With a full 8 year warranty as standard*

The Maxam Agrixtra range delivers minimal soil compaction, a comfortable ride and improved traction which surpasses all agricultural tyre expectations.

8-YEAR FARM TYRE WARRANTY

*Maxam farm tyres come with an 8-Year warranty against manufacturing defects. This offer includes a full tyre replacement warranty for the first 12 months and a pro-rata replacement warranty thereafter.

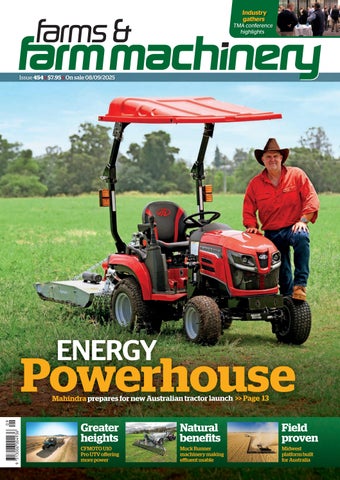

13 Mahindra prepares for new Australian tractor launch aimed at hobby farmers and lifestyle properties

6 Conference speaker looks ahead to agriculture in 2050

8 Highlights from Tractor & Machinery Association annual conference Farming

16 Experience helps Now Buildings tackle challenging rural shed projects

26 ifm teams up with Goldacres for display systems

59 Women in Horticulture award winner Melita Jurgens shares her story

20 Muck Runner helping farmers turn e uent into usable natural fertiliser

Editorial & Design

Editor Lincoln Bertelli

lincoln.bertelli@primecreative.com.au

Journalist Jackson Haddad

Contributors Trevor Whittington, Gary Northover

Design Danielle Harris, Jacqueline Buckmaster

Art Director Daz Woolley

Managing Editor Eugene Du y

Cover image Mahindra

24 Locally built Midwest platforms ready to deliver for farmers at harvest time

30 Elgra Engineering continuing to invest in manufacturing

32 Enorossi rakes a savvy choice for Victorian hay contractor

36 South Australian farmer backs Wattz lighting’s customer service

38 JCB backhoe’s versatility proving crucial for Queensland cattle farmer

42 Alliance tyres celebrating double milestone

45 CFMOTO UTV range proving popular with farmers

54 Australian researchers develop world- rst vaccine for foot-and-mouth

54 Beef industry urges biosecurity focus around American imports

55 CNH introduces retro ttable tractor steering system

55 Multi-state research project aims to boost canola yield

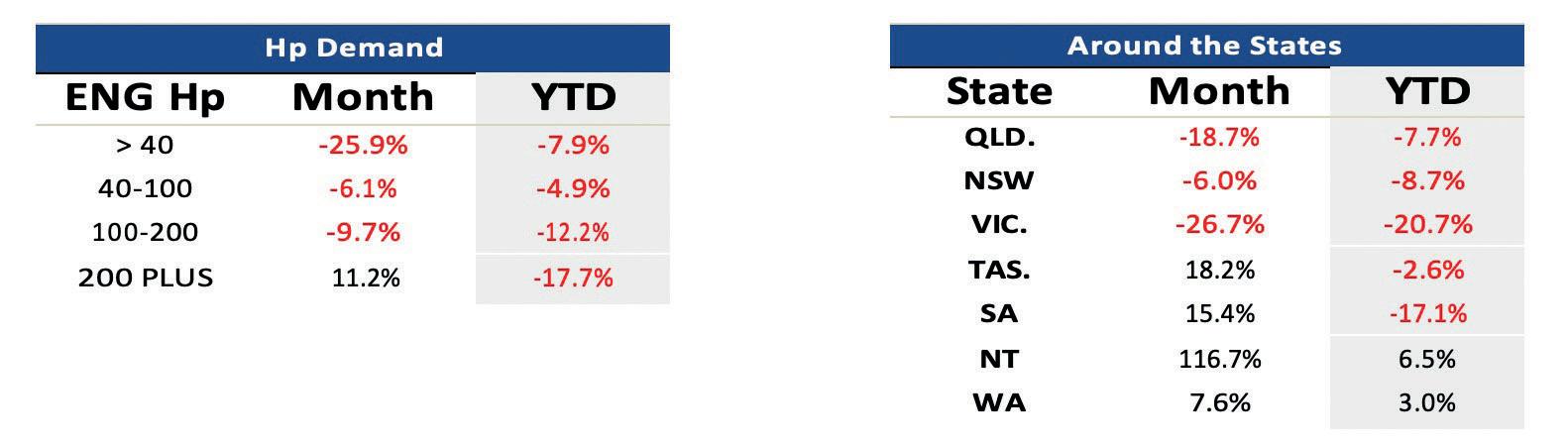

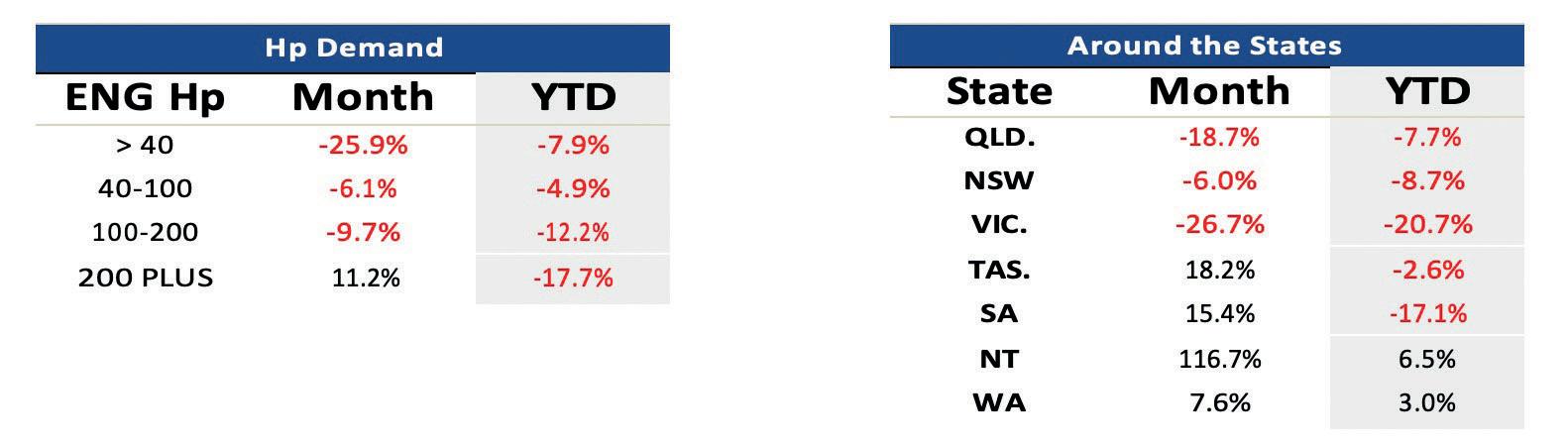

48 Tractor sales were down in July, data from the Tractor & Machinery Association shows, however large units and multiple states recorded an increase

50 WAFarmers CEO Trevor Whittington is calling for longterm drought preparedness to be front of mind across the state

4 Editor’s note

52 Calendar of upcoming events

74 List your item for sale!

New forkli operator training facility aims to address growing demand in WA

As events season rolls on for 2025, it was inspiring to be at the Tractor & Machinery Association’s annual conference in Melbourne.

A large crowd pondered the question “are we future ready?” and the day was lled with engaging presentations.

Among these was a prediction of how Australian and global agriculture may look in 2050 and we go into detail about this presentation, along with an overarching look at the day.

Plenty more event coverage is planned in our coming editions, which will include the highlights from AgQuip in Gunnedah, FutureAg in Melbourne, the National Renewables in Agriculture Conference in Bendigo and some pro les on award winners from this year’s Hort Connections in Brisbane – one of which also features in this edition.

At Farms & Farm Machinery, we aim to cover the length and breadth of the nation in our storytelling to represent the full spectrum of Australian agriculture.

This edition again pro les farmers from around the country.

We speak to a Queensland cattle farmer about the range of jobs his JCB 5CX Pro backhoe loader is completing, hear from a Victorian hay contractor about his pair of Enorossi rakes, and learn why a South Australian cattle farmer is such a big fan of Wattz lighting products.

Our cover story focuses on tractor manufacturer Mahindra, which has teased the launch of an exciting new tractor aimed at hobby farmers which is set to arrive next month.

There is a look at some of the signi cant projects undertaken by shed manufacturer Now

Buildings and how they help Australian farmers overcome design challenges.

We discuss the partnership between Victorian sprayer manufacturer Goldacres and tech company ifm.

Other highlights in this edition include a pro le on New South Wales business Elgra Engineering, which continues to grow a er decades of manufacturing post drivers and other important attachments.

We shine a spotlight on both the CFMoto U10 Pro UTV range and the well-established Alliance Tyres brand.

Finding solutions that lower costs are a goal of every farmer, so we also look at how the Samson and Pichon products from Muck Runner are helping to turn e uent into a natural fertiliser.

Our industry news section includes reaction to the recent American beef import decision, a potential vaccine for foot and mouth disease, plus a new retro ttable tech product for Case IH and New Holland tractors.

Lincoln Bertelli Editor

One speaker at the Tractor & Machinery Association’s 2025 conference explored what the future of farming could look like across the globe

It’s o en said that no two farms are the same due to the diverse nature of every operation.

Every farm is unique, whether that be through di ering soil and climate to varying agricultural practices and local ecosystems.

When it comes to observing these di erences in person, Victorian Lachlan Monsbourgh has seen it all.

Growing up in the Macedon Ranges, between Melbourne and Bendigo, Monsbourgh has spent more than 15 years overseas in distinct agricultural landscapes.

This has included working on a plantation and running a cocoa business in Papua New Guinea, providing land valuations in Mexico, delving into the world of sustainability in Indonesia and returning to the cocoa industry in West Africa.

Now based back in Victoria as the Agri and Environmental Lead for Rabobank, Monsbourgh was invited to the Tractor & Machinery Association’s 2025 conference to present his personal perspective – not

Monsbourgh believes that agricultural machinery will be around 50 per cent electrified in 2050. Image: scharfsinn86/stock.adobe.com

of Rabobank’s – of what the future of farming could hold and what it would look like in 2050.

“Across the globe, there is an unwavering transition from rural to urban populations,” he says.

“In 2023, I think it was the rst time in history that more than 50 per cent of the world’s population were living in urban environments.”

Monsbourgh says that trend is also occurring in Australia, with rural populations declining excluding major regional centres.

“There’s around 85,000 farmers in Australia, with 60,000 being commercial farmers,” he says.

“By 2050 I think there will be between 25,000 and 30,000 farmers based on the rate of consolidation over the last 50 years,” he says.

While these numbers may seem dire, Monsbourgh says the increasing

Lachlan Monsbourgh presented his personal perspective of what the future of farming could look like at the Tractor & Machinery Association’s 2025 conference. Image: Prime Creative Media

consolidation means larger farms are continuing to acquire land from smaller farms to grow themselves further.

Monsbourgh is of the view this will continue globally but at a much slower rate for smallholder environments such as in Africa and Asia. This may contribute to the African yield gap, which Monsbourgh says is 40-90 per cent lower than elsewhere in comparable crops.

“A lot of the population don’t have the same security over their land title that we do, which makes it very hard to invest when you don’t have the governance to back that up,” he says.

“If you don’t have security over your land, you don’t have the security to invest, so I don’t see the African yield gap correcting itself in the next 25 years.”

In terms of machinery, farming in 2050 is set to look very di erent to what is considered the norm now.

Farm equipment across the globe has always been heavily reliant on diesel-powered machinery, but as the world focuses on reducing emissions and achieving sustainability goals, there may a signicant shi in the agricultural industry.

Compared to other industries, Monsbourgh says the electrical transition has been slower in agriculture, but this may change with Australia having already set a bold goal of achieving net zero greenhouse gas emissions by 2050 and the rest of the world following suit with its own objectives.

“I believe that agricultural machinery will be around 50 per cent electri ed in 2050,” he says.

“I think this will be dominated by Asia,

with China already producing around 70 per cent of the market’s batteries.

“This will ow on to agricultural equipment, but whether farmers put trust in those brands will be a question that will need to be answered in future,” he says.

With many technological advancements yet to come, he adds farm data may be automated by 2050, driven by the requirements of local regulation and export markets.

Growth in R&D is certain to occur, which Monsbourgh says will lead to a greater understanding and acceptance of genetically modi ed crops. By 2050, he says that GM crops will be considered conventional and no longer the subject of ethical debate.

While some industry gures have predicted a collapse of food systems, Monsbourgh can’t see it happening. Instead, he believes certain staples will become niche and be replaced by others.

“Over the course of the last 150 years we’ve seen di erent staples come and go. Di erent crops will become more prevalent in di erent markets due to the changing climate, but it won’t collapse.

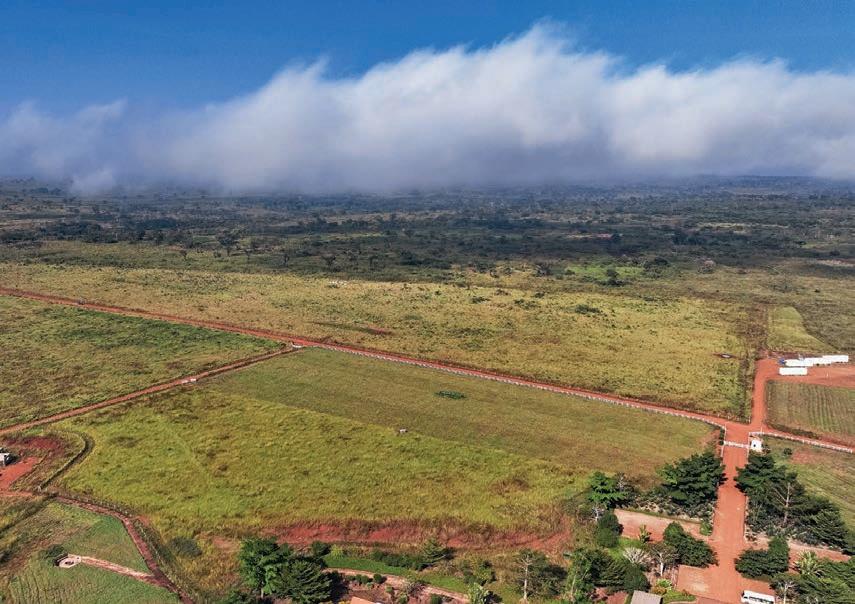

Monsbourgh says global food systems won’t collapse due to the agricultural potential of countries such as Angola. Image: Dave/stock. adobe.com

“Pricing will indicate whether farmers should plant something or not,” he says.

Another reason food systems aren’t likely to collapse is the untapped agricultural potential for various countries.

For example, Monsbourgh says Angola – a southwest African country above Namibia – has huge opportunity due to its vast amount of land suited to agriculture, its favourable climate, and its water resources.

Despite this, he says the country’s civil

war has le an abundance of landmines scattered throughout potential agricultural land and is a large reason why it has not taken up farming opportunities.

Once it is cleaned up and the land is deemed suitable, Angola could be transformed into a thriving agricultural market.

“This is why I don’t see a collapse of the global food system,” Monsbourgh says.

“If there is the demand, if there is the will, if there is the security, these opportunities will take place and people will invest.”

This spring, get the most out of your machinery with Shell Lubricants and enjoy rewards that work as hard as you*. Simply stock-up on Shell Rimula R4 L, Shell Rimula R4 X or Shell Spirax S4 TXM (as tabled below) from your participating distributor.

This year’s Tractor & Machinery Association conference was based around one pressing question – ‘are we future ready?’

Australia’s agricultural machinery industry gathered in Melbourne on July 24, with a range of speakers discussing the future and whether the nation was prepared for what lies ahead.

About 200 people were at the Hyatt Essendon Fields and heard presentations based on topics as broad as arti cial intelligence, mental health and the state of the economy.

The day’s opening speaker was Rabobank’s Lachlan Monsbourgh, who looked ahead to 2050 and what both Australian and global agriculture could expect.

One of the day’s highlights was a presentation from Se ons founder Robbie Se on, who spoke about innovation, growth and opportunity along with the importance of leadership.

She told Farms & Farm Machinery the

TMA was a “really important organisation” and described the conference as an annual opportunity to get together and discuss critical issues and opportunities that are facing the industry.

“As always, farmers are facing challenges like dry weather and global uncertainty with their products,” she said.

“Why Se ons is here is to just talk a bit about what is happening in agriculture; the innovation, the opportunities for young people and how dealerships and the TMA members can start to understand farmers a little bit better and how they make decisions, and how they can integrate young people and women into their businesses, whether that is in dealerships or through the supply chain.”

One of the conference’s regular speakers is Kynetec’s Melinda Haley.

Kynetec provides the monthly machinery sales gures which are reported in Farms & Farm Machinery and which

provide an insight into how the market is performing on both an annual basis and compared to the same month last year.

Among the insights she shared is that as of June, 4,840 tractors had been sold across Australia for the year-to-date, a gure which was 10 per cent below the rst half of 2024, with roughly two-thirds

of these being above 60hp units.

During the 2024-25 nancial year, there was 9,696 tractors sold in Australia and this was 12 per cent down from the 202324 nancial year.

“Through the data collection that we do in the machinery industry, we are very proud partners of the TMA to provide

insights back to the industry,” Haley said to Farms & Farm Machinery

or true Hydrostatic! NO COMPROMISE on power!

Visit your closest dealer

“Kynetec is one of the leading companies that will provide agricultural insights across the board and we’re quite proud to be able to work with the machinery industry and provide valuable insights to help guide them with what has been going web: www.antoniocarraro.it/au

on and where their future developments can occur.”

The wider economy was looked at by Westpac senior economist Justin Smirk, who is another regular speaker at TMA conferences.

Among his insights were that the global tari work would have a “small but manageable” impact on Australia, while a cautious easing of domestic interest rates by the Reserve Bank would lead to a slow consumer recovery.

He believes agriculture is transitioning back to the average following a better than average period and says that continued productivity improvements will be critical for the industry’s longer-term sustainability.

Other speakers included Gus Hogan from Delta Agribusiness who provided

insights from on-farm advisors on machinery and technology, along with Jem Richards from Red Bear who discussed cybersecurity and arti cial intelligence in agriculture.

The event’s a er-dinner speaker was former Australian cricketer Brad Hogg, who shared stories from his playing career.

This was alongside a powerful message about the importance of mental health –particularly in rural communities – thanks to Hogg’s role as the national ambassador for Grain Producers Australia’s Farmer Mates Mental Health program.

Full presentations from the conference are available on the association’s website at www.tma.asn.au

The U10 PRO and U10 PRO HIGHLAND rede ne what a top-tier full-size UTV can be, launching a new era for the UFORCE family. More powerful, capable, and advanced than their predecessors, these models feature an all-new technology-appointed and quieter interior, elevated exterior design, and an extensive list of standard features for both work and play.

$29,990

$23,990

Mahindra is preparing to launch its OJA tractor range, which it says will provide power, comfort, and innovation for Australian hobby farmers

As the world’s largest tractor manufacturer by volume, Mahindra knows what matters on the land: tough, reliable machinery that is easy to use and built to keep landowners productive.

Already well established and with a strong suite of tractors to suit a variety of local farming needs, Mahindra’s o ering is set to grow even further.

Landing in Australia this October, the Mahindra OJA tractors are set to make a strong impression throughout the farming community.

The all-new Mahindra OJA range brings the qualities of toughness, reliability and productivity together in a package that perfectly suits Australian hobby farmers and lifestyle property owners.

Whether it is early morning starts or late-night shi s, Mahindra says the OJA combines versatility, strength and comfort for a new generation of operators.

Settle into the seat and it is clear this is no ordinary tractor.

Mahindra’s plush mComfort seat features foldable armrests, intuitive colour-coded controls and responsive joystick steering, which helps to make long days in the paddock feel far less demanding.

The layout is driver-friendly, with a digital display and ergonomic platform engineered for ease of use.

Power steering cuts operator fatigue, while projector headlights transform night into day when the work goes late.

The OJA name itself, which means “pow-

Power and innovation will be features of

erhouse of energy” in Sanskrit, sums up the range well.

These tractors balance power-to-weight e ciency with precision hydraulics and smart, connected features – delivering both muscle and nesse.

Launching rst in Australia are three models, the 1123, 1126, and 2126.

Together, Mahindra says they will o er a step forward from earlier machines, with the versatility to support both lifestyle and professional farmers.

Manufactured in Mahindra’s innovative facility in Zaheerabad, India, the OJA series blends global expertise with practical functionality.

With more models expected to follow beyond the initial October local launch, Mahindra says this is only the beginning of a story that promises to reshape expectations in the eld.

Find out more about Mahindra tractors at www.mahindraag.com.au

To simply describe Now Buildings as a shed manufacturer would be doing a disservice to the reputation it has built in rural communities over nearly two decades

To say Australia’s farmers have di erent needs to their inner-city counterparts might seem like an obvious statement, but it can lead to problems if it is not fully understood.

Success in agriculture relies on dealing with companies who understand the unique requirements and that what works in suburbia is o en grossly inadequate for Australia’s harsh rural environments.

One manufacturer who has established its entire business around this premise is Now Buildings, which prides itself on designing and building high-quality sheds speci cally designed for rural Australia.

Not only are these sheds strong enough to easily withstand the harsh conditions faced in the country’s most remote areas, but Now Buildings also knows that a ‘one size ts all’ approach simply does not work for large-scale farmers.

“We build some of those sheds in the most remote parts of the country and the biggest di erence with us is there’s no compromise on quality,” Now Buildings director Trevor Walker says.

“One of the things our customers talk about so much is the quality of the building and the fact that we’re an Australian company - those things are really important to the customer base.”

Adapting to all

Now Buildings has a comprehensive range of sheds listed on its website, covering everything from hay sheds, drive-through sheds, open-bay farm sheds and small acreage sheds.

This speaks volumes about Now Buildings’ point of di erence – the company does not try and cover every possible shed buyer in Australia but focuses entire-

ly on the rural market and what Australian agriculture requires.

This expertise, combined with the company’s ability to meet the individual design requirements of di erent agricultural sectors, has made Now Buildings a trusted company for thousands of clients.

No job is too big for Now Buildings, as evidenced by a large-scale commercial project at Julia Creek in north-western Queensland last year.

Now Buildings was able to achieve an enclosed building which measured 135m long, 21m wide and 5.1m high, becoming one of the longest structures built during the company’s history.

A total of 175 rolls of insulation were used to make this project happen, along with a whopping 30 whirlybirds to keep the machinery inside well ventilated.

Having the ability to design and build sheds to such unique speci cations is one of many reasons why Now Buildings has an endless list of repeat customers.

Among those repeat customers is Terra Firma, which rst contacted Now Buildings in 2020.

Seeking a large shed concept, Now Buildings was able to utilise its ‘Mammoth’ system to meet the requirements of that project.

“While this shed system does mean having posts in the middle, the project didn’t necessarily call for a clear-span option, so the cost savings were hugely bene cial,” Walker says.

Another shed is currently being constructed for Terra Firma, and once this project is completed there will be more than 10,000sqm of Now Buildings sheds on the one property.

Chalmers Vineyards is another major and ongoing fan of Now Buildings’ work.

A er making its rst purchase in 2019, Chalmers Vineyards has continued its

growth and has bought six sheds during the past six years.

These sheds are spread out from to northern Queensland to Heathcote in central Victoria, along with another in Merbein which is near Mildura and the Victoria-South Australia-New South Wales border.

Chalmers Vineyards’ purchases provide just one example of the national footprint which Now Buildings has with its products, and why customers in every state are nding them ideal for their needs.

Ever lasting Across the nation, Now Buildings has

thousands of happy customers who have dealt with the company since its inception 17 years ago.

The company’s website is lled with testimonial reviews from farmers who have purchased sheds in every part of Australia.

It is the quality design and engineering,

Wattz provides durable, high-quality LED Lights for Tractors and Implements, enhancing safety and efficiency on the farm.

Designed by farmers for farmers, our affordable lighting solutions offer brighter, more reliable visibility, making your job easier and safer, whether you’re working late at night or early in the morning.

“We have these relationships where they’ll go above and beyond because we support them and they’ll also put in whatever systems are needed to make sure it’s right.”

In addition to these networks, top quality materials and expert engineering combine to make sheds which customers can be con dent will last.

All Now Buildings sheds use high tensile bolts and Class 4 fasteners, with gutters and downpipes included.

Site-speci c engineering from an independent structural engineer is provided, along with heavy duty connection and footing design plus high-grade industrial strength materials being used throughout the process.

plus the care in customer service, which these positive experiences can be put down to.

Walker founded the business a er selling half of a large shed company, which the decision to start Now Buildings stemming from “wanting to do things better” and “where the customers were put rst”.

This is something he says Now Buildings does not take lightly, having used its time in business to establish long-term supplier relationships, along with a large network of builders around Australia who can help the customer.

This has all been done with the goal of providing the best quality product and customer service experience possible,

while also keeping costs down for the end user without compromising on quality.

“There were a lot of product improvements I’ve worked with over time, based on ways I’d like to do things,” Walker says.

“They weren’t necessarily the most economical way to do things but it was just going to provide a superior product that was going to withstand and have the ease of construction.

“It meant we had to get our supply chain right to build better.

“Now Buildings is in its 17th year and we’ve been with BlueScope steel that whole time. As far as bracketry and key components, we’ve been with Allplates that entire time.

Grade 4 screws are also used throughout, which do not rust or degrade even when close to salt or oceans.

“It’s the same with the high tensile galvanised bolts - your whole building is held together by these components and if those components aren’t any good, your whole building is useless,” Walker says.

“We are proud of the product and we won’t compromise.

“We’re happy to satisfy any questions customers have got in any scenario, but we know that if they go with us – and our team members know that if they go with us – they’re going to end up with a fantastic product that they’re proud of and they’ll be raving about.”

Now Buildings’ products can be viewed online at https://shed.sale/FFM or calling on 1300 491 839.

Tackle the toughest agricultural jobs with the Dieci AGRI PLUS 40.7. Engineered for heavy duty performance, this telehandler delivers a 4,000 kg maximum lift capacity and a 7.0 m reach, powered by a robust 93 kW (125 hp) FPT engine. Its advanced Powershift transmission and precision inching pedal ensure smooth, controlled movements even at full extension. Inside, operators enjoy first class comfort with a ROPS-FOPS approved cab, air suspension seat, electric window, and semi-automatic air conditioning system — all designed to keep you productive and comfortable through long, demanding days.

Dairy e uent is o en seen as a waste problem, but Muck Runner is helping farmers turn it into a natural fertiliser through its range of Pichon and Samson machinery and attachments

Many livestock farmers across Australia will be all too familiar with e uent, as the liquid waste derived from farms can have a negative e ect on the environment if not managed carefully.

For this reason, Australia has strict dairy e uent guidelines, which farmers can o en perceive as an extra problem to deal with on top of their already busy schedules.

However, what most don’t realise is that liquid manure e uent from dairy farms,

piggeries and broiler farms can be an invaluable asset as a natural fertiliser for growing pastures and crops.

This resource is o en underutilised by farmers, not realising the bene ts that the e uent can provide.

South Australian business Muck Runner aims to help farmers understand this, o ering liquid e uent handling machinery made by trusted European manufacturers.

Based in Mount Gambier, Muck Runner

is the exclusive Australian importer and distributor for Pichon and has recently been appointed an Australian dealer of Pichon’s parent company Samson.

“E uent is a nutrient rich resource that when managed e ectively boosts soil health and pasture production,” Muck Runner director Tom Paltridge says.

“Its value is not just limited to the macro and micronutrients, but also the organic matter found in it which is bene cial for soil health and structure.”

Farm dairy e uent typically contains a range of nutrients that are readily available including nitrogen, phosphorus, and potassium, as well as other macro and micronutrients and trace elements such as calcium, magnesium, and sodium.

By using the dairy e uent as a natural fertiliser for soil, Paltridge says farmers can reap the bene ts of increased organic matter content, water holding capacity, cation exchange capacity, and soil structure.

“Dairy operations import nutrients in

the form of bought in feed such as grain, hay, silage, other fodder sources, and fertiliser, and those nutrients are transferred through the cows as they eat the feed,” Paltridge says.

“The manure can then be applied in the form of e uent back onto pastures and to replace nutrients that have been removed by the cow in the milk production process.”

Muck Runner has a wide range of Pichon and Samson machinery that specialise in this process, with its e uent tankers being an e ective and e cient way of transferring the nutrients captured in manure evenly across farmland.

These machines provide the exibility needed to transport this valuable nutrient source to the areas that need it the most.

Paltridge says the most basic method of applying e uent onto paddocks is through a splash plate, but due to the variable nature of organic nutrient availability in e uent, farmers o en apply it too intensively to one area, which can smother the pasture or crops.

“It is o en applied to a paddock close to the dairy, as that is as far as manure

manure e

can be used as a natural fertiliser for growing pastures and crops

sprinklers can reach, but that means other parts of the farm that could bene t from e uent nutrients miss out,” he says.

Muck Runner has an extensive range of both Pichon and Samson application attachments designed to o er exibility depending on the farmer’s circumstances.

This includes attachments that allow for direct injection of e uent into worked

up soil before crop sowing, precision placement of e uent on top of the soil while growing pasture or crops, as well as a variety of splash plates.

While many Muck Runner e uent tankers already in Australia run a splash plate, Paltridge is an advocate for the

Scan here to see how your fleet can work smarter, not harder.

application of dairy e uent through a trailing shoe boom (TSB) attachment, so much so that he uses one on his own farm.

Fitted to the rear of the tanker, these attachments trail several hoses just above the ground, placing e uent on top of the soil and underneath the leaf

of the plant – as opposed to spraying it on top of the plants.

Paltridge says liquid e uent tends to have a higher concentration of inorganic nitrogen, which is more susceptible to losses during storage and a er application, however a TSB can help

reduce nitrogen loss and reduce odours associated with e uent spreading.

In addition, he says TSBs can minimise the time that livestock are withheld from that pasture as any fouling of plant leaves is drastically reduced.

“The trailing shoe boom is a much larger investment and appeals to those farmers and contractors that are keen to minimise the impact of e uent application on growing pasture as part of a rotational grazing strategy,” he says.

Other application equipment o ered by Muck Runner includes drip hose booms, disc and tine injectors and incorporators.

The current range of Pichon machinery stocked by Muck Runner includes SV slurry tankers with capacities of 6,600 to 21,000 litres, MK muck spreaders from 10 to 24 cubic metres, and slurry mixers from 5m to 10.5m – all fully galvanised.

Extra-large volume tankers and spreaders can also be acquired through Muck Runner’s new Samson products, such as the PG 11 Genesis slurry tankers which are available in capacities between 18,500 and 34,500 litres, as well as the US spreader range in capacities between 23 and 40 cubic metres.

“We think the trailing shoe boom attachment has wide appeal for Australian farmers who grow lots of pasture,” Paltridge says.

“It is increasing in popularity and the rewards are palpable.”

For more information, visit muckrunner.com.au or call Tom Paltridge on 0419 851 543.

Australian made and eld proven, Midwest platforms are ready to deliver for your toughest harvest

The

When harvest season arrives, there is no room for compromise.

Your gear needs to work hard, adapt fast, and deliver results with no delays, no breakdowns and no in ated running costs.

That’s exactly why more Australian farmers are turning to Midwest for their harvest platforms.

Manufactured in the Queensland town of Dalby, Midwest is the country’s only Australian-made harvesting platform and their machines are built for real Aussie conditions and terrain.

With more than 27 years of eld-tested engineering and a national dealer network, Midwest has earned a reputation for delivering simple, tough and reliable harvest gear that helps farmers harvest more, for less.

There are several unique di erences and advantages that make Midwest stand out and continue to win over farmers across the country.

A lot of machinery in the paddock today is designed overseas for di erent crops, climates, and soil types, whereas Midwest platforms are the exception.

Every platform is 100 per cent Australian made using local materials, local trades, and local insight.

From the way the cutterbar follows undulating country to the way the cross auger handles bulky crops like canola or mung beans, Midwest platforms are purpose-built for Australian elds.

The result is better performance, less modi cation, and machinery that’s ready to work straight o the truck.

Across fuel, wear parts, and servicing, Midwest says its platforms consistently deliver lower operating costs compared to equivalent imports.

With fewer wearing components, mechanically driven systems, and minimal electronics, there’s simply less to break and less to maintain.

Features like high-capacity draper belts and smooth crop ow reduce load on the combine, saving fuel and reducing strain during long harvest days.

For higher pro tability, Midwest delivers measurable savings per hectare.

Midwest platforms are also not built to last just a few seasons – they’re built for the long haul.

Core components like the reinforced chassis, wear-resistant belts, and integrated vertical oat systems are designed to handle Australia’s harshest harvesting environments.

Whether cutting through melon holes in the Western Australia’s Wheatbelt or tackling sticky stubble in northern New South Wales, Midwest platforms keep going when others slow down.

That reliability also leads to strong resale value.

Thanks to their reputation and local parts support, second-hand Midwest platforms remain in high demand.

Tailored

Midwest o ers two platform models, both engineered with exibility in mind.

The Durus platform is a proven all-rounder compatible with all major combine brands including John Deere, Case IH, New Holland, Claas, Gleaner and Fendt.

Available in widths up to 60 (18m), there is a size for every harvest operation small to large-scale.

Midwest’s other o ering – the Legacy platform – is speci cally developed for John Deere X9, 10 and 11 Series combines.

Legacy is a high-capacity option with structural upgrades and a reinforced centre mount to support the power and output of the latest models.

Both come standard with Midwest’s key features of hydraulic tilt, exible cutterbars, integrated cross augers, and advanced otation systems.

Each one is designed to reduce crop loss, increase throughput, and handle tough conditions with ease.

Choosing to avoid chasing ashy features, Midwest stays focused on practical, eld-tested solutions.

Their innovations are driven by one thing: feedback from farmers. Every improvement is developed and trialled in real conditions before going to market.

Recent updates to the Midwest product includes hydraulic tilt for better ground adaptation, high-capacity draper belts to prevent bottlenecks, upgraded otation kits for varied terrain and a re ned frame design for greater strength and longevity.

Midwest also backs every platform with real service and support.

Their national dealer network means faster delivery, easier servicing, and better access to parts wherever you’re working around the country.

Dealers are supported with technical resources, training, and a dedicated portal to keep their customers up and running throughout harvest.

Midwest has its own support team and smart phone app that provide service when you’re out in the eld, far from anywhere. This comprehensive approach ensures you’re never far from help when you need it.

Unlike platforms that rely on a ermarket kits, Midwest accessories are designed in-house to work seamlessly with your machine.

That includes cross augers for bulky or u y crops, auger extensions for safer unloading, otation kits for undulating ground and braking trailers for road transport compliance.

Everything is made to the same high standard as the platforms themselves, with parts and service readily available through Midwest or your local dealer.

Midwest doesn’t rely on hype – it relies on performance.

Farmers across Australia value Midwest for its lower running costs, strong resale, and dependable performance season a er season.

They know they’re investing in gear that is made for Australian conditions and backed by a team that understands what a harvest truly demands.

When you speak to Midwest, you’re talking to people who live and breathe harvesting and who are committed to making your next season your most e cient yet.

Whether you’re upgrading, expanding, or exploring your options, now is the time to see why more and more farmers are backing Australian made.

To speak with the Midwest team, visit midwest.net.au or call (07) 4662 2137.

has worked with Goldacres for their sprayer control systems.

Australian manufacturer Goldacres uses ifm technology to deliver next-generation agricultural sprayers

Australian agricultural conditions are among the harshest and most demanding operating environments in the world.

This is why Australian manufacturer Goldacres specialises in building agricultural sprayers that are rugged, reliable, and in step with evolving farm technology.

These are qualities they share with ifm, whose robust mobile screens are built to withstand tough conditions whilst enabling smart control and real-time visibility of a machine’s condition.

Goldacres chose to partner with ifm to enhance their agricultural sprayers with next generation display technology to bring engineered intelligence into their mobile machines, while making it easy for operators to use in the eld.

Since 1978, Australian-owned and family-operated Goldacres has been designing and building spraying equipment that meets the growing demands of modern farming.

ifm provides advanced software and expert engineering when working with manufacturers. Image: ifm

meeting requirements in the eld.

Driven by the philosophy to put farmers in the driver’s seat of best- t technology, Goldacres combine durability with innovation to design machines suitable for Australian agricultural conditions.

With this understanding – boosted by continuous feedback from their customers – every Goldacres sprayer is a t-forpurpose build.

Robust to smart

A core ethos of Goldacres is to listen to customer feedback to ensure each iteration of agricultural sprayers is

This is what prompted the journey to develop a display and control solution that would meet shi ing customer expectations.

“Being an Australian company, we’re very close to our users and feedback was that people wanted to know more about what was going on with the machine,” sales and marketing manager Stephen Richards says.

“That meant developing display solutions that would give them as much information as we could.”

Historically, Goldacres had focused on being robust and mechanically simple, which made their sprayers ideal for tough jobs but limited on smarts and data.

They realised there was a clear need for digital integration which would not only improve functionality and control but provide real-time visibility of key machine metrics and ll levels.

In addition, Goldacres understood that their customers required a reliable, stable product.

Their team has strong empathy for farmers, with many having grown up in regional Australia.

“I grew up on a farm and the last thing you want is your machine to fail out in the eld,” Goldacres engineer and electrical integration manager Luke Myers says.

“With that perspective, we needed to develop a solution that would meet this requirement but was also easy to use.”

Finding a solution

To bring smart control to their sprayers without sacri cing reliability, Goldacres integrated ifm’s ecomat display screens – rugged, intelligent hardware designed

speci cally for mobile machines.

Two screens now serve every machine: an external display for managing all ll functions, and an internal display that acts as a digital dashboard, giving the

operator full visibility and control of machine operations.

The internal screen displays key metrics such as engine speed, RPM, and spray control, while the external screen

simpli es pre-operation tasks, such as lling and setup.

Both are IP-rated to withstand exposure to dust, mud, water, and vibration, ensuring dependable performance, even in Australia’s most remote and unforgiving paddocks.

The displays are also fully programmable using CODESYS 3.5, allowing Goldacres engineers to create custom interfaces suited to speci c machine work ows and operator preferences.

This means user-friendly design is not an a erthought, it’s embedded in the system.

“The external screen does all the ll function of the sprayer, whilst the internal screen is a dashboard showing speed, RPM, and the engine side of the tractor,” Richards says.

“But it also gives the operator full control of the sprayer itself.”

Importantly, the visual displays are underpinned by sophisticated technology, even though for the end user, it’s not complicated to use at all.

“The implementation of a comprehensive control system, featuring robust controllers and I/O modules, was pivotal in ensuring the success and e ciency of these Goldacres’ sprayers, enabling seamless operations and unparallelled precision,” ifm Australia’s mobile vehicle automation expert Aditya Kunder says.

The result is a control system that doesn’t just meet current customer expectations. It gives Goldacres a exible platform to rapidly develop and deliver

new capabilities, while staying true to their reputation for delivering tough, purpose-built sprayers.

For Goldacres, entering the world of smart, so ware-driven control systems wasn’t just about meeting evolving customer expectations – it was a strategic step to stay ahead in a competitive market.

The move demanded a technology partner with deep engineering capability, proven product performance, and a commitment to long-term collaboration.

“As we were taking that step into what for us was an unknown space, ifm really rose to the top,” Myers says.

“Their product o ering, their quality, and their technical know-how gave us the complete package.”

What stood out was not just the rugged build quality of ifm’s screens and control units, but the local support and hands-on expertise.

ifm’s team worked directly with Goldacres engineers – supporting early trials, assisting with programming, and o ering technical guidance as new display features were developed and rolled out.

The partnership has been built on shared values: a passion for innovation, a drive to create better outcomes for farmers, and a practical approach to solving complex challenges.

The relationship isn’t simply transactional, but instead supports growth – in this case, helping Goldacres evolve their product o ering by building smarter machines.

According to Kunder, the system solutions that ifm can o er companies such as Goldacres are designed to handle Australian conditions.

Besides agriculture, he says ifm has a great track record in providing reliable and robust mobile solutions for the mining, construction, waste and transport and logistics industries.

“For everything from sensors and cameras to cables, rugged HMIs, decentralised I/O modules and powerful controllers, we are basically a one-stop supplier of high-quality components built speci cally for mobile applications,” he says.

“What sets us apart though isn’t just the hardware, but the integration.

“Comprehensive so ware libraries make it easy for manufacturers like Goldacres to embed advanced functionality, save engineering time and reduce development costs.”

By integrating ifm’s ecomat display systems with innovative programming, Goldacres has delivered a new generation of sprayers that combine rugged reliability with digital intelligence.

The result is more control in the cab, full visibility across the machine, intuitive and safer operation in the eld, and faster innovation from the workshop to the paddock.

With robust hardware, exible so ware, and strong local support from ifm, Goldacres is empowering Australian farmers with smarter, easier-to-use, and safer technology – built for the eld and for a rapidly evolving future.

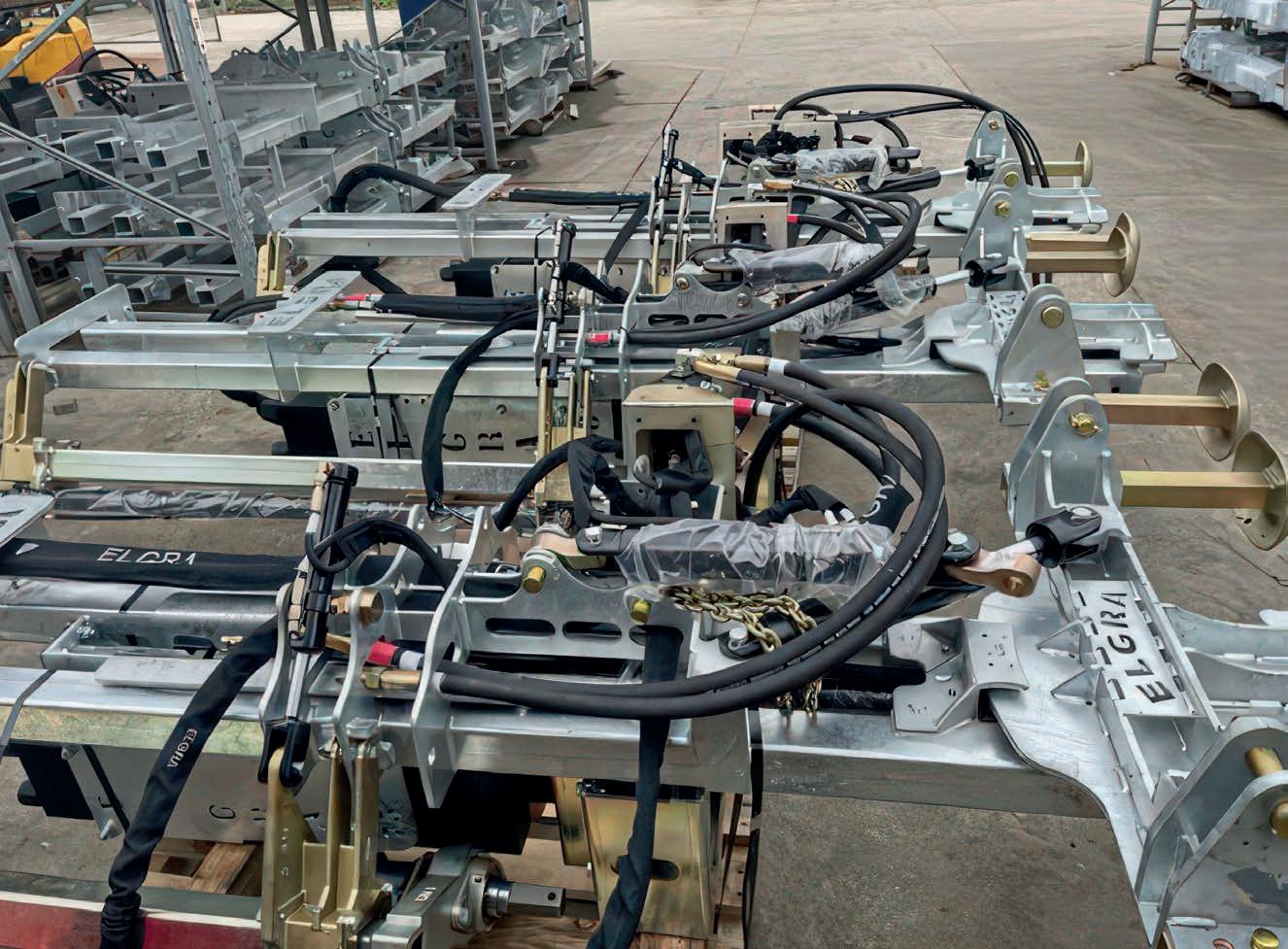

Australian farmers have long relied on the post drivers and other attachments produced by Elgra Engineering, a company that keeps investing in local manufacturing

Continually investing in manufacturing equipment and re ning its products to meet evolving customer needs, New South Wales-based Elgra Engineering continues to be a strong example of Australian manufacturing.

Founded and co-owned by father and son duo Elton and Graeme Robinson, Elgra Engineering is a company backed

by 35 years in business and a lifetime of passion for the machinery it creates.

Elgra was a pioneer of hydraulically driven post drivers and this product remains an important part of its range in 2025, along with various attachments which it designs and builds with Australian farmer needs at the forefront.

The company says its post drivers have “set a completely new standard” since their introduction and are purpose-built for farmers, along with other sectors such as earthmoving contractors.

Despite its longevity and proven success, Elgra is also a company which never rests on its laurels.

It continually re nes its products and invests heavily in its manufacturing equipment to ensure it is catering for the evolving needs of Australian farmers.

One example of this comes from its latest product, an all-new slasher range set to be added to its lineup.

Fully developed by the Elgra team, the company says this has been “engineered with precision and developed with

durability in mind” and will handle the toughest tasks with ease.

It features a hot dip galvanised body, enhanced strength and reliability thanks to the rugged materials it is built with, and an advanced design which has been modernised for a better t, nish and performance.

Slashers sit alongside the likes of cement mixers, tree root removers, paddock cleaners, shrub pullers and the hydraulic percussion post drivers in the Elgra range of attachments.

Based in the town of South Nowra, which is about two hours south of Sydney, the founders have a rural background and remain constantly engaged with farmers around the nation to ensure they are meeting the evolving needs of Australian agriculture.

Design and innovation are done inhouse, with sophisticated computer-aided design (CAD) so ware being used from the very beginning of the process.

This means designs can be fully tested before prototypes are manufactured, which are then put through their paces in Australian conditions.

This is something which happens regularly, as Elton says Elgra is constantly conducting market research with working farmers and listening to customer feedback to develop new and improved products and further enhance its existing range.

Once the prototype has proven to be a winner and enters full production, every unit which is built is rigorously tested for quality assurance before being sent to customers around the nation.

In recent years, the company invested about half a million dollars in state-of-theart welding and laser equipment including a six-axis industrial welding robot, along with other enhancements such as numerical machine control, plasma cutting and incorporation of surface plating.

This advanced technology, along with designing and manufacturing in-house, means Elgra can cater to individual needs and ensure each customer receives a product perfectly suited to their requirements.

For all Elgra’s versatility and growth of its attachments o ering, the hydraulic post drivers remain the product which the company is most associated with.

By pioneering the manufacturing of fully hydraulic post drivers, Elgra was able to phase out the old-fashioned drop hammer which was previously relied on.

The hydraulic post driver is a much safer machine, Elton says, not requiring screens around the hammer and ensuring the hammer cannot accidentally fall and eliminating the injury risk.

It also has greater reliability on slopes, he says, along with reduced noise and the ability for it to be operated remotely.

Elgra says its post drivers are built to outperform anything else on the market and can withstand the harshest conditions which Australia can throw at them such as dust, heavy rain and extreme heat.

This is due to their construction from high quality nylon blocks that guide the Power Cell, hot dipped galvanised equipment, plus no greasing of the main rail system which eliminates wear and tear.

The framework construction means it can take the largest cell on the market, Elgra says, delivering 2,500 joules of impact power from its 200-cell unit.

This is the largest of four sizes o ered by Elgra and is aimed primarily at contractors needing size and speed.

While these post drivers – along with

Elgra’s entire range – have proven to be winners over an extended period, the company’s continued investment in its production facilities have enabled products such as its new slashers to be developed.

Elton says the company does not get recalls on products which do not work, simply because of its in-house control and rigorous testing to ensure each unit

works smoothly before they are sent to customers.

A wide network of dealers around the country backs up Elgra’s products, while Elton says he will answer the phone 24 hours a day for customers requiring assistance.

Elgra’s full range can be viewed at www.elgra.com.au

Purchasing two Enorossi rakes has provided value for money and no-nonsense operation for a Victorian hay contractor over a number of years

Tom Scott admits he is the type of person who likes to do thorough research before purchasing new equipment.

The Victorian hay contractor’s decision to initially invest in Enorossi hay equipment was therefore a measured one, and his subsequent purchase on a second Enorossi product is arguably even more telling.

For Tom, whose business Ascot Valley Contracting is based at Ravenswood near Bendigo in central Victoria, his rst Enorossi purchase was a batrake acquired about seven or eight years ago.

This was followed up with an RR 350 rotary rake that has now completed three seasons of work.

It was a combination of providing value for money while still “doing the job perfectly” that has made Tom such an Enorossi fan.

As a contractor, every new machinery purchase needs to be treated as a business investment.

The need to maximise this investment helps to explain why Tom was so thorough during his research – but also speaks volumes as to what the Italian-made Enorossi range provides.

“I did some research, had a look on some forums online and then had a look at them in person at the eld days as well, and then made my own opinion based on all of that,” he says.

“There were other manufacturers that had similar things available, but almost twice the price.

“Once I’d seen the product and realised that it was every bit as equivalent to products from other manufacturers that were twice the price, it was an easy decision to purchase the batrake.”

The batrake was Tom’s rst Enorossi purchase, made through Australian distributor Clark Equipment.

With a Clark branch being located less than an hour from him in Bendigo, Tom admits this dealer proximity made the investment an “easy decision”.

“It does all things from raking up rows in front of the round baler to smaller rows for the small square baler and it has been doing that job perfectly in that time,” he says.

“Compared to the competition, it was a lower upfront cost machine and the cost-bene t has been very good in terms of the job it’s done over that time period versus the cost to purchase it and the maintenance required.

“It’s been fantastic and I’d happily buy another one.”

Enorossi’s bat rake is a wheeled rake designed in a V formation and is available with the choice of 10 or 12 wheels.

It has a trailed connection behind a tractor and requires a minimum 50hp from the machine.

There are 40 teeth per wheel, tapered roller bearings and independent movement of each arm to make it easier to adapt to the ground and produce an excellent swath formation.

Described as being ideal for all types of ground contours, the batrake is available with a working width of 5.6m or 7.4m depending on the model.

Crucially, it can fold up to under 3m wide for safe road transport and this is something which has bene tted Tom.

“Being hay contractors, we’re carting gear a long way down roads,” he says.

“The good thing about the batrake is that you can tow it behind your ute e ortlessly.

“It’s easy to manoeuvre by hand, whereas with certain other rakes you need little dollies to be able to tow them behind your ute.

“Its manoeuvrability was another big reason that we went with the bat rake.”

Double up Tom’s next Enorossi purchase was the RR 350 rotary rake.

This is a single rotary rake with a 3.5m working width, nine tine arms per rotor and 27 double tines.

It works with a three-point linkage connection and only needs a 35hp minimum requirement from the attached machine. There is also oil bath rotor transmission and mechanical working depth control with this unit.

Australian distributor Clark Equipment describes the RR 350 as being a “professional machine” that provides perfect adaptation to the ground and preserves the quality of the product.

“The rotary rake is mainly used for our small square baler and again we’ve had absolutely no problems whatsoever,” Tom says.

Speaking about his two Enorossi purchases, Tom cites the ‘keep it simple, stupid’ principle as being one of the biggest bene ts during their daily work.

“There’s just not a lot that can go wrong with them,” he says.

“Either rake can be run o any of our tractors, because the batrake for example only needs one hydraulic outlet, so it can be used across the eet with no problems.

“The rotary rake is a three-point linkage unit, so it can just go on the back of any tractor as well and it has super low power requirements.”

Getting excellent value for money with his rst rake was the reason Tom chose Enorossi the second time around, and the “fantastic” service he has received from Clark Equipment helps to explain why he plans to stick with them.

“I’ve had fantastic dealings and we had such a good run with the batrake that it was a no brainer for me to go back to Clark and get a di erent rake within the Enorossi range that suited our requirements at the time,” he says.

“They’re the only two rakes we’ve got

and when it’s time to get another one, I’ll be going back to Clark and working out a deal.

“All dealings we’ve had with Clark have been positive; they’ve been able to source parts quickly in hay season when it’s required and we have needed certain things.

“Their service is as good as anyone that I’ve dealt with in my career in the agricultural industry.”

The Enorossi range available through Clark Farm Equipment includes a variety of rakes, along with other products such as hay mowers, balers and wrappers.

The full range can be viewed online at www.clarkfarmequipment.com.au or through Clark’s national dealer network.

Machinery lighting supplier Wattz aims to put customer service at the heart of everything it does by going above and beyond for every farmer

The value of mateship permeates through rural Australia, with communities quick to band together for a greater good during times of challenge or crisis.

Realising the signi cance of this to the nation’s farmers – and the need to do so authentically – has become the entire ethos of machinery lighting provider Wattz.

Authenticity in its customer-centric approach comes easily to founder Andre Meyer, who is a farmer himself and knows what those keeping the industry operating require.

Since launching to the Australian market earlier this year, Wattz – which supplies a ermarket lighting solutions to farm machinery that considerably increases its output – has set about being more than just a distributor and seller of products.

The company aims to establish itself into the Australian agricultural market by

embedding itself into rural communities, treating every customer as a valued friend and developing ongoing relationships that extend well beyond the transaction at hand.

“The relationship that we establish with customers has meant that we o en call up our customers and check in to ask what the farming conditions are in their area,” Meyer says.

“We can connect them with other like-minded farmers around them, invite them to events we are attending in the area, and ask if we can drop in and say hello if we are passing through.”

Developing and nurturing these friendships goes hand-in-hand with authentic relationship building for Meyer and the Wattz team.

This is borne from a desire to give customers the best experience possible, by seeking out honest feedback and o ering tailored solutions for each customer’s needs.

One Wattz customer who is already reaping the bene ts is South Australian Nathan Collins.

Collins farms at Mingbool in the state’s south-east, right near the Victorian border, and milks about 500 cows in addition to doing his own silage and cultivation work.

He has already converted three of his ve tractors to complete Wattz lighting packages with plans to do the same for his remaining two.

Meyer’s service even extending to personally installing some of the lights for him, something which Meyer says he will o er wherever it is practical.

This has created a happy customer who plans to keep working with Wattz.

“I’m very happy overall and I de nitely recommend them,” Collins says.

“They’ve got every tractor model listed on their website and what lights are required, so you just click on that and it’s easy.

“You’re getting a good product and service from someone with the knowledge, because he’s driven machines before and knows what you need.

“I know it’s not possible, but I reckon you’re better o to order a new tractor without lights and get Andre to sort it out for lights.”

From Wattz’s perspective, the relationship continues long a er the transaction has been completed.

Having a genuine care about the customers it deals with is the philosophy which Meyer started the company with, along with wanting to ensure every single customer has a positive experience.

what it means to be part of a community,” Meyer says.

customers and we take their number instead of giving ours out so they know we genuinely care about assisting with their upgrades.

would be continuous and frequent check-

The simplest de nition of Wattz is a distributor of a ermarket lighting solutions for tractors and other popular farm machinery such as harvesters and sprayers.

that is the trusted voice – farmer to farmer.”

The company o ers a complete package that covers everything from headlights through to roof lights and boasts an improvement of up to 400 per cent in the lighting output over standard factory- tted lights.

It o ers this while providing easy to install lights which do not alter the machine’s overall look – and have the added bonus of being a ordable without compromising on quality.

Wattz’s website also includes a handy 3D Con gurator which lists tractor and machinery models to help customers quickly identify the lights which are suited to their needs.

The company aims to be a one-stop shop for all machinery lighting needs, something which is further emphasised by the desire to help customers with any le - eld requirements.

“We can also order in speci c lights for models that we don’t supply on the websites, because we do our best to ful l customer needs,” Meyer says.

“We also like to keep in touch with customers to let them know if we are expanding our product range, because we keep in mind what other machinery models they have on their farms.

“We also want them to know they are getting genuine, great quality lights and not getting ripped o .”

The full Wattz range can be viewed online at www.wattz.com.au

O ering the versatility and strength to handle jobs on remote cattle properties has a JCB 5CX Pro Backhoe Loader owner feeling like he has hit the jackpot

For Queensland cattle farmer Mick McCoy, JCB’s 5CX Pro Backhoe Loader is the “most versatile machine that I’ve seen on a property”.

Cattle properties can be some of Australia’s most isolated agricultural setups and involve tough and unforgiving conditions, making the need for reliable and rugged machinery which can complete multiple jobs even more pertinent.

McCoy is based in Richmond, roughly 500km south-west of Townsville, and has three cattle properties.

Each of these properties has a dedicated backhoe, with the two most recent purchases being JCB.

He rst bought another manufacturer’s backhoe in 2007 before investing in a JCB 5CX Pro in 2017.

When it came time to add a third one last year, the decision to go back to JCB was easy.

“They’re the most versatile machine that I’ve seen on a property and they’re not only versatile, but capable,” he says.

“These JCBs are a very good machine. They get the power to the ground and because of that they dig like anythingthey’re just an all-round machine.”

Power packed

JCB describes the 5CX as being the “ agship model” of its backhoe loader range and calls it “quite simply the most e cient in the world”.

It o ers a 109hp (81kW) engine, maximum digging depth of 6.14m and a

bucket capacity of 1.3 cubic metres, along with hydraulic side shi .

These machines can reach road speeds of up to 50km/h, which McCoy highlights as being a signi cant advantage for his work in isolated environments.

“They’re fast, they’re mobile and you can

drive them quickly along bush roads and get to where you’ve got to go,” he says.

“You can cover big distances quickly and they’re very user friendly.”

Part of this user friendliness comes from the ergonomically designed in-seat servo controls which also help minimise operator fatigue and allows the backhoe to be operated throughout 90 degrees, along with a design that ensures excellent visibility.

A hydraulic power slide ensures repositioning – an important process during compacting, picking and sorting – can be done e ortlessly, safely and with precision.

Full power hydrostatic steering utilises the main hydraulic pump and gives operators the choice of front-wheel steering, four-wheel steering and crab steering modes, each of which can be selected via a rotary switch on the front dashboard.

Getting maximum power for di cult jobs while still remaining e cient is crucial for operators such as McCoy.

A powerful Diesel Max engine produces high power and torque at low revs, with JCB saying the 5CX Pro o ers average fuel savings of up to 16 per cent and therefore extends the time period between ll ups.

The six-speed automatic transmission combined with a lock-up torque converter reduces fuel consumption by up to 25 per cent while on the road, JCB adds.

Trend setter

JCB has had decades of experience producing backhoe loaders and this has allowed them to make intelligent adjustments designed to maximise the user experience.

It was one of these design features which ultimately sold McCoy on the JCB 5CX Pro.

“The thing that swung me in the end was the fact the JCB was the only one at

the time that has the forks mounted on the loader frame and not the bucket,” he says.

“Most backhoes have got the pallet forks mounted on the actual top of the bucket, which I didn’t like at all.

“These were the only ones that didn’t have that – the pallet forks on these are mounted on the loader frame behind the bucket, which means we can have the bucket and the pallet forks with us wherever we go with it, so that was why we went with the JCB in the rst instance.”

While McCoy previously owned another backhoe loader prior to discovering JCB, there has been no looking back since then.

The word “versatile” keeps coming up when McCoy describes its daily usage and bene ts, which speaks volumes as to the JCB 5CX Pro’s bene ts.

His loyalty to the JCB product has been locked in, while his loyalty to the backhoe as a broader concept is also in no doubt.

“We use them on basically a daily basis for everything from installing troughs to xing roads to feeding cattle,” he says.

“At our home property we’ve got a feed lot as such, although we only feed weaners in it, and we load our mixer wagon with it too. Another thing I like about these backhoes is their industrial strength – they’re just so strong.

“We went from using a farm tractor with the front-end loader on it, which I’ll probably never buy again because they’re not up

McCoy has added various attachments to

to the job and they’re not versatile enough.

“Front end loaders are nowhere near as strong as these – they’re just the most versatile piece of equipment.”

Doing it all

This strength and versatility means McCoy can add various powerful attachments to the JCB 5CX Pro to complete a wide range of jobs.

On such a remote property where labour can be scarce and machines which can handle plenty of jobs are worth their weight in gold, McCoy has hit the jackpot.

“The thing I love about them, and this is only one example, is one man can take a big cement trough, poly pipes and all the gear he needs to go out and install a trough on his own,” he says.

“You don’t need anybody with you, because his machine just makes so many things happen.

“We’ve got an earthquake hydraulic post rammer, a hydraulic post hole auger, and a trench digger which attaches to the hoe arm with the hydraulic quick-hitch.

“We’ve got hydraulic hitches front and back which allows for quick changes on the loader frame between the four-in-one bucket, hay forks, pallet forks, and grain bucket that we built for it, which we also use for picking up the 8x4 large square hay bales to load into the mixer wagon.

“They’re basically an independent tool carrier. There’s just nothing you can’t do with them and that all adds to the machine’s value.”

McCoy dealt with Queensland JCB dealer Honeycombes for his purchases, and a positive experience throughout this process has just further solidi ed why he is such a fan of the product.

“The service was very good, they’ve treated us very well and it was a smooth process to get them,” he says.

“They’re just the handiest piece of equipment - these are an exceptional machine. We bought one backhoe from JCB and then we bought another one, so that’s pretty much speaks for itself.”

JCB’s 5CX Pro Backhoe, along with the manufacturer’s full agricultural range, is distributed nationwide by JCB CEA’s extensive dealer network.

The full range and list of dealerships can be found online at www.jcbcea.com.au

Design features mean the tyres excel in all conditions

Alliance Tyres is marking a pair of signi cant global milestones, with the products’ quality and longevity continuing to appeal to Australian farmers

Reaching one million sales of its trusted AgriStar II tyre and ticking 70 years of production are two reasons for Alliance Tyres to celebrate its achievements.

Such a sales milestone naturally means plenty of happy customers, particularly in an industry like agriculture where tyre performance is paramount.

A seven-year comprehensive warranty on the AgriStar II tyres further shows the manufacturer’s commitment to ensuring Australian farmers can purchase from Alliance with con dence that their tyres are ready to handle the nation’s demanding agricultural conditions and do so for the long haul.

At the essence of Alliance AgriStar II’s long-term popularity and success is a feature-packed tyre.

The tyre has more distinct features than any other brand in the same class, the manufacturer says, and these cover the areas most important to farmers.

Having spent 35 years making radial tyres, Alliance has the experience to know what farmers need in their radial tyres and how to implement it.

AgriStar II tyres feature Strati ed Layered Technology (SLT) which is a dual-layered lug design where the top layer is a single angle pro le and the bottom layer is a multi-angle pro le.

These two distinctive lug pro les help to prolong traction and enhance roadability, while polyester casing construction ensures dimensional stability and heat resistance.

This, along with superior stubble guard compound, are among the reasons why Alliance has such con dence in its product and can o er such a comprehensive warranty.

Minimising soil compaction is a critical goal for most farmers when selecting tyres, and Alliance’s AgriStar II ensures this by providing wider tread width to give a higher contact area, which the company describes as being 13 per cent more than a standard radial tyre.

A smooth pro le and lug angle nose design are also based around preventing crop damage, which in turn can lead to increased yields.

Aware of the need for farmers to use these tyres on roads as well as paddocks, AgriStar II tyres feature overlapping of the central lugs for superior roadability while the tyre’s design also prevents lug shu ing.

Roadability has also been factored in

with the D Speed rating of up to 65km/h for usage in these environments.

More than 80 sizes covering aspects rations from 65 to 95 are available, and AgriStar II also has deeper non-skid depth in most tyre sizes.

AgriStar II tyres also act as mud breakers and ensure self-cleaning, while also featuring dual step tie-bars and o ering improved aesthetics.

It is worth reiterating Alliance tyres’ milestones as a reminder of how these features came about.

The brand’s 70th anniversary is testament to its ongoing engineering excellence and long-standing commitment to meeting the needs of the agricultural sector.

Ticking over one million AgriStar II sales also shows the level of trust placed in Alliance tyres by farmers needing reliability.

Combined with the impressive warranty o ered and the product being readily available through local tyre dealerships around the country, the time is now to be part of AgriStar II’s next million.

Alliance tyres are available nationwide through local dealerships.

CFMOTO’s U10 Pro UTV range o ers more power and advanced technology than its predecessors, enabling farmers to reach new o -road heights

It’s been just over one year since CFMOTO released its U10 Pro UTV range to the Australian market and these vehicles have proved to be a huge success for many farmers around the country.

Launched in August 2024 as part of the UFORCE UTV family, the U10 Pro range was built on the foundations of its predecessors, taking o -road utility to new heights with enhanced power, advanced technology and a rede ned design.

Two distinctive models make up the range, the U10 Pro and the U10 Pro Highland, both available with standard (three seat) or XL (six seat) con gurations, o ering greater optionality for customers.

Operator features are the main di erentiator between both models, as the Highland variant includes extra features such as a sealed cabin with a full heating, ventilation and air conditioning system, electric tilt glass windshield, and full doors with electric windows.

This model is designed for those farmers who demand the ultimate comfort and capability in any climate and weather conditions, making the Highland variant ideal for those who need a versatile vehicle.

While the standard U10 Pro may lack some of the extra comfort features such as the sealed cabin, it features all the same performance capabilities of the Highland at a more cost-e ective price point.

“The U10 Pro range has been very well received since its introduction,”

CFMOTO o road vehicle marketing manager Stephen Carrington says.

“We are nding farmers opting for the premium U10 Pro Highland model over the standard U10 Pro.

“It o ers incredible value for our agship

UTV. You only need to compare it against the competition, and you will quickly see why.”

Both models set the benchmark in CFMOTO’s UTV segment, with the U10 Pro range powered by a 998cc triple-cylinder naturally aspirated engine, which delivers 90hp (67.1kW) of peak power and 94.5Nm of peak torque.

The introduction of CFMOTO’s Variable-Valve-Timing system enhances power delivery, maintaining torque over 90Nm from 3,000rpm to 7,000rpm, which the company says surpasses various competitors.

“This optimises performance throughout the rev range for smoother throttle response,” Carrington says.

The U10 Pro Highland o ers extra features, including a sealed cabin, HVAC system, electric tilt glass windshield, and full doors with electric windows

An updated powertrain features on the U10 Pro range, paired with CFMOTO’s in-house-developed CVT transmission, o ering a smooth and reliable driving experience at low speeds.

Changes to the CVT pro le and Electronic Fuel Injection (EFI) system have also optimised the driving experience.

“By having smooth control over the power delivery, it can bene t farmers across several applications including low speed work – such as moving livestock, spraying, towing or driving across technical o -road terrain with greater con dence,” Carrington says.

Two drive modes are o ered as part of the EFI system – work or normal – to

further re ne the driving experience for farmers in di erent scenarios.

Work mode has a more subtle throttle response, which requires more pedal movement to obtain full power, giving the driver greater control in slower work environments or when undertaking challenging o -road terrain.

Meanwhile, the normal mode has a more responsive throttle that works best in a wider range of driving conditions.

The 1,134kg tow capacity and 454kg rear cargo tray capacity of these vehicles is a signi cant enhancement on past models and has been made possible by a stronger chassis, designed to handle the most challenging tasks with ease.

“All sorts of things can be towed including di erent types of trailers, harrows, wood splitters, feeders or spray units,” Carrington says.

“That’s the beauty of a UTV, the versatility it provides. The rear tray comes with a hydraulic tilt function as standard to make it as easy as a touch of a button to tip the tray.

“Having a serious tow capacity not only demonstrates what the UTV can tow, it

also represents how powerful and robust the build of our U10 Pro range is.”

Several cutting-edge technologies have also been introduced, including an E-Shi system that allows for seamless gear changes, an Electronic Parking Brake that automatically engages for secure parking, and an 8-inch MMI touchscreen dash with wireless CarPlay compatibility.

These features, combined with upgraded comfort options like an adjustable steering wheel and bench seat, make the U10 Pro a true leader in its class.

Other notable features include 330mm ground clearance, 29-inch tyres, and o -road-tuned suspension for superior stability and handling.

The series is available in a variety of nishes, including Forest Green for the U10 Pro, available for a manufacturer’s suggested retail price of $23,990 Ride Away* and Bordeaux Red for the U10 Pro Highland, available for a manufacturer’s suggested retail price of $29,990 ride away*.

The U10 Pro Highland will also be showcased on Australian television series All 4 Adventure, with CFMOTO having

been the o cial o -road vehicle partner of the show since 2022.

Supplying a eet of hard-working UTVs over the last couple years, CFMOTO is proud to announce that season 17 of All 4 Adventure – premiering later this year – will spotlight the U10 Pro Highland and test it in some of the toughest environments Australia has to o er.

For more information on the CFMOTO UFORCE U10 Pro range, visit www.cfmoto.com.au or contact your local CFMOTO dealer.

Tractor sales were down in July, data from the Tractor & Machinery Association shows, however large units and multiple states recorded an increase

National tractor sales dipped again in July a er exhibiting some promising signs the previous month.

With just on 700 tractors delivered for the month, which is 10 per cent below the sales recorded in July 2024, the industry is now 10 per cent behind last year on a yearto-date basis.

The biggest drop occurred in the small, under-40 hp range which was 25 per cent behind the same month last year.

While there are several issues with the

overall health of the sales market, there appears to have been some tax management in place here which partly accounts for the steep drop.

Tractor sales were down in pure volume terms; however the story was di erent in value terms.

Total retail turnover was in line with July 2024, supported by an improvement in high horsepower machine sales.

Tractors above 200hp had an 11 per cent increase compared to July 2024, while all

& Machinery Association of Australia (TMA). He can be contacted on (03) 9813 8011 or at gary@tma.asn.au

other weight categories were down.

Tasmania, South Australia, Northern Territory and Western Australia each recorded increases in tractor sales numbers compared to the same month last year, and this means NT and WA are both ahead of 2024 on year-to-date sales.

The biggest monthly decrease was in Victoria, with sales down almost 27 per cent compared to July 2024.

Sales of combine harvesters remain challenging around the country and it is clear the market is well stocked for machines at this stage.

Sales are up 1.6 per cent on last year to this point, but order intake suggests that a number well down on last year’s overall total is to be expected.