for research and development

EnhancingPrecision inDefence: Optical Components forTargetingPods

Quantum Computing and Its Impact on Defence and Military Applications

Thermographyforthe Analysisof Combustionand ExplosionProcesses

High-performance cameras for Airborne

It is my pleasure to welcome you to this edition of our magazine, dedicated to the cutting-edge world of high-tech instrumentation for defence and security R&D. In an era where technological superiority is paramount, innovation in this field plays a crucial role in ensuring global stability and national resilience. This publication highlights the latest advancements, collaborative efforts, and visionary research shaping the future of defence capabilities. I extend my thanks to all contributors and partners for their insights and dedication. QDUKI has a long history of working with major defence tech, weapons, aerospace, military and information security companies. Together, we continue to push the boundaries of what’s possible in science, technology, and strategic innovation.

In a world marked by rapid change and growing uncertainty, one thing remains clear: the need for resilience, security, and preparedness has never been greater. Yet within these challenges lies immense opportunity. Across the spheres of military, security, and defence, research and development is lighting the path forward—driving innovation that not only safeguards our present but builds a foundation for a safer, more stable future.

This magazine celebrates the minds and missions behind cutting-edge technologies and strategic advancements that are reshaping how we protect our nations and support global stability. From breakthrough materials and autonomous systems to cyber defence and intelligence capabilities, R&D is not just responding to the world’s evolving threats—it’s proactively shaping a future where peace, safety, and strength can thrive together.

Quantum computing, once a theoretical concept, is rapidly evolving into a transformative technology with the potential to reshape multiple industries none more significantly than defence and military sectors.

Unlike classical computers, which process information in binary (0s and 1s), quantum computers use quantum bits or "qubits" that can exist in multiple states simultaneously. This allows them to solve certain problems exponentially faster, offering profound advantages in areas like cryptography, logistics, intelligence analysis and autonomous systems

One of the most immediate defence implications of quantum computing lies in cryptography

Modern military communications and data security rely heavily on encryption protocols such as RSA, which are extremely difficult to break using classical computers. However, a sufficiently advanced

quantum computer could crack these protocols in minutes using algorithms like Shor’s algorithm. This has led to a global race toward “quantum-safe” encryption methods, prompting defence agencies to invest in postquantum cryptography research and implementation

Beyond encryption, quantum computing holds promise in optimising complex military logistics and battlefield strategy. Quantum algorithms can rapidly evaluate countless scenarios to identify optimal routes, supply chains, or mission plans under dynamic constraints For example, during large-scale military operations involving thousands of assets, quantum optimisation could enable real-time decision-making with unprecedented speed and accuracy.

Quantum sensing is another area of intense interest These sensors, leveraging quantum entanglement and interference, could detect submarines, stealth aircraft, or underground bunkers more effectively than current technologies Such advancements could drastically alter the balance of power, enabling new forms of surveillance and reconnaissance that are harder to evade or jam

Artificial intelligence (AI) and machine learning, already integral to modern defence systems, could also benefit significantly from quantum computing. By accelerating training and pattern recognition, quantumenhanced AI could support faster threat identification, autonomous navigation, and adaptive responses in combat scenarios.

What’s Next?

Despite these potential benefits, significant challenges remain. Quantum hardware is still in its infancy, requiring extreme conditions like near-absolute-zero temperatures to function. Moreover, practical and scalable quantum systems suitable for defence applications could be years away.

The Race is on...

Nevertheless, Governments and militaries worldwide including the U.S. Department of Defense, NATO, and China’s PLA are investing heavily in quantum research. As this technology matures, its integration into defence strategies is expected to redefine global security paradigms, demanding new doctrines, alliances, and safeguards to navigate the emerging quantum battlefield

We don’t make quantum computers; we enable those who do...and will” “

Photonics

Spin/quantum dots

Superconducting circuits

Trapped ions

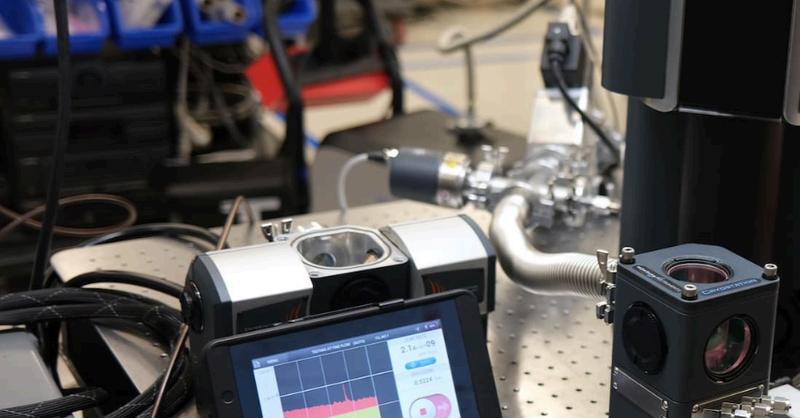

Montana Instruments has overcome the cryogenic barriers to entry for ion trap, photonic, and superconducting circuit research and development. They've done this by helping alleviate the following common experimental challenges:

Disruptions to the local sample environment such as mechanical vibrations can impart energy to the qubit states and destroy the quantum environment

Trapped ion experiments require high vacuum conditions to reduce the number of molecular collisions with trapped ions

Cryogenic conditions are required because thermal energy can excite vibrational motion that disrupts the quantum computing operations

Montana Instruments has developed a line of cryogenic products to meet the needs of the quantum computing industry for research and development, production testing, and critical quantum computer infrastructure There are multiple active architectures under consideration fortherealisationofascalablequantumcomputer. The most promising candidates are those utilising photonics, spin/quantum dots, superconducting circuits,andtrappedions.

Thermal radiation can drive undesirable internal RF transitions in trapped ions or can raise a superconducting circuit above its critical temperature

Power fluctuations in laser sources as well as RF power source instabilities perturb the QC system

Fluctuating external magnetic fields can alter atomic transitions (Zeeman effect)

A high vacuum, low vibration, and stable cryogenic environment are required to prevent any unwanted excitation of the qubit state. Superior optical access (low working distance and high numerical aperture) for spatially resolved laser excitation and high collection efficiency fluorescent readout is also necessary for trapped ions and some spin/quantum dots

Low vibration

Low vibrations are key to preventing energy transfer to qubits and distortion of the quantum state

Stable, low temperature (<4K)

Cryogenic environments minimise thermal excitation of qubits. <10mK temperature stability is important to minimise thermal excitation.

A low working distance objective with a high numerical aperture (09 NA, for example) provides a narrow excitation spot for individual trapped ions and provides high collection efficiency Our objective is temperature controlled to virtually eliminate drift This eliminates the need for frequent realignment and maximises data collection time.

Additional window ports may be used to laser ablate (generate the ions) or laser cool (prepare the quantum states) Our cryogenic systems can be configured with multiple side windows and a top window. In addition, the availability of larger sample spaces make it easy to address the sample from multiple incident angles

Many electrical feedthroughs may be required to either generate the RF trapping potential or operate the superconducting circuit. Our base panels can be used to add low frequency/DC wires in addition to coaxial wires for low loss and higher frequency signal (up to approximately 20GHz) The sample space is kept uncluttered through the use of specially designed low thermal heat load cryogenic ribbon cables

Molecular and atomic collisions can excite qubits out of their quantum state or completely knock an ion out of the trap, destroying the quantum crystal. Our integrated charcoal cryo-pumps enable high vacuum operation for months at a time.

Discover cryogenics for quantum.

Optical communications — the transmission of data using light are becoming increasingly critical to modern defence and military systems.

By using lasers or fibre-optic technologies, optical communication systems offer highbandwidth, secure, and lowlatency data transfer, making them ideal for the demands of modern warfare and defence infrastructure.

One of the key advantages of optical communication is its resistance to electromagnetic interference (EMI) In the battlefield, where electronic warfare and signal jamming are common, traditional radio frequency (RF) communications can be disrupted Optical systems, particularly those using fibre-optic cables or free-space lasers, are immune to most types of EMI, providing a more reliable communication channel in contested environments.

Fibre-optic communication has long been used in secure military networks due to its high bandwidth and difficulty to tap without detection Military bases, command centres, and naval vessels rely on these cables for internal communications and for linking different parts of a defence network.

Unlike copper wiring, fibre-optic cables can transmit large volumes of data over long distances with minimal loss, which is essential for supporting modern, data-intensive operations including real-time video feeds, intelligence sharing, and satellite communications.

Free-space optical (FSO) communications using light to transmit data through air or space are an emerging frontier in defence. FSO systems can enable point-to-point communication between aircraft, drones, satellites, and ground stations without relying on traditional RF spectrum, which is often congested or vulnerable to interception Laser communication terminals in satellites and UAVs are being developed to provide ultra-fast, secure data links that are difficult to detect or jam, enhancing the resilience and stealth of military communications.

Optical communications also play a critical role in advanced sensor networks and targeting systems Highspeed data transmission is crucial for integrating information from radar, lidar, and imaging systems into a cohesive battlefield picture. This allows for faster decision-making, precision targeting, and coordinated action across multiple domains — air, land, sea, and cyber.

Moreover, the future battlefield will depend heavily on autonomous systems and artificial intelligence, both of which require rapid and reliable data sharing. Optical communication networks offer the capacity needed to support the growing number of connected sensors, platforms, and decisionmaking nodes in a military Internet of Things (IoT)

Despite the benefits, challenges such as line-of-sight requirements for FSO, weather interference, and deployment logistics in combat zones remain However, ongoing research aims to overcome these limitations through adaptive optics, hybrid communication systems, and ruggedised optical hardware

As military operations become more information-driven and dependent on speed and security, optical communications will be a foundational technology, enhancing the agility, survivability, and effectiveness of modern defence forces.

The optical components and systems involved in transmitting, relaying, and receiving these signals must be held to rigorous controls at every functional wavelength.

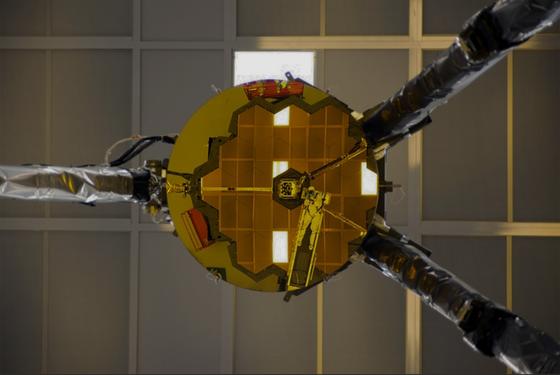

4D Technology has been leading the development of metrology for spacebased optics since its inception over 20 years ago. 4D offers multiple solutions to measure surface quality, transmitted wavefront quality, and surface roughness of these critical optics and systems.

The AccuFiz SWIR Fizeau Interferometer and PhaseCam Twyman-Green SWIR Interferometer both operate around the 1550 nm wavelength Their advantages for optical measurements include:

unique capability to accept external sources at

compact, lightweight design that simplifies test setups highly accurate measurement of focal and afocal optics, aspheres, optical systems and telescopes, prisms, corner cubes, etc

4D PHASECAM PHASECAM TWYMAN-GREEN INTERFEROMETERS

Excel at measuring large, concave optics and optical systems at 1550 nm. The unique, external port enables external laser sources to be used at wavelengths throughout the C-Band.

Measures flat, concave, and convex spherical optics at functional wavelengths in the CBand (1535-1565nm wavelength band).

Excessive surface roughness can scatter the beam, leading to signal loss, reduced data transfer rates, and crosstalk.

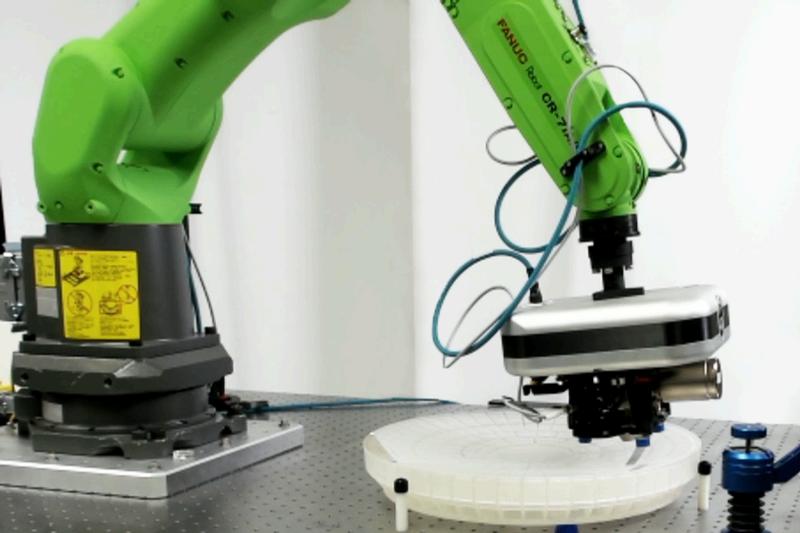

The NanoCam HD optical profiler measures roughness on optical grade surfaces Robotmounted or handheld, the NanoCam measures rapidly at multiple locations around an optic to ensure that roughness falls within specifications

4D TECHNOLOGY NANOCAM HD OPTICAL PROFILER

Robot-mounted or handheld, the NanoCam HD optical profiler measures surface roughness on smooth and supersmooth optics.

ADVANTAGES OF FSO FOR MILITARY APPLICATIONS: Resilience to Jamming

Cost-Effectiveness

High Bandwidth and Speed

Scalability

In aerospace and defence industry optical systems, being able to take measurements in the presence of vibration and turbulence is often vital.

Consequently, imaging technologists in the defence industry as well as researchers in planetary sciences depend on 4D’s interferometers to measure and align their optics

INFRA-RED TO ULTRA-VIOLET WAVELENGTHS

The use of longer and shorter than visible wavelength sensors for imaging is commonplace in space and defence systems. In imaging systems used to look through Earth’s atmosphere, there are infra-red wavelengths that are preferred because of their lack of absorption by water and atmospheric gases

Having to depend on your aircraft’s full performance makes defect inspection during maintenance a mission-critical process. Military engine components and rivets get inspected by 4D InSpec, for fast, repeatable, handheld parts qualification.

4D Technology has built numerous systems in IR operating wavelengths, and we understand well the issues caused by using a sensor that sees all hot bodies including the radiating and reflecting walls of an interferometer enclosure as a light source. 4D Technology has solved those problems more than once

UV sensing is less common in defence applications, but has good potential in astronomical imaging. It’s important to measure and align optics in their use-case wavelength to obtain reliable results. Being able to handle the peculiarities of a diffractive and scattering wavelength is rolled into the challenges we have handled well

Cutting edge aerospace and defence optics are being lab-tested under field conditions Field conditions may include cryogenic freezing, turbulence, vibration, vacuum conditions and more. Because 4D’s dynamic technology is the best way to obtain good measurements in extreme environments, we offer the best choices and the greatest experience in measuring in these circumstances.

To learn more and discuss your application, contact our Technical Sales Manager, Dr Luke Nicholls by email or call (01372) 378822.

The defence industry demands unprecedented optical performance:

Superior durability in extreme military environments

Ultra-precise wavelength control for targeting systems

Advanced coatings for multi-spectral imaging

High damage threshold optics for laser applications

Specialised IR filters for thermal detection

Space-qualified components for satellite systems

Reliable performance in battlefield conditions

As defence technologies advance toward more sophisticated surveillance, targeting, and communications systems, Andover Corporation delivers mission-critical optical solutions that enhance everything from thermal imaging to laser-guided systems.

Andover Corporation’s specialised optical technologies and custom solutions enable critical defence capabilities across:

Thermal imaging and night vision

Target acquisition systems

Missile guidance

Reconnaissance platforms

Secure optical communications

Hyperspectral imaging

Laser rangefinding

Space-based surveillance

From tactical field systems to advanced aerospace platforms, Andover Corporation’s reputation is built on advancing national security through precision optics Andover Corporation delivers mission-critical componentsfrom ultra-durable IR filters and high-transmission coatings to custom dichroic beamsplitters and radiation-hardened optics. Their military-grade components ensure superior performance and reliability when failure is not an option

In the rapidly evolving world of defence technology, targeting pods play a pivotal role in modern military operations. These advanced systems provide critical capabilities for target acquisition, surveillance, and reconnaissance, enabling precision strikes and enhancing situational awareness. At the heart of these pods are sophisticated optical components, and Andover Corporation is proud to celebrate a long history as a top-rated supplier for the manufacture of targeting pods in the defence industry.

Optical interference coatings, such as bandpass filters, are critical components in targeting pods, selectively allowing specific wavelengths of light to pass through while blocking others. This capability is crucial for improving target detection and tracking, particularly in challenging conditions like low visibility or nighttime operations.

At Andover Corporation, our optics are engineered for high performance and reliability With our industry-leading customer satisfaction and exceptional coating expertise, we ensure that each filter provides the precise wavelength isolation required for optimal performance. Our filters are used extensively in defence applications to isolate infrared wavelengths, enhancing the thermal imaging capabilities of Forward-Looking Infrared (FLIR) sensors, and allowing for accurate detection of heat signatures from vehicles or personnel, even in complete darkness or adverse weather conditions.

Targeting pods rely on a combination of advanced optics elements to provide precise real-time data, enhancing the ability to acquire, track, and engage targets effectively

Lenses:

Objective Lenses: These lenses focus incoming light onto sensors, ensuring clarity and accuracy over long distances and through various environmental conditions from bright daylight to atmospheric interference.

Zoom Lenses:

These allow for dynamic changes in magnification, offering flexibility for wide-area searches and close-up target tracking. This adaptability is essential for operators to meet different mission requirements effectively.

Mirrors and Prisms:

Optical Mirrors and Beam Splitters: These components are designed to handle multiple sensor inputs simultaneously, enhancing efficiency and accuracy in targeting Andover Corporation produces high quality

mirrors and beam splitters with antireflective optical coatings that optimise light paths within the pod’s optical system.

Modern targeting pods incorporate several advanced optical technologies, and Andover Corporation excels in crafting these vital components to ensure superior operational performance.

Infrared (IR) Filters and Sensors:

FLIR Sensors: High-performance Forward-Looking Infrared (FLIR) sensors can provide thermal images even under low-visibility conditions.

IR Filters: Complementing FLIR sensors, these filters must ensure maximum transmission and durability in even the most demanding operational environments. Our IR filters are meticulously engineered to allow only specific infrared wavelengths to pass through, enhancing thermal signature detection for night vision and thermal imaging applications.

Modern targeting pods incorporate several advanced optical technologies using cutting-edge lasers, light sensors, and stabilisers.

Laser Designator and Rangefinder:

Laser Designator: These components use highly-specialised bandpass filters for YAG lasers to guide munitions precisely to their targets, ensuring high accuracy and effectiveness in missions.

Laser Rangefinder: We provide components optimised for laser rangefinders, crucial for determining the exact distance to a target and enhancing precision-guided strike capabilities.

CCD and CMOS Sensors: Both CCD (charge-coupled device) and CMOS (complementary metal oxide semiconductor) imaging sensors are used in conjunctions with optical filter coatings that maximise image clarity and sensitivity in all lighting conditions. Our filters and coatings are tailored to enhance daylight operations while ensuring power efficiency and durability in challenging environments.

Gyroscopes and Stabilised Platforms: Stabilisation systems help to maintain steady and clear images, even during high-speed manoeuvres. Our hybrid solutions are designed to perform under dynamic conditions, ensuring reliable data capture in critical moments.

The effectiveness of targeting pods pods hinges on the quality and performance of their optical components Our commitment to precision and service drives us to produce optical elements that provide superior clarity, faster data processing, and precise target identification, all of which are vital for mission success

As the defence industry continues to demand higher precision and versatility, the need for top-quality optical components grows.

At Andover Corporation, we are

dedicated to meeting these evolving requirements, building on our extensive experience in defence applications, such as our involvement in Lockheed’s Sniper ATP system, and Wescam’s MX-Series Airborne Surveillance and Reconnaissance Pods.

Thin-film coatings on advanced IR substrates such as chalcogenides, as well as our superior binding techniques for optimal adhesion, are just a few examples of our long history as a preferred optics partner to the defence industry

Rick Shagoury, Marketing Manager, Andover Corporation

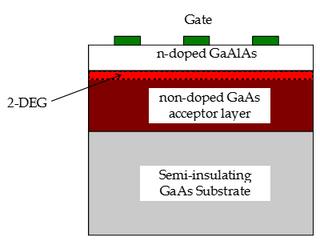

HEMTs (High Electron Mobility Transistors) are crucial for microwave and millimeterwave analogue amplifiers in defence and military applications due to their highfrequency performance, low noise, and high linearity. HEMTs, especially those made with gallium nitride (GaN) or indium phosphide (InP), are preferred for demanding environments where high power and highfrequency operation are essential.

InP-based HEMTs produce lower noise figures and higher gain at higher frequencies than GaAs-based HEMTs – exceeding 100GHz2

This has been of particular importance in military and commercial communications applications - these transistors are used in various systems like radar, electronic warfare, and communications.

HEMTs are used in radar systems for signal amplification and processing, enabling the detection and tracking of targets.

They play a role in electronic warfare systems, such as jammers and communication interceptors

HEMTs are used in communication systems to amplify and transmit signals at high frequencies

HEMTs are used as power amplifiers in various defence and military systems, including radar, EW, and communications.

This approach enables the extraction of individual carrier mobilities and concentrations, offering a more comprehensive understanding of both majority and minority carriers within the device

This white paper delves into advanced techniques for analysing High Electron Mobility Transistors (HEMTs), which are pivotal in high-frequency and low-noise applications The paper discusses the limitations of traditional single-field Hall measurements, which provide only bulk mobility and carrier concentration. To overcome these limitations, the authors advocate for variable magnetic field and temperature Hall measurements combined with Quantitative Mobility Spectrum Analysis (QMSA)

The paper presents temperaturedependent data for GaAs-based HEMTs, highlighting the nuanced behaviours of carriers under varying conditions Additionally, it underscores the importance of precise epitaxial growth techniques, such as Molecular Beam Epitaxy (MBE), to achieve the atomically smooth heterojunctions essential for optimal HEMT performance The white paper provides valuable insights into the methodologies for detailed electronic transport characterisation, crucial for the development and optimisation of HEMT devices

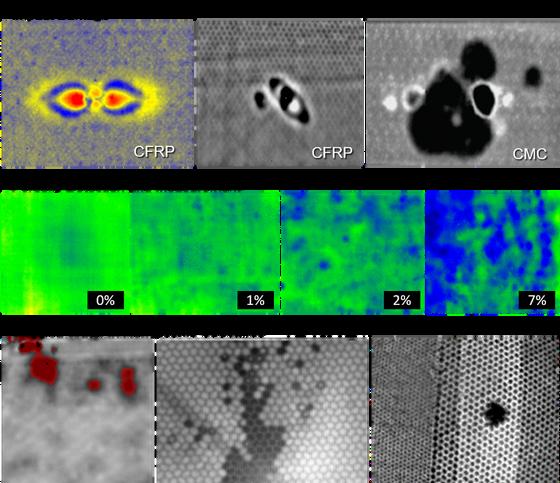

In the last 25 years, use of pulsed thermography as a viable NDT modality has evolved from a curiosity to a “go to” technology for many applications previously addressed by other standard NDI techniques like UT, X-Ray, eddy current, etc Today, pulsed thermography is widely used in the aerospace, power generation and automotive industry sectors all over the world Much of this success is attributed to TWI’s vision and passion to advance, develop and introduce to market stateof-the-art solutions to meet a broad range of application requirements

Thermographic Non-Destructive Testing (Thermographic NDT)

What it is: Uses infrared imaging to evaluate the integrity of materials or structures by detecting heat variations.

Defence/Security Applications:

Aircraft and vehicle maintenance – detecting hidden defects in composite materials or fatigue cracks in metal.

Structural health monitoring – e.g., in submarines, missiles, or armored vehicles. Inspection of munitions or ordinance – finding degradation or defects in storage.

Can be used in perimeter intrusion detection when integrated into surveillance systems.

TWI systems are a proven solution in the aerospace industry for both manufacturing and maintenance NDT Whether it’s fast handheld inspection in the field or manufacturing quality control, our systems provide a degree of reliability and sensitivity that is unrivaled

Common Applications:

Impact Damage

Delaminations

Water Ingress

FOD Detection

Thickness Measurement

Porosity

Disbonds

Leading OEMs rely on TWI systems for NDT in manufacturing, rework and maintenance.

Common Power Generation

Applications

Wall and Coating

Thickness

Structural Integrity

Hole Blockage

Disbonds

Adhesion

Cracks

Corrosion

Ellipsometry is a technique that measures the change in polarisation of light reflected off a surface—mainly used to determine film thickness, optical properties, and surface roughness.

Coating inspection on stealth or aerospace materials (e g , radar-absorbing coatings on stealth aircraft).

Quality control in semiconductor manufacturing for defence-grade electronics

Detection of tampering or degradation in protective coatings, like on missile guidance optics or sensors

Can also be used in thin film analysis for MEMS/NEMS in military tech.

There is continued customer demand for integrated devices that provide increased situational awareness within the natural environment and that enable immersive experience for both technical and recreational purposes. Tech innovators are rapidly developing hardware that meet these demands ranging from headsets to integrated, wearable sensors Ellipsometry is used in the development and production of many of these devices from detecting polarising effects such as birefringence and dichroism to characterisation of anti-reflection coatings, touchscreens, and flexible displays We are excited to contribute to the development and production of such an exciting and rapidly growing field.

PURE ELECTRICAL INSULATORS ARE HIGHLY TRANSPARENT, BUT HIGHLY CONDUCTIVE METALS ARE OPAQUE. SO WHAT MATERIAL CAN BE USED THAT IS BOTH TRANSPARENT AND CONDUCTIVE? WE MUST FIND SUCH A MATERIAL TO MAKE OUR DISPLAYS AND TOUCHSCREENS WORK.

Indium tin oxide (ITO) is both transparent and conductive. ITO optical properties vary a lot with deposition conditions and annealing, so monitoring the quality of the ITO and its thickness is important. Ellipsometry is used for monitoring ITO film thickness and transparency at visible wavelengths while also being sensitive to absorptions in the ultraviolet, but it is very important for monitoring absorption in the infrared, which corresponds to the film’s electrical conductivity

Improvements in display speed are critical for fast action in movies and sports Imagine a baseball, golf ball, or hockey puck leaving a comet tail behind on the screen because the display cannot refresh fast enough.

Display pixel speed has been significantly enhanced using crystallised silicon films on the rear panel of the display Ellipsometry is used to monitor the thickness and crystallinity of these deposited polysilicon films.

LCD displays used to be small, monochrome in colour, and used in calculators, digital watches, etc Modern displays are full colour, extremely fast, and very large. The coated films must be uniform over the entire panel size, and film uniformity has been a limiting factor in the size of displays for decades With each new generation of larger displays, the film uniformity must be maintained. An ellipsometer can fly over the large panels as they move on a production line to monitor film quality.

Forgery and tampering continue to provide unnecessary economic burdens Although new anti-forgery and counterfeiting technologies arise, they inadvertently lead to the sophistication of forgery techniques over time, to a point where detection is no longer viable without technological aid. Among the various optical techniques, one of the recently used techniques to detect counterfeit products is HSI, which captures a range of electromagnetic data. To aid in the further exploration and eventual application of the technique, this study categorizes and summarizes existing related studies on hyperspectral imaging and creates a mini meta-analysis of this stream of literature The literature review has been classified based on the product HSI has used in counterfeit documents, photos, holograms, artwork, and currency detection.

ForgeryDetection

DocumentAuthentication

HologramAuthentication

CounterfietCurrencyDetection

PhotoAuthentication

have different spectral signatures.

Surveillance and reconnaissance –identifying objects, people, or materials (e.g., weapons, explosives, vehicles) Environmental monitoring –detecting chemical or biological agents from a distance

Border security and counter-narcotics –spotting drug crops, tunnel entrances, or illegal movements.

Hyperspectral imaging is an entirely nondestructive, highly accurate, and fast way to identify different materials or define their properties.

Since every material and compound reacts with light differently, the reflectance measurements result in unique spectral signatures that identify different materials, similar to fingerprints.

A uniform carbon film coating on metallic bipolar plates enhances fuel cell efficiency Hyperspectral imaging enables precise layer thickness measurement and real-time quality control, helping manufacturers ensure uniform coating, reduce variability, and optimise fuel cell performance

Carbon Film Inspection on Metallic Bipolar Plates:

Layer thickness measurement (nm)

Homogeneity of coatings

Coatings are essential for product quality, functionality, and durability across industries. The surface of a product can reveal important details about its structural integrity, performance, and appearance. Defects, impurities, or inconsistencies in coatings and surface layers can reduce product reliability and performance or cause safety hazards.

Evaluating the thickness and uniformity of protective coatings on sensitive electronic components is essential for ensuring performance, durability, and aesthetics. Hyperspectral imaging enables precise inspection, detecting variations that could impact reliability or functionality, ensuring consistent quality, and enhancing product performance.

Hyperspectral imaging can detect different types of coatings, identify inconsistencies, measure layer thickness, and ensure uniform application across surfaces:

Functional coatings

Protective coatings

Barrier layers

Anti-fingerprint coatings

Vapour deposition coatings

Permanent surveillance and process control of sites, plants and storage facilities

Savings in maintenance thanks to lowmaintenance operation of infrared measurement and monitoring systems

Reduction of surveillance staff and manual controls

Continuous operation due to special industrially-suited instrumentation

Use even in adverse industrial environments

Provision of alarm and process data to higher-level control systems

Increase in production and plant safety

Prevention of fires, disruptions and stoppages

Reliable systems for automatic site surveillance enable early detection of critical temperatures in bunkers, warehouses, buildings as well as on open spaces. Protect your investments efficiently with infrared monitoringsystemsfromInfraTec.

Even in complete darkness, smoke or fog, our thermographic monitoring systems provide you with reliable data Under such harsh conditions you benefit from the enormous thermal and geometrical sensitivity of the thermal imaging cameras Special algorithms support you during the subsequent evaluation of your specific measuring task. In the event of particularly demanding systems, infrared cameras in conjunction with pan-tilt heads and visualcamerasarepossible.

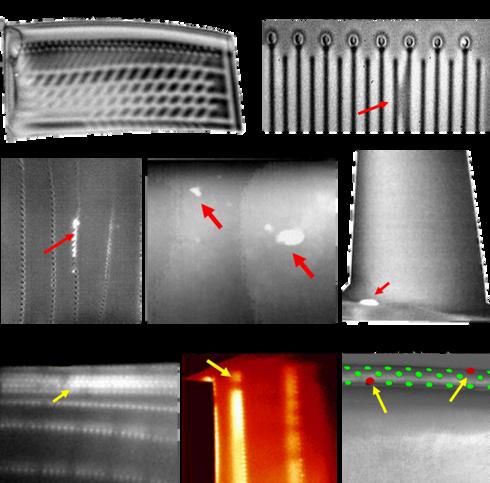

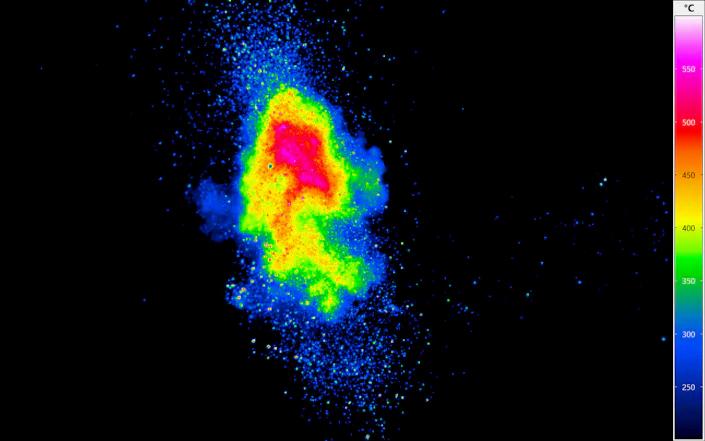

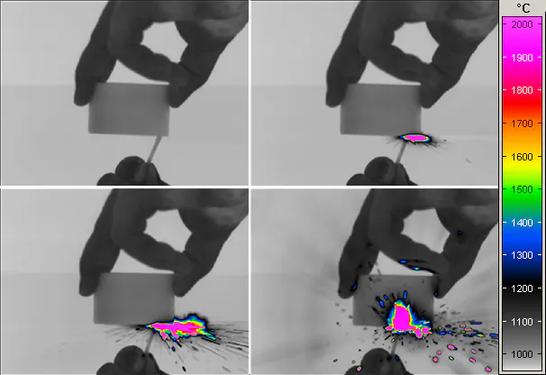

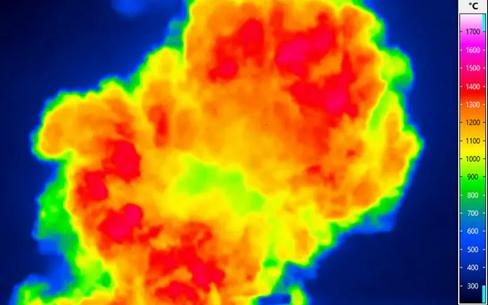

Explosion and combustion processes are highly dynamic processes with big temperature changes. In order to be able to comprehensively analyse and optimise these processes high-performance thermography systems have to be used.

In combustion analysis highly dynamic sequences of combustion processes are visualised and analysed by recording temperature distributions and their temporal change with a thermal camera contact free and without feedback effects. As a result, hotspots and anomalies, among other things, can be identified, which enable conclusions concerning inefficiencies or the detection of safety issues

By using thermography, not only process optimisations are made possible, but safety risks for people and the environment are reduced as well.

The applications for thermography cameras in the field of combustion analysis are many and varied as a result:

Analysis of the temperatures and their distribution in combustion furnaces

Optimisation of internalcombustion engines and their components

Monitoring of temperatures on moving parts of turbines and compressors

Analysis of heat transfers in exhaust systems

Analysis of burner components for cracks or corrosion

Characterisation of fuels (e.g. in respect of their ignition properties)

Conclusions for energy saving potentials

In order to be able to record dynamic temperature changes precisely the thermography camera used has to have very short integration times and a wide temperature measuring range These requirements are met by the infrared cameras of the ImageIR® camera series by InfraTec. Moreover, these cameras come with a Multi Integration Time Mode and the High Dynamic Range function for achieving exceptionally wide temperature measuring ranges. This allows a interrupt-free and consistent thermographic analysis of objects which can have a very large temperature gradient of up to several 100 K By up to two integrated, motor controllable filter wheels these cameras are perfectly applicable in spectral thermography as well.

As a result, up to 35 different filter combinations are available and directly accessible by the remote control of the camera. Time-consuming filter changes are a thing of the past now The performance of the cameras is further expanded by assorted precision telephoto lenses for high-grade measurements at large measurement distances, but also by the option of combining them with close-up lenses to analyse combustion processes inside measuring chambers at highresolution. Temperature stabilised protective housings and the possibility of integrating the fully automated operation in an existing software environment complete the spectrum of beneficial features for the combustion analysis.

Thermography is a contact free and very efficient measurement method without feedback effects, which is commonly used to observe and analyse thermodynamic processes running in explosions. Thanks to the image presentation of the radiation emitted during the explosions by suitable thermography systems radiation distributions and their changes can be visualised, measured, recorded and comprehensively analysed and documented with the corresponding software

Just as in the case of combustion analysis, very brief integration times are required in the analysis of explosions to be able to record the intensely dynamic temperature changes without smearing effects. The thermography systems from InfraTec can also be equipped with application-specific spectral filters. Motor driven filter wheels make it possible to choose out of up to 35 filter combinations with a mouse click in the software and to adjust the camera quickly to changed measurement conditions

Using high-end thermographic solutions the heat distribution throughout and after the detonation of explosives can be visualised and recorded and thereby the energy released can be analysed Moreover, thermography makes it possible where required to measure the flame propagation speed and the combustion efficiency

For images of explosions with large-scale expansions which are rich in detail thermography systems are available with a geometric resolution up to (2 560 x 2 048) IR pixels InfraTec provides a wide selection of interchangeable lenses of different focal lengths up to 200 mm and options for motordriven focussing including various autofocus modes With the High Dynamic Range (HDR) function a temperature measuring range of -20°C to 3,000°C can be achieved The insights derived from the measurement data help, among other things, in the preparation and review of safety protocols for explosive materials or in the calculation of the amount of explosive required.

At Quantum Design UK and Ireland, we’re passionate about providing high-tech scientific instrumentation to researchers, universities, and industries across the UK and Ireland.

Based in Leatherhead, Surrey, we’re a small but dedicated team, bringing deep expertise and a personal touch to everything we do.

We specialise in materials characterisation, cryogenics, non-destructive testing, imaging cameras, microscopy, and spectroscopy. But more than just supplying instruments, we work closely with our customers to understand their unique research challenges and help them find the best solutions.

What sets us apart? We’re knowledgeable, approachable, and always happy to help. Our Sales and Service departments are second-tonone, offering expert support, training, and advice to make sure our customers get the most out of their equipment.

At Quantum Design UK and Ireland, we take pride in being more than just a supplier we’re a trusted partner in scientific discovery.”

For more than 40 years Quantum Design (QD) has been providing technology solutions to researchers in the fields of physics, chemistry, biotechnology, materials science, and nanotechnology

Established in 1982 in San Diego, California, Quantum Design is the leading commercial source for automated materials characterisation systems offering a variety of measurement capabilities

QD instruments are found in the world’s leading research institutions and have become the reference standard for a variety of magnetic and physical property measurements.

Dr. Luke Nicholls Acting Managing Director Quantum Design UK and Ireland

Quantum Design instruments are cited in, and provide the data for, more scientific publications than any other instrument in the fields of magnetics and materials characterisation

An essential part of providing scientific solutions to researchers around the globe is to also offer state-of-the-art instruments from other leading manufacturers

These manufacturers are chosen by QD not only for their innovative products, but also because they believe in the same level of customer satisfaction and support that scientists have come to expect from QD products worldwide.