SHIFT CREATING A PARADIGM

The next major step in the evolution of asset management

Measuring confidence

A new report outlines the sector’s optimism and challenges for the future Future proofing

Advanced methods are helping to condense decades of research to only months

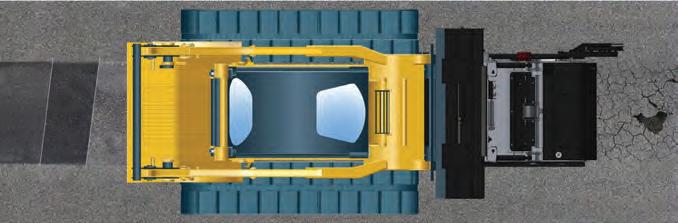

The Most Innovative Paver Technology!

VÖGELE SUPER 1700-3(i) / SUPER 1703-3(i)

VÖGELE SUPER 2000-3(i) / SUPER 2003-3(i)

The number one paver manufacturer on the global market presents innovative “Dash 3” pavers and screeds for Australia. Equipped with state-of-the-art Cummins engines available in either Tier 3 or Tier 4 Final / Euro Stage V emission standards, are the perfect choice for any application in the Universal (2.5m) and Highway (3.0m) paver classes. Thanks to the easy-tounderstand ErgoPlus 3 operating system which is common across all VÖGELE products both paver and screed operators can handle all VÖGELE pavers simply and safely. These machines are also available with vibrating screeds or high compaction tamping & vibrating screeds for those critical jobs. In combination with advanced optional features, such as VÖGELE EcoPlus, AutoSet Plus and Navitronic Plus 3D, these models are the stars of any road construction site.

www.wirtgen-group.com/australia

COVER STORY

6 Creating a paradigm shift

GBM Konect represents the next major step in the evolution of location-based data collection applications, offering industry, state and municipal infrastructure authorities’ real-time access to essential information.

THOUGHT LEADERSHIP

10 Assessing industry progress

Kennards Hire’s Construction Confidence Check report has assessed optimism levels among key industry players, as productivity inefficiencies, delays, and labour shortages continue to impact the sector.

INNOVATION

12 Defying transport testing

The National Transport Research Organisation’s Accelerated Loading Facility is making its way out west.

15 Built for resilience, designed for the future

As Australia’s infrastructure boom continues to drive demand for smarter, more adaptable manufacturing solutions, one company stands out for its ability to evolve with the times while staying true to its founding vision: Civilcast.

17 Maintaining a coastal paradise

SAMI Bitumen Technologies’ SAMIfloat polymer modified high float emulsion has once again surpassed expectations, this time assisting in road rehabilitation works in a popular coastal municipality.

SAFETY

20 Last line of defence

Meridian is providing the first and final line of defence, with its variety of portable crash and car barriers helping to improve the safety and viability of roadside and infrastructure works.

COMPANY PROFILE

22 From flood to force

In its short three years of operations, RoadAid has made its mark in providing maintenance and operational support for roads and tunnels across the country.

SUSTAINABILITY

24 The path to Net-Zero

As the global push toward net-zero accelerates, Sripath Technologies is leading the charge in the asphalt industry with sustainable, highperformance additives designed to reduce emissions, extend pavement life, and support a circular economy.

26 Driving safety up, emissions down

With over 30 years of experience in commercial vehicle systems, Dr Air Brake has developed a revolutionary two-pronged approach that is delivering measurable environmental benefits alongside dramatic safety improvements.

TECHNOLOGY

29 More than just roads

Asset Vision’s venture into the council market has been met with interest and acclaim. Roads & Infrastructure learns more about what the switch means for the platform, and how it’s already helping to improve council services.

32 Ace your fleet

Geotab has unveiled a powerful new tool poised to transform fleet management across the roads and infrastructure sectors.

MACHINERY AND EQUIPMENT

35 Aligned on cultural change Amarapave’s strong ties with industry have been epitomised by its ongoing partnership with the Wirtgen Group and Patten Pavement Services, which are helping the fully female and nonbinary business take the next step.

38 An important lesson

Specialised Roading Equipment is using its connections and expertise to educate the industry on a prevalent knowledge gap – the benefits that lie beyond conventional bitumen spraying equipment.

41 Power, with combined control

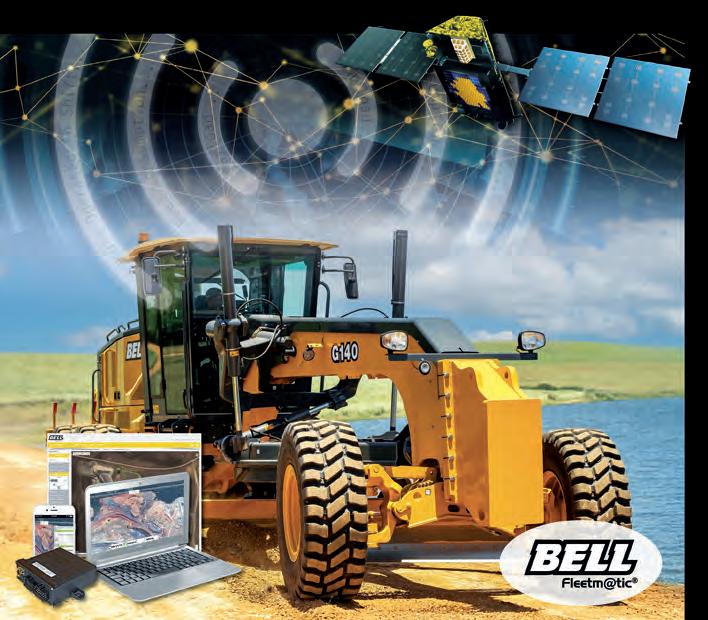

The launch of the RM800 road stabiliser signals a shift towards larger equipment for Caterpillar, to cater for works on major infrastructure projects.

44 Smart, safe and synced Bell Equipment is delivering significant innovation through its agnostic approach to safety, autonomy and control technology.

47 The road to global innovation

Secmair’s presence and reputation in Australia continues to grow. Local dealer and representative Darryl Byrne highlights the products that have laid the foundation for the company’s success domestically.

50 Precision blending

Crusher Screen Sales & Hire’s IMS PM120020TB pugmill has become a gamechanger for increasing accuracy in road base production.

52 Back to where it began

Bielby Holdings continues to strengthen its compaction capabilities with recent acquisitions of advanced Dynapac machinery reinforcing its commitment to performance, efficiency, and long-term project success.

55 Sensing done smarter

Non-contact, maintenance-free level monitoring can be hard to come by, but VEGA’s lineup of limestone and cement management technologies have changed the game.

59 Same machine, better results Simex will soon be releasing its second generation of the ART 1000 attachment, which is set to revolutionise zero waste asphalt repair.

CONTRACTS AND TENDERS

60 Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market across the Australian infrastructure sector.

Brand new technologies and important education is advancing for the sector’s betterment, as we learn in this edition of Roads & Infrastructure magazine.

CEO

Christine Clancy

christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker

sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Loren Katie Logan lorenkatie.logan@primecreative.com.au

CLIENT SUCCESS MANAGER

Sabrina Zor sabrina.zor@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE adobe.stock.com/FiledIMAGE

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

HIGH ‘TECH’, HIGH IMPACT

DURING PRODUCTION OF THE OCTOBER EDITION of Roads & Infrastructure, the advancement and implementation of technology quickly came to the fore. Not only during discussions that appear in this edition, but also in wider conversations with decision makers.

The adoption of new technologies is always a push and pull within the sector. For what is generally a conservative industry, the emergence of new systems and opportunities for adoption is helping to dilute the impact of current challenges and issues.

Platforms such as GBM Konect are doing just that. GBM Konect captures a wide range of field data, including asset inventories such as roads, trees and signage. It’s also capable of capturing inspection records, defect reports and work orders for maintenance. Councils using the application are able to deliver road maintenance services quickly and easily, ultimately benefiting residents.

Another platform that’s helping to increase the efficiency of services is Asset Vision, which is providing an end-to-end solution for asset management, particularly suited for councils and organisations managing diverse asset portfolios. For years, major road and transport agencies have entrusted the platform to collate data and information that can be actively used to deliver improved transport results. Now councils are set to reap the benefits.

Also in this edition, we learn more about the ALF, or Accelerated Loading Facility, a system that’s used to rapidly test and understand the performance of road pavements and materials. ALF applies heavy, repeated loads to experimental pavement sections to simulate years of traffic in a much shorter time. This helps researchers and engineers quickly gather evidence on how different road designs and materials will perform, allowing them to improve design methods and ensure roads are durable and reliable for years to come.

Our team also had the chance to sit down with Caterpillar to learn more about what is the first major product release from the company’s soil stabilisation range in some time. The brand new RM800 promises to provide the largest ever output from an Australian Caterpillar soil stabiliser, with the unit geared toward delivering major infrastructure projects. Experts delve into the features and additions that come with this new iteration.

This and much more, in the October edition of Roads & Infrastructure magazine.

Happy reading!

Tom O’Keane

TOM O’KEANE – EDITOR

CREATING A PARADIGM SHIFT

GBM KONECT REPRESENTS THE NEXT MAJOR STEP IN THE EVOLUTION OF LOCATION-BASED DATA COLLECTION APPLICATIONS, OFFERING INDUSTRY, STATE AND MUNICIPAL INFRASTRUCTURE

AUTHORITIES’ REAL-TIME ACCESS TO ESSENTIAL INFORMATION.

According to the Grattan Institute, councils in Australia manage more than 75 per cent of the national road network.

Legislative and regulatory requirements necessitate that local councils must develop what’s known as an Asset Management Policy and Strategy,

covering how they intend to preserve service standards, conduct asset condition assessments, implement proactive maintenance and develop longterm planning.

All of this and more aims to ensure that councils are responsibly, sustainably and cost-effectively managing road

Images:

GBM

Konect

GBM Konect represents a new era for asset management, offering councils more data and insight than ever before.

Having initially worked on threedimensional modelling in the mining industry in the early 1990s, Global GBM began developing GIS (Geographic Information System) software and field data collection tools for mining applications.

The company recognised soon after that the software could serve much broader markets beyond mining. As such, it began developing related products and web-based solutions.

With the introduction of the first iPhone and other significant

to locate and manage assets in the field using geospatial awareness (mapping assets with X, Y coordinates).

“Through the geospatially aware Konect app, users can build quite a comprehensive set of tools to help manage road assets, from potholes and resurfacing, through to road

Understanding that unique challenges require bespoke solutions, the Konect platform has also been designed to cater for virtually any application.

As John Ivett, Director – GBM Konect explains, the process often starts with a trial or proof of concept, where the platform is configured to capture a

“YOU CAN COLLECT THE DATA THAT YOU WANT, WHEN YOU WANT IT, AND HOW YOU WANT IT. IT DOESN’T MATTER HOW, WHEN OR WHY. THANKS TO KONECT, THERE ARE NO LONGER BARRIERS FOR THOSE WHO NEED TO COLLECT DATA.”

the QR to connect with our team

modify those components for them.”

Konect is designed to be fully flexible and customisable, allowing users to tailor the platform to cater for specific parameters, without requiring programming skills.

maintaining and delivering services to the community. Especially its road network. With essential road links across the region, such as the gateway to the

been set up to be really streamlined and given us greater control over the flow of information,” he says. “On the flip side, Konect makes it really simple for us, importantly, to get that information back out to our teams.

“After all, if it’s worth capturing, then it’s worth reviewing.”

Konect is used to manage all field work, with jobs logged by customer service officers or inspectors, before being assigned to supervisors, and then dispatched to crews.

The system streamlines information flow and data collection, including job details, comments, photos, and safety questionnaires, all into one platform.

Hardiman adds that the map-based interface, ease of use, and ability to extract data for reporting and compliance are among the key benefits

“The fact that it’s map-based really helps to reduce travel time. It’s a big region, so some days our team might complete 20 jobs, or three, depending on the travel time,” he says. “With Konect, teams can be more efficient with the travel between jobs, therefore increasing our work throughput and coordination.

“Now we’ve got a better idea of the square meterage and how long each of these jobs takes.”

City of Greater Geelong is also

“It almost seems too good to be true, but as it’s a fully customisable and flexible system, it can virtually accommodate whatever you want to throw at it,” Ivett says. “You can collect the data that you want, when you want it, and how you want it. It doesn’t matter how, when or why. Thanks to Konect, there are no longer barriers for those who need to collect data.”

It’s features such as this that have seen Konect become popular among a number of segments in the transport and infrastructure space, as Shooter explains.

“The Konect app is already widely used in roads and road infrastructure, but it’s most widely used in the context of local government road maintenance,” he says.

FIRST-HAND

The City of Greater Geelong is just one municipality that’s benefiting from the use of the Konect platform.

“WITH KONECT, TEAMS CAN BE MORE EFFICIENT WITH THE TRAVEL BETWEEN JOBS, THEREFORE INCREASING OUR WORK TH ROUGHPUT AND COORDINATION”

Great Ocean Road, City of Greater Geelong is heavily relied upon to uphold local infrastructure.

Across the organisation, about 300 council staff are using Konect. The rollout began with the City Works department in late 2020 and has recently expanded to the Parks & Natural Assets department, adding about 120 more users.

Alex Hardiman, System Support Analyst – City of Greater Geelong, says Konect has been used primarily by field staff involved in tasks such as pothole repairs, graffiti cleanups, line marking, and tree cutting.

“Through Konect, our systems have

piloting the use of Konect with external contractors, aiming to further streamline work allocation and reporting.

Hardiman says the feedback he’s received so far from council staff has been overwhelmingly positive, particularly around the flexible nature of Konect.

“It’s great to use a platform that has so much freedom for making adjustments,” he says. “If someone in our team asks for a minor change, I can have that sorted in 10 minutes.

“Konect really fills us with confidence that the information we’re getting is accurate, usable and potentially impactful.”

Above, L to R: Russell Shooter, Chief Executive Officer – GBM Konect; John Ivett, Director –GBM Konect.

SRE’s telescopic bitumen sprayers or our newly developed 8m fixed wing bitumen sprayers are available for late 2026 delivery.

Fully compliant with all Australian regulations our sprayers meet all Austroads performance requirements for bitumen sprayers and are ready to go straight to work.

INDUSTRY PROGRESS ASSESSING

KENNARDS HIRE’S CONSTRUCTION CONFIDENCE CHECK REPORT HAS ASSESSED OPTIMISM LEVELS AMONG KEY INDUSTRY PLAYERS, AS PRODUCTIVITY INEFFICIENCIES, DELAYS, AND LABOUR SHORTAGES CONTINUE TO IMPACT THE SECTOR.

Accurate reads on the sector’s ambition and mood are often rare, but a relatively new resource from one of the nation’s largest equipment hire providers aims to change that.

Kennards Hire’s annual Construction Confidence Check (CCC) was developed to provide further insight into the industry’s sentiment towards future opportunities and challenges.

The 2025 report, the fourth CCC to be released, assessed the confidence levels of key senior leaders in the construction industry across Australia and New Zealand.

More than 600 senior leaders from mid to large-scale businesses were surveyed, with the CCC evaluating their outlook for the next five years. This included expectations for future projects, the overall project pipeline, broader macroeconomic conditions, and the main drivers affecting their businesses.

Tom Kimber, General Manager Sales –Kennards Hire says the CCC offers significant insight into the factors that are affecting decision makers, sector-wide.

“It’s really a barometer around the confidence of key players in the industry,” he says. “Among many things, what we’re looking for is validation of what we’re seeing from our own perspective in the market. That means mapping out what our expectations are, versus the reality faced by the construction segment, as well as looking at any current trends or highlights.”

KEY FINDINGS

Kimber describes the overall feel of the sector as “cautiously optimistic” with the CCC painting a positive picture for the next half-decade. The CCC states that 91 per cent of business leaders have confidence in further growth in the construction sector, over the next five years.

The positivity is a far cry from the general mood felt across the past few years, says Kimber.

“It was surprising and pleasing to see such

strong confidence and positivity, which we haven’t been hearing in the general media or in our general state of play over the past couple of years,” he says. “It seems as though we have come through the worst of it, and the outlook is definitely not as bleak as what we’ve had to manage in previous years.”

Despite this positive outlook, it’s clear challenges remain, with 99 per cent of participants saying that their business is currently exercising caution or looking at cost savings.

Among the biggest and lingering challenges are constraints around capital investment, with many in the sector facing difficulties

committing to long-term projects or new equipment.

Persistent shortage of skilled workers has further constrained growth, while ongoing supply chain disruptions have continued to affect the industry, causing delays and operational challenges. Companies are also finding it increasingly difficult to be both cost-effective and sustainable, especially with project stakeholders demanding lowemission equipment and environmentally friendly solutions.

Importantly, the CCC provides Kennards Hire with greater context and understanding around these challenges.

Kennards Hire’s Construction Confidence Check report is a barometer for the industry’s current progress and issues.

“If you don’t listen to what your customers and the sector at large is telling you, then you can’t be informed on how to serve it in the best way,” Kimber says. “From that perspective, the CCC is a vital tool. It defines and influences our outlook and many of the decisions that we’ll make.”

Just one of these customers is Total Construction. Steve Taylor, Managing Director – Total Construction says the industry’s current challenge is managing increasingly complex projects across fragmented supply chains.

“Juggling multiple suppliers, managing outdated equipment, and navigating material shortages isn’t just frustrating, it’s expensive,” he says. “To be on the front foot, the key is to stay agile, adapt quickly, and partner smartly. In today’s shifting economic environment, it’s not just about managing costs – it’s about building a more resilient and scalable business.”

Again, reflecting the key findings and importance of sustainability within the CCC, Taylor adds that companies must adapt and embrace modern construction techniques to ensure successful project outcomes.

“Today, success in construction isn’t just about delivering projects, it’s increasingly about how you deliver them,” he says. “The old ways of working simply don’t cut it anymore. Prioritising ESG (Environmental, Social, and Governance), outsourcing, equipment hires, and investing in our people has made a real difference in our ability to deliver on time and at scale.”

It’s here that Kennards Hire’s solutions come to the fore. As Kimber explains.

“We’re always looking to innovate and ensure that our customers have the right solution for the right project,” he says. “Kennards Hire doesn’t just supply gear; it provides a suite of

solutions that can create greater efficiency. We pride ourselves on having quality and reliable gear, which if you don’t have access to, can lead to downtime and disruptions.

“We play a significant role, I feel, in alleviating those issues.”

Kennards Hire’s model allows companies to access equipment as needed, reducing the need for large capital investments and supporting cost-effective project management.

By providing the right equipment, Kennards Hire can help customers save time and reduce the need for additional labour, a critical aspect that can help to minimise the impacts of industry-wide skills shortages.

This model also promotes sustainability by maximising asset utilisation, while reducing the environmental impact of ownership.

Kennards Hire’s constantly updated fleet also ensures customers have access to the latest, most efficient, and lowestemission technology.

“Hire equipment has always been rooted in sustainability,” Kimber says. “It provides a ‘use as needed’ scenario, without any hidden costs. It’s all about staying close to our customers and understanding where they’re at, as well as making sure that we’re agile and able to adapt, to service them as best as possible.”

And Kennards Hire provides much more than just equipment and machinery. With a dedicated division and vast experience in project management, Kennards Hire can provide a dedicated team that works with project stakeholders to deliver optimal outcomes.

It’s potentially a “game-changing” service, especially with 35 per cent of CCC participants saying that they struggle to attract project management expertise, and a further 36 per cent saying that time is often wasted when managing multiple suppliers and project stakeholders.

Kimber believes that with Kennards Hire’s support behind it, the outlook for the sector is brighter, with significant projects ahead and a renewed willingness to invest.

“We’ve got a number of significant projects in the pipeline that will stimulate construction and infrastructure,” he says. “I see a much brighter outlook for the 2026 calendar year and beyond.”

To learn more, visit: https://www. kennards.com.au/latest-news/constructionconfidence-check-2025

Industry confidence levels remain high, despite challenges, according to the Construction Confidence Check.

to create barriers for effective project delivery.

TRANSPORT TESTING DEFYING

THE NATIONAL TRANSPORT RESEARCH ORGANISATION’S (NTRO) ACCELERATED LOADING FACILITY IS MAKING ITS WAY OUT WEST, PROVIDING AN OPPORTUNITY TO CONDUCT YEARS’ WORTH OF PAVEMENT TESTING IN JUST A MATTER OF MONTHS.

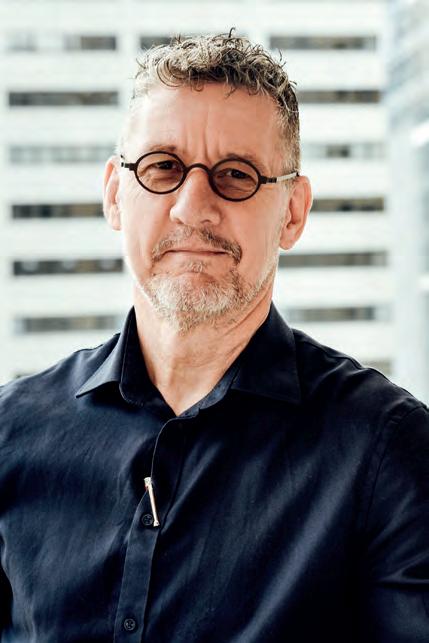

With 35 years of research and management experience in the sector, National Transport Research Organisation (NTRO) Chief Operating Officer Dr Richard Yeo has witnessed significant evolution and progress in the transport sector.

Despite this advancement, he says the industry has failed to overcome factors responsible for the ageing and depreciation of road surfaces and pavements.

While there’s no silver bullet, Yeo says action taken many years ago has laid the groundwork for exciting developments in surface testing and rehabilitation.

“Normally, roads deteriorate due to traffic or the environment, or a combination. Regardless, we always need to know how and why. In the old days, they did it by building a road at a certain thickness and seeing how long it lasted,” he says.

“If it lasted three years, ten years, 20 – or however long – that was a way to assess performance.

“It was clear that we needed a way to accelerate the knowledge of how pavements and materials perform, as well as a way to assess the design methods that these structures were based upon.”

After commissioning a review in 1978 into the future research needs of the sector, the National Association of Australian State Road Authorities identified that conventional methods were obsolete, in particular the time required to fully assess long-term pavement performance, which risked slowing adoption and further innovation.

It wasn’t until 1982 that design and construction commenced on what would become a central component in Australian pavement research for decades to come.

As Yeo fondly recalls, this ‘component’ and his career have been inextricably linked.

“I graduated in 1988 and got my first job, which was as a design engineer,” he says.

“I can still remember, I started reading and found early reports of something called ‘ALF’. As I read, I thought ‘that’s exactly what I need

to see and use if I want to learn how to be a pavement design engineer’.”

ALF, or Accelerated Loading Facility, is a system that’s used to rapidly test and understand the performance of road pavements and materials.

It applies heavy, repeated loads to experimental pavement sections to simulate years of traffic in a much shorter time. This helps researchers and engineers quickly gather evidence on how different road designs and materials will perform, allowing them to improve design methods and ensure roads are durable and reliable.

Introduced initially in 1984, ALF has been instrumental in groundbreaking research that’s helped to deliver safer, more durable and sustainably conscious transport routes nationally. As Yeo explains, ALF provides important findings to inform design methods and underpin design reliability, by helping to determine how different materials, thicknesses, and construction methods perform under heavy loading.

“To introduce new innovations into our design or construction, we need evidence,” he says.

“We need some early findings of how they perform. ‘What works, and what doesn’t? What are the boundaries of what works and what doesn’t?’ That’s the beauty of ALF. We can test and get answers in a matter of

The Accelerated Loading Facility applies significant weight to simulate years’ worth of traffic.

months, then with confidence predict what will happen over the course of decades.”

In 2001, Yeo was appointed as the Program Manager of ALF, the culmination of his initial interest and passion in the years prior.

“Around 1990, two jobs opened up at the Australian Road Research Board (now NTRO),” Yeo continues. “One was as a graduate role as a material scientist, and the other was to be the ALF manager. I was knocked back as it was a senior role, but you could say that I’ve always had an interest in the ALF.

“My career as a pavement engineering expert has a lot to thank the ALF for. The ability to gather the evidence that we’ve needed to enact change, while also changing our thinking about design and construction, on top of examining the interaction between loading and the environment; through all of that and more, the ALF has always been there,” Yeo says.

WESTERN EXPANSION

The NTRO celebrated the ALF’s 40th anniversary in 2024, reflecting on the 32 million load passes and more than 300 million heavy vehicle trips that have been simulated by the unit thus far.

Its legacy is entrenched in addressing a wide range of road infrastructure challenges, predominantly on the east coast. But what about the rest of the country?

“It’s been based in Dandenong for several years,” Yeo says, “but it has operated in many sites across Queensland, New South Wales and South Australia for many years.

“Across those 40 years, ALF had never made the journey out west.”

In collaboration with the Western Australia Government, as well as the Department of Transport, the NTRO recently launched its second-ever ALF to address region-specific issues across the state.

Coloured in the iconic blue and gold of the West Coast Eagles’ football team, the new ALF will be stationed in Neerabup, north of Perth. Yeo believes the new facility will open new doors for the state.

Just one example is access and haul roads for Western Australia’s booming mining sector. ALF will be deployed to evaluate the performance of mine haul roads under extremely heavy loads of up to 20 tonnes per axle, much higher than typical public road limits in other states.

ALF will also be used to assess how local materials and construction methods perform under other unique environmental

and loading conditions, including the use of limestone, sand, and recycled materials.

This also includes learning more about road performance in harsh climates, flooding events and remote locations.

There will also be scope for assessments on runway and port surfaces. All of which will be undertaken for a variety of stakeholders from several industries, with organisations in both the public and private sectors able to engage with the NTRO to use the ALF unit to test and validate their specific road infrastructure needs and solutions. Yeo says the eastern and western-based ALFs will continue to play a fundamental role in the delivery of suitable infrastructure, while catering for the rapid development of transport technology like electric and autonomous vehicles.

“The environment that we operate in is constantly changing,” he says. “The

community expects more out of our roads, and the freight demands have never been greater.

“Road trains and axle loads are increasing; there’s a push to change dual tyres to single tyres. What does that mean for electric and heavy vehicles? Then consider the environment, how can we increase load and weather resilience? What’s the life cycle of these materials, and how do they perform?”

Filling critical knowledge gaps such as these, between stakeholders like material manufacturers, road designers, and asset managers, has been ALF’s staple for 40 years. Yeo says expectations are high around what the next 40 could have in store.

“There are many questions that we’re yet to answer,” he says.

For more information on the ALF, contact info@ntro.org.au

Images: Sam Crees

National Transport Research Organisation Chief Operating Officer Dr Richard Yeo.

ALF is now able to be used by the wider industry, not just state and local road agencies.

BUILT FOR RESILIENCE

AS AUSTRALIA’S INFRASTRUCTURE BOOM CONTINUES TO DRIVE DEMAND FOR SMARTER, MORE ADAPTABLE MANUFACTURING SOLUTIONS, ONE COMPANY STANDS OUT FOR ITS ABILITY TO EVOLVE WITH THE TIMES WHILE STAYING TRUE TO ITS FOUNDING VISION: CIVILCAST.

Established in 2010 by civil construction veteran John McQuaid, Civilcast began with a clear mission: to deliver reliable, high-quality products to the civil construction and infrastructure sectors. Fifteen years on, that mission remains unchanged, but the scale, scope, and sophistication of the business have grown exponentially.

From humble beginnings, Civilcast has become a key player in the national infrastructure supply chain, serving major projects and contractors with a growing portfolio of precast standard and custommanufactured products.

The turning point came in 2018, when a consortium of private shareholders – bringing deep expertise in manufacturing and building product supply – acquired the business. What followed was a period of strategic growth and product diversification that has positioned Civilcast as a partner of choice for complex, large-scale infrastructure works.

Today, the company operates from a stateof-the-art manufacturing facility in Cowra, New South Wales, with a supporting logistics and warehouse hub in Erskine Park, and regional branches across Newcastle, Victoria, and Queensland. This national footprint enables Civilcast to supply and support critical infrastructure projects across the eastern seaboard and beyond.

CUSTOM SOLUTIONS FOR A CHANGING INDUSTRY

One of Civilcast’s defining strengths is its ability to adapt to the evolving needs of civil construction. The company’s investment in custom manufacturing capabilities has enabled it to take on high-spec, largescale precast works for major national infrastructure programs.

Projects like Western Sydney Airport, Snowy 2.0, Western Sydney Metro, and North Wellington Solar Farm are just some of the landmark developments that have benefited

Civilcast has grown into a respected provider of critical infrastructure components.

from Civilcast’s tailored approach. Beyond transport and utilities, the company is also supplying to data centres, substations, transmission infrastructure, and renewable energy projects, all of which are key growth areas in Australia’s infrastructure pipeline.

At the core of this adaptability is innovation. Civilcast has made continuous improvement a cornerstone of its growth, regularly updating its manufacturing processes and expanding its product range to stay ahead of industry trends. The recent launch of its Glass Reinforced Concrete (GRC) product line is one example, with another major product release planned for later this year.

CULTURE, SERVICE, AND THE CIVILCAST EDGE

While product innovation has propelled Civilcast forward, it’s the company’s team culture and service ethos that underpin its reputation in the industry. Civilcast fosters a collaborative, solutions-oriented environment, where every team member plays a role in ensuring projects are delivered smoothly, on time, and to specification.

“Customer service for us isn’t just about delivery,” Tina Griffiths, Civilcast Chief

Marketing Officer says. “It’s about being a genuine partner by understanding project requirements early, identifying risks, and delivering a seamless experience from design to install.”

That level of dedication has earned Civilcast a renowned reputation for service, especially in a market where supply chain reliability is more critical than ever.

LOOKING AHEAD:

BUILDING FOR THE LONG TERM

As Australia’s infrastructure needs continue to expand, driven by population growth, energy transition, and urban renewal, Civilcast is preparing for the future by staying customerled and innovation-driven. The leadership team remains focused on investing in product development, responding to feedback from clients, and scaling operations to meet emerging demand.

For Civilcast, every challenge is an opportunity to grow. With a strong foundation built on quality, reliability, innovation, and service, the company is well-positioned to remain a vital force in Australia’s civil construction landscape for years to come.

We know that every project demands strength, precision and reliability. That’s why leading contractors across Australia turn to us for precast solutions they can count on.

LARGE STOCKS

FAST LEAD TIMES

EXPERT ADVICE

CUSTOM SOLUTIONS

COASTAL PARADISE MAINTAINING A

SAMI BITUMEN TECHNOLOGIES’ SAMIFLOAT POLYMER MODIFIED EMULSION HAS ONCE AGAIN SURPASSED EXPECTATIONS, THIS TIME ASSISTING IN ROAD REHABILITATION WORKS IN A POPULAR COASTAL MUNICIPALITY. REPRESENTATIVES FROM SAMI, COLAS AND CENTRAL COAST COUNCIL EXPLAIN.

Central Coast Council in New South Wales is home to some of the state’s most iconic beachfronts and scenery, making it a highly frequented area by locals and tourists alike.

With many essential links and arterial roads – all exposed to coastal weather fronts – Central Coast Council is required to regularly maintain connections while reducing disruptions to traffic.

Just one of the challenges has been road surface flushing and bleeding on a number of roads located within the municipality. As such, Central Coast Council has been on the lookout for innovative solutions to support the delivery of taxpayer-led transport services.

A chance encounter at an industry event gave the council its first exposure to SAMI Bitumen Technologies products, with one product in particular standing out.

SAMIfloat, a polymer modified cationic high float emulsion, designed to have a viscous structure (thixotropic) that prevents the flow of residual binder.

With a higher softening point and elastic recovery, SAMIfloat can withstand higher traffic loads and harsher weather conditions.

Due to the gelly nature of the residue, SAMIfloat’s structure prevents bleeding or flushing at high temperatures and reduces aggregate loss at low temperatures.

Shortly after the industry event, SAMI began discussions with Matt Nazemi, Team Leader, Geotechnical and Pavements –Central Coast Council, to learn more about the municipality’s needs and challenges.

As Nazemi explains, a mixture of geographical and climate factors makes the long-term performance and application of conventional bitumen untenable.

“In the Central Coast we have many rural roads and highways that have dense tree cover and therefore shade, which makes curing more difficult, especially in the colder seasons,” he says.

“That’s why we identified SAMIfloat as a product of interest. Because its water based, we wouldn’t need to use cutters, oil or wait for its evaporation. Using environmentally

friendly SAMIfloat creates a durable seal that resists bitumen excessive flow in hot days and aggregates embedment. Therefore, it reduces the risk of foamed bitumen stabilised base layers’ softening and flushing at the surface by eliminating cutter oil and reducing curing time.

“A new seal design incorporating SAMIfloat, developed by the Central Coast Council’s Geotechnical and Pavement Team and in collaboration with COLAS resulted in a satisfactory project delivery.”

Hamidreza Sahebzamani, Research & Development, and Technical Support Manager – SAMI Bitumen Technologies, says close consultation with clients helps the company to determine the best course of action for application and longterm performance.

“The initial direct discussion between SAMI, as the main supplier, and the client, gives us the opportunity to hear their problems and focus so that we can customise a solution and provide appropriate technical support,” he says.

Images: SAMI

SAMIfloat has once again proved to be a sustainable alternative to conventional mix additives.

APPLICATION TIME

SECOND WORKS

Tumbi Umbi, a coastal township situated within the Central Coast Council, was identified as an ideal suburb to apply SAMIfloat.

The first of two applications took place late in 2024, at Palm Valley Road.

COLAS, the contractor engaged for the works, was tasked with sealing over foam bitumen stabilised pavements where traditional spray seals had failed due to flushing (where the hot binder had reacted negatively with the pavement, causing failures).

Andrew Carter-Meggatt, East Coast Regional Spray Seal Manager – COLAS, was appointed as the lead applicator.

“As SAMIfloat is cold, not hot, it doesn’t tend to activate the binder that’s in the road base; one of the reasons why it was so ideal for this three-to-four kilometre stretch of road,” he says.

SAMIfloat can be sprayed at lower temperatures, reducing energy consumption and making the process safer for both workers and the environment.

Roads treated with SAMIfloat also tend to have increased longevity, requiring less frequent repairs and reduced resource use over time.

“Central Coast Council is committed to implementing more sustainable solutions for its road network,” Carter-Meggatt says. “Moving forward, using SAMIfloat is a greener way for them to be more environmentally friendly.”

Nazemi says he and his team take pride in embracing sustainable and efficient products and processes where possible.

“Central Coast Council is always seeking sustainability and innovation within our pavement rehabilitation programs, which provide an opportunity to reduce potential defects in our network,” he says.

The success of the initial project paved the way for a second, which took place at Hansons Road, also within the suburb of Tumbi Umbi.

These works consisted of a reseal project over an existing pavement – a first for the team using the SAMIfloat product, which comprised a single coat application with 14-millimetre aggregate.

“We took the job on as an opportunity, knowing that it would present a challenge,” Carter-Meggatt says. “We’d never done anything like that with this product before.

“Traditionally, emulsions are placed in a double-coat seal treatment, just because you want to lock down that larger aggregate size. We went with a single coat, and it worked perfectly well, with no signs of stripping. SAMIfloat grabs hold of the aggregate quite well, and it’s got great stone retention.”

Proving to be effective in cold weather and high traffic, SAMIfloat’s performance characteristics were supported by consistent collaboration of all parties, which contributed to the success of both projects.

The project highlighted the importance of collaboration between the supplier, contractor and end client.

“From beginning to end, the collaboration was fantastic. Every party was open to listening and learning from other’s experiences and benefitting from that shared knowledge,” Nazemi says.

“There was great teamwork, with all parties on site, monitoring the construction stages. That filled us with confidence that we’d get the outcome we were after.”

For SAMI, the successful works mark the beginning of what could be a long-term partnership with Central Coast Council, as Sahebzamani explains.

“I’m thrilled and very happy that this connection has started,” he says. “I’m also happy for the whole industry, as this is yet another SAMI product that can contribute to the commitment of using more sustainable solutions, that also incorporate safety factors for people and the environment.

“At the end of the day, these projects with SAMIfloat have delivered whole-oflife savings in terms of cost and carbon emissions, while providing better roads for taxpayers as well.”

Central Coast Council is always looking for innovative products, like SAMIfloat.

Smarter Road Management with Konect.

LAST LINE OF DEFENCE

MERIDIAN IS PROVIDING THE FIRST AND FINAL LINE OF DEFENCE, WITH ITS PORTABLE VEHICLE BARRIERS HELPING TO IMPROVE THE SAFETY OF WORKERS ON FOOT AT ROAD AND INFRASTRUCTURE WORKS. GENERAL MANAGER PADDY CALVERT-JONES EXPLAINS.

It’s no secret that roadside worker safety continues to be a prevalent topic across the industry.

With fatal and serious incidents continuing to occur, industry is examining the use of new technologies and systems to reduce the risks associated with construction sites in and around live roadways.

It’s Paddy Calvert-Jones, General Manager, Australia, New Zealand – Meridian’s belief that the days of searching and waiting, are over.

Meridian engineers, manufactures, and distributes modular, mobile anti-vehicle barrier systems designed to protect crowds, workers, and infrastructure from hostile and errant vehicles.

Meridian’s mission is to enhance safety in roadwork sites, and critical infrastructure projects.

Meridian delivers this through a fully modular system called the Meridian Archer

Guard System also know as the MAG System. It entails three barriers that are linked together using specialised cables. Emergency access gates can also be implemented into a barrier line to provide controlled site entry and exit.

In road construction and infrastructure projects the system can be configured for hard closures on freeways, on/off ramps, bridges, and tunnels, providing protection for workers in both high-speed and urban environments.

Calvert-Jones says it’s addressing a prevalent issue in the sector.

“We call it a last line of defence. There’s no reason why you shouldn’t be using the

best possible equipment to keep your workers safe. There’s no other product out there that can do that on this level,” he says.

“We have systems that are used to protect hundreds of thousands of people at events. Why should they be more protected than a road worker on-site who’s got cars passing by at high speeds?”

Each barrier is manufactured in Australia, giving Meridian oversight and influence to ensure that each system is directly catered for domestic applications.

The modularity of Meridian’s offerings allows the system to be adapted to different site requirements, whether it’s protecting workers in open areas, creating safe zones in confined spaces, or providing flexible access points.

The barriers are also rapid-deployable and require no heavy machinery, making them easy to reconfigure and suitable for both temporary and long-term applications.

“All it takes is a single person. There’s no need for external power or heavy machinery, as it’s a mobile barriers system,”

Calvert-Jones says.

To further assist efficient setup, Meridian provides training, support and auditing to encourage proper use.

Calvert-Jones says this certified training includes where and how to deploy the barriers, including standard occupational health and safety (OHS) planning.

Safe deployment practices and movement

Whether it’s highway, roadside, or utility works, Meridian’s barriers ensure that workers are kept safe.

All of Meridian’s barriers are crash tested at a variety of speeds.

“WE CALL IT A LAST LINE OF DEFENCE. THERE’S NO REASON WHY YOU SHOULDN’T BE USING THE BEST POSSIBLE EQUIPMENT TO KEEP YOUR WORKERS SAFE.

of barriers are also covered in a training program, which can be customised to suit customer or project needs. Meridian also offers follow-up training service when required.

“We stay very close to all of our customers to make sure that they’re deploying the equipment correctly,” Calvert-Jones says.

Each of these barriers have been crash tested in more than 20 different scenarios, at speeds ranging from 50 to 100 kilometres per hour, and passed MASH (Manual for Assessing Safety Hardware) Test Level One, Two and Three, a recognised and significant benchmark for roadside safety devices.

The success is no surprise to CalvertJones – each barrier is made with

Meridian’s advanced kinetic absorption technology, designed to be non-lethal, and reusable after impact. All backed by a lifetime warranty.

With a focus on innovation, customer collaboration, and continuous improvement, Meridian is set to make a significant impact as it pursues key certifications and expansion across Australia.

“We provide the fastest stopping product in its class,” Calvert-Jones says. “Having these units on site would be a genuine game changer for any operation.”

Meridian’s barriers are of a modular design, allowing for customisation depending on the application.

FROM FLOOD TO FORCE

IN ITS SHORT THREE YEARS OF OPERATION, ROADAID HAS MADE ITS MARK IN PROVIDING MAINTENANCE AND OPERATIONAL SUPPORT FOR ROADS AND TUNNELS ACROSS THE COUNTRY.

RoadAid is redefining the standard for road and tunnel maintenance across Australia’s transport infrastructure.

Since its origins in 2022, the company has rapidly grown into a trusted name for highrisk and high-compliance environments, offering end-to-end services that range from planned closures and emergency response to skilled labour supply and operational consulting.

Founded by an industry veteran, RoadAid emerged successful from a moment of crisis that became an opportunity for transformation.

In the wake of Brisbane’s devastating floods, which submerged the Breakfast Creek Tunnel and caused widespread infrastructure damage, Chris Couldrey, Director and Founder of RoadAid saw not just a challenge, but a chance to build something different.

“At that point I had spent over a decade with Transurban Operations,” Couldrey recalls.

“When I thought about starting my own business, I knew I wanted to bring a fresh approach to tunnel operations and maintenance, one that focused on people, safety, and delivering reliable service every time.”

Restoring Breakfast Creek Tunnel became a pivotal project in the history and foundation of RoadAid.

With water damage taking out key systems, from traffic monitoring to pump operations, Couldrey and a small team

spent seven months on-site, assisting with critical repairs works in the tunnel and proving their capability to clients and contractors alike. It wasn’t long before the word spread.

Since the early days, RoadAid has now grown into a multi-state operation delivering specialist maintenance and labour hire services across Queensland, Victoria, and New South Wales, with ambitions to expand further.

PEOPLE FIRST

One of the first team members to come onboard was David Lightfoot, Service Delivery Coordinator Queensland for RoadAid.

Lightfoot joined RoadAid as a 40-year industry veteran and as a ground crew member on the Breakfast Creek Tunnel remediation works.

Today, Lightfoot leads the company’s Queensland operations.

“While Chris manages from the office, I enjoy being the person on the ground, building connections with the work and the team,” he says.

“I stayed because of the culture. From day one, the values were clear, this company was built the right way.”

RoadAid’s values are embedded in every aspect of its work.

Its acronym S.H.I.R.T. stands for Safety, Honesty, Integrity, Respect, Teamwork, which Lightfoot says is more than just a slogan.

“It is really a framework for how we operate as a team,” says Lightfoot.

RoadAid deploys a pink vest to increase clarity and visibility for key personnel on site.

Chris Couldrey, Director and Founder of RoadAid.

“These values are imprinted in the business to ensure our workers are happy and align with our values.”

From learning modules to leadership decisions, everything filters through these principles.

“Our goal is to create a workplace where people genuinely want to show up each day and we do that by giving them the right tools, a strong support system, and a clear purpose,” says Lightfoot.

“Something that makes them want to get out of bed in the morning and come back with energy.”

Couldrey says he wanted to foster a culture which cares about getting the job done on time and safely.

“Our people are our greatest product. I believe that when you invest time and effort into your team, it creates a culture of pride and professionalism that is reflected in the quality of service we deliver every day” he says.

To that end, RoadAid has invested heavily in workforce development.

Through its Learning Management System (LMS), team members complete tailored training when joining the team, including a custom “Tunnel 101” module designed by Couldrey himself.

The module system is designed to equip every staff member with deep knowledge of tunnel systems including how they’re built, common devices and their purpose, and how those devices are designed to work.

“After using the LMS, workers arrive on site ready, confident, informed, and aligned with RoadAid’s standards,” he says.

SAFETY

IS KEY

Innovation, safety and practicality go hand-in-hand at RoadAid. Recognising a gap in worksite clarity, Couldrey introduced the use of pink vests to be used for plant and confined space safety observers (or spotter).

“The pink vests highlight who the safety representative is on site, so when someone walks onto a site, they immediately know who to go to,” he says.

“It enhances communication and ensures a safer environment for everyone, it is simple but very effective and has been praised many times by safety officers on multiple projects.”

In addition to the pink vest, every RoadAid vehicle is equipped with defibrillators and full first-aid kits,

underlining the company’s commitment to rapid response, proactive health and safety management.

“We want to be prepared for the unlikely event where if something happens and we need it close by, we are ready to go,” he says.

The company’s reward and recognition program further supports a culture of ownership and mutual respect. During which team members are encouraged to nominate their peers who go above and beyond on the job, reinforcing the idea that at RoadAid everyone contributes to success, not just upper management.

“It reinforces our mission to always work as a team,” reflects Couldrey.

“We are one team, we work together to get the job done and we all support each other to achieve our goals.”

For Couldrey, that’s the ultimate source of pride.

“I started this company alone,” he says.

“Now we’re a national team making a real impact, thanks to our incredible state leaders,people and culture manager, and the account team who make it all possible.”

From a single flood-ravaged tunnel to a national infrastructure partner, RoadAid has grown steadily and deliberately.

Today, RoadAid is recognised as a trusted partner in road and tunnel infrastructure, supporting asset owners and maintenance principles with reliable maintenance support. They have secured contracts on

major projects including Airport Link Tunnel, CityLink, North East Link, and other critical infrastructure across Australia’s east coast.

“We’ve relied heavily on word-of-mouth, and we believe we are progressing in the right direction,” Couldrey says.

Looking ahead, the company is set to expand its maintenance division into new markets, including South Australia, Tasmania, and Western Australia, while further extending the reach of its road operations consultancy services.

Couldrey also envisions a broader role in the transport industry, not just as a service provider, but as a collaborative partner.

“We are aiming to build relationships with key stakeholders across the industry and create a collaborative platform where we can bring together transport sectors across road, rail, operations, and maintenance, to openly discuss shared challenges, best practices, and future improvements,” he says.

“We will continue to collaborate with local partners because we know we can add value, not just to their operations, but to their clients also.”

This collaborative spirit reflects RoadAid’s commitment to progress, not just for itself, but for the industry as a whole.

As RoadAid continues to expand and evolve, one thing is clear: this is a company built not just to serve the infrastructure of today, but also to help shape the roads and the workforce of tomorrow.”

RoadAid has grown from humble beginnings to become a well-known name in

Images:

the sector.

THE PATH TO NET-ZERO

AS

THE GLOBAL

PUSH TOWARD

NET-ZERO ACCELERATES, SRIPATH® IS AMONG THOSE LEADING THE CHARGE IN THE ASPHALT INDUSTRY WITH SUSTAINABLE, HIGH-PERFORMANCE ADDITIVES DESIGNED TO REDUCE EMISSIONS, EXTEND PAVEMENT LIFE, AND SUPPORT A CIRCULAR ECONOMY.

In a rapidly evolving world, Sripath exemplifies what it means to innovate with purpose.

Across industries and around the globe, from energy to construction, environmental responsibility is reshaping how companies operate, design, and deliver. The paving and road construction sector is no exception – sustainability now influences materials selection, mix design, production, and business operations.

With over 107 countries, including Australia, committing to net-zero emissions by mid-century, the pressure is on to rethink materials, technologies, and lifecycle performance.

The Federal Government’s Net Zero Plan is just one such example, targeting greenhouse gas neutrality by 2050.

In this context, Sripath stands out as a company that has embedded sustainability into the very fabric of its operations.

“Sustainability for us has long been a huge part of our DNA, our vision, and our mission,” says Dr. Deepak Madan, Chief Operating Officer at Sripath Technologies.

“We integrate sustainability principles from the outset of our product design process, carefully selecting sources and ingredients that are more environmentally friendly and have a lower carbon footprint.

“Similarly, we choose manufacturing methods that minimise environmental impact and reduce carbon emissions.”

Through a science-driven approach, Sripath develops high-performance additives that help asphalt contractors and agencies reduce carbon footprints and deliver desired performance.

PRODUCT PORTFOLIO

Sripath’s product portfolio is purpose-built to tackle key environmental challenges in asphalt paving by reducing carbon emissions, excessive virgin material usage, and

premature pavement failure.

Through a combination of science-backed additives, rigorous lifecycle assessments, and region-specific collaboration, Sripath is helping the asphalt industry shift toward a more sustainable, resilient future using products like ReLIXER®, PHALANX® and PGXpand®.

ReLIXER is a Bio-Oil Rejuvenator used for High-RAP (Recycled Asphalt Pavement) Mixes, specifically designed to restore the functionality of the aged binder in RAP.

One of the biggest hurdles to increased use of RAP is the aged RAP binder, which can limit workability and performance.

A notable case study comes from Queensland where the Australian Flexible Pavement Association (AfPA) led a rehabilitation project using mixes with up to 40 per cent RAP. ReLIXER outperformed other rejuvenators in fracture toughness and ageing resistance. Laid as a wear course on a quarry road in Gaven, Queensland, the trial clearly demonstrated the product’s field viability.

From an environmental perspective, ReLIXER delivers renewable raw materials and carbon sequestration benefits, allows for reuse and recycling of higher levels of reclaimed pavements, makes a high-RAP mix easy to pave, and delivers desired roadway performance and durability.

Dr. Krishna Srinivasan, President of Sripath

Technologies says the development of advanced asphalt additives aid the asphalt industry in delivering pavements that perform better while aligning with global sustainability goals.

“Bio-oil based rejuvenators like ReLIXER enable the use of higher levels of RAP and reduce the reliance on virgin materials. Our innovative warm mix technology, PHALANX, helps lower the energy demand and emissions, both during mix production and paving operation,” he says.

“By focusing our innovation on these practical, high-impact solutions, we can help contractors and agencies achieve measurable progress toward net zero while ensuring long-term roadway performance.”

Another avenue for decarbonising paving operations lies in reducing the heat and energy required during asphalt production and compaction. With heating responsible for roughly 80 per cent of constructionphase energy use and emissions, the right Warm Mix Additive (WMA) technology can offer considerable savings.

Sripath’s warm mix additive, PHALANX, is highly dosage efficient and is designed to lower mix production and paving temperatures, enabling temperature

Above: Sripath’s Environmental Product Declarations (EPDs) are helping to increase the transparency of performance and sustainability levels.

Image: Sripath

reductions of up to 30 degrees Celsius (°C), significantly cutting energy consumption and emissions.

In a Queensland field trial using M1000 binder, a small dosage of 0.25 per cent PHALANX delivered a mix production and paving temperatures of 136°C and 120°C, respectively. In comparison, conventional mix production and paving temperatures were at 163°C and 150°C, respectively.

Sripath’s next-generation polymeric additive, PGXpand, has been designed to solve the challenge of pavement distress, such as rutting, cracking or fatigue, which result in more frequent road repairs and higher levels of lifecycle emissions.

Ravi Rajagopalan, General Manager, Sripath Asia-Pac, says that Sripath customers are looking for solutions that are both practical and measurable.

“Sustainable additives like bio-based rejuvenators, warm mix technologies, and advanced polymers give our customers a way to lower emissions without sacrificing performance,” he says.

every step of the product lifecycle.”

“We recognise that sustainable solutions aren’t always possible in every situation, but wherever we can, we aim to make a meaningful difference. These considerations are deeply integrated into our product development and manufacturing processes.”

“It’s about delivering materials that work in the field today while supporting the industry’s long-term carbon reduction goals.”

According to Steve Halligan of Road Surfacing Solutions, “It is important for us to find the right blend of both focusing on sustainability and delivering desired roadway performance.”

“Results show Sripath products can deliver both performance and sustainability, helping the industry move toward net-zero.”

ENVIRONMENTAL PRODUCT DECLARATIONS

Sripath’s Environmental Product Declarations (EPDs) further highlight its commitment to transparency and continuous improvement.

The company has invested in conducting EPD’s for its core products, offering independent, third party-verified data on environmental impacts from cradle to gate for its products.

“As part of our EPD journey, we took a close look at our technologies, manufacturing processes, and overall operations to identify areas for improvement, and we’ve been actively working to implement those changes,” says Madan.

“We’re focused on increasing the use of recycled materials, sourcing more sustainable and lower carbon-impact materials, incorporating more sustainable energy sources, and making conscious choices at

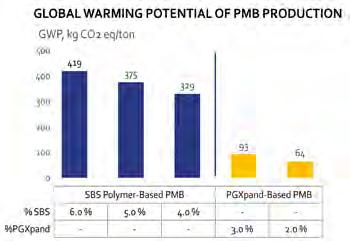

As an example, Sripath’s bitumen-friendly polymeric additive PGXpand, has a Global Warming Potential (GWP) value of 2.95 kilograms (kg) of CO2 (carbon dioxide) eq / kg (kilograms of carbon dioxide equivalent) PGXpand. In comparison, the GWP value of a traditional elastomeric polymer is typically reported to be around 4.5 kg CO2 eq / kg polymer.

During the production of a Polymer Modified Bitumen (PMB) based on an elastomeric polymer, such as a PMB with 5 per cent SBS (Styrene-Butadiene-Styrene), the process has an estimated GWP value of 375 kg CO2 eq per tonne.

A PMB produced using 2.0 per cent PGXpand delivers the performance equivalent to the 5 per cent SBS based PMB, but with PGXpand, the PMB operation generates considerably lower levels of carbon dioxide emissions, as is evident by its significantly lower GWP value of 64 kg CO2 eq / tonne PMB. Thus, by using PGXpandbased PMB, an 83 per cent reduction in GWP can be achieved.

Jill McConaghie, Marketing Specialist at Sripath, says Sripath is helping to bridge the knowledge gap in the industry by advocating knowledge sharing and promoting educational seminars or webinars showcasing its sustainable additives.

“There’s growing advocacy for solutions like high RAP or warm mix asphalt,” she says.

“But some jurisdictions remain hesitant, often due to a lack of awareness or comfort with these technologies.

“At Sripath we believe in sharing our

Above: Clear performance improvements can be seen when Sripath’s additives are deployed.

knowledge, explaining the science and the data behind our products, and demonstrating that our products and technologies are no longer ‘new’, but have been tested, proven and trusted by our customers worldwide.”

LOOKING AHEAD

Rajagopalan says Sripath’s focus remains on expanding the reach of its products in the Australian market.

“That’s why we’ve established a strong presence here. We believe the Australian economy is positioned for growth,” he says.

“Like any evolving market, there are shortterm challenges, but we’re confident that in the long-term, Australia’s economy and paving industry will grow.”

Sripath currently have a robust pipeline of products in development.

“Some are expected to launch within the next six months, while others are scheduled for release over the next one to three years,” he adds. “Our innovation strategy always includes a mix of short-, mid-, and long-term projects, all designed with sustainability at the core.”

With Sripath leading the charge, the road to net zero is not just possible, it’s already being paved.

Image:

Sripath

Sripath is helping the sector as a whole to improve its sustainability performance and legacy.

WHERE SAFETY MEETS SUSTAINABILITY

WITH OVER 30 YEARS OF EXPERIENCE IN COMMERCIAL VEHICLE SYSTEMS, DR AIR BRAKE HAS DEVELOPED A REVOLUTIONARY TWO-PRONGED APPROACH THAT IS DELIVERING MEASURABLE ENVIRONMENTAL BENEFITS ALONGSIDE DRAMATIC SAFETY IMPROVEMENTS.

As the transport and road construction sector races towards net-zero targets, fleet operators face a critical challenge: reducing emissions without sacrificing safety, productivity, or profitability.

For many, the solution lies not just in electric vehicles or alternative fuels, but in the intelligent application of proven technology that’s already available today.

For Dr Air Brake, this presents a unique opportunity to provide transformative solutions, geared towards not only increasing safety, but also sustainability.

Providing a full range of braking and electronic diagnostics – and as the company’s name suggest, heavy duty air brake systems – Dr Air Brake’s comprehensive solution combines awardwinning workshop diagnostic tools with cutting-edge driver safety technology, creating a sustainability framework that proves environmental responsibility, and profitability can go hand in hand.

This focus is echoed in the company’s approach to product development and distribution worldwide. Despite being based in the United Kingdom, Dr Air Brake has a Sydney depot that was opened in 2009 and has since provided Australian operators with solutions tailored to the unique mix of European and North American equipment.

THE KEY TO FLEET SUSTAINABILITY

When Dr Air Brake analysed workshop operations across a typical 50-trailer fleet in the United Kingdom, the results were “staggering”.

Its integrated diagnostic tools, such as Code Talk II, Mobile Trailer Check (VTC), Trailer Check, and Test-a-Tow, generated annual savings exceeding $100,000. But dig deeper, and these aren’t just cost savings; they represent a fundamental shift towards sustainable fleet management

So, what are Code Talk II, Mobile Trailer Check (VTC), Trailer Check, and Test-a-Tow?

Code Talk II has transformed trailer diagnostics from educated guesswork into a precision instrument that’s simple to use. This compact hand-held unit communicates directly with WABCO (Westinghouse Air Brake Company), Knorr-Bremse, and Haldex systems, reading fault codes and live data without the need for laptops, dongles, or ongoing software subscriptions.

For sustainability-conscious operators, this technology reduces travel for diagnostic consultations, cuts return visits through accurate first-time diagnosis and minimises parts waste by enabling targeted repairs rather than component swapping.

The Mobile Trailer Check represents perhaps the most dramatic efficiency breakthrough, enabling single-person brake testing and revolutionising workshop productivity. This innovation cuts technician requirements by 50 per cent per test while eliminating the need to move tractor units around the yard during testing procedures.

per test, but multiply across hundreds of annual inspections and the environmental impact becomes significant.

Trailer Check takes a comprehensive approach to electrical circuit testing, identifying potential failures before they cause roadside breakdowns. This proactive capability prevents the emissions associated with emergency callouts, improves MOT(Maintenance of traffic) first-time pass rates to eliminate re-test journeys, and catches energy-wasting electrical inefficiencies before they impact fuel consumption.

Meanwhile, Test-a-Tow enables trailer circuit validation without requiring a tractor unit, reducing vehicle movements, enabling on-site verification, and dramatically accelerating turnaround times.

The environmental mathematics are compelling. Faster diagnostics mean trailers spend dramatically less time stationary with engines idling while technicians troubleshoot problems. As Jeff Lowe, Managing Director of Dr Air Brake explains.

Dr Air Brake has emerged as a preferred provider of innovative braking and safety systems.

“Our technology isn’t just about safety, it’s about smarter vehicle use, longer asset life, and achieving environmental targets. It’s a small change with transformative impact across every aspect of fleet operations,” Lowe says.

One-person brake testing eliminates the need for multiple vehicles during maintenance procedures, while improved first-time fix rates slash the number of repeated journeys between depots and workshops. The cumulative effect represents thousands of litres of fuel saved and tonnes of carbon dioxide prevented from entering the atmosphere.

Equally important is how precision diagnostics extend asset lifespans by preventing minor issues from becoming catastrophic failures. Better maintenance quality keeps trailers operational for longer, reducing the frequency of premature replacements and the enormous, embedded carbon footprint that comes with manufacturing new vehicles.

In an industry where a single trailer represents tens of thousands of pounds of manufacturing emissions, keeping existing assets road-worthy for longer delivers sustainability benefits that compound year after year. Dr Air Brake’s Reverse Smart automatic braking system is just one breakthrough that demonstrates how safety technology can deliver unexpected environmental dividends.

This intelligent system uses advanced

extend far beyond accident prevention into measurable sustainability improvements. Fewer collisions mean fewer repair jobs requiring new parts, extended vehicle operational life, and reduced insurance claims with their associated administrative carbon footprint. The company has reported zero reversing incidents since installation, alongside lower fuel consumption and enhanced driver confidence that translates into more

per 50-trailer fleet, up to 17 per cent reduction in idling fuel consumption through using Doctor Air Brake Mobile Trailer Check and Code Talk improving fleet uptime, longevity, and compliance that reduces operational risk and enhances competitive positioning.

These figures demonstrate that environmental progress doesn’t require financial sacrifice, it can actively enhance profitability.

For operators serious about reducing their environmental footprint without compromising safety, productivity, or profitability, Dr Air Brake offers a proven pathway that thousands of vehicles are already following.

Its integrated approach demonstrates that sustainability leadership requires neither revolutionary technology nor massive capital investment, just intelligent application of proven solutions that deliver measurable results.

The evidence is clear: workshop efficiency and driver safety technology can work together to create a sustainability multiplier effect that benefits operators, drivers, communities, and the environment. In an industry where every litre of fuel and every day of vehicle operational life matters, Dr Air Brake’s comprehensive solution represents the practical future of sustainable fleet management.

Visit www.air-brake.com to learn more.

Images:

Dr Air Brake

The company’s motto of ‘braking into the future’ reflects its commitment to delivering innovative solutions that will perform for years to come.

Customers can reap both sustainability and safety benefits from Dr Air Brake’s implementations.

BINDER SPRAYERS - CHIP SPREADERS

SYNCHRONEOUS SPRAYER SPRADERS MELTERS - PATCHERS

BEYOND THE BITUMEN: TRANSFORMING COUNCIL ASSET MANAGEMENT

ASSET VISION’S MOVE INTO THE COUNCIL MARKET HAS BEEN NOTHING SHORT OF TRANSFORMATIVE. IN JUST THE PAST FIVE MONTHS, EIGHT COUNCILS HAVE COME ON BOARD, A POWERFUL ENDORSEMENT OF THE PLATFORM’S ABILITY TO SIMPLIFY, STREAMLINE AND STRENGTHEN ASSET MANAGEMENT.

Asset Vision’s history is rooted in supporting more efficient, safer and sustainable road maintenance outcomes.

For years, major road and transport agencies have entrusted the platform to collate data and information that can be actively used to deliver improved transport asset portfolio results.

Now the company is looking to take on new horizons, by supporting municipalities in their asset management quests.

As Marius Dragan, Client Delivery Manager –Asset Vison explains, the company’s focus on the council market was a natural evolution.

“When we initially started, the platform was more built towards linear assets and linear asset inspection,” he says. “So obviously, roads were the main asset type that we focused on initially, and then, with identifying certain opportunities in the market, we moved into other verticals.

“We had some clients using it for buildings, some clients using it for water, open spaces and so on, and when you think about it, the council segment is an amalgamation of all those different asset types.”

Asset Vision’s platform provides a comprehensive, end-to-end solution for asset management, particularly suited for councils

and organisations managing diverse and complex asset portfolios.

Its applicability across a vast range of assets allows the platform to cater to the entire asset lifecycle, from acquisition and maintenance to operations, disposal, and overall financial management. This is delivered through built-in reports for asset condition, financials, and compliance, reducing reliance on external tools, therefore, offering a centralised and streamlined method of asset management.

“There’s obviously increasing pressure for councils around budgets and compliance, as well as increased community and ratepayer expectations,” Dragan says. “We’ve got a solution that’s able to be introduced easily and is applicable and flexible across all asset types.”

It was this versatility that caught the eye of the City of Greater Dandenong last year.

“I met the Asset Vision team at the 2024 Municipal Works Australia Conference in Bendigo,” says Arran Gray, Team Leader, Civil Maintenance – City of Greater Dandenong. “At the time, I was looking for future-proof solutions regarding work management, as well as streamlining our processes and efficiencies.”

After learning more about the platform and meeting with Asset Vision’s existing clients, Gray says Asset Vision’s platform looked like a promising tool to add to Council’s arsenal, and

Above: City of Greater Dandenong has benefited from the ability to assign and manage jobs in real time.

they started a trial as an interim deployment to accelerate benefits while longer-term options were assessed.

“It’s been a fantastic journey working closely with the Asset Vision team to bring this project to life. From day one we were aligned on our goals of improving visibility, control, and efficiency across our works maintenance operations. To see it all come together in just 10 weeks is a true credit to the collaboration, dedication, and professionalism on both sides.”

LOCAL SOLUTIONS FOR LOCAL GOVERNMENT

Situated 35 kilometres southeast of Melbourne’s CBD, the City of Greater Dandenong extends across 129 square kilometres, with a population of 167,000 people.

According to the Victorian Government, this municipality is the most culturally diverse in Australia, with residents originating from more than 150 different birthplaces. The region is also one of the fastest-growing areas in Melbourne.

City of Greater Dandenong’s main use of

Images: Asset Vision

the Asset Vision platform includes planning and scheduling maintenance and operational works, as well as assigning and managing jobs for field and office staff – the majority of which consists of proactive and reactive asset inspections. As an interim solution, this configuration prioritises operational uplift and reliable service delivery to the community.

One of the biggest perks so far has been the ability to create custom roles and allocate work to roles instead of individuals.

Gray says sign maintenance is just one segment that has benefited from this capability.

“We’ve got one person who does all the allocation. That person will allocate all the relevant work to the sign maintenance team, then the team leader will see ‘right, there’s x number of jobs here, I’ll put these staff members on them’,” he says.

“The team on the ground can then log in and see the work they’ve been assigned. A lot of other systems make you allocate to a person. But if they’re not working that day, or something changes, you need to ‘unallocate’, reallocate – a lot of work is involved in that.