VOLUME 117/10 | NOVEMBER 2025

AIMEX 2025 ROUND-UP

COPPER SPOTLIGHT

TECHNOLOGIES TRANSFORMING HOW THE INDUSTRY MANAGES WASTE?

VOLUME 117/10 | NOVEMBER 2025

AIMEX 2025 ROUND-UP

COPPER SPOTLIGHT

TECHNOLOGIES TRANSFORMING HOW THE INDUSTRY MANAGES WASTE?

Across Australia’s resources landscape, the question of how waste is managed has become one of the defining challenges of modern mining. It is no longer a peripheral consideration, nor a matter of simple compliance. Effective waste management sits at the heart of what it means to operate responsibly, efficiently and sustainably in today’s industry.

The evolution has been driven by necessity. As mines grow deeper and processing becomes more complex, the scale of waste increases. Tailings, waste rock and by-products can represent the largest physical footprint of any operation. How these materials are handled – stored, treated, reused or rehabilitated –goes a long way in shaping a company’s environmental legacy and social licence to operate.

In the past, waste management was often viewed through a somewhat narrow technical lens: a cost of production, a by-product to contain. Today, however, it is increasingly recognised as a strategic opportunity.

Advancements in engineering, monitoring and material recovery are reframing waste not simply as a liability but as a potential resource. Tailings reprocessing, for example, can recover valuable minerals while reducing environmental risks. Similarly, improved water recovery and dry-stack tailings systems are helping to reduce operational footprints and conserve vital water resources in arid regions.

The shift also reflects broader expectations around environmental, social and governance (ESG) performance. Investors, regulators and communities now expect mining companies to demonstrate transparency and accountability in how they manage waste. Reporting frameworks, independent audits and global standards are establishing a new baseline for best practice.

Australia’s mining sector has responded with innovation. Modern tailings facilities are designed with long-term closure and rehabilitation in mind, incorporating advanced geotechnical and hydrological modelling.

Operators are investing in real-time monitoring systems to detect and mitigate risks early, while progressive rehabilitation is increasingly being integrated into the mine life cycle rather than left to closure.

CHAIRMAN JOHN MURPHY

CHIEF EXECUTIVE OFFICER CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

Email: paul.hayes@primecreative.com.au

ASSISTANT EDITOR

ENGEL SCHMIDL

Email: engelbert.schmidl@primecreative.com.au

COVER IMAGE: Darren - stock.adobe.com

JOURNALISTS

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

PAUL HOWELL

Email: paul.howell@primecreative.com.au

BEN CARTWRIGHT

Email: ben.cartwright@primecreative.com.au

ETHAN BENEDICTO

Email: ethan.benedicto@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

This growing sophistication reflects a broader cultural change within the sector. Waste management is now viewed as an essential part of business resilience rather than as a secondary operational concern. Mines that manage waste effectively tend to operate more efficiently, face fewer regulatory hurdles, and maintain stronger community relationships.

Importantly, the conversation on waste management also speaks to the future of mining itself. As demand rises for the minerals critical to renewable energy and technology – lithium, copper, nickel, rare earths, et al – Australia’s production volumes are expected to increase. With that comes the responsibility to ensure the environmental impact of extraction does not outweigh the benefits of decarbonisation and technological progress.

Sustainable waste management provides the bridge between these two imperatives. It enables continued resource development while minimising long-term environmental footprints and ensuring mined lands can be safely and productively repurposed. It also demonstrates that mining can adapt and innovate in response to global sustainability pressures, rather than resist them.

What is emerging is a more holistic approach to resource development, one where efficiency, safety and stewardship are intertwined. In this context, the management of mine waste becomes a measure of technical development and ethical responsibility. It represents how the industry chooses to define success: not solely by tonnes produced or profits earned, but by the legacy it leaves behind.

Mining has always been an industry of transformation, of landscapes, economies and technologies. Waste management is now part of that transformation, evolving from an operational challenge to a defining characteristic of modern mining excellence in Australia.

Paul Hayes Managing Editor

BUSINESS DEVELOPMENT MANAGERS

JAMES PHIPPS Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN

Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00

For subscriptions enquiries please contact (03) 9690 8766 subscriptions@primecreative.com.au

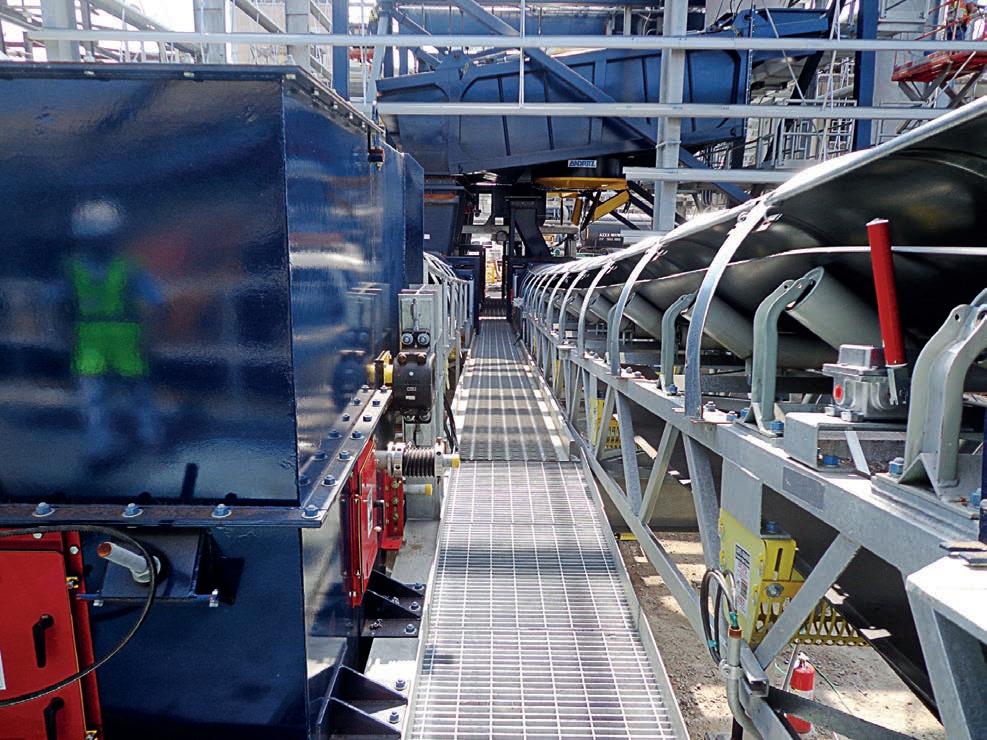

Serving the mining industry across Australia. Whether you’re in Western Australia’s iron ore heartland, the coal fields of Queensland, or the mineral-rich regions of New South Wales and South Australia, our regional service centres are ready to support you with expertise, repair and machining services.

FLS’s state-of-the-art Service Centres in Australia are strategically located near major mining regions.

You can be sure our team is ready to meet your needs by providing the most suitable parts and services required to safely and efficiently assist you in keeping your equipment up and running, maximising up time and boosting productivity.

www.fls.com

■ Reduce downtime - mining experts on your doorstep, for planned maintenance or an unplanned outage

■ Local machining facilities - reduce lead time for spare and wear parts, repairs, rebuilds, exchanges

■ One-stop-shop supports performance improvement –training, engineering or onsite support

AIMEX 2025 delivered a landmark showcase for Australia’s mining sector, transforming Adelaide into the centre of dialogue, innovation and recognition for three dynamic days.

12 MINE WASTE MANAGEMENT

Australia’s mine waste makeover

With immense volumes, long lifespans and complex environmental legacies, mine waste has always been one of the mining sector’s defining challenges.

16 MINE WASTE MANAGEMENT

Clutch S.H.O.T.

A collaboration between Jenike & Johanson and Crescend Technologies promises a major breakthrough in the ore treatment process.

20 MINE WASTE MANAGEMENT

Smooth operator

The same ultra-smooth material that helps artificial joints move freely is now solving one of mining’s most persistent headaches.

24 MINE WASTE MANAGEMENT

A new era for flotation

Flotation has long been one of the most powerful and adaptable concentration methods in mineral processing, and its importance is only set to grow.

34 SHELTER

The shelter built for extreme conditions

DomeShelter Australia’s engineered fabric structures are providing mining operations with durable and relocatable infrastructure solutions wherever they’re needed.

40 INDUSTRY INSIGHT

A major copper-tunity

With the global energy transition fuelling unprecedented demand for copper, SA’s vast mineral wealth is positioning the state as a cornerstone of a decarbonised future.

58 GREEN IRON

Forging Australia’s green iron future Green iron is on the global mining agenda, with companies like Bedeschi creating the path forward through technical excellence and design versatility

74 MINING MACHINERY

‘Instrumental’ equipment for mining operations

Liebherr continues to lead the way in giving miners the edge with its new hydrostatic dozer.

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING RIO TINTO, PERENTI, PEMBROKE RESOURCES AND MORE.

Rio Tinto recently appointed a former trainee from its Local Aboriginal Person (LAP) program as manager of its Amrun bauxite mine in far north Queensland.

Shiona Budby, a long-serving member of the team and proud Thanikwithi woman, will lead a team of more than 300 employees after beginning her career more than 10 years ago.

Budby said her aim is to inspire future LAP leaders to feel confident in who they are and where they come from, and to empower them to lead with strength and pride in their culture.

The LAP program has run since 2002, with more than 300 Indigenous participants taking part since it first started.

“Building strong relationships through shared lived experiences is the foundation of productivity and success,” Budby said.

“To me, being a manager means creating strong foundations that enable people to succeed in their roles.”

Budby described her leadership style as one grounded in empathy and collaboration, while having a deep commitment to empowering others.

“Shiona’s appointment marks a

significant step forward in building a more inclusive and representative future for our operations and our communities,” Rio Tinto general manager of Weipa operations Steve Dunstone said.

“This achievement is not only a testament to Shiona’s leadership, dedication, and deep connection to Country, but also a powerful symbol of progress.”

Rio Tinto recently began early works and final engineering studies to increase Amrun’s production capacity, aiming for first output in 2029.

Perenti has started a succession process that will see current managing director and chief executive officer (CEO) Mark Norwell step down from his position by the end of the year.

The Perenti board has initiated a comprehensive internal and external search for a successor to lead the company into its next phase of growth.

The company said the board and Norwell considered it an appropriate time to commence a succession process, following the successful delivery of the company’s 2025 strategy.

Perenti’s growth in recent years has given it significant scale and balance sheet strength, providing a new managing director and CEO with a robust platform to deliver future growth.

Norwell remains fully engaged and will work with the board and his successor (once determined) during a dedicated handover period. The company said he is committed to ensuring a seamless leadership transition and continuity across the business.

The transition process is expected to commence in the first half of 2026.

Pembroke Resources has announced Michael Rosengren as its new CEO following the company’s founder stepping down from executive responsibilities.

Rosengren brings decades of technical and operational mining expertise to the role and will lead the company’s next phase of growth.

The company said it is looking to consolidate production and advance the second-phase expansion of the Olive Downs Complex in the Bowen Basin of Queensland.

As one of Australia’s leading steelmaking coal mines, the Olive Downs Complex is a cornerstone asset for Pembroke with strong reserves and expansion potential to support growth for years to come.

Rosengren has extensive experience managing resource assets, previously holding leadership positions at BHP, Thiess and Mount Isa Mines. He most

recently held the position of managing director at QMetco.

Barry Tudor, who founded Pembroke in 2014, has stepped down from leadership after more than a decade, but will still maintain a board seat to provide “a seamless transition”.

Mineral Resources (MinRes) has appointed a new company secretary as it looks to bolster its governance regime.

MinRes announced the appointment of Sarah Standish as joint company secretary alongside Derek Oelofse.

Standish has 20 years’ experience in leading legal, governance, risk and compliance functions at ASX-listed and international companies involved in the mining and energy sectors.

She has held senior in-house legal and company secretary roles, most recently as general counsel and company secretary at De Grey Mining, which was acquired by Northern Star Resources in May.

Standish has also previously served as general counsel and company secretary at St Barbara, general counsel at Imdex and is a graduate of the Australian Institute of Company Directors.

Standish replaces Mark Wilson, who resigned from the role of joint company secretary. Wilson will continue in his role as the company’s chief financial officer. AM

AIMEX 2025 DELIVERED A LANDMARK SHOWCASE FOR AUSTRALIA’S MINING SECTOR, TRANSFORMING ADELAIDE INTO THE CENTRE OF DIALOGUE, INNOVATION AND RECOGNITION FOR THREE DYNAMIC DAYS.

With its move to South Australia, Asia-Pacific’s International Mining Exhibition (AIMEX) entered a new chapter, one defined by collaboration, fresh perspectives and a genuine sense of momentum.

Held at the Adelaide Showground from September 23–25, the event combined technical insight with industry celebration, uniting thought leaders, suppliers and operators around the shared goal of advancing the resources sector.

Setting the tone for progress

South Australian Treasurer and Minister for Energy and Mining

Tom Koutsantonis officially opened the event by championing the state’s growing prominence on the global mining stage. He highlighted copper as an economic powerhouse and a cornerstone of future growth.

“South Australia’s largest exported commodity is copper, both refined and concentrates,” he said during his keynote address. “That was up 17 per cent on the previous year, which reaped for our state a record of $4.3 billion in copper exports.”

Koutsantonis described how the state’s resource base, evolving infrastructure and investment pipeline are positioning South Australia as a magnet for new exploration and development, particularly across copper and critical minerals. His message set an upbeat tone that carried through the rest of AIMEX 2025.

BHP group procurement officer

Rashpal Bhatti captured the audience’s attention on day two with a keynote that helped to further crystallise the central role of copper in the Australian and global energy transition. Bhatti outlined a bold strategy for scaling production

and building smarter, technology-driven supply chains to meet surging demand.

“We are part of that copper revolution,” Bhatti said. “And if you thought that the electrification revolution was only in the early 1900s, you’re mistaken.

“We are in the midst of the second electrification revolution here and now, and the demand for copper in that electrification revolution is paramount.”

Bhatti’s address positioned copper not just as a commodity but as an enabler of a cleaner, electrified future – a theme that echoed across many of the conference’s discussions.

South Australian Chamber of Mines and Energy (SACOME) chief executive officer Nicola McFarlane opened the final day with a reminder that the global push for decarbonisation depends on the success of the mining industry.

Her comments reflected a recurring idea throughout AIMEX 2025: that mining’s future will be built on technological advancement, environmental accountability and strong partnerships across the supply chain.

Technology, safety, collaboration and excellence AIMEX’s diverse conference program went beyond policy and production, exploring the technologies that are helping to reshape mine operations. From artificial intelligence (AI) and automation to data-driven safety systems, the sessions provided practical insights into how digital tools are enhancing decision-making and risk management.

The ‘Tailoring solutions to unique mine site challenges’ panel was among the event’s standouts. It examined

BHP GROUP PROCUREMENT OFFICER RASHPAL BHATTI OUTLINED A BOLD COPPER STRATEGY.

that Adelaide got AIMEX this year,” she told Australian Mining on the exhibition floor.

“We’ve loved AIMEX and really appreciate how good the Prime Creative team has been to work with. We’ve really enjoyed it, and we’ve got a lot out of it.”

That appreciation was not limited to local exhibitors.

THE CONFERENCE PROGRAM DELIVERED INSIGHTFUL PANELS AND PRESENTATIONS.

WE’VE LOVED AIMEX AND REALLY APPRECIATE HOW GOOD THE PRIME CREATIVE TEAM HAS BEEN TO WORK WITH. WE’VE REALLY ENJOYED IT, AND WE’VE GOT A LOT OUT OF IT.”

The exhibition floor, filled with new technology zones and futurefocused displays, showcased the state’s ambition to lead the next generation of mining excellence.

For exhibitor Grace Frayne, marketing coordinator of Adelaidebased RTS Group Australasia, the move to South Australia was a very welcome one

“As a brand, we really wanted to establish our footprint and make sure that people know this is our home turf, so it’s very exciting

“We’re a national business, but we do have a number of Motion branch business segments in Adelaide, so the show was important from a local aspect,” Motion Asia Pacific managing director of national business Darrin Sergeant told Australian Mining.

“We had a good spread of customers and visitors from all over the country – Perth, New South Wales and Queensland – and we had some good leads across the total Motion product range.”

By the close of AIMEX 2025, one message was clear: Australia’s mining sector is not standing still. It is advancing with purpose, supported by visionaries, innovators and communities that see opportunity in transformation.

From Koutsantonis’ optimism and Bhatti’s copper blueprint to McFarlane’s call for growth through sustainability, AIMEX 2025 captured the spirit of a sector in renewal. The event acted as a declaration that Australian mining’s next chapter is one of insight, innovation and shared success. AM

WITH IMMENSE VOLUMES, LONG LIFESPANS AND COMPLEX ENVIRONMENTAL LEGACIES, MINE WASTE HAS LONG BEEN ONE OF THE SECTOR’S DEFINING CHALLENGES.

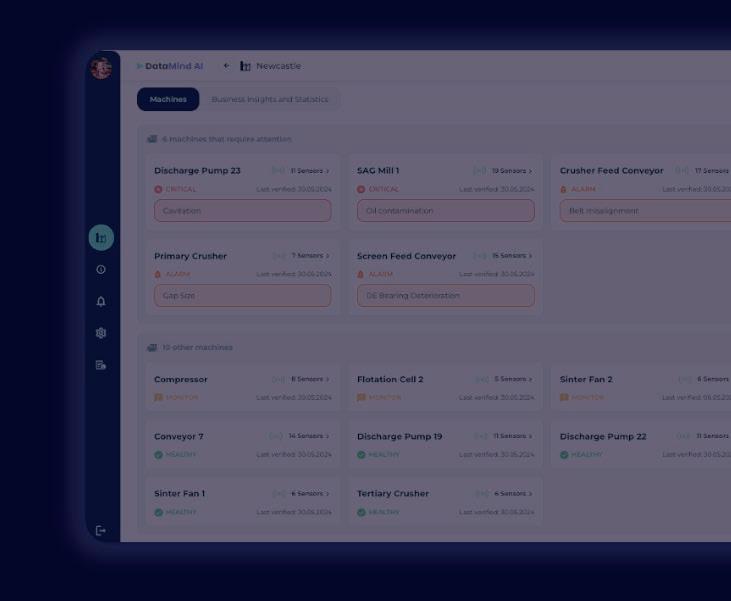

Australia’s modern mining industry is meeting the challenge of mine waste with a new generation of technologies, practices and partnerships that are reshaping how waste is handled from the moment ore is extracted to decades after a pit is closed.

The story is not one of neat fixes but of pragmatic, measurable progress, and an industry increasingly confident it can meet environmental, social and governance (ESG) expectations while continuing to underpin the national economy.

Designing waste out of the loop

A fundamental shift is happening at the design stage. Modern projects now plan for waste management as an integral part of mine design rather than

as an afterthought. This means smaller footprints for waste storage, higher containment standards, and processes that prioritise water recovery and reuse from day one.

Thickened and filtered tailings are replacing loose slurry in many new developments. These approaches help to reduce the need for large tailings ponds, lower water use and create a more stable material that can be placed in engineered landforms or returned underground. The net effect is a reduction in long-term liability and improved operational flexibility. Design-led thinking is also enabling co-location and multiple-use approaches. Waste rock and processed residue are increasingly viewed as potential inputs for construction materials, road base and other local uses, turning what was waste into value for regional

communities while reducing transport and rehabilitation costs.

Digital technology has moved from pilot stage into routine use across the field. Remote sensing, drones and satellite monitoring now allow operators and regulators to monitor large waste facilities with greater frequency and precision than ever before.

Satellite imagery, aerial surveys and automated drone flights give teams detailed deformation and volumetric data; real-time geotechnical sensors embedded in dams and waste stacks provide early warning of seepage or movement. These feeds are increasingly combined into digital twins, virtual replicas of assets that enable scenario testing, predictive maintenance and faster response planning.

Artificial intelligence (AI) and machine learning are being layered on top of these data streams to flag

anomalies and model stability under extreme weather scenarios. The value is twofold: improved safety and a stronger evidentiary record for environmental compliance and community reporting. One of the most constructive trends is the reappraisal of legacy tailings and waste rock. Advances in mineral processing, hydrometallurgy and sequencing mean old tailings can be reprocessed economically to recover residual metals, including critical minerals in demand for batteries and renewables. Where reprocessing isn’t viable, novel treatments can stabilise contaminants or unlock by-products such as construction aggregates, lime or silica for industrial applications. These circular strategies reduce the environmental footprint of historic operations while creating new revenue pathways and jobs in host regions.

TECHNOLOGICAL ADVANCES MEAN TAILINGS CAN BE REPROCESSED ECONOMICALLY TO RECOVER RESIDUAL METALS.

DATA FROM SATELLITE MONITORING ALLOWS OPERATORS TO VIEW LARGE WASTE FACILITIES WITH GREATER FREQUENCY AND PRECISION.

management. Australian operations have tightened water balances across their assets and are deploying advanced treatment solutions to close water cycles. Mobile and modular treatment plants enable targeted remediation of seepage and process water, while membrane filtration, ion exchange and constructed wetland systems offer options for meeting discharge criteria with lower energy intensity.

Reclaimed process water is increasingly reused in areas such as comminution and dust control, further reducing water demand in a continent where its stewardship is an environmental and social imperative.

rehabilitation programs are designed with local stakeholders, including Traditional Owner groups, to align outcomes with cultural values and regional economic objectives.

Regulators and communities expect mine-closure planning to start on day one, and many operators now demonstrate this through staged, progressive rehabilitation.

Rather than leaving landform construction until the end of mining, progressive rehabilitation rebuilds landforms, soils and vegetation in parallel with mining activity,

Governance practice around mine waste has also tightened. Companies are embedding tailings and waste management into board-level risk frameworks and reporting on performance with greater granularity.

Industry adoption of global and regional best-practice standards, combined with enhanced regulatory oversight and transparent community reporting, is lifting expectations and performance across the sector.

Universities, research organisations and private providers are collaborating with miners to scale promising innovations from trial to mainstream use. Pilot installations for novel backfill chemistries, phytoremediation trials and new monitoring arrays are increasingly common.

Beyond the technological, these collaborations help to build local capability through training, supplier development and the transfer of skills into regional workforces.

The transformation of mine waste management in Australia is less about a single silver bullet and more about a convergence of better design, smarter

technology, commercial creativity and stronger governance.

The net result is a mining sector that is reducing its environmental footprint, producing new economic value from legacy materials, and building more resilient closure plans, all while maintaining safe, productive operations.

For communities and regulators, the shift translates into more predictable environmental outcomes and clearer pathways for land restoration. For miners, it reduces long-term liabilities and unlocks new sources of value.

Australia is moving from reactive waste management to proactive resource stewardship, a transition that bodes well for the sector’s social license and its role in supplying the metals and minerals the world needs for a cleaner future. AM

Across the globe, miners are re-examining what waste really means.

Tailings, once written off as liabilities, now hold the potential to deliver new revenue streams, critical minerals, and major environmental gains.

For more than 140 years, FLS has provided the technology, knowledge and services that empower customers to meet complex operational challenges. In recent years, many of those challenges have focused on minimising environmental impacts. FLS’s longstanding and proven legacy of innovation has enabled the company to be at the forefront of driving efficiencies while delivering sustainable outcomes.

With governments tightening regulations on tailings storage and the demand for metals accelerating, the pressure is on to extract more value from less material, while ensuring that mine operators achieve their environmental, social and governance (ESG) goals.

“Every mine has hidden value sitting in its tailings,” FLS business development manager for REFLUX technologies Anson Gilbert said.

“The challenge has always been to recover that value efficiently, safely and at a scale that makes economic sense. That’s exactly where our REFLUX technology family steps in.”

Redefining beneficiation

At the heart of FLS’s solution is the REFLUX Classifier (RC), a compact gravity separator combining a fluidised bed with a system of closely spaced inclined lamella plates. The plates accelerate the settling of dense particles

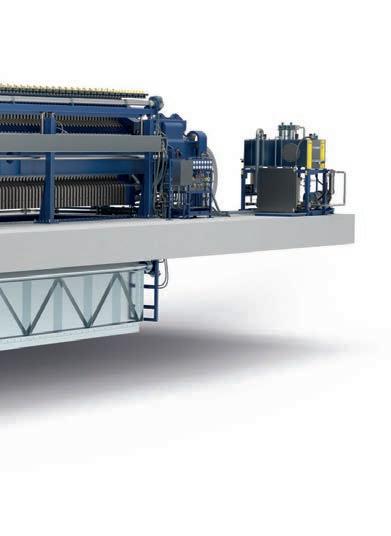

THE FLS AFP2500 COMPLEMENTS THE REFLUX TECHNOLOGIES BY PRODUCING STACKABLE, LOW-MOISTURE TAILINGS.

while desliming and classifying fine material. The result is a sharp densitybased separation with exceptional throughput. Developed in partnership with Laureate Professor Kevin Galvin at the University of Newcastle, the REFLUX Classifier family – including GradePro and the REFLUX Flotation Cell (RFC) – combines gravity separation, classification and flotation principles to recover value from fine and low-grade feeds.

Originally designed for coal, the RC now operates successfully in iron ore, base metals, manganese, chromite, mineral sands and spodumene. The technology is applied in more than 200 installations worldwide.

According to FLS, tests in Canada and Brazil have shown 20 per cent higher recovery and Fe grades exceeding 63 per cent in a single stage, replacing complex multi-stage flotation circuits. In coal and iron ore applications, the RC’s

lamella design has delivered probableerror (Ep) values below 0.06, said to be more than double the precision of traditional spirals.

Building on this foundation, FLS released the REFLUX Classifier Concentrator (RCC) – now marketed as GradePro, an advanced version tailored for low-grade ores and tailings re-treatment. The GradePro integrates secondary fluidisation water and a smaller mixing chamber, cutting bed-

build times by a factor of seven and increasing upgrade ratios more than 30 times for tin and tantalum tailings.

“GradePro takes all the learnings from the RC and adapts them for the world of low-grade feeds and mine waste,” Gilbert said. “It’s robust enough for plant operation, but selective enough to recover fine, high-value minerals that other devices simply miss.”

From tailings to treasure FLS said recent pilot campaigns underscore the step change. At a tin operation treating 0.15 per cent Sn tailings, the GradePro achieved 447× tin upgrade (67 per cent tin product grade) with over 75 per cent recovery.

In Brazil, it was demonstrated that a simplified SAG–RC circuit can replace traditional flotation, reducing operating expenditure by 42 per cent and capital expenditure by five per cent while maintaining of more than 68 per cent Fe concentrate.

Meanwhile, in Canada, the RC has delivered consistent high-grade iron ore concentrates with outstanding recovery and stability.

“Every one of these projects proves that you don’t need more stages; you just need smarter separation,” Gilbert

said. “The REFLUX approach achieves cleaner cuts, smaller footprints and faster payback.”

Recovering value is only half the story. Managing what remains is equally important.

FLS’s AFP2500 automatic filter press complements the REFLUX technologies by producing stackable, low-moisture tailings that can be safely stored or repurposed as backfill. Together, the technologies form a closed-loop system: recover the metals, recycle the water, and drastically reduce tailings dam volumes.

“This integration aligns perfectly with our MissionZero commitment,” Gilbert said.

MissionZero is FLS’s sustainability program that aims to reduce emissions and waste in mining to zero by 2030. In adopting the commitment, FLS has endeavoured to offer its customers the required technological and digital solutions to move towards greener mining processes.

“We’re helping customers move toward dry-stacked, resource-positive operations, where tailings dams become a thing of the past,” Gilbert said.

Of course, the shift to a more sustainable world is further driving

demand for minerals like copper, lithium, and other critical minerals.

These critical minerals are foundational to the global green transition because they enable the technologies driving decarbonisation.

Copper is vital for renewable power and electrification. Its superior conductivity makes it indispensable in wind turbines, solar panels, electric vehicles (EVs) and power grids.

Lithium is central to energy storage, forming the core component of lithiumion batteries that power EVs and balance renewable energy supply through gridscale storage systems.

Beyond these, minerals such as nickel, cobalt, rare earth elements and graphite are equally important.

These minerals underpin the infrastructure of a low-carbon economy – renewable energy systems, electric mobility and advanced storage technologies.

Growing research points to rare earth and critical mineral recovery from coal and historic tailings.

The GradePro’s ability to separate on subtle density differences makes it suitable for extracting fine rare earth elements bearing phases, further

extending its relevance as the energy transition accelerates.

“Critical minerals are the new frontier,” Gilbert said. “The chemistry is complex, but the physics of separation still matters, and that’s where our technology gives miners an edge.”

A circular future for mining

Corporate governance and ESG compliance have become mandatory expectations; however, many companies still grapple with the challenges of how they can reconfigure operations for longterm sustainability.

As mining companies face increasing ESG expectations, technologies that turn waste into resources are reshaping the industry narrative.

By combining scientific innovation with proven field performance, FLS’s REFLUX technologies can offer economic viability, environmental responsibility and operational simplicity in one platform.

“The conversation has shifted,” Gilbert said. “It’s no longer just about compliance or waste management; it’s about value creation, decarbonisation and future-proofing our industry. REFLUX technology allows us to do all three.” AM

ORE BEFORE MECHANICAL BREAKAGE.

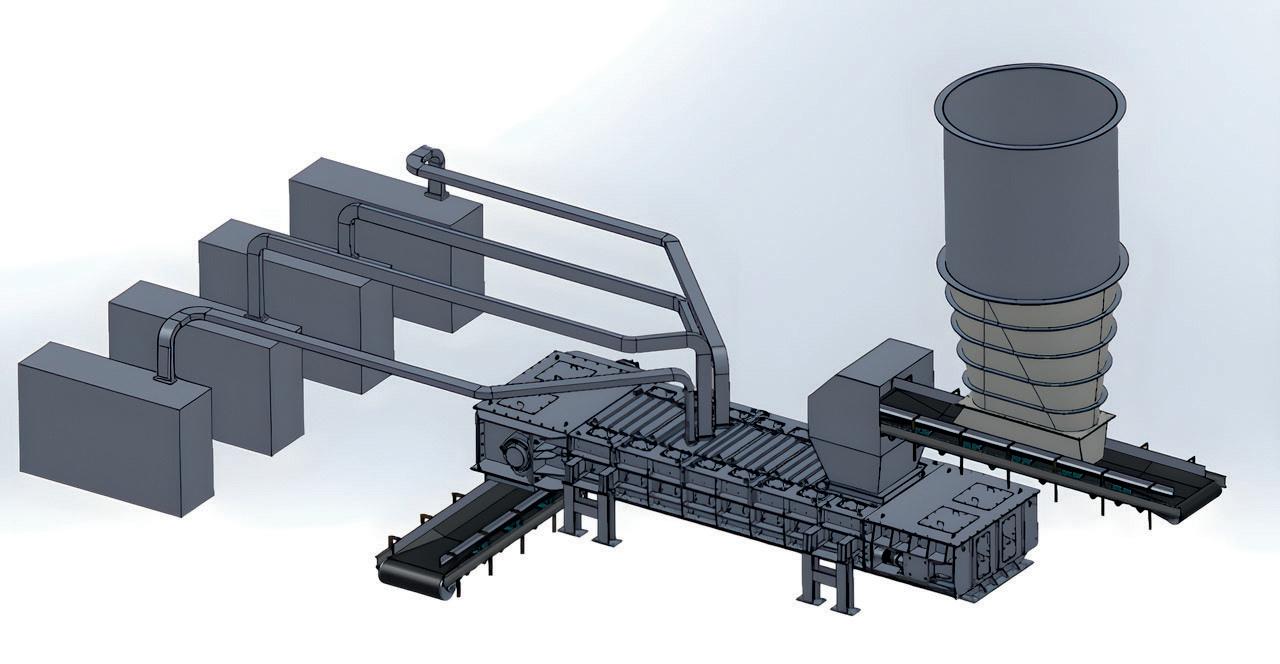

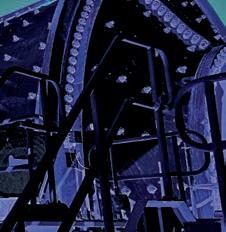

A COLLABORATION BETWEEN JENIKE & JOHANSON AND CRESCEND TECHNOLOGIES PROMISES A MAJOR BREAKTHROUGH IN THE ORE TREATMENT PROCESS.

Companies don’t operate for six decades without doing something right. For almost 60 years, Jenike & Johanson has been a global leader in bulk material handling.

The company has established such a strong legacy by constantly seeking to innovate its technology and better support its clients with products and services that understand the demands of the modern mining industry.

That spirit of innovation, collaboration and support is borne out by its recent strategic partnership with Crescend Technologies, a leader in solid-state microwave power systems, to accelerate the development and commercialisation of the innovative Selective Heat Ore Treatment (S.H.O.T.) process.

The collaboration unites two topflight technologies: Jenike & Johanson’s expertise in advanced material handling design and process engineering, and Crescend’s precision solid-state microwave systems.

Together, these capabilities deliver a scalable, energy-efficient solution

for microwave-assisted comminution, offering the mining industry a new approach to ore treatment.

“We’d been exploring microwave treatment of ores for quite some time,”

Jenike & Johanson chief executive officer Herman Purutyan told Australian Mining

“We came across Crescend, who have fantastic expertise in microwave generation and control. A big part of the challenge is being able to deliver that microwave energy to the ore in a controlled and safe way, and Crescend has great technology to do exactly that.”

Purutyan said the partnership represents a significant advance for sustainable ore processing technologies.

“When we met them, it was clear this would be a great partnership,” he said. “Our strength is in handling the material uniformly and reliably as it passes through the microwaves, while Crescend’s strength is in generating and applying those microwaves effectively.

“It’s a perfect match to move this technology forward.”

How S.H.O.T. works

S.H.O.T. applies solid-state microwave energy to ore before mechanical breakage.

By selectively heating minerals within the rock matrix, the process weakens grain boundaries, causing fractures that make the ore significantly easier to crush and grind. This not only reduces the energy required for comminution but also

energy control and integration flexibility. This is designed to ensure that microwave energy is delivered exactly where and how it is needed in S.H.O.T.’s selective heating methodology.

Purutyan said the technology works

S.H.O.T. REPRESENTS A TIMELY INNOVATION AS THE SECTOR CONFRONTS DECLINING ORE GRADES AND RISING SUSTAINABILITY EXPECTATIONS.

JENIKE & JOHANSON’S STRENGTH IS IN HANDLING THE MATERIAL AS IT PASSES THROUGH THE MICROWAVES, WHILE CRESCEND’S STRENGTH IS IN GENERATING AND APPLYING MICROWAVES EFFECTIVELY. IT’S A PERFECT MATCH TO MOVE THIS TECHNOLOGY FORWARD.”

“For the technology to be at its most effective, you need a particular type of mineral in the rock body, typically one surrounded by very hard rock,” Purutyan said. “The way it works is that the microwaves target certain parts of the ore that absorb energy, while the hard rock – being transparent to microwaves – doesn’t heat up. The heating parts expand, creating microcracks, and that’s where the benefits come from. For that to happen, the ore has to have a certain texture.”

Purutyan said the approach is especially valuable because harder rocks usually take much more energy to grind.

Tackling comminution

Among the most significant

S.H.O.T. SIGNIFICANTLY REDUCES THE AMOUNT OF FORCE REQUIRED TO FRACTURE ORE.

According to Purutyan, this process is the single largest consumer of energy in most mining operations. As orebodies age and average grades decline, the energy intensity of comminution only increases, driving up costs and carbon emissions.

S.H.O.T. offers an alternative.

“This technology significantly reduces that energy requirement,” Purutyan said.

“In terms of energy reduction, we’re seeing potential cuts of 20 to 30 per cent in comminution energy for suitable ores. Considering how energy-intensive that process is, that’s a major saving.”

By introducing a non-mechanical, solid-state microwave targeted treatment step prior to grinding, S.H.O.T. significantly reduces the amount of

brute force required to fracture ore. The process uses relatively low microwave energy inputs, typically in the range of 0.3–3 kilowatt-hours (kWh) per tonne yet delivers substantial weakening of the ore.

Differential heating at mineral grain boundaries creates micro-fractures, enabling equivalent liberation at coarser grind sizes and reducing the demand on downstream crushers and mills.

Purutyan said delivering such a process at scale requires a commitment to stringent design methodologies alongside iterative testing that demonstrated real gains for mine operators.

The S.H.O.T. process itself has been demonstrated successfully at a 150-tonne-per-hour pilot scale, showing strong potential to scale to commercial operations.

Alongside the primary gain of a significant reduction in comminution energy requirements, the S.H.O.T. technology provides a compelling set of advantages for mining and mineral processing operations.

These include an increased plant throughput for grinding and beneficiation circuits, equivalent liberation at coarser grind sizes, reducing grinding intensity, and improved leaching recovery, boosting metal yield from ore. By lowering the energy intensity of comminution, S.H.O.T. not only reduces costs but aligns with the mining industry’s commitments to decarbonisation and environmental stewardship.

Jenike & Johanson is currently looking to move S.H.O.T. from pilot testing into full commercial deployment. Mining companies seeking to increase throughput, cut operating costs, and unlock value from lower-grade or previously uneconomic ore bodies stand to benefit significantly from this new approach.

As the resources sector confronts the dual challenges of declining ore grades and rising sustainability expectations, S.H.O.T. represents a timely innovation.

By combining Jenike & Johanson’s expertise in bulk material handling with Crescend’s advanced solid-state microwave systems, the partnership is unlocking a pathway to smarter, greener and more profitable ore processing.

In a sector where incremental gains are celebrated, S.H.O.T. stands out as a step change technology with the potential to transform one of mining’s most energy-hungry processes into a model of efficiency and sustainability.

In an industry where any downtime can cost millions of dollars, managing waste in a manner that does not disrupt work isn’t just important to become more sustainable – it’s an operational imperative.

With a greater emphasis on environmental, sustainability and governance initiatives in mining operations, it’s critical to ensure dayto-day performance and efficiency are being balanced.

KOR – exclusive distributor of Cappellotto industrial vacuum products – provides equipment to help ensure operations remain running while waste recovery and asset cleaning are completed in a timely manner.

“KOR was initiated 15 years ago because we identified the market was not truly addressing the need for equipment that allows higher productivity whilst putting safety as a top priority,” KOR head of product and commercial Tim McGregor told Australian Mining

“Our offering is allowing work to be completed with less manpower. This

not only keeps operations efficient, but it also means operators are kept safe, too, which we know is top of mind. By having more capable machines, you typically have a better return on investment for the customer.”

As a specialist in vacuum and water jetting equipment, KOR is committed to delivering solutions and value with its wide range of equipment, parts and accessories, and nation-wide servicing capabilities.

The CAP VAC INDUSTRIAL 3200 10x4 can be used to vacuum up all nonhazardous dry and wet waste material, with other models specifically designed for dangerous goods.

With its long-distance, eight-inch vacuum hose with 270° boom rotation, it offers manoeuvrability and flexibility with greater productivity.

“Instead of needing two or three trucks on a job, you can go back to having one truck only, which decreases the footprint required, decreases the labour required, and decreases the risk of injury,” McGregor said. “We provide people with the ability to keep their

assets online with a conveyor system or pond that would normally have to be shut down when there is a period of cleaning or maintenance; they can work remotely without ever needing to send a person to that area because of using robotics.

KOR also offers Gerotto and Falch robotics that, when coupled to the vacuum and ultra-high pressure water equipment, enables a no-person entry approach to cleaning and waste removal that is safe and productive.

The equipment comes with several other advantages – providing mine sites with safer waste management strategies while also providing more environmentally-friendly waste disposal.

“Reliability is always an issue when we look at large industrial vacuum trucks,” McGregor said.

“What sets us apart is that we have the world’s most reliable equipment with a supply chain that really helps people make notable change to the way waste is managed. You don’t want to shut down equipment for cleaning and with us; you don’t have to.

“On top of that, you’ve also got selfcleaning automated filter systems, which reduces the downtime of the equipment itself. Gone are the days when you need to clean the filter box manually by putting sludge into a wheelbarrow or bin.”

With innovations that help keep sites at the fore of operational safety, KOR also offers accredited competency-based training programs that increase the skill level of those using vacuum and highpressure water equipment in the mining industry. The company provides tailored and general training to designed to ensure sites are adding the right skills.

“It’s all about working safely on site and this accredited training, along with delivering higher performing safer equipment, has really helped improve the industry practices of working safely, but yet, still being productive,” McGregor said.

With equipment that is compatible with KOR’s Gerotto remotely operated vehicles for greater efficiency and safety, it’s clear to see why it’s a premier destination for industrial service equipment across New Zealand and Australia. AM

CUSTOM-FIT ARTERRA UHMWPE PIPELINES

ALLOW PRECISE INTERNAL DIMENSIONS, OPTIMISING FLOW AND REDUCING WEAR.

THE SAME ULTRA-SMOOTH MATERIAL THAT HELPS ARTIFICIAL JOINTS MOVE FREELY IS NOW SOLVING ONE OF MINING’S MOST PERSISTENT HEADACHES.

Weir’s advanced pipeline solution

Arterra is an ultrahigh molecular weight polyethylene (UHMWPE), material proven in medical implants and marine applications that dramatically extends pipeline life in some of Australia’s harshest environments.

With more than 15 operational installations across the country and around the globe, some stretching up to 20km, the technology is demonstrating that materials engineered for barnacleresistant fenders and friction-free knee replacements can deliver results when pumping abrasive mine tailings.

Weir’s pipeline solutions manager in Australia Tatum Hall said the technology delivers significantly lower operating costs.

“The surface smoothness of this material offers friction benefits that translate directly to reduced power requirements and extended service life,” she said. “We’re seeing significant yearly savings at sites that make the switch.”

The reality of pipeline failure hit home at an iron ore operation in South Australia a few years ago. The site was using conventional high-density polyethylene (HDPE) pipelines, which were wearing through in 3–4 weeks. The culprit wasn’t corrosion – it was physics.

“They had some slack flow portions of the pipeline. Because of the steep slope, the material was moving faster than it was being pumped; we’re talking up to 12m per second, which is incredibly fast for pipeline operations,” Hall said.

“When you’re pushing particles at that velocity through a pipe filled with highdensity solids, the wear is relentless.”

The site’s initial response – replacing failed sections every 4–6 weeks – was costly and operationally disruptive. After switching to Arterra UHMWPE pipeline, the same sections now last 16–18 months, a 16-fold improvement in service life.

Beyond wear from abrasion, chemical scaling presents another challenge. In operations with heavy chemical processing, such as uranium transport and mining, minerals crystallise on pipe walls, progressively narrowing the internal diameter and choking flow capacity.

“It’s a constant maintenance headache,” Hall said. “The scaling builds up into hard crystals, layer upon layer, until you’re losing significant capacity.”

The secret to the performance of Arterra UHMWPE pipelines lies in the molecular structure of UHMWPE itself. Arterra pipes have a molecular weight of 3.5x106 grams per mole (g/ mol), compared to HDPE with a molecular weight of 0.5x106g/mol. With a surface roughness of just 0.2 microns, the material is exceptionally smooth, almost hydrophobic in its resistance to adhesion.

“It’s this smoothness that gives it the edge,” Hall said. “We’re talking about a material roughness that’s incredibly low compared to other pipeline materials. Nothing really sticks to it.”

That property made UHMWPE a natural choice for marine applications, where its slipperiness prevents barnacle growth and bio-fouling. In medical applications, the same characteristics

allow hip and knee replacements to move freely without friction or adverse tissue reactions, thanks to the material’s chemical inertness.

But translating those properties into mining pipelines required solving a significant engineering challenge. The very smoothness that makes UHMWPE so effective also makes it impossible to weld.

“Around 2014, we developed a way of flanging the ends and creating connections that seal reliably at the pressures required for

mining,” Hall said. “That was the breakthrough that opened up this material for pipeline applications.” Another key advantage is customisation. Where conventional pipelines come in standardised diameters, Arterra UHMWPE pipelines can be specified to exact internal dimensions based on an operation’s specific design requirements. The wall thickness is then calculated from three components: pressure rating, temperature de-rating, and wear allowance.

Arterra UHMWPE pipelines at an operation dealing with heavy chemical processing helped the site dramatically reduce its maintenance burden.

“They were pressure washing their pipes monthly at 3000 kilopascals [kPa], which introduces significant safety risks for workers,” Hall said. “After switching to Arterra pipelines, they went to quarterly cleaning at just 1000kPa.

“That’s a much safer operation and far easier to schedule.”

The reduced friction also means lower pumping power requirements, with savings becoming increasingly

•Mask down feature as standard delivering strong results in mining.

significant on longer pipeline runs.

On installations exceeding 5km, the optimised internal diameter and smooth surface combine to significantly reduce energy consumption.

Arterra UHMWPE pipelines are available in two configurations, depending on application requirements.

The bare plastic pipe offers maximum flexibility for tailings applications where extreme pressures aren’t a factor. For higher-pressure environments, a lined steel option uses Arterra UHMWPE pipes as an internal lining within steel pipe, capable of handling pressures

• Up to 5,278m2 Light Coverage

• 420Wp solar panel

secure your stock today with our exclusive

• Compact design

• Robust HardHat® canopy

exceeding 10,000kPa, whereas a bare pipe can handle pressures up to 4000kPa, depending on size.

The technology has found its natural home in tailings transport, typically the longest pipeline runs on a mine site, where abrasive slurries must travel from processing plants to disposal areas.

With installations now proven across Australian operations, Arterra UHMWPE pipelines represent a case where borrowing innovation from other industries has delivered tangible improvements in durability, safety and operational efficiency for mining. AM

IN MINING, DOWNTIME

IS COSTLY. WASTE INITIATIVES DELIVERS PROVEN WASTE MANAGEMENT SOLUTIONS THAT KEEP OPERATIONS RELIABLE, EFFICIENT AND COMPLIANT.

Reliable equipment isn’t just nice to have on a mine site; it’s pivotal in providing lower operating costs and ensuring long-term business success. Waste management is no different.

When waste compactors, balers, shredders or sorting systems break down, the ripple effects include increased labour costs, missed collection deadlines and a damage to reputation.

Waste equipment specialist Waste Initiatives believes it’s not about throwing a single solution at each problem, but rather working with sites to find solutions that best suit the challenge at hand.

“There are multiple ways to skin the cat – it’s about looking at each site as an individual and working with them, their waste contractor, and staff to find the best solution to fit the problem,” Waste Initiatives managing director Dwayne Smith told Australian Mining. “We work with top international partners from Germany, Ireland and America to bring in quality and reliable equipment that gives customers in Australia complete solutions. We then back that with local spare parts and local service to ensure they’re getting all they need and more.”

tyre shredders, over-the-road (OTR) tyre debeaders and cutters, roll packers, compactors, balers and conveyors, all available with custom layouts, mobile options, and diesel or electric drives.

Services extend beyond simp supply, supported further with project management, installation, commissioning and servicing. With a national service team and a locally stocked parts network, Waste Initiatives delivers long-term reliability and responsive support.

With considerable scrutiny from environmental authorities, correct disposal of waste generated from site is essential in ensuring compliance and hitting key environmental, social and governance (ESG) metrics.

Now more than ever, consideration of ESG issues is becoming more important to the mining industry, with exploration pinned as a key opportunity.

Guides from industry bodies such as the Association of Mining and Exploration Companies encourage ways mine sites can better understand and implement ESG related activities, something in which Waste Initiatives also engages through its sales after-care, including training.

Having worked with several highprofile clients in the past, Waste Initiatives solutions partner Brenton Sargeant said challenges are easy to overcome with the right know-how.

“We offer waste management solutions to mine sites that can really help with their operational output and how waste is disposed. We can help with reducing the amount of waste going to landfill.”

One key challenge for mines is handling end-of-life OTR tyres.

Waste Initiatives provides the Eagle International OTR tyre debeader, capable of removing bead bundles from tyres up to 4m in diameter and 63-inch rims.

When combined with the Eagle International OTR tyre cutter, large tyres can be prepared on site for easy transport and further processing.

With approximately 330,000 tonnes of tyre waste being recovered in Australia every year, new technology is being used to better recycle the material. This kind

of volume and durability can be seen as a challenge for many sites.

Waste Initiatives provides a range of equipment designed for tyre waste recycling. By investing in these solutions, businesses and communities can effectively manage tyre waste, reduce environmental impact and contribute to a more sustainable future.

“If you need to lift recycling rates, process OTR tyres, or simply reduce the cost of moving and storing waste, we can help,” Sargeant said.

With more than 40 years of experience in waste solutions design and supply, Waste Initiatives offers mine sites a true one-stop shop for shredding, compacting and recycling, all backed by a national service network and locally stocked spare parts. AM

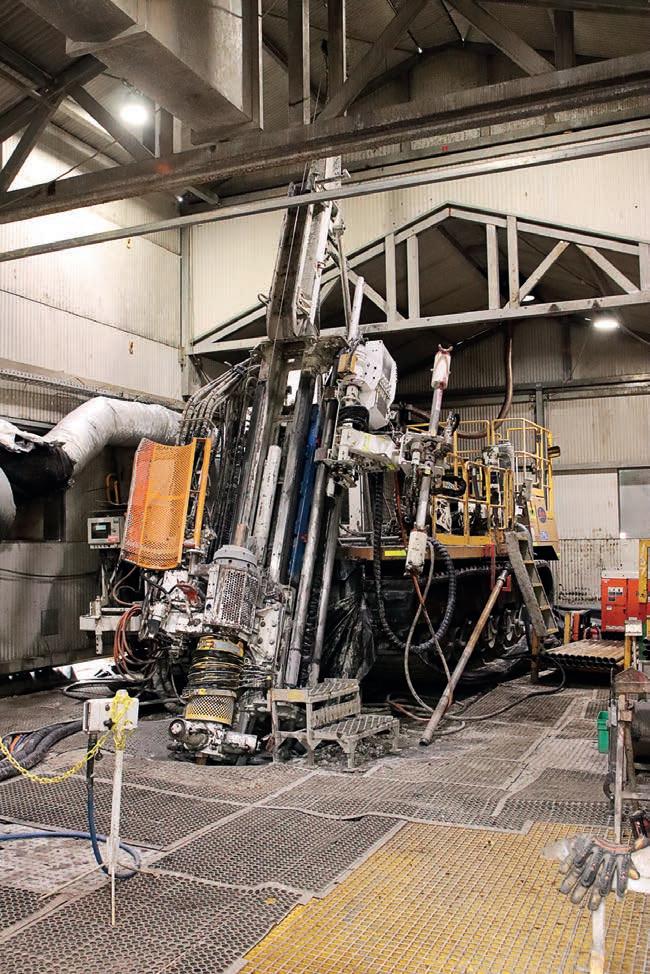

FOR DECADES, FLOTATION HAS BEEN A CORNERSTONE OF MINERAL PROCESSING – AN ADAPTABLE AND EFFICIENT METHOD WHOSE IMPORTANCE IS ONLY EXPECTED TO GROW.

As ore grades decline and environmental expectations rise, miners are under increasing pressure to recover more metal using less energy, less water, and less space.

Eriez, a global leader in separation technologies, has been at the forefront of this transformation.

With more than 80 years of expertise in magnetic, flotation, and materialhandling systems, the company has built a reputation for helping customers achieve the delicate balance between metallurgical performance and environmental responsibility.

The company’s latest breakthrough – the StackCell flotation system – represents a decisive step in that direction. Designed to recover fine and ultrafine particles while reducing energy consumption and plant footprint, StackCell has rapidly emerged as one of the mining industry’s most versatile and sustainable flotation solutions.

According to Eriez senior global product manager Homie Thanasekaran, the technology was born directly from customer feedback.

“At elevations approaching 4000m – as seen across many South American mine sites, or in remote operations across Western Australia’s red-sand deserts – building and installing larger

flotation tanks is a constant challenge,” Thanasekaran said.

“What customers really wanted was a compact, energy-efficient system capable of achieving top-tier metallurgical performance, especially in the recovery of fine particles, rather than simply adding more and bigger flotation cells. With many of these remote sites constrained by limited access to energy and water, efficiency had to be engineered into every aspect of the design.”

Originally developed from Eriez’s proven column flotation technology, the StackCell was designed to deliver selective recovery of fine particles within a far more compact and energy-efficient platform, specifically engineered to replace conventional cells in rougher, scavenger, cleaner, and cleaner-scavenger circuits.

Thanasekaran explained that the innovation was shaped by customer demand for flotation systems that are smaller, enclosed and easier to install and maintain, particularly in operations challenged by space constraints, extreme climates or high elevations.

energy use. StackCell evolved through that continuous collaboration with our customers over the past decade.”

“We took that feedback to heart,” he said. “In regions like North America, where sub-zero temperatures mean most equipment must be housed and heated indoors, there was a clear need for a system that minimised both size and

The result is a flotation cell that, according to Eriez, consumes roughly one-third of the energy of comparable conventional systems, with a footprint 50 per cent smaller and foundation loads reduced by up to 70 per cent.

With its focus on energy efficiency, fine particle recovery and reduced environmental impact, StackCell

exemplifies how technology and innovation can work hand-in-hand to make mineral processing more sustainable, while simultaneously delivering higher recovery of fine and ultrafine particles.

At the heart of StackCell’s success is a deceptively simple idea: separating the particle-collection and phase-separation stages of flotation.

Traditional cells perform both functions in one tank, forcing engineers to compromise between turbulence (required for particle–bubble attachment) and stability, essential for separation.

By decoupling these zones, StackCell focuses energy precisely where it’s needed. The turbulent dissipation rate in its collection chamber can reach 120 watts per kilogram (W/kg), which Eriez said is up to five times higher than in conventional mechanical cells. The result is faster bubble–particle collisions, superior fine particle recovery and higher grade concentrates at minimal residence time.

“Fine particle recovery has taken on new urgency as ore grades drop,” Thanasekaran said. “Where processing one tonne of ore once produced between 0.8 and 1kg of copper, it now yields only about half that. To sustain production levels, miners must process nearly twice as much material, making efficiency and selectivity more important than ever.”

This makes energy-smart flotation essential for miners chasing productivity and environmental, social and governance (ESG) goals simultaneously. Thanasekaran said StackCell delivers that balance.

“We’re seeing sites that need to increase throughput by 15 to 20 per cent just to meet production targets, but they don’t have the real estate or the power capacity to add that within their existing operations,” he said. “StackCell allows them to add capacity at the back end of the circuit with minimal footprint, a key advantage in brownfield operations.

StackCell’s modular, compact design means it can be easily retrofitted into existing circuits as a scavenger or cleaner scavenger unit, enhancing recovery from tailings stream and improving overall circuit performance.

Thanasekaran said many customers are now deploying StackCell in tailings recovery applications, where its ability to capture ultra-fine particles delivers immediate and measurable value.

“When particles get very fine –around 20 microns or even as small as five microns – they tend to escape conventional flotation due to the lack of sufficient turbulent dissipation rate and report straight to tailings,” he said. “StackCell can recover those fine, valuable minerals and return that lost revenue back to the operation.”

The technology also complements Eriez’s HydroFloat coarse-particle flotation system, with the two working in tandem at opposite ends of the particle-size spectrum. HydroFloat handles the coarse material – “the sand on the beach” as Thanasekaran puts it – while StackCell captures the ultra-fine “dust”. Together, they deliver complete recovery coverage across the circuit, maximising overall metallurgical performance

StackCell’s environmental credentials are equally compelling. Lower energy consumption, reduced reagent use, and a smaller installation footprint all contribute to improved sustainability performance. Eriez reports that the design aligns directly with mining companies’ decarbonisation and ESG commitments, including long-term netzero targets.

Eriez’s long-standing culture of innovation is deeply embedded in its DNA. Founded in 1942 and headquartered in Erie, in the US state of Pennsylvania, the company now operates in 12 countries, including Australia, where it maintains offices in Victoria and Western Australia and supplies equipment to the nation’s largest mining regions.

Thanasekaran said that culture stems from the vision of Eriez’s leadership team and founder.

“Our CEO Jaisen Kohmuench and VP of technology Mike Mankosa both did their PhDs in flotation at Virginia Tech about 30 years ago,” he said.

“They started the research that became StackCell and HydroFloat in a small laboratory. Today, that same innovation is operating at full industrial scale worldwide.”

Thanasekaran also credits Eriez’s owner Richard Merwin for fostering a research-driven mindset that continues to shape the company’s technological breakthroughs.

“Richard believes in developing technologies that stand out,” he said. “He doesn’t want to buy ideas – he wants us to build them That’s why Eriez has

such a strong in-house R&D [research and development] capability.”

This philosophy has paid off, with StackCell installations now spreading rapidly through key global markets. In Australia, the technology is being used across coal operations in Queensland, as well as copper, gold and rare-earth sites in Western Australia.

“In Queensland alone, we have more than 15 StackCell units operating,” he noted. “In Western Australia, we’re seeing strong adoption in copper, gold and rare-earth processing, too.”

Interest is rising fastest in copper and gold projects around the world, where soaring demand meets increasingly complex ore bodies. Thanasekaran expects the next decade to bring continued expansion.

“The demand for copper is projected to remain very strong for at least the next 10 years,” he said. “As ore grades fall, technologies like StackCell that can process higher volumes efficiently will only become more important.”

For Eriez, that combination of market demand, technical innovation and sustainability focus is what defines the company’s purpose. StackCell isn’t just a smaller, faster flotation cell; it represents a shift in how the industry thinks about mineral recovery.

By marrying high-intensity particle collection with low-impact design, the technology shows that superior metallurgical performance and environmental stewardship can truly go hand-in-hand.

“Our goal is to help customers recover more metal with less energy, less water and less waste,” Thanasekaran said. “That’s what StackCell is all about.” AM

WITH ITS FOCUS ON ENERGY EFFICIENCY, FINE PARTICLE RECOVERY, AND REDUCED ENVIRONMENTAL IMPACT, STACKCELL EXEMPLIFIES HOW TECHNOLOGY AND INNOVATION CAN WORK HAND-IN-HAND.

ERIEZ FLOTATION SYSTEMS ARE DESIGNED TO WORK WELL IN A RANGE OF LOCATIONS AND SITES.

SMARTER WASTE MANAGEMENT FOR MODERN MINING.

TAILINGS

As mineral operations target higher recovery rates from increasingly

This shift is resulting in a growing proportion of ultra-fine tailings –particularly those under 45 micrometre

particles, these tailings exhibit poor packing densities. This limits their ability to develop sufficient material

due to fine particle sizes, and the need to stabilise leachable constituents.

reliance on traditional tailings storage facilities, in-pit disposal or low-strength demands of dewatering large volumes.

• Brine management challenges – tailings and brine disposal are closely linked, particularly during mine closure. Effective management requires an integrated strategy that begins early in the mine’s life and continues through closure and monitoring.

Beca’s expertise

Modern mining operations are being met with rising expectations to reduce the environmental and community impacts of tailings. Key priorities include minimising surface tailings storage, improving long-term stability, and expanding opportunities for repurposing.

responsibly. Several critical risks must be addressed to help ensure safe, sustainable

Escalating liabilities – large tailings

constrained by factors such as distance achieving sufficient material strength

Beca brings leading expertise across the full tailings lifecycle, from identifying suitable geological and geotechnical conditions for storage facilities to mine closure and postclosure monitoring. The team designs optimal slurry characteristics tailored to the intended storage method, whether traditional slurry, paste, or filter cakes. It also develops backfill formulations, manages tailings dams and leads innovative repurposing strategies.

“What sets Beca apart is our pioneering work in tailings reuse,” Beca chief metallurgist Paul Language said. “We focus on enhancing mineral

recovery and enabling the beneficial reuse of tailings both on-site and off-site, contributing to more sustainable and economically viable mining operations.”

Geotechnical, geochemistry and hydrogeology

The long-term stability of any tailings storage facility depends on selecting landforms with robust geotechnical characteristics. Given the extended operational life of these facilities, confidence in early-stage data is critical.

Beca offers deep expertise through a team of more than 160 geotechnical engineers, engineering geologists, and hydrogeologists across Australia, Southeast Asia and New Zealand.

“We deliver comprehensive studies to identify and assess suitable landforms for safe, sustainable tailings storage,” Beca minerals and metals segment director Tristan Musgrave said.

Optimising slurry for efficient handling

Slurry thickening and handling are central to effective tailings management, whether for traditional storage lowstrength backfill or dewatering. With over 40 years of scientific and engineering experience, Beca understands the importance of slurry rheology in transport and dewatering systems.

“Our approach includes fundamental slurry testing to inform pump system design and dewatering to ensure project success,” Language said. “We design systems that accommodate variability in tailings feed, optimise water recovery, and reduce energy consumption, all key challenges for operators today.”

Filter cake dewatering, handling and storage

As demand grows for higher tonnages and drier filter cakes, equipment suppliers are scaling up and automating dewatering technologies. While pressure filtration is often the default technology, centrifugal and vacuum filtration can offer viable more cost-effective and higher-capacity alternatives.

to poor water recovery and inefficient use of storage capacity. This can create significant challenges during closure and long-term maintenance.

And that’s why Beca takes a proactive approach.

“Our hands-on approach to leveraging technical knowledge of rheology together with practical constraints of safety and operability of deposition systems is a key strength,” Beca market director resources and sustainable fuels Matt Kebbell said.

Unlocking value from tailings

Regulatory and environmental pressures are driving the need to minimise surface tailings storage and explore repurposing opportunities. Beca is at the forefront of developing high-strength applications for tailings, including concrete, building materials, and engineered backfill.

“Our innovation includes modifying particle size distribution through agglomeration and sizing, and separating particles in slurry form for use in high-consolidation applications,” Language said.

“These processes also enable the recovery of trace minerals, adding further value.”

Closure and environmental compliance

Mine closures are becoming more complex and costly, often exceeding planned budgets and timelines. With increasing commodity volatility and climate-related risks, early integration of closure planning is essential.

“Our multidisciplinary team of engineers, scientists and metallurgists embed closure strategies from the earliest design stages.” Musgrave said. “We provide ongoing operational advice and deliver closure solutions

that address a wide range of technical scenarios, enabling compliance and long-term sustainability.”

Project management and delivery

Delivering technically challenging tailings projects requires deep insight and a balanced focus on immediate needs and long-term outcomes. Beca excels in managing complex brownfield projects, earning trust from regulators, communities and operators.

“Our project leads bring passion and experience, ensuring practical solutions that meet today’s challenges while preparing for future closure and compliance,” Musgrave said.

“With over 4500 engineers, planners, environmental scientists, project managers and commercial specialists, we’re ready to form the core of your tailings team, working alongside your in-house experts and other specialists.” AM

Beca’s equipment selection process is grounded in strong relationships with vendors and test laboratories.

“We explore options such as modified drainage characteristics, staged filtering and slurry additives,” Language said. “Ultimately, the solution developed by Beca is a seamless system integration of dewatering, storage and conveying.

“Our differentiator in producing drier filter cake is the understanding of creating a durable drystack in tropical and wet climates, adding to the stability of landforms over time.”

Smarter tailings deposition for long-term stability

Tailings deposition can often be treated as an operational afterthought, leading

This project formed part of the requirement to secure permitting for a new mine and mineral processing plant, with a key condition: surface tailings storage to be minimised and no additional surface storage permitted beyond the first five years of operation.

The project was delivered in two stages:

• Stage 1: A desktop study identified large-volume re-use options to reduce surface tailings storage.

• Stage 2: Selected concepts were developed to pre-feasibility level, supported by laboratory testing.

The adopted solution included a portion of the tailings to be agglomerated and sized to achieve a coarse particle fraction which would result in an ideal packing density and hence high compacted strength.

The concept was tested by producing a “synthetic aggregate” from tailings that utilised a low-carbon, high-strength cement alternative (geopolymer). This was blended with the bulk of tails resulting in backfill mixes with high comprehensive strengths (greater than 4MPa). Geopolymer binders – made from industrial by-products – were activated with a basic solution. This matrix resulted in the total “non-tailings” material addition (binder) to the backfill of less than 15 per cent, a reduction of 40 per cent over traditional backfill tailings approaches.

The net benefit for the project was threefold: 70 per cent reduction in surface tailings storage; 90 per cent lower CO2 emissions from binder use; mine life extended by almost 50 per cent.

The project is now in final design and expected to move into execution in the near future.

THE FUTURE OF MINING DEPENDS ON EXTRACTING MINERALS EFFICIENTLY AND MANAGING THE BY-PRODUCTS AND RESIDUES THAT COME WITH THE PROCESS.

Waste streams such as tailings, fines, dust and sludges are an inevitable consequence of mineral processing. But in an era of heightened environmental scrutiny, rising costs and the push for sustainable practices, they have become one of mining’s biggest challenges – and, increasingly, one of its greatest opportunities.

That opportunity lies at the heart of Picko Global’s philosophy.

As a specialist in agglomeration and waste transformation, the company helps clients convert waste materials into usable, transportable and even saleable products.

By combining proven engineering with a circular-economy mindset, Picko is working to redefine what mine waste management can achieve.

Vast quantities of fine and residual material are produced every year across mining and metallurgical operations, from smelter dusts and tailings to ultrafine ore particles that are difficult to process or store.

Traditional waste-handling methods such as tailings dams and large-scale containment facilities can carry high maintenance costs and long-term environmental liabilities. They can also represent lost value, since many waste

streams still contain recoverable minerals or potential by-products.

Managing these materials is technically and economically complex. Fine particles typically have poor flowability and low cohesion, making them hard to transport, stockpile or reuse. Their variability and high moisture content add further challenges for handling and storage systems, while binder selection can be costly or unreliable. The abrasive nature of mineral fines also leads to significant wear on equipment.

Instead of treating waste as an issue to contain, Picko treats it as a feedstock that can be engineered into stability, value and usability through agglomeration – the process of binding fine particles into larger, more stable and manageable forms.

At its simplest, agglomeration transforms waste into consolidated products such as briquettes, pellets or extrusions that are easier to handle, transport and store. These agglomerates can be reintroduced into production streams or sold, turning waste into revenue.

Picko has built its reputation on this approach, offering end-to-end wasteto-value solutions that help miners convert fines and sludges into durable, reusable materials. The company’s integrated service model includes pilot

testing, modular plant construction and operational contracts, allowing clients to adopt these technologies without heavy capital investment.

Founded in 2008 by Piet van Schalkwyk, Picko began with a contract to manage a pelletising plant for BHP at Meyerton in South Africa. Tasked with transforming smelter waste into reusable products, the project proved so successful that it became the foundation of Picko’s business model and global expansion.

The company has grown into a recognised leader in waste valorisation, with an ongoing commitment to research and development in binder chemistry, process optimisation and scalable plant design.

Because no two waste streams are alike, Picko offers three main agglomeration technologies –briquetting, pelletising and extrusion – each suited to specific material types and operational needs

Briquetting uses mechanical pressure to compress fines into dense, shaped briquettes. It is particularly effective for feeds that include fine and coarse fractions, typically up to 6mm in size. This method requires minimal binder and produces a robust, transportable product that maintains its integrity through handling.

Pelletising, by contrast, forms small, spherical pellets that are cured using

heat or chemical hardening. The process is suited to finer or more uniform materials and produces a product that can be precisely dosed or blended into downstream processes. However, because pellets are more fragile than briquettes, they require careful handling during transport and storage.

Extrusion is suited to clay-rich or sludgy materials below 2mm in size. Wet feed is forced through a die to create a continuous or semi-continuous profile. Though sensitive to moisture and abrasion, this method provides excellent control over product shape and density.

To help ensure the best solution for each application, Picko operates containerised pilot plants and modular production units that allow clients to trial multiple methods under real-world conditions before committing to a full-scale installation. This ability to fine-tune process parameters – from particle size to moisture content – is designed to arrive at a precise match between technology and material.

As global demand grows for cleaner, smarter and more responsible mineral production, the future of mine waste management will rely on companies that can engineer value back into the materials once left behind.

For Picko Global and its partners, that future is already here. AM

QUEENSLAND MINE REHABILITATION COMMISSIONER JAMES PURTILL RECENTLY SET OUT HIS VISION FOR TURNING MINE CLOSURE INTO INDUSTRY OPPORTUNITY.

When speaking at AusIMM’s Life of Mine Conference in Brisbane in July, James Purtill shared his vision for how mine closure can evolve from a regulatory challenge into a driver of innovation and opportunity.

Since assuming the role of Queensland’s inaugural Mine Rehabilitation Commissioner in 2021, Purtill has focused on improving how the state approaches mine closure and rehabilitation.

The role was established following reforms between 2017 and 2019 that strengthened life-of-mine planning, introduced the financial provisioning fund, and emphasised progressive rehabilitation.

Purtill spoke to AusIMM chief executive officer Stephen Durkin

as part of a new interview series Leading Conversations that explores the careers and impact of work from experts in the mining and minerals sector. He discussed how his position is intended to guide government and industry in adopting leading practices for transitioning mines to land uses following mining.

“My role was established as an advisory role to government in leading practice in progressive rehabilitation and mine closure planning or, as I prefer to call it, transitions to post-mining futures,” Purtill said.

The commissioner’s office prioritises collaboration over enforcement, enabling open discussion with mining operators about what works and what does not. This approach allows systemic challenges to be identified across the sector without the threat of compliance action.

This independence, Purtill said, has been critical in fostering candid dialogue and practical solutions.

One of the most significant challenges in mine rehabilitation is achieving the successful surrender of mining leases. Complex geology and geochemistry, long operational histories and legacy practices can make closure difficult.

Queensland, for example, has only seen one small coal mine successfully surrendered under contemporary environmental regulations.

Purtill said these challenges are not unique to Queensland but reflect broader global experience, highlighting the need for more proactive planning and innovative approaches.

He said his office works as a “twospeed advisory service”. For new greenfield operations, the team provides guidance on embedding best practices from the start. For existing, long-running

mines, the focus is on retrofitting leading practices where possible.

This dual approach is designed to ensure that even legacy issues can be addressed constructively while supporting industry growth.

The commissioner is also driving a vision for Queensland to become a global leader in mine rehabilitation.

By integrating lessons learned internationally and collaborating with stakeholders, the state aims to maintain a healthy, economically viable industry while managing environmental responsibilities.

This vision is reflected in innovative projects such as New Century’s reprocessing of tailings at the Century zinc mine, which has allowed the site to become one of the world’s largest zinc producers through re-mining.

Likewise, EQ Resources’ Mount Carbine tungsten project demonstrates circular economy principles by extracting value from low-grade stockpiles and reusing benign materials for construction.

Part of Purtill’s role is to find what barriers exist that are stopping these innovative post-mining land uses or reprocessing projects.