ACKNOWLEDGED BY THE INDUSTRY AS THE LEADING MAGAZINE

ACKNOWLEDGED BY THE INDUSTRY AS THE LEADING MAGAZINE

Where great partnerships can take talent

MTA NSW on the EV training that matters Border glory for bodywork specialist

YOUR GO-TO RESOURCE FOR ACCURATE VEHICLE INSIGHTS

Don’t miss out on leveraging this powerful feature to elevate your quote writing and overall shop’s performance

SCAN to sign up for a 30 day FREE trial or visit www.ibodyshop.com

AUTO SELECTION MADE EASY

Simply enter the vehicle registration and let us do the rest

ALWAYS IMPROVING

Stay updated with the latest information for your convenience

AFFORDABLE ACCESS

Just 55 cents per lookup for instant information

COMPREHENSIVE DETAILS

Get the make, model, series, variant, body style, paint colour, fuel type and year of manufacture at your fingertips

SMART ACCURATE CHOICES

The correct parts list and time schedule will automatically appear for your selection every time

Chairman John Murphy john.murphy@primecreative.com.au

CEO Christine Clancy christine.clancy@primecreative.com.au

HEAD OF SALES

Andrew Morrison andrew.morrison@primecreative.com.au

EDITOR

Eugene Duffy

eugene.duffy@primecreative.com.au 0412 821 706

BUSINESS DEVELOPMENT

MANAGER

Michael Ingram

michael.ingram@primecreative.com.au 0423 266 991

PUBLISHED BY

Prime Creative Media

379 Docklands Drive, Docklands, VIC 3008

03 9690 8766

www.primecreative.com.au

DISCLAIMER

The National Collision Repairer magazine is owned by Prime Creative Media and published by John Murphy. All material in National Collision Repairer magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published. The opinions expressed in National Collision Repairer magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2024

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Automotive industry

Keep up to date with a selection of industry news

More developments from the world

Milestone reached in the recognition of

that does it right.

It has been the privilege for many years for National Collision Repairer magazine to not only report on one of the most radical periods in automotive history but to tell the stories of those who are adapting and thriving in it.

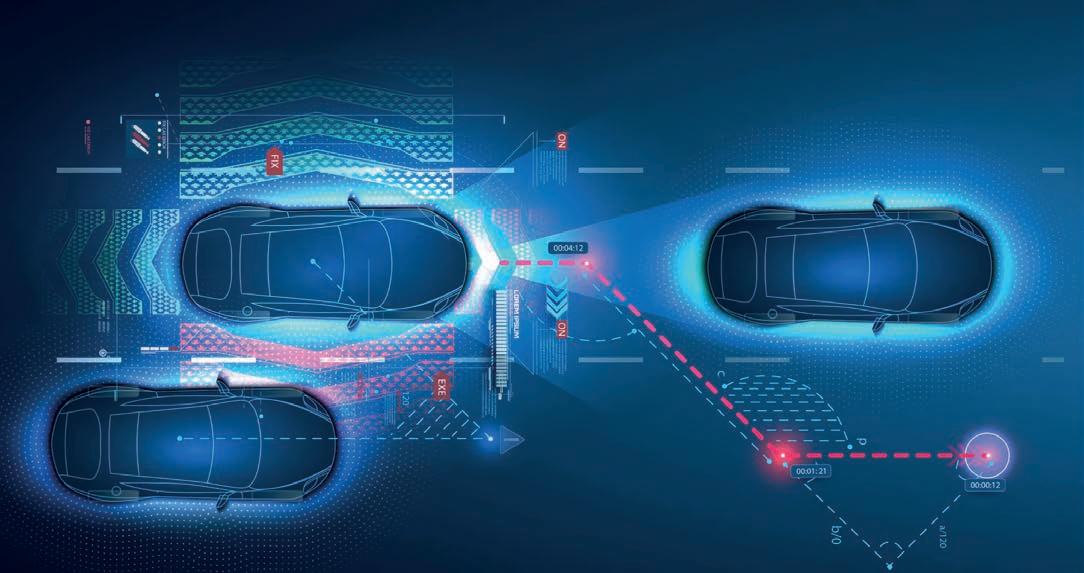

The last ten years have shown that advanced automation, which begins its life in sophisticated robotics and defence technology invariably finds its way into our cars. One stream of this technology is focused on efficiency. New power sources are notching up new milestones in output, efficiency and lower emissions. Another arm of technology pursues the user experience, enhancing comfort and safety by effectively removing the element of human error from our driving experience. Both streams share the impetus driven by

The NVES coming into affect in July and a rush of new models is finally seeing a market push toward lower emissions vehicles after a year or two of sluggish uptake. But the electrification of personal transport seems almost inevitable if global markets are anything to judge by. There have been adjustments to targets and some sober reconsideration after initial optimistic predictions, but nearly every major car manufacturer knows where the future lies and it lies with

demand. The business case here, apart from the OEM’s commitment to the environment, is a fundamental need to stay relevant to what customers want.

Similarly, the increasingly advancing technology centred around driver ease and safety, like ADAS systems, will also be driven by consumer demand. AEB is now mandatory in new vehicles in Australia and it is hard to guess how many more systems will be standard in a new vehicle within years. That will dictate just what repairers need to know to repair and calibrate these cars. It is another challenge to stay relevant.

If all this change can seem daunting or overwhelming, this is not an industry that is easily intimidated. The stories we have had the privileged to run on these pages are all about those who have grappled with the challenge and continue to grow.

Extraordinary as every new change seems, many industry veterans have noted this is not unusual and more part of a continuum of change and automotive innovation over a century. Similarly, the repair industry has kept pace with this constant change and the best have found new ways to not only improve the outcomes but ease the whole repair experience.

Whatever the rate of change, it is preparedness and adaptation that best serve businesses large and small. Training and knowledge best drive this adaptation, because these keep the eyes set firmly on the future. It is a focus we at the National Collision Repairer have been proud to foster.

We hope you enjoy and learn something from this edition.

Eugene Duffy Editor

The National

Collision Repairer

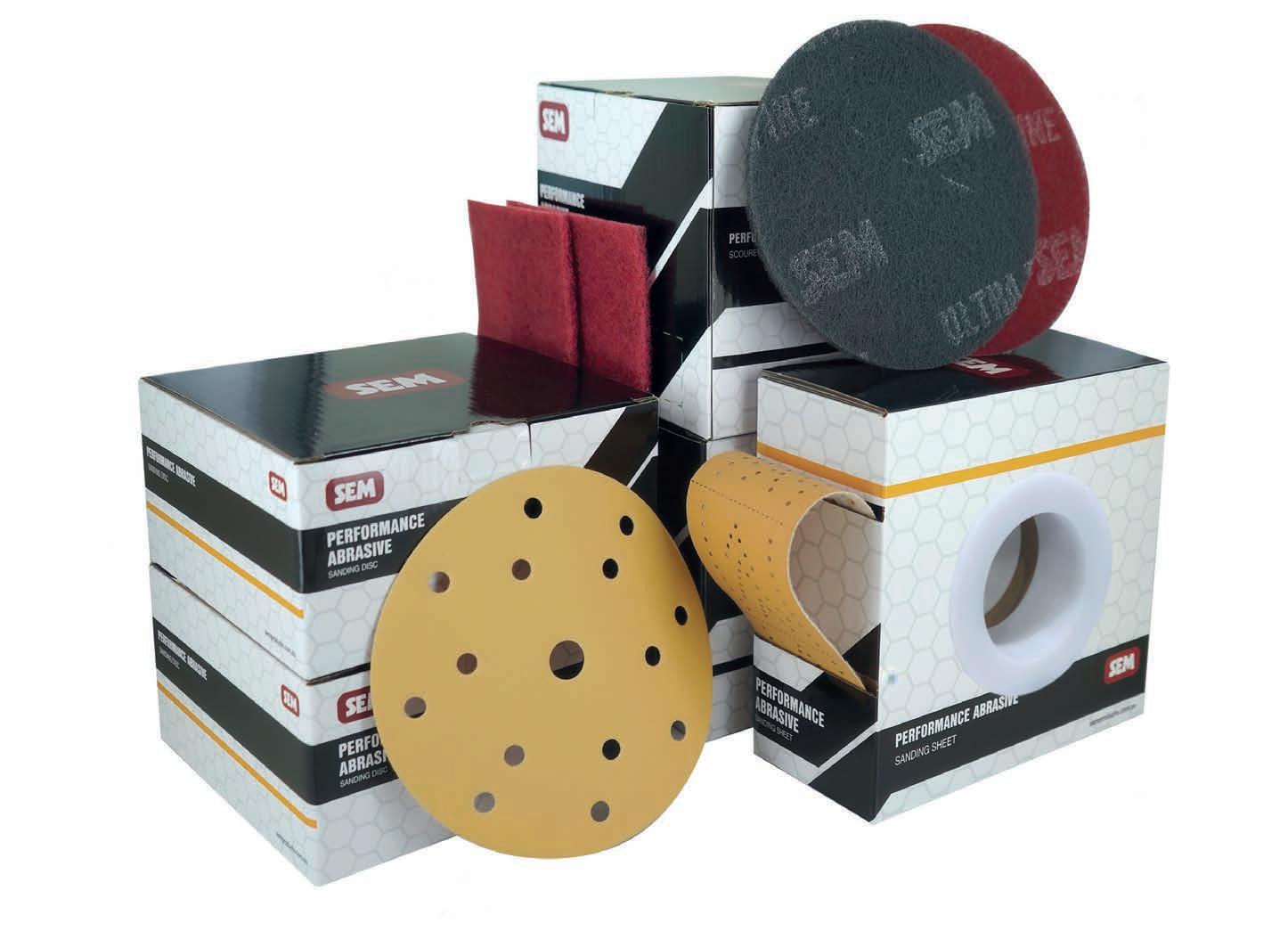

When you’re in the middle of a job, the last thing you want to worry about is whether your abrasives are up to the task. That’s where SEM Products - a PPG business unit - steps in. Their new SEM Gold and SEM Scuff performance abrasives are purpose-built for day-in, day-out sanding and finishing, giving tradespeople simple, reliable options without breaking the budget. Every product in the new SEM abrasives range delivers consistent, high-quality performance, but each is tailored for a specific role in the workshop.

SEM Gold abrasives

Still using old-school abrasives for prep work, paint removal, or sanding primer? It might be time for an upgrade. SEM Gold abrasives are made with premium aluminium oxide grains, a durable resin bond, and a flexible latex-coated paper base. This means they cut quickly, last longer, and handle even aggressive sanding jobs.

The lineup includes 150mm grip discs in 15-hole and PSA nohole styles. The 15-hole

versions, available from coarse P40 grit right through to ultra-fine P800 grit, are designed for orbital sanders and to maximise dust extraction. The hook-andloop backing makes swapping them out quick and easy, while the open-coat, load-resistant surface reduces clogging for smoother cutting control.

The no-hole 150mm option uses a pressure-sensitive adhesive (PSA) backing for a firm hold and easy changeover, which is perfect when you need an uninterrupted, flat sanding surface. Available grits include P80, P120, and P240.

Rounding out the Gold range are Perforated Grip Rolls, ideal for block or hand sanding. They come in two roll sizes, 70mm x 12m and 115mm x 12m, and both come in four popular grits: P80, P120, P180, and P240.

SEM Scuff abrasives

Some areas simply won’t fit a power tool, but that doesn’t mean they can’t be prepped properly. SEM Scuff abrasives excel in tight corners, curves, and intricate profiles, making them a go-to

for scuffing finishes before painting.

The flexible non-woven fibre construction bends to awkward shapes without tearing or rusting, which is a big advantage over steel wool, and the open-web structure resists clogging, so you can keep working without interruption.

The range includes three practical options to suit a range of jobs. The 152mm x 230mm Scourer Pad in maroon comes in a very fine P360 grit and is great for hand sanding. The 150mm Scourer Disc, in P360 grit (maroon) and ultra-fine P800 grit (grey), works for both hand sanding and orbital machines. And the 115mm x 10m Scourer Roll, also in P360 and P800 grits, can be cut to whatever length suits the job.

What SEM have nailed in their new performance abrasive product range is cost-effective simplicity and versatility. They are ready-to-go solutions that perform across common workshop tasks.

Please contact your local PPG Distributor for more details on SEM performance abrasives, including SEM Gold and SEM Scuff product ranges.

Abrasive Snapshot

A global leader in automotive innovation and technology for more than a century, Hella Gutmann is making new inroads in vehicle diagnostics and keeping workshop efficiency front of mind in everything they do. Their MEGA MACS S 20 takes vehicle diagnostic excellence to the next level.

The Mega Macs S 20 from HELLA Gutmann Australia is redefining vehicle diagnostics in the industry.

Now covering 88 per cent of the Australian car parc and 95 per cent of the top car brands in Australia, this revolutionary device puts industry-leading diagnostic tools directly into the hands of mechanics or workshop technicians.

The S 20 is specifically designed for speed, accuracy, and simplicity – ensuring a smarter, more costeffective solution to help achieve an efficient workshop.

At its core, this entry-level, Androidbased diagnostic tool features a fault code-based system, providing mechanics with an immediate access to an extensive knowledge database - all at their fingertips.

With this advanced capability along with a three selectable software modules and associated usage licenses, the S 20 can be tailored to your specific workshop requirements - saving both time and money.

This tool operates on HELLA Gutmann’s innovative SDI software,

developed by their expert engineers from Germany, making it possible for you to access this next-level software that was previously exclusive to their toptier products.

Beyond that, futureproofing is guaranteed with support for DoIP (Diagnostics over Internet Protocol) and CAN-FD data transmission protocols, ensuring the tool can meet diagnostic demands today and well into the future.

The Mega Macs S 20 package comes with the HG-VCI S 20 module and features Bluetooth® and USB-C

connectivity. This makes it possible for technicians to connect seamlessly to the vehicle’s OBD interface, ensuring reliable communication throughout the entire diagnostic process.

The Mega Macs S 20 guides repairers to easily identify issues, recommend

basic software updates at no ongoing cost. This makes the S 20 not just the ultimate diagnostic tool, but also a long-term investment that can boost workshop performance.

With HELLA Gutmann as your trusted partner, you will have access to dedicated

Right: The HG-VCI S 20 module enables the convenience of Bluetooth and USB-C connectivity.

Hella’s extensive history and expertise in technology have been focussed on meeting the demands of the busy repair workshops and Mega Macs S 20 provides simple, cost-effective diagnostics for their day-to-day needs, now and into the future.

Highlights:

Rapid access: Database covers 95 per cent of top vehicle brands

Three software modules: Tailor it to your workshop’s needs

Futureproofed: Support for DoIP and Can FD data

Reliability and convenience: Bluetooth and USD- connectivity.

Smarter diagnostic, faster results

Covers 88% of the Australian car parc and 95% of the top car brands in Australia

Developed by expert German engineers

Utilizes HELLA Gutmann’s innovative SDI software, ensuring speed, reliability, and precision

Future-ready technology

Support DoIP and CAN-FD data transmission protocols, providing lasting compatibility

Next-Level Intelligence for Vehicle Diagnostic Excellence

Western General Bodyworks director Danny Buzadzic epitomises the energy and good humour of many business owners in the collision repair industry. But when it comes to the gear he invests in, he is not only serious but adamant.

“I’ve been dealing with Car-O-Liner for decades,” Danny says.

“I reckon it was 35 years ago, the first time we bought a Car-O-Liner and I reckon I’ve got about 20 Car-O-Liner benches now, and all their spot welders and equipment.

“Out of everything I’ve ever done in life, their service has been absolutely tip top. And their equipment, honestly, you can put a Rolls Royce tick on everything they sell.”

Danny says their range also allows their shops the flexibility to take on the array of work the 11 shops in the Western General Bodyworks group are often dealing with.

“We’ve got the Speed benches, which

are the tiny little ones and they’re used for the rapid repairing stations. Then we’ve got the 4200s and they are the ones we use mainly every day. We’ve also got some of the 5000 benches, for the big ones.”

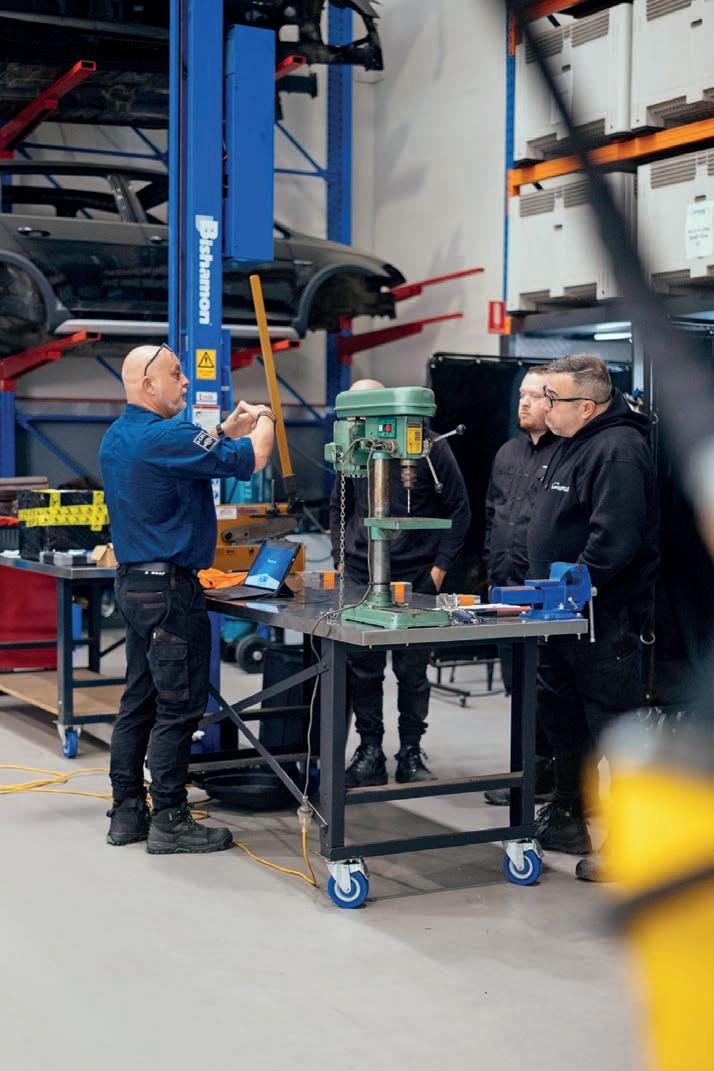

The Western General Bodywork Group has a strong focus on training, evidenced by their vigorous pursuit of I-CAR Gold Class accreditation for all its shops. The group believes training not only hones the latest technical skills but also instils a proactive learning culture.

A look at the accreditation of the Western General Bodyworks Group, including as a Tesla Approved Repairer along with BMW, Porsche, Subaru and now Xpeng, shows this commitment to prestige brands and staying up with the most modern technology. Danny explains that he believes in backing up this support to develop staff by

investing in the best equipment.

“Our training is really important, it’s imperative, and we have about 250 staff now,” he says.

“We also have other guys who have been with us for over 20 years and they’re good guys, and when it comes to equipment, if they want the best equipment, I buy the best equipment.

“The training is one thing, but the equipment makes it a lot easier too and, without doubt, Car-O-Liner is the best.”

Danny believes the quality and the efficiency of the equipment is so widely recognised across the industry that it also means most workers are familiar with it.

“In Australia, it’s like every panel beater that has worked for a panel shop knows how to use it. It’s like giving someone a microwave; they just press start/30 seconds. Every worker knows how to use it from start to finish. They are very robust and simple to use”

All this adds up to a valuable business investment for Danny and he has had the support of Car-O-Liner all along the journey .

“And they are really patient with me,” he says. “When you spend that kind of money it can make you a bit nervous too, but everything they’ve sold me, it’s made my shops more productive and more profitable.”

“They are a pricey item, like a Rolls Royce, but then it comes with a reason why it’s so good.”

Car-O-Liner’s back up support extends to expert advice and problem solving and Danny is glowing about the help he gets from the team, including Australian chief Julie Thomas.

“Julie’s is a lady in the industry but she’s better than most blokes I’ve ever met in life,” he says. “She’s top of her game. And all the staff I deal with on a Melbourne base or Australia-wide base are really good. It’s indicative that she’s got the best people working for her.”

From this team, Danny singles out Car-O-Liner’s Vic/NT sales manager

“Lindsay is my superstar,” he says.

“If I rang him up now and said, ‘Lindsay this is really urgent, come right now, the machine is not working.’ He would be out there in half an hour.”

He says this level of support has developed over the years into a loyal business partnership.

“If I ever have a baby I am going to call them Lindsay Carolina,” he jokes.

“But I’m not kidding, they really are next level to deal with.”

In the fast-paced world of the automotive aftermarket, precision, durability, and innovation are non-negotiable.

Saint-Gobain Abrasives, through its powerhouse brands Norton and Farecla, delivers cutting-edge solutions that meet the evolving demands of vehicle repair, restoration, and customisation across Australia and New Zealand.

Saint-Gobain’s abrasive technologies are engineered for excellence in cutting,

leader under the Saint-Gobain umbrella, Norton offers a comprehensive range of abrasives tailored for the automotive sector. Its cutting and grinding wheels, sanding discs and surface preparation solutions are designed to improve productivity, reduce dust, and deliver consistent cool surface finishes. Norton’s commitment to innovation ensures that body shops and repair centres can work faster, cleaner, and more efficiently.

SG_NCR0925_Ad_Half_HR.pdf 1 9/09/2025 11:57:28 AM

Sometimes the glitter of an awards ceremony doesn’t reveal what really makes a business tick. Chris and Fiona Bourke have won more than their share of awards but at heart it is their principles, energy and determination that have built a successful regional repair business.

Chris describes what he calls a gut feeling when it comes to some of the key decisions he has made over his long career in collision repair.

And with partner Fiona, this has led to some major success in the 25 years of growth at the multi award-winning Complete Body Craft in Rutherglen, Victoria.

But as many business owners would know, some of these decisions have been difficult and fraught with risk; like the first bold step into going out on your own.

“I had come out of an apprenticeship in Rutherglen at the local Holden dealer and being a local too, got to know a lot of local people,” Chris explains.

“I had worked for a large smash repair business in Wodonga, and learned how to use straightening body equipment, because the car dealership never had any of that equipment in those days. I got the experience, and then moved on to a shop in Corowa, and ran that for eight years, and had two or three apprentices come through under me.

“And then I thought, You know what? I reckon it’s time to give this a crack myself.

“I was 30 and we decided to start Complete Body Craft. But in those early days, we’d just built a house and Fiona was pregnant with our first child. And I can tell you, for the first few years I was pretty bloody nervous.”

But as Chris and Fiona know, success prompts growth and presents fresh challenges.

“When we got going, we were just renting a little shed, and we just outgrew it,” Chris says.

“We went gangbusters. All the locals supported us and followed us, and then I transitioned into doing heavy vehicles, which is what I sort of always wanted to do, but the old premises just didn’t have the capacity to do that.

“We purchased a block of land down the road, with the vision to build a facility on there, and then, lo and behold, there’s a property next door to the vacant block of land that we had come up for sale. So, we grabbed that as well. The old debt just went up and up pretty quick!”

The gradual development of this integrated complex at Complete Body Craft took many years but the Bourke’s explain there were also many constants they adhered to during the long journey.

“Fiona and I both being locally born and bred, that was the big plus to start with,” Chris says.

“But moving on, I think quality of work and customer service is the main thing that keeps you in a good stead.

“It’s the same old story, it takes a long time to get a good name, but not very long to get a bad one.”

Fiona explains that reputation must be built not only on the quality of individual jobs but an ongoing philosophy of a commitment to service.

“When Chris worked at the shop in Corowa, a lot of people had got to know him in that time while he was there. The business then followed Chris. Repeat business, which was obviously, all to do with quality and care,” she says.

But Fiona says this needs to be actively replicated with their whole team of 22 staff, from the old hands to the new apprentices.

“That’s part of the training,” Fiona says. “With the young apprentices we get in, we’ve taught them and told them how Chris and I respect people’s

our own.

“We always pass that thought on, and ensure it is part of their mindset. It just comes down to that 100 per cent of quality. A hit and miss repair or paint job is not going to cut it. Do it right the first time and if you need that bit longer to do it right. Well, that’s how we’ll do it.”

Chris highlights how quality checks of the work then become a vital part of ensuring this intent converts into the completed work.

“If it’s not 100 per cent, it doesn’t go out the door,” he says. “You let the customer know that there’s an issue, or we’re not happy with some part of the repair and they respect that. The car stays for an extra day or so and they’d prefer that than have it not right.”

Training is key

To ensure this commitment to quality Complete Body Craft has a long and developed history of training and skills development. They utilise I-CAR Australia’s modules and the training programs of the paint companies to ensure staff are equipped with the latest knowledge and techniques.

“We’ve sent painters to training centres in Sydney and Melbourne over the years just to try and keep up with it, but we have a good relationship with our paint companies. They come in regularly and often spend a week with us if we need to brush up on things. You have got to be able to use what they’re offering.”

A proactive approach to training at

evolving automotive technology and the changing nature of the car parc.

They have got in early with EV training and have a group on the staff who are up to date with the specialised training and this helps with an increasing number of the alternative vehicles they are seeing in Rutherglen.

“We’ve just done a couple of Nissan LEAFs,” Chris says. “They’ve got a plug in set up on them, and we’ve had to remove and refit that particular part of the car to be able to do a front-end collision. But it’s all doable stuff, if you’ve

learning is reciprocated with a passion from the staff, and a flexibility and appetite for the increasing sophistication of new technology and changing techniques.

“The other guys, especially the younger ones, they love it. They love a challenge. And even the painters. Some of these new paints that are on these cars are six, seven or eight different applications for one colour. And they take it and run with it.”

Fiona highlights fostering this enthusiasm is also about leading by example.

passionate,” she says. “And I think Chris’ confidence and in trusting them, washes onto them and that gives them the confidence to move forward and try these sophisticated new cars and tricky techniques.”

Keeping good staff longer

For Chris and Fiona this involvement is important for the whole team. They believe developing this passion, is one of the keys to retaining apprentices and

bit repetitive but with our apprentices, for instance, they jump right in. They’re not hanging off a broom or just washing cars for the first year. From their first jobs, I get them right into it and try and keep them interested in the trade. You need to mix it up a bit. They’re not just doing little dings but big jobs as well, from the start. I think that that makes a big difference. And it shows in their trade school training as well.”

When it comes to staff engagement,

workplace, they have a bit of fun and a bit of banter,” Chris says. “They don’t just get in at eight o’clock, and don’t talk to each other until 4.30 and then you go home. I like to see them having a bit of fun and a few laughs and jokes, and long as it’s, fair and reasonable. They’re all good friends.”

When it comes to his own particular interests, Chris says this was what prompted him to diversify the business in 2006 into truck body repairs.

“I always had a passion for heavy vehicles,” he says. “I just loved trucks. My dad drove them and I just wanted to challenge myself, to be able to repair these big monsters.”

The proximity of Rutherglen to the Hume Freeway and major transport hubs nearby in Wodonga and Wangaratta, makes Rutherglen an ideal central hub for this work and their reputation has spread to Melbourne and other centres.

Complete Body Craft has an enviable trophy cabinet and multiple awards to its credit including the best regional repair business in the recent VACC awards.

And while they love the recognition for their and the team’s hard work, they still return to the basic satisfaction of what has kept them going for decades.

“We’re pretty passionate about what we’re doing, and we love the industry,” Chris says. “So the accolades are good, but you can’t beat a customer when they pick their vehicle up. Whether it be a truck or a car that’s come in on a tow truck and it goes out

looking like a new one. That’s a high.”

But the 25 years at Complete Body Craft hasn’t all been smooth sailing. Sometimes the blows a business experiences are incidental, like the floods of January 2022, which brought 100 cms of rain to Rutherglen in four hours.

“The storm water and the drainage systems couldn’t keep u. We had over a foot of water right through our whole workshop,” Chris recalls.

“We lost pretty much a full week of not being able to trade. The water went pretty quickly but then we had to rebuild the whole workshop because it’s a brick building and the water undermined the

footings. It took 18 months to have our shed rebuilt. We couldn’t work in areas that we normally would because, we had construction workers trying to repair our shed while we were still working.”

“It wiped out all our security fences, the whole lot, they had to be replaced. There was a lot of bits and pieces of damage,” Fiona says.

But she reflects on the same spirit of challenge that helps them pick themselves up again.

“You say to yourself, ‘Well it’s happened, let’s run with it. Let’s do what we have to do to get through it.’”

Sometimes the risk of running a successful business comes with serious investment and the strain of uncertainty. One of the low points they relate from their early days was the delay and frustration at becoming a recommended repairer for insurers, even after they had made considerable investment in equipment and skills development.

“The insurance companies came back to us and said. ‘You’ve got that inverter spot, welder, you’ve got the chassis alignment machine but because you’re in regional area, population is not huge, the volumes of vehicles on the road is not huge, we just don’t think that you’re right fit to be one of our selected repairers.’

“We’d spent all this money to do their work, and we know we can do their work, but they wouldn’t have us.”

But their commitment to quality and service won through eventually and they got the recommendations that brought with it the flow of work.

The rapid influx of more work came with challenges, including the shortage of skilled workers that were available, often felt acutely in the regions.

“We ended up going and bringing some offshore guys over,” Chris says. “We have three Filipinos here, and we’ve got another one that’s coming next month, and that’s been the best thing ever. They has just been a breath of fresh air.

“Accommodation, housing was a bit of a challenge, but we ended up pulling that one off. We got them in two houses.

They just come with two bags. They have no tools or furniture, obviously, so we had to furnish them. But anyway, I’d do it again tomorrow if I had to, because they’re just such good workers.”

One of the other outcomes of their thriving workplace is developing workers to a level of skill and passion that they too are willing to take on the risk of starting their own businesses, a legacy the Bourkes are proud of.

“I take my hat off to anyone who wants to have a go at any business in this day and age, because it’s not easy,” Chris says

“I’m proud of the fellas that we’ve had that have worked for us and have now got their own businesses, and we’re really good friends with them and their families,” Fiona says. “And like Chris said, it’s not easy at all being in business and then juggling other things of your life. But we are so proud that we’ve had a

crack it, because it’s better to have a go rather than later in your life you end up saying. ‘I wish I’d tried that.’ and then you haven’t done it. You’ve got to have a go.”

What they both believe is their own commitment to quality is shared around many parts of the industry and this bodes well for its future.

“I think the industry is probably in one of the better positions that it has been for a long time now,” Chris says.

“The repairers that have closed the doors or are not doing the work anymore, have done that for a reason, or they haven’t been able to comply with the insurance company criteria.

“But I think the vehicles that get repaired today are getting repaired by some of the best repairers in Australia because they’ve got to be the best repairers to be able to produce the levels of work that the insurance companies are asking of us.”

Renowned for software development that is focussed on efficient, customerdriven solutions for business, iBodyshop is now setting its sights on the future.

Australia’s leading bodyshop management system, iBodyshop, is charging ahead with bold plans for growth, innovation, and industry transformation, both locally in Australia, and abroad. To fuel this next phase of expansion, Nash Capital has stepped in as a strategic investor, creating new opportunities for development and technological advancement.

Steve O’Brien, Managing Director of Clear21, the company behind iBodyshop, says the investment opens a new chapter in the company’s journey.

“I’m excited to speed up the pipeline of innovation that we plan to bring to market,” O’Brien explains. “Now, with Nash’s expertise and investment, we can match the required resources with our vision for the Australian and international markets.”

For more than 35 years, many of iBodyshop’s customers have relied on its suite of tools. According to O’Brien, the company’s philosophy has always been about investment back into the product, ensuring its customers never feel the need to look elsewhere.

“By aiming to bring a continual stream of improvements to the market, our goal has been to ensure our customers never need to look for a ‘better’ solution,” O’Brien says. “We’ve consistently invested our profits into upgrades, new features, and complete rewrites that enhance performance and productivity for users.”

This customer-first focus will remain at the core of everything developed at Clear21, driving the company to become the go-to solution provider in Australia and abroad. As traction increases overseas, particularly in the UK collision repair market, Clear21 is already making its presence felt.

For its Australian customer base, iBodyshop’s expansion means one thing: greater innovation at home. Among the newest developments is the return of the Last Known List Price, now included across all subscription tiers with no

additional charges. This feature helps repairers quickly make critical new, used, or repair part decisions with accuracy and efficiency.

O’Brien highlights how the company is leveraging AI and advanced technology to make these features even more powerful:

“With advancements in AI and emerging technologies, we’ve developed a more precise parts list derived from our parts catalogues. This delivers consistent, reliable coverage that will only improve over time. The real benefit is giving repairers instant, accurate insights that support smarter decisions on the spot.”

Haydn Tomlinson, Head of Product at Clear21, points to another exciting innovation soon to launch for iBodyshop users: Online Payment Support. This new functionality allows repairers to send customers a secure link to pay

invoices online, automatically receipting the transaction back into iBodyshop.

“This is just another way we’re giving our customers more efficiency while helping shops deliver a seamless experience to their end-customers,” Tomlinson says.

With Nash Capital’s investment strengthening its vision, iBodyshop is poised to not only raise the industry standards in Australia but also to redefine standards globally. AI projects currently in the pipeline for iBodyshop include AI Estimating from images, AI-assisted accounting, AI-assisted support, and AIassisted training - the company is making it clear: this is just the beginning of a new era for bodyshop management software.

For long-time customers and new markets alike, iBodyshop’s commitment remains unchanged - continual innovation, tangible efficiency gains, and helping repairers stay ahead of the curve.

Repair shop owners are often faced with a dilemma when tempted to use aftermarket or parallel parts. Are they willing to save costs in exchange for exposure to potential risks? The decision needs to be made with a full understanding of the implications for safety, durability, fit and future-proofing. Nissan makes the case clear.

What Nissan Genuine Parts bring to any repair is certainty that the parts fitted are purpose-built for the vehicle.

For collision repairers who want the best possible outcome for every repair job, this is a lot more than reassuring. Nissan Genuine Parts bring with them the commitment to safety, durability and quality that has become a hallmark of the Nissan brand.

Genuine parts are just that - genuine items made by the OEM with the same rigorous attention to testing and quality control as the original vehicle. This means it is not just in the workshop that they can make a difference but also in the performance and lifespan of the vehicle.

Safe vehicles after every repair

“One area of reassurance for both the repairer and the owner is that Nissan Genuine Parts deliver the

same standards, experience and collective expertise of a global vehicle manufacturer,” says John Galvin, Nissan General Manager for TCS & Engineering.

“These are the parts they want in their vehicles to meet the standards of that brand.”

Nissan uses its automotive engineering expertise to develop genuine parts that are manufactured with knowledge accumulated across design iterations, operational data, and testing cycles. These parts are the result of engineering decisions that define

performance and safety and help ensure that any repair brings the vehicle back as close as possible to its new condition.

“A part’s shape and material is designed specifically to work in conjunction with safety systems that are themselves designed for the Australian vehicle program,” he says.

A genuine bumper, for instance, is designed with a specific material and exact shape to ensure the active safety systems of a vehicle dependent on cameras and sensors, are not obstructed or affected, either directly or through transmissivity of the material.

A clear picture of safety

Additionally, the use of genuine parts for auto glass and headlights, helps ensure these advanced driver-assistance systems (ADAS) are working exactly as intended and expected by the driver.

“The glass is important, and particularly the windscreen”, John says. “Most of our newer vehicles, where they incorporate the radar as

certainty to repairers and owners.

Nissan conducts durability validation testing as part of the vehicle program and the genuine parts fitted on the assembly line are part of this standard.

“We have on-road testing and a durability rig which tests the car in different conditions to assess durability,” Galvin says.

“These same genuine parts are the parts you will buy – meaning they have been subject to the same level of testing.”

Critically, this durability testing directly influences vehicle design with Nissan setting higher severity ratings for its SUVs and LCVs due to Australia’s uniquely tough motoring conditions.

Long term solution versus short-term fix

Tight budgets and the urgency of turnover can prompt workshops to consider substitute parts but the decision to use Nissan Genuine Parts

brings known compatibility and peace of mind long after the vehicle has left the workshop.

The contrast in potential repair outcomes between genuine and nongenuine parts could mean that whatever initial cost may be saved with a nongenuine part, may turn out to be a false economy if there are long term costs associated with imperfect fit, poor safety or reduced durability. If Nissan Genuine Parts can remove the potential risk and uncertainty that alternative parts bring to a repair, the tested durability of Nissan Genuine Parts can also add longevity. In this way they can bring more substantial value to the repair process than only considering the item price.

Repairers pride themselves on doing the job right. With Nissan Genuine Parts they are partnering with an OEM that shares the same objective and has made the investment in safety and durability, to help ensure each part delivers what a good repair demands.

New EVs on our roads had a record sales quarter this year. If numbers still seem small, they are a growing proportion of the car parc and the automotive future. So, it’s only time before they become a standard appearance in repair workshops. EVs are changing the industry and as the MTA NSW’s Collin Jennings explores, it needs to be ready for them.

The automotive sector has always been defined by change, but the rise of electric vehicles (EVs) represents one of the most significant shifts we’ve ever faced. What was once seen as a distant possibility is now part of our everyday reality, with EVs increasingly rolling into workshops across the country.

This transition brings enormous opportunity, but also responsibility. If our industry is to meet the moment, we need to make sure our workforce is ready. The transformation required goes far deeper than simply swapping out combustion engines for batteries. We’re witnessing a fundamental shift in the skills, training, and mindset needed to service and repair the vehicles of tomorrow.

High-voltage EV systems present unique risks, and without the right training, workers can be exposed to serious danger. For consumers, confidence in the safety and quality of repairs will be essential if EV sales are to continue their upward trajectory.

At the heart of this transformation lies a non-negotiable priority: ensuring our workforce is properly trained so that workers remain safe and consumers have complete confidence in EV repair and servicing.

This reality demands that we raise our standards across the board. We cannot allow the lowest common denominator to become our industry benchmark. The confidence of consumers and the safety

of drivers must be paramount if we want to see continued EV adoption and growth in this sector.

New South Wales is leading this charge with the introduction of a new EV licence class currently being implemented. As the peak industry body for NSW’s automotive sector, MTA NSW has been the leading voice from industry in constructing this licence framework and determining how it will operate in practice. Once commenced, this system will ensure we have a well-skilled workforce capable of meeting the technical demands of electric vehicle servicing.

However, licensing is just the beginning. We need to ensure that skills development in EVs continues to evolve, and it needs to be done in concert with the repair sector. Battery chemistry is advancing, charging systems are becoming more sophisticated, and autonomous driving features are becoming standard. Our training programs must keep pace with these developments, and quickly.

This evolution also presents an unprecedented opportunity for our industry to demonstrate its transformation from traditional blue-collar work to high-tech, precision-focused careers. Today’s automotive technician is as likely to be troubleshooting software bugs as they are to be diagnosing mechanical issues. This shift opens up exciting

career pathways and helps attract a new generation of talent to our industry.

For automotive leaders across Australia, the message is clear: investment in training, both for apprentices and existing workforce upskilling, is a business imperative. The workshops and service centres that recognise this reality and act on it now will be the ones that thrive in the EV era.

This means partnering with training providers to develop comprehensive EV training programs, investing in the necessary equipment and facilities to provide hands-on experience with high-voltage systems, and creating clear career progression pathways that recognise the enhanced skill sets required for EV servicing.

The automotive industry has always been one of adaptation and innovation. From the introduction of fuel injection to the adoption of computerised diagnostics, our sector has consistently evolved to meet new technological challenges. The EV transition represents perhaps the most significant of these changes, but it’s one our industry is well-equipped to handle, provided we commit to the necessary training and skill development.

The future of automotive work is more STEM-focused, technologically sophisticated, and exciting than ever before. The question isn’t whether EVs will reshape our industry, because they already are. The question is whether

There are never enough hours in the day. Repairers want to fix cars, not waste time chasing paperwork that doesn’t move the business forward.

But for many workshops, outdated paper receipts for essentials like parts continue to slow things down. Manual handling, double-checking, and misfiling all add up. It complicates reconciliation, invites errors, and works against the lean, efficient, sustainable operations that modern repairers are aiming for.

This is the daily admin headache most businesses put up with. But it doesn’t have to be that way.

Let’s follow the frustrating journey of a single paper receipt.

A part arrives at the workshop. A delivery driver hands over the part, along with a paper invoice. So far, so normal. The receptionist gives it a quick once-over, signs it off, and places it on a growing pile of paperwork. That’s when the chaos begins.

Next, someone — maybe the workshop manager or estimator — pulls it out again to cross-check it against a job sheet or purchase order. There’s scribbling, manual marking, maybe even Post-it notes. Eventually, it’s “filed” in a drawer, on a desk, or under a coffee cup.

And the cycle continues.

Sometimes, someone scans the receipt, renames it, and files it digitally, hoping it ends up in the right folder. Repeating this process dozens of times a day becomes a huge drain on time and energy.

When it’s time to reconcile or invoice, the accounts team is left rummaging through piles, deciphering handwriting, correcting mistakes, and keying in data manually.

All this time isn’t just frustrating, it’s costing your business productivity, profit, and peace of mind.

There’s a smarter way

This is where Smart Receipting comes in, cutting through the chaos with a cleaner, paperless way to manage parts and invoices.

Built into PartsCheck, Smart Receipting is a sleek new tool designed to eliminate paperwork altogether and streamline how your workshop handles receipting and invoicing.

Before we get into how it works, here’s why it makes a difference:

• Time savings: What once took hours now takes seconds.

• Cost savings: Spend less on paper, printing, and filing.

• Fewer errors: No more lost receipts or manual data mistakes.

• Better supplier relationships: Instant, accurate communication keeps things running smoothly.

• Sustainability: Going paperless shows you’re serious about ESG and reducing your footprint. This isn’t just about speed. It’s about transforming how your business runs.

Here’s how Smart Receipting simplifies everything:

• Activated suppliers send a digital invoice directly into PartsCheck.

• The system instantly matches it to your quote or order.

• Discrepancies are flagged automatically.

• You can receipt or invoice the parts straight from your device, in real time.

It’s fast, accurate, and completely digital.

step forward for ESG and smarter business

Going paperless isn’t just good practice, it’s smart business. ESG is quickly becoming a key priority in the industry. Smart Receipting helps your workshop walk the talk when it comes to sustainability, governance, and efficiency. By reducing paper usage, you’re cutting waste, lowering your footprint,

and showing customers and suppliers that your business is serious about how it operates.

It’s time to ditch the chaos Smart Receipting by PartsCheck isn’t just another feature. It’s a smarter way of working.

If your workshop is ready to move

faster, reduce errors, save time, and work more sustainably, now’s the time to go digital.

Say goodbye to the paper pile. Say hello to Smart Receipting, available now in PartsCheck, simply log in and click ‘Activate Now’ or sign up if you’re new! Your workshop deserves nothing less. Welcome to the future.

It’s been three years since the ground-breaking legislation that sought to give repairers better access to up-to-date OEM repair information.

AASRA’s Joe McFadries looks at what the law is and why it matters.

As I move around the industry, whether delivering formal presentations, participating in panel discussions, or catching up with repairers one-onone, I am continually surprised by the number of independent repairers who are still unclear about the Right to Repair legislation. This is especially surprising given that the Motor Vehicle Information Sharing (MVIS) scheme has now completed its third year under the stewardship of the Australian Automotive Service and Repair Authority (AASRA).

Why am I so surprised? Ironically, in August 2022, the National Collision Repairer and several other publications across both the collision and mechanical sectors published a press release from the Australian Automotive Aftermarket Association (AAAA) which stated: “Independent workshops across Australia started a new chapter this month thanks to a transformational law that promotes a fair and level playing field in the automotive service and repair industry and ensures consumers have a choice of repairer.”

The release also noted that joining

AASRA provides workshops with a single location to easily and quickly access all participating manufacturer portals, covering around 90 per cent of the vehicles sold in Australia.

So, despite the extensive coverage in 2022, it seems appropriate to provide a refresher.

This ground-breaking legislation is wide-ranging, but at its core it ensures that all repairers can access the OEM information required to complete a mechanical service or repair, or a collision repair, on any post-2002 passenger or light commercial vehicle. This includes software updates such as those needed to connect a new part to the vehicle, full diagnostic scans, and access to security codes for vehicles’ computerised systems.

AASRA was appointed Scheme Adviser to oversee the day-to-day operation of the scheme. Three years on, service and repair procedures for 87 per cent of vehicles on Australian roads remain accessible through the

AASRA website. While workshops must still pay for manufacturers’ information, the legislation guarantees that this information is available at a fair market rate, something AASRA actively monitors.

This may sound straightforward, but as with many things, the devil is in the detail. Each manufacturer has its own systems and processes for accessing information. For the many “all makes, all models” repair businesses across the country, this can initially feel daunting. However, once you become familiar with the brands you deal with most often, the process quickly becomes second nature. It is also worth remembering that while many new brands have entered Australia in recent years, the ten most common brands still account for 78 per cent of all vehicles on the road.

The importance of the Right to Repair legislation lies in the fact that it allows independent repairers to compete with dealer networks on a level playing field.

According to the AAAA, before the MVIS was introduced, workshops were turning away an average of 20 vehicles per month due to a lack of access to information. Since the introduction of the scheme, this figure has dropped to 12 - a reduction of 40 per cent.

Workshops have also reported significant improvements in their customer relationships. 68 per cent said that increased access to detailed vehicle information has improved customer satisfaction, while 66 per cent reported that it has enhanced customer convenience.

Similarly, the Motor Trades Association of Australia recently highlighted that the MVIS represents a major step forward in supporting independent repairers’ access to essential service and repair information. Since its introduction, many workshops have reported easier access to service schedules and diagnostics, more consistent availability of digital records and programming functions, and the convenience of a single entry point across multiple manufacturers. These

for by the MTAA and its members in securing a nationally consistent right to access vehicle data.

Quite simply, all the information available through the AASRA portal comes directly from the manufacturers’ own databases and is therefore live, genuine, and complete every time. This ensures that you can return a vehicle to its owner with the confidence that the repair has been carried out in line with the manufacturer’s authorised procedures. The alternative can be costly and dangerous. In 2017, US collision repairer John Eagle Collision, under instruction

panel rather than welding it as required by the manufacturer. The vehicle was involved in a subsequent collision, which left the occupants trapped, suffering severe injuries. The resulting lawsuit led to a US$42 million payout. Beyond the obvious moral obligation to follow the correct procedures, no repairer wants to be in that position.

The Right to Repair legislation ensures you have access to live, genuine, and complete repair procedures. The onus, however, is on you to use them. This is why this ground-breaking legislation matters so much.

For more information, contact AASRA on

with Steven Theron

Tired of replacing damaged plastic parts? The SikaForce® Plastic Repair System is a game-changing solution for professional automotive repair shops and DIY enthusiasts alike. Powered by innovative Purform® technology, this system of adhesives and accessories provides a fast, strong, and sustainable way to fix everything from cracked bumpers to broken headlight clips.

The Purform® advantage: A smarter approach to performance

The secret to SikaForce’s superior performance lies in its patented Purform® technology. This isn’t just a catchy name—it’s a commitment to PURE, POLYURETHANE, and PERFORMANCE.

Traditional polyurethane adhesives use monomeric diisocyanates as a raw material. Purform® technology

significantly reduces this content, allowing us to create a product that delivers enhanced performance while meeting strict new European regulations.

The biggest advantage for you is this: because the monomeric diisocyanate content is below the 0.1% limit set by the European REACH regulation, professional users and workshops don’t need to complete the specific REACH training to handle these products. This saves

valuable time and resources, all while providing a high-quality, reliable repair.

Key benefits of the SikaForce System

Beyond its safety features, the SikaForce system offers a range of practical benefits that improve the repair process and the final result:

• Cost and Time Savings: Why replace a part when you can repair it? The SikaForce system saves you money and eliminates the time spent waiting for replacement parts. Repairs are completed quickly and on-site, getting you back on the road faster.

• Restore Original Appearance: This system allows you to easily rebuild and reshape plastic components, ensuring a high-quality finish that restores the part to its original look and function.

• Efficient and Durable: The adhesives are fast and easy to apply, and their multi-material bonding capability means you can fix a wide range of plastic types, from thermoplastics to thermosets.

• Eco-Friendly: By repairing instead of replacing, you reduce plastic waste and lower your carbon footprint. It’s a simple way to contribute to a more sustainable workshop.

The SikaForce product lineup

The SikaForce Plastic Repair System is a comprehensive solution with a full range of products, including adhesives,

primers, cleaners, and other accessories. The two main adhesives are:

• SikaForce®-301 (Purform®): This fastcuring, two-component adhesive has a working time of 3.5 minutes and is sandable after just 30 minutes. It’s ideal for general plastic repairs, like mending cracks in a bumper. It’s overpaintable, won’t shrink, and has a 24-month shelf life.

• SikaForce®-302 (Purform®): Need a quick fix? This super-fast-curing adhesive has a working time of only 90 seconds and is sandable in just 10 minutes. Its quick-curing properties make it perfect for vertical applications and tasks that require rapid modelling, such as rebuilding a broken eyelet or a small clip. Complementing these adhesives are essential accessories like Sika® Cleaner G+P and SikaForce®-300 Primer, a clear, solvent-based adhesion promoter that ensures a strong bond on various plastics. You can also use Contouring Film and Reinforcement Mesh to help with shaping and reinforcing the repair area.

Common applications

The versatility of the SikaForce system makes it suitable for a wide range of applications:

• Automotive Workshops: Use it for bumper repair, rebuilding broken eyelets, recreating clips, bonding sensor holders, and closing sensor openings.

• A lternative Uses: This system is also perfect for RV and camper repair,

The bonding technique offers a key advantage over other repair methods: it provides a smooth, aesthetically pleasing finish, can be applied in a single shot to achieve the desired thickness, and reduces the risk of air pockets, ensuring a faster turnaround time.

includes adhesives, primers, cleaners, and other accessories.

For more information on the SikaForce Plastic Repair System or other Sika automotive solutions, contact Sika or visit their website at: www.sika.com/aftermarket.

Disclaimer: This information is for educational purposes only and is not a substitute for professional advice. Always consult with a qualified professional before using any products.

In an industry where skills are not just desirable but an essential tool that gives a business the competitive edge, the level of platinum carries prestige and value. Leading repair trainer I-CAR Australia has hit a major milestone, celebrating 1,300 Platinum Technicians.

A milestone for the Industry

I-CAR Australia is proud to announce a significant achievement in its mission to raise the standard of training and recognition within the collision repair industry. More than 1,300 technicians across the country have now reached I-CAR© Platinum Individual recognition – the highest individual training accreditation available in our industry.

This milestone is more than just a number. It represents the commitment, passion, and professionalism of the men and women working within the Australian collision repair sector. Each Platinum Technician has demonstrated not only their technical capability but also their dedication to ongoing learning, industry excellence, and the safety of every customer vehicle they repair.

Platinum: The benchmark of excellence

The I-CAR Platinum program is designed to recognise technicians who continually invest in their skills, stay current with the latest repair methods, and adapt to rapidly evolving vehicle technologies. Achieving Platinum is not a one-off event; it requires sustained learning, assessment, and professional development across multiple disciplines, from structural repair to refinishing, estimating, ADAS systems, and beyond.

For technicians, Platinum recognition isn’t just a credential – it’s a statement. It says, “I am committed to being the best at what I do.” It elevates them to the highest level of training within our industry, bringing with it respect, credibility, and prestige amongst peers.

When I-CAR Australia launched the Platinum program, the vision was clear: create a pathway where every technician, regardless of where they work, has the opportunity to demonstrate their skills and align with global standards of excellence.

Reaching 1,300 Platinum Technicians marks a turning point. It shows that the industry is embracing structured, recognised training as a non-negotiable part of collision repair. It means that more workshops across the country are staffed with technicians who carry the knowledge and skills to repair vehicles to manufacturer standards, ensuring safety and quality for customers.

And importantly, it sends a strong message to the rest of the industry: if 1,300 of your peers can achieve Platinum, you can too.

For those who haven’t yet begun their Platinum journey, the time is now. The collision repair industry is evolving faster than ever. Vehicle construction, electrification, advanced driver assistance systems, and complex materials are reshaping how we repair cars. Customers, insurers, and

OEMs are all raising their expectations. By achieving Platinum, you are future proofing your career. You are placing yourself in the top tier of technicians nationwide. And you are showing your peers, your employer, and your customers that you are not just keeping up – you are leading the way.

So, ask yourself: What’s stopping you from becoming an I-CAR Platinum Master Technician and joining this unique group of industry leaders?

The prestige of platinum

Beyond the technical training, Platinum recognition carries with it a sense of pride and achievement. It’s something tangible – a benchmark that your colleagues, employers, and the broader industry recognise and respect.

When you achieve Platinum, you join a community of professionals who are shaping the future of collision repair. You earn the admiration of your peers, the trust of your customers, and the confidence of insurers and OEMs who know their vehicles are in safe hands.

road ahead

As I-CAR Australia celebrates the 1,300th Platinum Technician, we are committed to supporting every technician who wants to take the next step. Whether you’re an estimator, structural repairer, non-structural specialist, or refinisher, the pathway is open to you.

The journey requires effort and

Big or small, repair businesses can be instrumental in shaping the next generation of collision talent. WorldSkills Australia Gold medallist Jack Richards shows no matter how niche the business, with the right support and relationships, the sky is the limit for our best young apprentices.

Mentoring is a valuable part of many young careers in automotive repair, but few can demonstrate as close a relationship as the one Jack Richards enjoys at Sydney Classic Car Restoration. With owner Grant Browan, they make up a two-man team that specialises in hand crafted repairs at the business in Connabarabran.

Ironically, despite having had a love of cars since an early age, it wasn’t a career path Jack had taken active steps toward until his mother asked him to help an uncle who was assisting in the business moving into town.

“I’d just finished school and my mother sent me around to help him unload trailers and set up all the gear that Grant’s got,” Jack recalls.

“And he put me on from there and began showing me all the stuff he can do. And I thought, ‘I like doing that’, so I stuck with it and he gave me an apprenticeship.”

Jack will go into fourth year of his panel technician apprenticeship in November and recalls the first years were a steep learning curve but years that progressed in an atmosphere of support, where he was never afraid to ask.

“There was a lot to pick up at the time, but Grant’s made it pretty easy for me,” Jack says.

“He always gives me the time to show me how to do stuff, and if I don’t know something, I just go and ask him. He puts down whatever he’s doing and shows me how to do it.”

This support includes the invariable mistakes that newcomers are likely to make.

“When I was in first year, I was trying to

Jack’s initial foray into WorldSkills competitions was also done with the assistance of MTA NSW, who signed him up for a regional competition, where his performance was so impressive he was soon heading to the National Championship in Brisbane in June.

“I’ve never been away to very many places, so to go somewhere that far away for a competition and then end up winning. It was pretty bloody cool.”

Jack says the WorldSkills Australia National Championships’ atmosphere was a fabulous experience in honing his own skills but learning from many of the other competitors in automotive.

panel repair and then goes to them.”

He says the level of competition can be initially intimidating but the excitement of doing things well should be encouraged for all young skilled apprentices.

“It’s definitely worth the risk and getting entered into things. I’d encourage anybody to do that.”

After his win in Brisbane in the Autobody section, Jack has been selected to train with the Skillaroos squad and will now aim to win a place on the international team and compete in Shanghai in 2026. The WorldSkills

thing. I’m sure I’ll give it my best shot.”

While the competition is a thrilling part of the job, Jack is most often motivated by an artisan’s satisfaction in a job well done.

“It’s always good, you see what you’ve done and how well you’ve done the job. That makes you feel pretty good.”

He hopes more young people will tap into the pleasure of working with their hands, at the same time filling essential roles.

“It would be great for them to learn and find out how helpful a skill is to have,

“It seems to be that a lot of jobs are sort of getting taken over by AI but you can’t really do that in this industry. With skills, you’re never going to be out of a job.

For the present, Jack is concentrating on completing his apprenticeship. It has been a four-year journey where he highlights the support he has had from the MTA NSW, ensuring his training is complete and up to date.

“They’ve been very supportive and make it pretty easy for me,” he says.

But even when this is complete, he is in no hurry to rush off from Sydney

Capital SMART Repairs has officially opened its new multi-million-dollar Wingfield facility in Adelaide, raising the bar for efficiency, innovation, and customer experience in collision repair.

Purpose-built to meet the changing needs of both drivers and insurers, Wingfield is designed to solve complex drivable repairs and manage a broad spectrum of accident damage. By integrating advanced repair, paint, and drying technologies, the facility streamlines vehicle movement through each stage of repair, reducing handling and enabling faster, more consistent outcomes.

“Wingfield represents a significant investment in smarter systems and processes,” said David Chin. “It supports our teams to deliver more efficient workflows, helps us adapt to the changing mix of work we see every day, and ensures drivers and insurers benefit from improved turnaround times and enhanced service experiences.”

At over 4,000m², the Wingfield site has been engineered with operational flow

technology work seamlessly together to reduce delays and maximise productivity. The Glasurit 100 Line lowVOC paint system, LED lighting, a waterrecycling wash bay, and EV charging stations all underscore SMART’s commitment to sustainability while preparing for the transition to emerging vehicle technologies.

Designed around customers

While Wingfield delivers future-ready infrastructure, it also ensures customers and insurers have access to the right facilities in the right locations. With convenient access, dedicated service areas, and transparent communication at every stage of repair, the new site strengthens SMART’s reputation for providing a customer experience built on trust, convenience, speed and quality.

Strengthening the South

• Multi-million-dollar investment

• 4 ,000m² purpose-built site

• Advanced booth and drying technology

• G lasurit 100 Line low-VOC paint system

• Sustainability features: LED lighting, water recycling, EV charging

existing South Australian sites at Holden Hill and Mile End, expanding accessibility and creating new trade and apprenticeship opportunities for the community.

“This is about building more than a new workshop,” added Chin. “It’s about creating infrastructure that delivers for customers, empowers our people, and reinforces SMART as the trusted partner of choice for the industry.”

• Smarter job flows reduce handling & turnaround times

• Designed for more complex drivable repairs

• Enhanced customer and insurer experience

• Stronger local accessibility with three SA sites

New data has highlighted a missed opportunity to fill the extensive skills shortage in automotive trades, with only one in forty roles taken up by women.

Data released by the Mining and Automotive Skills Alliance reveals that women represent only 20 per cent of the automotive workforce, and within this only 2.6 per cent in automotive and engineering trade roles.

The research lands as the Australian Automotive Aftermarket Association (AAAA) estimates the industry is short of almost 40,000 technicians.

That gap comprises 27,000 qualified technicians and 13,500 apprentices, leaving workshops across the country struggling to keep pace with demand.

According to the Job Services Australia Skills Priority List, almost 35 per cent of key automotive occupations are flagged as being in shortage.

AAAA CEO, Stuart Charity says women remain a largely untapped resource within the industry.

“We know that increasing female participation isn’t just a matter of equity—it’s a practical and urgent response to near-term labour shortages. Even a modest rise in the number of women enrolling in automotive trades could make a substantial difference.”

“We aren’t pointing fingers—this is about partnership, opportunity, and readiness for change. AAAA is committed to supporting initiatives

that bridge gender gaps—through promotion, training access, career visibility, and creating inclusive, flexible work environments. Addressing skills shortages goes hand in hand with harnessing female talent,” says Charity.

A separate report from Impact Economics and Policy for Chief Executive Women, research found that increasing women’s participation could generate up to one million full-time equivalent workers nationally.

The AAAA hopes to bridge the difference by:

• Championing recognition and funding for female automotive apprenticeships and vocational training.

• Collaborating with initiatives like AAAA Women

• M entorship and leadership pathways

• Recruitment actively encouraging women into trade-based roles.

“Our goal is clear: to strengthen our workforce, build a sustainable future, and reflect the communities Australia serves. Expanding women’s participation in our trade pipelines is not just fair—it’s vital.”

The frequency of animal strikes continues to write off one in five cars, new insurance data has found.

AAMI insurance has released new data on car accidents involving wildlife on regional roads nationwide. In NSW and Victoria, the winter months of June and July are the worst for animal strikes partly due to short daylight hours and winter road conditions.

Analysis of 23,840 claims received last financial year highlights a need for increased driver awareness on country roads, particularly between dawn and dusk as nocturnal wildlife becomes more active and visibility decreases.

One in five of these crashes with wildlife (18 per cent) resulted in a total

write-off, with the average damage bill around $8,000.

Like an earlier RACV report focussing on Victoria, kangaroos are the biggest culprit and animal numbers in nondrought periods and particularly in peri-urban areas, relate directly to the frequency of the strikes.

Data also revealed Friday to be the worst day of the week for animal collisions, most likely due to increased activity on the roads as people travel for weekends with Victoria recording the highest number of animal collisions, totalling 7,851 accidents between July 1st 2024 and June 31st 2025.

AAMI Executive General Manager Motor Claims Customer Tim Buckett says the

alarming stats highlight the importance for awareness on country roads.

“These figures show the serious and often costly consequences of wildlife collisions on our country roads.”

“Not only do these accidents pose a significant risk to motorists and their vehicles, but they also have a tragic impact on our native wildlife.”

“We urge all drivers to exercise extreme caution, especially when driving during dawn and dusk, and in known wildlife areas.”

The most common animals involved in collisions are kangaroos. With wallabies, wombats, deer, dogs, cows, emus, pigs, foxes, and rabbits also cited by the leading insurer as fauna to avoid.

success story has been recognised as a significant contributor to community and business.

The Nissan Casting Australia Plant in Melbourne’s southeast has won the 2025 Excellence in Manufacturing Award by the Greater Dandenong Chamber of Commerce.

The Nissan Casting Australia Plant employs 192 people and is the global sole supplier for 40 different components that are used in vehicles including the Nissan LEAF, X-Trail and Patrol.

NCAP General Manager Markus Spindler and Toolroom and GK Manager Carlos Pereira Da Silva accepted the

the Chamber’s annual Business Awards Gala Dinner.

“This award is a testament to the incredible dedication, innovation and hard work that each member of our team brings every single day. Whether working on the factory floor, in the office, or supporting operations behind the scenes, every NCAP team member has contributed to this achievement,” Spindler says.

Research found the Australian Made symbol is one of the country’s most loved and recognised.

Managing Director of Nissan Oceania Andrew Humberstone says on top of

the recent Australia Made accreditation, it highlighted the success of the manufacturing operation.

“This Excellence in Manufacturing Award is well-deserved recognition of the team’s continued commitment to world-class manufacturing that supports both local jobs and Nissan’s global operations.” Humberstone says.

“NCAP demonstrates that Australian manufacturing can compete on the world stage. The plant’s evolution from traditional ICE components to cuttingedge EV and e-POWER technology shows how Australian innovation and expertise are helping drive the future of sustainable mobility,”

Roy Morgan research indicates 99 per cent of Australians recognise the Australian made logo and 91 per cent of Australians want to see more Australian Made products.

“This (Australian Made) certification will undoubtedly enhance your brand’s credibility and trust with customers who value genuine Australian products,” City of Greater Dandenong Mayor Jim Memeti says. “I have no doubt that this achievement will open new opportunities and help you continue to grow.”

The operation’s 1.2-million-part annual output includes high-pressure die-cast aluminium electric vehicle (EV), e-POWER, Final Drive and ICEengine components.

Australia’s leading collision repair trainer is gaining momentum with a new leadership structure and new corporate support.

I-CAR Australia has elevated Jason Trewin to Chief Executive Officer, after five years as Chief Operating Officer.

The training organisation made the CEO position redundant in 2020 as it underwent a restructure to deal with the impact Of COVID-19.

I-CAR Australia’s Board of Directors says realignment of CEO responsibilities was essential to position I-CAR Australia for its next phase.”

“His (Trewin’s) deep understanding of the collision repair industry, combined with his proven leadership and vision, makes him the right person to guide

I-CAR Australia into its next phase,” I-CAR Australia board chair Glenn O’Donnell says.

“We are equally proud of the commitment and expertise of the entire I-CAR team, whose passion and professionalism continue to set the benchmark in training and standards across the industry.”

Industry veteran, Trewin says he is honoured to take on the position.

“With the support of the board, management team, and above all our dedicated I-CAR team, I look forward to guiding the business into its next chapter. Our people are the heart of this organisation, and together we will continue delivering innovative, industry-leading training solutions

for the collision repair community.”

I-CAR Australia has also won the support of Mirka, a global leader in high-quality abrasives, sanding systems, and polishing solutions as it becomes corporate member with I-CAR Australia.

Trewin says he looks forward to working together toward common goals.

“Mirka’s reputation for innovation and excellence in abrasives and surface finishing makes them a valuable partner in our mission to raise industry standards,” Trewin says “We look forward to working together to support technicians and businesses across Australia.”

Mirka will gain access to I-CAR Australia’s extensive training programs, technical resources, and certification pathways.

The future of the controversial road user charge remains in focus after state treasurers agreed solutions to the road funding gap should not undermine the EV transition.

In a combined statement, the state and federal treasurers say “reforms should be designed to not deter the continued take up of electric vehicles.”

The progress comes as the governments grapple with a decline in revenue from the fuel excise as more vehicles shift to alternative energy sources.

The Electric Vehicle Council, Australia’s chief body representing the EV industry, supported the statement in a media release shortly afterward.

“This commitment gives longneeded certainty and shows that EV adoption remains a national priority,” Electric Vehicle Council CEO Julie Delvecchio says.

“This confirms that EV adoption is a national priority for Treasurers across the country and must be supported through sensible, future-focused reform.”

“This position sends a strong, positive signal to manufacturers, investors, and consumers that Australia is backing the growth of electric transport.”

The fuel excise revenue has been decreasing over a significant period with the Treasury estimating it will account for 3.9 per cent of the total tax take in the

the 7.4 per cent tax take in the 19992000 financial year.

The reduction is in large part due to the increasing popularity of EVs, PHEVs and hybrids, all of which use less fuel and pay less toward government revenue.

According to the Australian Automobile Association’s quarterly review, EV sales made up 9.31 per cent of all new car sales in the last quarter.

While the Albanese government has consistently positioned itself as supportive of the EV transition, a road user charge remains likely.

Yet the Electric Vehicle Council urges the government to handle the transition in a way that doesn’t “stall the shift” in Australia’s transition to cleaner transport.

“It’s important that a road user charge for cars is well-designed and properlytimed; that means one charge must apply to all cars and it must only be introduced when 30 per cent of all new car sales are battery electric.”

Other bodies like the Federal Chamber of Automotive Industries want the user charge to be energy agnostic and to eventually replace the fuel excise.

FCAI CEO Tony Weber says the time was right for a federally led road user charge as a part of broader tax reform in the sector.

“FCAI has long been a supporter of a nationally consistent road user charge that ultimately can be applied to all types of vehicles, not just EVs. As the

governments must support a smooth transition away from fuel excise. A road user charge is needed to provide an enduring revenue stream to support road and recharging infrastructure,” Weber says.

The treasurers meeting is expected to be the first in a series of ongoing negotiations as governments attempt to balance fiscal pressures with Australia’s broader transition to electric transport.

Attempts by the states to go it alone on a road user charge have been less successful. In 2023, the High Court of Australia found a Victorian road user tariff was unconstitutional and the government was forced to repay the fees.

But some research highlights the public is not averse to the charge. Surveys conducted by the centre for Future Urban Mobility at Swinburne University of Technology found a majority of respondents (70 per cent in Sydney and 65 per cent in Melbourne) supported the introduction of measures to reduce traffic congestion in their respective cities.

The survey of almost 1000 motorists found respondents in both cities were most supportive of road-user charges if the revenue raised was used to improve public transport, with opposition to a road user charge falling to 20 per cent in Sydney and to 23 per

Cost pressures on tow truck drivers in Victoria are threatening their future, and more delays at crashes, a leading industry body warns.

A bid by the towing industry to raise accident towing fees has been rejected by the Essential Services Commission. It found current regulated towing and storage fees for the Melbourne controlled area were appropriate and “should not be changed beyond the annual adjustment mechanism”, along with an unchanged productivity adjustment factor.

But the Victorian Automotive Chamber of Commerce says despite mounting evidence of unsustainable cost pressures facing the industry the fees will stay the same.