With a full 8 year warranty as standard*

The Maxam Agrixtra range delivers minimal soil compaction, a comfortable ride and improved traction which surpasses all agricultural tyre expectations.

8-YEAR FARM TYRE WARRANTY

*Maxam farm tyres come with an 8-Year warranty against manufacturing defects. This offer includes a full tyre replacement warranty for the first 12 months and a pro-rata replacement warranty thereafter.

10 Quality machinery and work lights from Wattz are backed up by the technical expertise to help Australian farmers to shine in any environment

6 Highlights from Hort Connections

55 FarmFest machinery wrap

62 Telehandlers feature at Hire25

17 Big investment in horticulture automation

18 Biosecurity budget passes $1 billion in NSW

18 Pest response funding in WA budget

19 Case IH debuts new Quadtrac undercarriage

20 Hort Innovation continues event partnership

20 Last chance to be involved in TMA conference

21 Gatton to host vegetable agtech showcase

Editorial & Design

Editor Lincoln Bertelli

lincoln.bertelli@primecreative.com.au

Journalist Jackson Haddad

Contributors Trevor Whittington, Gary Northover

Design Danielle Harris, Jacqueline Buckmaster

Art Director Daz Woolley

Managing Editor Eugene Du y

Cover image Wattz

22 Drought relief available for Victorian farmers

22 Research nds organic fertiliser soil health bene ts

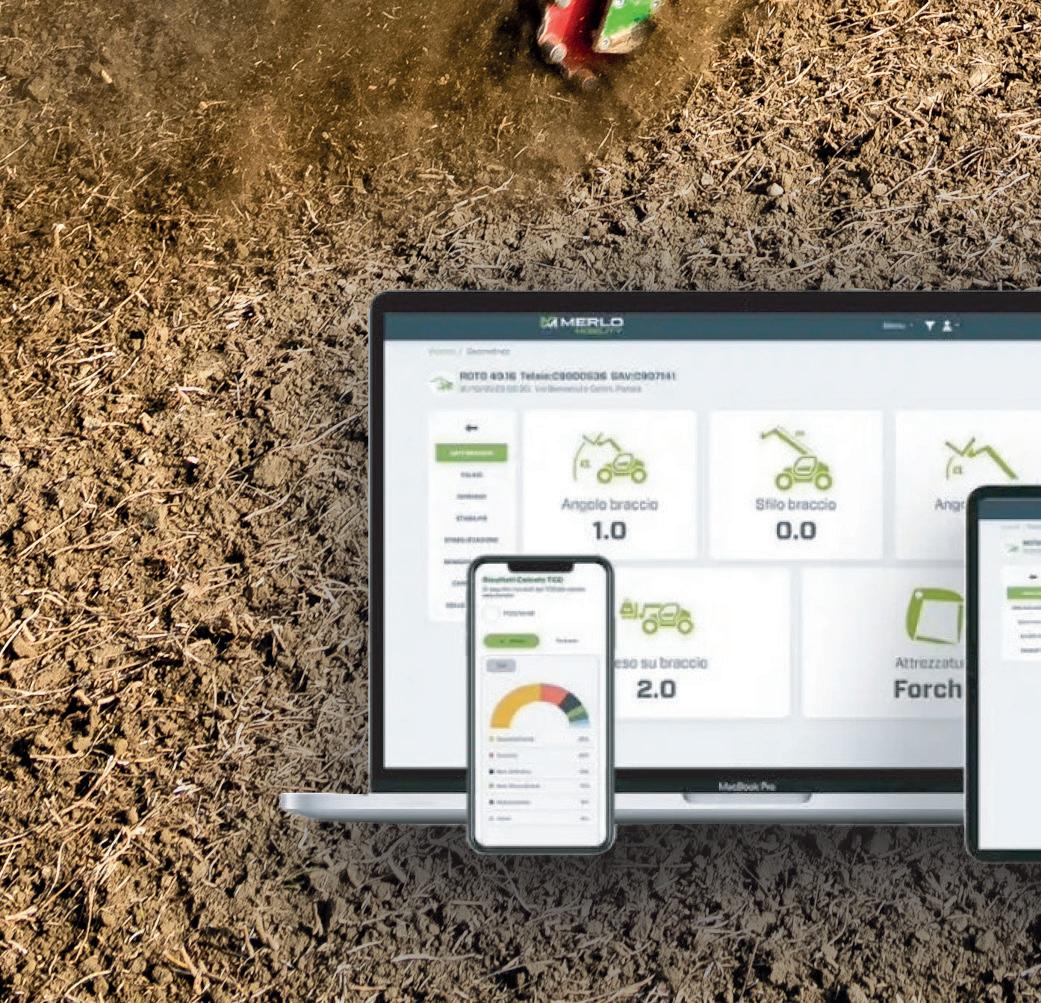

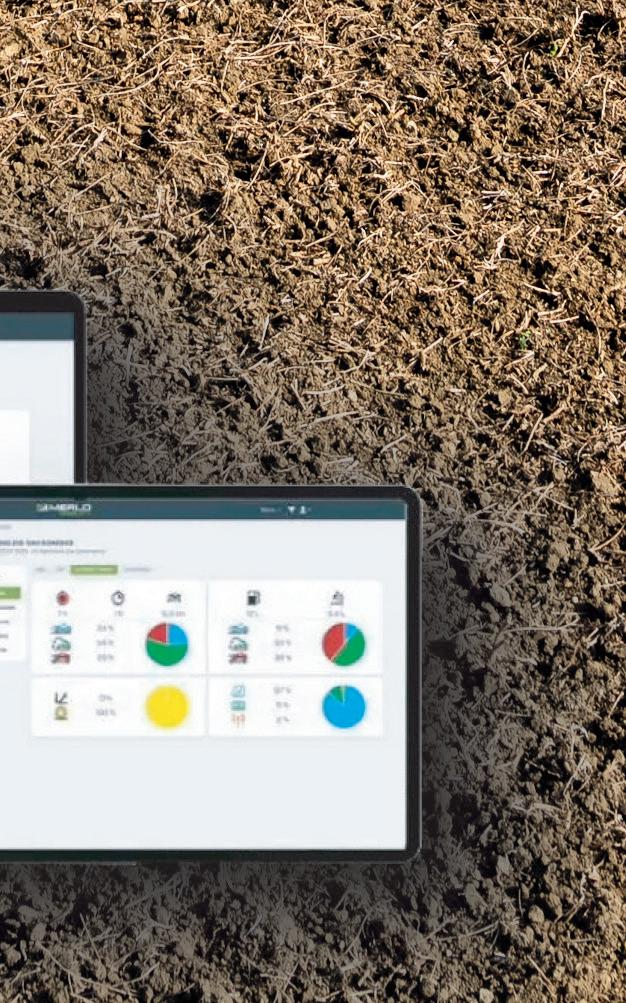

24 Merlo telehandlers giving AgConnex versatility

28 Mahindra’s journey from humble to hero

32 Plant hire business advocating for Hercules loaders

36 Cobra’s customised Shantui equipment helping farms thrive

38 JCB Fastracs the only choice for sugar cane grower

44 Moira Farming diversifying with vegetables and cotton

48 The Tractor & Machinery Association says weather conditions in multiple states impacted on May’s tractor sales, which were well down

50 Having attended a rural connectivity workshop, WAFarmers CEO Trevor Whittington says xing mobile coverage issues needs a greater government commitment

4 Editor’s note

52 Calendar of upcoming events

74 List your item for sale!

81 Royal milestone Manufacturer Crown Equipment is celebrating its 80th anniversary

The Farms & Farm Machinery team had eagerly been awaiting our visit to both FarmFest and Hort Connections – both held during the same week in Queensland last month.

This was a great opportunity to connect with both the horticulture and broadacre sectors and plenty of exciting stories came from each event.

There is a full machinery wrap from these events in this edition, while we also participated in a pre-event tour of Moira Farming, who have found success by combining cotton and vegetable growing to increase their market diversity.

Further coverage from Hort Connections –including extensive pro les of award winners – will feature in the coming months.

Another event which took place last month was Hire25, and we show you a number of telehandlers that were on display which have relevance to the agricultural sector.

Speaking of events, the Tractor and Machinery Association’s annual conference in Melbourne is just around the corner.

Farms & Farm Machinery is excited to be the o cial media partner of this event and more details about what to expect on the day – and how you can attend – are included in this edition.

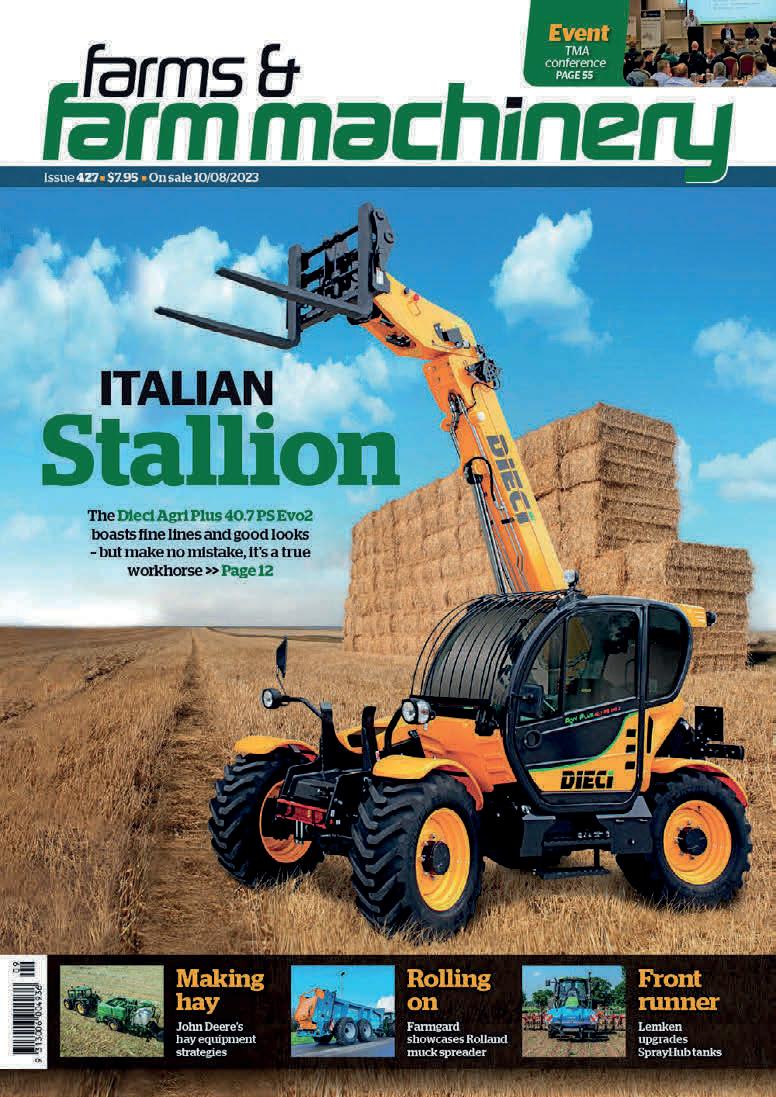

Our cover story this month is from lighting provider Wattz, who discuss the technical expertise it can o er farmers looking for a powerful alternative to factory- tted machinery lights, along with the key aspects they should be considering.

Customer testimonials are something we aim to include in every edition and this month has been no exception.

We speak to a New South Wales grain handling business about the versatility which their

two new Merlo telehandlers have provided.

Queensland provides another two testimonials – via a sugar cane farmer who didn’t think twice about sticking with JCB Fastrac tractors, along with a plant hire business that has become an uno cial ambassador for Hercules Machinery Group’s wheel loaders.

Celebrating the long histories of various companies is also worth doing, which is why we discuss Mahindra’s journey towards becoming the world’s largest tractor seller by volume while also entrenching itself in the local market.

WAFarmers CEO Trevor Whittington also takes a look at mobile connectivity in rural areas, fresh from sitting down with Telstra representatives to discuss the ongoing issue.

Our industry news section this month delves into the New South Wales and Western Australian state budgets and what farmers can expect from each, plus some of the developments which emerged from both Hort Connections and FarmFest.

We hope you can join us at the TMA conference this month and look forward to bringing you all the news from this signi cant industry gathering.

Happy reading!

Lincoln Bertelli Editor

The latest machinery and technology in the horticultural sector were displayed at Hort Connections 2025, Australia’s largest horticulture conference and trade show

Hort Connections 2025 drew thousands of delegates to the Brisbane Convention & Exhibition Centre from June 4-6.

The 2024 version of the event held in Melbourne was previously Hort Connections’ largest ever conference, but this year’s iteration was even bigger and better, hosting more than 220 exhibitors and welcoming around 4,200 delegates.

The trade show was the focal point of the event, showcasing the latest machinery and technology to visitors across 12,000sqm of exhibition space.

Various speakers also took the stage throughout the trade show, with sessions held throughout highlighting industry challenges.

Kicking o the trade show was an industry breakfast and keynote speaker, while a gala dinner at the end of event included the announcement of the Horticulture Awards for Excellence winners.

Visitors also had the option to attend an o -site farm tour before the conference

began, enabling them to learn from some of the region’s most innovative horticulture growers.

The Farms & Farm Machinery team was on-site over the three big days – here are some of the highlights from the trade show.

Multi-brand dealer Vin Rowe Farm Machinery had many visitors inquire about the Ferrari Growtech Futura twin automatic transplanting machine.

Developed to have high-technology characteristics, this piece of machinery

has been projected for the automatic transplanting of vegetables stored in trays, with just one operator required to load the trays into the charging slide of each single planting element.

Each element of the machine is provided with a system, which automatically pulls out, from the longer side of the tray, the plants of the same row. These plants will then be taken from further movable grippers which supply the distributor.

John Deere

At the very centre of the trade show was a John Deere 6M 250 utility tractor, encompassing a 250 rated horsepower (183.9kW) engine.

The spacious cabin provides maximum operator comfort and includes John Deere’s largest ever screen, the new G5 and G5 Plus CommandCenter, which o ers more space for the operator’s information and a faster processor for shorter boot-up times.

Advanced technology can also be integrated with the John Deere Operations Center for seamless precision agriculture, enhancing data management and decision-making.

Another highlight of the booth was John

Deere’s 5130ML low-pro le utility tractor tted with the Smart Apply Intelligent Spray Control System, which was acquired by John Deere in 2023.

Delivering precision spraying and precision data capture and analytics to growers, the Smart Apply technology can reduce water use and chemical costs by up to 50 per cent.

New Holland

The star of New Holland’s booth was a T5.120 utility tractor with an engine producing 117 rated horsepower (86kW).

Customers have the choice of di erent transmissions on all T5 tractors, which help them excel in a wide range of applications from eld, loader and yard work to high-speed transport.

The model on show was equipped with the Auto Command transmission and New Holland’s premium comfort Horizon cabin, which utilises a four-post concept, suspended seats and ample legroom.

Even more optionality is o ered with a dealer-installed 800LA Series loader option, increasing the number of jobs that can be completed with the utility tractor.

Having celebrated its 40th anniversary in 2024 and launching the Ferrari tractors from Italy, Inlon showcased the Ferrari Vega V95 with STD cabin.

Featuring a low cabin, this model stands just under 1.7m tall, making it well-suited to vineyard applications.

The low-pro le curved-roof cabin has integrated ROPS in the structure with air conditioning.

Also renowned for its traction in hillside applications, this tractor is powered by a 91hp (67kW) four-cylinder intercooled turbo diesel engine.

Massey Ferguson

Massey Ferguson’s 6S.135 tractor was on display to Hort Connections delegates, as the smallest model in the MF 6S series.

Released to Australia in 2022, the MF 6S series o ers the choice of ve compact and versatile four-cylinder tractors.

The 6S.135 boasts max power of 135hp (100.7kW), with operators bene ting from superior control rst seen on the award-winning MF 8S series.

This includes an easy-to-use new Multipad, o ering single lever comprehensive control and a new armrest linked to the seat, which contains everything needed to operate the engine, such as the transmission, hydraulics, linkage and PTO as well as switches for the radio and phone.

Fendt

With a focus on higher horsepower tractors, Fendt presented its awardwinning 728 Vario Gen7 tractor.

Announced as the 2023 Tractor of the Year at the EIMA in Bologna, Italy, this model is the largest in the 700 Vario Gen7 series, boasting a 303hp (223kW) engine.

The intelligent and newly developed Fendt VarioDrive driveline stands for stepless, dynamic driving at any speed from 0.02 to 60 km/h.

Front and rear axles are driven separately and thanks to an intelligently controlled all-wheel drive clutch, manual control of the 4WD system are no longer necessary.

Kubota

Before visitors entered the doors of the trade show, they were presented with Kubota’s 95hp (69.9kW) M9540 utility tractor fitted with the OEM’s VP1400 vegetable planter and a Burder forklift attachment.

A four-metre frame width features on

Kubota’s VP1400 vegetable planter features a four-metre frame width

the VP1400, as well as 7.00-12AS tyres, which ensure low soil impact during sowing.

All models in the VP1000 Series including the VP1400 can handle single, twin double row units, and the Clear Air Set system as standard conveniently blows seed coatings to the ground.

The seeding heart for the VP1000 Series is made of cast aluminium and ensures highly accurate placement.

Individual seeds are sucked to the seed disc holes by a vacuum and then proceed via the rotating disc to the machine’s ejection area, where the vacuum is interrupted, and the seed is placed precisely in the ground. Surplus seeds are returned to the seed flow, for maximum efficiency.

Within the trade show, Kubota also off its other implements including its precision planter range.

In most people’s daily lives, we rarely give a second thought to the quality of light around us, provided it is adequate enough to ‘do the job’.

Beyond perhaps buying a different globe to better illuminate a kitchen light or bedroom reading lamp, it is easy to accept this merely adequate lighting as being enough.

This is not how agricultural machinery lighting provider Wattz chooses to operate though, knowing that moving beyond

Quality machinery and work lights from Wattz are backed up by the technical expertise to help Australian farmers to shine in any environment

‘adequate’ will lead to game changing benefits for Australian farmers.

The Wattz team lives and breathes terminology like lux and lumens, which means anything they sell has been carefully engineered and built to be exactly what its end users need.

Know your terms

Wattz launched to the Australian market earlier this year with a simple but powerful aim – to revolutionise the

lighting available to local farmers.

It does this by offering high-quality alternatives to factory-fitted lighting, which can increase the light output by up to 400 per cent and therefore significantly boost the capability to safely work in otherwise challenging light conditions.

Wattz is so much more than simply a product supplier though, with its expert knowledge enabling farmers to get something perfectly suited to their needs along with showing clear evidence of its benefits.

While many people may simply look at wattage when buying household light globes, it is not the measurement Wattz founder and farmer Andre Meyer says should be front of mind for farmers.

“Nowadays, wattage isn’t the go-to measure for how effective a light really is. What matters is the difference between lux and lumens,” he says.

“Watts mainly tell you whether a particular bulb or light will work with your vehicle. They indicate how much power the light needs to run - essentially how much energy it uses.

“But if you’re after visibility, it’s the lumens you need to focus on - plus considering measured lumens against real lumens..

“Measured lumens is the total light an LED bulb can produce in perfect lab conditions and it’s the “best case” number manufacturers might use to make their product sound brighter. Actual lumens

is the real light you get from the bulb in everyday use, after losses from things like lenses, heat, or the fixture itself.”

Measuring lumens indicates how bright the light is overall, while also factoring in the lux provides a deeper insight into how much light falls on a specific area.

If a lamp emits 1,000 lumens, it will deliver 1,000 lux over an area of one square metre, Meyer explains.

If those lumens are spread over 10 square metres, the intensity of light will drop to 100 lux.

The mounting height is also a factor, Meyer adds, as the light will be distributed more evenly if the lamp is placed higher.

This is particularly important for lighting inside workshops or sheds, which Wattz supplies along with its machinery lighting.

Kelvin is another important measurement to factor in, according to Meyer.

This measures colour temperature, with 1,200K mimicking candlelight and 10,000K corresponding to bright sunlight.

Most of the work lights provided by Wattz are about 6,000K, which Meyer says is equivalent to daylight and can be referred to as ‘cool white’.

Understanding the differences between these technical terms, and knowing how they affect real-world requirements, is just one part of Wattz’s expertise.

Another aspect relates to beam angle, as not every farmer will want their additional light to be focused on the same spot – depending on the types of jobs being completed.

“Modern agricultural tractors are increasingly fitted with LED lighting that offers different beam angles, allowing you to choose between spot or flood light,” Meyer says.

“The 40-degree angle is ideal for the front section of the tractor’s roof, as that best illuminates the area in front, while the 60-degree angle works best for the rear.

“When working with wider implements, you can even mix both angles for the best coverage. Interestingly, the difference in beam angle isn’t visible on the outside of the LED work lights - it’s achieved through clever adjustments of the lens and reflector.”

It also does not need to be simply one or the other, as Wattz recommends fitting

LED lights with a 40-degree beam angle on both the front and rear of the roof, with 60-degree beam angles on lights above the indicators and on the fender, although there is no ‘one size fits all’ solution and Wattz can individually adjust as needed.

This confi guration will deliver 360-degree visibility and light up to 50m in front of and behind the tractor, Meyer says.

All lights supplied by Wattz are LED, rather than halogen, which carries multiple benefits in terms of light output and overall quality.

“While halogen lights serve their purpose, they are not as efficient as LED lights,” Meyer says.

“LED headlights convert more energy into light rather than heat, offering a brighter, more authentic light that significantly improves visibility.

“The white LED light not only enhances

the working area but also creates a more comfortable working environment, contributing to safer operations on the field.

“Another significant advantage of LEDs is the brightness and clarity of their light. Not only does LED lighting enhance light intensity, but the light itself is much whiter.

“This ‘white’ light allows for clearer differentiation compared to the yellowish glow of halogen lights. In short, with white light, you see more than you do with yellow light.”

All of this knowledge and technical expertise needs to be backed up with products to match, and this is something Wattz has hit the ground running with since its launch.

Thanks to its partnership with leading European manufacturer Crawer, Australi-

an farmers have access to a wide range of tried-and-tested products.

Meyer and the Wattz team are heavily involved with product development, meaning an array of lights specifically designed for the Australian market will also be rolled out over time.

One major benefit of having an established European manufacturer on board though is the ability to provide model-specific lights for the world’s major tractor brands.

This is backed up by a 3D Confi gurator on the Wattz website, which enables customers to enter their tractor’s model details and be shown which products are right for their needs.

Importantly, all Wattz lights are designed to reflect the factory look and blend seamlessly into the tractor.

The lights are also being constantly

refined, with one recent example being the addition of a new valve which vents moisture produced by condensation in the unit.

Coupled with a new, thicker, and smoother powder-coated finish, this helps to ensure a significantly longer lifespan.

Something for all Wattz also knows not every tractor which farmers are looking to upgrade the lighting package on is brand new.

Referring back to the wattage – or how much power is needed to run the light –multiple power options are available for the differing needs of various tractors, from brand new models with sufficient electrical capacity to support higher power consumption to older and smaller tractors, plus everything in between.

While improving the lighting output of a tractor ultimately comes down to increased lumens, Meyer says there is plenty for farmers to consider – all of which can be made easier by tapping into the Wattz team’s expert knowledge.

“In addition to the number of lumens, there are other important factors to consider, such as the colour temperature of the light, even light distribution, compliance with safety standards, long lifespan, resistance to weather conditions, energy efficiency, ease of installation and adjustment,” he says.

All lights supplied by Wattz meet and exceed these criteria, he adds, also offering excellent road illumination and ensuring safe usage.

They also meet CISPR standards, which ensures there will be no radio interference during operation.

Wattz does all of this while remaining price competitive and giving farmers back up service from an Australian company passionate about helping them.

“These lights are not just for people working the night shift, it might just be getting an hour in early in the morning or hour later at night,” Meyer says.

“You don’t realise all the effort and the development and thought behind it from ease of installation to the looks and everything in between – there’s a lot that goes into each light.

“We cater for all the big brands and for the price and what you get, I think it’s tremendous value.”

The full product range can be viewed online at www.wattz.com.au

Hort Innovation – the grower-owned, not-for-pro t research and development corporation for Australia’s horticulture industry – has invested more than $220 million in productivity boosting projects, from automation, AI and on-farm management to data collection, and business analysis.

Leveraging advanced AI technology, this multi-year project will aim to accelerate the adoption of precision autonomy in Australia’s nut industry and automate labour-intensive farming operations. This will boost productivity and reduce reliance on manual labour across the sector.

These projects will involve new technology which has the potential for one grower to operate multiple tractors at once, slashing the labour input costs and enabling around-the-clock operation with minimal human intervention.

With this, a single operator can remotely manage and optimise a eet of tractors from any device – including mobile, desktop or tablet.

Partnering with United States agtech leader Bluewhite, the project will bring cutting-edge technology that retrofits existing tractors, converting them into fully autonomous machines, to the Australian horticulture sector.

Hort Innovation says the research promises revolutionary change in Australia’s almond, macadamia, and pistachio industries and beyond.

With the potential to scale to other industries in the long term, this technology could help to boost productivity across the entire horticulture industry.

“Nut production and harvest are labour-intensive, and the sector relies heavily on seasonal workers, particularly backpackers and holidaymakers to meet demands,” Hort Innovation CEO Brett Fi eld says.

“However, since the changes to labour programs and ongoing changes to regulations, growers have faced increasing

challenges sourcing reliable labour.

“The technology we will be trialling in this project is already being used successfully by some of the largest nut, citrus, and vineyard operations in the United States, delivering higher productivity, improved crop consistency, and reduced exposure to human error and fatigue.

“We hope that with grower consultation and plenty of technology testing, we will be able to see similar results come out of this for our Australian nut growers.”

The AI-driven platform also enables real-time data collection and analysis, allowing growers to make informed, data-driven decisions about their crops.

In addition to operational gains, the autonomous system enhances worker safety by limiting human exposure to hazardous tasks, chemicals and extreme heat – major risk factors in orchard operations.

Strengthening biosecurity forms a major part of the NSW government’s funding. Image: Dejan/stock.adobe.com

integrated biosecurity model”.

The other major theme of the NSW government’s funding announcement is for modernising research and development.

Bolstering biosecurity and research capabilities form the basis of $140 million in new funding for agriculture in New South Wales.

The funding was announced as part of the state’s budget, with $100 million of the total being in extra biosecurity funding, which pushes the state’s total biosecurity investment to $1.05 billion.

“These signi cant budget investments build on the work we have carried out over the last two years to turbo charge the ght against ferals, pests, diseases and weeds,”

NSW agriculture minister Tara Moriarty says.

New South Wales’ total biosecurity investment will pass $1 billion thanks to newly announced state government funding

“Biosecurity is receiving unprecedented attention from our government due to the increasing risk to our farmers and landscapes.

“We are standing with our farmers to show them the way on how to deal with these problems and to battle any feral problems head-on to make a real di erence.”

The biosecurity funding will enable the strengthening of surveillance and improve the state’s emergency response capacity in the event of a biosecurity incursion, the government says, while driving the development of a “new, sustainable and

This will include upgrading digital infrastructure to promote research in emerging areas such as AI-assisted farming, along with supporting a graduate program to give a pathway to young scientists.

The government says the funding will also support sta undertaking research in areas such as animal nutrition, climate change, biosecurity surveillance and responses, and aquaculture breeding.

“We are committed to modernising our research and development e ort for primary industries… and it is bringing a stronger, strategic and resilient focus to the future of primary industries,” Moriarty says.

“Establishing a graduate pathway for young scientists and researchers into our primary industries research program is essential to maintaining a continuous and dedicated specialist workforce driven by purpose and achievement.”

Upgrades to Albany Port for grain handling are among the WA government’s budget announcements. Image: Michael Evans / stock.adobe.com

Western Australia’s government has handed down its state budget, with biosecurity among the funding for agriculture

Limiting the spread of polyphagous shot-hole borer is among the agricultural projects to receive funding in Western Australia’s 2025-26 budget.

This follows a national decision to transition the biosecurity response to a management phase, a er the National Management Group determined it was “no longer technically feasible” to completely eradicate shot-hole borer from WA.

A $26.5 million budget announcement is designed to focus on managing this invasive pest – which was rst detected in WA in 2021 – with the aim of slowing its spread, limiting the impact on healthy trees and protecting the state’s horticulture industry.

“The WA community, our state’s

biosecurity teams, and local government authorities have worked incredibly hard since 2021, and as a result we have a strong foundation to manage this pest going forward,” WA agriculture minister Jackie Jarvis says.

“These e orts and our strong, decisive action mean we have limited the spread of the shot-hole borer to the Perth metropolitan area, stopping the impact it could have had on our state’s horticultural sector.

“We will continue to look for alternative solutions by supporting local scientists to undertake more research under WA conditions.

“The more we can learn about this pest, the better equipped we will be to protect

and support our state’s tree canopy and agricultural industry.”

Three new research projects to help limit the spread of shot-hole border will also be funded by $2.17 million in budget funding.

Other announcements in the state’s budget included $11 million for planning and development work for upgrades at Albany Port in the state’s south, which is hoped to increase grain export trade.

There was also $7 million towards two aerial strike teams to mitigate crop re threats during grain harvest season, while $3 million will be spent towards improving marron habitats at dams in the state’s south-west.

Case IH high horsepower product manager for ANZ Justin Bryant showing o the heavy-duty suspended undercarriage. Image: Case IH

FarmFest was the ideal event for the debut of Case IH’s Quadtrac suspended undercarriage, o ering enhanced comfort for operators

Case IH debuted the heavy-duty suspended undercarriage option on its Quadtrac tractors at FarmFest, Toowoomba, from June 3-5.

Displayed on a Steiger 645 Quadtrac model, FarmFest attendees were provided with the very rst Australian public viewing of this option.

Case IH high horsepower product manager for ANZ Justin Bryant says the suspended undercarriage signi cantly enhances operator comfort.

“This one of the many and latest evolutions of the Quadtrac design,” he says.

“Idler rollers are now able to move vertical-

ly, and the mid rollers are able to operate on their own double axis. This allows the machine to follow the contours of the ground far better, thus increasing operator comfort.”

Key features of the heavy-duty suspended undercarriage include:

• Six per cent larger footprint to minimise ground pressure and compaction

• Longer track life with an 11 per cent larger drive wheel and 5 per cent longer track than the previous model

• Higher eld travel speeds in rough conditions – 11 per cent faster road speed than the previous model

• An automatic track tension system tied

to the tractor hydraulics

• Independently suspended roller and idler wheels in the undercarriage to provide a smoother ride

• Ease of maintenance with grease-less, maintenance-free bushing and pin design

The heavy-duty suspended undercarriage option will be available on all Quadtrac models from 475-715, with these models having undergone vigorous in- eld testing before the option goes to market in early 2026.

Launched in 1996, the Case IH Steiger Quadtrac will also celebrate its 30th anniversary next year.

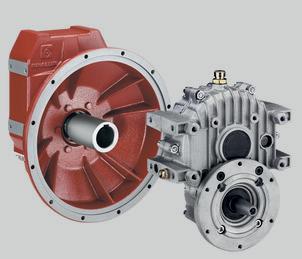

The JCB 542-70S Loadall is the ultimate tool for a wide range of tasks with unmatched versatility. This isn’t just a telehandler; it’s an investment in your farm’s efficiency and output.

Why buy the 542-70S?

• Increased Productivity: Move more, lift higher, and stack smarter with 4.2-tonne lift capacity and 7-meter reach.

• Enhanced Safety: Superior visibility, stability, and control keeping your operators safe and your operations running smoothly.

• Fuel Efficiency: Advanced engine technology and hydraulics mean more work for less fuel.

• JCB Reliability: Backed by industry-leading support and parts availability, ensuring your machine is always ready for work.

D

Don’t compromise on performance, speak to your nearest JCB CEA dealership today!

Pic caption: Hort Connections is Australia’s premier horticulture industry event. Image: Prime Creative Media

A freshly signed partnership will ensure Australia’s premier horticulture industry event continues to feature the latest research and innovation for growers

Hort Innovation has signed a sixyear agreement to continue as Hort Connections’ Principal Convention Partner until 2031, supporting development and innovation in the horticulture industry.

The partnership is dedicated to continuing industry growth, leadership development, and unlocking and demonstrating new investments and innovation to the sector.

Hort Connections – which took place in Brisbane from June 4-6 – is Australia’s premier horticulture industry event run by AUSVEG and the International Fresh Produce Association Australia-New Zealand (IFPA ANZ).

It is considered a must-attend event for key decision-makers across the fresh produce supply chain and it provides a pow-

With only days until this year’s Tractor and Machinery Association conference, time is running out to secure your ticket and get involved

erful platform to bring industry leaders together to learn, grow, and connect due to the event’s scale and reputation.

Hort Innovation CEO Brett Fi eld says Hort Connections has a signi cant impact, and Hort Innovation is committed to further strengthening its involvement to ensure it continues to drive leadership in the industry.

“Hort Connections is the must-go event in Australian horticulture, actively engaging growers and industry stakeholders to foster direct communication and knowledge sharing,” he says.

“It o ers an opportunity for growers and stakeholders to engage in discussions that drive real and positive change across the sector.

“Together with AUSVEG and IFPA ANZ we hope to promote the exchange

Everything from careers awareness to mental health will be hot topics at this year’s Tractor and Machinery Association conference.

Melbourne – and speci cally the Hyatt Essendon Fields – will host the conference on Thursday July 24 as delegates gather to answer the question ‘are we future ready?’.

Ticket sales are strong for this year’s conference, which looks to surpass last year’s record-breaking attendance at the Melbourne Cricket Ground.

One major aspect of the conference will be the rst look at key statistics related to the TMA’s industry-wide Careers Awareness Campaign.

Running since the beginning of the year, the TMA says the campaign’s rst phase has reached more than 10 million social media and game users across Australia in an e ort to broaden awareness of careers and opportunities in the industry.

A recently announced speaker is cybersecurity expert Jem Richards from Red Bear, who will discuss the critical issues of cybersecurity and arti cial intelligence in agriculture.

of knowledge by showcasing grower levy-funded investments in research, development, and marketing, with the shared goal of presenting results, enhancing industry capabilities and encouraging growth and collaboration.”

This year’s event saw a packed, threeday agenda with speakers from across the horticulture supply chain, industry booths, and side events for engaging network opportunities.

AUSVEG CEO Michael Coote says the long-term partnership will have a major positive impact on the horticulture sector, as well as the future evolution of Hort Connections.

“Hort Innovation plays a crucial role in the horticulture industry through investment in research, development and marketing programs that bene t Australia’s fresh produce growers, and we welcome this ongoing support for Hort Connections,” he says.

“Building on Hort Innovation’s previous long-standing commitment to Hort Connections, this partnership will ensure the event continues to feature the latest research and innovation for growers, at a time when exposure to productivity-enhancing advances and initiatives is critical to the long-term viability of the sector.”

One of the conference’s high-pro le speakers is former Australian cricketer Brad Hogg, who is also the national ambassador for Grain Producers Australia’s Farmer Mates mental health program, and who will discuss the importance of mental health in rural communities.

Rabobank’s agricultural and environmental lead Lachlan Monsbourgh will discuss the future of farming and the role of data, particularly in an agricultural lending context.

Se ons founder Robbie Se ons will also speak under the heading of ‘primed for progress: innovation, growth, and opportunity in agriculture’, while there will also be an economic update and conversations around precision agriculture and marketing.

This annual event is an important opportunity for dealers, manufacturers, advisors and agricultural stakeholders to engage with the industry and learn more about the challenges facing Australian agriculture – plus their solutions.

Tickets can be purchased online by visiting tma.asn.au/2025-annual-conference/

Vegetable growers will be o ered Australian- rst demonstrations of global agtech with the return of the Gatton Agtech Showcase in Queensland

The Department of Primary Industries (DPI) and Hort Innovation have announced the return of the Gatton Agtech Showcase at the Gatton Smart Farm, taking place October 15-16.

Vegetable growers will have the opportunity to see new global agtech in action for the rst time on Australian soil and talk to manufacturers about how these technologies can help their businesses be more productive and pro table.

Attendees will also experience Australian- rst demonstrations of agtech options including the Ecorobotix ARA Smart Sprayer and a range of protected cropping technologies.

DPI director of vegetables, systems and supply chains Ian Layden says the event – delivered as part of the Queensland Smart Farm initiative – was created to ll a gap in the market for automated and

practical on-farm solutions.

“We are thrilled to announce the return of the Gatton Agtech Showcase for 2025, particularly o the back of the massive success of the 2023 event,” Layden says.

“The live demonstration in 2023 attracted 800 people, including 200 growers from across Australia, with feedback indicating growers and technology companies see value in an interactive regional event that demonstrates the technologies in real-world conditions.

“Our Gatton Smart Farm is the perfect location to host an event like this, providing a unique opportunity to grow crops in the eld and under protected cropping and apply technological solutions to those environments. Our goal is to nd the best agtech for Australian growers, with this year’s showcase set to highlight

5 reviews 400% more light 3 YEAR warranty Premium LED lights, custom designed to your tractor.

those technologies in action.”

Hort Innovation’s research and development manager Tom McCue says the 2025 showcase would further strengthen Australia’s position on the global agtech map.

“Through this program, we’re seeing international manufacturers starting to seriously consider Australia as a key market for their technology – not just because of the scale of our industry, but because events like the Gatton Agtech Showcase create a platform for direct engagement with growers,” McCue says.

“For manufacturers, this is a rare opportunity to understand the unique challenges of Australian farming and to shape their products to suit local conditions. For growers, it’s about seeing this technology working in the paddock and having real conversations about whether it ts their operation.”

The On-Farm Drought Infrastructure Grants program has opened for Victorian farmers. Image: dudlajzov/ stock.adobe.com

The Victorian government has opened its On-Farm Drought Infrastructure Grants program statewide, with updated guidelines based on farmer feedback and expanded eligible activities.

The program, managed by Rural Finance, makes co-contribution grants of $5,000 available for all primary producers in Victoria, with $10,000 available for eligible farmers in south-west Victoria and parts of West Wimmera to help those who have been in drought longer.

Eligible activities under the grant program now include pasture re-establishment and water carting – re ecting the wide-ranging pressures farmers are facing

The Look Over The Farm Gate farmer mental health and wellbeing program is also now open, bringing communities together and supporting farmers and farming families under stress.

A variety of drought support packages are now available to Victorian farmers, as they battle some of the driest conditions on record

and ensuring support reaches where it is needed most.

Agriculture Victoria’s technical decision-making services are also now live, o ering the state’s farmers access to a free one-on-one consultation with a farm advisor.

Farm advisors can help to make the di cult decisions primary producers are facing, particularly due to fodder and water shortages.

Agriculture Victoria has engaged 60 consultancy businesses within the state, including more than 90 individual farm advisors, who will assist farmers to take action to develop a drought action management plan.

Managed by the National Centre for Farmer Health on behalf of the government, the program will provide grants of up to $5,000 for community-led events that promote social connection and mental health awareness.

“We are listening to what farmers are telling us and tailoring our support to meet their needs,” Victorian agriculture minister Ros Spence says.

“It’s so important that farmers and their families know they are not alone, which is why the Look Over The Farm Gate program gives them the opportunity to come together with their community and connect with their neighbours.”

For more information about available drought support, visit agriculture.vic.gov.au/dryseasons or call 136 186.

Research was conducted on farms with three di erent soil types. Image: Andrii Zastrozhnov/stock.adobe.com

incomes have been estimated with and without carbon values.

Data was collected through crop yields and a survey of these farmers.

Organic fertilisers have the potential to improve soil health when combined with chemical variations, according to new research from Charles Sturt University

Charles Sturt University has released new research outlining fertiliser alternatives for farmers, which will contribute to sustainability and pro tability.

The research titled ‘Assessing economic feasibility and bene ts of adopting highgrade organic fertilisers recovered from waste streams’ explores on-farm variable inputs in southern New South Wales to establish the economic bene ts of the use of organic matter in agriculture.

It identi ed potential organic fertilisers

that farmers can use and assess their impacts on crop yields, soil health and associated co-bene ts. The results showed that organic fertilisers, when combined with inorganic (chemical) fertilisers, could be used as substitutes to solely using the nitrogen mineral fertilisers in growing crops, as these treatments sustained productivity while improving soil health.

Assessments were conducted on farms with three di erent soil types at Holbrook and Tamworth and, as a result, farmers net

“Organic fertilisers are increasingly being used in cropping systems to improve soil health and crop yields in Australia, however, their impact is complex and depends on a variety of factors, in particular their economic feasibility to use and any risk involved,” Charles Sturt University professor and study lead Richard Culas says.

“To estimate their impact, Agriculture Production System Simulator (APSIM) modelling was done.

“APSIM simulates crop growth, soil water movement, nutrient cycling, and soil organic carbon dynamics.

“The outcome of this project makes a signi cant contribution to the sustainability and pro tability of Australian agriculture by reducing the cost of inorganic fertiliser use and to produce more food with less environmental impact.

“The framework and tools developed from this project can help farmers and industry to assess the multiple nancial and environmental bene ts that the use of organic fertilisers can bring.”

Two Merlo TF50.8 telehandlers have proven a savvy purchase for New South Wales grain handling company AgConnex

Grain handlers often have different machinery needs to other agricultural sectors.

Moving the precious product quickly and safely while also ensuring it remains clean and dry means its choice of equipment is paramount.

For New South Wales-based AgConnex, a thorough and extensive search for the telehandlers which would steer the company forward ended with the purchase of two Merlo TF50.8T-170EEHF units from local dealer Franks Service Centre.

The carefully considered decision has proven to be a good one, with the telehandlers’ additional flexibility meaning multiple jobs can be completed with the one machine.

“The decision was about trying to get the right solution for our situation and we took months to spec these up and get them correct,” AgConnex operations manager David James says.

“Franks took that process very seriously and didn’t just try to sell us something off the shelf. We’ve been really happy with them and there are no complaints from the operators.”

The primary role of the Merlo telehandlers for AgConnex is loading grain trucks, with the two new purchases having completed approximately 150 and 200 hours of work each.

It is not simply a one-trick pony lift ing the grain though, as the grain is kept secure by weighted tarps which must be safely removed before unloading.

This is a busy process, James says, with two or three trucks often being loaded simultaneously, and it is imperative the machines can both keep up with the speed required and remain free from breakdowns.

By working with Matteo Scappucci from Franks Service Centre during the design process on some further customisations, AgConnex now has telehandlers which also excel during the adding and removal of the protective tarps.

“Matteo worked with us pretty closely to come up with the machine that was the right size and spec, and we actually designed the buckets specifically to do the job we wanted,” James says.

“We use the telehandlers to open and close our bunker tarps and we can do that

safely with the hook they’ve supplied with the machine.

“Then we use it for lift ing the weights off our tarps, and again we’re doing that safely with a properly designed tool for the job in this hydraulic grab as opposed to what a lot of people do - and what we used to dowhich was just using a single pallet fork.

“Picking up the weights with either pallet forks or a chain is pretty dangerous, so that has been revolutionary for us.

“We also move a bit of sand for weighting down our tarps as well, so the telehandlers have got a lot of versatility.”

Finding one machine which can complete all these parts of the grain handling process but also excel in the primary job of loading trucks was the reason why AgConnex undertook such an extensive search.

Getting the loading efficiency of a wheel loader, along with the additional tasks only a telehandler can complete, means James is happy with the investment.

“Its main role is loading trucks and that relies on fast cycling and efficient loading, so it has to be fast, safe and efficient. We’re getting the same sort of loading efficiency out of those machines then we are out of a 16-tonne wheel loader,” he says.

“We’ve paid a fair bit less money and have a lot more flexibility with being able to drop the bucket, put a GP bucket on and move sand, or put pallet forks on occasionally.

“It also has a high travel speed, so when we move from one loading point we’ll often be loading two or three trucks simultaneously, so it’s very important that we can cover 500 metres or a kilometre quickly as well.”

Merlo’s TF50.8 is among the highest capacity of the Italian manufacturer’s Turbofarmer series.

Within the TF50.8 range are four different confi gurations, each of which offer slightly different maximum loading capacities and overall machine weights.

AgConnex has the TF50.8T-170EEHF, which is a 10-tonne unit that features a 170hp (125kW) engine, 5 tonne maximum load capacity, 7.9m maximum lift height and 4.2m maximum reach – along with a 40km/h maximum travel speed.

All Merlo telehandlers are built on the company’s four pillars of comfort, efficiency, performance and safety, with

features including boom suspension and an air-conditioned cabin.

The TF50.8 range has the ASCS safety system which adjusts the speed and maximum extent of the movements based on the attachments in use, load being handled and its position – therefore eliminating the risk of the unit overturning.

James also highlights frame levelling as a “luxury” feature which has been beneficial to AgConnex, while the presence of scales as standard rather than an optional extra was an “attractive” feature that swayed the decision towards Merlo.

He also says the high hydraulic flow, which is capable of delivering between 160-250L/min, has been advantageous during the telehandlers’ daily use – as has the crawl function which enables precise movement.

“The high flowing hydraulic spec has been very handy for being able to cycle

fast again and carry out multiple operations at the same time,” he says.

“We’ve also used the machine to roll up our tarps on a hydraulic tarp roller.

“Having the crawl function built into the machine means we can operate the hydraulics at full flow and regulate the speed of the machine to suit the rolling process.”

AgConnex had previously hired machinery from Franks Service Centre but the Merlo telehandlers marked the company’s first purchase with the Griffith-based dealer, although James had previous personal experience with Franks when working at a different business.

In addition to getting a product they have been happy with, AgConnex have also now further developed the relation-

ship with Franks – which is Merlo’s longest serving Australian dealer.

“They’ve been very good to work with on the hire side of things and it was a very positive sale process,” James says.

“We were looking pretty closely at another make and I would say the decision to choose Merlo came down partly to value for money, but also very high in our matrix was the service and the relationship with the dealer.

“They’ve been right on to any teething issues and have been very proactive to make sure things were sorted to our satisfaction and in a timely fashion, so we couldn’t be happier.”

Merlo’s full product range, including the TF50.8, can be viewed online at www.merlo.com/aus/en - while Franks Service Centre can be contacted via www.fscforklifts.com.au

ROBUST | FLEXIBLE | RELIABLE

Celebrating both Australian and global milestones in 2025, Mahindra has no intention of slowing down in its quest to remain a tractor powerhouse

From humble beginnings as a steel trading company in India to becoming the world’s biggest selling tractor brand by volume, Mahindra’s journey has been an eventful one.

With the company celebrating its 80th anniversary in 2025 – the same year it marks two decades selling tractors to the Australian market – it is timely to look at the brand’s evolution in order to understand why local farmers have joined those from around the world in trusting Mahindra tractors.

Following Mahindra’s initial journey in steel trading, it quickly pivoted to both tractor and vehicle manufacturing.

The company signed a joint venture with International Harvester in 1963 and this led to the iconic Mahindra B-275 being developed, which was a move that cemented the brand’s agricultural legacy.

From there, Mahindra marked production of its 100,000th tractor in 1981 before another signi cant event occurred two years later.

This was when Mahindra became the largest tractor seller in its native India – a title it has maintained ever since.

Mahindra then sold its one millionth

tractor in 2003, before continuing to grow signi cantly in the years since.

In 2010 came the brand’s ‘pièce de resistance’ – when it became the world’s largest tractor manufacturer by volume.

Another signi cant point in the brand’s evolution came in 2007, when it was awarded the coveted Japan Quality Medal for “excellence in customer focus, overall quality and business processes”, also becoming the rst tractor company to receive this honour.

Now, Mahindra has manufacturing and assembly operations in more than eight countries, sells to over 100 global markets and has ticked over 2.1 million tractors sold worldwide during its history.

For its most recent scal year which nished on March 31, Mahindra sold 424,641 tractors - its record for the most ever.

Mahindra’s initial foray into the Australian market took place in 1990, but it was the rst structured presence in 2005 that is considered the brand’s local debut.

Initially targeting the Queensland and New South Wales markets, Mahindra

assembled its tractors in Brisbane before expanding across the country.

Mahindra Australia now operates as a wholly owned subsidiary, with Brisbane remaining the brand’s national headquarters and being supported by a dealer network across regional and rural hubs.

Mahindra says this steady growth of the brand’s Australian operations can be credited to adapting to local needs, particularly focusing on reliability, a ordability and a er-sales support.

Ongoing research and development ensures new tractor models meet the evolving needs of Australian agriculture, speci cally around technology, sustainability and ease of maintenance.

Mahindra Australia has also made a recent investment in its people – employing Matt Kruger, who boasts considerable experience in the farming sector, as its agricultural sales manager late last year.

This journey of growth throughout the company’s history speaks to Mahindra’s ongoing ambitions, something which will hold it in good stead to keep developing

within the Australian market.

An expansion into utility vehicles and plans for electric models re ect a global strategy for growth and innovation, the company says, with a clear goal to drive advances in farm productivity and sustainability, both locally and globally.

Any manufacturer’s success comes down to whether it can provide quality, reliable tractors which serve the needs of Australian farmers in the tough conditions they work in.

For Mahindra – which describes its tractors as being “synonymous with durability, a ordability, and farmer- rst engineering” – the past two decades have proven its products are well suited to these Australian needs.

Robust, cost-e ective and prioritising reliability in all of its units, Mahindra has carved a particular niche in the 30hp to 90hp segment of the Australian market.

This means everybody from hobby farmers through to graziers have benetted from Mahindra tractors, with these customers particularly being drawn to the simplicity and reliability provided.

Unlike the broadacre market, where tractors can easily work for more than 14 hours every day and the most advanced technology is imperative, Mahindra has instead chosen to target customers who do not work their tractors as hard on a daily basis but who still need something which will reliably do the job every time.

“Mahindra tractors are the type which you can turn on for a few hours and not really have to do much preparation with. You turn it o , and then when you next jump on it’s good to go and ready to work for you again,” Kruger says.

“In that market segment, we think

we’re very well priced relative to some of the competitors.

“For customers that are looking for a smaller or utility tractor, these o er the simplicity and reliability needed.”

Highlights of Mahindra’s range for the hobby farmer market include the 4025 and 3650.

“The 4025 is a very simple tractor at a price point we feel is well suited for customers that really like simplicity and probably like to work on things themselves,” Kruger says.

“This is the sort of tractor that anyone with a bit of mechanical knowledge could work on.”

The 4025 has a 40hp engine, which steps up to 50hp on the 3650 along with also o ering some additional ‘creature comforts’ for operators.

In the utility and grazier market, Kruger highlights the 7580 and 7590 tractors – which o er 80hp and 90hp engines respectively.

“These are the tractors I feel are best suited to those grazier and utility markets,” he says.

“From a price point, they’re also considerably cheaper compared to anything else on the market between 75 and 90 horsepower and they’re just as good. I think they’re a little gem at the moment.”

Two decades after establishing itself in the Australian market, Mahindra has become renowned for supplying the reliable and rugged tractors which farmers in its native India have known about for more than half a century.

With an eye on the future, Mahindra

says its vision for Australia “includes deeper market penetration, new product launches, and a continued focus on supporting rural communities” while also ensuring its tractor development is meeting the needs of the market sectors it targets.

With an ever-growing Australian presence and backing from an established international powerhouse, the brand’s local future looks to be as solid as the products themselves.

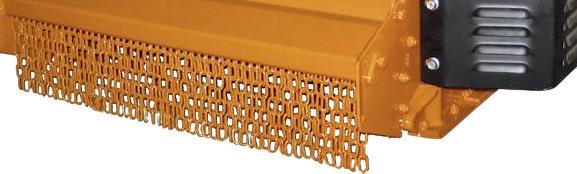

So impressed with a Hercules wheel loader from Hercules Machinery Group, Burrows Plant Hire has become a key point of contact for farmers looking to purchase

Having versatile machinery is always going to be handy, as it increases the number of jobs you can take on.

Wheel loaders can be seen as the pinnacle of machine versatility, suited to not only agricultural applications, but also other sectors including civil construction, quarrying, municipal works and waste management – to name a few.

Peter Burrows of Burrows Plant Hire can attest to this, having been thrilled with the performance of his Hercules loader from Hercules Machinery Group (HMG) –formerly known as Brisbane Mini

Excavator Sales – in local council work.

He’s such an advocate for it that HMG o en directs potential customers to call Peter for an in-real-time review of the Hercules loader, and more o en than not, they tend to be farmers.

“The best part of the Hercules loader is that it’s very much a mechanical loader with very simple electrics,” Peter says.

“It’s not a complicated machine – there’s not a lot of components that have the potential to break down, which is well suited to those in the agricultural industry where they’re o en isolated from a dealer.

“In the odd chance they do have an issue, most mechanics will be able to work on these loaders without an issue.”

The seed for Burrows Plant Hire was planted more than three decades ago, when Peter was working for his stepfather’s own civil company.

Using the experience he gained, Peter founded Burrows Plant Hire in 1996 and has been running it ever since.

Based on the Sunshine Coast, the business mainly serves local governments

and councils, o ering a variety of machinery, including excavators, bulldozers, compact track loaders, skid steers, and wheel loaders.

One of these is a 12-tonne Hercules H1250-2 wheel loader, powered by a 180hp (132.4kW) genuine Cummins engine.

“It’s a perfect t for us and the council work it’s doing,” Peter says.

“It’s a good size, has good clearance, heaps of horsepower and it’ll re up every morning without a worry – I can’t fault it.”

Being used to load a 10 cubic metre tip truck, the Hercules wheel loader makes use of a 1.7 cubic metre GP bucket and a 4-tonne load capacity – two key stand outs.

In addition, it comes as standard with a hydraulic quick hitch, an air-conditioned cabin, and a reverse camera.

HMG has found these models to be quite popular in the beef industry and for the all-round use on rural properties, thriving in everything from moving hay to clearing country, reinforcing the versatility the machine provides.

Many years ago, Peter originally procured HMG’s 7-tonne Hercules H-700 wheel loader, marking the beginning of an ongoing relationship.

“I had always seen their ads and they

always stood out to me,” Peter says.

“They have always been prevalent in the machinery literatures, and they have good gear.”

Before purchasing the H1250 model, Peter was using a ‘lower quality’ loader

HMG has found these models to be popular in a variety of industries

from another brand. Looking to get a larger bucket for this loader, he instead came home with a larger machine.

“I spoke to HMG sales representative Ross Ricca for the part but ended up buying the loader,” he says.

“I decided I needed a bigger and a better-quality machine.”

Owning the Hercules H1250-2 wheel loader for about four years now, Peter says it has been a signi cant upgrade on the other-branded loader.

In his own words, the ‘lower quality’ loader just wasn’t doing the same job that his Hercules is currently doing.

If it wasn’t for the long-lasting relationship with HMG however, Peter may have had to settle for less.

HMG’s fully dedicated spare parts and service division has also been critical for Peter, having bought parts for his excavators and relying on their trustworthy a ersales support.

In the rare cases that he’s had any machine issues, Peter says HMG has solved the problem ‘straight away with no questions asked’.

“I couldn’t fault them as a company, they

supply a very good service,” he says.

“The quality for the price is really good – Hercules is great value for money. The brand also runs good components like the Cummins engines.”

Customers can rest assured they will be backed by HMG’s comprehensive warranty of 12 months parts and labour, therea er 12 months parts only (whichever comes rst).

Counting to actively advocate Hercules machinery, Peter says it comes down to

his relationship with HMG.

“Ross is o en getting farmers to call me about the wheel loader, so I’ll happily tell them how useful it has been for me,” he says.

“I don’t mind that at all, because I want to help him out with the product and ask him to return serve when I need help.”

For more information on the Hercules H1250-2 wheel loader, visit herculesmachinerygroup.com.au or call (07) 3807 4333.

A Shantui DH24-C3 customised with a variety of attachments, including a stick rake and heavy-duty forestry protection guards. Image: Cobra

Cobra Equipment’s customised Shantui machinery continues to be popular with rural contractors and landholders, evidenced by sales of bulldozers tted with stick rakes and tree spears

Procuring custom-built equipment is a highly bene cial way of ensuring your machine is built to thrive in the speci c conditions thrown at it.

For Shantui machinery authorised distributor and dealer Cobra Equipment Sales, customisation is becoming an increasingly popular option within its customer network.

Cobra Equipment founder George Nason says the option to customise machinery and equipment is key for many rural contractors and landowners.

“I’ve been in and around the industry for a very long time, so I have a good understanding of what our customer base wants,” Nason says.

“We’re starting to deal with more people that want extra options on their equipment, so we’re o ering customisation.”

Various recent sales of the Shantui DH17-C3 bulldozer models are evidence of Cobra’s customisation ability, with many additional options able to be integrated onto the machine at the speci c request of the business’ customers.

Weighing in at just over 19.2 tonnes with three shank rear rippers and boasting a 152kW (204hp) fuel-e cient Weichai engine, one of these DH17-C3 models has been tted with a 16 (4.9m) stick rake, tree spear and additional forestry protection to take on hilly country on a farmer’s property in Sarina, south of Mackay, Queensland.

These additional options provided by Cobra will boost the bulldozer’s ability to clear scrub and knock down vegetation regrowth.

“When he knocks down the regrowth, he

can rake it into a windrow and then reseed the paddock once it’s cleared,” Nason says.

“Most of the machines we’re selling have got the extra forestry protection to protect the cabin in rough terrain.”

Nason adds the stick rake option has been popular with many rural contractors and farmers, as Cobra has the capacity to source them from a workshop that custom-builds.

Making use of a ‘walk-in’ design, Nason says an extra bene t of the stick rake is that it can be easily attached.

“The stick rake is designed to stand up by itself, so you can walk the dozer in behind it and pick it up with the blade,” he says.

“Depending on the terrain, the stick rakes can also be built di erently.

“In atter and more open country the rakes can be wider.”

For this reason, another customised

DH17-C3 model – sold to a customer in the central-west Queensland town of Alpha – is making use of a wider 20 (6.1m) stick rake.

Working in atter terrain, this dozer also has a tree spear and 600mm wide track plates, which Nason says gives the machine more feet on the ground.

Standard features on the DH17-C3 dozer include 510mm track shoes and track guard plates, engine side guards, a battery isolated lockout switch, warning lights and LED lights, an air-conditioned ROPS cabin with radio, a suspension seat and a re extinguisher.

Star of the show

Cobra recently took the opportunity to display one of its DH17-C3 models at one of Queensland’s largest agricultural machinery eld days, FarmFest.

Held from June 3–5 in Toowoomba, Nason says the showcase of the machine helped Cobra gain greater exposure to many potential customers and explain its customisation capability.

The customised machines o en begin with an initial inquiry, where Nason will have a conversation with the customer to work out what speci c requirements that are needed on their machine.

Where possible, he aims to meet his customers face-to-face a er these conversations, and by this time Cobra has already informed its factory what is speci cally required on the machine.

With many customisable options available, Cobra o ers a customer-centric approach to supplying machinery.

A double warranty that is factory supported but honoured and supported

by Cobra directly can instil con dence in Shantui purchasers that they will have the ongoing one-on-one care provided by a company operating since 2005.

“We’re now doing a few machines with remote hydraulics, so our customers can use hydraulics to li attachments o the ground such as disc ploughs,” Nason says.

“Other customisable features o ered include reverse cameras, air suspension seats. We do SALT [sealed and lubricated track chains], alligator links, wider and heavier track plates, and heavier duty blades.

“There’s quite a few options that we can provide to tailor-make them to the customer’s requirement.”

For more information, visit cobraequipmentsales.com.au or call 07 3379 9419.

The decision to stick with JCB’s latest Fastrac tractors at upgrade time was a no-brainer for one North Queensland sugar cane farmer

Ever since JCB’s latest iteration of its Fastrac tractors hit the Australian market, two words have consistently been cited by customers using them – comfort and speed.

Complete with the new iCON control suite, the upgrades have drawn many new local customers towards JCB while also providing a tempting catalyst for existing Fastrac owners to make the shi .

One of these dyed-in-the-wool Fastrac owners is North Queensland sugar cane grower Shane Kattenberg, who did not think twice about sticking with JCB when it came time to upgrade his existing Fastracs.

Kattenberg owned two Fastrac 3230 tractors, which had completed about 19,000 hours of work, before choosing to upgrade these to Fastrac 4420 iCON models through local dealer Honeycombes Sales & Service.

JCB is appealing to large-scale farmers across the country with its tractors, knowing that operators who spend long hours inside the cabin each day need to travel long distances quickly and remain

comfortable while doing so.

With a maximum travel speed of 60km/h on the 4420 model (and a 70km/h maximum speed on its larger 8330 model),

JCB has de nitely put the ‘fast’ into Fastrac and this means valuable time can be saved when travelling between locations.

“There are obviously some people that cover a lot more distance than us, but for what we’re doing you do travel more than you would in a conventional tractor around the farm,” Kattenberg says.

“We’re hauling sugar cane with them and they typically go for 10 or 11 hours every day, seven days a week.

“We start at about three in the morning and that goes for six months basically.

“They just keep going and going, and that’s what they seem to be good at.”

JCB’s Fastrac iCON is available in two models – the 4220 and 8330.

The 4220 – which Kattenberg owns two of – provides a 235hp (175kW) engine, o ers 1,000Nm of torque and has an 8,000kg rear li capacity.

This steps up to a 348hp (260kW) engine, 1,450Nm of torque and a 10,000kg rear li capacity on the 8330 Fastrac.

This means farmers can trust both tractors will comfortably handle even the heaviest implements, while a 50-50 weight distribution helps to optimise the tractive performance in the eld.

JCB’s recent addition of the iCON concept means users now have a technology-packed control suite to make their days easier.

This intuitive system includes a 30cm touch-screen display, a new armrest control and simplied operation of the joystick.

One example of this is that farmers now increase the tractor’s speed by pushing the joystick forward rather than tapping it to the right.

Farmers can also create a bespoke experience around their individual needs, as the main joystick o ers ve con gurable buttons and a roller thumb control, while the second joystick has another four congurable buttons and a rocker switch.

Being able to allocate virtually any function to each of these buttons means the us-

er-friendliness increases signi cantly and farmers can design the tractor’s operation around what suits them.

Many of the tractors’ other features – including a full-length rigid chassis, dual-line steering, and twin-caliper ABS disc brakes – are standard to both the 4220 and 8330 models.

The 4220 is the only one to o er fourwheel steering, something which JCB says increases its agility in settings such as vegetable farming and row cropping where the need to turn sharply is more important.

For a farmer like Kattenberg, all these features combine to create a tractor which is meeting his needs.

“The main reasons we like them are the speed they travel at and how comfortable a ride they are,” he says.

“It’s just the whole package really - the transmission’s good and it has four-wheel suspension which the old ones had as well.

“Another bene t is the fact that there

are no gears anymore – they’re a CVT transmission so the drivers aren’t having to change gears 100 times a day.

“You don’t have to push the clutch at all and it’s just so easy to drive.”

Kattenberg’s previous experience with the 3230 Fastracs means he can trust in their reliability, even in di cult conditions.

“These tractors don’t have the easiest life – they get driven reasonably hard and the

previous tractors had done 19,000 hours, which is quite a lot for a tractor, and we had no major problems,” he says.

“The transmissions haven’t been touched, the engines haven’t been touched, mechanically they were still good and we didn’t have any big breakdowns in those 19,000 hours.”

Kattenberg’s loyalty towards JCB – which has been based on the positive previous

experience – means he has invested in a style of storage bin that is designed around the Fastrac.

“Our bins are designed to suit that particular tractor now, so for us to change to a di erent brand of tractor we would have to change our bins as well that go on the back,” he says.

“That’s why we built the bins with the JCB though – because we like the con g-

uration and how they hook up, how they turn and everything.”

Kattenberg is based in the Atherton Tablelands in Far North Queensland and dealt with Honeycombes’ Tolga branch for his JCB purchase.

His customer experience here was positive, already knowing the dealership through other purchases, and he is excited about the long-term potential of his 4220 Fastracs.

“It was all good because we deal a lot of other stu through Honeycombes, so it was good being able to just buy a JCB o the dealer that we’re used to dealing with,” he says.

“We’ve only done probably 150 hours in them since we bought them, but Honeycombes have been good and have been straight out onto it whenever there have been any niggly issues – which you get with all tractors.

“I think they’ll have a good resale value too because they’re a fairly luxurious tractor compared to other ones.”

Having recently celebrating its 100th anniversary, mixed cropping business Moira Farming has found its perfect balance of growing fresh produce and cotton

As a fi ft h-generation farmer living on a rural property all his life, Mitch Brimblecombe was destined to take over the reins of his family’s operation – Moira Farming.

The family-owned and operated mixed cropping farm resides in Queensland’s Lockyer Valley, which is affectionally known as Australia’s salad bowl, due to the significant amount of fresh produce grown in the area.

Moira Farming is no different, growing various vegetables including red, white and brown onions, carrots, green beans, sweetcorn, beetroot varieties, and pumpkin. Its point of difference, however, is that it also grows cotton.

Now as the farm manager for Moira Farming and as the fourth generation of his family to work on the current acreage – and the fi ft h generation overall – Brimblecombe says growing cotton has become integral for the family’s operation.

“Our farm has got a lot of salty bore water, so we’re quite dependent on freshwater dams to irrigate our vegetables,” he says.

“When we faced drought and the dams were empty, we needed another growing option, so we looked back in our history for solutions.

“My grandpa successfully grew cotton many years ago before it was genetically modified but phased out of it because of the amount of spraying that was needed to combat Heliothis and other pests – it wasn’t economical.

“When cotton became genetically modified so Heliothis would die if they ate it, we decided to give it another crack.”

Having originated as a horticultural grower, Brimblecombe says Moira Farming’s cotton has grown to take up around 70 per cent of its 2,200 acres.

While not a lot of the land is used to grow veggies anymore, they are still a significant source of revenue for Moira Farming –making up approximately 50 per cent of its turnover. Brimblecombe says this is because vegetables have a lot higher turnover per hectare compared to cotton.

However, one of the issues the business has been dealing with is the daily price fluctuations of vegetables.

“They can be worth something today and nothing tomorrow and it’s also very domestic orientated unless you’ve got some decent export markets,” Brimblecombe says.

“This is not an issue with cotton, as it is a globally traded commodity.”

He adds cotton is also less labour intensive than growing vegetables, with the bonus of being able to sell in advance without worrying it will perish, making it a safer growing investment.

“If you cut some lettuce or broccoli, the next day it’s got to be packed and delivered, but cotton can sit in the farm or a shed and offers more flexibility,” he says.

“Cotton has given us another growing option – we’ve really enjoyed it, and it’s worked quite well for us.”

Now that Moira Farming doesn’t have to combat pests like it once did, Brimblecombe says it has made growing cotton much easier.

“The genetic technology is very impressive in cotton, and it’s really revolutionised the industry – we don’t even notice the difference anymore,” he says.

Vegetables are obviously still a large part of the farming operation – given the 50 per cent turnover –and while the market can be volatile, Brimblecombe says he still very much enjoys growing them.

Compared to other horticultural farming businesses though, Moira Farming doesn’t encompass a packing shed, with Brimblecombe emphasising the business is a grower for vegetable farming suppliers.

“Being a grower really suits us compared to having to constantly supply and plant half an acre a week or twice a week,” he says.

“That doesn’t really suit our farm or our system.”

A small workforce of around eight on-farm staff is in every day, with harvest periods often requiring casual and backpacker labour.

Of the 2,200 acres of farmland, only 1,200 are owned by Moira Farming, with the rest being leased from other farms – a deliberate approach to its growing strategy.

Since the area is prone to flooding, Brim-

blecombe says many other growers don’t want to take the risk of growing vegetables.

This presented the opportunity for Moira Farming to lease marginal fields and grow cotton instead, even if it gets flooded.

“You’re not going to pay big money and put veggies there, but you can pay a little bit less and grow cotton,” Brimblecombe says.

“Some of our marginal blocks got flooded earlier in the year, but we were still able to pick some of that cotton. There’ll be a 20 or 30 per cent yield penalty, but we will still pick it.

“We know that they will get flooded again but we’re happy to take a punt on them based on the low lease price.”

Although Moira Farming’s salty bore water can be pain, the business has found it to be handy irrigating the cotton, only if it doesn’t touch the leaves.

On the other hand, vegetables aren’t tolerant to this, so Moira Farming has strategically built freshwater dams.

Two separate 900-megalitre capacity dams are used to pump water to four different smaller 20-megalitre pressure dams on-farm, enabling Moira to irrigate different sections of the farm at the same time.

2025 marks the 100th anniversary of Moira Farming, and the family business recently celebrated in style.

A large party was thrown, with it being the perfect occasion to uncover some of the business’ hidden machinery gems which had been locked away for many years.

“We got some of the old tractors out and restored them, including a John Deere that is on show now,” Brimblecombe says.

“Having been here for 100 years – that

was quite exciting for us as a family.

“While there’s not huge upside potential on cotton compared to horticulture, we’ve found a real happy spot at the moment for our business, our staff and our machinery, and we aim to keep making it work.”

Farms & Farm Machinery visited Moira Farming in an on-farm tour that formed part of this year’s Hort Connections exhibition in Brisbane in June.

Moira Farming’s cotton has grown to take up around 70 per cent of its 2,200 acres

Tractor sales were well down in the month of May, the Tractor and Machinery Association says, with weather conditions in multiple states having an impact

Agricultural tractor sales fell signi cantly in the month of May, down 23 per cent compared to the same month last year.

With around 800 tractors sold nationwide during the month, this represents one of the lowest points in the cycle for around ve years.

It also means the year-to-date gure sits at 12 per cent below the same time in 2024, with decreases being felt across all size ranges and all states.