Introducing G® Lubricant, the cutting-edge graphene-based additive transforming the diesel and gasoline engine industry. Verified by the prestigious University of Queensland, this revolutionary lubricant delivers up to 8.4% fuel savings under high-load conditions, offering optimised performance and cost efficiency.

• Exceptional Fuel Savings: Achieve up to 8.4% improvement in fuel efficiency, even under demanding conditions.

• Minimal Concentration, Maximum Impact: Just 1:10,000 graphene-to-engine-oil ratio ensures safety and compatibility with any internal combustion engine and Group I,II,III and IV engine oil, not suitable for Group V oils. Suggest use in engines out of warranty.

• Proven Results: Backed by four years of advanced testing.

• Eco-Friendly Solution: Reduce fuel consumption and emissions while saving money.

Graphene, a carbon wonder material known for its strength and low friction properties, enhances lubrication at a molecular level. When added to your engine oil, it reduces internal friction especially around the pistons, optimizing performance and fuel economy without compromising engine integrity.

BE

Don’t get left behind in the race for efficiency. Upgrade your engine oil with G® Lubricant today and experience the graphene revolution firsthand!

Owner Drivers looking to save fuel costs. Fleet owners looking to cut operational costs.

•

• Industrial operators aiming for sustainable energy savings.

• Significant cost savings.

• Improved Fuel Efficiency & Performance.

• Safe for all diesel and petrol engines - suggest use in engines out of warranty.

Order now and join the global movement toward smarter, greener, and more cost-effective engine solutions. Automotive enthusiasts seeking peak engine performance.

It may stand out as seven massive cranes looming over the Port of Melbourne, but Sean Mortell discovered the impressive technology inside Victoria International Container Terminal is fast becoming a truck driver’s dream

The Gorski family enjoyed a well-deserved recognition of the half-century milestone of Gorski Engineering in August, celebrating the peaks and troughs of 50 years spent manufacturing for the transport industry

For the 40th anniversary of Boulder Wall Construction, Gavin Turner’s sons found the perfect Super-Liner for the occasion. Warren Aitken learns more about the man at the helm of the growing operation

40

While heading over to MJ Mahon’s Rocklea depot, Warren Aitken met Aiden, the operator’s first apprentice who is learning the game one drive at a time

44

As the inaugural winner of IVECO’s Master Technician competition, Justin Abood’s two-decade long trucking career to date continues to flourish

The popular packaging and logistics brand is undergoing a major fleet renewal, and Mercedes-Benz Trucks have been critical to this technology upgrade

48

Warren Aitken made his maiden trip up to North Queensland to take in the emerging charity truck show that is the Mackay Konvoy 4 Kids

58

Despite consistent dips in major markets, the overall truck sales for August in Australia maintained the consistent pace set in recent months

Daimler Trucks dealership about Cascadia today.

EDITORIAL

Editor Sean Mortell

E-mail Sean.Mortell@primecreative.com.au

Phone: 0468 577 166

Contributors Warren Aitken, Frank Black, Sarah Marinovic, Rod Hannifey, Michael Kaine, Craig Forsyth, Warren Clark

Cartoonist John Allison

PRODUCTION

Art Director Bea Barthelson

Print IVE Print

ADVERTISING

Business Development Manager

Tosan Popo Ph 0481 260 352

E-mail Tosan.Popo@primecreative.com.au

SUBSCRIPTIONS

www.ownerdriver.com.au/subscribe

Phone +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST)

Email info@primecreative.com.au.

Mail 379 Docklands Drive, Docklands, VIC 3008 Australia

EXECUTIVE GROUP

Chairman John Murphy

CEO Christine Clancy

Publisher Sarah Baker

Operations Manager Regina Fellner

Sales Manager – South Danny Hernandez

Owner Driver is published by

Prime Creative Media

379 Docklands Drive, Docklands Melbourne VIC 3008

Telephone: (+61) 03 9690 8766

www.primecreative.com.au

ISSN 1321-6279

OwnerDriver magazine is owned by Prime Creative Media. All material in OwnerDriver is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

Opinions expressed in OwnerDriver are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Hordes of responses to last month’s edition suggests there’s plenty that can be done to help the industry in a time of need. Let’s push forward together

Since the September edition of OwnerDriver hit the printers and graced the numerous truck stops around Australia, I’ve been fortunate enough to receive plenty of feedback on what the nation’s transport industry can do to reverse the current issues.

“Why are governments doing nothing?”

“There’s no adequate level of driver training.”

“Undercutting of rates means we will never be able to compete.”

“It’s a race to the bottom.”

The list goes on, but the message is coming through loud and clear – more must be done immediately to protect the hard-working owner drivers around the country who are doing their all to run timely, profitable and, most importantly, safe services.

Another interesting response I received came from someone who has been an owner driver for

“I am perplexed by the non-action of the bureaucrats, sitting behind desks, making stupid decision affecting truckers and road users.”

35 years, and in total a driver for 56 years in Australia. Throughout his career, including 3.8 million kilometres, more than two million of which were in smaller vehicles, he hasn’t once lost a demerit point nor received a traffic fine. His immediate point is that he feels there is no avenue for the industry, including drivers like himself, to be heard by decision makers.

“I am perplexed by the non-action of the bureaucrats, sitting behind desks, making stupid decision affecting truckers and road users,” he told me.

“The lack of knowledge of trucking manouevres and operation is paramount to driving on the roads with blind morons. I’ve mentioned many safety aspects to state members over the years, to no avail.”

What’s most alarming, and important, about this message is that it comes from a driver who has been retired from full-time driving for seven years. While still driving three to four days a week on smaller jobs, his love for the road is so strong that he had to say something in a time of industry need.

I’d like to thank you all for these messages, and reiterate that OwnerDriver will continue to represent you and cover the biggest issues for the sector in such a critical period of time. This edition, with our usual array of columnists, touches on these very challenges in a variety of ways, while our features provide a change of pace to the lighter and more satisfying parts of our great industry.

Warren Aitken’s superb Truck of the Month takes him to a unique 40-year anniversary for Gavin Turner at Boulder Wall Construction. Gifted by his sons at the Mack home base in Queensland, it made for a fitting prize for decades of hard work and passion. Check out the beautiful Bulldog on display on page 30.

It was a pleasure to be invited along to the 50th anniversary celebrations of trailer builder Gorski Engineering, where more than 600 people crammed into Melbourne’s Crown Palladium for a night of laughs, great stories and plenty of reflection. The recap of the emotion-filled celebrations can be seen from page 24.

While out on my adventures, I was fortunate to walk through the doors of the Victorian International Container Terminal (VICT) at the Port of Melbourne, where new-age technology on both the seaside (with its automated cranes that loom like skyscrapers) and its truck parking and processing areas is allowing trucks to get in and out within 40 minutes. This technology is remarkable, and has to be marvelled at from page 21.

On top of this, it was terrific to chat to the maiden winner of IVECO’s Master Technician of the Year in Justin Abood on page 44, while the growing success of Australian business Visy Logistics can be seen with its fleet renewal program on page 47 that involves stacks of Mercedes-Benz truck models.

All of this and more is packed into another busy edition of OwnerDriver. We hope you enjoy the read, and stay safe!

Unit 1/71 Axis Place, Larapinta, Brisbane, QLD, 4110, Australia

Ph: (07) 3276 9300 Fax: (07) 3276 9301

Ph: (07) 3276 9300 Fax: (07) 3276 9301

Email: mattc@gibbsparts.com davids@gibbsparts.com Web: www.gibbsparts.com

Email: sales@ggd.net.au davids@ggd.net.au Web: www.gibbsparts.com

ZFASTRONIC ZFClutchActuatorsForDAF,IvecoAnd ManTrucks.S37. TA950479. POA

MERCEDES-BENZG85-G280 ReconditionedMercedes-BenzTransmissions. MostMakesandModelsG100,G131,GO210, G240,G280,G330available.S3. TA431566. POA

ZFEcolitepowerpacks.S40. TA952390.

AT2512C,AT2612D&ATO3112D. S44. TA952399. POA

From further Bruce works to Victorian calls for duplication, plenty of road updates are coming through thick and fast in October

In Queensland, the fabled Bruce Highway upgrade is continuing to progress, with the $87 million connection of the route to the Mackay Ring Road now complete. Down in Victoria, a regional council is urging the state government to resume duplicating a very important freight route, while in New South Wales the notorious Macquarie Pass is beginning to receive a vital safety fix.

The Queensland government has confirmed the Mackay Ring Road connection to the Bruce Highway has been completed, allowing transport infrastructure along north Queensland to improve for freight vehicles.

This project has delivered a duplicated section of the Bruce Highway between the Mackay Ring Road and Bald Hill Road, improving safety and efficiency for people travelling through Glenella.

The upgrade provides a consistent journey for drivers by extending the duplication from the Mackay Northern Access Upgrade which was completed in September 2022, through to the Mackay Ring Road roundabout.

“Now completed, the Mackay Ring Road to Bald Hill Road Connection project will be an integral part of an integrated transport network in the region connecting to major infrastructure such as the Mackay Ring Road, the Mackay Northern Access Upgrade and the Walkerston Bypass,” Queensland transport and main roads minister Brent Mickelberg says.

“We understand the impact this had on local residents and road users and we thank the community for its patience while construction of these important upgrades was completed.”

Key features of the completed works include two new dual-lane overpass bridges and a new port rail overpass as well as an upgraded intersection at Bald Hill Road.

To minimise disruption to the 12,000 vehicles that use this section of the highway daily, a unique top-down temporary fill method was used during bridge construction which enabled works to continue without the need for road closures on the Bruce Highway.

The three overpass bridges required approximately 620 tonnes of reinforced steel. The project is estimated to have supported an average of 534 direct jobs over its duration.

The $87 million Mackay Ring Road to Bald Hill Road project was funded

with a $69.6 million commitment from the federal government and a $17.4 million commitment from the Queensland government.

The project is a continuation of the more than $410 million Mackay Ring Road construction project, which was completed in 2020.

“We’re investing more than $17 billion on projects along the 1,673km long Bruce Highway,” federal transport minister Catherine King says.

“While it’s tools down on this section of highway, we’re getting on with more than 40 other projects to improve the drive on one of Queensland’s most important roads.”

The New South Wales government has revealed crucial safety works along the notorious Macquarie Pass have gotten underway.

The $9.6 million work project has started to deliver new and improved essential infrastructure for Kiama and passing freight traffic.

This essential upgrade will include the delivery of wider lanes and new safety barriers, improving key sections at the top and near the bottom of the busy Illawarra Highway,

Once completed these upgrades will improve travel conditions for the 4,000 drivers who use this road daily. Further it will increase community resilience and reduce the risk of closures on the steep route following unprecedented wet weather as has been recently experienced locally.

“This funding is about making regional roads safer, more reliable and fairer, ensuring local communities get their fair share of road maintenance investment,” NSW roads and regional transport minister Jenny Aitchison says.

“Macquarie Pass is a critical corridor for local commuters, freight operators and the tourism sector.

“These safety upgrades will provide a safer road environment and are key to ensuring the resilience of this route.

“Work carried out on the Pass is complex due to the steep terrain of the site, slope stability challenges and the tight work areas that limit worker and vehicle access.

“The design and schedule have been developed to achieve maximum results while minimising impacts to the community wherever possible. We appreciate the community’s patience while this work is carried out.”

The first phase of work will be at the 200 metre stretch between the top two hairpin bends, a narrow and winding section of road frequently affected by severe weather and slope instability. In total, $7.5 million in upgrades will see three-metre-wide travel lanes in both directions, as well as new kerbs and safety barriers, making it safer and easier for motorists to navigate the top bends.

To stabilise the slope, long steel rods (known as soil nails) will be drilled into the embankment. A heavy-duty mesh and concrete spray (shotcrete) will then be applied to prevent further deterioration and reduce the risk of unplanned closures.

An additional $2.1 million under the NSW government’s Towards Zero Safer Roads program will allow safety improvements to be carried out about 900 metres up from the Cascade Falls Picnic Area.

Work will include installing a widened centre line along a 300-metre section, minor slope stabilisation and drainage upgrades to improve safety for road users.

This builds on the state government’s

investment of $3 million in accelerated funding to fill potholes and undertake road repairs, which has brought road maintenance investment in Kiama to over $35 million this year.

Night works are occurring from 8pm to 4am, Sunday to Thursday. The project is expected to take up to six months to complete, weather permitting. For the safety of workers and motorists, Macquarie Pass will be closed between Tongarra Mine Road and Mount Murray Road during work hours and detours will be in place that add 10 minutes for light vehicles.

Ararat Rural City Council has urgently called on the state and federal governments to recommence the duplication of the Western Highway as soon as possible.

The council is supporting a proposed motion to the Municipal Association of Victoria (MAV) that calls on the governments to re-begin the project.

The proposed motion seeks MAV’s support in calling for both governments to ensure sufficient funding and expedite the required legal and administrative processes, to enable the delayed section of works near Ararat to resume as soon as possible.

The Western Highway, Australia’s third-busiest interstate freight route, has been undergoing duplication since the Bacchus Marsh bypass in 1972. To date, the project has reached Buangor, with only about 38 per cent of the 408 km to the South Australian border completed.

Ararat Rural City Council is one of 10 member councils of the Western Highway Action Committee (WHAC), whose objective is to pursue the upgrade of the Western Highway to achieve improvements to safety, transport efficiency and amenity.

Advocating for the duplication of the Western Highway has been a long-standing priority for council, with the section from Buangor to Ararat remaining a top item in the council’s Advocacy Program 2025.

“There has been a lack of real progress on this project for some time,” Ararat Rural City Council Mayor Cr Jo Armstrong says.

“We’ve seen multiple incidents on this road, particularly on the section between Buangor and Ararat in recent months. We’d really like to see this project made a priority by both the state and federal governments.”

The NHVR has revealed its latest safety operation resulted in 90 non-compliance notices issued

The National Heavy Vehicle Regulator (NHVR) has released the results of its latest heavy vehicle safety operation.

Operation Quay, conducted from July 21 to August 17 at key port locations across Australia including Port Botany and the Ports of Brisbane, Melbourne, Adelaide and Bell Bay, saw more than 2,500 heavy vehicle inspected.

Mechanical and mass non-compliance emerged as significant safety concerns in the operation, with NHVR chief operations officer Paul Salvati saying it was a crucial effort to ensure heavy vehicles entering and exiting port precincts were operating safely and meeting all Heavy Vehicle National Law (HVNL) obligations.

“Over the course of the month-long operation, our Safety and Compliance Officers (SCOs) inspected 2,566 heavy vehicles, issuing 905 notices as a result,” Salvati says.

“Unfortunately, this is 905 times where some form of non-compliance was found during an intercept – each representing a preventable issue, and a potential risk to the safety of the driver and the wider community.

“SCOs found that heavy vehicle non-compliance was the highest in Victoria, closely followed by South Australia and New South Wales.”

Salvati says the results from Operation Quay showed mechanical and mass-related non-compliance were the top safety concerns.

“There were hundreds of defect notices issued for mechanical

transporting freight in shipping containers are more likely to be involved in safety incidents in comparison to vehicles carrying general freight, and these findings underline the ongoing need for vigilance within the industry to protect all road users.”

Salvati says the NHVR will continue to work alongside police to ensure safety is never compromised.

“Ports are high pressure environments where safety simply cannot take a back seat –the consequences can be severe, and the last thing we want to see are more families, friends and loved ones impacted by road trauma,” he says.

“We worked in close partnership with police during Operation Quay to inform and

“Unfortunately, this is 905 times where some form of non-compliance was found during an intercept – each representing a preventable issue, and a potential risk to the safety of the driver and the wider community.”

non-compliance throughout the operation, mainly for faulty lights, reflectors or brakes – 43 of which were major breaches, and 662 that were minor in nature,” he says.

“Additionally, mass non-compliance was a significant concern, with 65 breaches detected during the four weeks –18 of these breaches categorised

While Nansor Freightlines will operate as a separate division of the company, the acquisition will see the operator grow its national network

Melbourne-based operator Guru Hundal Freightlines has announced the acquisition of Nansor Freightlines.

The strategic move saw the Altona North based operator acquire Nansor Freightlines back in June, marking a significant milestone for Guru Hundal Freightlines as it continues to build its Australian freight network.

This acquisition sees Guru Hundal Freightlines expand its national

footprint while also strengthening its fleet and operational capacity.

The team has already welcomed members from Nansor Freightlines into the fold as it continues to invest in safety, service and sustainability.

“Nansor Freightlines has built a strong reputation for service and reliability for 40 years — and we’re excited to integrate their strengths into our growing network,” Guru Hundal Freightlines says.

“We welcome Wayne Somerville and his team of dedicated drivers as two great Australian companies work together to provide the best service across Australia. Nansor has continued to trade as usual and operates as

as either severe or substantial violations.

“Non-compliance with mass limits has the potential to result in the damage of critical infrastructure and compromise a vehicle’s braking ability, meaning these breaches could have ended in disaster had our SCOs not intervened.

“We know heavy vehicles

educate industry on how to meet their safety obligations, but also to enforce the law where required.

“The majority of drivers and operators do the right thing, and we thank them for their commitment to safety, but for those who aren’t, we’ll continue to take action – because no load is worth a life.”

Guru

The Mercedes-Benz Actros, with a spacious StreamSpace cabin, comes standard with 3-year/450,000km* Best Basic Service Plan. Drive your business forward with legendary fuel economy, innovative safety and star comfort.

A popular member of Australia’s road transport industry has become the newest person to be inducted into the

Elphinstone Engineering’s founder has been inducted into the Shell Rimula National Road Transport Wall of Fame.

Graeme Elphinstone is now officially part of the Wall of Fame, receiving the prestigious honour at the 2025 Festival of Transport in Alice Springs.

Sponsored by Shell Rimula, the recognition is a testament to Graeme’s lifelong commitment and outstanding contributions to Australia’s road transport industry, with the honour seeing him join an elite group of trucking pioneers and legends on the wall.

Held annually as part of the Festival of Transport, the induction ceremony for the Wall of Fame celebrates the men and women who have helped shape the transport industry through decades of service, ingenuity and dedication.

Since its inception over 20 years ago, the Wall of Fame has recognised and celebrated over 1,700 distinguished members of the road transport community – from legendary truck drivers to visionary engineers – ensuring their stories become part of national road transport history.

“Our objective with the Wall of Fame is to highlight the contribution that road transport, as an industry, has made to Australia’s economic wellbeing through the ingenuity of our trucking pioneers,” the Hall of Fame organisers say.

“It shows that road transport is much more than just the men and women who drive the trucks; there are many others in the industry who need to be recognised also.”

Graeme’s induction to this Wall of Fame is a testament to his five decades of innovation in heavy vehicle design and safety. Tasmanian born and bred, Graeme began his career in the early 1970s and quickly became a problem-solver for the transport challenges of the era.

In 1976, Graeme and his brother Dale imported and fitted Australia’s first on-vehicle truck weighing system – installing scales on a Tasmanian log truck to accurately measure its load. This step revolutionised load management, allowing drivers to know their weight before hitting the highway, and laid the foundation for modern onboard mass monitoring in heavy vehicles.

With Graeme’s help, Tasmanian Pulp and Forest Holdings’ woodchip mill in Triabunna introduced a groundbreaking “non-payment for overload” policy that removed the incentive for truck drivers to carry overweight loads.

This initiative, a collaboration between the mill, logging contractors and Transport Tasmania, is regarded as one of the first practical applications of today’s Chain of Responsibility (COR) principles in Australian transport.

Graeme’s efforts in ensuring trucks were no longer overloaded beyond legal limits improved safety and fairness for drivers and operators alike, inspiring a new era of innovation in the industry.

“Vehicle overloading was prevalent,” Graeme says when recalling the ‘70s and why he pursued onboard scales.

“One of the biggest problems for truck operators was accurately estimating the weight of their load. For the first time, logging transport had entered a new level of professionalism, with far fewer roadside weighbridge violations and drivers finally enjoying ‘peace of mind’ as they now had a legal load.”

By giving drivers real-time weight information,

the Elphinstone onboard weighing system helped improve compliance, reduce overloading and enhance overall road safety.

Over the years, Graeme has led the way with a series of engineering breakthroughs in trailer design, suspension technology and vehicle configurations. His ideas, often ahead of their time, have since become industry standards in Australia, significantly improving driver safety, regulatory compliance and operational efficiency across the road transport sector. Some of Graeme’s key innovations over his career include:

• 1976: Fitting the first on-vehicle weighing system to an Australian truck, enabling drivers to monitor axle loads and gross weight on the go. This was an Australian-first solution that set new benchmarks for load compliance and safety in trucking.

• 1980: Inventing the stretch mudguard for trucks – a longer, flexible mudguard design that is now an industry standard copied by many manufacturers, reducing road spray and debris for improved safety of following vehicles.

• 1983: Designing the world’s first self-loading road train combination, featuring a four-axle dog trailer that could automatically load cargo (e.g. logs) without external equipment. In the same year, Graeme introduced innovative air transducers for air suspension systems to more accurately measure and adjust load pressure.

• 1985: Developing the “Tri-Beam” suspension system – an inventive heavy-duty suspension design that earned Graeme the coveted BHP Steel Award for engineering innovation. This suspension improved load distribution and durability, contributing to safer and more stable heavy vehicles.

• 1986: Built the World’s First folding skeletal trailer, the Fold-A-Skel™.

• 1988: Designing one of Australia’s earliest B-double trailer combinations. Graeme’s configuration (tandem-axle lead trailer with tri-axle rear trailer) was the first of its kind, paving the way for widespread adoption of B-doubles in Australia’s freight fleet.

• 1989: Creating the Easyweigh™ Radio Remote Indicator – the world’s first onboard weighing system with a wireless remote display. This innovation allowed drivers to monitor weights

from outside the cab and, crucially, enabled trucks and trailers to interchange without recalibration, drastically improving operational flexibility.

• 1999: Winner of “Australian Trailer of the Year” for Easyloader™.

• 2005: Designed and built the world’s first self-loading B-triple.

• 2007: Designed and built world’s first self-loading Road-Train doubled trailer. The advantage of the self-loading Road-Train mean that operators can use short standard routes on the empty return journeys instead of the longer gazetted road train routes.

• 2008: Graeme launched the Easyloader™ Long Logger trailer – an Australian-first, PerformanceBased Standards (PBS) approved design that could carry 19-metre-long logs on a 26-metre B-double combination. This innovation, achieved under the then-new PBS scheme, dramatically increased payload capacity for the forestry industry while meeting stringent safety and handling standards, thereby enhancing operational efficiency and profitability for the industry.

• 2011-2013: Developing the Easysteer™ self-steering suspension system. This advanced trailer suspension automatically adjusts and guides rear axles during turns, reducing tyre wear and improving the turning ability of long combination vehicles. Easysteer™ enhanced safety and manoeuvrability for multi-trailer road trains, although it initially required persistent advocacy by Graeme to gain regulatory acceptance.

“His pioneering work, such as Australia’s first onboard weighing systems, has left an indelible mark on the industry,” the Tasmanian Transport Association said about Graeme when honouring his 50-year career last year.

In receiving the honour, Graeme expressed gratitude to those who have supported his journey.

“I’m truly humbled to be inducted into the Wall of Fame alongside so many legends of the road,” he says.

“When I built my first trailer and fitted that first scale system, I never imagined it would lead to this. I’ve always just tried to solve problems and make trucks, trailers and transport in general safer and more efficient for everyone. To have those efforts recognised by the industry I love is an incredible honour.

“This award isn’t just mine – it belongs to our whole team and the many customers and partners who believed in our ideas over the years.”

Elphinstone Weighing Systems general manager and Graeme’s son, Grant Elphinstone, also paid tribute to his father’s career to date.

“Dad has always been a trailblazer,” Grant says.

“For nearly 50 years, I’ve watched him push the boundaries of trailer design and challenge what’s possible with unique innovation. He was fitting onboard scales before most people knew such a thing existed. He was building PBS-approved trailers before PBS was even a common term.

“His focus has always been on making life easier and safer for drivers – and that’s why this recognition is so deserved. Our whole family and team are extremely proud of Graeme. His legacy will continue to inspire innovation in transport for years to come.”

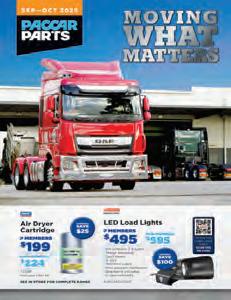

SA012TRP $104 $124

Suits Hendrickson HAS400 & HAS460, Airlight 2/HD series

SA001TRP $119 $139

Suits Kenworth front, parabolic spring

SA018TRP $119 $139

Suits Kenworth Airglide 9” ride height SEE

STORE FOR COMPLETE RANGE

The national

operator

has

officially started

operating out of its new depot in north Queensland as it continues investing in the region

Operator Followmont Transport has announced it has officially commenced operations at its new Innisfail Depot in north Queensland.

In a bid to support regional growth, the major milestone sees the company continue to invest across north and far north Queensland.

Located at 15 Goondi Mill Road, Goondi Bend, the new purpose-built facility replaces Followmont’s previous Innisfail site and significantly increases the company’s capacity and operational efficiency in the region.

The depot features an 800m² high-clearance warehouse, 800m² undercover loading area, dedicated office space, and 1,800m² of hardstand to support vehicle parking and third-party logistics (3PL) storage.

The project was delivered in partnership with long-term property partner Bootooloo Property and began in late 2024, reflecting Followmont’s ongoing commitment to investing in regional infrastructure that supports local business, industry, and jobs.

The Innisfail development forms part of a broader regional strategy that has seen almost $40 million invested into north Queensland communities since 2020.

This includes new Depot builds completed in Mackay and Cairns, the purchase of an existing site in Mareeba, a significant expansion of the Townsville Depot, and now the delivery of this new facility in Innisfail.

Followmont also recently completed a refrigeration and hardstand upgrade at its nearby Dickson Road produce site, doubling capacity to meet growing demand from agricultural and food customers.

Followmont CEO Ross Longmire says the scale of these projects speaks to the company’s confidence in the strength and future of the north Queensland economy.

“This investment in Innisfail is about more than just a new depot, it’s about building the right foundation to support our customers and people in the region,” Longmire says.

“We’ve seen consistent demand in far north Queensland, and this facility ensures we can continue delivering high-quality, reliable and flexible service that grows alongside our customers.

“We’re proud of the work being done across our network and the strength of the relationships we’ve built with our customers and regional communities.

“Our investment in north Queensland is a reflection of our long-term commitment to the region, and our confidence in its continued growth.”

The newly opened site is the seventh TRP store opened and owned by the Brown & Hurley Group and TRP’s 19th outlet in Australia types of heavy trailers, with 359 outlets around the world and 19 in Australia.

Popular brands, service and sales brand TRP has announced the opening of a brand-new parts, service and sales store at the Port of Brisbane.

Located in Hemmant within Queensland’s Brisbane Port area, the new store is owned and operated by the Brown & Hurley Group, becoming the seventh TRP store the group has opened.

Globally, TRP is an affordable all makes supplier of high-quality parts for prime movers, rigid trucks and all

The Hemmant store stocks wellknown brand consumables for all major truck brands, with all TRP branded parts coming with a minimum 12-month warranty.

“This store is a natural progression for us and has been a few years in the making,” Brown & Hurley Group aftermarket general manager – truck and trailer Darron Rawson says.

“We look forward to being able to better service the needs of our loyal

business partners in this area and create new opportunities.

“Being able to offer service, parts and sales was important to us finding the right facility with easy access to and from the motorways, the customer feedback has been amazing, and we look forward to watching this store evolve.”

The TRP Brisbane Port site is located at 21 Inghams Place, Hemmant, with a contact number of (07) 3916 8400 and opening hours of 7am to 5pm Monday to Friday.

Every trailer connection counts. SAMPA parts are built for rugged performance, reliability, and long-lasting durability, keeping your trucks and trailers secure, stable, and ready for the road, day after day.

•Fifth Wheel – Tough cast structure and wear-resistant components for long service life, with adjustable locking and rubber cushions that reduce impact and simplify maintenance.

• Fifth Wheel Repair Kit – Precision-fit replacement components designed to restore locking strength, reduce wear, and extend coupling performance without replacing the full assembly.

•Landing Gear – Reinforced legs with advanced internal gearbox design for maximum durability and stable trailer support on any load and surface, tested to the highest standards.

• Peep your fleet moving with confidence, choose SAMPA for reliable, long-lasting performance.

Global connected vehicle technology supplier

Geotab has announced it has achieved a new company milestone, surpassing five million connected vehicle subscriptions around the world.

This rapid growth has seen the last million subscriptions added in less than two years to reinforce Geotab’s position as a global leader in connected vehicle solutions and a key innovator in leveraging data and AI to drive meaningful business outcomes.

“Geotab’s journey is about relentless innovation and with 630 global patents, we have made a significant impact on the industry over the last 25 years,” Geotab CEO and founder Neil Cawse says.

“This five million milestone proves that our data-driven approach to fleet management is solving real world challenges faced by businesses on a daily basis. With the rapid adoption of AI, we expect the next five years to be as transformative as the last 25.”

Geotab’s data insights help businesses improve their fleet operations, including reduction in unexpected vehicle downtime, improved safety and reduced daily mileage through optimised route planning.

These improvements help fleets save money

on fuel and other operating costs while also directly reducing environmental impact.

The ability to deliver these tangible benefits is powered by the massive volume of data generated from five million subscriptions, producing over 100 billion data points daily, equivalent to more than 37 trillion data points annually.

This data fuels Geotab’s AI and machine learning models with accurate benchmarks, predictive analytics and actionable insights that empower fleets of all sizes to make smarter, faster decisions.

2025 marks Geotab’s 25th anniversary,

growing from a two-person start-up to a more than 2,900 global organisation, highlighting the company’s focus on innovation and global expansion.

Geotab says it has maintained its position at the forefront of the industry with investments in research and development, continuously expanding its open platform capabilities and building an ecosystem of over 700 partners globally.

Over the past 10 years, the Geotab Marketplace has grown and evolved, now featuring nearly 530 solutions for customers to choose from.

“This five million milestone proves that our data-driven approach to fleet management is solving real world challenges faced by businesses on a daily basis.”

Monroe Magnum is engineered in Australia to withstand the toughest environments on and off highway, proven to deliver maximum uptime with minimal maintenance. Backed by 100+ years of suspension expertise Monroe is built to last the long haul.

• Trusted by Generations for 100+ years

• Durability Guaranteed for Maximum Uptime

• OE Supplier for Global Heavy-Duty Manufacturers

• Engineered and Manufactured * in Australia

• Scan QR code to find your Monroe Magnum.

• Monroe Part Number CB0294

• Engineered and designed to improve cab comfort

• Assembled in Australia

• Unique height adjustment capability

• Modular design for easier fitment

• Bonded rubber bushes

• Monotube for durability.

• Monroe Part Number BU10025

• Unique OE specific spherical design

• Maximum strength and durability

• Superior engineered bonded rubber bushing

• OE equivalent fitment

• On-highway / off-highway capability

• 12 month / 150,000 km warranty.

The winners of the eight annual awards have been announced as the VTA celebrated another successful night recognising the freight industry’s leading members

The Victorian Transport Association (VTA) has crowned the winners of the 35th Australian Freight Industry Awards (AFIA) at a gala event at Melbourne’s Crown Palladium.

The awards night recognised the outstanding achievements of individuals and organisations across the freight, logistics and transport sectors.

Hundreds of guests were in attendance for the evening, with winners of the eight awards revealed.

The personality of the year award, supported by CMV Truck & Bus, went to Duncan Gay AM, with Peter Sadler Removals & Logistics’ Mariella Tueira taking home the women’s leadership award sponsored by Viva Energy Australia.

The emerging leader award, supported by Daimler Truck Australia Pacific, went to Jack Di Losa from Cold Xpress, while DHL Supply Chain Australia was the winner of the best practice safety award, supported by Gallagher.

Wettenhalls took home the application of technology award, Linfox won the investment in people award, Brooklyn Recycling Group was the winner of the Greenstart sustainability award and TOMRA Cleanaway received the waste and recycling business of the year award.

VTA CEO Peter Anderson opened the evening by acknowledging the vital role freight and logistics play in Australia’s prosperity.

“Every day, our industry keeps Australia moving – delivering goods, connecting businesses, and supporting livelihoods. From ports to paddocks, we are the engine room of the economy,” Anderson said.

“Tonight, we bring that work front and centre to celebrate the people and organisations who go above and beyond. These awards honour not just success, but the spirit of innovation and resilience that defines our sector.”

Anderson also noted the continued growing interest in the awards, with a record number of entries received across all categories.

“This year we saw an exceptional number of nominations, reflecting the depth of talent

example and push our industry forward,” Ryan said.

“Strong industry associations like the VTA provide a trusted platform for collaboration, where operators, suppliers and regulators come together to solve shared challenges and influence meaningful change.

“Equally important is the opportunity to celebrate excellence and innovation – because recognising achievement inspires progress.

“Every day, our industry keeps Australia moving – delivering goods, connecting businesses and supporting livelihoods. From ports to paddocks, we are the engine room of the economy.”

and innovation across our industry. It’s clear that organisations are investing in their people, their technology, and their sustainability goals – and they’re proud to showcase that work. The judging panel had a tough job, and every finalist should be commended,” he said.

AFIA Chair Dennis Ryan echoed the importance of recognising excellence and fostering industry-wide collaboration.

“For 35 years, these awards have celebrated the individuals and organisations who lead by

Congratulations to all our finalists and winners. You make this industry one we can all be proud of.”

The AFIA Committee extends its sincere thanks to major event supporters, Team Super and Viva Energy Australia, whose continued connection makes the AFIA possible, as well as Freight Cyber, providing the pre-dinner drinks in The Lounge.

The Australian Freight Industry Awards will return in 2026.

The first movement on official amendments being made to the Heavy Vehicle National Law has gotten underway in Queensland

The Heavy Vehicle National Law Amendment Bill has officially been introduced into Queensland Parliament in a milestone for the governing law.

The bill includes many of the results of the HVNL review that first started in 2019, with other changes from the review to be featured in future amendments to the national regulations.

The bill was introduced into state Parliament by Queensland transport and main roads minister Brent Mickelberg.

He says the bill provides operators with more flexibility in how they can demonstrate compliance with prescribed requirements such as fatigue management work and rest hours or general mass limits.

“This approach will be achieved through the introduction of an enhanced accreditation framework.

This framework strengthens the National Heavy Vehicle Accreditation Scheme by requiring operators to implement a safety management system, commonly known as an SMS, that is scalable to their organisation

and operations,”

He says the bill will expand the use of formal cautions and warnings.

“This is particularly important when dealing with minor breaches such as clerical work

diary errors,” he says. The Heavy Vehicle National Law applies in the eastern states and South Australia. The scheme is underpinned by a Queensland law that the other participating states have agreed to adopt.

Kenworth stands by its history of design of trucks that are easy to operate and maintain. The new generation Kenworths integrate the latest technology while upholding this philosophy, making our newest models smarter than ever. Put the future to work for your business.

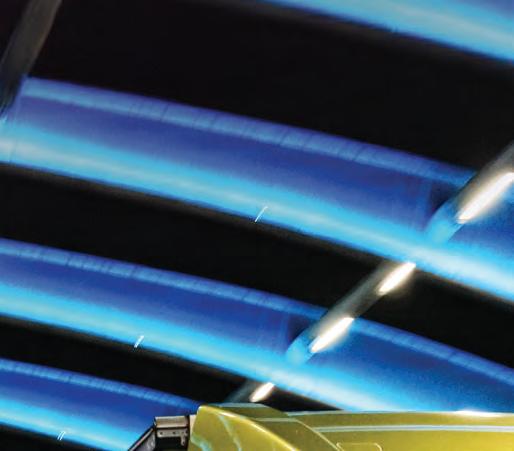

It may stand out as seven massive cranes looming over the Port of Melbourne, but Sean Mortell discovered the impressive technology inside Victoria International Container Terminal is fast becoming a truck driver’s dream

It presented like any other office on a Friday morning. A bunch of young office staff at their desks, wearing headphones while concentrating on multiple screens in front of them, coffee and energy drinks at hand. A small chat among them, an occasional laugh, a quick toilet break.

However, it’s not your normal workplace. Instead, this office is actually the control centre for Victoria International Container Terminal’s (VICT) cranes that unload containers off of ships around the clock. At the click of a computer mouse, these operators are completing the most intricate of crane manoeuvres, controlling machinery nearly 50 metres tall more than a kilometre and a half down the road from their desks.

Down by the dock, five ship to shore (STS) cranes stand at 39 metres tall, pulling shipping containers off of vessels to process. Next to them are two newer STS cranes that are another 10 metres taller. They’re controlled in the comfort of the office, away from the bristling wind of Port Phillip Bay and the constant movement of the crane cabin.

It’s technology that is only seen in three places around the world – the ports of Rotterdam, London and Melbourne. The latter, which is where the VICT is based, is Australia’s first and only fully automated container terminal, featuring these seven STS cranes, 17 Automatic Container Carriers (ACCs) and 26 Automatic Stacking Cranes (ASCs).

Many Melbourne residents would’ve even realise

the depth of technology that has quickly evolved within their own port. It was only in 2014 that the Port of Melbourne appointed VICT to design, build and operate Australia’s first fully automated container terminal.

As a subsidiary of International Container Terminal Services Inc. (ICTSI), the largest independent terminal operator across six continents, VICT is the product of ICTSI’s experience, having been at the forefront of global port management for over 34 years. Within three years the terminal had commenced operations, and it now captures over a third of Melbourne’s international containerised market.

Currently, it adds 33 per cent capacity to the Port of Melbourne, enabling the growth of beyond 1.4 million TEUs to support the long-term trade expansion that is ongoing at the port.

However, the importance of what VICT has built over the past decade in Melbourne isn’t just for its workers and the ease that shipping companies get to enjoy when they unload at the terminal. This port technology has extended to the landside operations of VICT, where a variety of innovations have ensured there are never any long, winding queues of trucks waiting to get in and out of the terminal for hours at a time.

Instead, VICT has created a system that ensures no truck takes longer than 40 minutes to go gate to gate, with a maximum 33 minute turnaround time.

It’s in stark contrast to other terminals, even VICT’s neighbours in Melbourne, and forms the key to its evolution and success.

VICT CEO Bruno Porchietto says the idea behind this investment is to make life easier for truck operators. It’s resulted in VICT being the terminal of choice to collect from for truck drivers.

“The more reliable you are, the higher your success is. Automation allows us to be very constant and for truck drivers to rely on us,” Porchietto told OwnerDriver.

“On the shipping side, vessels come and go here, but we almost every time berth them on arrival, so we don’t leave them in the bay waiting for a few days.

“On the landside, trucks come and go very quickly, we have the lowest turnaround time in Victoria for sure, it’s so fast and efficient. It’s top class. Having less than 40 minutes to wait is very efficient.

“Truck drivers love it as they don’t have to come here and wait. That means more productivity for the trucks that can do more than one trip, either here or somewhere else. They know when they come here it’ll be a short trip. It’s part of our focus to keep both sides happy on the water and landside.”

Through a paperless truck booking system and optical character recognition gates, trucks only have to slow down upon hitting the entrance to VICT rather than wait for people or slow machines. Then, 11 inbound gates and four outbound mean there’s plenty of options and space for trucks to take to smoothly

“While sitting at a vantage point to see the gates in action, a collection of trucks of all shapes and sizes, from B-doubles to a single trailer set-up, glide on by, barely stopping.”

flow in and out of the port while collecting or discharging their loads.

While sitting at a vantage point to see the gates in action, a collection of trucks of all shapes and sizes, from B-doubles to a single trailer set-up, glide on by, barely stopping. The technology reads the truck’s plate and container number to ensure the right truck and cargo are arriving for their planned pick-up time slot. Once they hit the secondary inbound gate, further identification checks are swiftly completed and they head straight on through to the automated yard, where the display of technology makes it clear as to what makes VICT an innovative leader in port logistics.

Located at Port of Melbourne’s Webb Dock East, VICT is the only terminal within the port precinct to have unrestricted navigation and berthing. Head on further to the other terminals in Melbourne and you hit the West Gate Bridge – a key height restrictor for massive ships. This provides a significant advantage for accommodating larger vessels in an efficient manner.

Left wide open to Port Phillip Bay, the record for the largest container vessel to reach the Port of Melbourne is at VICT when CMA-CGM Pelleas, a ship with dimensions of 350 metres by 43

metres and a TEU capacity of 9,661, docked at the terminal. On the landside of this, 13 container yard blocks provide 65 container pick up and drop off lanes, with everything neatly organised for standard containers and refrigerated/reefer containers.

When we drive into the massive yard on a Friday morning, I’m told it’s a busy time, with trucks constantly doing their best to reverse into the bays. However, there’s still expansive room and it doesn’t feel crowded – the abundance of bays means not everywhere is taken, making it convenient for trucks to manoeuvre around the terminal.

Upon completing perhaps the most challenging part of the operation where the trucks are reversed into their bays, this is where VICT’s technology comes to the fore. Once the driver has finished removing the pins holding the container, the software ensures the truck and trailers are in the correct spot and instructs the automatic cranes to begin their jaw-dropping activities.

The ASCs are what the landside relies on, with these massive cranes swivelling in all directions on rails. There’s no human behind these – instead, the automatic cranes spend all hours around the clock organising the containers so that it’s as simple as picking what is needed off the top of skyscraping piles and placing them carefully onto the backs of trucks. Once the transaction is done and the driver has secured the pins, the driver is free to go, with the technology even ensuring that everything is lined up correctly and made safe.

Behind this, I’m soon taken around to the waterside, where these seven giant cranes controlled by the workers back in the control centre constantly load and unload along a 735-metre-long quay. With mooring dolphins included, the entire length of the quay is 769 metres, allowing two 367 metre vessels to operate simultaneously.

It’s here that the seven cranes are constantly remotely controlled, unloading and then loading shipping containers on and off the ships. In between this and the cranes on the landside that load and unload the trucks are the 17 ACCs that also run without any human controlling them. Instead, magnets embedded underneath the asphalt allow this nimble fleet to run containers in between the two cranes without any human interference.

While this speedy process is making life a dream for the growing number of truck operators using the terminal, VICT also has a direct road connection with Appleton Rail to ensure containers continuously move between the rail line and VICT. This means there’s no additional cost for shipping lines and no disruption.

Now firmly entrenched in the Port of Melbourne’s everevolving operations, VICT has wasted no time in stacking milestones higher than it does its containers. The company has celebrated receiving its fifth million TEU since the start of operations in 2017, while it’s continuing to eye new growth opportunities both in its waterside space and in its landside technology.

It’s also committed to sustainability and efficiency, with this technology providing a safe gateway for goods that support the Victorian economy. VICT supports The Mission to Seafarers Victoria, allowing ship crew to enjoy the city and receive some luxuries after spending up to weeks at a time on the high seas. Alongside supporting Backpack for VIC Kids, the company also sponsors the Wayfinder initiative by the Australian Logistics Council (ALC) which promotes women’s careers in the transport and logistics industries.

On the safety side, its 14.4 Rural Tailgate Inspection biosecurity measures allow containers destined for rural Victoria to be properly checked and cleaned before leaving the terminal. When it comes to energy efficiency, the cranes use an energy recovery system that represents 16 per cent of the total operational energy use. LED lighting systems on equipment and office spaces and the use of electric and hybrid vehicles within the terminal’s four walls ensure the terminal isn’t just leading the way in innovation, but also sustainability.

It may not be renowned as one of Melbourne’s leading landmarks – instead, tourists often tend to marvel at Federation Square, Eureka Tower or Flinders Street Station. But what VICT has built at the Port of Melbourne is fast putting the city in shining lights in the global port industry. For truck drivers, it’s quickly becoming a major highlight of transporting freight in Melbourne.

“The growth areas for us are more to do in building and getting new equipment, as well as getting new cranes coming in,” Porchietto says.

“This will, in itself, improve our productivity and capacity even more and deliver on our focus to make life easy for truck drivers. This will then improve the whole industry’s productivity in the state.”

•Eaton Reman Transmission

•Clutch Installation Kit

•BONUS: Meritor Brake Drum Pair INCLUDES:

•20L Synthetic Transmission Oil (PS-368)

Change gears with confidence with a remanufactured gearbox bundle from Eaton.

The bundle includes an Eaton reman transmission, an Eaton clutch installation kit and 20 litres of fully synthetic Eaton-approved engine oil. As a bonus, customers will also receive a pair of Meritor brake drums to suit their application.

The Gorski family enjoyed a well-deserved recognition of the half-century milestone of Gorski Engineering in August, celebrating the peaks and troughs of 50 years spent manufacturing for the transport industry

The year 1975 was a defining time for both global and local history. Around the world, the Vietnam War came to a close, while in the UK, Margaret Thatcher became the leader of the Conservative Party. From an Australian perspective, Prime Minister Gough Whitlam was dismissed.

But, 50 years ago, one enduring moment in Australia’s transport history was the establishment of trailer builder Gorski Engineering. Back in the swing of the ‘70s, Ken Gorski had a vision to build and deliver premium quality tipper bodies to the expanding transport industry.

Fast-forward half a century and Gorski Engineering is a popular name in the sector, with the Gorski family expanding the empire. The rich history of the trailer builder was on full display in August as the Gorski family held a gala event to celebrate 50 years of success in the transport sector.

The event saw over 600 customers, employees, suppliers, dealerships and wider transport industry members descend on Melbourne’s Crown Palladium, with a raft of presenters and team members charting the enduring legacy of Gorski Engineering over the past half century.

But how did the Gorski family come to provide 50 years of hard work and dedication to the industry, reinventing and then leading the tipper market in Australia?

It all started in 1950 when Wally and Eugene Gorski arrived in Melbourne from Poland with their daughter Maria. Spending time at a migrant camp, son Ken was born in Mildura at a refugee hospital.

When Wally began working at a truck builder yard in Reservoir in Melbourne’s inner northeast, Ken wasn’t far away. By the ‘60s, Ken, aged 13, was working beside his father in a newly created backyard workshop they forged together, providing repairs for operators in the local Lalor and Thomastown area.

Just a few years later, Ken’s business savvy nature shone through when he attached repair business flyers to cars parked at the local pub. By 1968, he was starting a fitter and turner apprenticeship while working multiple jobs.

It all kicked off in the ‘70s when Wally and Ken bought their first factory in Epping, naming the business W & K Gorski. It took until 1975 for the Gorski business to officially get underway, veering away from repairs and into full tipper body production.

The move immediately paid off as the Gorski name gained traction and, by 1979, they were delivering tipper bodies to councils and local dealerships, all from their humble shed in Epping.

John Serrano from El Dorado Transport remembers these early days and the surrounds the Gorski Engineering origins were founded in. His first memory of Ken involved tackling the dangerous walk through the Epping yard to the office.

“I went down to the Epping yard, and there was no signage, so I didn’t know where it was, but we were in the market for a new trailer so I made my way to the front of the building,” he said.

“I found a little shed in the back corner and it was a battle to get there – I had to duck past steel beams and

around people working. I got to the office and asked for Ken, only to be told he was outside, so back out I went.

“I accidentally walked into a bloke lying under a trailer, and when he came out I only remember a gold tooth shining. That was the first time I met Ken, and I ordered a trailer straightaway.”

This relatable nature paid off, with Gorski pairing this intimate service with innovation in the ‘80s. Gorski built the first twoaxle dog trailer and two-axle semi-trailer, expanding its range to meet growing demand. This success allowed Ken to buy a second 32,000sqm site in Epping in 1983 before launching Gorski Transport in 1987 and running his own fleet of International S Line trucks.

By the end of the decade, he’d sold it for a cool $1.3 million and shifted his focus back to the trailer builder.

But this success wasn’t ongoing and guaranteed. In 1991, Gorski Bodyworks collapsed, with Ken buying it back from the liquidators for only $14,000 and renaming it Gorski Australia. He began rebuilding from two small sheds in Epping before launching the quick release tipper a year later.

This saw the Gorski fortunes turn around and Ken upgraded to the Hume Highway site in 1993 that the company continues to base its expanding operations from to this day.

While the 2000s saw complications come, first through the implementation of the GST and then through a combination of financial and family challenges, the business endured. Throughout these challenges, innovation and trailer technology evolution was never far from the Gorski family’s DNA.

In 2001, Gorski built its first three-axle range specified for semi-trailers, while by 2006, Gorski had met Performance Based Standards (PBS) requirements for its models. Despite these developments, tougher times faced the family.

Financial strain in 2015 and health issues meant Ken had to step back. At the time, it was an alarming period for the future of the business. However, the Gorski family led from the front, stepping forward to cover Ken’s absence. With the likes of daughter Amelie, her partner Paul, Tim and Jeremy, the next generation of Gorskis re-shaped the structure of the business.

It culminated in a new wave of success that included Gorski’s return to Queensland, this time triumphantly breaking into the market, last year. The site is headed up by long-term team member Alex Powell, who has been there through all versions of the company after first starting as an apprentice in 2006 to now managing the Queensland site and team.

In 2024 alone, Gorski delivered 441 units, proving it has turned its fortunes from a backyard shed in Lalor to becoming a national leader in tipper manufacturing.

Crowning the celebrations was a wave of families and industry legends who have been involved in the business and the Gorski family in one way or another. With Richmond Football Club AFL legend Matthew ‘Richo’ Richardson MC-ing the night, fellow

An entertaining segment saw ‘Richo’ chat to a Gorski customer from each decade of its existence to date, from John Serrano to the likes of Pat Papaluca from Patlin Transport, about their experiences with Ken and the family. Laughs were aplenty, as were tears.

Bottom: A wide range of Gorski family, friends and customers

To finish the proceedings, the current generation of Gorski Engineering leadership took to the stage to recap their journey and thank all 600 people at the event who have been involved with the business. Much like its origins, Gorski celebrated its 50-year milestone in the way it started – with a close group of friends that it continues to innovate for and dedicate its time to.

Clark calls

the road

We have an opportunity at the moment to make sure that, in the future, the trucking industry pays a road charge which is equitable for all operators and rewards productivity. At the same time, we need to develop an alternative solution to the current road user charge model to deal with the move towards zero emissions vehicles and the adoption of alternative fuel and power options.

It has been clear for a number of years that the system for charging trucks for the use of Australia’s roads is broken. The government has been able to blatantly overcharge the trucking industry while the system for claiming fuel tax credits is cumbersome and onerous, especially for smaller trucking operators. At the same time, the quality of the roads

used by trucks has deteriorated.

The road user charge, an excise duty on the fuel the road freight industry burns, alongside fuel tax credits for kilometres travelled, was introduced as part of the creation of the GST over 20 years ago. The charge was supposed to reimburse governments for the wear and tear on roads caused by heavy vehicles, but the process for setting the rate was flawed and vulnerable to government interference. Fluctuating fuel prices also added to the confusion and uncertainty for both road transport operators and the federal and state road managers.

The trucking industry is also kept in the dark about how funds are allocated across the road network, both federally and in the states. The funding priorities do not take into account the need to improve the

“Truck drivers on the roads of Australia can see this dysfunctional road funding system play out daily: while they are held up in unnecessary road congestion and driving on poorly maintained and inadequate roads.”

productivity of road freight as a whole. The process appears to prioritise political considerations at the expense of rational decisions aimed at improving freight productivity.

Truck drivers on the roads of Australia can see this dysfunctional road funding system play out daily: while they are held up in unnecessary road congestion and driving on poorly maintained and inadequate roads. The flawed funding priorities process leads directly to poorly maintained roads, which leads to increased damage to equipment and increased off-road time for the industry’s rolling stock.

Any move to simply increase the excise rate on fuel, which has been proposed as part of the discussions around the federal government’s recent Economic Reform Roundtable, will have a negative effect on productivity and increase overall costs for trucking operators who are already working with extremely tight margins.

NatRoad members and other road freight operators continue to improve fuel costs per tonne of freight by using the latest truck technology and higher productivity combinations. This has the effect of increasing overall productivity in the economy, which is one of the stated priorities of the Economic Reform Roundtable. However, the increased take-up of alternative power sources, as we move towards zero carbon emissions, will also reduce the fuel excise revenue for the government, putting pressure on vital funding to improve the quality of our road system.

The New Zealand government recently locked in ‘per kilometre’ road user charges for all light vehicles (petrol, diesel, hybrid and electric) from 2027. Is there a lesson for Australia about how we can ensure all road users pay their fair share?

Now is the time to think ahead towards a more equitable road charging regime. One that not only raises enough funds to maintain and improve the overall road stock, but will also drive improved productivity across the entire road freight transport sector.

The new system has to take all of these different priorities into account. Economic growth requires a profitable and effective road freight industry. Improved productivity across the supply chain is vital for future economic growth and improved productivity. Reduced carbon emissions is also a major priority across the economy.

Any road user charge being developed needs to be able to tick all the boxes for the foreseeable future, and avoid favouring one priority over the other. The economy needs an effective and efficient road transport sector moving towards zero carbon emissions, and the road transport sector needs a well-funded road network to do its job safely and effectively.

The

groundbreaking

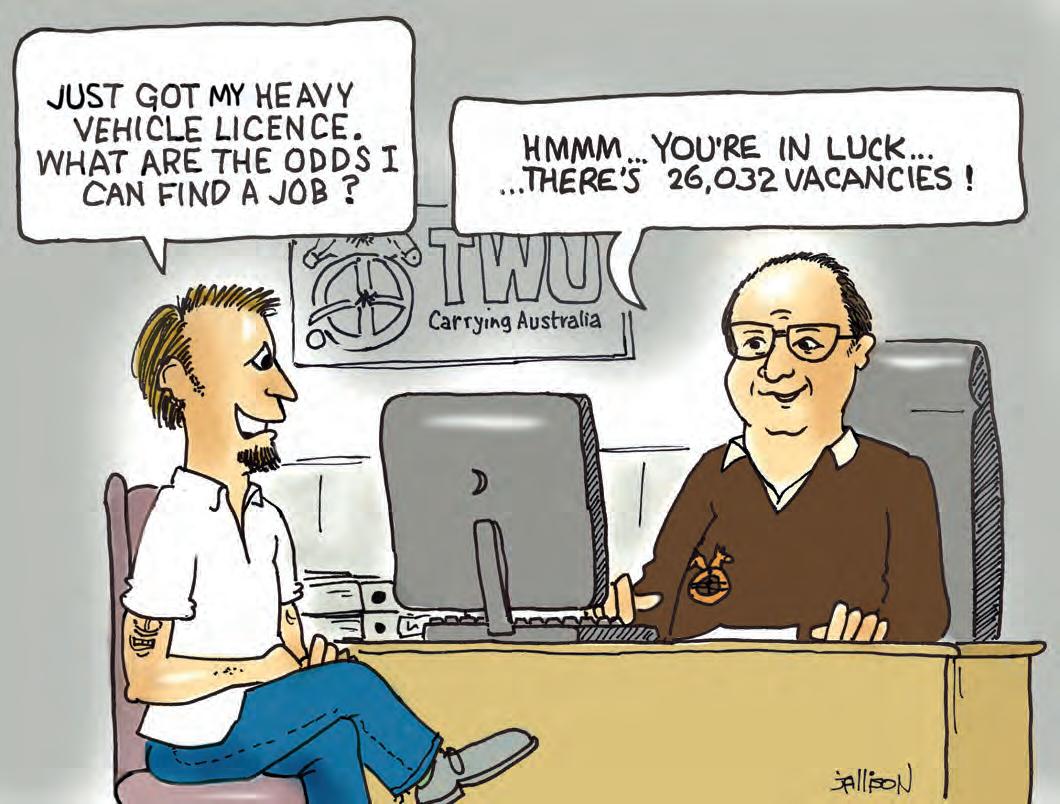

You don’t often get a group of a couple of dozen truck drivers, baggage handlers, food delivery riders, employers and union officials walking through Parliament House. But at the beginning of September we took a transport delegation to Canberra to talk about the impacts of new laws on the industry so far, and what still needs to be done.

What’s refreshing is that this government is willing to hear what the transport industry has to say about what needs change. And there’s a lot that needs change – we made that clear.

We have powerful tools now to start fixing road transport. Our first industry applications to start making transport better have almost finished the consultation phase, and soon we’ll see new, better standards to start lifting the industry.

But the work is not over yet. These first applications are just the start of improving the industry, and we’re working together to figure out what most urgently needs to be tackled next.

Over the couple of days we met with members of parliament from right across the political spectrum. Dozens of meetings in total, including with the Prime Minister and Deputy Prime Minister, who both commended the unity of our industry in driving change. They heard from some familiar faces – like Tony Matthews, an owner driver who’s been in the industry for decades and wants to leave it a better place than what he found it.

Like Steve Newton, an employee driver delivering parcels out to Dubbo, seeing sub-contractors taking risks like using rear trailer breaks because their bosses have told them it’s too expensive to change brake pads. There was Cameron Dunn, an employer who pays his drivers in seven days, his tow operators in 14 – but sometimes isn’t paid by his clients for 120 days.

But there are also newer stories, not just from trucking but from the gig economy, which desperately needs standards to stop the free-fall. Yaser, who’s a rideshare driver, has a wife and three children to support, and a mortgage to pay. But after his rates were cut again unilaterally by Uber last year, he’s working 14-hour days just to make the same amount as he was a year ago. He’s purchasing second-hand tyres because he can’t afford new ones. Alexi, a food delivery driver, works across multiple apps because it’s the only way to get enough work. We also heard

from Simon Earle, the CEO of TEACHO, and the most recent research on road transport which has painted a stark picture of what needs to change – like how transport operators suffer as one of the lowest profit segments in the economy.

The study demonstrates that large client profits are built by increasingly shifting work to cheaper, more dangerous operations. Those in the industry will know this intimately: the sub-contracting out to the lowest bidder, not enough money in a contract to ensure proper safety and training.

As we heard in Canberra, more work is also going to the gig economy, which is why it is so urgent we get standards in place there with the new laws. The hope for this industry lies in our continuing to work together.

What was different about this time was that we also brought aviation workers with us. The aviation industry is plagued by many of the same problems as road transport: a race to the bottom on standards and conditions, clients like

188-390 Sussex Street, Sydney, NSW 2000. twu@twu.com.au

Qantas splitting up the workforce and splintering workers’ power.

At the end of last year, a young ground handler in Brisbane almost lost his leg in a horrific incident, at a company called Swissport which has received a large proportion of illegally outsourced Qantas work. Only recently, another labour hire worker in the Qantas supply chain was involved in a tragic incident – and this one, devastatingly, took his life.

Ground handling workers in Canberra spoke about companies with broken or outdated equipment, where there was pressure to rush just to get planes out on time. It’s the same as what we’ve seen in road transport with the immense and deadly pressure to work fast enough to keep a contract.

Recently, illegally sacked Qantas workers had a huge win in the Federal Court: a $90 million fine imposed on the airline, Justice Lee saying it had taken part in “performative remorse” over the sackings. The five-year court battle run by the TWU was one that to begin with, nobody thought we could ever win.

Qantas told these workers that they were delusional just for challenging the sackings. And much of the public believed them. Damo, one of the illegally sacked workers, joined our delegation to Parliament House, and spoke about how what Justice Lee said had rung true: depriving people of work illegally was depriving them of their dignity. In both aviation and road transport, we are steadily restoring dignity to industries that used to thrive.

60,000 TWU members stood behind those Qantas workers: truck drivers, garbage collectors, cabin crew, delivery riders, bus drivers, pilots all supporting them, because we knew it was a fight worth having. And so is the fight for our industries to be safer and fairer – like with the Qantas battle, if we keep sticking together we can make it happen.

“Dozens of meetings in total, including with the Prime Minister and Deputy Prime Minister, who both commended the unity of our industry in driving change.”

Have you ever wondered what MacGyver would be like if he was born in Australia? If you are unfamiliar with the antique reference, let me fill you in. Back in the awesome ‘80s there was a TV show about a secret agent that could basically solve all the world’s problems with a Swiss Army knife, a stick of gum and some corny catchphrases. They rebooted it in the 2010s, but I’m talking old school original Richard Dean Anderson MacGyver. Those who know, know. He was a

guy that just seemed to find a way to take control and handle any situation. He could put his mind to a problem, a challenge or even a new skill and just work away until he’d mastered the aforementioned situation. Yes, the show also contained cheesy bad guys and 1980s state-of-the-art terrible special effects explosions, but my focus is on the character development of the lead protagonist, not the leather jackets and cliché v illains. I’m referencing MacGyver’s ability to master his surroundings and succeed. Those attributes are what this preamble is all about.

The reason for the preamble and ‘80s nostalgia is because recently, while driving through the Keperra area of Brisbane, I found my attention accosted by an imposing, square edged Champion bonnet, sitting steadfast and staunchly on the front of a Mack Super-Liner. The Super-Liner in question, branded with an anniversary livery, turned out to be a surprise gift for a man whom I would come to learn epitomises many of MacGyver’s best attributes. For more than 40 years now, Gavin Turner has taken every opportunity, every

For the 40th anniversary of Boulder Wall Construction, Gavin Turner’s sons found the perfect Super-Liner for the occasion. Warren Aitken learns more about the man at the helm of the growing operation

conundrum, every situation, good and bad and has mastered it. Now, with his sons in tow, the industrial machine fitter-welder who began his business part time while working as a maintenance fitter at an air-conditioning factory has celebrated 40 years of operations with this impeccable Mack Super-Liner.

As seems standard with transport stories, sitting down to learn the ins and outs of a truck that has caught my eye often leads to an amazing origin story. The Gavin Turner and Boulder Wall Construction story follows that trend. It began back in 1984 when Gavin wandered home after a hard day fixing breakdowns at the air-conditioning factory to inform his lovingly tolerant wife Fiona that he

was going to buy a Bobcat and move some dirt around.

“I remember coming home one day and just saying to Fiona I think I’m going to buy a Bobcat,” Gavin laughs.

“I hadn’t driven one before. So, when I bought it, I went over to my cousin’s place who had some acreage and learned how to operate it. I kept working and would do odd jobs on the weekend. I would pick the jobs that weren’t technical while I was learning, like moving dirt into a chook shed, or knock the fill over. I got the hang of it pretty quick.”

Gavin hadn’t grown up surrounded by earthmoving influences, but he grew up with a fascination of the industry.

Above: The BWC Super-Liner was purchased as an anniversary present, however it is still a workhorse. BWC’s Keperra Quarry is a second home to this impressive unit and very picturesque when we needed some working photos

“We’ve got Tridents and Super-Liners; I do love the Super-Liners. What is a labouring day for the Tridents is a stroll in the park for the SuperLiners. They are perfect for us, and the turning circle is exceptional.”

“I’ve always loved everything earthmoving,” he exclaims with passion.

“When I was a kid, everyone else was getting Matchbox sports cars, but I was buying toy dump trucks and dozers.”

It was that enthusiasm that gave Gavin the drive to purchase that original Bobcat. For those wondering, it was an old petrol 632 with a 1300 Cortina motor in it. Not exactly state of the art, even back then, but it did the job.

Almost hand in hand with an earthmoving addiction was a growing truck obsession forming. The two genres are not mutually exclusive. In fact, they are almost codependent. There’s no better example of this than the fact t hat with the purchase of Gavin’s first Bobcat also came the purchase of his first truck.

“The first truck I bought was a second hand J3 petrol Bedford, I bought it to move the Bobcat around,” Gavin says.

“I had to make ramps up to get the Bobcat into it, and I’d flit off to jobs throughout the weekend.”

It wasn’t BWC back in those days – that name didn’t originate until a bit later. In fact, Gavin was Turnico Bobcat Hire for quite a while. That changed to Brisbane Earthmoving Pty Ltd once he’d gotten more gear under his belt. Odd jobs changed to specialised jobs and pretty soon specialised jobs with a finesse for forming rock walls, leading to the creation of the name Boulder Wall Constructions.

Among the gear acquisitions, Gavin’s truck resume was getting quite creative as well. As mentioned, it began with the J3 and then its successor, a T4100 Mazda. Both early acquisitions for BWC were in Gavin’s ‘learning the ropes’ phase. By the time he had progressed from site clean-up jobs to more specialised work, which involved carting rock to job sites himself, he had a D-series Ford and a CAT powered Louisville. Gavin even ran at one stage, I kid you not, a Fuso with a 671 in it. His truck affection knew no limits as he was building the business. Instead, it was driven by his MacGyver-ness.

“Back then it was all about the body rather than the truck,” he admits.

“It was what we could get to do the job without compromising that mattered.”

F rom that first petrol Bobcat and J3 Bedford, Gavin found himself and the company on a slow and steady expansion to the point that they currently have over 80 staff on board, not including subbies. As far as equipment goes, along with over 30 truck and dog combinations, there is every possible piece of earthmoving equipment the Tonka Toy dreamers could conceive, but in real life. Excavators ranging from 1.5t all the way to 90t. Dozers, loaders, graders, jaw crushers, reclaimers. Let’s not forget the dump trucks, water trucks and service trucks. I am unsure how big Gavin’s Matchbox earthmoving collection was, but his BWC collection has it all.

Back to my MacGyver comparisons again – the rise and success of BWC hasn’t been an accident, it also hasn’t been a directive. It has come about from Gavin’s natural response to opportunities, good and bad.