6 minute read

DDT: Colbrook Industries bringing Lamtrac 6160T mulcher to Oz

community

spirit

Strong local ties have helped Excavator Parts remain resilient during unexpected adversity in recent years

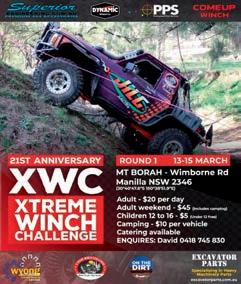

Above: Excavator Parts is a major sponsor of the ComeUp Xtreme Winch Challenge Series. Based in Wauchope, near Port Macquarie on New South Wales’ mid-north coast, Excavator Parts has experienced bushfires and flooding in the area in addition to the COVID-19 pandemic.

But, according to Excavator Parts director Peter Jilg, it has been the two-way street of community loyalty that has helped.

“It has been a few tough years in our local area,” he says.

“As a small business, we hold on, thankfully with the support of our wide range of customers and local community.”

Excavator Parts sponsors several local events in addition to its core business of supplying new and used parts, seal kits and a wide range of undercarriages.

The family-run business has been in the industry for more than 20 years and dismantles a wide range of excavators, ranging from one to 50 tonnes.

“We specialise in an exchange unit service for our customers – including repairs and maintenance for final drives. This includes a three month warranty on rebuilt parts,” says Jilg.

“Our technicians and sales team provide a highquality and the most efficient service available.

“During this process we take the time to personally evaluate the final drives, conduct testings and rebuilds with new parts if required.

“We also specialise in breakdowns of final drives and hydraulic pumps and have a dedicated and loyal customer base that keeps coming back for our specialised services.

“We are also beginning to provide our new range of hydraulic oils, lubricants and transmission fluid with our technician on hand for customer needs.”

Excavator Parts is located at 18 Production Drive, Wauchope and can supply parts anywhere in the world.

Excavator Parts Pty Ltd is located on the mid north coast in NSW. We supply an extensive range of new & used excavator parts, seal kits and undercarriage worldwide.

We specialise in rebuilds for Hydraulic Pumps, Travel Motors & Final Drives and have on hand a wide range of stock available for your immediate needs. Having been in the industry for the past 20 years, we can offer expert technical advice and repairs for all your excavator & hydraulic needs.

Our Service

Dismantling Rebuilds Hydraulic Parts Undercarriage Seal Kits

Our Products

Construction Equipment Mining Machines Excavator Farm Machinery Processing Equipment

Leading Suppliers of Spare Parts for:

18 Production Drive, Wauchope, NSW, 2446 | PO Box 617, Wauchope, NSW, 2446 Ph: 02 6581 1589 | Fax: 02 6581 1508 | Mobile: 0400 646 082

neighbourhood

watch

Australian-designed and innovative, the Sentinel Safety systems produced by PRM Engineering offer advanced safety solutions for mobile machinery

The team at PRM Engineering Services is known for its innovative and flexible approach to safety solutions in the mobile machinery arena.

Sentinel Vision AI uses the latest in artificial intelligence and pedestrian recognition technology to keep pedestrians safe around mobile machinery, negating the needs for tags and avoiding the false alarms and detections, and onerous tag-based admin procedures, that plague some existing pedestrian systems.

Vision AI has been robustly trialled by various Tier 1 companies over the past 18 months, strongly evaluated against competitive systems and has seen a strong uptake nationally.

With Sentinel Height, height limiters, slew limiters and safe load indicators meet the required customer standards but can also be customised for the unique needs of clients in the earthmoving, construction, waste, rail, local and state government industries.

Designed in Australia using top-quality componentry and local programming, the system is upgradable and can be retrofitted to any machine with articulated booms.

PRM Engineering Services is also renowned for its customised solutions in crush prevention technology in elevated work platforms, bespoke solutions for water carts and mobile working elevated platform control systems, and a suite of other safety solutions.

Above: Sentinel Vision AI keeps personnel safe, while Sentinel Height detects overhead hazards

To find out more, visit PRM Engineering’s website www.sentinelsafety.com.au or email engineering@primeng.com.au

Innovative Safety Solutions for mobile machinery

Human Detection in restricted zones using Artificial Intelligence Height Limiters / Slew Limiters / Safe Load Indicators Cabin Intrusion Protection

Australian designed products with local engineering and support

x v a

www.sentinelsafety.com.au +61 (0)7 3711 2779 engineering@prmeng.com.au

mean machine

Colbrook Industries is working with Lamtrac Canada to bring a brand new generation of mulcher carriers to Australia

Above: The new Lamtrac 6160T has been designed to fill the niche between skid steers and larger forestry mulchers

Colbrook Industries says its new dedicated mulcher is a solid middle ground between the two most popular mulching options available on the Australian market – and the Lamtrac 6160T is anything but average.

Lamtrac is a Canadian company that has been in the vegetation management business for over 20 years. Originally designing machines to groom trails for snowmobiles across Canada’s skifields, Lamtrac was one of the first companies to invest in the development of the now booming mulching industry.

The new Lamtrac 6160T is an impressive selfpropelled machine that is sat in, just like a skid steer. Designed specifically for mulching, its cooling capacity, horsepower, undercarriage and safety features have been upgraded to allow operators to work all day in comfort and safety and to mulch in all types of applications.

Colbrook Industries is doing a soft launch of this brand new platform at Diesel, Dirt & Turf. With a need for a Tier 4 machine, the 6160T is an evolution from Lamtrac’s first generation 6140 and 6170 options.

Colbrook Industries managing director Rob Plageman says this will be Lamtrac’s first representation in Australia, adding that he is excited to release the platform. “We want to get it out there, we want people to know about it, and then later in the year, when we have the machine here, we will put it through its paces, and people can see it and sit in it,” he says.

The 6160T sits between a compact track loader and the large forestry mulcher, Plageman adds, filling a niche in the market where it isn’t as heavy as the largest mulchers, and has the versatility and agility of a skid steer with substantially more horsepower.

The latest Cummins B4.5 diesel engine is used, generating 155 horsepower (116kW), and a new torsion axle suspension undercarriage has been used, which provides a smoother ride, allowing the machine to be extremtly agile and still achieve good traction and prevent track roll off.

Plageman adds that the Lamtrac 6160T uses the quick hitch system and can hook up to just about any implement you would put on your skid steer.

“Due to the machine’s ability and its agility, it is unique in the fact that it can run both a drum mulcher and a disc mulcher,” he says.

“So it can also run our very large rotary mowers, which you can’t do with a lot of the dedicated machines, they just don’t have the arm movement, as they can only lift a little way. They don’t have the ability to run a disc mulcher where you need to be manoeuvring and working the head. It is a very dymanic machine.

The cooling capacity in this machine is superior, making it ideally designed for Australian conditions, adds Plageman.

“It has a three tier radiator, which allows the engine and the hydraulics to run at a nice, constant, low temperature,” he says.

Other standout features include an impressive max hydraulic pressure of 6000psi, flow ratings dialable from 0 to 166.5L/min and a falling object protection system (FOPS) that exceeds the level 2 required for forestry equipment.

Expected to arrive mid-year, Colbrook says that it will be holding demonstration days and encourages clients to register their interest.