Wettenhalls Making History

INDUSTRY

Fleet: CTI Logistics

Showcase:

INNOVATION

Carrier: Dardania Logistics

Feature: Polyfoam

Tow Trucks: RAA

Test Drive: DAF CF B-double tipper

The all-new Isuzu truck range. Reliability redefined.

The all-new range of Isuzu trucks has arrived. With a sleek new cab design, more advanced safety features and a smoother, more comfortable drive, the new range will change the way we rely on our trucks. Forever.

To find out more, visit your nearest Isuzu Trucks Dealer or visit isuzu.com.au

MEET THE TEAM

Christine Clancy | CEO

With more than two decades of experience as a media professional, Christine has worked in newsrooms across Canada, Vietnam and Australia. She joined the Prime Creative Media team 12 years ago, and today oversees more than 43 titles, including a dozen print and digital transportation titles. She continues to lead a team that focuses on continuous improvement to deliver quality insights that helps the commercial road transport industry grow.

William Craske | Editor

As the Editor of Prime Mover magazine since 2018 William has reported on the commercial road freight and logistics segments extensively. During that time he has been privileged to lead a team entrusted with covering the latest developments in trucks, transport, technology and the rapidly evolving domain of international supply chains and the role of leading Australian eets.

Peter Shields | Senior Feature Writer

A seasoned transport industry professional, Peter has spent more than a decade in the media industry. Starting out as a heavy vehicle mechanic, he managed a fuel tanker eet and held a range of senior marketing and management positions in the oil and chemicals industry before becoming a nationally acclaimed transport journalist.

Sean Gustini | Journalist

Australia’s leading truck magazine, Prime Mover, continues to invest more in its products and showcases a deep pool of editorial talent with a unique mix of experience and knowledge. www.primemovermag.com.au

Having completed a Bachelor of Arts majoring in Media and Communications at the University of Melbourne in 2024, Sean looks forward to bringing his passion for writing and journalism to the road freight and transport industries. He previously lived in the Philippines, Vietnam, Indonesia and Malaysia. In his downtime he enjoys playing the guitar and running.

Ashley Blachford | Business Development Manager

Handling placements for Prime Mover magazine, Ashley has a unique perspective on the world of truck building both domestically and internationally. Focused on delivering the best results for advertisers, Ashley works closely with the editorial team to ensure the best integration of brand messaging across both print and digital platforms.

CEO Christine Clancy christine.clancy@primecreative.com.au

Editor William Craske william.craske@primecreative.com.au

Managing Editor, Luke Applebee Transport Group luke.applebee@primecreative.com.au

Senior Feature Peter Shields Writer peter.shields@primecreative.com.au

Business Ashley Blachford Development ashley.blachford@primecreative.com.au Manager 0425 699 819

Art Director Blake Storey blake.storey@primecreative.com.au

Design Jacqueline Buckmaster, Danielle Harris

Contributors Sean Gustini sean.gustini@primecreative.com.au

Client Success Ben Sammartino Manager ben sammartino@primecreative.com.au

Head Of ce 379 Docklands Drive, Docklands VIC 3008 info@primecreative.com.au

Subscriptions

03 9690 8766 subscriptions@primecreative.com.au

Prime Mover magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher.

Annual rates: AUS $110.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

PRIME MOVER magazine is owned and published by Prime Creative Media.

All material in PRIME MOVER magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in PRIME MOVER magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

MAN delivers the powerful performance you expect with the superior support you deserve.

POWERFUL PERFORMANCE,

SUPERIOR SUPPORT.

Scan the QR code Up to 5 year, 1,000,000km driveline warranty Up to 4 year, 800,000km entire vehicle warranty

Subvented contract maintenance packages available

Available to the Australian market, this offer ends on 31 December 2025 and applies to select trucks. Terms and conditions apply.

42 38

COVER STORY

“In that market there are a lot of blue chip players. Once you start working with some of those on innovative solutions the opportunities just snowball.”

Prime Feature STORIES CORNERING THE MARKET 30

FLEET

FOCUS

24 Making History

Wettenhalls this year celebrates a rich 100-year history, but as a generational enterprise it has an unwavering understanding of where it wants to be in the future.

30 Cornering the Market

Sydney-based Dardania Logistics continues to optimise its truck fleet with new prime movers from MAN as it celebrates its 30th anniversary this year.

34 Light and Easy

Transporting the lightest of loads has its own set of challenges as evidenced by manufacturer Polyfoam.

38 Bread and Butter

Last year CTI Logistics went looking for an OEM partner that was able to provide reliable, versatile trucks to stand up to the tasks of its metro operations in Perth. It found one in DAF.

TRUCK & TECH

42 Three’s Company

Plumbers’ Co-Op’s interstate value proposition has recently been strengthened with the delivery of six new Fuso Canters this year, with the help of Sydney Truck Machinery.

58 Quiet Achiever

The versatility of the DAF CF makes it suitable for many applications in addition to typical linehaul work.

William Craske Editor

Last week I learned of an aviation charter specialist that has the unique capability to manage high-value falcon movements for Middle Eastern royal families and VIP clients. Somewhere in the skies right now, as falconry season ramps up, a royal is having their prized bird own back home, on a private jet likely in a passenger seat. The falcon, oddly enough, will remain hooded throughout the journey to ensure they are calm and comfortable. It’s standard practice, if I’m reliably informed, in falcon transportation.

More often than not in transport the priority is to prevent the animals boarding. Shippers, landside operators and customs brokers ready themselves annually in Australia for another season, certainly less festive than it sounds, dedicated this time to stink bugs.

The Brown Marmorated Stink Bug, as it is less endearingly named, prefers to stowaway in imported goods or within packing spaces. The smell it emits, mainly as a defence mechanism is not, despite its name, the main threat it poses. If established, stink bugs would eat crops, destroy plants, not

First Class Freight

to mention become a likely nuisance in homes and buildings. Cross border transport is subject to strict regulations regarding invasive species and the carriage of certain foods and products that might conceal something with the potential to cause ecological harm. In the world of international trade, freight vessels are sought out routinely by a litany of undesirables looking to hitch a ride. Containers being an obvious one.

Whatcom County earlier this year was the site of a truck accident in which 14 million pollinating bees were set free after a truck rolled over.

The overturned truck was carrying an estimated 70,000 pounds of honeybee hives, which contained live bees. More than two dozen beekeepers responded to the site where hive boxes from the overturned truck were recovered, restored and returned to use. The bees eventually found their queen bee and re-hived. Interestingly enough, for the past ve years teams in Washington State have been eradicating invasive murder hornets. The insects — more formally known as northern giant hornets — pose a signi cant threat to honeybees and other native insects in the Paci c Northwest. They can kill an entire hive in as little as 90 minutes by decapitating the bees. They were rst spotted in British Columbia, Canada in August 2019 and con rmed in Washington in December of that year. The general consensus is they most likely arrived on commercial

shipping containers

The Australian Fumigation Accreditation Scheme (AFAS) is a bilateral arrangement between the Australian Department of Agriculture, Fisheries and Forestry and participating overseas government agencies. AFAS manages the high biosecurity risk posed by ineffective treatments performed offshore on associated packaging for quarantine and pre-shipment purposes. A registry is in place for accredited pre-border biosecurity treatment providers. These will specialise in heat treatment methodologies, methyl bromide fumigation, controlled atmosphere treatment, sulfuryl uoride fumigation, ethyl formate fumigation, insecticide treatments in addition to a host of other applications. WorkSafe Victoria has two health and safety solutions in place just for the clearance of methyl bromide and venting prior to unpacking primarily for the safety of the end-user.

Christmas, especially for many young families this year will come, at some stage, on a container. It calls to mind a comic moment in Barfly when Mickey Rourke is asked about his previous employment at a toy factory: “You don’t know how men suffer for children.”

> Wightman Transport adds four Kenworth K220s

South Australian refrigerated linehaul specialist, Wightman Transport has landed the first two Kenworth K220s of an order of four.

The first pair of day cab units have been active in the fleet on a new contract running between Adelaide and Melbourne. Wightman Transport Business Development Manager Josh Starke said the K220s were able to meet some of the changes tasked of the fleet on a new contract with potential for even longer trips to New South Wales and Queensland.

“The Kenworth K220 is better suited to the latest developments in our workflow,” he told Prime Mover “For this linehaul run we had to have a more fuel and better fuel consumption.”

The Kenworth K220s are powered by a Euro 5 emissions compliant Cummins X15 producing up to 550horsepower and 1850 lb/ft. This incorporates an 18-speed automated manual transmission which feeds a set of Meritor axles and differentials specified at a 4:3 ratio. With a few months under their belt the drivers have had a solid period in which to evaluate the new Kenworths according to Starke.

“The trucks are going great, and the drivers absolutely love them,” he said. These two new K220s are 114-tonnerated. All four units feature the retrofit advanced driver assistance Bendix Fusion system.

The fitment of Advanced Emergency Braking (ABE) to most heavy vehicles over 3.5 tonnes Gross Vehicle Mass (GVM) is now required by law, specifically ADR 97/100. ABE detects probable forward collisions, alerting drivers, and automatically applies the brakes if the driver does not respond. With nose-to-tail collisions the second-most common type of accident involving trucks after rollovers, the Bendix Fusion system is now considered essential.

“All of our customers want it and it’s something we need,” said Starke. “Safety is at the forefront of what we do, and having systems that optimise our operational safety certainly helps with future contracts and customers.”

Bendix Fusion also includes Enhanced Autonomous Emergency Braking, Enhanced Stationary Vehicle Braking, Multi-Lane Autonomous Emergency Braking, and Highway Departure Warning and Braking.

The other two Kenworth K220s due soon for delivery in the fleet are big cabs fitted with bullbars.

These units are destined for long haul into New South Wales and Queensland return.

Wightman Transport had its 60th anniversary last year. Starke’s grandfather, Doug Wightman was instrumental in helping build the company. His son-in-law Peter Starke, became Managing Director in 2010.

The 1980s was a particularly fertile period for the business in which it saw significant growth.

Some of its success was initially sustained on the back of a Mitsubishi Fuso that did everything from local PUD in Adelaide to trips across the Nullarbor to Perth.

That Fuso had a red underside trim that the newest Kenworths, as part of a tribute to its legacy, display via a striking dragonfly red vinyl wrap.

South Australian family business Panagraphix supplied the signwriting and design.

“It was something that caught my eye and I thought it would be good to get away this time from having all white,” said Starke. “We’re happy to support a local business doing great work.”

One of the new Kenworth K220 B-doubles.

THE POWER OF PROVEN TECHNOLOGY.

THAT’S ANOTHER HINO

HINO QUALITY MEETS TOYOTA TECHNOLOGY.

The Hino 300 Series Hybrid Electric utilises a parallel diesel electric hybrid driveline design, powered by Toyota Group technology proven in over 15 million hybrid vehicles worldwide. With maximum torque generated at low rpm, real-world tests prove up to 22%* fuel savings and emissions reductions. Leading the way with low-emissions, there are no recharge requirements or range limitations. Fully backed by Hino Advantage, giving you more support and solutions for the long run. That’s the power of change, that’s the Hino Hybrid Electric. Visit hino.com.au

> Chugh Transport outlays $1.2M on new trucks

Customer service is driving success for Chugh Transport, a small familyowned operation that is growing its business offering, powered by Scania. In 2011, Peter and Kirsty Chugh founded the fledgling business in Dandenong South, armed with one second-hand Scania prime mover. Today, the business operates 15 Scanias and has evolved from its original removals work into container cartage and recently added warehousing and container unpacking services at its new, larger premises.

The new facility on busy Remington Drive has benefited from exposure to passing traffic boosting its awareness, in turn luring new clients.

“It’s a big opportunity for us to expose ourselves more in the market,” Kirsty Chugh said. “Moving to Remington Drive in March 2025, we expanded our footprint from 5,000m³ to 12,000 m³, boosting our onsite capacity from 100 to 500 containers, but already we’re getting full,” she said.

Much of the business hinges on carting containers on A-doubles and B-doubles off the wharf in Melbourne and delivering to the yard, as well as using the company’s six sideloaders to deliver to customers’ premises. With 20 employees on the books, mostly truck drivers and the all-important reach stacker drivers, the business has grown organically from the early days of the two directors doing everything themselves.

Peter and Kirsty have around 40 years of transport industry experience between them, initially starting in Queensland. As the Operations Manager for a transport company there, Kirsty was transferred down to Melbourne and Peter came with. He had worked with Wridgways Removals prior to their demise and managed to secure one of their Scania trucks, a 4×2 P 360, and used this in Melbourne to start Chugh Transport.

That truck now has more than a million kilometres on the clock and was

recently overhauled, so it is still able to earn its keep when required.

While Peter started off driving for Chugh Transport, Kirsty managed the business, but now Peter is now out of the literal driving seat and focused on building sales, and daughter Georgia helps out on the front desk in between her nursing studies.

Initially, the work was removals and then carting to and from the wharf for freight forwarders but now delivering directly for customers is becoming a growing component of the daily schedule, as well as warehousing.

After a couple of years, the business purchased its second truck, a second-hand R 480 prime mover from the Scania Used Truck team in Campbellfield.

“That truck cost $125,000, which was a great deal of money for us,” Chugh said. “Recently we put down $1.2 million on three new Scania trucks, so the times have changed. Early on we bought three or four second-hand Scanias, and then we started buying them new.”

Peter said the tempo of purchasing has increased.

“I am looking forward to the day when I can order ten in one go,” he said.

Peter’s love of Scanias started long ago according to Kirsty.

“He had driven Scanias in previous jobs and just liked the way they

drove. So, he wanted to keep buying them. We formed a good working relationship with Tevfik Onguc, and then latterly with Mat Staddon, Scania Account Managers at the Dandenong Branch [and] it just went from there,” she recalled.

“Last year we bought three brand newies, and this year we have bought three as well; G 560 six-cylinder prime movers and R 590 V8s.The V8s pull the A-doubles and the G 560s pull the sideloaders.”

The fleet also includes a G 440, 130-tonne rated R 590 V8, an R 620 V8, 460 P Supers and an R 540.

The fleet is starting to log bigger annual kilometres now that it is expanding its customer base and services but no more than 85,000 kilometres per year on average across the fleet.

“We are really pleased that the new Scania Supers that we have had on the fleet have been delivering what we were promised in terms of fuel efficiency improvements. We do monitor the fuel use, and we have a 60,000-litre tank on site, which is another way of keeping our fuel bills down,” Kirsty said.

“The combination of buying bulk fuel and the fuel economy of the new Scanias is making a big impact on our fuel costs, given we use around 25,000 litres each month.”

Image: Scania Australia.

Scania prime mover pulls an A-double.

> COPE Sensitive Freight expands fleet, property footprint

COPE Sensitive Freight has broken ground on a new state-of-the-art facility in Sydney. Last month the carrier marked the development approval and commencement of works to deliver a new 38,500m² warehouse and distribution site at the Alspec Industrial Business Park in Orchard Hills. The latest company investment which is going to incorporate modern offices, warehousing and staging facilities in addition to its growing transport operations, will support the continued growth of its operations in New South Wales.

Nick Linnett Chief Operating Officer thanked project partners HB+B

Property and CIP Constructions for helping to bring the company’s vision to life.

“We look forward to watching it take shape in the coming months,” he said. “This facility will further strengthen our network and ensure we can continue on deliver what matters when it matters most for our clients.”

Part of the Federal Group, the oldest continually operating hotel group in Australia, COPE Sensitive Freight has become an increasing presence on major metropolitan arterials. The fleet has also recently replaced four older trucks with new Mercedes-Benz Actros prime movers.

The 580 horsepower rated vehicles,

> XFM continues major fleet expansion

XFM has added five new prime movers to its growing fleet.

The national logistics company recently introduced new Fuso Shogun 400s along with nine new Vawdrey trailers as part of its continued expansion.

XFM’s five Fuso Shogun 400 models feature a Daimler Truck-sourced 11-litre six-cylinder engine, paired with a 12-speed Automatic Manual Transmission (AMT).

The units’ Euro 6-rated engines produce 400hp, enough power for short- or long haul work.

XFM Managing Director, Les Sharpe, said the company’s recent fleet upgrade is in-line with its commitment to operate modern high-quality equipment and first-class depots across major Australian cities.

“Our customers can attest that we are 100 per cent committed to providing the highest level of service, and that means we operate quality trucks that are safe, efficient and well-maintained,” he said. “Safety for our drivers and other road users is important, so we are also pleased that the Fuso Shogun comes with a really

delivered by Daimler Trucks Hungtingwood, will be covered by a Daimler Complete Service Plan package.

“We’re proud to announce the latest arrivals into our fleet with the delivery of four new Mercedes-Benz Actros prime movers. This investment reinforces our commitment to safety, efficiency, and delivering exceptional service within the sensitive freight sector,” said Matt Heffernan, COPE Sensitive Freight National Network & Assets Manager. “We are confident these vehicles will be a valuable asset to our operations team and a key part of our ongoing partnership with Mercedes-Benz.”

high level of safety as standard. The overall business case for the Shoguns, including the low operating costs, also makes it something that is hard to say no to.”

XFM’s Shoguns come with Advanced Emergency Braking Systems technology fitted as standard, enabling them to automatically carry out full brake application in response to stationary and moving objects. The Fuso Shoguns can even brake in response to moving or halted pedestrians.

Sharpe also expressed his

appreciation for the help of Daimler Truck Australia Pacific Director of Strategic Partners and Business Development, Richard Eyre, who was able to help him get the right trucks for the job in a timely fashion.

The Fuso Shogun 400s also benefit from lengthy 50,000 kilometre service intervals that ensure the truck spends more time out on the road getting the job done.

The truck units also include a manufacturer warranty that lasts for five years or 500,000 kilometres — whichever comes first.

Images: credit

Three of the five new Fuso Shoguns delivered to XFM.

> FedEx introduces EVs in Adelaide

An initial 55 electric vans and trucks are being deployed by FedEx Australia, commencing in Adelaide, with plans for major cities on the east coast also underway.

The Fuso eCanters and Mercedes-Benz eSprinter vans will operate in parcel pickup and delivery services across metropolitan areas. The initial rollout will commence in Adelaide with the introduction of 15 Fuso eCanter trucks hitting the road.

This marks the first phase of a broader expansion, with the remaining EVs to be deployed in Melbourne, Sydney and Brisbane. The company plans to expand into additional regional and metropolitan areas as new charging infrastructure is installed.

The Fuso eCanter trucks are estimated to avoid up to 13.2 tonnes of CO₂ tailpipe emissions per vehicle annually when travelling 30,000 kilometres compared to diesel models, with

an estimated range of up to 200 kilometres on a single charge. Meanwhile, each eSprinter is projected to avoid up to 8.5 tonnes of CO₂ tailpipe emissions per year based on estimated distance travelled compared to a diesel-powered equivalent, featuring a 1.5-tonne load capacity and a 264-kilometre range on a full charge.

“The introduction of these electric vehicles to our pickup and delivery fleet in Australia marks a pivotal moment in our operations,” said Peter Langley, Regional Vice President, FedEx Australasia.

“It is an important initial step we have taken to help reduce the environmental impact of our pickup and delivery operations while continuing to provide the efficient and reliable service our customers expect.

“As e-commerce continues to grow and consumers become more environmentally conscious, we believe

that embracing electric vehicles is a strategic imperative for a cleaner and more sustainable future.”

This electrification initiative reinforces the goal of FedEx Australasia’s parent company, FedEx Corporation, to electrify the entire FedEx global parcel pickup and delivery (PUD) fleet by 2040 and achieve carbon-neutral operations by 2040 across its global business lines.

The introduction of the new EV fleet in Australia follows a recent successful launch of EVs in New Zealand, further reinforcing FedEx Australasia’s efforts to support FedEx Corporation’s wider global strategy to reduce operational emissions across its network.

Beyond vehicle electrification, FedEx Corporation is also investing in other areas such as aircraft modernisation, sustainable fuels, renewable energy, efficient facilities, and is also supporting carbon sequestration research in pursuit of the company’s sustainability goals.

> Blenners Transport opens new facility in Central QLD

Rockhampton is the new home of the latest company-owned facility by Blenner’s Transport.

In addition to warehouse and office space, the purpose-built 2,500m² depot contains a temperaturecontrolled anteroom as well as chiller and freezer rooms available for storage of dry, chilled, or frozen products.

The site itself employs 11 staff and is equipped with onsite diesel storage for refuelling trucks.

There are also five docks for vehicles. For the increase in volume of freight, Blenners is running four B-doubles from Brisbane out to site at Rockhampton daily. Here a semitrailer, a 16-pallet Isuzu, three 14-pallet Isuzus and an 8-pallet rigid provide local deliveries.

Blenners Transport will service out of Rockhampton customers in Emerald, Biloela, Blackwater and Gladstone.

Leanne Dun, Blenners Transport Sales Manager confirmed the new facility

had already generated new customers since it opened.

“We’ve had a heap of new customers come on board since the depot has opened which is why there is four B-doubles a day running up here,“ she told Prime Mover. “Previous to that it was only one, sometimes two.”

Just this year Blenners has deployed ten new Kenworth K220 prime movers across its Queensland operations.

Powered by a 550hp Cummins X15 producing up to 2050ft-lb of torque, each Kenworth K220 is spec’d with an Eaton Endurant XD Pro transmission running through Meritor MT21-165G drive axles at a ratio of 3:91.

Blenners Transport had leased a site prior to this in Rockhampton, which now joins seven other Blenners-owned depots in the state. The latest purposebuilt site is proof of Blenners Transport continuing its reinvestment back into the business with new depots, vehicles and safety systems.

“It shows how we are here for the long-term and our team are proud to work for the Blenners family and watch the business continually grow,” said Dun. “We pride ourselves on providing a superior service to all of our customers [by] looking after their individual freight and storage requirements.”

The Rockhampton depot, according to Dun, has provision for expansion and additional cold rooms as future growth is anticipated.

“Now with five docks the workflow of the site is much better,” said Dun.

“We can offer a superior service to our Rockhampton customers to have extra B-doubles run up from Brisbane as well.

We’ve already got storage customers coming on for Christmas. They can buy in bulk now as there was no other facility previously in Rockhampton that has what we’ve now got.”

The new facility is located at 14 Barton Court, Parkhurst, Rockhampton.

Put the future to work

Kenworth stands by its history of design of trucks that are easy to operate and maintain. The new generation Kenworths integrate the latest technology while upholding this philosophy, making our newest models smarter than ever. Put the future to work for your business.

> Federal Govt pledges $1.1B towards low carbon fuels

Low carbon liquid fuels are set to receive a $1.1 billion injection from the Federal Government. The investment, according to a statement issued today, has been made to strengthen supply chains for the more sustainable fuels that can power trucks, cargo ships and planes into the future.

The new ten-year Cleaner Fuels Program will stimulate private investment in Australian onshore production of low carbon liquid fuels, such as renewable diesel and sustainable aviation fuel. The first production of ‘drop-in’ cleaner fuels, which can be directly substituted for existing fuels and work in today’s engines, is estimated by 2029. Australia already possesses the ingredients needed to make cleaner liquid alternatives to fossil fuels, with ready access to feedstocks like canola, sorghum, sugar and waste.

Liquid fuels make up around half of Australia’s national energy use. While Australia exports nearly $4 billion of suitable feedstocks like canola and tallow, the Clean Energy Finance Corporation (CEFC) estimates an Australian low carbon liquid fuel industry could be worth $36 billion

by 2050 Ă highlighting the untapped potential of developing local refining and value-adding capability. The new production-linked incentive builds on the Government’s support through the Sustainable Aviation Fuel Funding Initiative and the Future Made in Australia Innovation Fund.

Recipients will also need to deliver benefits according to the community benefit principles under the Future Made in Australia Act.

The Government said it was also supporting the market by expanding the Guarantee of Origin Scheme to include low carbon liquid fuels and has established a fuel quality standard for renewable diesel.

A recent report from the CEFC found that a mature Australian low carbon liquid fuels industry could deliver around 230 million tonnes CO₂-e in cumulative emissions reduction by 2050. This is equivalent to 2.3 times Australia’s current annual transport emissions, or the annual emissions from 86 million cars.

NatRoad CEO Warren Clark welcomed the announcement which is in line with NatRoad’s recommendations as part of its advocacy efforts.

> Evans Petroleum acquires new Kenworth T420SAR

Fuel and lubricants distributor, Evans Petroleum, has taken delivery of a new Kenworth T420SAR from Hallam Truck Centre.

Received last month, this new unit now marks the 17th Kenworth in the fleet which is put to work moving fuel in and around Gippsland and other parts of Victoria. This T420SAR model, which was launched at the Brisbane Truck Show, stands out among its counterparts.

It features an Australian Design Rules (ADR) 80/04 compliant PACCAR MX-13 engine which delivers 510 horsepower and is paired with an 18-speed Eaton Endurant transmission. These specifications were ideal for Evans

Petroleum General Manager, Stuart Evans.

“We selected this Kenworth model because we like the brand and it aligns with our fleet,” he told Prime Mover “We run other models of Kenworth

“It’s good to see the Federal Government is listening to industry and taking action. NatRoad has been working behind the scenes for years now and thanks the Government and the Departments for making solid progress,” he said. “We have provided multiple submissions recommending low carbon diesel as a key component of the broader plan, and providing monetary support to help kick-start the support and businesses required to reduce heavy vehicle emissions as we transition to net zero.”

Treasurer Jim Chalmers said low carbon liquid fuels are an enormous economic opportunity for Australia.

“It’s about making Australians and our economy big beneficiaries of the global net zero transformation,” said Chalmers. “Developing this industry has potential to make us an indispensable part of growing global net zero supply chains. This is a downpayment on developing an entirely new industry in Australia.

“From the farm to the refinery, from primary production to processing, this will create more jobs and more opportunities for Australian workers and businesses.”

trucks in our fleet and were excited to give the new model a go.”

The new T420SAR also has 75-tonne gross capacity. The truck is being used to cart fuel in a 19-metre Holmwood Highgate tanker from Melbourne fuel terminals throughout Victoria. Other features include a JOST fifth wheel, a greasing system by Groeneveld and stainless steel trims by Longhaul. Ando’s Detailing Services were also engaged to dress up the truck.

“The drivers have certainly been happy with it,” said Evans. “The truck looks good and feels good to them, particularly the transmission and how smooth it is. No one’s complaining at all.”

Kenworth T420SAR.

We’re clearing all stocks of the DAF CF530 at the low price of $249,900* (ex. GST and Gov’t charges). Plus get a $30,000* BP Fuel voucher or 0% finance* (Max. 48 month term). Only while stocks last. See daf.com.au/CFrunout.

DAF CF530 $249,900* *Terms and conditions apply. See daf.com.au/CFrunout.

> Former Kings Transport CEO appointed at Carroll Group

Carroll Group Australia has announced a new Chief Operating Officer (COO).

Experienced road transport and logistics executive, Barry Thompson has accepted a position as the new COO at the company, effective immediately.

Thompson was at Kings Transport for eight years in several senior leadership roles previously.

With 25 years industry experience including roles at Linfox, Thompson is considered proficient in mentoring and coaching executive teams, driving operational excellence, and achieving impactful results across government, private, and nonprofit sectors.

“It’s very good for us,” said Troy Carroll, Carroll Group Managing Director. “As a company we’ve been growing so quickly over the last couple of years, at 30 per cent or even more every year.

“With that type of continual growth, we want to make sure our processes and our people are growing with the company so that our customer service is still second-to-none.”

Considering the fast-changing landscape of the industry and Carroll Group’s upward trajectory within it,

Carroll understood it was time to bring in someone of Thompson’s calibre. “Bringing those layers of management – that C suite in – is important,” said Carroll. “Some people have questioned why I’m doing it given our size. But it’s not about what I’m looking at now, it’s what I want it to be. As we proceed to push to that next level, I want to make sure our customers and partners are getting looked after on the way through.”

Thompson is dedicated to fostering sustainable change and empowering executives to realise their full potential. He told Prime Mover that Carroll Group is an organisation led and run by passionate individuals who are driven to continually improve on delivering excellent solutions to their customers.

“We service our clients in sometimes very challenging supply chains operating in some of Australia’s harshest conditions and we do it reliably and safely earning our customers acknowledgement and praise,” said Thompson.

It was a chief motivator behind Thompson joining the organisation. One of his aims will be to guide and

improve the functional capability of the organisation focusing on operational excellence and customer satisfaction.

“Going forward we aim to target further growth with our existing clients and expand our service offering to a broader market,” said Thompson.

“I bring considerable operational experience from my years in larger scale domestic and multi-national organisation and am excited for our journey ahead.”

Carroll Group also recently appointed Tim Schneider as its new Chief Financial Officer. Schneider previously worked at Asahi, Lion and Toll Group, as its Financial Transformation Manager.

“When we say we’re going to do something we want to ensure that we do it right every time,” said Carroll.

“Barry and Tim bring a wealth of experience to our business — a business we want to be truly generational so that my daughters can one day take it over and it becomes something a lot bigger than perhaps what we all initially envisioned.”

Carroll Group has also injected nine Euro 6 prime movers into its fleet.

Images: Carroll Group.

Troy Carroll with Barry Thompson.

The MAN TGX trucks are hauling PBS 30-metre pocket roadtrains from Brisbane to either Roma or Gladstone daily.

It’s a vote of confidence in the brand which has been fast finding homes in some of the major fleets across the country.

“We went to the MAN for the safety features they have got such as crash detection and lane assist and the suite of other systems in them,” said Carroll. “But also for the fuel economy which is appealing and reduced fuel burn being a Euro 6 phase II engine. With the second series of that engine the emissions are really low on that truck.”

Carroll is awaiting an annual data report that is presented to him internally by his operations staff but in terms of fuel burn numbers it’s very much a case of so far, so good. “Hence the reason why we bought the trucks. We knew the fuel burn was going to roughly be with the

roadtrains on it and compare it to the Euro 5 engines on the task and even in contrast to some other brands it was a lot better fuel burn,” he said. “Emissions is a huge factor for us as well. We had a goal set for our company to have all Euro 6 by the end of 2025 which we will achieve. ”

Carroll Group is finalising the eventual phase out of its Euro 5 equivalent engines over the next few months.

Carroll said the trucks were sometimes reporting 2.1km/l on HML maximum weights.

The new units have been delivered across different power outputs from 540, 580 and 640hp.

Eight of latest trucks are rated to 90 tonnes to satisfy the PerformanceBased Standards requirement.

The 640hp-rated MAN TGXs are 120-tonne rated. There is one new 640hp in the fleet with two more due later this year.

The trucks have been handled from

the Penske Brisbane dealership through Sales Manager Jayme Deves. “That’s a really good strong relationship for us. We don’t just buy trucks. If anything goes wrong with those trucks I just call Jayme and he’s on top of it. It’s one point of call for me – that’s it.”

Driver feedback is undeniable having been heavily skewed by the benefits of comfort the MAN TGX prime mover offers. The powertrain is also proving a noteworthy feature.

“If you put it to the equivalent of another European brand the actual torque of the MAN is really strong,” said Carroll. “The drivers love how it takes off with a load on it. It’s a lot better than the other brands. It’s literally the driveability of the truck that they are raving about. Though it’s got an air ride cab you don’t get what the drivers call the washing machine movement. It’s really quite a smooth ride in the cab.”

> Autonomous tech company expands deal with Canadian retail giant

Gatik, a provider of autonomous freight for regional logistics networks, has announced a significant expansion of its commercial partnership with Loblaw, Canada’s largest retailer. Marking a milestone for the autonomous trucking industry, the companies have signed a first-of-its-kind, multi-year growth agreement to deploy Gatik’s autonomous fleet across Loblaw’s distribution network in the Greater Toronto Area (GTA). Under the initial phase of the expansion, 20 autonomous trucks equipped with Gatik’s next generation sensor suite will be deployed by the end of 2025, with a further 30 autonomous trucks to be deployed by the end of 2026, creating a scalable platform for future growth phases.

This growth agreement signifies the largest planned roll-out of autonomous trucks in North America, a move that transitions Gatik and Loblaw from initial deployment to commercial operations at scale, an industry-first in the autonomous vehicle (AV) sector.

The expanded fleet will initially be deployed with safety drivers onboard, before transitioning to driverless operations across Loblaw’s regional distribution networks in the GTA, delivering goods to over 300 Loblaw stores. Under the expanded partnership, Loblaw has made a strategic investment in Gatik, strengthening Loblaw’s commitment to scaling Gatik’s autonomous solution within its

extensive supply chain and helping to rapidly accelerate fleet expansion and geographic growth within Loblaw’s priority markets.

Gatik and Loblaw previously made history in 2022 with the deployment of Canada’s first driverless commercial fleet, setting the foundation for last month’s historic expansion.

“This is a transformational moment, not just for Gatik and Loblaw, but for the autonomous trucking sector globally,” said Gautam Narang, CEO and CoFounder of Gatik. “It’s the first time a major retailer has transitioned from pilot to commercial scale with autonomous trucks, directly addressing Canada’s growing driver shortage, delivering the true benefits of autonomous logistics - reliability, safety and scalability - to millions of Canadians.

“Loblaw’s investment is a powerful endorsement of our market-leading AI Driver, Gatik’s purpose-built technology that has logged extensive miles on public roads while maintaining an exemplary safety record, and underscores our commitment to revolutionising regional distribution through intelligent, autonomous solutions.”

Loblaw Companies Limited Chief Administrator Rob Wiebe recognised the expanded partnership as a significant step forward in its commitment to innovation and supply chain sustainability. “Autonomous logistics will enable us to move more orders more frequently

for our customers,” said Wiebe. “We are excited to continue leading the way nationally in retail distribution with Gatik’s groundbreaking technology which has already been proven across our operations.”

This expansion leverages Gatik’s proprietary Gatik Driver, “a scalable and interpretable AI driver” purpose-built for autonomous trucks proven in real-world commercial operations per a company statement. The new fleet will include cold chain-ready vehicles optimised for the movement of time-sensitive grocery and household items.

In preparation for Gatik’s multiyear expansion with Loblaw, Gatik worked closely with the Ministry of Transportation of Ontario (MTO) to inform the development of the Automated Commercial Motor Vehicle (ACMV) Pilot Program, a new provincial regulatory framework that recently launched on 1 August, 2025 and enables the operation of Gatik’s medium-duty autonomous trucks on all surface streets and highways in the province.

With the ACMV Program now in effect, Gatik and Loblaw are well positioned to continue to scale autonomous driving operations.

The ACMV Program has been carefully developed to facilitate the safe and rapid roll-out of autonomous trucks in Ontario, ensuring that the province continues to lead the way nationally in transportation innovation. Gatik’s regional network approach with Freight-Only (driverless) operations underway in markets such as Texas, Ontario, Arkansas and Arizona.

Last year Isuzu Motors agreed to further enhance the development of the North American autonomous driving business announcing it would invest US$30 million in Gatik. The agreement between the two companies focuses on the development of middle mile autonomous driving and will include the design and development of a new chassis that ensures safety when equipped with an autonomous driving system.

Gatik.

Isuzu Motors struck a deal with Gatik last year.

Fuso’s PPE gear for EV.

> New EV PPE pioneered by Fuso

Mitsubishi Fuso Truck and Buck Corporation (MFTBC) has developed the world’s first personal protective equipment (PPE) designed specifically for operations involving electric vehicles (EVs) — known as ARCTECT GEAR for EV. Jointly developed with Japanese manufacturer, Midori Anzen, and global material science company, W.L. Gore & Associates G.K. (GORE), the PPE has been designed to accommodate an increasing number of EV maintenance requirements as the technology becomes more commonplace. Scheduled for rollout at select overseas service centres in 2026, ARCTECT GEAR for EV has been designed for use in high-voltage environments like EV workshops, balancing safety and comfort in equal measure. Specifically, all PPE used for EV maintenance needs to meet several critical needs in a workshop setting. The equipment must offer flexibility for working in tight spaces, provide effective

temperature and moisture control in enclosed areas, and deliver consistent protection for frequent transitions between high-voltage and low-voltage systems. Additionally, the equipment must also not significantly deteriorate its safety performance throughout its intended service life.

The garment satisfies these needs by incorporating GORE Japan’s PYRAD Fabrics by GORE-TEX LABS, a highperformance fabric engineered to be lightweight and moisture permeable while offering protection against arc discharge. Drawing on more than 70 years of safety equipment development, Midori Anzen collaborated with GORE Japan to develop high-voltage protection without compromising comfort and mobility. The PPE has already been certified under multiple international standards including arc flash protection.

MFTBC’s development of ARCTECT GEAR for EV is the latest of the

KEEPING YOU COOL

HEAVY DUTY SOLUTIONS TO BEAT THE HEAT THIS SUMMER

We’ve sourced quality ranges and partnered with industry leading brands to stock the world’s biggest brands in heavy duty air conditioning. The best in compressors, condensers, evaporators, fans and belts, fittings, hose, receiver driers, consumables and workshop equipment for all types of heavy duty vehicles, and fleets of all sizes.

You’re also guaranteed reliability with our OE First Fit solutions. Get the right parts for the correct application to keep you moving.

company’s efforts to establish an EV ecosystem where EV trucks are as easily operated as conventional diesel vehicles. This is part of a larger plan to contribute to the Japanese Government’s target to realise a decarbonised society by 2050. “As we expand our eCanter operations globally and work toward Japan’s 2050 decarbonisation goals, innovations like this remind me that the future of transportation includes everyone who builds, maintains, and services these vehicles safely,” said Karl Deppen, President & CEO Mitsubishi Fuso Truck & Bus Corporation. “We’re planning to introduce this gear to our overseas service centres in 2026, with Midori Anzen bringing it to market broadly.”

More than parts, NAPA is with you for the long haul. We make it our business to drive yours. Visit napaparts.com.au

Image: Daimler Truck.

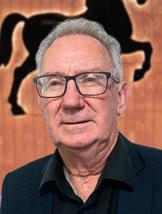

HISTORY MAKING

Wettenhalls this year celebrates a rich 100-year history, but as a generational enterprise it has an unwavering understanding of where it wants to be in the future.

Scania R 620 V8 hauling an A-double with precast 16-tonne concrete culverts.

All transport companies are alike. No two, however, are the same. In the case of the 100-year-old Wettenhalls, the fundamentals always have applied even if the systems and protocols are vastly different than they were in 1925. That immense journey is chartered in a sumptuous new coffee table book launched by the Colac-born company this month in which the anniversary celebrations, initially teased with the unveiling of a newly minted commemorative

Kenworth T909 sporting a refrigerated trailer by Freighter Group adorned in a monochromatic livery of historic images, are set to culminate with several events to mark the occasion including a family eld day and a gala dinner. The book authored by Charles Happell is a well-researched volume that lays out the origins and remarkable history of Wettenhalls across four generations commencing with Reginald Amezdroz and a two-tonne Federal Knight tray truck. The son of Swiss migrants, Reginald began freighting vats of cream from the western district dairy he worked, daily to Melbourne when a government regulation prohibited the transportation of perishable goods on passenger trains. Today the national business though

still plying its trade predominantly in Victoria, by concentrating heavily in the regional area southwest of Geelong, runs dedicated contract logistics operations in Sydney, Brisbane and as far north as Townsville in drastically different applications. The Altona depot opened in 2020 and is one of four main company-owned sites it operates in the state. Each includes a state-of-the-art workshop, automatic truck wash, cross-dock and warehousing facilities, of ces and solar arrays. Not the least impressive thing about its newest facility is the selection of prodigious high productivity units that come and go. Though not widely publicised, Wettenhalls is a keen proponent of Performance-Based Standards and through its specialty

Environmental Solutions Division

(ESD) has made increasing strides in this area of the business in recent years.

“It continues to grow sustainably,” says Wettenhalls Managing Director Martin Kelly. “In that market there are a lot of Blue Chip players. Once you start working with some of those on innovative solutions the opportunities just snowball.”

Now with a dedicated team double shifted that features driver-trainers, an operations manager and eet controller, ESD works around the clock, having initially been bolted on to another division when it was rst created in 2017.

“My dad always said there was money to be made in waste,” says Martin. “It seemed like there was a need in the marketplace for someone who specialises in it. When I joined the company that was in the back of my mind and from there some of the relationships with these larger players in the market have really grown.” A little of over three years ago,

Wettenhalls purchased a business in the Southern Highlands of New South Wales that services a blast furnace owned by Boral. Here they use B-double walking oor trailers to transport recycled wood to the furnace for a third-party.

Another growth area for the business is in servicing infrastructure and major projects. Today it accounts for a signi cant amount of company revenue. The increased capacity of longer combinations has afforded the eet the exibility to move bulk goods, and raw materials like steel on split quad axle trailers combined with 8x4 prime movers. At present Wettenhalls is deploying six A-doubles for the North East Link to complement its single trailer eet. They are moving up to 20 precast concrete sections on any given day. Maximum weight is 85.5 tonnes under PBS, but is much less on these combinations due to overall height. These combinations are pulled by Scania V8 prime movers and use a low pro le drop deck trailer

joining two 45-foot trailers coupled as an A-double with ballasts. They are something to behold even only when being moved around the yard. With a multitude of single trailer applications still of paramount importance to the business, Wettenhalls had a benchmark from which it could refer as it looked to scale capacity during the planning and execution process. It took about six months according to Martin.

“Because these culverts are coming from regional Victoria, we wanted to do half the amount of the trips,” he says. “Once you know those parameters you know what it is you’re pushing for. Talking to Kenny [an experienced Wettenhalls driver] using an A-Double would burn about 1.5 times the amount of fuel as a single trailer. Clearly, emissions have been reduced massively, not to mention the cost.”

While there are a few rigids operating regionally to load general freight mainly in the western district, Wettenhalls is rst and foremost a prime mover eet. Altona alone handles some 50 heavy rigs mainly hauling skels and palletised freight.

“We’ve got a lot of PBS gear that might not be running at the optimum weights initially, but you build it in the anticipation of infrastructure upgrades,” says Martin. “It’s a continual process of pushing the boundaries.”

He adds, “Basically every customer that we’ve got in the ESD division is being serviced with high productivity vehicles be it A-doubles or 20-metre quadaxle walking oor combinations with high capacity.”

Infrastructure projects in a country that looks to build for escalating population offer opportunities beyond the backyard.

Growth achieved, most crucially, with balance, is the company’s lodestar.

“That pipeline is really strong in terms of tender activity and there are huge opportunities depending on the amount of growth,” says Martin. “We are really interested in sustainable growth and being able to integrate those jobs into the business without

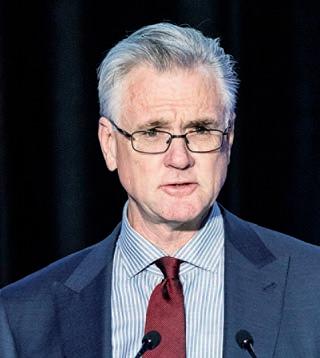

Wettenhalls Managing Director Martin Kelly.

breaking anything.

We could easily double in size quickly but if your systems and processes and people can’t keep up with it then what’s the point?”

The bulk food component of the business remains its largest concern.

Wettenhalls has highly sophisticated systems in place for dry, chilled and frozen goods in sharp contrast to the ice and wet sacks Reg Amezdroz used to cool the Dairymaster steel cans of cream moved on those very rst trips a century ago.

Working with some regional food factories, Wettenhalls is often a one-stop shop in which they will also warehouse, in addition provide transport, for its customers. More recently it rolled out Thomax, a new warehouse management system, across the business. It’s integrated with the SAP system of a key account. Endto-end, the process at the factory has been optimised so that carrying the raw materials and packaging can be provided at the Wettenhalls warehouse. Having a container transport capability is also an advantage.

“We can unpack the containers, transport the raws to the factory and then move the nished goods out of it,” says Martin. “It makes that whole process seamless. We’re always looking for ways to add more value for our customer relationships.”

Pumpa Manufacturing have delivered several PBS-approved mezzanine-style

dry freight vans 4.6 metres in height and 20-metres long for light bulk food. Along with Barker Trailers, they are preferred partners for specialised bulk equipment such as bins and walking oors.

Freighter Group and Vawdrey are more often engaged for the curtainsider spec. Wettenhalls uses Marcus Coleman of Tiger Spider as their engineering rm on much of their innovative heavy vehicle designs.

“That’s how we build our knowledge talking to guys like that who are in the know as well as the trailer manufacturers,” adds Martin. That relationship goes back long before road transport to university where Marcus was actually Martin’s football coach at Uni Blues in the highly rated Australian Rules Amateurs league. Martin’s journey at Wettenhalls of cially began in 2014 when he came across after spending the initial seven years of his career at PricewaterhouseCoopers where he was working in the private clients division. He is a self-described “country boy who married into the Amezdroz Family” with a professional services background. The previous year, as a result of a management buy-out, largely funded by the Amezdroz Family, Wettenhalls was purchased back from private equity, the grounds for affording a revised leadership structure. Wettenhalls had, around the time, acquired Rodon Transport,

a Brooklyn-based out t which served as its entrée into the construction sector and later on projects for big consortiums like the West Gate Tunnel, regional rail upgrades and Victoria’s ‘Big Build’. Martin basically cut his teeth in the organisation initially on the integration, and then running, of that business unit.

“That helped me build my transport speci c skills,” he recalls. “I had a good background in dealing with nance and numbers and the skills learnt growing up on our family farm translate well. But for transport itself I really needed to live and breathe it.”

When Chief Executive Of cer Mike Lean, announced he was leaving last year Martin put his hand up for the Managing Director’s role knowing he had a great team of staff and mentors around him.

The eet, until earlier this year, was evenly split between PACCAR – mainly DAF CFs – and Scania product, when Head of Fleet Marcus Prato, introduced several Mercedes-Benz Actros units. Speci cally for the new Actros units, Wettenhalls has been able to negotiate decisive exibilities around their contract maintenance arrangements.

The Kenworth is quite a statement particularly in a eet of some 200 trucks, few of them small, nearly all of them cabover top shelf European variants. Approximately 70 per cent of its mobile assets are powered by Euro 6 standard drivetrains.

Depot diversity: Kenworth T909 with a Tesla Model 3.

The rst Kenworth in the eet arrived in 1967 when it had no more than a handful of trucks. This followed the introduction of its rst refrigerated van purchased circa 1965 second-hand from Freighter. A new Transicold unit was suspended under the chassis. Up until then the company had been building its perishable goods gear inhouse, with the cream carrying trailers framed, insulated then sheeted with plywood.

The Wettenhalls 100 Years book details, through dozens of interviews with extended family and long serving staff,

a mosaic of memories, historic nuggets and once buried anecdotes such as the border hopping operation into Moama adapted in the mid-1970s to comply with disruptive government trade protectionism of the railways.

That rst green and cream truck differs notably from the maroon and yellow vehicles today, one of the best colour schemes of any heavy vehicle eet on the road. It can now also be seen on three recently introduced Tesla Model 3 company cars that are perfectly suited for high frequency carpooling and inter depot travel. The cars can be charged comfortably in three hours on site using electricity from the solar systems.

“There’s always a conversation about fuel allowances or fuel cards or company cars and it helps to get around all of that sustainably,” says Martin. “Often, they are used during daytime and you come back and plug them in. That’s been more than suf cient.”

Wettenhalls is also avidly pursuing low emission battery electric and fuel cell vehicle options.

In addition to being nalists in two other categories: Women in Leadership and Investment in People, Wettenhalls was also recognised as the Application of Technology category winner at the Australian Freight Industry Awards (AFIAs) for

Marcus Prato, Chief Operations Officer Gary Peatling, Martin Kelly in Altona.

its successful adoption and rollout of JOST’s JSK37 sensor coupling across a subset of its heavy vehicle eet.

Every truck, meanwhile, in the entire eet is tted with a Guardian driver fatigue camera from Seeing Machines. Wettenhalls was one of the rst companies to invest in the technology. Telematics partner MTData is also utilised for its latest 7000AI Series device that monitors driver behaviour and vehicle data, streamlining communications between drivers and their eet managers during transport journeys. The latest MTData units have ve external and internal cameras.

“The Guardian system has de nitely saved lives,” says Martin. “We see all the footage. You’ll interview the driver after they’ve been told to pullover, and they don’t even realise they’ve had a microsleep. It’s an expensive outlay at

the start but if you don’t have them, it’s a lot worse — It’s cheap in that context.”

Innovations, like the aforesaid, are nothing new at the business. In fact, they date as far back to the Amezdroz & Menzies prewar out t applauded in the in 1939 by the Colac Herald for what it described as “dependability and speed, combined with a proper regard for the handling of goods entrusted to their care.”

That goes for people, too. Wettenhalls has several recognition and reward programs the pinnacle of which is the Ned Club for 20-year servants to the business. Of which there were well over 20 drivers inducted into the club launched late last year. Named in honour of Ned Amezdroz, Brett Amezdroz’s late father,

the Ned Club will have its second inaugural dinner later this month. Brett, who is Martin’s father-in-law, currently serves on the Board as a NonExecutive Director.

Heritage is of vast importance not only to maintaining Wettenhalls’ strong multi-generational culture but in forging future directions. While the consumer economy is sustained by population growth transport and logistics for food will continue to grow according to Martin.

“Where we’ve got specialised solutions, and specialised equipment which itself is a barrier to entry, those are the markets we like to play in,” says Martin. “In 30 years-time a lot of the commodities we transport today I think we’ll still be transporting. It’ll just be smarter, more ef cient, safer.”

MAN TGX

en route to a distribution centre in western Sydney.

MARKET CORNERING THE

Sydney-based Dardania Logistics continues to optimise its truck eet with new prime movers from MAN as it celebrates its 30th anniversary this year.

Culture is an avowed bellwether at the best of companies. At Dardania Logistics it’s considered a strength. This year the business celebrates turning 30. Like many medium-size operations to have survived the caprices of industry and economies over three decades its origin is humble. The rst calling for the farming family was fresh produce. Transport was a means of moving freight from Sydney’s west to the markets and some businesses directly associated with it. In the early days Jimmy and Hysni Dardania steered the business founded by their father. Later on, a third brother, Adam, joined them. The transition to transport took place in the mid ‘90s and by 1996 the business was a fully- edged transport operator. Trucking by then was lucrative enough to increase the scale of operations.

Ever since it has ourished from strictly a produce carrier to a complete logistics operation delivering into majors with a client portfolio just as impressive for its longevity as it is the names: Coles, Woolworths, Aldi, Metcash to name just a few.

In the quick turnaround temperature control area pertaining to Sydney metro distribution Managing Director Tim Dardania con rms a number of Dardania Logistics’ long-term clients have got customers who have been with the business for over 25 years.

“Our top ten are probably all over ten years’ service with us,” he says. “People don’t stick around unless you’re doing the right thing. That’s usually the way.”

Being the youngest in the family, Tim had the bene t of attending university, where he studied economics, and a few other pursuits such as the Army Reserve, before returning to the family business. That was in 2007. His return was a catalyst for the company to embark on a new direction.

“In a way it helped sway us to make decisions based on the numbers rather than emotions,” he recalls.

“I saw trucks as a tool more than a

toy and they could be used to chase pro tability.”

At that stage the business had started servicing several clients outside the Sydney markets. The path into freight management and goods delivery by then was well underway.

Come 2015 it was a fully- edged logistics provider in the temperature control sphere offering warehousing, cold storage and refrigerated transport.

The Sydney-centric business excels in point-to-point inbound deliveries to distribution centres carrying chilled and dry goods. While it does handle general freight as a niche, customised solution for most customers, it prioritises fast moving consumer goods (FMCG) such as produce and confectionary.

“That was one of things that I pushed hard for during the time,” recalls Tim. “Instead of doing everything, we just needed to focus on what we do well and do it well enough and stick to that and make money from that.”

Recently Dardania Logistics took over a temp-controlled facility of almost 20,000m2 in Eastern Creek which has allowed it to gear up its operations and

capability, signi cantly. Being in the geographical centre of western Sydney’s industrial heartland the site is within a ten-kilometre radius of all the major food chain distribution centres. The business works around the clock with three active shifts. Fleet utilisation, because of this, takes precedence.

“Trucks are like aeroplanes. You’ve got to keep them moving otherwise they are just costing you money,” says Tim.

“That’s always been a big thing for me. At the end of the day it’s going to be costing you insurance and registration while it sits there for 12 hours so you probably should keep moving it, keep utilising it.”

On that front, the company maintains strict fealty to Penske Australia, more speci cally MAN trucks from which it operates nearly 40 prime movers. The eet has always revolved around European trucks. But in the last 15 years Tim says they have migrated the entire eet to MAN in the heavy range.

“The MAN TGS 26.540 has been the backbone of our eet. In recent years, we have spec’d our range closer to the larger end with TGX510, 540s, 580s and recently the 640- agship,” he says.

“We have a combination of the TGS and TGX larger cab variant which we use for longer distance jobs. We don’t do a lot of linehaul but when we do, the TGX is deployed as it offers better driver comfort.”

In the main part these longer trips might involve direct farm pickups to the mid north coast of NSW or out to Bathurst, Orange or Canberra. That’s essentially the perimeter of daily operations notwithstanding the odd job down to Melbourne or up to Brisbane. For the main part it’s the quick cross-docking distribution model that Dardania Logistics excels. They have 12 MAN 26.540 prime movers with two more on order.

Tim likes the midsize cabin as do his drivers.

“Drivers seem to be very happy with their performance and turn around and from a business point of view we’re very happy with their economy,” he says. “It’s our go-to workhorse in that the 540 gives you the best of both worlds — the easier single trailer stuff and the heavier B-double work. It kind of marries us up perfectly that range.” That versatility makes it something of

Tim Dardania.

a poster child. In any event, that’s how Tim likes to describe it to Penske.

“You can throw a 540 at both ends of the application without sacri cing fuel or power in a way,” he says. “The lower cab makes it easier to climb in and out of and the drivers love the combination of agility and power.”

With the truck spec centred around high volume, quick turnaround applications the vehicles are still rated to 90-tonnes GCM. The two latest additions in the eet are a pair of MAN TGX640hp powered by an inline sixcylinder engine displacing 15.2 litres. These come in a high-cab GX sleeper spec with an array of creature comforts to look after the driver when they are away from home. The cab offers a maximum standing height of 2,150mm and lower bed length of 2,000mm.

Dardania Logistics is running the 640s on a B-double linehaul application up and down the east coast.

“While the largest powerplant we operated before them were 580s, the extra power is certainly not going to waste,” he says. “We also believe they will prepare us for additional PBS combinations.”

On the opposite end of the spectrum,

a new MAN TGS 26.440 has been deployed for locations that are typically hard-to-reach for heavy vehicles like the Cruise Ship terminal in Circular Quay.

The upfront cost of a truck is the number one factor ahead of a purchasing decision closely followed by total life cost. Generally, a prime mover at Dardania Logistics enjoys a life cycle of between four and ve years.

“We don’t clock up large kilometres that other eets do. So that time span is our sweet spot to maximise the value of a trade in or the secondary life of the truck,” explains Tim. Those are probably the three main metrics: the initial purchase price, the overall cost and obviously the fuel economy the vehicle offers. Labour and fuel being the two main cost drivers followed closely by maintenance costs.”

The MANs are serviced to the OEM recommendation of 70,000km/annual intervals. Penske has provided On-site servicing, which Tim says has been helpful in reducing downtime and added a very convenient bene t to its servicing regime. They deal with Chipping Norton Penske in Sydney. “Gordon Taylor looks after us along with his team — they are very

responsive to our needs and requests. Gordon is pretty much everything you want in a salesperson,” says Tim. “He’s got that old school customer service about him. He will pick up the phone. He delivers what he promises. He won’t tell you stories along the way. People like that these days are hard to nd.” So too are experienced truck drivers and high calibre trained personnel, but Tim has noticed improvements over the last 12 months. It’s a good time of year to have key staf ng roles lled as the business navigates the peak period that will last until March looking after large multinationals like Unilever, Aldi and Ferrero, who it still counts as clients after more than a decade. That’s the Dardania Logistics point of difference according to Tim — its agility and commitment to 100 per cent DIFOT (delivery in full on time).

“We’ve always retained strong customer loyalty and they’ve come to expect it in return,” he says. “My biggest selling point these days when I’m sitting in front of a new customer: ‘Here’s my top ten and this is how long they’ve been with us. Make of that what you will.’”

AND

LIGHT EASY

Transporting the lightest of loads brings its own challenges.

Typically, most transport operators look to maximise their payloads and run at the upper limits of their legal weights. In contrast, Melbournebased Polyfoam Australia’s products are probably the lightest by weight and largest by volume encountered in the road transport industry.

The company, which celebrates 40 years in business in 2025, is owned and run by Bruce and Simon Pickett. Polyfoam’s core business is manufacturing expanded polystyrene packaging products for use in the produce, seafood, medical, and food industries as well as for construction and insulating products.

Polyfoam also produces a range of moulded Expanded Polypropylene (EPP) packaging, speci cally designed for the protection of expensive pieces of equipment.

Polyfoam Australia has manufacturing facilities in Victoria, New South Wales, Queensland, and South Australia and now has two factories in Tasmania which provide key support for the local salmon export industry through production of expanded polystyrene foam packing boxes.

“Our product is so light, even a fully loaded 14-pallet rigid or 24 pallet drop-deck semi-trailer would not add even a tonne to the total mass of the combination,” says Polyfoam’s General

Manager Nick Tandy.

Around ve years ago, Polyfoam turned to Scania for the supply of rigid trucks to transport the expanded polystyrene food boxes because their previous Japanese supplier could no longer offer a suitable vehicle.

“We made the mistake of buying very light weight trucks in consideration of carrying light weight products,” says Nick. “What we needed was a lightweight truck that could also be stable on the road when it’s loaded or unloaded, because we often have no backload.”

The rst Scania to join the Polyfoam eet was a P 280 rigid, and subsequent rigid trucks have shifted up to the P 320 speci cation, and single and dual axle trailers were added on some routes to maximise the volume of product delivered per journey. Two Scania G 450 prime movers have since been added in combination with drop-deck curtainsider trailers manufactured by Vawdrey.

The low weight, high volume of the loads is due to the fundamental designs of products such as foam food boxes.

“Our boxes have to be strong, so they are as wide at the top as the bottom, which means we can’t nest them and therefore transport more product in a given space,” says Nick. “The boxes for the sh weigh 25 kilograms when full of salmon and ice, and they’re

Images: Scania Australia.

One of two new Scania G 450 prime movers.

often stacked ten high, so the box at the bottom is supporting 250kg. This is important for our customers, as they need to get the most amount of product in the smallest space to keep their export transport costs to a minimum.”

Polyfoam sells to all the major salmon farmers in Tasmania, who need a robust, leak-free container that will keep their produce fresh. The boxes meet the Australian standard for seafood airfreight approval, which means they won’t leak seawater in the plane.

Foam boxes used for agricultural products are often used in the eld where fresh vegetables such as broccoli are picked straight into the boxes. This contributes to the produce’s freshness and quality when it arrives at market. Due to the combination of light payloads and large surface areas, both rigids and trailers can exhibit the characteristics of large sails that can be affected by cross winds when traversing locations such as across Melbourne’s

Westgate Bridge. The Scanias provide a stable ride, and the inbuilt electronic stability control is always there as a backup if the side winds are too extreme.

The introduction of the Scania trucks to the Polyfoam eet received a good response from the drivers and an ongoing commitment from senior company executives.

“From the start everybody loved the Scanias”, says company Founder Bruce Pickett who, himself, still occasionally drives trucks. “The cabin layout, the access, the simplicity of the vehicle to operate. And it is great to drive. We now have three Scania rigids and two prime movers in Victoria, one Scania prime mover in Bridgewater in Tasmania, one rigid in Westbury in Tasmania at the new factory, and in Queensland I’ve got six rigids in service and two more on order. We’re also introducing Scania to our NSW operation with two going in there, and there will be a new prime mover for Westbury in Tasmania as well.”

The modernisation of the eet incorporating the new Scanias has helped with driver retention and has contributed to the image of the business. From the base in Dandenong South, Polyfoam’s trucks deliver all over Victoria, from Portland to Bairnsdale and up to Shepparton.

The Victorian trucks travel on average 100,000 kilometres annually, while in Queensland each may cover around 200,000kms per year, due to the longer distances involved.

Although weight may not be an issue, wind resistance is an area where the aerodynamic Scanias have an advantage, in combination with the nose cone de ectors tted to the fronts of the rigid and trailer bodies.

“We’re pleased to see that the Scanias are returning better fuel ef ciency than our older trucks, even though the payload is so light,” says Nick.

The Scanias are on contracted repair and maintenance programs providing Polyfoam with the predictability of knowing exactly what the monthly

A 24-pallet dropdeck loaded with foam food boxes.

servicing costs are going to be.

The Scanias are expected to be replaced after performing around 700,000 kms.

“They will have had a relatively easy life, of course, although the rigids do deliveries to farms and also to building sites, so they’re often on poor roads and dirt,” says Nick.

Scania’s driver scoring feature is a valuable management tool.

“I get the report every Monday and I go through it,” says Nick. “If I see a lot of harsh braking, I might have a word with the supervisor at a particular site and ask them to talk with their drivers.

Harsh braking and harsh acceleration are things we watch pretty closely. It’s useful to us to provide feedback to the drivers and suggest ‘Hey mate, just settle down’.”

Polyfoam imports the raw materials in granular form from all over the world and then subjects them to steam which uffs them up. After sitting for a period to stabilise, the now uffy granules are then poured into a mould and steamed a second time to fuse them into shape.

“As a business we’re constantly looking for ef ciencies, just like Scania,” says

Nick. “We try all sorts of ways to shave a few grams of base stock out of the design, and we have updated European machinery that can now mould multiple boxes at a time.”

Polyfoam takes its environmental responsibilities seriously and it is committed to helping its customers close the loop in product lifecycle by providing comprehensive endof-life recycling options for all its foam products. Up to nine tonnes per week of recycled foam is ground up to be reused, in combination with some virgin pellet stock, and the recycled material is then turned into the polystyrene pallets on which products such as food boxes are placed for transport or used to make foam

waf e pods for use in construction. A typical unladen wooden pallet weighs around 60kgs, in contrast to the 2kgs of the polystyrene pallets used for Polyfoam’s products.

“Our plastic pallets often weigh more than the load that is strapped to them,” Nick says. “We say that our polystyrene product is more economical to recycle than cardboard, because polystyrene products come back, are ground up and are then ready to reuse.”

The late model Scania trucks are integral in Polyfoam Australia’s provision of practical eco-friendly expanded polystyrene solutions for packaging and construction applications in a growing list of industries.

Polyfoam General Manager Nick Tandy.

New Scania units in Melbourne.

BREAD AND

CTI Logistics has invested in 20 prime movers from DAF in the last 12 months to meet the challenges of its time sensitive schedules that connect directly to interstate and regional networks.

Last year, CTI Logistics needed to re-evaluate new prime movers to support its metro operations in Perth, Adelaide, Melbourne, Sydney and Newcastle. The goal was to nd vehicles that deliver reliability, exibility and strong support from an OEM partner. After a detailed review and trialling an evaluation unit from CJD Equipment, CTI chose to invest in 20 Euro 6 DAF CF450 units.

This decision marked a signi cant shift for CTI. Like many operators, the company had spent several years navigating equipment shortages and unpredictable supply. Replacement