NOVEMBER/DECEMBER 2025

NOVEMBER/DECEMBER 2025

Café Joyeux’s Co-Founder on using coffee as a vehicle for change

The new tech and equipment launched in Italy

The roasters taking to the skies Host Milano highlights Billionaires’ coffee club Come brew with me

Who’s purchasing beans for more than $10,000 per kilo?

popularity, could the centuries-old coffee market finally be facing a real rival?

10 Spreading Joy-eux

Café Joyeux’s Co-Founder on using coffee as a vehicle for change.

“Others in the sector thought our concept was too complex, but we were looking at it from a different perspective.”

Yann

Bucaille-Lanzerac CO-FOUNDER, CAFÉ JOYEUX

14 Regions on the Rise: Mexico

As yield falls in many Latin American countries, Mexico continues to bounce back post-coffee leaf rust epidemic.

53 The overlooked key to productivity?

GCR explores whether enough is being done to protect coffee farmers’ health.

18 Billionaires’ coffee club

With coffee auctions breaking records, who are the buyers willing to pay more than $10,000 per kilogram?

22 Coffee’s evolving economics

Eversys’ Managing Director and Marketing Director discuss coffee’s shifting business model.

36 Matcha’s moment

As the green-tea drink surges in

46 Come brew with me

Roasters are increasingly identifying the airline sector as a space to grow their brands.

48 Delivering flavour at scale

How Flavourtech is fostering further evolution in the instant and ready-todrink segments.

50 The Aussie bucket list

Discover firsthand why Melbourne is internationally renowned for its coffee.

24 Bringing the heat

OhmIQ’s new water-heating technology aims to benefit the entire coffee community.

26 Built for today, ready for tomorrow

Franke unveils the New A Line of automatic espresso machines.

28 Fanatical about flavour

A trio of new grinders from Ceado are set to shake up the specialty sector.

30 Super-automatic Supera-ority

The low-down on LaCimbali’s new fully automatic machine.

32 The post-show glow

IMA Coffee Hub reaffirms its commitment to tackling some of the industry’s biggest challenges.

34 A united front

SEB Professional Beverage on presenting its fi ve key brands under one umbrella.

40 The missing link

Introducing a bold new era of the iconic Nuova Simonelli AURELIA line.

42 The future of manufacturing

In the era of Industry 5.0, Cama Group launches a new program to improve productivity and sustainability.

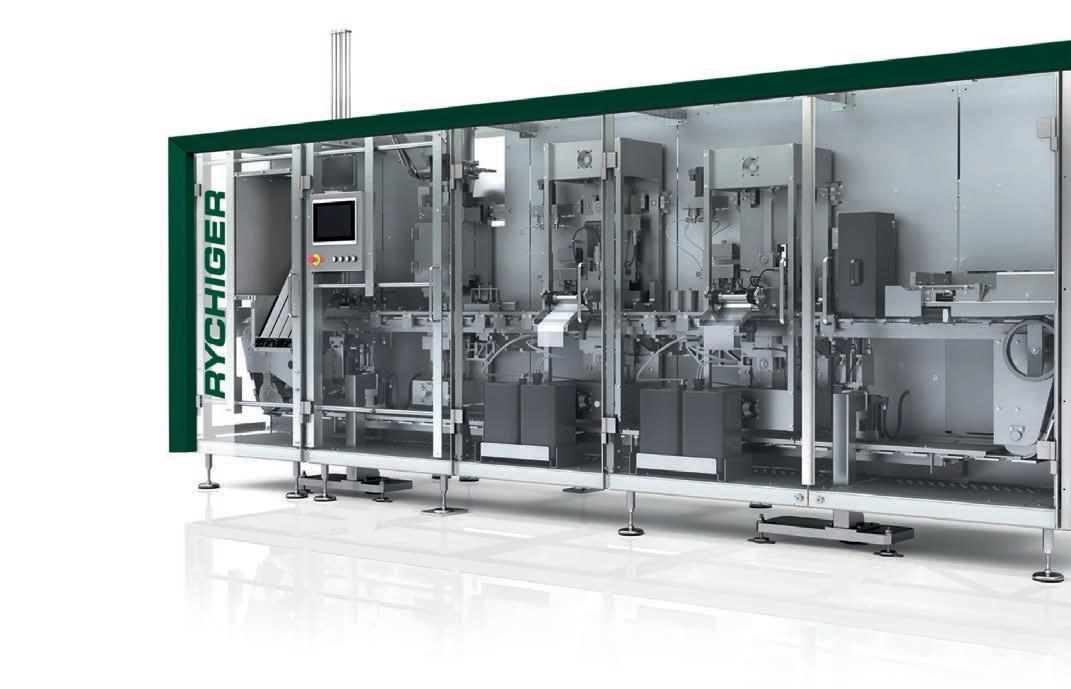

44 From data to action

Keeping pace with the rapid evolution of manufacturing, Rychiger introduces its RyConnect platform.

58 The sensor that could save milk

An Australian university has found a way to test milk’s freshness without opening the carton.

OR MANY PEOPLE around the world, co ee is an everyday luxury that brings a small moment of joy to their morning – whether they have the time to sit back and enjoy it in good company or as a much-needed ca eine hit on their way to work.

Familiar with the emotional bene ts, social connections, and functional properties of the popular beverage, entrepreneur Yann Bucaille-Lanzerac saw an opportunity to further broaden co ee’s advantages while looking for a solution to his own conundrum.

A er opening foundation Café Joyeux in France in 2017 to provide employment for people with intellectual disabilities, Bucaille-Lanzerac needed a revenue stream to prop up the project. Already in the café industry, the answer was right under his nose.

Almost a decade later, Café Joyeux’s line of co ee beans is available in supermarkets across the country, as well as in the brand’s 30 venues in Europe and the United States. As part of its success, the foundation now employs more than 220 people with intellectual disabilities and has extended its reach by setting up a dedicated school that provides training and nationally recognised certi cations for people with Down syndrome and autism.

In this issue’s cover feature, BucailleLanzerac reveals how the power of co ee as a social connector and breaker of barriers has been core to the success of the foundation. e interview also explores the brand’s rapid expansion and why it

will never be able to keep up with the unwavering demand for more locations across the globe.

ere are plenty more upli ing stories to raise the spirits in this November/ December edition. For example, we take a look at some of the healthcare projects underway at origin, such as ensuring farmers have access to eye tests and glasses to not only improve the welfare of workers but also increase productivity.

With the industry convening in Italy for Host Milano 2025 last month, we’ve included a round up of some of the most exciting new products and technology releases from the biennial tradeshow.

From the future of water-heating tech to long-awaited new espresso machine lines, the next generation of equipment marks an exciting new era for the industry. Find it all in our dedicated post-Host showcase.

Also, we explore the rise of partnerships between co ee companies and airlines around the world, and why the consumer experience of brandless, bitter co ee at 35,000 feet is quickly becoming a thing of the past.

Enjoy the issue!

P.S. I’ll be on maternity leave for the next few months, but the magazine will be back in the safe hands of Sarah Baker while I’m away. See you in the new year. GCR

Kathryn Lewis Editor, Global Coffee Report

CHIEF EXECUTIVE OFFICER

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Myles Hume myles.hume@primecreative.com.au

EDITOR

Kathryn Lewis kathryn.lewis@primecreative.com.au

JOURNALISTS

Georgia Smith georgia.smith@primecreative.com.au

Daniel Woods daniel.woods@primecreative.com.au

ART DIRECTOR/DESIGN

Daz Woolley daz.woolley@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

BUSINESS DEVELOPMENT AND SALES MANAGER

Charlotte Murphy charlotte.murphy@primecreative.com.au

CLIENT SUCCESS

Cailtin Pillay caitlin.pillay@primecreative.com.au

PHOTOGRAPHY

Daniel Quinlan

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 info@primecreative.com.au gcrmag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Co ee Report Magazine is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Co ee Report is owned and published by Prime Creative Media. All material in Global Co ee Report Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Co ee Report are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

In the early 2010s, Mexico, along with the wider region of Central America, endured one of the worst coffee leaf rust epidemics of modern times. It is estimated that up to 70 per cent of the region’s coffee plants were impacted by the fungal disease.

The worst of the epidemic was seen between 2012 and 2014. According to the USDA, it caused the output in the 2013/14 harvest to drop by 700,000 60-kilogram bags. The lowest recorded harvest year was 2015/16 at an estimated 2.3 million bags.

While it took three more years to overcome the ripple effects of the epidemic, the industry has now rebounded to preepidemic levels with the 2025/26 harvest forecasted at 3.9 million bags.

See page 14.

In August 2025, the coffee community collectively splu ered over their morning brews when news broke that a Hacienda La Esmeralda lot at the Best of Panama auction sold for US$30,204 per kilogram. The winning tender after 549 bids more than tripled the previous highest price secured at the 2024 edition of the event, which stood at $10,013 per kilogram.

The lot winner was Julith Coffee & Roasters in Dubai, which had opened just one week prior to the auction. At the price paid for the beans, the Emirati roaster would need to charge about $545 per 18-gram double shot to break even without factoring in labour, equipment, or other overheads.

See page 18.

Instead of the traditional water-heating method inside espresso machines that uses a resistance element, OhmIQ’s technology makes the water heat itself through the use of positively and negatively charged electrodes that promote movement of the water inside the boiler.

US$30,204 per kilogram

The record coffee price at the Best of Panama

“There are minerals in water and every mineral is either positively or negatively charged,” says CEO Frederique Pirenne.

“OhmIQ works by placing two electrodes in the water – one is positively charged and the other is negatively charged. The negatively charged minerals will go to the positive electrode, and vice-versa.

“We heat the water by switching the polarity of the electrodes, which moves the minerals from left to right and right to left to create heat.”

See page 24.

While for years brews at 30,000 feet were mostly brandless and bi er, airlines have turned to boosting their coffee capabilities through partnering with some of their regions’ leading brands.

From giants such as Peet’s Coffee and Costa Coffee taking to the skies with Southwest and Jet2 respectively, to Bootlegger Coffee and Saudi Coffee Company breaking new ground with Fly SafAir and Riyadh Air, roasters are finding fresh ways to connect with customers.

See page 46.

14

According to third-party data cited by Australian café chain The Coffee Club, 56 per cent of Gen Z beverage orders are for cold drinks. This statistic is in stark contrast to Baby Boomers, who opt for hot beverages 86 per cent of the time. The company found that the vibrant look and layered presentation of drinks like the Iced Strawberry Matcha La e make them especially appealing for social media, further fuelling their popularity.

See page 36.

While the ready-to-drink and instant sectors hold huge potential, they offer unique challenges in the preservation of aroma and flavour. Flavourtech is reshaping how these products are created with the aim of retaining elevated flavour and quality. “Our technologies reduce thermal damage and the production of off-flavours, allowing manufacturers to deliver a more authentic, freshly brewed taste consistently,” says Global Sales Manager Paul Ahn.

See page 48.

This year, 31,708 visitors descended upon Melbourne International Coffee Expo (MICE) to experience the Southern Hemisphere’s largest dedicated coffee tradeshow. According to MICE moderator Sarah Baker, the expo has become the world’s destination for coffee.

“Australia is a bucket-list destination for many people. It’s a commitment in distance, but once you’re there, it really is a land of opportunity – and a coffee lover’s paradise,” Baker says.

See page 50.

The provision of eyeglasses has been found to be the most powerful enhancer of productivity of any medical intervention, according to Anshu Taneja, Managing Director of VisionSpring Foundation in India.

“In 2018 we did a detailed study in partnership with Amalgamated Tea Plantations and Queen’s University Belfast, Orbis and Clearly” says Taneja. “We found the productivity increase in tea pickers and tea sorters who were given eyeglasses was anywhere between 22 to 32 per cent.

“Coffee farming is a similarly intuitive practice: it’s very vision intensive work. I believe if we did the same study in coffee we would see similar results.

See page 53.

VibMilk – a breakthrough innovation aiming to transform how coffee shops monitor milk freshness – was developed by researchers at the University of New South Wales in Australia with the primary goal of reducing food waste and improving food safety.

“Globally, about 20 per cent of dairy products are wasted each year, with spoiled milk contributing significantly to this,” says Professor Wen Hu, Lead Researcher.

See page 58.

In France, less than two per cent of the 750,000 people with intellectual disabilities have long-term jobs. Globally, there are about 250 million people with such disabilities and that employment percentage is even lower in many other countries.

In 2017, entrepreneur Yann BucailleLanzerac opened the first Café Joyeux in

Rennes, Frances with an aim to promote inclusion of people with disability –especially those with intellectual disabilities – through employment, vocational training, and encounters.

To date, the café group, which now includes 30 venues across Europe and the United States, has employed more than 220 crew members with intellectual disabilities.

A 2023 survey of Café Joyeux employees found 91 per cent said they had developed professional skills that reassure them about their future and integration.

See page 10.

While quality and ensuring a fair price for all parties along the supply chain have long been the focus of specialty venues, these businesses have traditionally been more resistant to adopting automated technology. However, Eversys Marketing Director Miranda Caldwell says this tide is starting to turn – especially in mature specialty markets.

“In big cities where we’re clearly seeing the impact of cost-of-living, labour shortages, and price rises, the shift from traditional to super-automatic espresso machines is building momentum,” she says.

“Especially in busier venues, managers and owners are considering how they can speed up service and reduce hours needed for staff training while maintaining quality. Interestingly, we’re still not seeing the same uptake in the café sector in mainland Europe and that’s because it only recently started to embrace specialty.”

See page 22.

The team at Franke Coffee Systems say efficiency and sustainability guided the development of their New A Line.

They report that boiler insulation system HeatGuard reduces energy loss by up to 44 per cent in the A600 compared to the Classic A600, while still ensuring the machine remains ready for use during peak hours. What’s more, the IndividualClean technology adapts cleaning cycles to actual usage, reducing detergent consumption, streamlining workflows, and easing staff workload.

“The New A Line embodies that approach – se ing new benchmarks today and preparing our customers for the expectations of tomorrow,” says CEO Marco Zancolò.

See page 26.

One of three grinders in Ceado’s new REV series, the Zero is spotlighted for its wastereduction capabilities. With the ability to slightly reduce the dose due the clarity delivered, reduced readjustments, and less retention between the burrs, the grinder can save coffee shops a huge amount of coffee waste, according to Head of Sales Cosimo Libardo.

“I calculated that the average coffee shop might waste 120 kilograms of coffee per year – that’s a huge cost to a business, especially given the heightened coffee prices we’re currently experiencing,” he says. “With the Zero, that could be reduced by 80 per cent.”

See page 28.

To address the needs of different venue types, LaCimbali has created two versions of its latest machine: Supera Senso and Supera Dolcevita.

The Senso model is aimed at operators who prioritise ease-of-use and reliability, offering complete functionality in a streamlined package.

Dolcevita, on the other hand, is the premium version, equipped with the more advanced automation, smart features, and milk management capabilities.

See page 30.

For IMA Coffee Hub, one of the highlight of Host Milano 2025 was showcasing the TTR25 Evo, a hot-air recirculation roaster designed with eco principles at its core.

With a production capacity of up to 100 kilograms per hour, the machine is known for its significantly reduced energy consumption and carbon dioxide emissions through advanced thermal efficiency and airflow optimisation.

According to the company, Host visitors praised the TTR25 Evo for enabling highquality roasting while helping producers meet circular economy and carbon reduction targets.

See page 32.

Host Milano 2025 was the first time SEB Professional Beverage’s newest pair of brands – Zummo and La San Marco – were displayed alongside the more established members of the family.

La San Marco was acquired by the group in early 2023 and has considerable heritage in the Italian espresso machine and grinder manufacturing space, dating back more than 100 years.

Zummo, on the other hand, was acquired by the company a year earlier in 2022.

Founded in Spain in 1992, it specialises in the manufacturing of automatic fruit juice

extraction machines – a shift away from the original coffee- and tea-based trio of WMF, Schaerer, and Curtis.

See page 34.

The NUOVA Aurelia’s C-Automation is a flagship new technology for Nuova Simonelli. It’s not just a singular, individual feature but an integrated system that works across the machine and grinder.

According to the team at the Italian manufacturer, it has been created with the barista at the centre of the innovation. The aim of the function is to simplify workflow complexity and variability while ensuring customers can be confident in receiving the same standard of drink every time.

See page 40.

While the first industrial revolution began in the 18th century, according to European researchers we have since advanced through four more iterations as we move into the era of Industry 5.0.

Secondary-packaging machine manufacturer Cama Group is embracing this new era of industry. Its team believe we’re in the middle of a cultural change that redraws the boundaries between humans, machines, and artificial intelligence.

See page 42.

As coffee companies increasingly look to automate their production lines, Rychiger has set out to introduce a solution that can effectively digitise the entire coffee manufacturing value chain.

“Coffee producers face pressure to increase flexibility, handle multiple capsule formats, and meet strict compliance requirements while maintaining high efficiency,” says Nathan Cerveny, Key Account Manager Customer Service.

“As a result, automation and digitalisation have shifted from optional initiatives to essential factors for competitiveness.”

See page 44.

120 kilograms per year

The amount of coffee saved by Ceado’s new REV Zero grinder.

“Of the 220 crew members who have worked with us over the past 10 years, only five have left as we convinced them to go to other companies .”

Yann BucailleLanzerac FOUNDER, CAFÉ JOYEUX

In France, less than two per cent of people with intellectual disabilities have long-term jobs.

Image: Café Joyeux.

Co-Founder and CEO Yann Bucaille-Lanzerac reveals how Café Joyeux uses coffee as a vehicle to create opportunities for people with intellectual disabilities, and why meeting the unwavering demand for more locations across France and beyond is an impossible task.

Before launching Café Joyeux in Rennes, France, in 2017, entrepreneur Yann BucailleLanzerac didn’t have any personal connections to people with intellectual or developmental disabilities. He hadn’t studied or worked alongside them, and it was for this reason he believed a new platform was needed to foster encounters and break down barriers.

While skippering his catamaran that provided sea trips for vulnerable people, a young man with autism called eo asked him for a job. Bucaille-Lanzerac stumbled on his answer and didn’t have a clear reason to say no. e interaction led him to re ect on his limited experiences with people like eo.

“My wife and I started talking and realised neither of us had gone to school, university, or worked alongside anybody with an intellectual disability,” Bucaille-Lanzerac tells Global Co ee Report

“ is community was being le out of many of our social spheres and there were few opportunities to connect with them, which naturally produces barriers.”

In France, less than two per cent of the 750,000 people with intellectual disabilities have long-term jobs. Globally, there are

more than 250 million people with such disabilities and that employment percentage is even lower in many other countries.

“ ey hardly ever work because there are so few employment opportunities for them. When I meet someone new, one of the rst questions that’s asked is, ‘what do you do for a living?’. Just because someone has Down syndrome or autism, they are o en le out of this conversation,” he says.

“People with intellectual disabilities are regularly perceived as not being e cient or capable enough. is is an unfair outlook, because how can you know this when you haven’t given someone a chance? ey are not provided the opportunities to prove themselves.”

Inspired to do something about the issue, the entrepreneur and his wife Lydwine wrote a mission statement, despite not yet having a platform from which to ful l it. e aim was to promote inclusion of people with disability – especially those with intellectual disabilities – through employment, vocational training, and encounters.

“ e idea was to create an encounter so we could erase the barriers that stood between this community and the wider public,” he says.

“We spent some time thinking about which industry would be the best vehicle to achieve this. e service sector, especially cafés and restaurants, very much aligned with providing opportunities for these encounters.”

Bucaille-Lanzerac says, at rst, people in the industry thought their idea was too challenging and wouldn’t work out. Yet, in 2017 they opened the rst Café Joyeux in Rennes, in the northwest of France. Training was at the heart of the concept, with all pro ts from the venue going back into the foundation to upskill more people with intellectual disabilities.

“Others in the sector thought our concept was too complex, but we were looking at it from a di erent perspective. Of course we needed to generate income to continue funding the project, but our number one target was social impact and human improvement,” he says.

e rst venue was met with huge enthusiasm and was very successful in many ways due to the overwhelming support from people in the community and the friends and families of the rst employees. However, Bucaille-Lanzerac

and team soon realised the initial business model wasn’t going to work on its own.

e labour cost at Café Joyeux is twice or three times that of a standard venue of its size because more team members are needed to execute tasks. Naturally, training of crew members takes more time and more supervisors are needed to oversee duties.

“We knew we were onto something great, but we could not expand our mission past two venues to other locations without rst xing the business model. e answer for us lay in co ee,” he says.

“In 2018, we launched our own co ee brand and it was a game-changer. At rst, we sold the beans as a retail product in our venues and that’s now grown to include an online store and supermarkets across France.”

e Café Joyeux team knew that to make the retail o ering a success they needed to provide a quality product. To achieve this they enlisted Daniela Capuano – the rst and only woman to receive the Meilleur Ouvrier de France in Roasting – to help cra the brand’s signature blends.

Powered by beans

All sales from the beans go back into funding the social project and have directly supported the organic growth of Café Joyeux. Today, the brand employs 220 crew members with intellectual disabilities and operates 23 cafés across France, ve in Portugal, one in Belgium, and another in New York, United States (US).

e 500 tonnes of co ee roasted per year for the European venues and retail o ering is produced at the roastery in Strasbourg, where 30 per cent of the workforce are people with learning disabilities.

Bucaille-Lanzerac recently travelled with the roastery team to Central America to visit some of the producers they work with and start a conversation about employing people with intellectual disabilities to help with the harvest on the farms.

“It’s the beginning of what I think will be a long discussion, but these things take time and you have to start somewhere,” he says.

“It will be a challenge to implement as some of these production countries don’t share our vision on disabilities. However, by starting the conversation we can hopefully inspire change.”

When Café Joyeux opened its rst venue outside of Europe in New York in March 2024, it also established roasting operations in the US to cater to the

di erent tastes of the local consumers.

“A lot of people wanted us to open a café in New York, but at rst we said no. We had enough to do in Europe,” says Bucaille-Lanzerac.

“However, the community there was very insistent. In the end, a fantastic landlord gave us a free 10-year lease in the centre of Manhattan. We found a great roaster in Brooklyn, who roasts blends in line with our core European selection but tweaked to appeal to local taste preferences.”

e co ees served in its Portuguese venues are also tailored to the local palate, which Bucaille-Lanzerac says favours a stronger avour compared to consumers in France.

“Adapting to local habits is what makes our project special. Our recipes are broadly similar, but we want the venues to be autonomous for each place. In each country, we set up a local foundation to train crew members and share knowledge about inclusion,” he says.

“We think global and act local. e product is so human that it doesn’t align with the traditional model of industrial growth.”

With each new Café Joyeux that joins the family, demand increases for more locations. Bucaille-Lanzerac says the team receive thousands of requests for new café venues, many of which come from the families of people with intellectual disabilities who want employment opportunities.

While of course he would love to ful l

these requests, launching a new café requires a signi cant investment. ere are certainly plans for more venues, but Bucaille-Lanzerac believes expanding the retail co ee side of the business is the best way to provide more opportunities for this community.

“A er a few years of running the rst cafés, we realised our venues were also becoming educational hubs through the training we o ered. erefore, we launched a dedicated training school in France where people with intellectual disabilities can earn an o cial certi cate, equivalent to a university diploma, over two years,” he says.

“So far, we’ve had more than 70 students complete the program. It’s very powerful because with the certi cate they can go on to work at other restaurants and cafés, and not be limited to working at Café Joyeux. Unfortunately, we’ll always have limited space as people love working here – of the 220 crew members who have worked with us over the past 10 years, only ve have le as we convinced them to go to other companies.”

e reason for such impressive retention can perhaps be found in a 2023 report Café Joyeux conducted to measure the impact of the project to date. For employees with intellectual disabilities, 91 per cent said they had developed professional skills that reassure them about their future and integration, while for the families of those team members 92 per cent said they were less worried about their loved ones since they began working.

e report also found that Café Joyeux customers were bene tting from their visits. Of those surveyed, 81 per cent said they had changed their perception of disability, 92 per cent had become aware of the abilities of people with disabilities, and 85 per cent showed more solidarity towards people with disabilities a er visiting one of the cafés.

Of everything Café Joyeux has achieved over the past decade, the Co-Founder says he is most proud of the people he’s worked with.

“We have such beautiful teams – they are truly diamonds who have been hidden for too long,” he says.

“I am also very proud of our managers who support our crew members. A lot of them are from the younger generations and their enthusiasm and generosity are so inspiring to witness.

“To be able to sell a product that’s based on solidarity and generosity is a very special thing.” GCR

With coffee production yields in many key Latin American origins falling, how is Mexico bucking the trend with steady growth since its coffee leaf rust epidemic in the 2010s?

FOR DECADES, Central and South America have formed the bedrock of the world’s co ee production.

While in recent years Asian nations such as Vietnam and Indonesia have levelled up to become some of the world’s largest producers, Brazil and Colombia still combine to produce almost half of the world’s co ee, with neighbouring regions such as Peru, Honduras, and Guatemala contributing far from negligible amounts. Overall, however, co ee production is falling in some of these key South American production regions. Frosts in Brazil have seen cascades in harvest projections, while climate change continues to impact yields in Central America.

One outlier in this region is Mexico. While far from immune from the issues in uencing neighbouring nations, since rebounding from a co ee leaf rust disaster in the 2010s it is on a slow and steady growth trajectory, with key market indicators projecting a consistent annual growth rate of 0.5 per cent per year between 2024 and 2028.

Bouncing back from an epidemic

Co ee was rst introduced to Mexico in the 18th century and over the next 100 years became a signi cant export crop. Today, the country’s co ee production is mainly based in the south’s mountainous regions – predominantly Chiapas, Veracruz, and Puebla – where the high altitudes, cooler temperatures, and well-distributed rainfall favour Arabica production.

“ e majority of co ee from Mexico is grown in Chiapas, but we do quite a bit of work in Oaxaca and even Veracruz,” says John Cossette, Vice President of Royal Co ee, a United States (US) green bean importer that’s been active in the Mexican co ee industry for decades.

“Pretty much all we buy is Arabica, but there are certain places – Oaxaca in particular – that still have a lot of the older Arabica strains of co ee growing such as Typica and Bourbon. In Chiapas, the majority of co ees are modern hybrids.

“Some Mexican producers are even growing the Pluma varietal, which comes

from co ee trees more than 50, 60, or 100 years old. ey’re becoming less and less available because people are pulling them out of the ground, but we still have sources for these kinds of co ees.”

Since being rst identi ed in Africa in the 19th century, co ee leaf rust – also known as Hemileia vastatrix or CLR – has spread to all co ee growing regions of the world, where it is estimated to cause billions of dollars of economic damage every year.

Mexico, along with the wider region of Central America, endured one of the worst CLR epidemics of modern times in the early 2010s. It is estimated up to 70 per cent of the region’s co ee plants were impacted by the fungal disease, which restricts the plant from photosynthesising and therefore leads to reduced yield, weakened plants, and in many cases plant death.

In Mexico, the worst of the epidemic was seen between 2012 and 2014. According to the United States Department of Agriculture (USDA), it caused the output in the 2013/14 harvest to drop by 700,000 60-kilogram bags. e lowest recorded

harvest year was 2015/16 at an estimated 2.3 million bags.

“Chiapas, in particular, got hit pretty hard – especially in the lower areas where it funnels through from Guatemala. It was like a virus just sweeping through Central America. We had a farm we worked very strongly with for years that pretty much got wiped out,” says Cossette.

As the crisis worsened, the Mexican government worked with a number of NGOs to establish training programs with farmers to reduce the spread of the disease and set up breeding nurseries to supply them with disease-resistant co ee plants.

While it took three more years to overcome the ripple e ects of the epidemic, the industry has now rebounded to preepidemic levels with the 2025/26 harvest forecast at 3.9 million bags.

e majority of growers in Mexico are small family farms performing their own labour, or those who have access to labour in their own communities.

“ e regions where co ee is grown are remote and rural, and not being replaced by real estate ventures or population incursions – something we see in other origins,” says Cossette.

“Mexico has a very strong domestic market and a demand for co ee that’s still growing, so in addition to their export market, they also have the ability to sell their co ee domestically which makes for a stable situation.”

“The country that has benefi ed the most out of this [the US import tariffs] is Mexico, because at this point it’s the only coffeeproducing country that is not being tariffed.”

John Cosse e VICE PRESIDENT, ROYAL COFFEE

Over the past couple of years, the Mexican Government has introduced a series of initiatives to support domestic co ee production. In 2024, it launched Café Bienestar, an instant co ee brand developed to support local co ee producers and remove intermediaries that could reduce their pro ts.

“We want to create a Bienestar brand that purchases directly from farmers at fair prices, processes the co ee, and o ers it as instant co ee under this brand,” said Mexican President Claudia Sheinbaum at the time.

What’s more, in April 2025 the government approved the Law for the Sustainable Development of Co ee Growing. is legislation is designed to

strengthen the domestic co ee industry through training, research, quality improvement, nancing, fair trade, and environmental sustainability to support farmers impacted by CLR and climate change.

Despite the strong domestic demand, the US is by far the largest consumer of Mexican co ee. e USDA reports a forecast estimate of 1.9 million 60-kilogram bags of Mexican co ee imported into the US for 2024/25, a small increase from the 2023/24 estimated total of 1.86 million bags.

“Most of our sales are to roasters in the Western US where we see strong demand for Mexican co ee. It’s popular in California in particular, but also in other regions such as Wisconsin, Illinois, and Minnesota,” says Cossette.

Lupita Sanchez founded Café Metzli in Los Angeles in 2022. Her business only sells Mexican beans and the name translates to ‘moon’ in a native language of the Latin American nation.

Michoacán, where she was raised, is not one of the major co ee-producing regions of Mexico. Yet, before her family moved to the US when she was a child, her father operated a farm.

Sanchez believes added transparency in dealing with producers has been key to elevating the standing of Mexican co ee in the export market.

“I always put the name of the producers

or their farm and then the state it is grown in on the co ee,” she says. “I’m super transparent with them. ey know how much I sell their co ee for. Now, three of the producers I brought to the US for the rst time are selling their co ee to places such as Japan and South Korea.

“Producers like Rancho El Separo in Veracruz, and Director al Origen from Puebla, have grown to rank in the top 10 in Cup of Excellence. I have such a beautiful relationship with my producers, and every

year my volume grows.”

Sanchez says in her time operating Café Metzli, she’s seen a huge increase in interest in Mexican specialty co ee.

“When I started, I would estimate about one in 15 specialty co ee shops had Mexican co ee. It wasn’t really a thing and I couldn’t understand why – it was close to the US, so I assumed it would be cheaper and easier to get,” she says.

“People are now learning that Mexican co ee exists. Five years ago, a lot of

the co ee shops would say the co ee was from Colombia or Guatemala, but in fact it was from Mexico and they were lying, which is really sad.

“But the new generation of co ee drinkers is pushing for change in the industry, and they’re more attuned to specialty co ee and where it is produced, and Mexican co ee is really starting to shine.”

Demand for Mexican co ee in its leading export market of the US has reportedly surged this calendar year as a result of President Donald Trump and the Republican Government’s ‘Liberation Day’ tari s on a range of co ee producers.

Brazil, where the US imports most of its co ee from, has been hit with tari s as high as 50 per cent between April and October, while other major producers including Vietnam, Indonesia, and Colombia have also seen tax hikes.

Cossette says, at least for those few months, the Mexican co ee industry has bene tted from the higher rates being imposed on other origins.

“ e country that has bene tted the most out of this is Mexico, because at this point it’s the only co ee-producing country that is not being tari ed. at has markedly escalated demand this year.

“It’s been an easy decision for us to buy Mexican co ee, and buy as much as we can. Fortunately, we have longstanding relationships so it hasn’t been a huge challenge for us to do so.”

Sanchez sees major opportunities in the community that is being built around Mexican co ee production, and the free knowledge sharing she sees among the producers she works with.

“When I rst bought co ee from La Salitas, they were scoring around 83 or 84. Now a lot of it is around 85 or 86. ey’re putting so much love and passion into what they do, and they’re not being greedy or sel sh with information to help those around them grow better co ee,” she says.

“It’s beautiful to see the community working together and putting so much love into it, and they’re teaching their children to grow co ee when they get home from school. I’ve seen 10-year-olds learning how to cup co ee.

“Some of my producers, their grandfather was the owner of the rancho, which is now run by the grandchildren. Co ee is continuing through generations in Mexico, and that’s super important.”

www.camagroup.com - packaging@jllennard.com.au

Julith Coffee & Roasters broke the world record in August 2025 when it purchased a Panamanian Geisha for US$30,204 per kilogram. Image: Adobe Firefly/ stock.adobe.com.

With lots reaching record-breaking prices, how has the coffee auction landscape changed over the past 25 years – and who are the buyers willing to pay more than $10,000 per kilogram?

IN AUGUST 2025, the co ee community collectively spluttered over their morning brews when news broke that a Hacienda La Esmeralda lot at the Best of Panama auction sold for US$30,204 per kilogram. e winning tender a er 549 bids more than tripled the previous highest price secured at the 2024 edition of the event, which stood at $10,013 per kilogram.

e lot winner was Julith Co ee & Roasters in Dubai, which had opened just one week prior to the auction. At the price paid for the beans, the Emirati roaster would need to charge about $545 per 18-gram double shot to break even without factoring in labour, equipment, or other overheads.

Commenting just a er the auction success, Julith’s Head Co ee Roaster – and Turkish Barista Champion – Serkan Sagsoz outlined his ambitions at the new venture.

“Bringing the world’s most celebrated co ee to our roastery in Dubai is a true honour,” he said. “At Julith, we believe that exceptional co ee deserves a global stage, and this acquisition is a bold step towards that vision.”

Yet, this mammoth bid wasn’t a one o . Over the past few years, record auction

prices have continued to not just be exceeded but obliterated.

In September 2025, Alo Co ee in Ethiopia sold a single lot for US$1739 per kilogram, exceeding the country’s previous record achieved just a few months earlier. In the same month, Best of Yemen set a new benchmark of $1878 per kilogram – the third consecutive year the auction had broken the global record for Yemeni co ee prices.

While these auctions of the top 0.1 per cent of co ees make great headlines, they also raise questions such as, what’s their impact on the wider industry, will this trend for extreme prices continue, and who’s purchasing $500 espressos? To answer these, it’s worth rst exploring the history of co ee auctions.

Auctions have long played a role in the history of co ee trading, with the formalised sales system rst introduced in the early 20th century and soon becoming a common method of trading beans. Yet, by the end of the century, auctions had largely fallen out of favour as the futures market matured, origin countries were liberalised, and direct

trade became more common place.

Not long a er this, however, trading via auction was adopted by the organisers of the Cup of Excellence (CoE) competition to connect farmers with buyers who were willing to pay a premium for quality.

“Initially, CoE began as an experiment to see if buyers would come to origin, discover co ees they did not know existed, and then pay a higher price for co ees they felt were a higher quality,” says Susie Spindler, Founder of Cup of Excellence.

“We built a mechanism to allow any roaster anywhere in the world the opportunity to buy these co ees. Previously, many of these co ees never had the chance to be experienced. Online auctions to sell co ees are more common now, but CoE was the rst organisation to do this.”

In the 26 years since the competition was established in Brazil, CoE has given thousands of farmers across the world the opportunity to have their co ee evaluated by international experts, and roasters the opportunity to access some of the best and most interesting beans.

“More than simply rewarding an outstanding lot, the program was designed to create opportunities for lasting relationships between producers and buyers

– relationships that continue to change lives and markets today,” Spindler says.

While the organisation now operates annual auctions in 17 producing countries, the beans featured in the competitions only represent an incredibly small proportion of the co ee grown around the world each year. However, Spindler believes the events have had a profound impact on the wider co ee industry over the past quarter decade.

“CoE has set new benchmarks for quality and fairness,” she says. “It introduced a trusted system where traceability and integrity are non-negotiable, inspiring other competitions, direct-trade relationships, and even the way specialty co ee is de ned today.”

In the specialty sector, relationships with farmers are o en a key marketing tool and many roasters make trips to origin to meet the producers they work with. Spindler says that before CoE, it was uncommon for buyers to meet farmers and build personal relationships.

“Twenty- ve years ago, it was extremely rare to identify regions, much less farmers. However, regions in co ee growing nations are now identi ed and traceable,” she says.

“ ousands of farmers have been introduced to the global market through these auctions, and many have gone on to build strong, long-term partnerships with buyers that outlast the competition itself. at’s the real measure of impact: sustainable business, not just a single sale.”

Erwin Mierisch, Executive Director of CoE, believes the culmination of these ripple e ects from the growth of auctions and competitions such as CoE has resulted in a focus on quality and innovation right across the co ee industry – not just the top 0.1 per cent.

“Auctions with inclusiveness and judged by independent non-in uenced judges show the true value of co ee. ey create a transparent platform where quality sets the price, and this encourages farmers to invest in excellence,” he says.

“Even if only a handful of lots sell at record-breaking levels, the ripple e ect is much broader: it sparks innovation at farm level and gives roasters powerful stories to share.”

If there’s one country, and speci cally one varietal, that exempli es the broader impact of co ee auctions, it’s Panama Geisha. Known for its delicate oral and stone-fruit notes, it is associated with

“Coffee has entered the same lane as wine and whiskey. People are chasing rare drops, bragging rights, and unforge able experiences.”

Kirk Bedrossian FOUNDER, ANGELINO’S COFFEE

extremely high-cup quality and is one of the world’s most well-known co ees –o en used by World Barista Champions on the international stage.

e varietal rst rose to fame in 2004, when family-run co ee farm Hacienda La Esmeralda won the Best of Panama auction for its pioneering Panama Geisha. e lot set a new price benchmark in the auction space, achieving a world record of $9.50 per kilogram, and launched the farm in the Boquete Highlands into international stardom.

Rachel Peterson, a member of the Peterson family who run the co ee farm, says the 2004 auction was a “before and a er moment” for Hacienda La Esmeralda. “ e Geisha lot’s performance rede ned what Panama, Geisha, and Arabica more broadly could express in the cup,” she says.

“It catalysed our modern approach: ner plot separations, rigorous sensory quality control and agronomic research development, and direct long-term partnerships. It also helped open the market’s ceiling for many other producers to pursue co ees of di erent varietals at sustainable premiums.”

Since 2004, Hacienda La Esmeralda has taken the top spot at Best of Panama on six more occasions as well as securing rst place in the Geisha Natural category four times and the Varietals category twice.

Peterson says since their early success with the varietal, many new farms have had the time to cultivate Geisha and the competition has become much ercer.

Despite this, in 2025 the farm won the triple crown at Best of Panama, achieving rst place in all three categories (Geisha Washed, Geisha Natural, and Varietals). Since 2008, it has also held its own private estate auction. Peterson says these events have bene ted the wider co ee sector in many ways.

“Auctions have raised the ceiling on price and prestige, rewarding excellence. ey’ve opened spaces for price di erentiations according to cup quality, varietals, origins, and processes,” she says.

“ ey’ve also accelerated traceability and consumer education, which li s origin brands. What’s more, they’ve allowed investment in processing and innovation techniques by rewarding precisely these things.”

Peterson does admit that there are also downsides to the system, highlighting that these record-prices can skew conversations on pricing.

“On the downside, volumes are small and price signals can be misunderstood. Auctions serve the co ee ecosystem as a marketing tool, but absolutely not as a pricing tool,” she says.

“However, for top producers, auctions deliver global validation, new relationships, and halo e ects that support broader lines.”

Coffee’s most expensive marketing tool?

Receiving ve minutes of fame for scoring the world’s most expensive co ee is all well and good, but does buying recordbreaking lots actually work as a marketing tool for specialty roasters?

In 2024, Los-Angeles-based roaster Angelino’s Co ee purchased 16 CoE winners, including 12 rst-place lots.

Founder Kirk Bedrossian says his motivation wasn’t only to secure rare

co ees but also to de ne the Angelino’s brand and demonstrate the level his team are willing to play at.

“I had had my eye on CoE for years because it is the gold standard. But in 2024, we decided to step up and compete at the highest level,” he says.

“Why? Because it is the purest way to honour farmers and push quality. It is where reputations are made, and where you nd co ees that remind you why this industry matters.”

For a specialty roaster like his, Bedrossian says there are two major bene ts of buying award-winning co ees: impact and experience.

“Farmers receive life-changing premiums and customers get to taste co ees that defy expectations,” he says.

“It’s not just drinking co ee, it’s like opening a vintage bottle of wine you will never forget. We do not just sell beans, we share experiences and stories through cups that can stop you in your tracks.”

Bedrossian explains that these co ees will never be Angelino’s bread and butter, but instead the brand’s “crown jewels that de ne who we are and what we stand for”. Despite this, he says when they do release the award-winners they don’t stick around for long.

“We release them in carefully roasted batches and once customers get a taste, the word spreads quickly. ese co ees have a

way of moving faster than most, which adds to the excitement of each release,” he says.

“Co ee has entered the same lane as wine and whiskey. People are chasing rare drops, bragging rights, and unforgettable experiences. We are building that bridge between everyday co ee drinkers and the luxury tier.”

So, who are the people buying these record-breaking beans and what’s driving the market for luxury co ees? Someone who knows this emerging sector well is David Paparelli, CEO of auction, technology, and nancing provider M-Cultivo.

Established in 2020, the company was launched to create opportunities for specialty co ee producers to grow their businesses through connection with buyers. It served as the auction platform for CoE from 2022 to 2025, and now hosts specialty co ee auctions across the world with private producers, businesses, and organisations.

“Over the past three years, we’ve seen an evolution of the auction space into the next level of luxury class, where it deserves to be among wine, whiskeys, watches and art,” says Paparelli.

“ e beautiful thing about auctions is the e ciency of them. e co ees are worth whatever someone is willing to pay for them.

“Most importantly, information is transparent. You don’t have the problem of asymmetry where one party is negotiating as one of the biggest importers in the world and the other is a small producer trying to compete on price.”

Paparelli portions the buyers of these luxury co ees into four categories: importers, roasters, luxury brokers, and personal shoppers for billionaires. He says for roasters and importers, the beans provide a ‘halo e ect’ for the brand, while for private buyers they o er the thrill of experiencing the crème de la crème of the co ee world.

“For a private producer or producing country in general, auctions are an excellent marketing, branding, and promotional event,” he says.

“It also sets an anchoring price for any future negotiations. If a producer sells a co ee for $30,000 per kilogram, it’s going to be hard to argue that the rest of their co ee is worth $4 per pound at the C market price. It has ripple e ects on the rest of their brand and their local ecosystem – it certainly bene ts the wider market, just look at Panama and more recently Ethiopia.”

With this new class of luxury beans, Paparelli predicts the trajectory of incredibly high auction prices will continue.

Spindler also believes the consumer demand for memorable co ee experiences such as those presented with ne wines and whiskies will see a continued willingness to pay more.

“Record prices are an expression of passion, rarity, and recognition. While not every year or every origin will break records, the long-term trend points to a growing appreciation of co ee as a luxury product at its highest level,” she says.

Following Angelino’s huge year of pursuing CoE lots, these winning beans will continue to be a priority for the roaster. Bedrossian believes these auctions play a signi cant role for the entire co ee industry.

“When a co ee sells for hundreds of dollars per pound, the entire industry pays attention. Farmers rethink what is possible, importers raise their standards, and consumers begin expecting more,” he says.

“Auctions are where the future of co ee is written, and the ripple e ects spread everywhere.”

Eversys

Caldwell discuss coffee’s shifting business model, why maintaining value is essential, and the role of automation in this developing landscape.

AS LEADERS of one of the most innovative manufacturers in the industry, Eversys Managing Director Stefano Barato and Marketing Director Miranda Caldwell must have their ngers on the pulse of what’s going on in the wider co ee market. While their day to day is focused on superautomatic espresso machines, they must also be looking at the bigger picture and how broader developments such as green-bean prices, café trends, and consumer expectations will trickle down to their customers.

Like all industries, co ee is continuously evolving. With more than 20 years in the sector in a variety of roles, Caldwell has experienced its evolution. When re ecting on the most signi cant innovations over the past few years, she highlights the shi in business model across venues serving co ee.

“Previously, there were two distinct types of co ee businesses: specialty venues that charged a premium and served high-grade beans and pourovers, and multi-location enterprises serving commercial-grade co ee on a large scale,” says Caldwell.

“However, the line between these types of venues has now blurred and their business models have shi ed. Quality beans are being served in traditionally commercial environments, while specialty cafés are diversifying their menus to cater to a broader audience.”

Caldwell believes this shi is being driven by the consumer, who is increasingly demanding beverage innovation and variety. While the previously distinct business models have become more homogeneous, she says it’s actually created more diversity in the sector.

“Businesses are introducing menus and styles of service that work for their broad range of customers. People used to identify as a Starbucks person or a specialty co ee person, but that’s becoming more interchangeable. eir choice of venue is now being determined by what they’re in the mood for that day,” says Caldwell. “ is is driving innovation in co ee, syrups, alternative milks, and equipment. It’s greatly in uencing us at Eversys to modify our products to serve the industry’s dynamic needs.”

Among younger generations,

consumption of traditional “pure co ee” drinks such as espresso, latte, and cappuccino is declining. As co ee’s role shi s from being the star of the show to one of a group of ingredients within a beverage, Caldwell says the industry faces a new challenge of maintaining co ee’s value in a way that makes sense from farm to cup.

“With record-high prices and supply issues over the past year, the challenge has become getting the consumer to pay more for co ee. While drinks have become more expensive, is the consumer actually just paying more for syrups, alternative milks, and ice instead of the co ee component?”, she says.

“Maintaining quality is a key to ensuring the value of the co ee is preserved, even within these signature drinks. Eversys’ machines are a great solution to help maintain that value by producing fantastic quality co ee.”

Managing Director Stefano Barato believes Eversys is well positioned to help the industry overcome this challenge. As a super-automatic espresso machine manufacturer established with a focus on exceptional brewing and steaming, he says

these functionalities are fundamental in all the brand’s products.

“ e way our machines brew co ee and foam milk are pillars of the brand. e objective has always been to deliver the best extraction and to do that consistently. For the milk, the aim is consistent taste, texture, and temperature,” he says.

“To maintain value, of course you need quality ingredients, but you also need the way they are processed – from grinding to infusion to steaming – to deliver the best possible result. We have worked alongside baristas for years to ensure the processes within our machines mirror that of a very skilled industry individual.”

While quality and ensuring a fair price for all parties along the supply chain have long been the focus of specialty venues, these businesses have traditionally been more resistant to adopting automated technology. However, Caldwell says this tide is starting to turn – especially in mature specialty markets such as the United States and the United Kingdom.

“In big cities where we’re clearly seeing the impact of cost-of-living, labour shortages, and price rises, the shi from traditional to super-automatic espresso machines is building momentum,” she says.

“Especially in busier venues, managers and owners are considering how they can speed up service and reduce hours needed for sta training while maintaining quality.

“Interestingly, we’re still not seeing the same uptake in the café sector in mainland

Europe and that’s because it only recently started to embrace specialty. ey are still in the era of exploring manual co ee tools such as pourovers.”

One of Eversys’ solutions that is proving particularly popular with co ee venues that are shi ing towards this more centreline business model is the Legacy machine. With up to four grinders and an optional integrated powder unit, it can prepare a wide variety of drinks to keep pace with expanding menus.

“ e Legacy’s four grinders mean a venue can have two specialty espresso options, a co ee for iced drinks, and then a decaf all prepared by the one machine. e powder unit adds an alternative too, such as matcha,” says Caldwell.

“It’s a bean-to-cup machine, but you can do so much more with it. It serves the needs of this new era of co ee shop and the customisation and variety consumers crave.”

Such businesses, especially those with a eet of machines, are also being lured by the telemetry systems included in many super-automatic machines. Barato says that, although this technology was rst introduced to Eversys’ models to help with internal research and development products, it is now a major draw for businesses that want to focus on maintaining quality and consistency.

“Our research department uses telemetry to continuously improve our machines, but the systems have also become a helpful

tool for service technicians to monitor the eet and for roasters and co ee managers to adjust recipes across multiple venues,” he says.

“It’s become a real ecosystem that helps drive the business to become more pro table.”

e Managing Director says the strategic tool will continue to be central to Eversys’ product development.

“We are improving the way our customers can interact with the telemetry platform and we will add more services in the future to make it even more useful to co ee businesses,” says Barato.

In terms of the broader future of automated equipment and its role in the co ee industry, both Barato and Caldwell are hesitant to make any long-term predictions. However, they believe there are still barriers to be broken down and huge opportunity for further innovation.

“ e skill of the barista is a critical resource for us. We don’t want to eliminate them – we want to focus their skills on recipe development and service to create additional value for the customer,’ says Barato.

“Our plan is to continue working closely with the barista community to help develop our so ware and integrate their experience into our machines.” GCR

For more information, visit eversys.com

OhmIQ partnered with espresso machine manufacturers to trial its waterheating technology. Image: qunica.com/stock.adobe.com.

new heating-water technology was launched at Host Milano in October. CEO Frederique Pirenne explains how this method stands to benefit the entire coffee community.

THERE IS NO bigger stage to promote new technology in the HoReCa space than Host Milano. With more than 1700 exhibitors and well over 100,000 attendees, it is a mecca for organisations and people who want to showcase and discover the equipment that will help the industry take its next great leap forward.

In October 2025, among the hum of the Fiera Milano exhibition complex was a company based in the United States that has the potential to totally change how water is heated in hot beverage machines. Crucially, it could also remove the problems that arise from pesky limescale buildup on traditional heating elements.

OhmIQ has already partnered with

espresso machine manufacturers to trial its technology, but Host Milano represented the company’s international debut to the industry.

CEO Frederique Pirenne says the opportunity to expose those at the tradeshow to OhmIQ’s technology represented a signi cant opportunity for the business.

“Seeing is believing,” he says. “We have spent quite some time showing what our machine can do and how it can be integrated with some of our clients, and the response has been positive. We presented some of those integrated machines at Host and see ourselves ful lling a real need in the industry.

“We’re currently working with espresso machine manufacturers, but we’re also working with steam ovens and a whole range of applications within the professional foodservice industry. We’re very excited to start new integration projects with players in di erent categories and make a substantial di erence.”

Typically, espresso machines heat water through a boiler tted with a resistance element. However, this method can result in the limescale present in water latching onto the element, which can slow water ow, reduce capacity, create heating problems, and eventually cause blockages.

Instead of the traditional method,

OhmIQ’s technology causes the water heat itself through the use of positively and negatively charged electrodes that promote movement of the water inside the boiler.

“ ere are minerals in water and every mineral is either positively or negatively charged,” says Pirenne. “With a resistance element you create a temperature of about 190 degrees Celsius, which causes limescale to stick to it, crystallise, and harden.

“OhmIQ works by placing two electrodes in the water – one is positively charged and the other is negatively charged. e negatively charged minerals will go to the positive electrode, and vice-versa.

“We heat the water by switching the polarity of the electrodes, which moves the minerals from le to right and right to le . at creates heat. It’s a little bit like putting players on a football eld. e more and faster you make them run from le to right and back again, the hotter they’re going to become. It’s the same e ect.”

e act of using an electric current through the water changes how the limescale reacts according to Pirenne, who says it doesn’t latch onto the electrodes because the electrodes don’t get warm.

“Unlike a resistance element that generates heat and then disperses through the liquid, our electrodes don’t heat up. ey become warm because the water in which they lay heats up ” he says.

“Since the electrodes never become hotter than the water, they don’t become hot enough for the limescale to attach to them.”

To truly di erentiate how OhmIQ’s process of heating water di ers from traditional resistance-element boilers, Pirenne says the business uses the acronym STEP.

“‘S’ stands for scaling, which OhmIQ doesn’t do. Scale can build up and make your resistance element less e cient before making it burn out, which means you have to replace it,” he says.

“‘T’ stands for time to temperature.

e resistance element is basically a middleman in the heating process, but we take out the middleman which means we are faster at heating the water.

“‘E’ stands for energy e ciency – most instant heater espresso machines need to keep a vat of water warm, but we don’t. Our technology can warm water instantaneously, which means it is signi cantly more energy e cient.

“We’re not saying we take the limescale out of the water – that’s what filters are for – but you don’t have to run as frequent descaling cycles to keep the machine running smoothly.”

Frederique Pirenne CEO, OHMIQ

“Lastly, ‘P’ stands for precision – as we are much more precise at heating water than current resistance technology. We can control the speed the minerals move, and you immediately see the water moving and heating up.”

Pirenne says three key problems associated with the e ects of limescale buildup showcase exactly why OhmIQ’s technology is needed, in addition to

the added energy e ciency, speed, and precision it can provide.

“ e main things are service costs, warranty, and uptime,” he says. “When you’re looking at a co ee machine, you’re working with four- and six-millimetre tubes. At the moment if you have limescale buildup in the machine, all it takes is one minor obstruction and the machine goes down.

“Not only do you then have to call out a service technician to take care of it, which is a cost for the machine operator, you now also have a co ee shop that has severely limited its capacity to serve co ee – or it can’t at all. at could lead to signi cant nancial loss for the café.

“Finally, you don’t have to descale the machine all the time. We’re not saying we take the limescale out of the water – that’s what lters are for – but you don’t have to run as frequent descaling cycles to keep the machine running smoothly.”

Although it o en takes time for new technology to become standard in any industry, the beauty of events such as Host Milano is the exposure given to new and exciting innovations that could change the future of hospitality.

Pirenne admits the most di cult part of championing new technology is gaining that initial traction in the industry. However, he believes as OhmIQ’s capabilities continue to expand, so too will its application in professional and semi-professional co ee machines.

“We’re a new technology, and adoption of new technology is always the hardest part. at being said, this concept has been around for 100 years or so, it’s just never been commercialised because you couldn’t have the control you need – but we have that now,” he says.

“It’s like walking on ice: people will always look for footprints to know someone went before them, but we’re looking to be the rst to take these new steps.

“I think this is the future. We’re only at the beginning of this technology and it will only get cheaper and more accessible as time goes on. What we want to do for the co ee community is introduce a new technology that solves a very real issue for the industry.” GCR

For more information, visit ohmiq.com

How Franke Coffee Systems’ New A Line of automatic machines is primed to take on the challenges of the evolving beverage market for operators, baristas, and coffee lovers alike.

WHEN Franke Co ee Systems introduced the New A Line at Host Milano 2025, the manufacturer known for its Swiss engineering wanted it to feel less like a typical product launch and more of a bold new era.

e New A Line is a con gurable platform, designed to deliver uncompromising and consistent incup quality with operational e ciency, reliability, exibility, and an eco-friendly mindset. ese components were brought together to match today’s business needs – from independent cafés to multinational operators.

Fully automatic machines are typically associated with speed and convenience, but Franke Co ee Systems CEO Marco Zancolò emphasises that Franke’s vision for the category goes far beyond that.

“Premium expectations are rising even as sta ng and cost pressures grow,” says Zancolò.

“With the New A Line, operators get consistent in-cup quality at scale, true exibility for dairy and non-dairy menus, and simpler day-to-day running. All of this

is backed by Swiss precision engineering. e New A Line is built for today’s realities and ready to evolve with future customer needs.”

Zancolò’s view is mirrored in the six guiding values that have fostered the evolution of the A Line: premium incup quality, enhanced o er, ease of use, cost e ciency, aesthetic design, and an environmentally friendly footprint.

Over the past decade, the Classic A Line has become a trusted partner in cafés, hotels, and convenience stores worldwide. e New A Line aims to build on that legacy while introducing major technological advancements engineered to push the standard of fully automatic machines.

As part of this evolution, Franke has released a suite of new and updated technologies. e New FoamMaster function has been developed to deliver consistent barista-grade foam and full undiluted avour at high temperatures with unprecedented precision and repeatability.

e new digital backbone, FrankeOS, underpins the technological improvements. e digital platform aims to bring so ware, connectivity, and user experience together in one simple-to-navigate system to streamline daily routines, reduce training needs, and provide clarity for users.

ese innovations have been created to continue the heritage of the Classic A Line at the heart of the New A Line, while also addressing expectations of what co ee lovers can nd in a fully automatic machine.

Premiumisation with precision

Franke Co ee Systems’ patented iQFlow technology will now come as standard in the new A600 and A800. e system is designed to continuously control and adjust extraction time and ow in real time to deliver consistent aroma and avour in every cup.

IndividualMilk is a further key function that can be built into the new generation. It allows operators to serve both dairy and plant-based alternatives from the same machine while keeping the milk types completely separate and guaranteed free of cross-contamination from cooling unit to the cup.

To ensure every co ee bean and delicate tea is brewed at its optimal temperature for maximum avour, consistency and versatility, PrecisionTemp has been developed to empower businesses with unparalleled temperature control.

Streamlined user experience

In addition to the technological innovations, ease of use was a design priority. e creation of a large graphical interface, visual prompts, and streamlined menu ow were introduced to make the machines more accessible and easier to train new users on.

Furthermore, the Design Spout Light was developed to provide guidance for users to support both sta ed counters and self-service environments – as well as contributing to the distinct design element of the machines.

anks to Franke Co ee Systems’ modularity approach, the New A Line can be precisely con gured to match each operator’s performance goals, space, and work ow – from small cafés to largescale venues.

Add-ons and options such as up to three grinders and two powder hoppers, Flavor Stations, and payment integrations extend this exibility further.

Franke Co ee Systems Product Manager

Patrice Schaer says the modularity of the New A Line re ects the evolving demands on fully automatic machines from the brand’s partners and customers.

“Every business is unique, and our machines must re ect that,” says Schaer.

“ e New A Line is a con gurable platform – the capacity and features needed can be scaled as their operation grows.

“Consistency is the base line; creativity is the opportunity. Our goal was to make both achievable in the same shi , on the same machine.”

Low footprint, high confidence Franke says e ciency and ecofriendliness guided the development of the New A Line.

Boiler insulation system HeatGuard is reported to reduce energy loss by up to 44 per cent in the new A600 compared to the Classic A600 (no milk version), while ensuring the machine remains ready for use during peak hours. What’s more, IndividualClean adapts cleaning cycles to actual usage, reducing detergent consumption, streamlining work ows, and easing sta workload.

e new FoamMaster is not only designed to ensure top-level foam consistency and temperature but also helps to signi cantly reduce food waste through enhanced process optimisations. ese improved technologies are part of the overall intent to lower the New A Line’s environmental footprint while supporting cost e ciency and helping extend the lifespan of the machines.

Launching the New A Line

e New A Line, introduced with the new A600 and A800 in its rst rollout phase, is said to be the pinnacle of Franke’s co ee-brewing excellence.

e new A600 has been created as a versatile, premium all-rounder machine for cafés, bakeries, and restaurants that need to o er a wide variety of beverages with consistency.

e new A800, by contrast, has been created to be the performance specialist designed for high-venue environments where speed and volume matter most. It introduces features such as parallel dispensing, which enables two beverages to be prepared simultaneously.

Together, the new A600 and A800 have been released to give operators choice between exibility and high-capacity performance, depending on business needs.

Designed for reliability and trust

e New A Line not only carries forward the engineering of the Classic, including high-quality materials and durable components, but has been constructed to build upon it with intuitive work ows and connected data.

Following their launch at Host Milano 2025, the new A600 and A800 will become available in stages across di erent regions, reaching global availability by the end of 2026.

Zancolò says the New A Line demonstrates how far fully automatic machines have come, and how far they can still go by raising standards in beverage quality, e ciency, and eco-friendliness.

“Our strategy is simple,” he says. “We invest in innovation that matters.”

“ e New A Line embodies that approach – setting new benchmarks today and preparing our customers for the expectations of tomorrow.” GCR

For more information, visit aline.franke.coffee

Ceado developed some of its most advanced patentedtechnologies to date for the

SINCE IT WAS established in Venice in 1999, Ceado has been fuelled by a erce focus on avour. Innovation has been the method through which the grinder manufacturer has continued to pursue this purpose and its ultimate goal of helping passionate baristas produce the best possible cup of co ee.

According to Ceado Head of Sales Cosimo Libardo, over the past quarter century this fascination with avour has produced some groundbreaking equipment.

“Our mission is designing precision instruments that ensure avour is maximised and consistent,” says Libardo.

“ is drive has meant that at some points Ceado has been ahead of its time. is can be a good thing, but if the industry doesn’t yet understand the need for a piece of equipment, they o en just don’t get it.”

For this reason, much of the technology behind the brand’s new REV series of grinders has been sitting in a theoretical draw since 2017. A er the explosion of grind-by-weight models around this time, the team quickly saw an opportunity to further improve the technology.

“We identi ed four parameters – the amount of retention, temperature of the ground co ee, granulometry, and weight

– that can actively manage and positivitly a ect the avour consistency by minimising variations in extraction time,” says Libardo.

“With this information, our mission was to create a series of grinders that could actively manage these parameters simultaneously without input from the operator. e project resulted in a series of three models, each of which uniquely in uences the avour of the co ee.”

In order to meet the four parameters, the Ceado engineers developed some of the manufacturer’s most advanced patented technologies to date for the REV series.

To ensure weight precision, they developed the Weight Adjustment Model (WAM) to deliver “consistent dosing and extreme precision”. e feature is an interchangeable module – which can be installed in less than two minutes – to provide resistance to high-level stress and ease of maintenance and replacement.

Addressing retention control is the Sweep-Out system, designed to ensure each dose is fresh and free from contamination of residual grounds. is runs alongside the Steady Lock system, introduced to maintain granulometry stability by keeping the distance between the burrs consistent –

even under heavy loads.

Finally, to address temperature management, the team developed Grounds Temperature Management (GTM) to regulate thermal accumulation and maintain a stable temperature of the ground co ee for uniform extraction. e system is composed of three main parts: a 2.5-kilogram heat sink to instantly extract heat from the burrs, distacing motor from burrs with insulation, and algorithmmanaged air ow.

“Testing these functionalities with people in the industry was a vital part of the development process. To date, hundreds of roasters have given us feedback, all of which has been overwhelmingly positive,” says Libardo.

While much of the technology within the new REV series has been in development for years, the Ceado team took their time to ensure the grinders delivered exactly what the industry needed. A er a gradual launch, the trio was o cially introduced as a complete set at Host Milano in Italy in October 2025. e rst in the series is the REV Steel. With 83-millimetre at steel burrs at a lifespan of 900 kilograms, it has been

developed for espresso blends to produce a balance between body and avour clarity.

Also equipped with 83-millimetres burrs, this time with a titanium coating and a 2.5-ton lifespan, is the REV Titan. ese hard-wearing burrs are designed to deliver fast extraction and consistent avour in busy environments.

Rounding out the trinity is the REV Zero, which o ers the longest lifespan (four tons) for the 83-millimetre burrs thanks to their red-speed coating of titanium and aluminium. Described as the most innovative model in the range, it features upgraded technology engineered to enhance the aromatic pro le of the co ee.