In the ever-evolving landscape of aerospace research, development, and maintenance, precision and reliability are non-negotiable. This edition of our magazine spotlights the high-tech instrumentation that empowers engineers, scientists, and defence specialists to meet the extreme demands of space and airborne environments.

From sub-PPM contaminant detection in quartz windows used in spacecraft, to advanced non-destructive testing (NDT) that identifies cracks and voids in solder joints, our technologies are engineered for mission-critical performance. We explore innovations in optical metrology, ellipsometry for stealth coatings, and high-performance imaging systems tailored for airborne platforms — all designed to enhance accuracy, durability, and operational readiness.

This issue also dives into the role of optical components in defence targeting systems, and the critical importance of composite material inspection through advanced NDT methods. Each feature underscores how our solutions contribute to the safety, efficiency, and advancement of aerospace technologies.

Whether supporting space research or securing the next generation of defence systems, we remain committed to delivering instruments that perform when it matters most.

Welcome to this aerospace magazine from Quantum Design UK and Ireland (QDUKI), dedicated to the latest advancements in aerospace research and development. This issue highlights not only the highperformance instrumentation we provide, but also the invaluable contributions of our trusted partners. Their innovations play a key role in pushing the boundaries of aerospace technology. Our dedicated sales team works closely with customers to understand their unique challenges, delivering tailored solutions that match applications with precision and care. From research labs to defence operations, QDUKI is proud to support those shaping the future of aerospace with exceptional technology and outstanding service

David Want MANAGING DIRECTOR

D e s i g n e d f o r y o u r m i s s i o n -

c r i t i c a l s p a c e r e s e a r c h

Space is undoubtedly a challenging environment for any electronic component. The success of any mission depends upon the reliability of the discrete components that must be able to operate in extreme cold, in vacuum, and under intense radiation not to mention the ability to survive the shock, vibration, and acceleration of launch. Failure of a single component can result in the failure of an entire mission.

Lake Shore offers a rich history of working with scientists and engineers at a number of aerospace institutions and agencies, including NASA, supplying thermometry and other technology that offer long-term stability and performance over the duration of a mission These include hundreds of flightqualified sensors for the NASA James Webb Space Telescope and sensors for the Mars Curiosity rover.

In situations where cryogenic temperature control or monitoring forms a critical component of a system and the cost of sensor failure far exceeds the cost of the sensor, subjecting sensors to a higher level of scrutiny becomes vital. Projects where outcomes are worth far more than the sum of their parts are prime examples of this and include: space telescopes, supercolliders, fusion reactors, research satellites, and maglev locomotives

The HR Series is a new line of high reliability cryogenic temperature sensors for mission critical applications. These off-the-shelf sensors that have already undergone extreme testing steps to assure you of extra reliability

Full material traceability for 15 years

Resistance and sensitivity data available for all sensors

Reduces lead time

Gain confidence from our test protocol

No hidden costs pay only for the sensors you buy

For when the best needs to be better

In situations where cryogenic temperature control or monitoring forms a critical component of a system and the cost of sensor failure far exceeds the cost of the sensor, subjecting sensors to a higher level of scrutiny becomes vital Projects where outcomes are worth far more than the sum of their parts are prime examples of this and include:

Space telescopes

Supercolliders

Fusion reactors Research satellites

Maglev locomotives

HR Series sensor features

Full material traceability for 15 years

Resistance and sensitivity data available for all sensors

Reduce lead time

Gain confidence from our test protocol

No hidden costs pay only for the sensors you buy

Discuss Lake Shore Solutions and YOUR Application

QUARTZ WINDOWS USED IN

through Sigray's Attomap-310 Synchrotron Grade MicroXRF

Want to learn more about Sigray?

The properties of glass used in space-based applications is very important as high heat resistance and thermal expansion are required for many applications, so understanding the composition of the glass can be vital to ensuring high performance for spacecrafts, satellites and other space vehicles.

Quartz is widely used by many space agencies and, with Sigray’s high vacuum Attomap 310 MicroXRF and patented SiC X-ray tube, the composition of and contaminants in the quartz was detectable on the order of sub-ppm sensitivity A wide range of the trace contaminants were easily detected in a small field-of-view. With the combination of high-spatial resolution and sensitivity, the Attomap-310 achieves data on par with synchrotron technology

Highest Resolution XRF Microscope on the Market.

Large Stage Travel and Enclosure

The powerful sensitivity and high resolution of the AttoMap produces synchrotron-quality elemental distribution mapping of trace elements for a wide range of research applications, spanning from the life and materials sciences to industrial use for pharmaceuticals, natural resources (oil and gas, mining) and semiconductor failure analysis

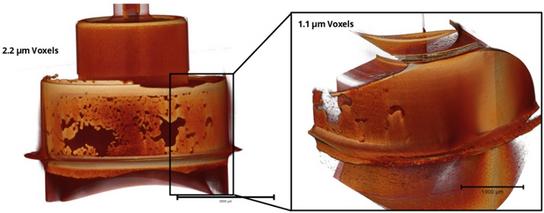

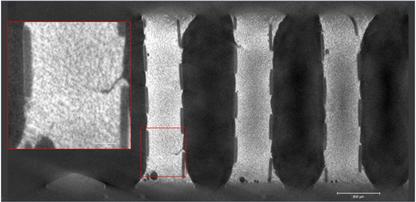

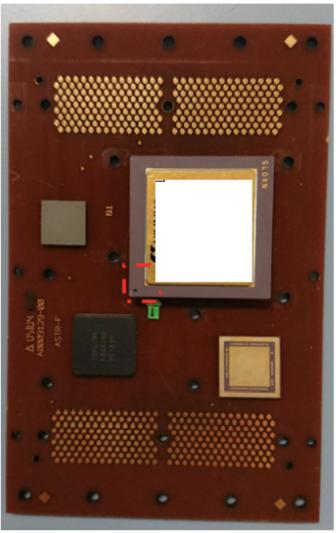

Using the Sigray Apex 3D X-ray Microscope

Cross-Section, sagittal view of PCB solder connections

1um Virtual Slice Analysis – visualising microstructure of joints, locating voids and defects

Rethink Impossible

Sub-Micron 3D X-ray In Minutes

Advanced semiconductor packaging & FA

Infrared optics play a pivotal role in the space industry due to their unique capabilities in detecting and analysing thermal radiation. In space exploration, infrared optics facilitate the observation of celestial objects obscured by cosmic dust or faint in visible light.

In earth observation satellites, they are used to monitor climate change, natural disasters, and environmental conditions by capturing thermal signatures and variations.

They are also crucial in free space laser communications, helping to provide secure, reliable and fast transmission over long distances. In all these applications, it is essential to test the optical components and systems at the infrared operating wavelength to understand the final optical performance, whether it be fiber coupling efficiency, system level wavefront error, or other performance metrics. Additionally, individual component metrology can provide quick feedback to correct the as-built optical design for optimum system level performance.

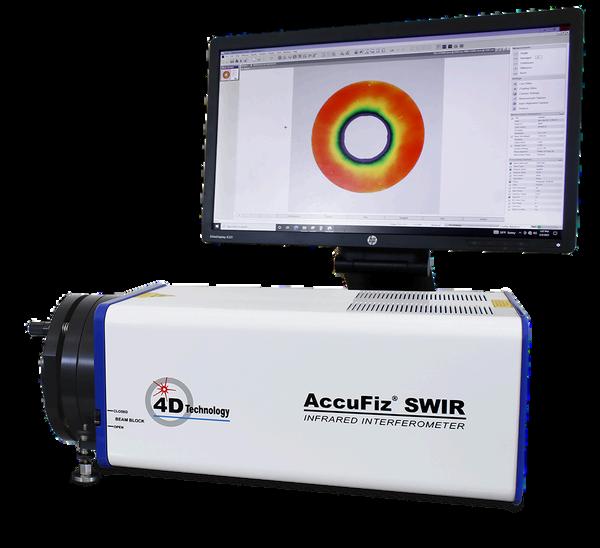

Space-based SWIR applications require optical systems that push the capabilities of today’s manufacturing and measurement techniques,”

Erik Novak, General Manager and Vice President of 4D Technology

“In response to this, we have strengthened our commitment to these application segments by providing a higher-resolution SWIR metrology system to provide precise measurements of wavefront error and surface figure at the critical SWIR wavelengths. Recent orders from industry leaders underscore the importance of investing in the development of our systems to meet the changing demands of our customers.” “

4D Technology has been leading the development of metrology for space-based optics since its inception over 20 years ago The company is uniquely positioned to support the development of U S defense and space-based IR applications, with capable metrology systems not only operating at SWIR wavelengths, but also from the NIR wavelength bands all the way to the LWIR wavelengths around 10 6µm

The new 1 MP AccuFiz SWIR laser interferometer continues 4D Technology’s tradition of offering some of the world’s highest-performing interferometers, backed by industry-leading service and applications support

The AccuFiz SWIR Fizeau Interferometer and PhaseCam Twyman-Green SWIR Interferometer both operate around the 1550 nm wavelength. Their advantages for opticalmeasurementsinclude:

unique capability to accept external sources at wavelengths throughout the C-Band,enablingmanufacturerstotest optical components and systems at everyoperationalwavelength

highly accurate measurement of focal and afocal optics, aspheres, optical systems and telescopes, prisms, corner cubes,etc.

Real-time optical system alignment and collimation.

4

AccuFiz Fizeau and PhaseCam Twyman-Green interferometers for vibration-insensitive testing throughout the C-Band

4D is proud to be one of the primary metrology partners in the development of the James Webb Space Telescope, and on dozens of other projects to explore space and understand our planet.

environments

Cutting edge aerospace and defence optics are being lab-tested under field conditions Field conditions may include cryogenic freezing, turbulence, vibration, vacuum conditions and more.

"Because 4D’s dynamic technology is the best way to obtain good measurements in extreme environments, we offer the best choices and the greatest experience in measuring in these circumstances."

Excessive surface roughness can scatter the beam, leading to signal loss, reduced data transfer rates, and crosstalk

The NanoCam HD optical profiler measures roughness on optical grade surfaces Robotmounted or handheld, the NanoCam measures rapidly at multiple locations around an optic to ensure that roughness falls within specifications.

NANOCAM HD

Robot-mounted or handheld, the NanoCam HD optical profiler measures surface roughness on smooth and supersmooth optics

High Bandwidth & Data Rates

Low Latency Communication

Immunity to Electromagnetic Interference

High Security

Lightweight and Compact

Scalable and Flexible

Weather Resilience (with Adaptive Techniques)

Applications: Surface metrology of mirrors and optics, flatness testing, transmitted wavefront error (TWE), optical quality control.

High-Precision Surface Measurement

Measures surface flatness and figure error down to sub-nanometer levels essential for highperformance satellite optics.

Non-Contact and Non-Destructive

Ideal for delicate and sensitive optics used in space telescopes, sensors, and imaging payloads.

Large Aperture Compatibility

Well-suited for testing large satellite mirrors or windows without needing extensive optical alignment

Robust Calibration and Reference Stability

Uses a known reference flat or sphere, ensuring traceable, repeatable measurements critical for qualifying space hardware

Real-Time Feedback

Enables immediate adjustments during optical fabrication and integration, reducing downstream risk in satellite assembly

Environmentally Stable Measurements

Can be performed in controlled environments to simulate thermal and vacuum conditions experienced in space.

Applications: Testing optics designed for SWIR imaging systems, transparent materials like IR lenses, transmissive elements, and lens assembly alignment.

SWIR Wavelength Compatibility

Enables precise testing of optical systems that operate in the short-wave infrared range (e.g., 1–2.5 µm), commonly used in Earth observation and defense satellites.

Transmission and Reflection Testing

Accurately measures both surface figure and transmitted wavefront errors of optical elements and lens assemblies.

Compact Setup with High Sensitivity

Ideal for integration in cleanrooms or satellite payload assembly areas, where space and vibration control are essential

Sensitive to Small Aberrations

Detects phase shifts and aberrations invisible to visible-wavelength interferometry, which is critical for SWIR payload performance

Alignment Verification in Final Configurations

Can be used to assess assembled lens systems in their operational path, ensuring real-world performance pre-launch.

Material Transparency Advantage

SWIR penetrates materials that are opaque in visible light, allowing evaluation of IR-grade optics like germanium, sapphire, and chalcogenides.

Andover Corporation has been at the forefront of addressing unprecedented challenges in aerospace optics for over 40 years. As space exploration and satellite technology continue to evolve, Andover delivers cutting-edge solutions that revolutionise everything from Low Earth Orbit operations to deep space missions.

Imaging systems

Navigation equipment

Communication arrays

Earth observation platforms

Space-based telescopes

Andover Corporation’s specialised coating technologies and custom solutions are optimised for the harshest space environments. Working across UV, visible, and IR wavelength ranges, we enable advanced:

From mission-critical space programs to breakthrough satellite innovations, Andover’s reputation is built on delivering precision optics that advance the boundaries of aerospace exploration. When performance cannot be compromised, Andover Corporation stands ready with unmatched optical solutions tested and proven in the harshest environments - from Low Earth Orbit to the depths of space.

Space-Qualified IR Bandpass Filters

Hard-Coated Narrowband Filters

Hard-Coated Broadband

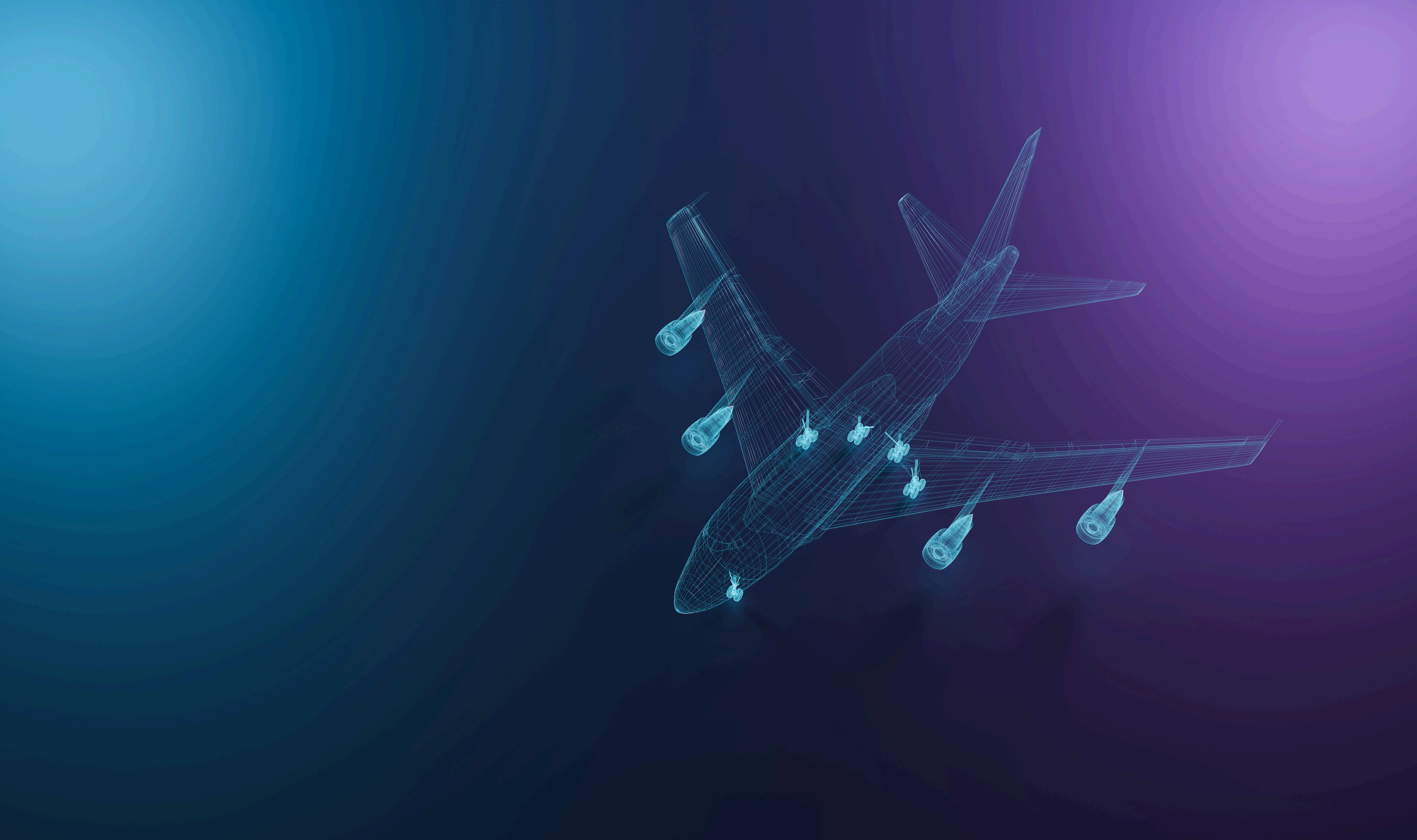

The aerospace industry has long relied on cutting-edge materials to meet its dema performance, safety, and w requirements.

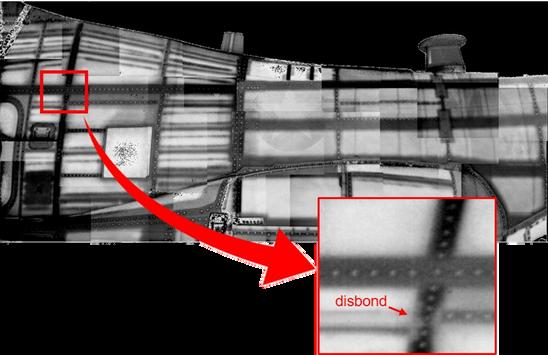

Among these, composites emerged as a vital compone both aircraft and t manufacturing, offering strength-to-weight ratios, cor resistance, and design flex However, the very propertie make composites advantageou make their inspection maintenance more complex This is where advanced Non-

particularly those developed by Thermal Wave Imaging

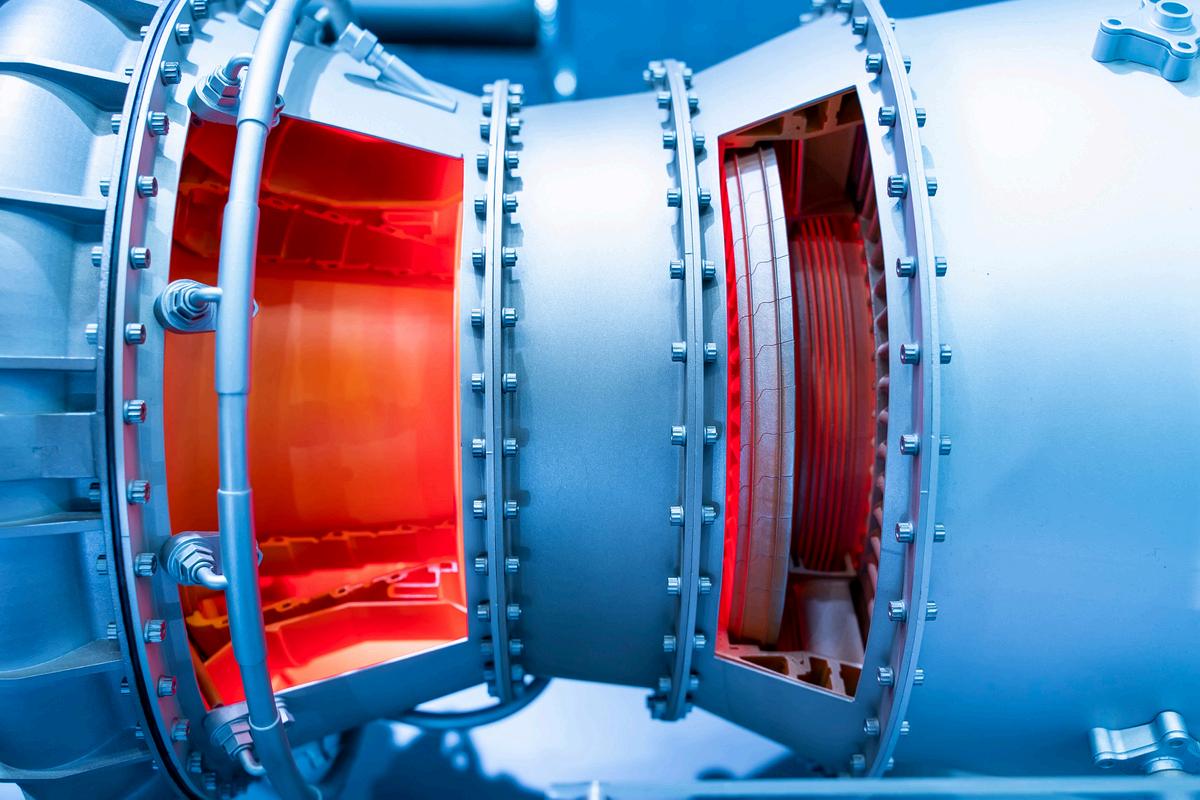

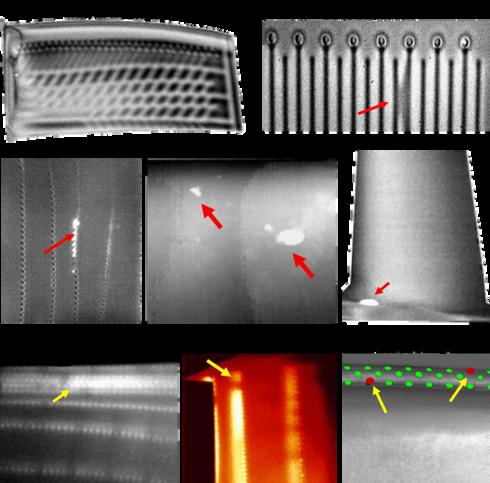

The value of TWI’s NDT solutions extends beyond traditional airframes. In the power generation sector—particularly within airborne and industrial gas turbines—leading OEMs rely on TWI technologies for comprehensive inspection across the manufacturing, rework, and maintenance lifecycle. These systems are essential for monitoring wall and coating thickness, detecting cracks, identifying disbonds and adhesion issues, and evaluating overall structural integrity

Aerospace composites are prone to various forms of damage, many of which are not visible on the surface Common issues include impact damage, delamination, water ingress, and foreign object damage (FOD), all of which can significantly compromise safety. TWI systems excel at detecting these defects early, allowing for proactive maintenance and minimising the risk of catastrophic failure.

Furthermore, TWI’s advanced capabilities also address more nuanced challenges, such as porosity, hole blockage, and corrosion—critical concerns in both aerospace and power generation environments. Their ability to perform detailed inspections without causing damage to components ensures that downtime is minimised while safety is maximised.

In an industry where precision, safety, and performance are nonnegotiable, TWI’s NDT systems stand out as a trusted and versatile solution. As composite materials continue to evolve and play a more dominant role in aerospace engineering, the importance of accurate, reliable inspection tools like those provided by TWI will only grow.

To discuss your application, contact our Technical Director, Dr. Shayz Ikram by email or call (01372) 378822.

Since integrating Janis Research into its product line in 2020, Lake Shore Cryotronics has manufactured numerous customdesigned cryogenic systems specifically suited for aerospace and astronomy applications. With decades of experience delivering rugged, mission-ready equipment, Lake Shore through its Environment by Janis division offers cryostats engineered to meet the extremes of space and high-altitude environments.

Custom cryogenic systems from Janis have been deployed in collaborations with NASA and other leading institutions:

The ARC Argus program (successor to ATLAS), enabling high-altitude atmospheric research using stable tracer detection. Qualification test hardware for the SIRTF (now Spitzer Space Telescope), operating at liquidhelium temperatures under mirror test protocols a project that earned Janis a Public Service Group Achievement Award from JPL. A terrain simulation chamber for Mars environment testing, built with NASA GSFC and UMD, replicating extreme cold and dust conditions.

These notable achievements reflect Janis’s reputation for uncompromising reliability, even in the most demanding space environments

Solid neon shielded superfluid helium cryostat for micro-gravity studies in the space shuttle environment

In 2000, Janis received its second NASA Public Service Group Achievement Award, again from the Jet Propulsion Laboratory This time it was for Janis' performance on the FACET program, the development of a cryostat to comply with the Shuttle Hitchhiker program, and providing a platform for microgravity experimentation. This second PSGAA, for a small company, is without precedent in the history of the JPL program and perhaps in all of NASA

Lake Shore’s cryogenic platforms—including closed-cycle refrigerators (CCRs), continuous-flow systems, and custom cryostats—support a wide array of aerospace research disciplines:

Precise measurement tools for photoemission, Raman, Mössbauer, ESR, NMR and other spectroscopy techniques.

Systems designed for vibration-sensitive microscopy, low-noise magnetic measurement, ion-source cooling, and material deposition studies

Formats that accommodate large sample volumes, narrow-gap magnets, ultra-high vacuum, and optical access architectures for astronomical instrumentation.

Engineered and validated through real-world space missions, these systems are built to withstand:

Extremely low temperatures and high vacuum conditions

High vibration, shock, and acceleration during launch

Long-term operational stability under cosmic radiation and thermal cycling

Lake Shore has even delivered hundreds of flightqualified temperature sensors for applications like the NASA James Webb Space Telescope and the Mars Curiosity Rover testimony to their performance and trustworthiness in critical missions

Ellipsometry is a technique that measures the change in polarisation of light reflected off a surface—mainly used to determine film thickness, optical properties, and surface roughness.

Pure electrical insulators are highly transparent, but highly conductive metals are opaque.

So what material can be used that is both transparent and conductive..?

We must find such a material to make our displays and touchscreens work.

To learn more about ellipsometry and to discuss your application, contact our Technical Director, Dr. Shayz Ikram by email or call (01372) 378822.

Indium tin oxide (ITO) is both transparent and conductive ITO optical properties vary a lot with deposition conditions and annealing, so monitoring the quality of the ITO and its thickness is important Ellipsometry is used for monitoring ITO film thickness and transparency at visible wavelengths while also being sensitive to absorptions in the ultraviolet, but it is very important for monitoring absorption in the infrared, which corresponds to the film’s electrical conductivity.

Improvements in display speed are critical for fast action in movies and sports Imagine a baseball, golf ball, or hockey puck leaving a comet tail behind on the screen because the display cannot refresh fast enough

Display pixel speed has been significantly enhanced using crystallised silicon films on the rear panel of the display. Ellipsometry is used to monitor the thickness and crystallinity of these deposited polysilicon films

LCD displays used to be small, monochrome in colour, and used in calculators, digital watches, etc. Modern displays are full colour, extremely fast, and very large The coated films must be uniform over the entire panel s, and film uniformity has been a limiting factor in the s of displays for decades With each new generation of larger displays, the film uniformity must be maintained An ellipsometer can fly over the large panels as they move on a production line to monitor film quality

the J.A. Woollam IRVASE II Ellipsometer

Stealth technology relies on reducing the detectability of objects particularly to radar and infrared (IR) sensors by manipulating surface materials to minimise reflected and emitted signals

A critical tool in developing and characterising such materials is the J A Woollam IR-VASE II spectroscopic ellipsometer, a sophisticated instrument designed for precise, non-destructive optical measurements in the infrared range (1 7 to 30+ microns) This capability makes it particularly valuable for assessing and engineering stealth coatings.

At its core, ellipsometry measures changes in the polarisation of light as it reflects off a surface. These changes are influenced by the material’s thickness, refractive index, and absorption properties parameters that define how a coating interacts with electromagnetic waves. The IR-VASE II extends this technique into the mid-to-far IR spectrum, which is crucial because many surveillance and targeting systems operate in these wavelengths

Helene Paquet

For stealth applications, one of the primary goals is to reduce infrared signatures. This can be achieved through coatings that absorb IR radiation instead of reflecting it, or by tailoring emissivity to blend with the background

The IR-VASE II allows engineers to precisely measure the complex refractive index (n and k values) across a broad IR range, enabling optimisation of materials to meet these stealth requirements. For example, by understanding the spectral absorption behaviour of a coating, one can finetune it to suppress reflection in specific IR bands used by thermal imaging systems.

Another key advantage of the IR-VASE II is its ability to characterise multilayer coatings Stealth materials often involve complex stacks of dielectric and conductive layers to achieve desired electromagnetic responses. The ellipsometer’s high sensitivity and advanced modelling software allow users to extract detailed information about each layer’s thickness and optical constants important data for ensuring the coating performs as designed.

In addition, the IR-VASE II’s nondestructive analysis is ideal for quality control in manufacturing environments. Reproducibility and uniformity are essential in stealth coating production, and this instrument provides rapid, repeatable assessments without damaging the sample.

The J.A.Woollam IR-VASE II spectroscopic ellipsometer offers unmatched capabilities for stealth coatings research and development. Its ability to measure and model the optical properties of advanced materials across the infrared spectrum makes it an indispensable tool for defence and aerospace applications focused on minimising detectability in hostile environments.

Ellipsometer for thin films and bulk materials characterisation

Features:

Wide spectral range

High sensitivity to ultra thin films

Non-destructive characterisation

No baselines or reference sample required

Highly accurate measurement

In a world marked by rapid change and growing uncertainty, one thing remains clear: the need for resilience, security, and preparedness has never been greater. Yet within these challenges lies immense opportunity.

This magazine celebrates the minds and missions behind cutting-edge technologies and strategic advancements that are reshaping how we protect our nations and support global stability. From breakthrough materials and autonomous systems to cyber defence and intelligence capabilities, R&D is not just responding to the world’s evolving threats it’s proactively shaping a future where peace, safety, and strength can thrive together.

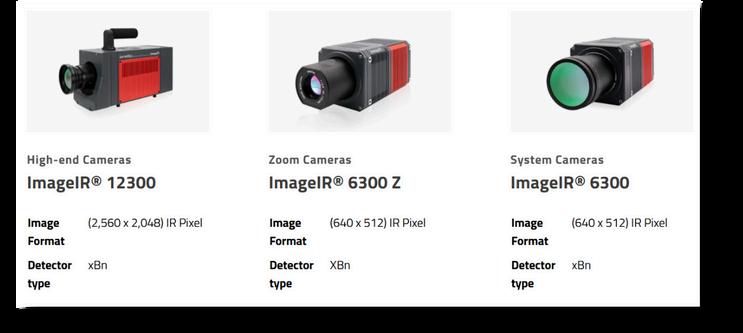

Highest demands on thermal resolutions for safety standards

High-speed data acquisition supports monitoring and controlling of fast processes

Active heat flow thermography allows testing of modern composite materials and lightweight construction elements

Non-destructivematerialtestingreducesexpensesofqualitycontrol

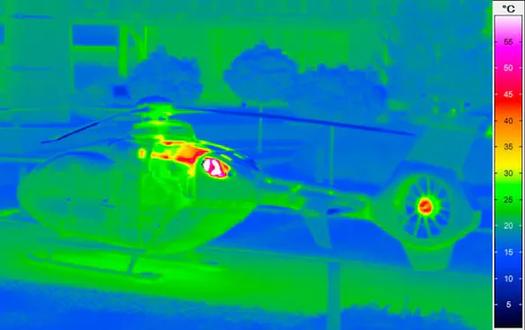

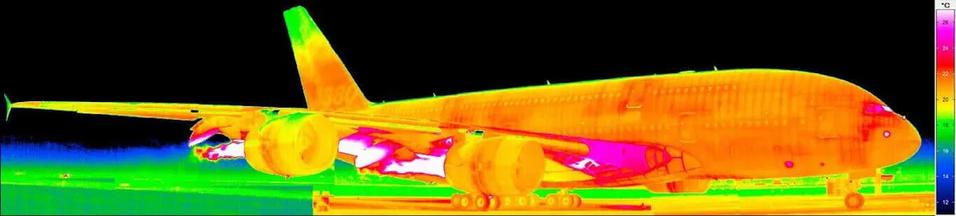

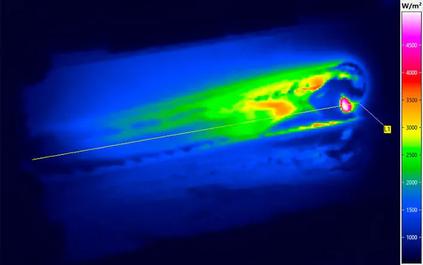

Measurement tasks of the aerospace industry often require infrared cameras with very high thermal resolutions of 20 mk and/or high frame rate of 100 Hz and more. Thus, for instance, accurate analyses of aero engine’s thermal behaviour are due to high safety and reliability requirements of the aviation authority. Moreover, quality controls of fuselages, wings and rotor blades of aeroplanes, respectively helicopters, can be carried out in form of efficient fault analyses with infrared camera systems.

In particular, the application of light and robust composite materials and other lightweight construction processes of the aerospace industry requires an accurate quality control For this purpose, active heat flow thermography is increasingly used for the production. Various activation and analysis systems allow efficient fault analyses with fast and highresolution infrared cameras, even inside materials or the construction.

Due to its thermography solutions, InfraTec was able to acquire customers, such as the German Aerospace Center or the European Aeronautic Defence and Space Company (EADS) Contributions to this were high thermal resolutions of the infrared camera series VarioCAM® and the high-end camera series ImageIR®.

Moreover, ImageIR® infrared camera systems can reach a remarkable speed of more than 10 KHz forming the basis of certain process analyses. Apart from the quality of infrared camera systems, engineers have been coping with another great challenge - the cameras’ integration Thus, clients benefit from customised and optimally integrated solutions which the modern and efficient thermographic software IRBIS® 3 is also part of.

At Quantum Design UK and Ireland, we’re passionate about providing high-tech scientific instrumentation to researchers, universities, and industries across the UK and Ireland.

Based in Leatherhead, Surrey, we’re a small but dedicated team, bringing deep expertise and a personal touch to everything we do.

We specialise in materials characterisation, cryogenics, non-destructive testing, imaging cameras, microscopy, and spectroscopy. But more than just supplying instruments, we work closely with our customers to understand their unique research challenges and help them find the best solutions.

What sets us apart? We’re knowledgeable, approachable, and always happy to help Our Sales and Service departments are second-tonone, offering expert support, training, and advice to make sure our customers get the most out of their equipment.

At Quantum Design UK and Ireland, we take pride in being more than just a supplier we’re a trusted partner in scientific discovery ”

David Want Managing Director Quantum Design UK and Ireland

For more than 40 years Quantum Design (QD) has been providing technology solutions to researchers in the fields of physics, chemistry, biotechnology, materials science, and nanotechnology.

Established in 1982 in San Diego, California, Quantum Design is the leading commercial source for automated materials characterisation systems offering a variety of measurement capabilities

QD instruments are found in the world’s leading research institutions and have become the reference standard for a variety of magnetic and physical property measurements

Quantum Design instruments are cited in, and provide the data for, more scientific publications than any other instrument in the fields of magnetics and materials characterisation.

An essential part of providing scientific solutions to researchers around the globe is to also offer state-of-the-art instruments from other leading manufacturers

These manufacturers are chosen by QD not only for their innovative products, but also because they believe in the same level of customer satisfaction and support that scientists have come to expect from QD products worldwide