Introduction

Unlocking Innovation Through Precision.

Welcome to Peak Product Solutions, where we turn complex industrial designs into reality. In a world of constant innovation, finding a manufacturing partner who can deliver on your most intricate visions is crucial. We specialize in overcoming the challenges of precision, time, and material constraints.

At our state-of-the-art, 35,000 sq. ft. air-conditioned facility in Houston, we are dedicated to exceeding your expectations. We use advanced CNC machining and the latest Coordinate Measuring Machines (CMM) for reliable, high-quality control on everything from single parts to high-volume production runs. As an AS9100D and ISO 9001:2015 Certified partner, we are committed to delivering high-quality components on time, every time.

Our Strengths:

Why Partner with Peak Product Solutions? Mastering Complexity

Machine Intricate Parts to Exact Tolerances: Our advanced CNC machines and expert machinists turn your most complex designs into reality. We specialize in holding tolerances as tight as +/-.0001” and achieving mirror finishes with a roughness average of less than 4 RA

Unwavering Consistency

Ensure Repeatability: Whether you need a single prototype or hundreds of identical parts, our advanced CNC machining processes guarantee consistent quality and precision throughout your entire production run.

Advanced Material Expertise

Handle Exotic and Challenging Materials: From titanium to Inconel and other specialized alloys, our team possesses the extensive experience and specialized tools required to achieve exceptional results with difficult-to-machine materials.

Reliability & Efficiency

On-Time and On-Budget Delivery: With a proven 97% on-time delivery rate, we ensure your project stays on schedule. Our continuous process optimization offers faster turnarounds and competitive pricing, so you can meet your budgetary goals without compromise.

Dedicated Partnership

Provide Excellent Customer Service: Our dedicated team supports you at every stage, from initial concept and design consultation through to final delivery, ensuring a seamless and collaborative experience.

Technology-Driven Solutions

Advanced CNC Machining Power: We leverage the latest in computer numerical control (CNC) technology, offering unparalleled precision and repeatability to overcome the limitations of traditional manufacturing.

Our Machining Capabilities

Advanced Technology for Unmatched Precision.

At Peak Product Solutions, we invest in cutting-edge machining technology and cultivate deep expertise to offer a comprehensive suite of capabilities. This allows us to tackle the toughest manufacturing challenges and produce parts of exceptional quality and complexity.

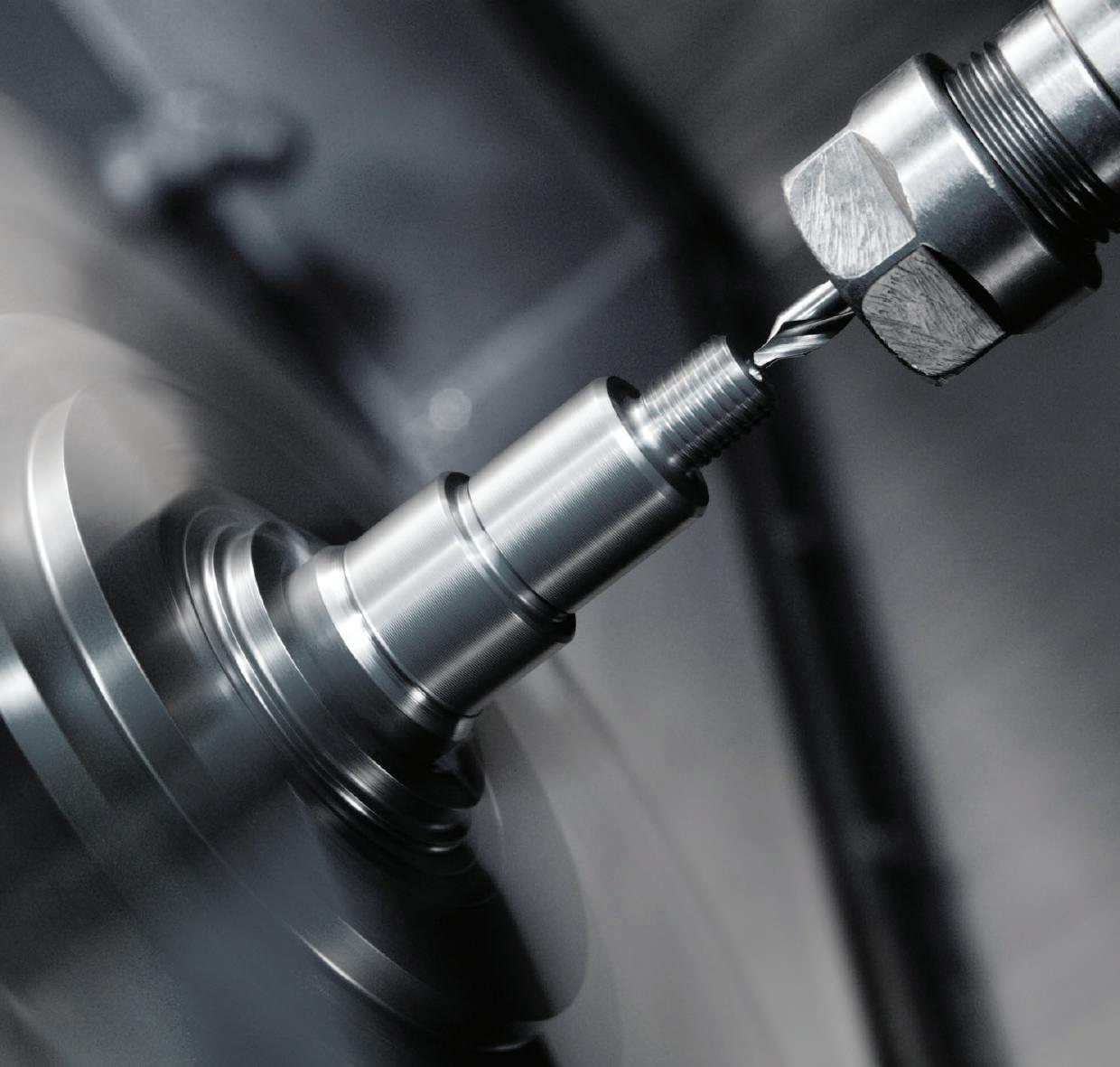

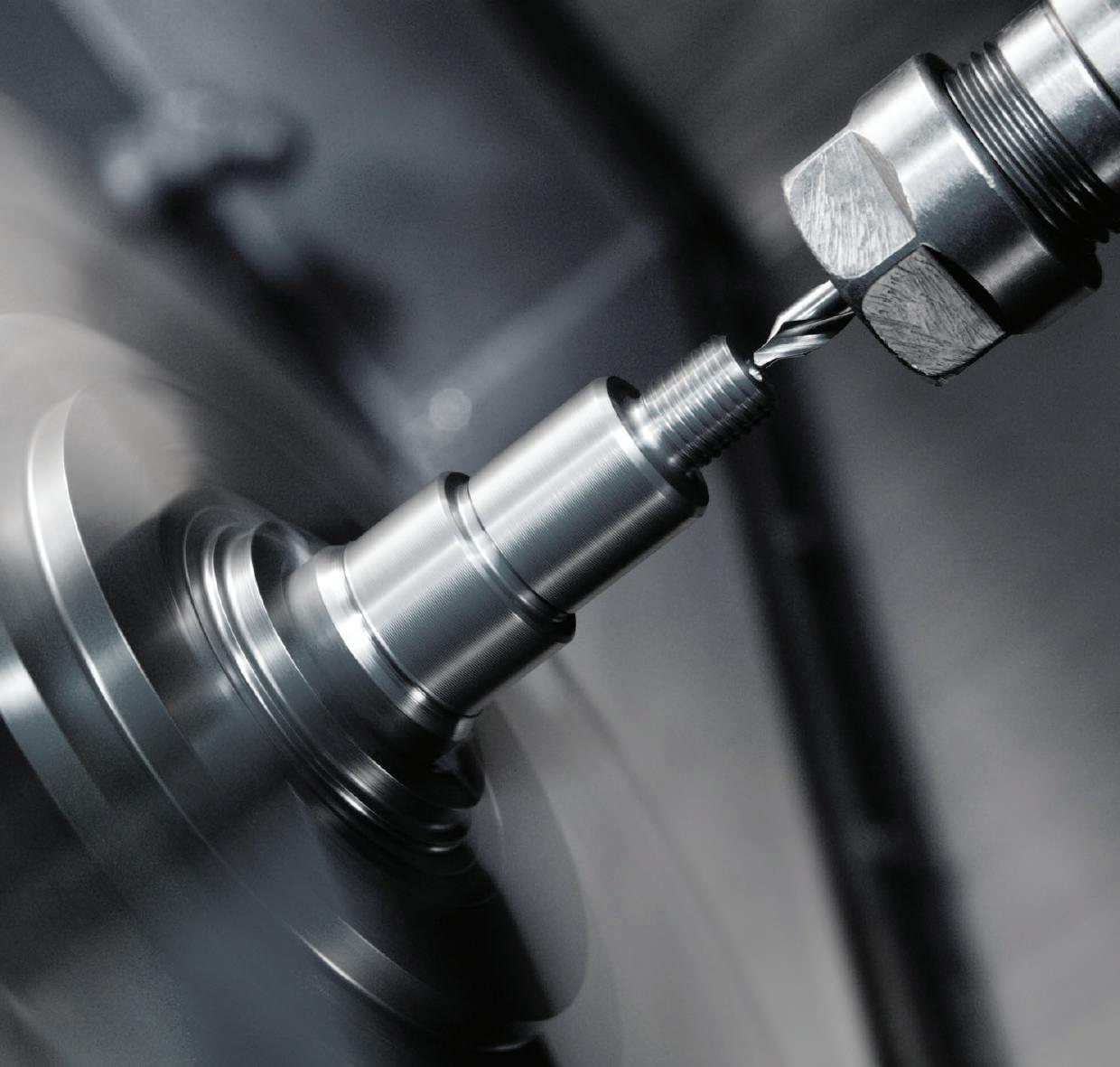

Our high-precision CNC milling and turning centers, equipped with 4, 5, and more axes, enable us to machine highly complex geometries, intricate contours, and challenging features with exceptional accuracy and efficiency. This reduces setups, improves precision, and allows for the creation of parts previously thought unmanufacturable. (Key benefits: Complex part production, reduced lead times, superior surface finishes.)

We use state-of-the-art Coordinate Measuring Machines (CMM) to ensure the highest level of accuracy and quality control on all of our projects. This allows us to verify the precision of every part, from the smallest component to large, high-volume production runs.

Precision CNC Turning up to 28" x 139"

Precision CNC Milling Machining up to 70" x 120

Multi-Axis machining capabilities

Our Machining Capabilities

Advanced Technology for Unmatched Precision.

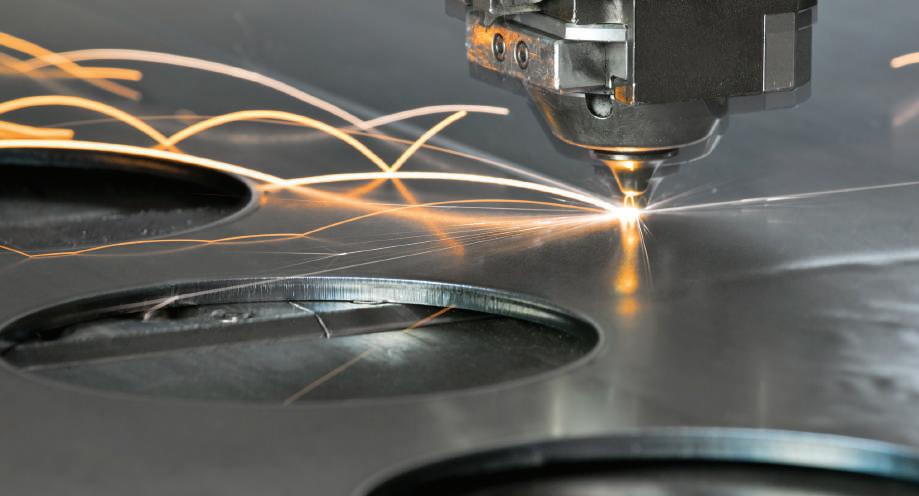

Electrical Discharge Machining

(EDM) (Wire and Sinker)

Additive Manufacturing

(3D Printing)

For intricate details, sharp internal corners, and machining of hardened or exotic conductive materials that are difficult to cut with traditional methods, we leverage specialized Wire EDM and Sinker EDM technology. This process achieves exceptionally fine details and tight tolerances. (Key benefits: Machining hardened materials, complex shapes, fine details, burr-free finishes.)

Complementing our subtractive manufacturing processes, we offer additive manufacturing services to rapidly prototype designs, create complex internal features, or produce functional parts from a variety of engineering-grade plastics and metals. This accelerates development cycles and unlocks new design possibilities. (Key benefits: Rapid prototyping, complex geometries, custom tooling, low-volume production.)

Our Industry Experience

Proven Expertise Across Demanding Sectors.

Peak Product Solutions is a trusted partner for precision CNC manufacturing across a wide spectrum of industries. We understand the unique challenges, stringent standards, and critical performance requirements of each sector, delivering tailored solutions that drive innovation and success.

Aerospace

We manufacture high-caliber components essential for flight and space exploration, meeting rigorous AS9100 standards. From critical structural parts to intricate instrumentation, we help you reach new heights with lightweight, durable, and precisely machined components. (Examples: Turbine blades, landing gear components, satellite parts, UAV components)

Defense

Our components meet demanding mil-spec standards, ensuring reliability and performance in critical defense applications. We provide robust parts for weapon systems, armored vehicles, and advanced communication equipment, supporting the safety and effectiveness of armed forces. (Examples: Weapon system components, vehicle armor parts, guidance system housings)

Our Industry Experience

Proven Expertise Across Demanding Sectors.

Oil & Gas

Automotive

Medical

With advanced CNC technology, we supply durable, high-quality parts for drilling, subsea, and refining operations. Our components withstand harsh environments and extreme pressures, keeping your operations efficient, productive, and safe. (Examples: Downhole tools, valve bodies, pump components, pipeline fittings)

We support the automotive industry's drive for innovation and performance, from high-performance racing components to specialized parts for electric and autonomous vehicles. Our precision machining ensures optimal fit, function, and durability. (Examples: Engine components, transmission parts, suspension elements, custom fixtures)

Precision is paramount in the medical field, and we deliver. We manufacture intricate components for medical devices, surgical instruments, and implants, adhering to strict quality controls and utilizing biocompatible materials where required. (Examples: Surgical tools, orthopedic implants, diagnostic equipment parts)

Our Precision Process

A Meticulous Path to Perfect Parts.

Our commitment to quality and precision is underpinned by a systematic and meticulously managed process. Every project undertaken by Peak Product Solutions follows a structured pathway to ensure your exact specifications are met, on time and to the highest standards.

01

Initial Consultation & Strategic Quoting:

It begins with understanding your vision. We engage in a thorough consultation to grasp your project requirements, application, and critical features. Within [Specify timeframe, e.g., 24-48 hours], you receive a detailed and transparent quote.

02

Material Sourcing & Verification:

We source only high-quality raw materials from trusted and certified suppliers. Whether it's standard alloys or specialized exotic materials, each batch is verified to meet stringent quality and compliance requirements before manufacturing begins.

03

Advanced CNC Programming & Simulation:

Our highly skilled programmers utilize advanced CAM software to translate your approved designs into precise CNC machine instructions. Programs are meticulously crafted and often simulated virtually to preempt any issues and optimize toolpaths for efficiency and quality.

Our Precision Process

Executing with Excellence, Every Step of the Way.

State-of-the-Art Machining:

Your project is assigned to the optimal CNC machining centers within our advanced facility. Utilizing multi-axis milling, precision turning, EDM, and robotic automation where appropriate, our expert machinists execute the programmed operations with meticulous attention to detail.

Rigorous In-Process Quality Control:

Quality isn't just a final check; it's integrated throughout the manufacturing process. We conduct regular in-process inspections, dimensional checks, and monitoring by skilled technicians to ensure every feature is within tolerance and any deviations are addressed immediately.

Finishing & Final Inspection:

Once machining is complete, parts move to finishing processes as required (e.g., deburring, surface treatment). If assembly is part of the project scope, it's performed with precision. A comprehensive final inspection, often utilizing CMM technology and other advanced metrology tools, verifies every critical dimension against your specifications. Full inspection reports are generated.

Secure Packaging & On-Time Delivery:

We take great care in packaging your components to ensure they arrive in perfect condition. We manage all logistics, coordinating with trusted shipping partners to deliver your order on time, every time, complete with all required documentation and certifications.