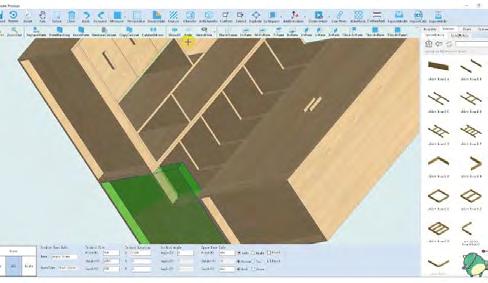

CNC NESTING

Sophisticated software enabling fast and efficient design and pro duction optimization, 3D preview and instant quotation generation with detailed pricing. Compatible with RADEK CNC drilling machines. HAIXUN LICENSED SOFTWARE (OPCIONAL)

UPGRADE CAPABILITY

Automatic panel loading with vacuum foot devices located on the bridge for material pickup from a lifting table. Au tomatic unloading with a device on the bridge for transferring processed pieces to a special conveyor belt.

With the CNC nesting machine, you get the best value for your budget. It is renowned for high precision, speed, productivity and flexibility when cutting, engraving and drilling. It also offers the option to upgrade with an automatic panel loading and unloading system for additional automation.

INDUSTRIAL 9KW MOTOR

The motor’s manufacturing, design and accompanying parts are 100% identical in quality to world-renowned brands. It operates at 24,000 RPM with air cooling, allow ing seamless processing of all types and thicknesses of materials.

MASSIVE GANTRY CONSTRUCTION

Made of rectangular steel profiles, structurally en hanced and additionally reinforced internally. This type of gantry construction ensures a high degree of rigidity, durability and guarantees high precision. The quality is significantly superior to other gantries on the market.

HIGH-PRECISION SERVO MOTORS

Specially designed for high demands and performance in combination with a reduc er from a highly renowned Japanese brand. Guaranteed precise positioning of the bridge and spindle without deviation and error and with a high speed of movement up to 30 meters per minute. Proven quality and stability in operation and in difficult industrial conditions.

The machine is equipped with two 7.5kW vacuum pumps with air cooling. Each pump has a capacity of 550m³ per hour, providing high absorption even for small panels, enhanced with pneumatic rollers pressing the panels.

TABLE

The working table is made of special wear-resistant plastic for use with the vacuum pump. Additionally, it features integrated “T” aluminum rails that allow for manual piece fixation using clamps.

Axis movement occurs via linear guides (30mm and 25mm) and a rack-and-pin ion system from the highly reputable HIWIN brand from Taiwan. This is proven to be the best and most efficient movement system in most CNC machines, ensuring smooth operation, low noise levels, and significantly reducing additional loads, thereby increasing durability and longevity.

Working area

Main motor power

Main motor speed

Main motor cooling type

Movement motor type

Movement motor power

Worktable

Vacuum pump power

Vacuum pump capacity

Vacuum pump cooling type

Number of vacuum zones

Operating system

Processing speed

Main motor collet type

Collet clamp diameter

Machine dimensions

Weight

2100x2800x250mm 9kW

24.000rpm Air-cooled

Servo motors

1.5kW

Vacuum table + aluminum rails

(x2)

Equipped with a ball screw on the Z-axis for exception al precision, low friction, maximum protection from rapid wear, and preventing overheating of elements during operation.

operating

from

Allows easy and orga nized access to all machine functions.

LNC

system

a highly reputable Taiwanese brand.

VACUUM PUMP

WORKING