improved and reinforced internally for superior precision and durability.

HIGH-PRECISION SERVO MOTORS

Designed for high perfor mance, combined with a high-quality reducer from a leading Japanese brand, ensuring precision without deviations, with speeds up to 30 meters per minute.

The working table is made of special wear-resistant plastic for use with the vacuum pump. Additionally, it features integrated “T” aluminum rails that allow for manual piece fixation using clamps.

Axis movement occurs via linear guides (30mm and 25mm) and a rack-and-pin ion system from the highly reputable HIWIN brand from Taiwan. This is proven to be the best and most efficient movement system in most CNC machines, ensuring smooth operation, low noise levels and significantly reducing additional loads, thereby increasing durability and longevity. X AND Y AXIS MOVEMENT

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

2100x2800x250mm 9kW

24.000rpm Air-cooled

Servo motors

1.5kW

Vacuum table + aluminum rails

7.5kW (x2) 550m³/h Air-cooled x8

Taiwan LNC

0-30m/min

ER32

2-25mm

11800x3000x2400mm

4500kg

A ball screw

ensures exceptional precision, low friction and maximum du rability, reducing wear and heat buildup.

LNC operating system, en suring user-friendly machine control.

Two 7.5kW vacuum pumps with air cooling and 550m³ per hour capacity, enhanced with pneumatic rollers for stronger panel absorption.

VACUUM PUMP

WORKING TABLE

system

AXIS MOVEMENT