Walking the thin RED line

By Inside Waste

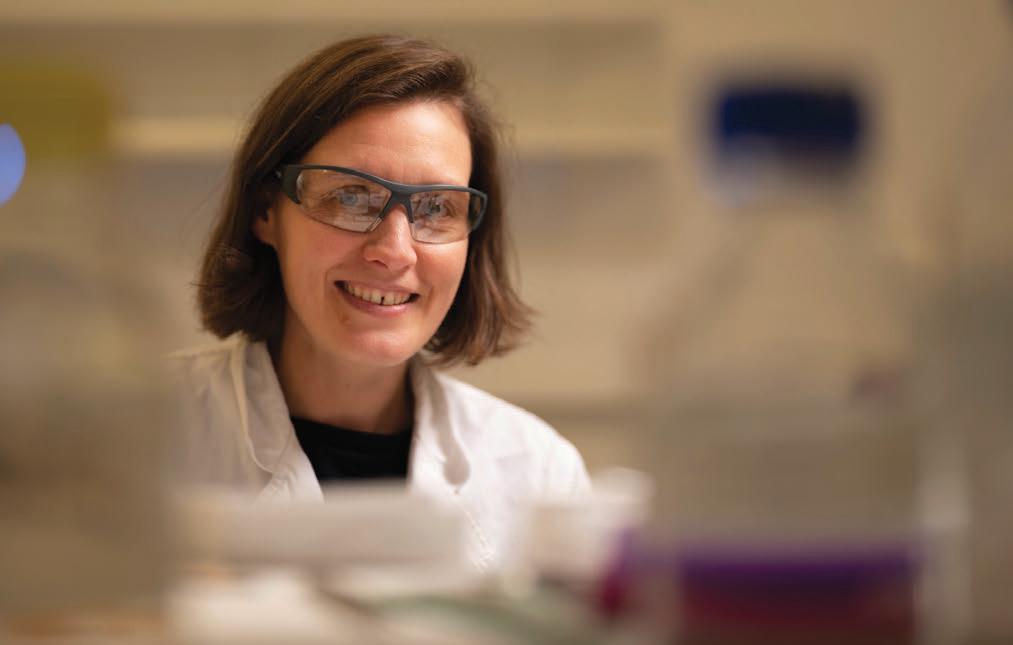

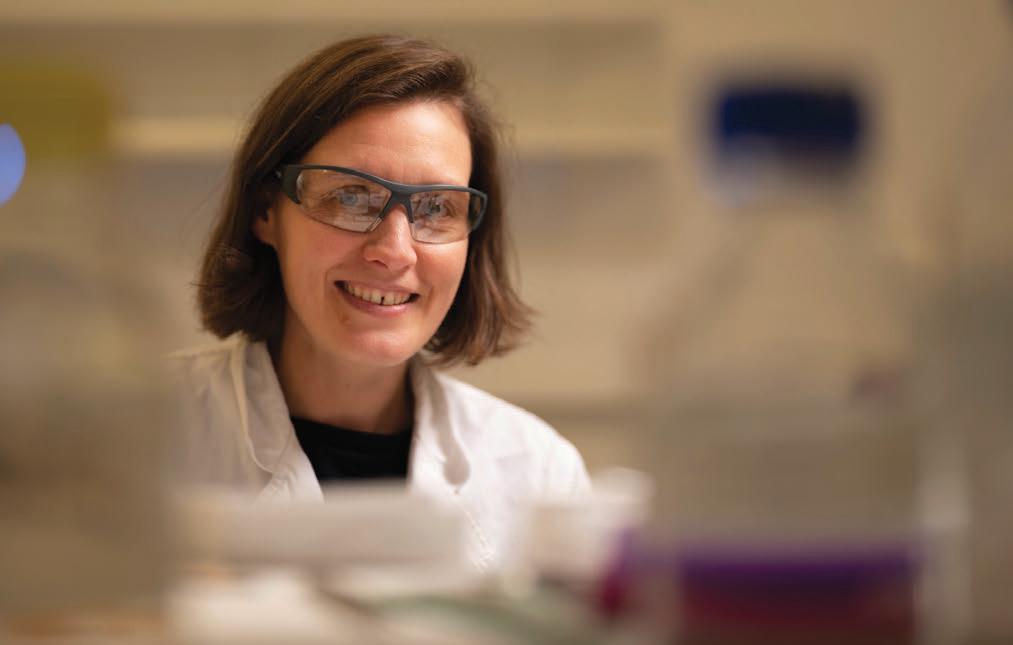

When the news broke that soft plastics collection business REDcycle had been storing soft plastics it had been collecting from Coles and Woolworths, company founder Liz Kasell knew it wasn’t a good look. Starting from an inkling of an idea she had 10 years ago, the scheme had grown too big, too fast – exacerbated by the COVID-19 pandemic.

The company recently went into liquidation despite Kasell and her team’s best efforts to make things right. So, what went wrong?

To find out, you need to start at the beginning of the end – when the news broke in the mainstream media about soft plastic bales being stockpiled in warehouses throughout Victoria and New South Wales.

It wasn’t that the bales of soft plastics had been found – after all there was no deliberate attempt to hide them – but the perception amplified by an over-excited media that inferred there were nefarious

reasons for the stockpiling. While Kasell readily admits REDcycle could have done things differently, she has not stopped working to find, and help build, end-markets for the plastics and to negate the partisan narrative that had been in the public arena.

To understand how the warehouse situation unfolded, you must go back the best part of 24 months during COVID. Kasell describes it as a perfect storm in terms of the timeline and how things happened.

COVID has been blamed for a lot of events and outcomes over the past three years – whether it be supply chain issues, supermarkets running out of stock, and a downturn in business for industries such as travel and hospitality. When it comes to the waste industry, there haven’t been too many knock-on effects, other than staffing shortages in some areas. With REDcycle, there was an opposite effect – too much feedstock.

“All of a sudden, all of our downstream capacity was affected,” Kasell said. “For five years, we knew for example, a bin would get

filled once a day, every day. We knew that bin was going to get filled seven times a week and so we allocated that much space all the way through the pipeline.

“Then, due to people staying at home all day through COVID, those bins were filling 12 times a day, or 15 times a day. If you multiply that by over a thousand locations, you realise the volumes I am talking about.

(Continued on page 21)

28 A new way to sort waste 34 No butts

36 Focus on FOGO

NSW EPA focussed on collaboration

ONE of the first things Tony Chappel did when he became the CEO of the NSW EPA was give a speech at the 2022 Australian Waste and Recycling Expo (AWRE), where he talked about “collective” collaboration between the state government, and waste and resource recovery stakeholders.

Nine months down the track, how is that collaboration panning out?

“I’ve been a little surprised by some of the entrenched positions, both within industry and the EPA itself.

“Changing the way we work with industry and transitioning to a more collaborative approach isn’t going to happen overnight, it will take time and commitment but I firmly believe it will achieve the best outcomes for the environment, economy and communities.

“The real focus is trying to look for opportunities to bring that conversation into the light and get people talking more productively.”

Arriving in Australia from South Africa when he was two, the now ‘Ausified’ Chappel’s tertiary education includes a raft of degrees – a Bachelor of Laws and Economics from Sydney University, a Masters In Environmental Change and Management from the University of Oxford, as well as another Masters, this time in Environmental Engineering Technology/Environmental Technology from the Imperial College London, and finally a Master of Business Administration, Banking, Corporate, Finance and Securities Law from AGSM UNSW.

(Continued on page 24)

ISSUE 113 | APR/MAY 2023

Meet the ZR - Low speed. High torque. Maximum performance. Visit a reference site | Book a trial | Request a free waste audit | info@focusenviro.com.au

PP: 100024538 ISSN 1837-5618

What now for soft plastic waste?

REDcycle founder Liz Kasell.

3-Stage Grinding Process

Provides Faster Reduction

Astec - Peterson's powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers are looking for.

The Impact Release System

Protects Your Investment

Astec - Peterson's patented Impact Release System's air bags provides uniform grinding and protection from contaminated feedstock, a feature unique to Astec - Peterson grinders.

The Impact Cushion System

The Second Line of Defence

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Astec - Peterson offers horizontal grinders from 433-839 kW, offering grinding solutions with output at the lowest cost per ton. Visit us at www.astecindustries.com and see why we have been leading the industry for over 35 years!

www.komatsuforest.com.au

Land clearing, mulch, compost, asphalt shingle tiles, scrap wood, biomass, green waste-we can handle it am

2710D Horizontal Grinder

Portable 6 Efficient

Engine 433 kW or 570 kW

Length 1612 cm

Weight 30900 kg

Feed Opening 153 x 81 cm

5710D Horizontal Grinder

High Production with Consistent Sizing

Engine 722 kW

Length 1800 cm

Weight 42184 kg

Feed Opening 152 x 102 cm

Astec - Peterson is represented by Komatsu Forest in Australia and New Zealand, providing industry-leading product support and expertise.

6710D Horizontal Grinder

Largest Grinder with Highest Output

Engine 839 kW

Length 1860 cm

Weight 48987 kg

Feed Opening 168 x 127 cm

Komatsu Forest Pty Ltd.

11/4 Avenue of Ame ricas

Newington NSW 2127 Australia

T: +61 2 9647 3600

E: info.au@komatsuforest.com

Ltd

Komatsu Forest Pty

GENOX’S NEW SHREDDER IS A PLASTIC PIPE’S WORST NIGHTMARE. THAT’S APPLIED THINKING.

EPA olive branch

IT’S no secret that the waste/resource recovery sector and the various state and territories’ EPAs haven’t been too friendly towards each other over the years. The former is trying to make a buck while finding ways to repurpose or dispose of waste, while the latter is charged with protecting the environment from indiscretions carried out by everybody (not just the waste industry!).

That a multi-billion-dollar industry is frequently at loggerheads with a state government-appointed agency designed to keep its (largely) minor excesses in check is of no surprise, nor that they eye each other suspiciously with regards to their various motivations.

Which makes it even more interesting that when I (yet again) approached a media team at one of the state EPAs about having a yarn to the CEO, the answer was a pleasant ‘yes’. By the time this magazine is distributed NSW EPA CEO Tony Chappel will have been in the job for about 10 months. Like his predecessors he is unapologetic about the role the organisation plays in the state’s environmental landscape. Where he tends to differ from those that went before him is that he is open to conversations about being more collaborative in the space – whether talking about product stewardship schemes or trying to cut through the screeds of red tape that appear when putting forward plans for resource recovery infrastructure.

I found Chappel a breath of fresh air. He indicated he intends to be around the

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Business Development Manager Chelsea Daniel-Young chelsea.daniel@primecreative.com.au

job for some time, and expects to leave a mark that will make the agency more user friendly. Time will tell.

Also in this issue, we talk to REDCycle founder Liz Kasell. To say the past six months has been stressful for Kasell and her team is the mother of all understatements. A lot of media scrutiny (some of it fair, a large amount of it not), and trying to solve what appears to be an insurmountable issue, has taken its toll. However, through it all Kasell and her team have tried to find solutions, co-operate with the EPA, try and repair a fractured relationship with two of the country’s biggest retailers, and is still hellbent on keeping that best part of 10,000 tonnes of soft plastics out of landfill.

As I write this, news is not good for the scheme. Both Woolworths and Coles have taken albeit light jabs at the scheme, and those that have transported the bales of plastics want to get paid and might take legal action if the account is not credited. However, there are bigger problems in terms of having infrastructure in place that would take care of soft plastics. That is a story for another day, but one we will be covering in the near future.

Finally, the Coffs Harbour Waste Expo is just around the corner. It’s hard to believe it has almost been a year since the last one. We talk to actress turned environmentalist and now Planet Ark CEO Rebecca Gilling about the event, and her role as a keynote speaker on the circular economy.

Inside Waste is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Genox’s new J-Series pipe shredder is specificially designed for HDPE plastic pipes.

With a unique multi-rotor design and long life counter knives, it quickly shreds different diameter and sized pipes. Like all Genox equipment it comes with the support and back up that only a true local machinery partner can provide.

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Design Blake Storey, Kerry Pert, Tom Anderson

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.insidewaste.com.au

Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au

Copyright Inside Waste is owned by Prime Creative Media and published by John Murphy. All material in Inside Waste is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Waste are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Call: 03 9706 8066 Email: sales@appliedmachinery.com.au Visit: www.appliedmachinery.com.au or www.genoxmachinery.com.au

Editor’s Note // Daily news updates at www.insidewaste.com.au 4 INSIDEWASTE APRIL/MAY 2023

People talk about being in the “building game” but it’s no game, it’s serious business. And you need a serious truck to handle bigger payloads. Isuzu Ready-to-Work trucks can carry around a tonne more than a typical ute, most only requiring a standard car licence. So if you’re ready to get serious, head to isuzu.com.au or visit your nearest Isuzu Truck Dealer now. Warranty is subject to the conditions outlined in the IAL New Vehicle Warranty. For further information please visit isuzu.com.au or contact your local dealer. Features shown are available across Isuzu 4x2 Ready-to-Work models only. FSA/ISZS1405 READY-TO-WORK RANGE Playtime’s over.

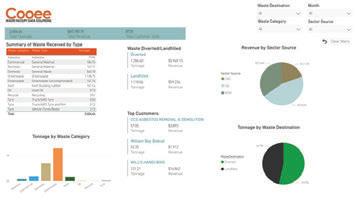

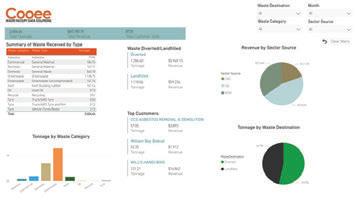

Get clarity with Cooee

New taskforce for soft plastics

THE Soft Plastics Taskforce has released a Roadmap to Restart, outlining the steps needed to launch a new supermarket soft plastic collection scheme, and the current state of play in the Australian recycling industry.

The Taskforce, made up of supermarket retailers ALDI, Coles and Woolworths, has been tasked with developing an interim solution to restore community access to soft plastic recycling following the suspension of the REDcycle program. The roadmap is that start.

Under the current plan, an initial in-store collection pilot is anticipated to launch in select stores in late 2023 – provided that REDcycle’s existing soft plastic stockpiles can be cleared. The new roadmap program would then be gradually rolled out nationwide next year.

While the Taskforce is working to launch in-store collections urgently, it is constrained by Australia’s limited access to infrastructure to deal with the issue.

At present, it would not be possible to recycle the volume of household soft plastics collected in a supermarket program using domestic infrastructure.

Accordingly, the Taskforce has plotted out the projected gradual increase in Australian soft plastic recycling capacity over the next year, as new operators launch, and existing processors expand.

From late 2023, the Roadmap Taskforce will meet the newly available processing capacity with a staged re-introduction of in-store collections so that the volume of incoming household soft plastics does not exceed the amount that can be recycled.

A spokesperson for the roadmap Taskforce said, “For the vast majority of Australian households, the only avenue to recycle their soft plastic waste has been through the REDcycle bins available at Coles and Woolworths supermarkets.

“…The Taskforce will reintroduce soft plastic collections when it can be confident that it will be properly recycled. We owe it to consumers to get this right.

“The best way to accelerate nationwide access to soft plastic recycling is through continued

investment in recycling facilities to bring forward existing plans to expand domestic capacity.

“We thank the Department of Environment, the Minister for Environment and Water Tanya Plibersek, and industry for their support.

“We look forward to their continued contribution as we design this stepping stone towards a circular economy for soft plastic.”

The current timeline to launch an in-store collection pilot by late 2023 is contingent on the ability to clear REDcycle’s existing stockpiles of soft plastic, of which Cole and Woolworths have recently been granted. Should new domestic processing capacity be taken up by the estimated 12,000 tonnes of stockpiled material for at least a year, the recommencement of instore collections will be delayed.

Accordingly, Coles and Woolworths intend to work through options to export the stockpiles to trusted recycling facilities overseas with the necessary transparency, traceability and government approvals.

This would allow access to advanced recycling beyond Australia’s existing domestic capabilities.

Over the coming months, the Taskforce hopes to engage other retailers, e-commerce platforms and consumer brands that generate soft plastics to contribute to the development of the new in-store collection program.

Daily news updates at www.insidewaste.com.au 8 INSIDEWASTE APRIL/MAY 2023

Cooee intuitively captures real-time data, saving time and money with easy reporting via customisable dashboards. Accurate data drives good decisions, so you can check waste quantities and revenues at a glance, seamlessly manage tip passes and even work in off-line environments. Call us on 0447 393 363 or visit us at cooeedata.com We can help for small to medium landfills and transfer stations

Is your

News //

The new taskforce involves ALDI, Coles and Woolworths.

Trial could help solve litter crisis

ROBOTIC dogs and artificial intelligence could help Australia fasttrack to litter-free status. In a trial by Veolia, dog-botics have been trained to collect littered waste, like plastic, paper and glass, proving they could help humans to clean-up the state of the environment.

Walking the streets of Sydney’s Bondi Beach, two dog-botics, aptly named Scoop Doggy Dog and Clean-up, have successfully collected littered bottles and cans from the promenade, to be recycled instead of potentially ending up in the ocean.

The robotic dog technology uses mechanical manipulation and camera detection intelligence to produce a series of custom-trained actions. As part of the Veolia trial, the dogs were taught to recognise waste in the street, and act by picking it up and disposing of it safely out of the natural environment.

With the ability to carry up to 14

kilograms, and a battery life of over an hour, the dogs swiftly moved along the length of the beach before having to empty their buckets.

Richard Kirkman, Veolia’s Chief Operating Officer, said the health of our waterways and our ability to solve Australia’s litter crisis could rely on the adoption of robotic technology.

“In all parts of our lives we use digital technology to improve our livability and this can include litter,” he said.

The machines accurately detected and collected littered waste, making it a potential gamechanger for cleaning-up the environment.

“The robo-dogs can recognise just about any object we train them to do – like a sophisticated version of fetch, only it could help solve our litter crisis and protect our oceans at the same time,” he said.

Millions of tonnes of waste

REDUCE DOWNTIME. INCREASE PRODUCTIVITY.

Recycling Made Easy.

is estimated to enter Australia’s oceans every year. Kirkman said the technology could help reduce this number, however humans still need to play their part.

“It’s not always possible to avoid waste in society, so when it can’t be prevented, people need to be vigilant about making sure it goes in the right bin as the first step.

“Technology is a great way to help us collect litter, but it should

never be our only line of defense,” he said. “We already use optical sorting to better recycle materials, we have biogas and energy-fromwaste projects to help recover more, and we’re committed to trialling all options on the market, so we stay ahead of advancements and drive ecological transformation in Australia and New Zealand. The robotic dog litter collection trial unleashed some promising results.”

KIVERCO PS122 PICKING STATION

• 4 bay sorting - Recovers clean stone, wood, paper, plastics, card or other recyclable materials at the option of the operator

• Combines air separation, magnetic separation, and manual sorting in one compact unit

• Adjustable belt speed - 1200 mm wide picking belt adjustable to suit waste material and desired recovery required

• The hydraulic jack leg support offers rapid set-up and transport

Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 9 // News

SALES | HIRE | SERVICE | PARTS 1800 182 888 | www.lincom.com.au | sales@lincom.com.au | OFFICE LOCATIONS | QLD | N QLD | HUNTER REGION | NSW | VIC | WA

Mechanical manipulation is just one of the technologies used by the robotic dogs to collect rubbish.

Design critical for circular targets

A NEW series of reports unveil a critical roadmap to transition Australia to a circular economy through design, to help businesses and industry make real environmental change. Commissioned by the Department of Climate Change, Energy, the Environment and Water, the ‘Enabling Design for Environmental Good’ reports were produced by experts in eco-design and sustainability from across research and industry to inform a coordinated approach by government and industry to transition Australia to a circular economy.

The recommendations highlight opportunities for Australia to use design to improve the sustainability of production processes, materials, products and business models across local industries, as well as the risks of not doing so.

Australia has a goal to transition to a circular economy by 2030, but RMIT project lead and Associate

Professor Simon Lockrey said Australia was still in the early stages of its circular economy journey. Countries such as The Netherlands, who are seven years into their transition, are already making progress within fashion, water and technology.

“We’re already seeing the impacts of climate change playing out now,” said Lockrey from RMIT’s School of Design. “It’s not just impacting the environment, it’s also impacting the global supply chain, causing delays and driving up costs.”

That is why the research team is calling for a central body run out of the federal government to coordinate Australia’s transition to a circular economy through design.

“This call for a new and coordinated approach to designing sustainable products and industries is not a nice-to-have, but an urgent necessity,” Lockrey said. “We need an approach that ties together the

interests of the federal, state and local governments, which will help businesses and industry work towards a common goal.”

Collaboration for real change

RMIT researchers led a consortium of experts with consultants from Arcadis Australia and One Planet Consulting to craft 10 recommendations to overhaul products made locally or allowed to be sold in Australia, and how we handle them during their lifespan, for four priority sectors – textiles, plastics, buildings and electronic goods.

“Australian industry sectors will become increasingly uncompetitive unless these recommended actions are taken to align with leading nations on better product design, sale and circularity,” said Helen Millicer, Churchill Fellow and Director of One Planet Consulting.”

VACANT

The importance of design

Arcadis Australia project lead Richard Collins said design was crucial to ensure materials, products and systems were environmentally and economically sustainable from the start of their lifecycle.

“Design contributes to up to 70 per cent of the environmental impacts of a product’s lifecycle,” he said. “For instance, before a building begins construction, design decisions made on what sort of materials are used, how it’s built, where the building will be positioned, and subsequently how it performs over its life, will determine the environmental and financial impact of the building. If poor choices are made, the building will have negative environmental impacts, and also cost more to run, maintain or upgrade. This is bigger than just construction – the same design principles need to be applied across textiles, electronics, plastics and more.”

WCRA is known to be the oldest industrially registered employer body representing waste & recycling organisations anywhere in the world. On 7th May 2023, WCRA will turn 75.

WCRA’s membership is representative of the bulk of the NSW and the ACT waste and recycling industry, and it is a very well-resourced, highly respected industry association.

We are seeking the services of a suitably experienced person (or persons) to fulfil the duties associated with this role. This will involve the following-:

• Reporting to the elected Executive

• Ensure compliance with relevant registered association legislation

• Supporting Members

• Maintaining relationships with Sponsors.

• Retention & growth of Membership & Sponsorship.

• Influence policy impacting the waste & recycling industry.

• Participating in industry working groups.

• Search for and apply for funding opportunities (and grants).

• Manage training offer (including cost, quality and possible delivery).

• Facilitate working groups of Members (C&D, Liquid/Hazardous, ACT, MRF, Scrap Metal, WHS)

• And manage staff, the office and oversee all aspects of the accounts.

Applicants should possess the following attributes, skills and experience -:

• Be self-motivated.

• Have the ability to work within a small office environment.

• Possess high level communication

and negotiation skills.

• Excellent report writing skills.

• Have an understanding of the waste and recycling sector.

Applications should visit WCRA’s website www.wcra.com.au and familiarise themselves with WCRA’s background, services and offerings, including the annual calendar of events and the detailed position description.

Remuneration (including employee or contractor arrangements), support and a structured hand-over will be discussed with short-listed candidates and agreed by the Executive with the successful candidate.

Please send applications including a signed covering letter and full CV by email, by COB on Wednesday 26 April 2023 to executive.director@wcra.com.au

Executive Director Waste Contractors & Recyclers Association of NSW (‘WCRA’)

Key strategic leadership role responsible for shaping the future of waste, recycling and resource recovery in NSW and the ACT

POSITION

Daily news updates at www.insidewaste.com.au 10 INSIDEWASTE APRIL/MAY 2023 News //

Microplastics and human health

AS millions of tonnes a year of microplastic waste mounts in marine environments, Flinders University scientists warn the ramifications to wildlife, food webs and human health are still little understood.

An Environmental Pollution review of how plastic waste and their associated chemicals impact marine food warns that the impact of this “omnipresent contamination” of marine environments is “not well understood”.

It can take hundreds of years for plastics to degrade, with synthetic byproducts breaking into ever smaller particles through hydrolosis of hydrocarbons by microbes and exposure to environmental conditions. These plastics of various sizes pose a substantial risk to life forms right down the food web, says Flinders University College of Science and Engineering PhD candidate Elise Tuuri, from the Plankton and Marine Microbiology

Lab at Flinders.

“This study highlights the complexity of microplastics as a pollutant and how this can lead to difficulties in determining accurate impacts to human health and local marine environments,” she said.

“We know that large plastic debris can directly result in the death of larger marine organisms, through entanglement, strangulation, choking and starvation through ingestion, while smaller organisms can filter the water and ingest smaller plastic debris.

“As well, from laboratory-based studies we know this affects sea animals’ feeding behaviour and reproductive outputs and can cause developmental anomalies, changes in gene expression, tissue inflammation and the inhibition of growth and development to both adults and their offspring.

“However, the impact of microand nano-plastics to marine

organisms in the environment are still relatively poorly understood and are considered a hidden threat.”

Microplastic is a complex contaminant due to the diversity in sizes, shapes, polymer compositions and chemical additives, which also could variously impact specific marine species. The researchers call for more research into plastic contamination and synthetic additives to understand and prevent further potential environmental and biological health problems.

“Marine microbes dictate the flow of energy and nutrients but we do not know how plastics and their associated leachates affect microbial life at the base of the marine food chain,” says co-author Professor Sophie Leterme, from the ARC ITTC for Biofilm Research and Innovation at Flinders University.

“Studies have found that plastic pollution has a direct impact on bacterial growth, protein production,

the acquisition effect of major primary producers phosphorous and nitrogen-fixing rates, photosynthesis and genome wide changes, so we need to understand what chemical additives do to macrophytes, phytoplankton, zooplankton and microbes in the sea.”

Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 11 // News Thank you for once again voting us Australia’s best small consultancy. BESTSMALL CONSULTANCY Call 02 8541 6169 or email info@mraconsulting.com.au mraconsulting.com.au Contact our award-winning team today to find out what we can do for you.

Microplastics have an insidious effect on marine life’s feeding habits.

Recycling Re-made

Visy is innovating and investing to find better ways to recover, recycle and re-manufacture packaging from recyclable materials.

Re-manufactured into new packaging

Global leader in packaging and resource recovery

Recovered recyclable material

150+ operations across Australasia For

We take 512,000* tonnes of glass. We make 3.2 Billion* glass bottles and jars.

A better way for a better world

more information VISIT VISY.COM

* Includes recyclable materials used by Visy and provided to other recyclers in FY2022.

SA EPA release drafts of PFAS guidelines

THE SA Environment Protection Authority (EPA) has released for consultation two new PFAS-related guidelines.

Per- and poly-fluoroalkyl substances, known as PFAS, are manufactured chemicals. They have been used in a range of industrial and consumer products since the 1950s.

They are of concern around the world because they are not broken down in the environment and can bioaccumulate in food and travel through groundwater.

All Australian states and territories are dealing with legacy PFAS issues.

The substances have been found at low levels across of a range of land uses. This is the first time the SA EPA has provided formal guidelines for site suitability and the re-use of PFAS-contaminated waste soils. As part of the EPA’s PFAS management regulatory strategy, it

has released:

• Draft PFAS-contaminated waste disposal site suitability guideline.

• Draft PFAS in waste soils guideline.

Australia’s Environment

Ministers endorsed the first PFAS National Environmental Management Plan (NEMP) in January 2018. It provides governments with a consistent, practical, risk-based framework for the environmental regulation of PFAS-contaminated materials and sites.

The draft guidelines are consistent with the NEMP but provide guidance tailored to South Australian environmental legislation. The EPA hosted two digital information sessions – one on each draft guideline – and invited interested members of the community to join online. The draft guidelines and further information are available online.

Heavy duty floor topping & repair system for waste handling sites Call us for more information NO DOWNTIME FLOORING 02 8840 8888 enquiries@ascoatings.com.au | www.ascoatings.com.au > Leachate Resistant > Industrial Strength > High Impact Rating > Rapid Cure Times > Joint Repairs AS/NZS 4801 Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 15 // News

PFAS has been found across a range of land uses in Australia.

Arking up for a circular economy

ONE of the keynote speakers at the upcoming Waste 2023 Conference at Coffs Harbour will be Planet Ark CEO Rebecca Gilling, whose topic will be A Carbon Neutral Circular Economy for Australia: Connecting the Dots. Getting to carbon neutrality is no easy task, but utilising the organisation’s three main planks, she thinks Australia can get there. Those three planks are carbon neutrality, circular economy and connecting people with nature.

“If we are going to achieve net zero emissions by 2050, about 55 per cent of those emissions can be dealt with by converting to renewable energy,” she said. “The remaining 45 per cent will be around how we use products and materials, as well as food and land. And we believe that it’s vitally important that people maintain that connection with nature, so that they understand what it is that we’re trying to protect.”

One of the issues to getting

companies onboard are the costs involved. When mandated to look towards a circular economy, companies have to comply. But what about voluntary adherence?

“We did a research project surveying a number of businesses,” said Gilling. “Most said that they thought that the circular economy was going to be important to their business sometime in the near future. We know that businesses are focused on net zero emissions and that’s driven partly by a need to reduce costs with increasing costs of fossil fuels to their businesses. But it’s also being driven by consumers and shareholders who are demanding these sorts of changes.

“You talk about the costs to business, and that’s certainly one of the barriers that is perceived by business. But what we know from experience abroad is that the circular economy is a cost saving to

business because it directs energies further up the waste hierarchy, to avoid, reduce and reuse ahead of recycling and waste to landfill.”

Gilling said lack of collaboration is an issue. During a visit to Australia last year, former Dutch Environment Minister Jacqueline Cramer noted that businesses in Australia were less willing to collaborate than their European counterparts.

“That is going to be one of the challenges moving forward,” she said. Gilling pointed out that it’s also for individual businesses to look across their value chain and see how they can work not just to make their own business more sustainable but connect with a value chain to avoid loss lost value. According to Gilling, this is because every time there is waste in a system, there is lost value. That’s the point at which stakeholders need to recognise they’re losing value and ask how can they capture that value and keep it

back in the supply chain.

Moving forward, Gilling would like to see more procurement from entities. Whether that is at council/state government level, or businesses, she doesn’t care. There is demand from the public, but governments need a push.

“Government procurement is a great place to start. And certainly, we’re hearing the right noises from government about their own procurement policies,” she said. “It’s also about education – for businesses, government, and consumers to look for products that contain recycled content because that’s how you close the loop.

“It’s happening. As we’ve seen in roads, for example where they contain soft plastics and textiles and various other things. They’re a low value use, but at least it’s replacing virgin material, which is important.”

Gilling will be speaking on Tuesday 9th May.

Daily news updates at www.insidewaste.com.au 16 INSIDEWASTE APRIL/MAY 2023 News // Maximise Recovery... Reduce Landfill Costs Eriez.com.au | 03 8401 7400 through… Superior Equipment Innovation Service Support Testing Eriez equipment enables the recycling industry to maximise the recovery of mixed metals from comingled waste, in turn increasing product purity to achieve the highest value.

Return and Earn $900 million in refunds

NSW has reached a new recycling milestone with nine billion bottles, cans and drink cartons returned by the community through the Return and Earn return point network.

Danielle Smalley, CEO of Exchange for Change, scheme

James Dorney, CEO of network operator TOMRA Cleanaway, said we can all be proud of what we have achieved working together for a cleaner and more sustainable state.

coordinator

for Return

for Return

and Earn said the community’s tremendous support for the scheme is delivering benefits to the environment and the people of NSW.

“While [the] milestone means thousands of tonnes of plastic, glass and aluminium has avoided ending up in litter or landfill, it also represents $900 million in container refunds back into the hands of the community,” she said.

“These funds are helping offset people’s weekly shopping costs, providing pocket money for kids and have become an important avenue for fundraising across the state, with more than $42 million raised for charities.”

When you combine the nine billion containers returned via the return point network together with kerbside recycled containers redeemed by local material recovery facilities, 11.73 billion bottles and cans have been collected since the scheme began in 2017.

This equates to 837,000 tonnes of materials recycled and a reduction in CO2 emissions equivalent to taking more than 400,000 cars off the road for a year.

“It’s humbling to know Return and Earn is having a positive and measurable impact,” he said.

“We have a proven record of success with 100 per cent of glass and plastic containers collected through the network reprocessed into new containers and other food-grade packaging right here in Australia.”

Up to 89 per cent of NSW residents support the scheme and 82 per cent have participated.

One example are siblings Isabella (15), Giovanni (14), Valentina (12) and Romario (10) Silva from Preston. NIcknamed the Bottle Kids for obvious reasons, they have been returning and earning with mum Collette since 2018.

So far, the family have collected 86,000 bottles and cans and hope to reach 100,000 by the end of the year.

“The kids like to encourage our neighbours to recycle too, and it’s great knowing we’re making a positive difference,” said Collette.

Return and Earn is delivered in partnership with Exchange for Change as scheme coordinator and TOMRA Cleanaway as network operator, and is funded by the beverage industry.

Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 17 // News

25-26

The returning of more than nine million containers has been the equivalent of taking 400,000 cars of the road in terms of C02 emissions.

October 2023 Melbourne Convention & Exhibition Centre Exhibit in 2023

Over 200 Council and government department attendees visited Waste Expo Australia.

Australia’s largest gathering of waste management and resource recovery professionals.

100% of exhibitors say they were extremely satisfied with Waste Expo Australia in 2022.

AR-512476_WMR HP Ad_105x285mm.indd 1 3/2/23 6:53 PM

93% of exhibitors rated the quality of buyers as ‘good or excellent’ at Waste Expo Australia.

From the CEO’s desk

Are we destined to repeat the same mistakes?

targets for recycled content in packaging.

• Increasing Australia’s domestic recycling capacity.

• Increasing the demand for recycled products.

• Exploring opportunities to advance waste-to-energy and waste-to-biofuels.

phoenix. But like the mythical phoenix, its success remains fictitious. Instead, we have an incoherent document with inadequately planned actions, such as the waste export bans (a sound idea in theory but problematic in reality). Four years on, the National Waste Data Report reveals we have a massive infrastructure shortfall, 14 million tonnes to be exact. Throw in our abysmal 1.8 per cent improvement in resource recovery over the past four years and that’s 17 per cent below where we need to be, miles off hitting the 2030 targets.

•Updating the 2009 Waste Strategy by year end, which will include circular economy principles.

It is time to take stock and examine what has been achieved since these decisions were announced. Now, seven (7) months may not seem like a long time, however in that time we have seen further markets close (Malaysia, Indonesia, Vietnam) and if you are an operator under continued financial stress, seven (7) months could make or break you.

Add in other important 2030 goals, like the pledge to protect 30 per cent of land in line with the UN Convention on Biological Diversity, as well as achieve 43 per cent carbon mitigation, and you realise the common denominator to push Australia closer to these targets is our WARR sector. If we reduce the reliance on virgin materials and use our sector’s secondary raw materials, we can significantly reduce emissions and energy. Recycling glass alone reduces as much as 87 per cent carbon and 82 per cent energy.

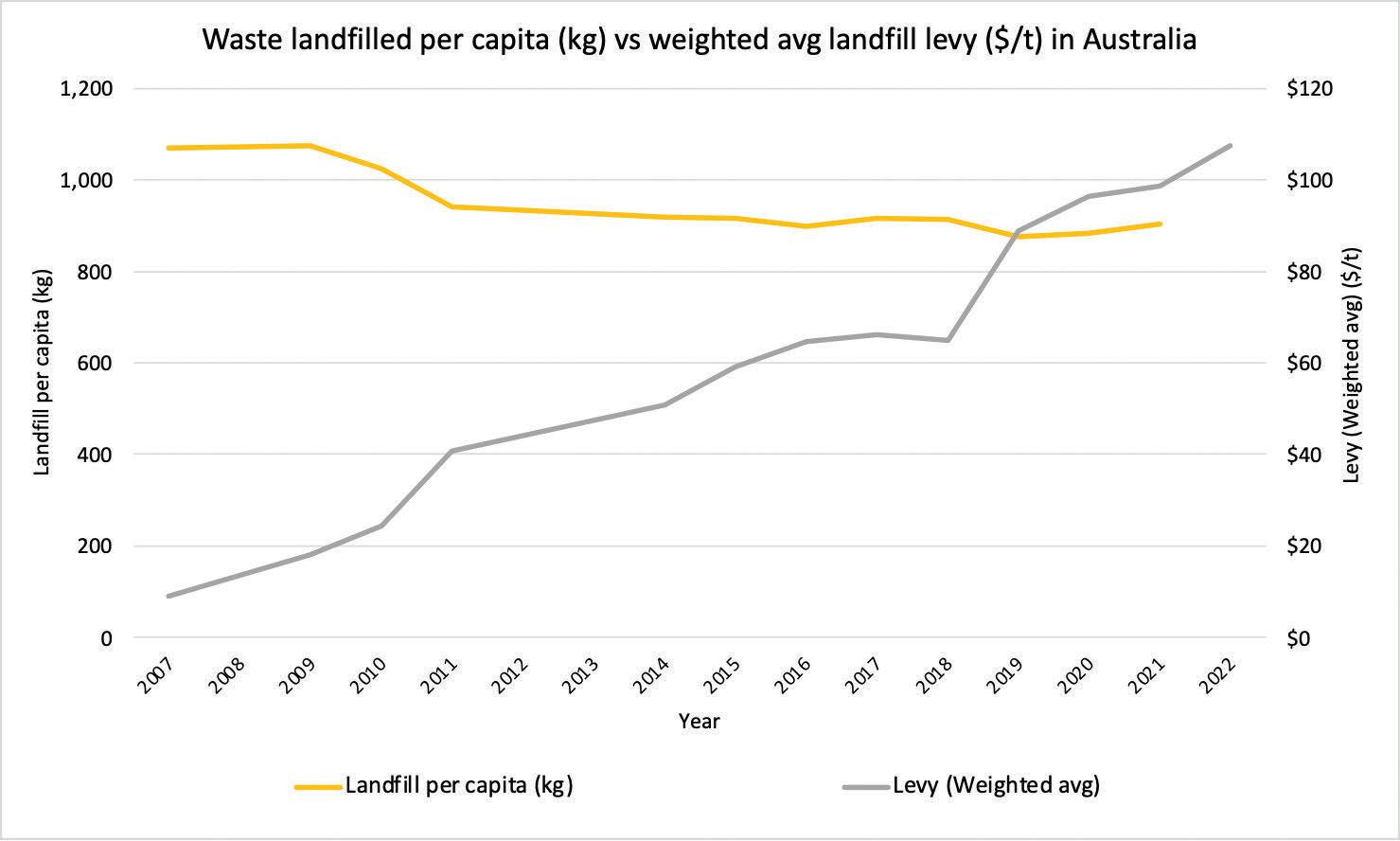

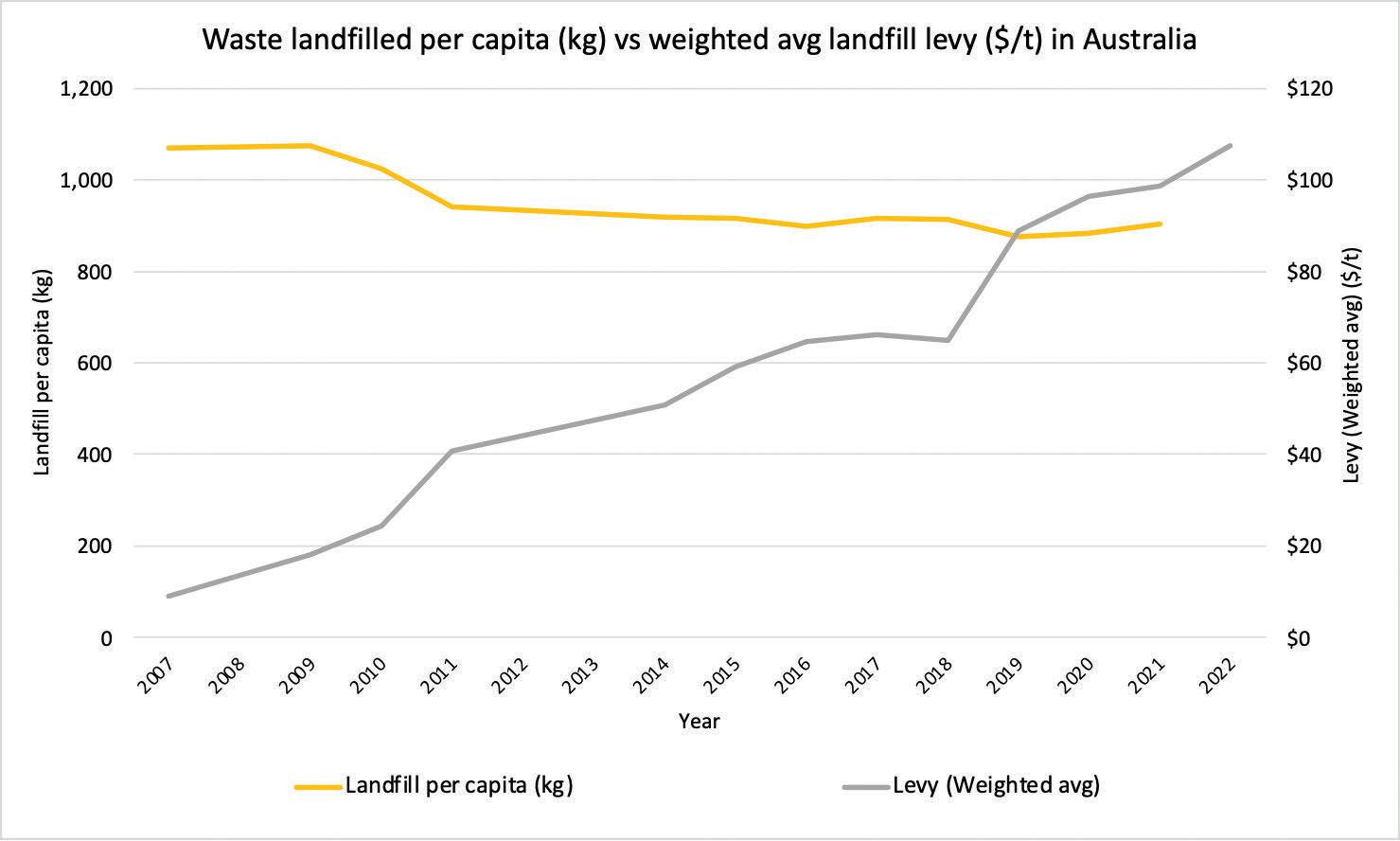

Following the April MEM, we have had three (3) states step in with varying degrees of financial assistance for industry (councils and operators). This should be expected considering almost all states (except Queensland and Tasmania) have access to significant waste levy income each year. On the eastern seaboard, Victoria has approximately $600 million in waste levy reserves in the Sustainability Fund and NSW raises more than $700 million per annum from the waste levy. There is certainly no lack of funds that can be reinvested into our essential industry.

Despite our sector being critical to the success of Australia in achieving these targets –we still have not seen the necessary paradigm shift. Instead, we’re in a constant state of market failure at real risk of becoming a dumping ground for low value materials, with our essential sector continuing to be at the receiving end of cost and risk transfers from the rest of the supply chain.

Funding helps but as we know, the money goes a much longer way with Government support and leadership, as well as appropriate policy levers.

VICTORIA

We are on the cusp of another crisis, and instead of running towards it, we need our governments to turn their attention to developing a new economic model that recognises the shared responsibility of material management and importantly, the value of materials our industry produces, while correcting the balance, so that resource recovery is more cost effective than landfilling. Even if we do all of these, there’s one more missing piece that we need or nothing else will matter and we will never meet our 2030 targets – markets.

Victoria has arguably been the most active and earnest in supporting the industry post-China, with two (2) relief packages announced to support the recycling industry, valued at a total of $37 million. The Victorian Government has also gone above and beyond all others states by announcing it would take a leadership role in creating market demand for recycled products.

SOUTH AUSTRALIA

Market intervention by the government is not unheard of (export bans anyone?). But what has so far been ignored is that we operate in a global market. We are a significant importer, and we have, over the years, lost much of our domestic manufacturing base. Export bans can only work if we have local markets for the materials we now need to process here. If all these crises we’ve been through and the most recent war in Ukraine have taught us anything, it’s that we desperately need to build our resilience. So, in the immortalised (but

Government announced a $12.4 million support package comprising $2 million of additional expenditure, $5 million additional funding for a loan scheme, together with targeted funding from the Green Industries SA budget. The Government has also offered grants for recycling infrastructure.

NEW SOUTH WALES

At first glance, New South Wales’ eye-watering $47 million recycling support package was heralded as the spark of hope industry needed. However, on closer inspection, the bulk of this package that was funded via the Waste Less, Recycle More initiative and therefore the waste levy, was not new, making it very difficult for stakeholders, including local government, to utilise the funds as they were already committed to other activities. Some of the criteria proposed by the NSW EPA also made it challenging for industry to apply to these grants. On the plus side, efforts are being made by the NSW Government to stimulate demand for recycled content through the intergovernmental agency working groups that have been established, though no tangible increase in demand or facilities have developed… Yet.

QUEENSLAND

Unlike its neighbours, Queensland did not provide any financial support to

W

WMRR: Suite 4.08 | 57 St Johns Road | Glebe NSW 2037 | t: 02 8746 5000 | e: info@wmrr.asn.au | w: www.wmrr.asn.au Daily news updates at www.insidewaste.com.au 18 INSIDEWASTE APRIL/MAY 2023

AUSTRALIA’S NEW ONLINE PORTAL DEDICATED TO BUYING, SELLING AND HIRING WASTE AND RESOURCE RECOVERY EQUIPMENT. Whether it’s a skip loader, shredder, wash plant or excavator, this is your onestop-shop for buying, selling and hiring a variety of machinery and equipment from both dealers and private sellers. Advertise on Inside Waste Marketplace to reach the right buyer. For advertising opportunities, contact ben.coleman@primecreative.com.au or call 0466 545 664 BUY. SELL. HIRE. Scan the QR code to find out more. MARKETPL ACE

(Continued from front cover)

“AT the other end of the scheme were downstream processors and partners who were trying to scale up as quickly as they could, but there wasn’t the infrastructure available due to the supply chain problems caused by the pandemic. Parts were stuck on docks as shipping avenues dried up. It was complete paralysis. The only thing that wasn’t paralysed was consumer participation, which increased massively.”

red line WALKING THE THIN

Europe is delayed by nine months’.”

As mentioned, one of the issues that hasn’t been a good look for the organisation is the portrayal that it was surreptitiously stockpiling the plastics. Plastic continued to be delivered and recycled by processing partners, but there was more volume coming in than could be accepted at the time. Ironically, several processing partners were concerned that as capacity was re-established post-pandemic, there would not be enough plastic feedstock

Added to all this was the lack of procurement by end markets such as local councils to the companies creating the end products being made from the recycled soft plastics.

“Our processing partners told us, ‘council orders have been placed on hold because councils are diverting all those funds to other areas’,” Kasell said. “We were told by downstream partners like ‘We are sorry, can you hold deliveries? We’re not able to take what we committed to take. The new processing line that we ordered from

available to supply new higher throughput lines. REDcycle was asked to provide confirmation it would be an ongoing supply partner and could provide the necessary feedstock. This gave Kasell confidence that as the country emerged out of COVID, the soft plastic recovery system would be back in balance and in a position to grow.

Kasell expected the bales to be kept for a little while as end market demand began to free up once COVID had run its course. Then processor Closethe-Loop’s facility had a catastrophic

Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 21 // Cover Story

“Then, due to people staying at home all day through COVID, those bins were filling 12 times a day, or 15 times a day. If you multiply that by over a thousand locations, you realise the volumes I am talking about.”

A bench made from recycled soft plastics.

fire and suddenly REDcycle’s most important recycling partner, was shut down for a minimum of 12 months. Call it overly optimistic or bullheaded, the one thing Kasell didn’t want was the stored plastic going to landfill. In a practical world, that is exactly what should have happened, said Kasell. However, the REDcycle team was working hard to make sure that didn’t happen. Even though REDcycle was under intense media scrutiny, as well as the watchful eye of the EPA, and the politicians who never miss an opportunity to make the most of a disaster, she was determined the plastic bales would processed into other products.

Kasell’s biggest enemy wasn’t the stored material, supermarkets, the media, government bodies, or even politicians. It was time . Again, she acknowledges that the stored plastic needed to be managed in compliant way. However, both the Victorian and NSW EPAs were under high-pressure scrutiny from both the public and their political masters to solve the problem as soon as possible. Then there was the recent revelation in a Sydney Morning Herald article that the company responsible for transporting the bales needed to be paid.

And it’s not as if REDcycle was not doing any forward planning. Kasell said that although there was very little redundancy built in, REDcycle had been running for many years and understood the consumer participation would increase – just not at the overwhelming rate it did. It went from collecting approximately 1500 tonnes of soft plastics to more than 7500 tonnes in just over two years. This dramatic increase could not have been predicted by REDcycle or any other industry organisation. There is still an estimated 350,000 tonnes of consumer soft plastic being placed in the Australian market each year, so REDcycle’s volume represented a very small fraction.

There is also an irony in the scheme falling over, because there is going to be a need for it, or a similar entity, in the near future, as acknowledged recently by the triarchy of supermarkets who are putting together their Roadmap to Restart – a supermarket-run soft plastics collection scheme. This is because there are companies that are going to need the feedstock to deliver outcomes such as turning the plastic back into oil to be reused in another capacity. And it won’t be a few thousand tonnes of feedstock that will be needed, but tens of thousands. Two companies already have either imported technology or about to

commission plants that will be capable of processing the plastics – APR Plastics and Licella. The latter will have the capacity – initially – to process 70,000 tonnes of product and will scale up to 120,000 tonnes. Not only will these processes give a new use to a product that would have been landfilled, but it will reduce the need for virgin plastics.

In June 2022, Inside Waste’s story, Softly Softly- the Troublesome Waste Stream of Soft Plastics, Replas then director, Mark Jacobsen is quoted that Replas processes about 3000 tonnes per year but has capacity for up to

10,000 with most of it coming from the aforementioned REDcycle Program.

Statements like these gave REDcycle the confidence that the capacity and end market constraints were temporary and well on the way to being unblocked.

“We used to cop a lot of blame for not having more locations and not having more retailers on board,” said Kasell. “That was a big criticism of REDcycle before this happened – that our network wasn’t big enough. We’d have at least 30 emails and comments every week about why we didn’t have locations here and there, and why we

weren’t bigger, and why we weren’t picking up more, why we didn’t have more bins? We only added a handful of trial locations over the past four years because we were trying to manage this system so carefully and responsibly.”

Another key to the scheme’s demise has been the lack of infrastructure and the lackadaisical approach by many in the industry to hit the reset button when it comes to soft plastics. As pointed out in Inside Waste’s February/March cover story written by wate consultant Justin Bonsey –“Two heartening trends to emerge from this somewhat histrionic media response and subsequent community outcry [over REDcycle’s stockpiling] have been an underlying devotion for soft plastic drop-off akin to that of a cultural institution, and that the rug of soft plastic complaisance has been

Daily news updates at www.insidewaste.com.au

22 INSIDEWASTE APRIL/MAY 2023 Cover Story //

“Ironically, several processing partners were concerned that as capacity was re-established post-pandemic, there would not be enough plastic feedstock available to supply new higher throughput lines.”

The first REDcycle collection bin.

Recognising excellence across the waste, resource recovery and recycling sectors. 2023 NOMINATIONS ARE NOW OPEN www.wasteawards.com.au/nominations To nominate visit 25 OCTOBER 2023 SPONSORS HELD IN CONJUNCTION WITH

Daily news updates at www.insidewaste.com.au 24 INSIDEWASTE APRIL/MAY 2023 Cover Story // Lack of processing infrastructure is a huge issue in the soft plastics recycling story.

pulled out from under us, leaving us squinting into the post-BAU glory of possibilities for a top-down strategically co-ordinated whole-of-value-chain approach. This has started to clear the way for bigger-picture thinking we desperately need to not just stop the bleeding but heal the wound”.

With that in mind, Kasell and her team have still been working hard to find a solution for the impasse.

“We’ve been working nonstop since the program paused,” she said. “I have reached out to many organisations about solutions, and many have reached out to us as well.

“This challenge has been a catalyst in a way; focusing much needed attention on this issue and connecting key stakeholders. REDcycle is close to announcing an important downstream processing opportunity for the legacy and future feedstock. It’s an onshore solution with a new technology partner.

“Over a decade ago, REDcycle took on a waste stream that no one wanted to touch and created a recovery pipeline where one didn’t exist with the collaboration of community, retail partners, brand partners, and recycling partners, and we are proud of what we have achieved .

How does Kasell feel about the supermarkets – Coles, Woolworths, and ALDI, who have recently put in place the aforementioned roadmap?

“During the pandemic, the supermarkets had so many other pressing issues happening around them – staff shortages, keeping basics on the shelves, as well as supply chain disruptions,” she said. “It was a different time, and we thought we would emerge out of this together, but the downstream and processing capacity couldn’t keep up.”

And what about the relationship now?

“I would say we’re working together,” she said. “REDcycle developed the stock movement and management plan, and destinations for the material. The supermarkets have offered to support the management of, and responsibility for, the stock to help ensure this material is successfully recycled and we are very grateful for this. We’re working together to execute that plan. It’s quite complex from a logistics perspective. REDcycle and our team are absolutely committed to doing everything possible to see this material recycled. And I’m unwavering in my belief that can happen, we just need the planned onshore processing capacity to come online between next 5 to 12 months. And I’m confident that it’s coming. There has just been a significant infrastructure lag.”

While some might wallow in their

plight, Kasell is far from finished in her fight against soft plastic waste. Is she disappointed? Yes. Has this been the toughest time of her life? Yes. Does she feel a victim of circumstance? To a certain degree. But she is still as passionate about making sure none of the stockpiled bales end up in landfill.

Even though the company is in liquidation, Kasell is still working on downstream solutions to make sure companies taking the stock. For example, SaveBoard, a company that has a processing facility located at Warragamba, southwest of Sydney, recently took in 20 tonnes of the stockpiled plastics. Not a lot, but it’s a start. And despite some reports, the various EPAs have been helpful in trying to make sure REDcycle is doing the right thing with regards to the excess plastics.

“I do want to say that EPA has been working with us,” she said. “I know that the mainstream media doesn’t portray it that way, but the EPA have been very helpful and collaborative in terms of providing information that we need and giving us time to get things in order.

“Also, one thing I need to correct is that no one was ordered to landfill anything. There were multiple options, including the successful reprocessing of the material and exporting with the correct licencing or exemptions. Onshore processing was the first priority, with landfill being the last resort if no other options were available. For me, my absolute commitment was to see this material recycled and that has not changed.”

Another point Kasell would make is that if the REDcycle program had been paused in the middle of the pandemic, the disruption would have been much greater. She says that in hindsight that’s probably what REDcycle should have done but the thought of thousands of tonnes of soft plastics going to landfill made her feel sick knowing that once there, it had little to no chance of ever becoming a resource. It is truly a waste. And even if it was able to be mined from landfill, the amount of energy needed to decontaminate it would make the exercise moot.

As for the future, there are many important learnings that will create a roadmap for better outcomes.

For example, Kasell is adamant that one of the critical elements for success is the need for soft plastic packaging to be designed so it is ready to be recycled – in other words ‘design for recycling’. Then there is the quality of the material.

“If we make sure that packaging entering the marketplace is of the highest quality for downstream processors, it will open up capacity, and in some cases, without needing to add infrastructure,” she said. “Organisations

“During the pandemic, the supermarkets had so many other pressing issues happening around them – staff shortages, keeping basics on the shelves, as well as supply chain disruptions.”

and processors that are already onshore will be able to utilise the post-consumer soft plastics stream as a feedstock where they can’t now because of the mixed laminate structure films, which are incredibly challenging to process.”

Kasell also thinks the work that APCO is doing transitioning the brand owners and the packaging producers to meet the new design guidelines is important. She said she knows it is a balancing act because packaging plays a role and it’s got to perform; preventing food waste, as well as keeping the product inside safe and protected.

“That’s work that I loved being a part of, but I think it’s hidden in terms of how important it is, to create better recycling outcomes at the end by introducing highly recyclable materials at the beginning that still function in their primary purpose ,” she said.

“The other part is the transition that leads to Australia’s extended producer responsibility.

“We’ve done a significant amount of modelling. Our model wasn’t funded well enough to cope with this unpredicted increase we saw. But having said that, it’s about having the building blocks of product stewardship already there. I think those are two critical factors if we’re going to see success in the soft plastics value chain in Australia. Creating a robust system designed for recycling is critical. And a transition to a more robust producer responsibility model is also critical.”

As for her own personal future in the industry, Kasell is not going anywhere. For a mother who more or less fell into the industry, the past 10 years have shown her that this is her calling. REDcycle’s demise may be a bitter pill to swallow, but it hasn’t diminished her passion of keeping landfills free of plastic waste that can be utilised as a resource.

“This is my life’s work. I’m as passionate about it and even though I’m sad right now – you’re catching me during a tough time – I’m unwavering in my commitment,” she said. “I am also completely and totally humbled by the engagement on the part of the Australian community. They are responsible for powering this pipeline; REDcycle just gave them the opportunity.”

APRIL/MAY 2023 INSIDEWASTE 25 Daily news updates at www.insidewaste.com.au // Cover Story

EPA focused on innovation and collaboration

(Continued from front cover) PREVIOUS roles to his current assignation included executive positions in the tumultuous energy sector working for the AEMO (Australian Energy Market Operator) and AGL Energy. Does he see any similarities in the roles?

“My career has been all about bringing business, policy and government together to create better outcomes,” he said. “That was the attraction of the EPA; that it’s a role that can help facilitate those outcomes and drive them. There was a lot of learning in the energy sector, which was transforming quickly to reach some big ambitions. That has been a useful lens to think about the transformation we need in recycling and waste.

“There’s some good synergy between those industries. For me, waste and energy are two parts of the broader puzzle about a sustainable economy that works for people and protects the environment.”

And while there are similarities between the industries, he acknowledges that the waste and resource recovery sector has its own challenges. It’s no secret that previous administrations who have run the EPA have been combative towards the industry – some would say over the top, while others believe that the industry has deserved the scrutiny. Whatever the case, Chappel hopes to foster a more collaborative environment including mutual respect. When at the AEMO he realised that although traditional regulatory boundaries were necessary, the industry would stay static – to the detriment of both the economy and society – if it didn’t start collaborating with all stakeholders. He sees the waste industry in the same light when it comes to the much-needed infrastructure and the red tape around it. However, the EPA still has a regulatory role to fulfil. Balancing the

two over the next few years will be the tightrope that Chappel walks as targets set by government impact on how the EPA does its business.

“Unless we can manage both successfully, we’re going to fail,” he said. “When I look at the EPA, I see a lot of the similar challenges [as I had in the energy sector]. In the waste industry, getting up to 80 per cent waste circularity is an issue, which is similar to the energy sector trying to get to zero carbon. We will always have a relationship with businesses –we regulate how they are or are not compliant. The community expects, and every minister expects us, to fulfil that role.

“There’s an equally important, much bigger potential role about how we collaborate to co-create the future settings to enable that shift. And in a time of significant transformation, you can only get that right if you’re harnessing the wisdom of the whole sector. We’ve got some very smart people here, but we can’t sit in an office alone and work out the answer. We can only properly get to the right settings if we try to understand what business needs; what different parts of the value

chain are seeing – the whole system. That’s not to say we’ll always be able to do what particular businesses would like us to do because they’ll have their own commercial lens. But, if we don’t at least understand, and have some empathy for the commercial realities, we’re not going to succeed.”

Infrastructure woes

A lack of infrastructure is one bugbear highlighted by the REDcycle scheme being postponed due to lack of facilities to process soft plastics. Then there is the case of the East Rockingham energy from waste facility that is soon to be commissioned in Western Australia. Plans for the plant were first mooted more than 10 years ago but got bogged down in red tape along the way. It’s a hot button topic, and one that Chappel is aware of in terms of the synergy needed to make sure that a circular economy is up and running. With that in mind, the independent report on the NSW Resource Recovery Framework authored by Dr Cathy Wilkinson had many recommendations, many of which stated that the EPA needed to make aspects of its regulations easier to navigate. Does Chappel think government departments responsible for such things, including the EPA, need to be more malleable?

“I think we need to be. This is part of the change that the EPA and government as a whole need to embark on,” he said. “Obviously, we have to regulate harmful things down, but we don’t want to shut the economy down – quite the opposite. We want to breathe new life into it.

“For us as an organisation, and working with our key stakeholders inside government like the planning department, one of our priorities is how do we enable innovation more readily? We’ve talked a bit about that with our response to the Wilkinson review of our own framework. We need a sandbox, or some other tool,

that lets us enable innovation. Because we’re not helping the community be sustainable and healthy and prosperous if we’re not enabling those [aspects of the industry].”

Getting among the industry

There are a lot of different pieces to the waste industry – collectors, MRFs, organics, recycling, product stewardship schemes, an array of associations –Chappel knows there is a lot to cover. Time is at a premium, but he appears to be in for the long haul.

“I’m trying to get out and visit facilities and meet with operators,” he said. “I’ve taken our executive out to Griffith where we toured a feedlot and abattoir. Last week, I was on the road with some colleagues from the Department of Primary Industry looking at timber mills and dairy farms down on the south coast… I’m on that journey of learning. And it’s probably going to take a few years before I really know all the players in all the different sectors that we connect to, but I’m always open to those conversations. I meet with industry virtually every day.”

The core of what the EPA does –making sure all industries within the borders of NSW don’t cause harm to the environment – is still Chappel’s priority. When it comes to juggling industry’s needs with community expectations, he is firm on what the EPA’s remit is and how it needs to be enforced.

“If a business isn’t taking its obligation seriously, we will come down on them,” he said. “My expectation of the industry is that compliance is not the standard to be met, it’s a baseline to be exceeded. All of these industries have challenges with social licence and the easiest way to destroy that is by not meeting their obligations at a minimum. Our obligation is to protect the community and the environment from harm. And we take that seriously.

Daily news updates at www.insidewaste.com.au 26 INSIDEWASTE APRIL/MAY 2023 Thought Leadership

NSW EPA Tony Chappel has been in the job for almost a year.

“What I’m saying is, there’s a new conversation we need to have, which is; how do we help those operators as they think about innovating and the things they want to do? How do we make it easier for them and take that into government? We do grants on infrastructure, but we also often make things very hard through the process.”

Wilkinson’s Report

Getting back to the Wilkinson’s recommendations, Chappel said the EPA is being transparent when it comes to instigating the proposals outlined in the report. He said the EPA deliberately shared the report with peer groups before it published its response. They did so to get industry feedback and understand gaps that others in the resource recovery might see.

“Now we’re moving forward to try and implement those recommendations one way or the other,” he said. “Hopefully that’s one data point the industry sees, and there’ll be others. Over time, I am very hopeful and confident that we will get to a position of deep mutual trust. That’s not to take away from the fact we’ll always have that regulatory construct around meeting standards, but that’s hopefully a much less significant part of our engagement over time.”

REDcycle

One trying issue during the initial phase of his appointment was the suspension of the REDcycle scheme. He concedes there is a difference between somebody deliberately stockpiling waste in warehouses with nefarious intentions, such as fly-by-nighters stockpiling tyres and then abandoning the stream having fleeced tyre retailers, and a scheme such as REDcycle. However, he says the EPA has a job to do, and they’ll do it.

“Our first duty is to the safety of the community,” he said. “Whatever the intention, if there’s an unacceptable risk of fire, or other toxic kind of pollution that flows from these things, then we have to act. For us, it’s not about the intention but the risk to the community. [The] REDcycle issue shows collectively the very significant market failure of the systems we’ve currently got to manage and recycle and deal with packaging waste. There are three things you need for any essential recycling service to succeed – the collection process, infrastructure, and markets. You’ve got to have all three of those.

He said that this is one of the problems small businesses often face when they’re doing something people love. Everyone wants a part of it, but they can’t scale up quickly enough. A lot of businesses fail for that reason. It’s

very hard to stay disciplined and say to your suppliers, ‘Sorry, I can’t take more’.

“REDcycle has gotten to where it has because of a series of failures,” he said. “And from our point of view, the industry that produces this material needs to be involved in contributing to solutions. And that includes the supermarkets who collected 98 per cent of it, and passed it through.

“It was a systemic failing. It is a significant market failure. Plastic is a wonderful material, but it’s devastating to the environment; it never breaks down, it only breaks up into small particles, which get reabsorbed into the food chain. It is a growing threat to all ecosystems, including human health. We need more rigorous solutions.”

Like a majority of those working in the resource recovery sector, Chappel sees landfilling as the last resort for problematic waste streams. He likes the idea of product stewardship schemes as long as they have proper governance. He said they could be transformational, but there needs to be a commercial element. He gave an example of the many container deposits schemes operating throughout the country. He believes one of the reasons more than nine billion containers have been returned in NSW since the scheme’s inception is the value chain it provides.

“There’s a lot of opportunity to leverage some of that type of infrastructure for some of these other challenges,” he said. “For example, we’ve been consulting on expanding the NSW scheme to recover more glass. Glass is a wonderful material as it’s infinitely recyclable if it’s kept in relatively pure strains. Plastic can’t be recycled any number of times, it’s got limits, but it’s also much more impactful on the environment.”

The future

What about a national EPA? Chappel didn’t want to be drawn too much on the idea and stated he liked the sound of it. However, with Australia being a Commonwealth, and the tyranny of distance between relatively small populations on such a large continent, he acknowledged the practicality of having state and territory administrations.

Finally, what if Tony Chappel was given carte blanche to do what he wanted in the waste space? What would be his wish list if he ruled the world? He laughs at the questions but does have a serious answer.

“It’s about a lot more joined up thinking across different priorities,” he said. That collaboration again.

“We’ve got to get to a net zero economy, but we need to get to a circular economy, too. How do we do those things together? I think from our point of view, I’d like to see us transform our literacy and understanding and commercial empathy for the different industry sectors. Waste is a great example where the solutions to these challenges come from the investment that those players make. How do we enable that and set the markets up in a way that is positive for all of that?

I’m thinking it’s when we’ve made a step change in our own thinking. Then I hope that we get to an economy that is working for everybody, because it’s keeping us safe, but it’s also providing great quality jobs and good infrastructure.

“It’s satisfying to be able to contribute to, and hopefully solve, some of these problems. It’s nice to have a job that lets me contribute in some way to part of that.”

Daily news updates at www.insidewaste.com.au APRIL/MAY 2023 INSIDEWASTE 27 // Thought Leadership

REDcycle’s stockpiled soft plastic bales have been a challenge for the EPA.

Wastewater is just one of the various waste streams where collaboration is important.

Squeezing the life out of wastewater

THROUGHOUT the diverse and cultural landscape of the resource recovery/waste industry many companies, individuals and academic institutions have been trying to find ways to make a dollar from recovering waste materials.

Whether it be tyres, soft plastics, metals or other streams, the common catchcry is “anything but landfill!”

With some waste streams – costs and government approval processes aside – there is an endgame. With organics it might be converting FOGO into compost; with soft plastics it can be repurposed into a number of products; while paper and cardboard have a plethora of uses. Wastewater, on the other hand, is a different beast. It’s messy, hard to get rid

of and can be a headache for developers, councils, and commercial companies.

9-11 May 2023

Register today to secure your place!

Don’t miss the industry’s leading waste management conference. Numbers are limited and spaces are filling fast.

• Learn from industry experts

• Network with like-minded waste professionals

• Visit the extensive indoor and outdoor exhibition

• Participate in the Equipment and Technology Expo

• Watch the live broadcasts in real time, or at a time convenient to you

Be inspired in a learning environment where you can tailor your own learning needs through:

• A four streamed program

• Concurrent panel discussions

• Interactive workshops

• 3 social events

Mark your diary and be a part of this industry leading event!

www.coffswasteconference.com.au

(02) 6583 8118 | 0474 629 908

With that in mind, scientists from the Australian National University (ANU) are looking at new ways of separating and extracting minerals, metals and nutrients from resource-rich wastewater. These scientists include Associate Professor Caitlin Byrt, and Doctors Annamaria De Rosa and Samantha McGaughey. Inside Waste spoke to Byrt about what they are trying to achieve. Navigating the intricacies and the science around how these materials can be recovered can be challenging, but if the team is successful, it could be at the forefront of a revolution that can tap an unlimited potential for minerals and metals.

Beginnings

Byrt and the rest of the team are plant biologists and have spent most of their careers researching the molecular mechanisms inside plant cell membranes that control what moves in and out of a plant’s system – this can include water, nutrients, metabolites, metals, minerals and signalling molecules. Then there are the proteins inside the cell membrane.

“Every single living cell has a cell membrane – a lipid membrane,” said Byrt. “Inside the membrane, you’ve got proteins. And some of these proteins e what we call selective membrane transport proteins – they only let certain things pass in and out of the cell.”

Byrt gives an analogy of going through airport security to explain the process. Some things are allowed through while others aren’t. In the case of molecules, these proteins might recognise a sodium molecule and allow it into the inner sanctum of the cell, while it might not be so accommodating to a lithium molecule that might be trying

“It is basically doing a three-

dimensional pat-down to identify what each different molecule is, and then either let it through or not,” she said. “We study the protein structure, their function, how they work. We want to know how the selectivity works. Why do they let through one type of molecule but not another?”

Byrt and the rest of the team didn’t start out trying to separate materials from wastewater. Their first foray into this type of research started with trying to improve crop yields – wheat in particular. The grains industry needed crops to be more salt tolerant due to the salinity of the soil in many agricultural areas.

“We found some wild wheats that had adapted to salty soils,” she said. “They had this molecular mechanism that helps them to push the sodium out of the key plant tissues so that it didn’t build up as much in the leaves. The mechanisms could restrict sodium building up in the transpiration stream that was going up to the leaves, which helped to ensure that the plant could maintain enough potassium in the leaves.

“Potassium is a critical nutrient for plants. The plant tries to accumulate the potassium, but it knows that sodium will try and get in at the same time. There are mechanisms are in place that stop too much sodium from accumulating in the transpiration stream, so that it doesn’t build up in the leaves.”

Having found this out, the trick was to try and mimic that principle so that they can create a mechanism that will help extract the aforementioned minerals, metals etc from wastewater. Luckily for the team, this was a reference point from which they could garner information.

The word “Aquaporin” is not only the name of a type of protein but also the name of a Danish company that worked with NASA to try and solve an important problem – how to make sure the recycled

Daily news updates at www.insidewaste.com.au 28 INSIDEWASTE APRIL/MAY 2023 Wastewater //

Plant cell membranes could be the answer to retrieving minerals from wastewater.

COVE RESORT

Harbour

OPAL

Coffs

water is as pure as possible for the astronauts at the International Space Station (ISS).

Because water is a heavy substance, it makes sense that most of the water transported into space needs to be recycled, so that there is less stress on the payload when moving supplies up to the ISS. The water filters Aquaporin built manage to recycle clean water from approximately 94 per cent of the wastewater. The cutting-edge Aquaporin filters replaced old size-exclusion filters that were originally used in space, which were not up to the task and would sometimes get clogged. This in turn meant contaminants would get through and the astronauts would become sick.

“The team developing the aquaporin filters thought, ‘Okay, what happens in nature? How does nature separate a water molecule from all the other stuff to get pure water?’” said Byrt. “They got interested in the aquaporin mechanisms because this is what living cells use to filter water.”

Aquaporin molecules are in all different forms of life. Humans have 13 of them in their body. They help with kidney function and hydration. The company “borrowed” the aquaporin mechanisms and installed them into a filter, which is now used in the ISS to produce water to a much higher purity. They are also

adapting these filters for other areas including fabric dyeing factories and even PFAS removal.