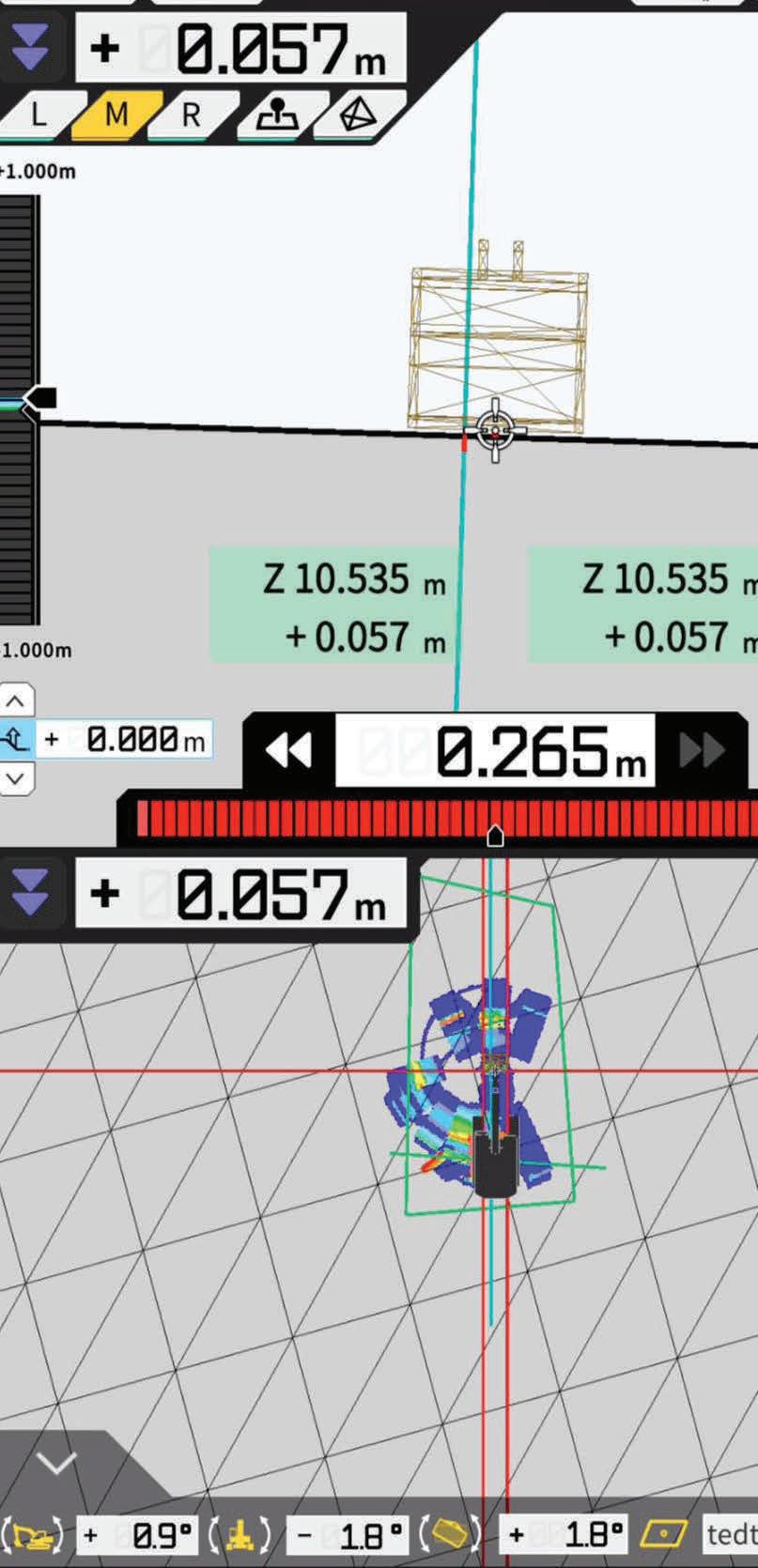

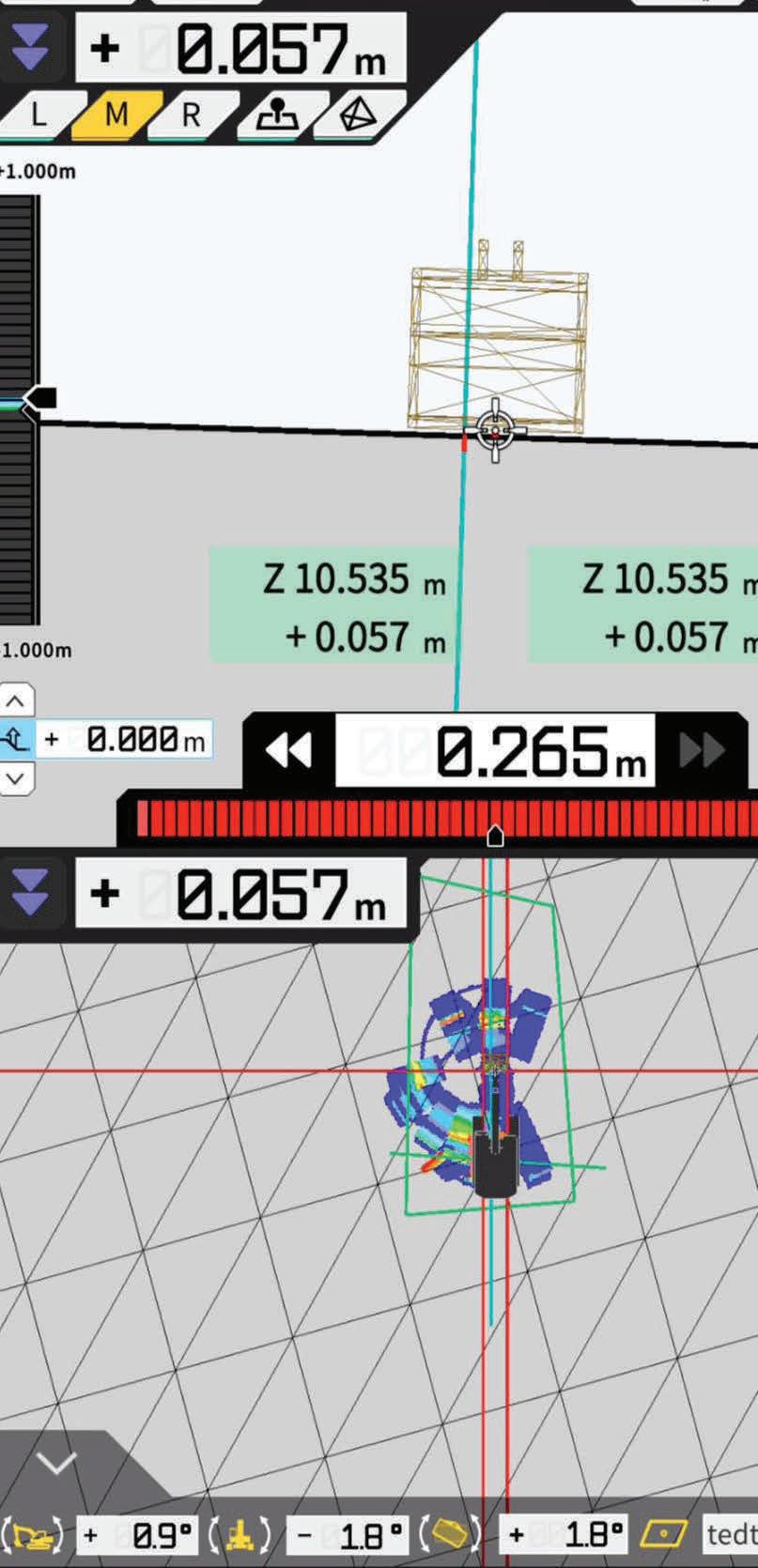

Komatsu’s first-fit tech bundle installed at the point of purchase –no third-party installs, no retrofit delays. Just accurate, productive earthworks from day one.

Available on all new 13–50t excavators, this game-changing bundle includes:

• 3DMG + Payload – Real-time 3D Machine Guidance + load monitoring

• Smart Construction Fleet Lite – Payload reporting from the jobsite

• Smart Construction Remote – Remote access and updates

• 12-Month Gold Support – Dedicated support

• 48-month / 8,000-hour warranty – Peace of mind built in This is genuine Komatsu technology – built, fitted and supported by Komatsu.

www.tradeearthmovers.com.au

Transform your material handling process with FlipScreen – handle any material at any time, anywhere 10

In this issue’s news coverage, CEA announces two new branches in Queensland, Tasmania’s Bridgewater Bridge wins an Australian Construction Achievement Award, Hyundai and Develon merge and Hitachi brings a new Bell grader Down Under, plus much more! 6

Excavator Parts has further expanded its range with new hydraulic hoses and fittings available 12 Toyota Material Handling Australia skid steers and forklifts are a firm favourite for Bjorn Baker Racing 14 The ExtremeFlex range of hosing from ContiTech brings high flexibility and a drag-reducing outer layer 16

All Civil is reaping the benefits of Komatsu’s preventative maintenance program 18

ALLU is advancing circular construction with its new screening bucket for asphalt recycling 20

A long-term trust in CASE and local dealer SA Tractors is powering KW Earthmoving’s success 23

For retired racer Josh Green, a Cat 301.7 mini excavator helps him bring his bike trail designs to life 26 Digger King’s mini excavator trailer package has been the ideal solution for a livestock farmer 30

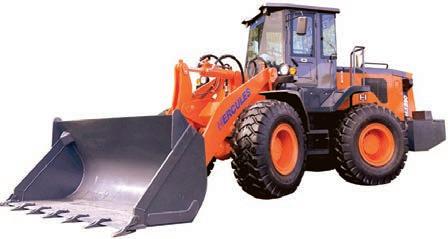

Easy to own and operate, the new Cat 980 GC

Editorial & Design

Editor Cat Fitzpatrick

catherine.fitzpatrick@primecreative.com.au

Journalist

Jackson Haddad

Contributors

Cathryn Greville, Trevor Schwenke

Managing Editor Eugene Duffy

Art Director Daz Woolley

Cover Image FlipScreen

wheel loader delivers low owning and operating costs

A s SA contractor SC Heinrich has grown over the decades, so has its love for Caterpillar machinery

A positive experience using Jetland loading ramps has led Breck Con Excavations to buy a second set JCB CEA has realigned its backhoe loader range with the reintroduction of the 3CX Classic model WA crushing and screening machinery specialist Striker discusses its Strikerlytics approach Demolishing Cronulla clock tower posed various challenges for Effortless Excavations

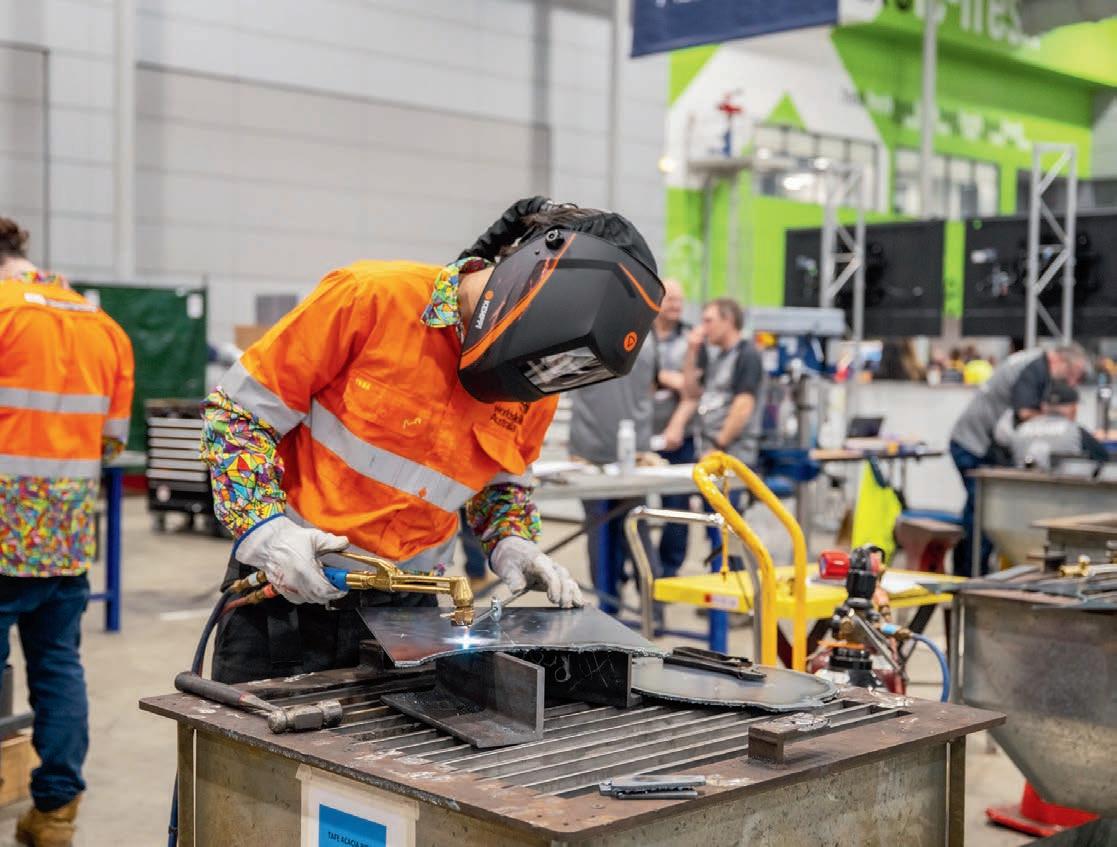

WorldSkills Australia CEO Trevor Schwenke announces the 2026 Skillaroos Training Squad NAWIC is asking industry to join it to make the sector more equitable

Calendar of upcoming earthmoving events Marketplace / DIY advertising Digger deals – hot classified deals! Private advertising coupon Index

CEA is expanding its presence with new sites in Rockhampton and Mackay

CEA, a supplier of earthmoving, construction and agricultural equipment, has announced a significant expansion to include two new branch locations in central Queensland – Rockhampton and Mackay (formerly Terrequipe).

This move aligns with CEA’s commitment to growth, while reinforcing its focus on supporting core industry segments throughout metropolitan and regional areas.

The official handover for the branches took place in late June with both locations now operating under the CEA business trading name.

The new Rockhampton and Mackay branches will form part of CEA’s Northern Region, with CEA’s Brisbane-based operation providing extensive support to ensure a seamless transition for the highly experienced staff currently at both locations.

As part of the acquisition employees previously working for the Terrequipe branches in these locations have transitioned to CEA, ensuring key product knowledge and strong customer relationships are retained within the business.

“The expansion into Rockhampton and Mackay is an exciting move for CEA,” executive general manager Northern Region Wes Henshall says.

“It’s a testament to our focus on

Tasmania’s largest ever infrastructure project has secured a prestigious industry award

Tasmania’s new Bridgewater Bridge has been awarded the prestigious Australian Construction Achievement Award. Presented by the Australian Constructors Association and Engineers Australia, the award recognises not only engineering and construction excellence, but how projects are advancing sustainability, workforce capability and social impact across the industry.

The new Bridgewater Bridge is Tasmania’s largest ever transport infrastructure project and was delivered by McConnell Dowell for the Tasmanian government.

growing the business and our dedication to working with customers across industry segments we know well and are highly proficient in supporting.

“We are also pleased to welcome the experienced teams at these locations into the CEA business and look forward to strengthening our relationships while providing exceptional service to customers within the region.”

Spanning 1.28km, the bridge connects key freight and passenger routes, including two new interchanges, seven intersection upgrades and a shared path for cyclists and pedestrians.

Australian Constructors Association CEO Jon Davies says the project redefines modern bridge building.

“This is a world-class example of innovation and collaboration under pressure – delivered on time and on budget through a pandemic, with meaningful outcomes for workers, communities and the environment,” he says.

A purpose-built precast facility on site enabled efficient and defect-free construction of more than 1,000 matchcast segments – weighing up to 90 tonnes each – keeping the project on track despite pandemic disruptions.

,

A merger has resulted in the Hyundai and Develon construction equipment brands being supported by a new entity

HD Hyundai Construction Equipment and HD Hyundai Infracore have merged to launch a new entity –HD Construction Equipment.

The combined new company will operate with a dual-brand system, continuing to support both the Hyundai and Develon construction equipment brands.

By 2030, the company aims to exceed USD $11 billion in global sales, positioning itself among the industry’s top-tier players.

“This merger marks a critical step toward long-term, sustainable growth,” HD Hyundai Site Solution president Cho Young-Cheol says.

“It represents a new chapter in the evolution of Korea’s construction equipment industry and will strengthen our global competitiveness.”

HD Construction Equipment says it will pursue balanced growth across its core business areas, including construction equipment, engines, and aftermarket services, by focusing on the following strategic initiatives:

• optimising product lines and regional manufacturing to achieve economies of scale

• expanding the compact equipment lineup to offer a complete range of construction machinery

• investing in high-growth areas, such as engine technology and aftermarket services

• accelerating innovation through electrification, smart equipment, and integrated total solutions.

Hitachi is introducing the new Bell G140 grader to the Australian market, with the machine making its debut at the Local Government Association Show in WA in August.

Hitachi says the Bell G140 grader is a boost to precision and productivity with its advanced automatic blade control system.

Production of the highly anticipated Bell motor grader range is planned to start in Q3 2025 for Stage 3 developing markets.

“We’ve been keeping a close eye on the development of this product, and now that we’ve seen its realworld performance and reliability, we’re confident it will hit the mark in Australia’s demanding conditions,” Hitachi product manager David Gallina says.

“Our customers expect durability, precision, and low total cost of ownership – and the Bell Grader delivers across all three fronts.”

The graders are fitted with Cummins engines and ZF transmissions. The G140 runs a 6.7L Cummins with a ZF ERGOPOWER transmission, while the G160 and using the antler controls or joysticks, this machine feels right.”

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

A FlipScreen can be used to screen material, such as topsoil, directly into a skip

Transform your material handling process with FlipScreen –handle any material at any time, anywhere

In an industry where productivity is key, having an attachment on hand that can take waste material and convert it instantly into something usable provides a huge advantage. That’s why contractors across Australia are turning to FlipScreen –the rugged screening bucket attachment that’s transforming how mixed material is handled on site.

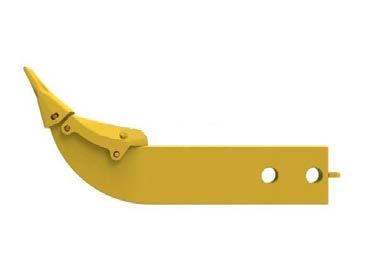

Designed to fit loaders, excavators, backhoes, telehandlers and skid steers, FlipScreen’s range of screening buckets allows operators to screen and separate material directly at the source.

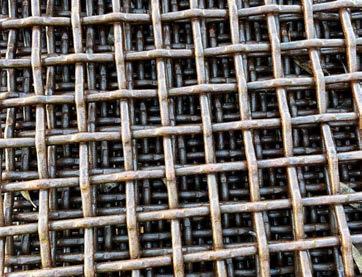

A range of FlipScreen attachments are available for compact machinery all the way through to 50-tonne excavators. It works like a bucket, scooping up a shovel-full of material, then rotating the load. Material passes through a mesh that separates out rocks from soil or different sizes of waste.

If an operator is switching between materials, it’s easy to change the mesh and get to the next job.

“The FlipScreens are designed so the operator can see right through to the leading edge of the bucket,

giving them a much better line of sight compared to a standard general-purpose, or GP, bucket,” FlipScreen inventor and managing director Sam Turnbull says.

“They scoop in exactly the same way as a GP bucket, making the learning process very intuitive.”

With a FlipScreen there’s no need for a separate screening plant, or having to remove waste material from site and transport fresh material back in. Oversize, fines, topsoil, rubble, and rock are processed on the fly –turning what was once waste into usable fill or saleable product.

The key to FlipScreen’s value lies in its versatility. Earthmovers frequently deal with unpredictable ground conditions: rock mixed through topsoil, clay pockets in spoil, or rubble left behind on cleared blocks. This, says Turnbull, is why the FlipScreen stands apart as a musthave attachment on site.

“Almost every customer we have starts out with one application in mind, but quickly expands into many other screening jobs,” he says.

“These often include concrete screening, separating mud from rock, improving the grade of gravel, washing river pebbles, cleaning firewood, and many more.

“We’ve seen FlipScreens applied in all sorts of unusual and unexpected ways. One standout example was a customer using a FlipScreen to separate bullet fragments and spent cartridges from soil at a rifle range, turning what would normally be waste into a valuable, reusable resource.

“FlipScreen attachments have also been employed by militaries as a powerful tool for de-mining postconflict zones, where unexploded ordnance and dangerous fragments are removed to make land safe for public use again.

“On the agricultural side, farmers have used FlipScreen attachments to clean seed, mix fertilisers, and reclaim topsoil from erosion projects. These examples highlight just how versatile the attachment is, often surprising customers with applications they had never originally considered.”

Instead of switching buckets or swapping machines, a FlipScreenequipped carrier handles screening and loading in one motion.

Interchangeable mesh sizes allow operators to tailor the screening process to suit job specs — whether that’s preparing clean fill for backfilling trenches or separating clay lumps from quality topsoil.

For subdivision work, civil infrastructure, or rural development, where site access may be limited and timeframes tight, FlipScreen

attachments cut down on equipment movement and streamline logistics. By reducing the need to cart materials away for processing, contractors slash fuel costs, machine wear, and downtime — all while increasing on-site productivity.

“The FlipScreen is essentially a recycling machine,” Turnbull says.

“Waste is, after all, just resources mixed into an undesirable pile. For example, when you remove concrete from dirt, you end up with crushable concrete and clean fill. When

Different mesh sizes are easily swapped in and out

refurbishing a lawn, traditional methods strip away truckloads of the best topsoil and cost money to dump. By contrast, when you use a FlipScreen to remove grass, you leave freshly aerated topsoil in place and take away only the grass, which compacts to almost nothing when loaded onto a truck.”

A FlipScreen is engineered to thrive in harsh conditions. With no internal moving parts to jam, clog or tangle, and no need to shake the machine or bucket to pass the material through the mesh, this means minimal maintenance and less downtime. The sealed, enclosed design prevents contamination and keeps the screening process reliable, even in sticky, rocky or dusty conditions. If you’re ready to screen smarter and move more with less, FlipScreen isn’t just another attachment – it’s a ground-level upgrade to your entire operation.

To learn more about FlipScreen and the perfect screening attachment for your machine visit flipscreen.net

In waste yards, material such as metal can be easily screened from soil

Excavator Parts has further expanded its range with new hydraulic hoses and fittings available

NSW-based earthmoving machinery parts business Excavator Parts has expanded its offering, with a range of new hydraulic hoses and fittings now available.

With a huge range of new and used excavator parts, seal kits, hydraulic pumps, motors and final drives, family-run Excavator Parts specialises in dismantling and rebuilds for all major excavator brands.

After expanding the Wauchopebased business by adding a second wrecking yard at the beginning of last year, a sandblasting facility and an expanded stock of final drives, the business is now taking the next step with new offerings for its customers.

“We’re excited to expand our

services with the introduction of hydraulic hoses and fittings, perfectly complementing our excavator repair work,” Excavator Parts’ Peter Jilg says.

Excavator Parts can repair and replace hydraulic hosing

“We stock trusted, high-quality brands including Hardy Spicer fittings and Gates hydraulic hoses, giving you reliable solutions for your machinery needs.

“After receiving strong demand and enquiries from local customers in the Wauchope area, we’re now offering this service in-store, with nationwide freight available for added convenience.”

Jilg says that this is the latest step for Excavator Parts as it positions itself to be the go-to provider for parts, with the company’s sandblasting facility saving its customers time and money.

“Our sandblasting facility has been operating since November last year and has already been used successfully for multiple jobs across a variety of industries,” he says.

Parts can now be stripped, rebuilt and tested on site, with final drives now in stock. Excavator Parts caters from one tonne to 70-tonnes –something that Jilg says makes them stand out on the market.

“These particular sized machines [70 tonnes] are rare, and we are lucky enough to be one of the only businesses within Australia currently to have these in stock,” Jilg says.

“We provide a final drive exchange basis. This in turn reduces costs, saving customers money, reducing waste to environment and recycling particular items for reuse in the future.”

With a distribution network that reaches out beyond Australia to the US, UK and Papua New Guinea, Excavator Parts’ new hydraulic hoses and fittings range is continuing to build its reputation as being a one-stop shop for machinery parts.

“Whether you need hydraulic hose repairs or restoration of machinery parts, we’re here to help,” Jilg says.

“Contact us today to learn more or place an order.”

Toyota Material Handling Australia skid steers and forklifts are a firm favourite for Bjorn Baker Racing

Successful Sydney-based thoroughbred trainer and Toyota Material Handling Australia (TMHA) ambassador Bjorn Baker has leveraged the excellent durability, safety and performance of TMHA products to help improve the efficiency and productivity of his business.

As the trainer of Bjorn Baker Racing at Warwick Farm in Sydney’s west, Baker oversees two stables

consisting of 117 boxes, with a total of around 250 horses under the stewardship of the business.

With 117 boxes to maintain, Baker’s team has leant on TMHA’s equipment to make stable maintenance easier, safer and more time effective.

Bjorn Baker Racing uses a Toyota Huski 4SDK4 skid steer loader and Toyota 8-Series forklift to help maintain the workplace. Baker says these have been a huge help on site.

“Each box has one horse, and the skid steer is used to put sawdust in each box, which is essentially the horse’s bedding,” Baker says.

“The skid steer definitely reduces labour with that immensely.

“Toyota Material Handling have done the specifics related to the bucket – they’ve got the one that’s suited to sawdust and the weight, and likewise with the tyres.

“So that works very well and we’re able to either fill up directly into the box or fill up bins, and then the bins can go direct into the stables.”

He adds the Huski skid steer is one of the most effective ways to enhance the efficiency of the workplace, while also offering improved safety outcomes for his employees.

“It’s helped with labour a lot, and in a horse training environment it’s very labour-intensive,” he says.

“A lot of industries are becoming automated and reducing some of the labour required, but unfortunately with horse racing, our biggest cost by far is labour and there’s not many shortcuts we can take.

“I guess this is one thing that with the way I run my business

A Toyota 8-Series 1.8-tonne diesel forklift has helped move feed and hay, as well as being useful in the construction of a new stable has definitely helped with efficiencies and reducing labour costs. It’s also much safer in terms of work cover and taking weight off human shoulders.”

Along with the skid steer loader, Baker also owns a Toyota 8-Series 1.8-tonne diesel forklift, which has proven to be something of a Swiss Army Knife for the company thanks to its wide range of uses.

While primarily used to move feed and hay, the forklift has proved immensely useful for Bjorn Baker Racing, particularly with the construction of a new stable on the premises.

“It’s actually got a remarkable amount of uses,” Baker says.

“I’ve got another stable that I redeveloped and rebuilt in the last year, which was a significant cost.

“The forklift was unbelievably handy in terms of helping with the building job and to move a lot of products. It’s got an amazing amount of uses that I never would have thought of prior to being involved in that building process.”

His positive experiences with TMHA products have caused Baker to consider adding more in the future to further reduce the manual labour around the stables, including a Toyota battery electric forklift and a sweeper.

He adds that the time and labour saved through using his TMHA equipment has allowed Bjorn Baker Racing to focus more on making sure the stable’s horses are in the best condition for each race.

“At the end of the day we’re very much results-driven in terms of what we do on the racetrack,” Baker says.

“Having good systems in place and having some of these efficiencies help us manage the labour demands and concentrate a little bit more on the horses and getting the maximum performance from them.”

The proof is in the pudding for Bjorn Baker Racing, which in the 2024-25

racing season had a breakout year with the second-best strike rate of any major trainer in the country, securing 157 race wins from 757 starts.

With Melbourne’s Spring racing carnival around the corner, it is imperative that as much time as possible is spent on preparing the horses for an exciting season.

Bjorn Baker Racing’s forklift operators have found the forklift and skid steer loader to be easy to use, with reliable operation and smooth driveability.

“They’re pretty good to drive, in particular the skid steer,” Baker says.

“We never hear a bad word, so it’s all going very smoothly. When you’ve got horses and staff, all you want is for things to continue to go smoothly.”

Thanks to the positive impact the machines have had on his business, Baker is a highly satisfied Toyota owner.

“I couldn’t be happier,” he says.

“It’s helped my business, it’s made my business more efficient and, from a safety point of view, a work cover point of view, and being able to concentrate on the horse’s point of view, it’s definitely had a positive impact.”

For more information, visit toyotamaterialhandling.com.au or free call 1800 425 438.

The ExtremeFlex range of hosing from ContiTech brings design to the fore with high flexibility and a drag-reducing outer layer

When transporting fluids in an industrial setting, having strong, reliable hosing is vital to avoid failures and spillage.

ContiTech, the industrial division of Continental, has created the ExtremeFlex range of hosing that provide industry-leading levels of flexibility and a design that reduces the amount of force required to move the hose.

The ExtremeFlex range can transfer fuel and oil under low pressure, as well as being available in a food-grade variant for dry food and liquids. The corrugated synthetic rubber covering reduces the surface area of the hose on the ground, reducing wear and the force required to pull or drag it into place. This reduces operator fatigue and lowers the risk of workplace injury when manoeuvring hosing into place.

Reinforced with spiral-plied synthetic fabric with a galvanized wire helix, the ExtremeFlex range is so flexible it can bend back on itself, making it a top choice for tight spaces and tight corners.

The most recent addition to the range is the ExtremeFlex FR4, which is a low-pressure and high temperature return line or suction line for petroleum and water-based fluids up to 135 degrees C.

ContiTech head of sales distribution – Aus/NZ Lee Cranswick says the ExtremeFlex FR4 hydraulic oil hose is a fantastic addition to the range, with the bend rating and high temperature resistance making it a valuable choice for use on earthmoving machinery.

“One of the main features of the ExtremeFlex family is its bend radius,” he says.

“I’ve had many phone calls from people saying: I think there’s a misprint on your bend ratings in your specification sheet. No, that’s correct, it does bend back on itself without kinking. We’ve had a lot of people in the market try and reverse engineer that product, that’s how good it is.

“Another feature is its corrugated cover. Because it’s got a corrugated cover, it means there’s less product on the ground, so there’s less force to drag, which makes it easier and safer to work with.”

He explains that ContiTech offers a hose fitting system so machinery owners can be assured that they are buying the correct hosing for their application and machinery.

“We can provide a complete match system for the end user,” Cranswick says.

“When you’re dealing with hydraulics, you want to make sure you have the correct products so you don’t have a failure and safety hazards.

“The ability of ExtremeFlex hosing to withstand high temperatures is also really important as these might be used on a site in the middle of the Australian desert where it can get hot.”

With ContiTech offering a wide range of hosing to meet any industrial need, Cranswick adds that customers can trust in the quality and durability of a premium product.

“We’ve been manufacturing industrial hose for 150 years,” he says.

The ExtremeFlex range has a corrugated outer surface to reduce the surface area of the hose on the ground

With the ability to bend back on itself, the ExtremeFlex range of hosing is ideal for tight spaces

“We know what we’re doing and, probably the most important part, we’ve been tried and tested in a really mature market.

For more information on ContiTech’s ExtremeFlex range, visit: www.hoseselect.com

Proudly backed nationally by Toyota Material Handling, Takeuchi mini excavators are rugged, dependable, and productive. They provide exceptional value and outstanding performance, measured by their longevity in the field.

And right now there’s never been a better time to buy a Takeuchi, with our super low 1.69% finance rate for up to 48 months available on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models.To dig out a great deal contact Toyota Material Handling today.

*1.69% finance offer is based on a chattel mortgage on 12, 24, 36 or 48 month term no balloon, minimum upfront deposit equivalent to 10% of the purchase price including GST on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models. Standard hitch and buckets included. Other interest rates may apply depending on loan structure, accessories and or attachments financed. Credit provided by MKP Finance ABN 56 611 706 784 to approved Australian business applicants only (GST registered). Offer valid on orders from 01/09/2025 while stock lasts. Finance must be settled with equipment delivered to customers before 28/02/2026.Toyota Material Handling Australia Pty Limited and, or MKP Finance reserves the right to change, extend or withdraw any offer at any time. Terms, conditions, fees and charges apply. Offers subject to change without notice and whilst stocks last. Images used for illustration purposes only and not indicative of Takeuchi models available. For more information contact your Toyota Material Handling branch.

Based on the Mornington Peninsula and working on major projects across Melbourne, Geelong and throughout regional Victoria, rail infrastructure and civil construction business All Civil Australia is relying on Komatsu machinery to keep it up and running.

To ensure that the fleet is always ready to go, the business recently made the switch to Komatsu’s preventative maintenance program – a move that’s already paying dividends.

All Civil has a fleet of eight Komatsu machines, including excavators, a dozer and loader, which undertake everything from trenching to conduit installations.

All Civil plant and operations manager Rebecca Lincoln joined the team earlier this year, bringing 15 years of experience in civil construction compliance and maintenance management. This understanding of how to get the

most out of machinery led her to suggest Komatsu’s preventative maintenance program to safeguard the fleet against surprise downtime.

“When I arrived, I could see straight away that the maintenance program needed updating,” she says.

“It was manual and reactive, leaving us vulnerable to costly delays. I wanted to introduce an automated, scheduled approach with the help of Komatsu to make sure we were never caught out with machine issues.

“The improvements have been immediate. We’ve seen greater cost efficiency, reduced fuel usage and better reliability across our entire Komatsu fleet. It also allows us to plan around our project windows, so we’re not holding up jobs or delaying transitions between sites.

“It’s pretty much set and forget now. We’re staying ahead of issues rather than scrambling to respond to them.”

All Civil specialises in rail infrastructure construction

Lincoln says that by identifying issues early, All Civil is able to make repairs before they escalate into costly failures.

“Little issues like hydraulic leaks, worn undercarriage components or clogged filters can set you back quite a bit, and for us we can’t accommodate lengthy periods of unplanned downtime as a lot of our projects need to be completed in a short shutdown period,” she says.

“Everything is time sensitive so it makes sense for us to mitigate issues where we can.”

A key advantage of the Komatsu preventive maintenance program has been the transparency around servicing costs. With Komatsu’s fixed pricing structure, All Civil has been able to lock in service costs over a longer period – something Lincoln says is crucial in today’s uncertain economic climate.

“Having set service pricing means we know exactly what we’re up for over the next 12 months, or even longer in some cases,” she says.

“Some machines have the capability to clock up to 2,000 hours in as little as 12–16 months, so it gives us long-term visibility, which is incredibly helpful for budgeting and planning. If something major were to happen in the market, we’re not suddenly hit with increased servicing fees as we’ve already got that agreement in place.

“It also helps manage our resale value of the machines – knowing their servicing has been wellmanaged and up to date.”

Another one of the standout benefits is the partnership with Komatsu itself.

“The team is honest, transparent and experienced,” she says.

“We have access to reliable, knowledgeable mechanics who understand our equipment and know exactly what to look for, and their expertise ensures issues are identified early.”

Learn more about Komatsu’s preventative maintenance at www. komatsu.com.au/support/services

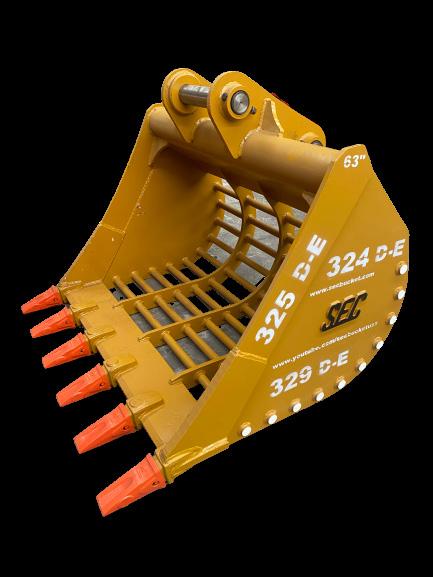

The ALLU asphalt bucket is engineered for processing cold-milled asphalt and reclaimed asphalt pavement efficiently and cost-effectively

Global attachment leader ALLU is advancing circular construction with its new screening bucket, which is set to transform asphalt recycling

Asphalt is one of the world’s most recycled materials, yet much of its potential remains untapped due to inefficient processing methods.

To help close this gap, family-owned global screening and crushing bucket leader ALLU has introduced its newest innovation to the recycling sector, the ALLU asphalt bucket.

With decades of experience manufacturing in Finland, ALLU is renowned for its innovative attachments that transform the way materials are processed and reused in the earthmoving, mining, recycling and industrial sectors.

Complementing the existing ALLU screener and crusher bucket range, the ALLU asphalt bucket is engineered specifically for processing cold-milled asphalt and reclaimed asphalt pavement (RAP) in a faster, cleaner and more costeffective way.

By crushing, screening and turning milled material into a high-quality resource on-site, the ALLU asphalt

A serrated cutting edge and reinforced frame features on the bucket, tailored for aggressive asphalt processing

bucket supports greener and leaner infrastructure development.

“Globally, there’s a clear shift toward sustainable infrastructure in construction business,”

ALLU Finland Oy CEO Peter Grönholm says.

“Asphalt recycling plays a major role in this movement, and our new ALLU asphalt bucket empowers

contractors to turn reclaimed and cold-milled asphalt into high-quality, reusable material directly on site.

“It’s a smarter, more profitable way to work, and we’re proud to help drive this transformation across the industry.”

As municipalities, contractors, and asphalt producers look for smarter ways to reuse milled asphalt, the

A hybrid blade configuration consisting of a mix of screening and crushing blades help to fine-tune performance

ALLU asphalt bucket delivers a transformative advantage.

This purpose-built attachment crushes clumps, screens fines and separates oversized particles – all in a single pass.

It has been designed to meet the rising demand for efficient and cost-effective asphalt recycling, offering customers a highperformance solution to reduce transport costs and reuse material directly at the jobsite.

One of the standout features of the ALLU asphalt bucket is its hybrid blade configuration – a mix of screening and crushing blades –which help to fine-tune performance and achieve consistently highquality end products.

This simultaneous crushing and screening combination allows operators to process cold-milled asphalt directly at the source, eliminating the need for additional crushing equipment.

“The hybrid blade setup is what makes this bucket so effective – it delivers just the right mix of crushing force and fine screening to process asphalt efficiently in a single step,” Grönholm says.

With nominal screen sizes of 12, 16 and 25mm, Grönholm says the bucket can produce over 95 per cent of finished material below target size, drastically reducing reprocessing needs.

Using the ALLU asphalt bucket also reduces the reliance on mobile impact crushers, cutting fuel consumption, wear part expenses and overall tonne-per-cost rates.

This can result in significant savings in both time and money, making the process not only more efficient but far more profitable.

Designed for today’s job sites, the ALLU asphalt bucket is available in several sizes for 25 to 45-tonne excavators and 15 to 30-tonne wheel loaders.

Models deliver a proven throughput of up to 250 tonnes per hour, with rapid drum change-outs thanks to the ALLU variable drum technology.

The attachment is available in several sizes for 25 to 45-tonne excavators and 15 to 30-tonne wheel loaders

The robust design of the bucket includes a serrated cutting edge and reinforced frame, tailored for aggressive asphalt processing. Whether it’s pre-crushed demolition asphalt or compacted cold-milled material, the ALLU solution is engineered for reliability, mobility and productivity – even in tight or urban work sites.

The ALLU asphalt bucket was officially launched in June in Finland and will see its Australian release in Q4 2025.

Manufactured in Finland, ALLU buckets are built for efficiency and durability. With distribution in over 30 countries, ALLU products are available across Australia through an authorised dealership network that provides maintenance and support.

For more information on the ALLU Asphalt, visit allu.net/products/asphaltscreening-bucket/ or contact the authorised ALLU dealer in your state: Queensland and Northern Territory: QLD Rockbreakers – rdw.com.au/qld-rock-breakers – (07) 3452 0772 Victoria, South Australia and Tasmania: Walkers Hammers – walkershammers.com.au – (03) 9315 3788 Western Australia: Total Rockbreaking Solutions – totalrockbreaking.com.au – 1300 921 498

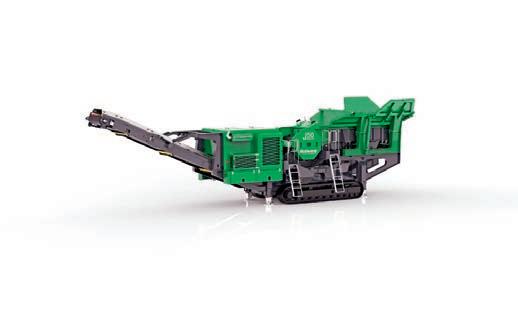

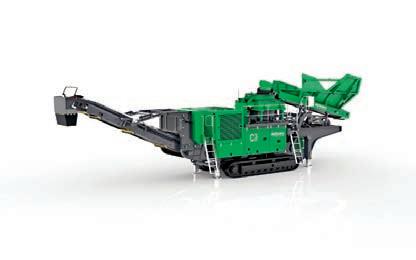

KW Earthmoving has been using CASE machines for over 15 years

A long-term trust in CASE Construction Equipment and local dealer SA Tractors is powering KW Earthmoving’s success

For Kane and Louise Whitworth of KW Earthmoving in Mildura, Victoria, their relationship with CASE Construction Equipment and local dealer SA Tractors goes beyond machinery. It’s built on reliability, loyalty and unwavering support.

Since purchasing their first CASE skid steer in 2008, KW Earthmoving has grown into a trusted name in the Sunraysia region, completing earthmoving projects with a wide fleet of CASE machines.

Over the past 15 years, Kane and Louise have invested in nearly every type of CASE machine available – from mini excavators to the mighty CX490C, the largest CASE excavator in Australia – relying on the performance and support that CASE and SA Tractors can provide.

“We’ve been running CASE

The business has invested in nearly every type of CASE machine available

machines for over 15 years now, and there’s never been a reason to change. They do the job, they’re priced right, and the support is always there,” Kane says.

The Whitworths’ commitment to CASE equipment is a direct reflection of the brand’s consistent reliability on site.

No matter the size of the project,

CASE local dealer SA Tractors has provided ongoing support to KW Earthmoving

KW Earthmoving remains committed to CASE as its brand of choice

Kane and his team trust their CASE fleet to deliver exceptional results without missing a beat.

“I find it all to be exceptional in performance and fuel efficiency,” he says.

“We don’t have any problems. They’re definitely not underperforming in any part of any job that we do.

“When you’re running a business, you need machines you can count on. CASE gives us that confidence –they’re reliable, economical and they just keep getting the work done.”

This strong reputation is reinforced by the ongoing support from the team at SA Tractors.

Director Matt Allen, who has worked closely with Kane and Louise over the years, credits the partnership’s success to a shared understanding of what matters most –keeping machines working and projects moving.

“We understand the machinery needs to keep running, and time is money,” Allen says.

“The power and support that they get from the CASE brand, and from SA

Tractors, goes a long way to making sure they stay CASE customers well into the future.”

SA Tractors’ commitment to after-sales service and responsive customer support has been critical to KW Earthmoving’s loyalty.

Whether it’s supplying new machines or providing parts and servicing, Allen and the SA Tractors team make it a priority to ensure that Kane and his operators have the tools they need to succeed.

“Our relationship with KW Earthmoving keeps going because we keep offering the support they need, and the machinery keeps on producing the results that they rely on to keep their business and customers happy,” Allen says.

Over the years, Kane and Louise’s CASE fleet has grown to include everything from nimble 1.7-tonne excavators for tight access jobs, powerful skid steers, robust dozers and large crawler excavators built for major earthworks.

The combination of highperforming equipment, competitive pricing and ongoing dealer support

has made a measurable difference to KW Earthmoving’s bottom line.

“Every time we’ve needed a new machine, CASE has had the right option for us,” Kane says.

“From the smallest excavators to the big gear like the CX490C, it’s all proven itself on our jobs.

“I recommend CASE equipment to pretty much everybody. It’s well priced to buy new, service is very economical, and fuel efficiency is very good – whether it’s a hard job or an easy job.”

As KW Earthmoving continues to grow and take on new challenges, Kane and Louise remain committed to CASE as their brand of choice – confident that, with SA Tractors by their side, they have the performance, reliability and support needed to keep building a strong future.

For retired racer Josh Green, a Cat® 301.7 mini excavator has been vital to help him bring his bike trail designs to life

Josh Green was on his Cat 301.7 mini excavator, deep in the bush and busy digging a mountain bike trail, when Earthmovers & Excavators gave him a call to have a chat about his digger.

Well known on the motocross bike racing circuit, Green has since built up a bike coaching business called Off Road Advantage with a sideline in building trails. This is

where his Cat 301.7 comes in with its manoeuvrability on difficult terrain, allowing him to sculpt trails out of challenging landscape.

“When I was a professional dirt bike racer I had my little Cat machine just to clean up because I used to race through the bush, which would get trashed,” he says.

“I had the excavator to trim and

tidy that up. From there I started building mountain bike trails for people and that’s now become a full-time business.”

Green has lived and breathed racing since the age of seven when he received his first bike and started competing at a local club.

“It was only a matter of time before I was properly hooked, and just wanted to race bikes every weekend,” he laughs.

“That turned into traveling the country with my family doing motocross and eventually I got into Enduro [endurance] racing.”

After winning a series of Australian championships and representing Australia on the world stage, Green retired in 2023 to focus on his coaching business, which he runs from a property in Stroud, NSW.

“I now travel the country, and I’ve had contracts with the Australian Defence Force, and a bunch of different opportunities to coach different riders,” he says.

“I now do a lot of the track inspections at racing schools and advise them on safety guidelines.

The Cat 301.7 mini excavator is perfect for Green’s business due to its compact but powerful design

Having been involved in racing for 20-odd years it’s quite cool to be on the other side of the fence now and making a difference to the sport.”

As for many, the COVID pandemic forced Green to change track as lockdowns and event restrictions put a temporary halt to his racing and coaching. This led him to operating machinery on a more regular basis.

“There was a small company that had just started building trails in my local area, and I approached them and asked if they had any work,” Green says.

“I learnt how to drive an excavator through them and, once COVID ended, I went back into racing but decided to buy my own machine.

“I’ve driven a lot of machines, but when I hired a Cat excvator I fell in

love with it straight away. From there I called WesTrac and bought my first machine and I wouldn’t use anything else now.”

With Green’s work building mountain bike trails, the terrain he is working in has a major influence on the size of machine he can use. His equipment of choice is a 1.9-tonne Cat 301.7 mini excavator that has a 15.7kW (21hp) engine and a dig depth of 2.5m, which

he says brings a mixture of digging force and manoeuvrability that best suits his needs.

“It’s perfectly built for what I do,” he says.

“I also like the open cab. As I’m on the side of a mountain most of the time in pretty steep country, having less weight up high is good. The power and the comfort of the machine is second to none.”

The building of bike trails he says is based on a mixture of imagination

and working with the landscape to create interesting and exciting paths for his clients.

“To explain it to someone who doesn’t ride bikes, it’s like designing a slide at a water park, but we’re building it out of dirt,” he says.

“Then you add in jumps and features for variation. Unlike the slides though, we actually want the water to stay off the track, so we also put drains in where necessary. This means you do need to understand how water works on the terrain and whether there are rocks there that can’t be moved or unsuitable soil conditions, but a lot of the work is down to your own imagination.

“We’re also working towards what the client wants. It’s like skiing where you have different difficulties, which then influences how steep a track is, how big the jumps are, whether the jumps are rollable, or just a big jump.

“You’ll be building it for a certain level of rider, but you still want it to be fun for everyone who’s riding. For instance, I build a lot of private backyard trails for people, and they’ve got a four-year-old kid, but they’ve also got a bunch of middleaged dads that want to go and have fun too.

“In my digger, I do the excavation and compaction, and then we have a follow crew with rakes and shovels who fine tune what I’ve done.”

With the steepness of the terrain and location of his work, which is often in national parks or state forest, Green says that his Cat 301.7 has enough power to dig the trail and move rocks, but is light and compact enough to traverse a challenging landscape.

“Even though we’re excavating a trail, you still don’t want to go and clear a 20m-wide path through it, so we can’t go in there with a bulldozer,” he says.

“Having a smaller machine reduces the impact that we’re having on the land.

“With other brands of machinery, I’ve gotten to a point where I can’t dig a rock out, or I can’t dig the soil because it’s too hard. Whereas, with the Cat excavator, it’s been no problem, which was a big decider for me in buying this machine.

“Most people can’t walk on some of the terrain we do trails on so it’s pretty impressive where we can take this machine.

“Also, some of the trails can be 10km in the bush, and I’ve got to

With a lot of his work on challenging terrain, Green says his 301.7 mini excavator can handle it with ease

be able to get it in there. With the machine only being two tonnes I can tow it behind my land cruiser and then drive it into most places.

“Also, with the small machine being light, if it is boggy you’ve got less chance of it sinking into the ground.”

Supporting Green and his Cat machine is dealer WesTrac from its base in Newcastle, which he describes as having “every part under the sun” in stock.

Having the support and parts quickly available is key for Green, having had problems with keeping machinery running with other brands.

“I’ve had excavators in the past where we had to wait a month or two for parts, so that’s a big thing for me now,” he says.

“With WesTrac having workshops and service crews pretty much everywhere I go on the east coast that makes life easy for me.”

Service is also a major draw, with Green happy to highlight the positive ongoing relationship he has with his local branch.

“The WesTrac guys go above and beyond,” he says.

“If I have even a slight problem I just contact my sales guy and he’s all over it. They touch base with me and ask me about my plans. When I was thinking of upgrading my machine they let me know of upcoming deals and interest rates. It’s good to have that contact and feel like they’re looking after me with the best deal they can.”

If you’re in NSW, ACT or WA and are interested in a new Cat machine, head to: www.westrac.com.au

© 2025 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

ALLU ASPHALT BUCKET – BUILT FOR RAP. DESIGNED FOR RESULTS.

Unlock the full potential of reclaimed and cold-milled asphalt with the ALLU Asphalt Bucket – a next-generation hybrid screening solution engineered for maximum efficiency and sustainability.

One-step processing – crushes and screens simultaneously

High productivity – up to 250t per hour

Hybrid blade tech – superior material separation in a single pass

Robust build – reinforced for heavy-duty asphalt applications

Fits your fleet – suits 25–45t excavators and 15–30t wheel loaders

The hybrid blade setup – a mix of screening and crushing blades – enables the bucket to crush clumps, screen fines and separate oversized particles all in a single pass, eliminating the need for pre-crushing or secondary equipment.

Launching in Australia Q4 2025. Register your interest today with your local ALLU dealer:

Scan for ALLU dealer locations in Australia: QLD | VIC | SA | WA | TAS | NT or visit attachmentspecialists.com.au/allu

IMS have added the new BP1200-48TB track electric twin power blender to its impressive collection of ed hopper each five meters long holding and controlled by a PLC control and recording system that can be operated from an iPad or phone from its own Wi-Fi system from a loader or ll fitted with invertors offering variable speed to each feed hopper conveyor. The generator can be connected to mains power and could power an

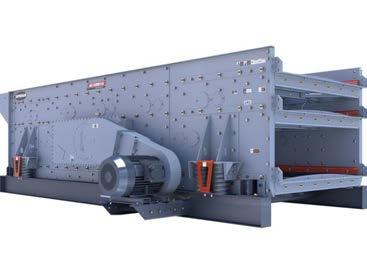

Scalping Screen with a 10 x 4 two deck screen producing three products on high rise tracks

Price $227,000 Plus GST

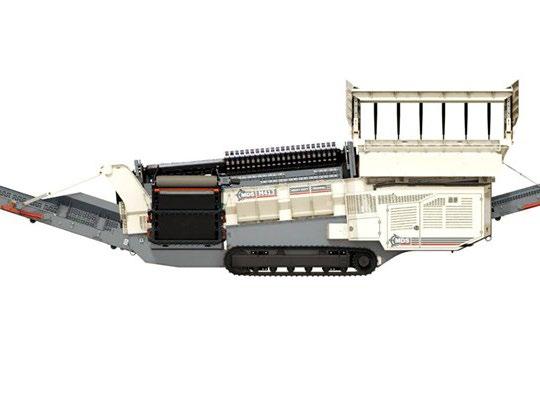

New IMS-MC1050-14TF

Track Conveyor with a five-meter-long feed hopper with a

Price $244,000 Plus

offered Braeside fines into roadbase to make spec or ol and CTB. The PLC control and recording

New IMS-BP1200-9TB

Twin five-meter-long feed hopper blender with mixer and water adding spray bar POA

Jaw Crusher with a single deck screen producing two finished products. Diesel electric which is very

and only uses

Digger King’s 1.5-tonne mini excavator trailer package has been the ideal solution for a livestock farmer who needed an easy way to transport his equipment

While excavators are traditionally seen in construction, earthmoving and landscaping projects, the versatility and manoeuvrability of these machines is making them increasingly popular with farmers.

Anton Nel’s experience with Digger King’s 1.5-tonne mini excavator is evidence of this, with the model being the perfect companion on his livestock farm in Tamban, New South Wales, situated between Coffs Harbour and Port Macquarie.

Only a year ago Nel was living the city life in Brisbane, so he says it’s been a significant lifestyle shift to look after around 20 Black Angus cows and 30 white Australian sheep across his 60-acre property.

“Over the last year, I’ve been getting more livestock and acquiring all the equipment needed to maintain the farm,” he says.

“I’m still busy ramping up the number of animals and splitting the paddocks, so I needed a mini excavator to help with a lot of the work.”

As an electrical engineer by trade, Nel also runs his own business working on high voltage power stations, with the farm running as a separate business.

Since his working days aren’t fully dedicated to the farm, he wasn’t

planning on breaking the bank buying from a large international OEM. Instead, he was looking for a cost-effective machine that would still offer the reliability he required –and turned to Digger King to get what he needed.

An important factor for Nel when purchasing his new mini excavator was finding a trailer

package that would enable easier transport for both the digger as well as his on-farm UTV.

After doing thorough research, Digger King’s 1.5-tonne mini excavator trailer package proved to be the ideal solution.

“I originally had a smaller trailer that wasn’t really suitable for my UTV, but Digger King’s trailer was perfect for what I needed,” Nel says.

“If I need to move the excavator

around the farm, I can quickly drive it up on the trailer, transport it to where I need to work, and then drive it off the trailer to do whatever I need to.”

This can always be done safely thanks to four-wheel electric brakes that are included on the trailer, as well as easy fold-down ramps.

Another important consideration for Nel was a mini excavator with a reliable engine, with Digger King’s 1.5tonne model powered by a Kubota 14hp (10.3 kW) engine.

“The price of Digger King’s mini excavator was very good for a machine running a Kubota engine,” he says.

“I knew I would be able to maintain it myself and I wouldn’t struggle to get parts if they were needed.

“I was also confident that I’d be getting a reliable machine because Digger King had an extensive range of machines available with some large equipment.”

Having had the Digger King mini excavator for a few months, Nel has been putting it through its paces in a range of tasks on his property, including expanding paddocks, laying pipes for water

troughs and digging holes for trees.

Nel says one of the largest benefits of the mini excavator is the efficiency in which it can complete these jobs.

“I’m digging one by one metre holes to plant the fruit trees, and it would take a significant amount of time to do this manually,” he says.

“I’ve just installed three additional water troughs on the farm, I’ve added extra paddocks, and I still have a few extra to go. At the end of the day, it turns into quite a few hundred metres of laying pipes.

“The excavator has also been

useful building barriers to keep wild dogs out, which can sometimes pose a threat to our sheep.”

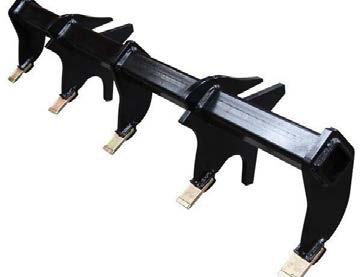

These jobs have been made easier through Digger King’s standard attachment selection, which includes a 200mm GP bucket, 400mm GP bucket, 500mm mud bucket, ripper, thumb grab and rake.

All these attachments can be quickly and easily swapped out with the machine’s standard quick hitch. At 950mm wide, the 1.5-tonne mini excavator is well-suited to tight access applications, and the retractable tracks feature only enhances this by bringing the machine down to 780mm.

This feature is key for Nel, as it enables the Digger excavator to access his narrow veggie garden.

Compared to other cost-effective OEMs, Nel says Digger King has done an excellent job of providing all the necessary information needed to operate the machine.

“Support has been very good, with training videos and guides on how to do service and maintenance yourself to a comprehensive manual that’s easy to follow,” he says.

“I’ve had absolutely no dramas with the mini excavator and it’s been exactly what I’ve needed.”

For more information on Digger King’s 1.5-tonne mini excavator trailer package, visit diggerking.com.au

Easy to own and operate, the new Cat® 980 GC wheel loader delivers high performance and low owning and operating costs

Caterpillar has announced the release of its new Cat 980 GC wheel loader.

Weighing in with an operating weight of 29.5 tonnes, the Cat 980 GC wheel loader comes with a Cat C13A Tier 3 engine that has a gross power @1,800 rpm of 307kW (412hp).

The new heavy-duty Cat 980 GC wheel loader offers low fuel consumption with an on-demand fan, load-sensing hydraulics, intuitive controls and Performance Series buckets.

With a focus on fuel efficiency, the Cat 980 GC wheel loader includes an engine idle management system (EIMS) to minimise idle rpm, auto engine idle shutdown that shuts off the engine after a set time period, variable speed fan and load sensing hydraulics, which combine to offer low fuel consumption and sound levels on the machine.

Four forward/reverse speeds reach a maximum 39.8km/h, and the Electronic Clutch Pressure Control (ECPC) shifting system provides smooth, efficient gear changes in all operating conditions.

Available ride control improves operating smoothness over rough terrain while ensuring material retention and increasing efficiency, and the optional limited slip differential axle increases traction in poor underfoot conditions.

With a bucket capacity range of 4.3–5.8 cubic metres, easy-to-load Cat Performance Series buckets use a system-based approach to balance bucket shape with the machine’s lift and tilt capacity, weight and linkage.

The bucket design improves material retention and reduces dig time with build options that include general purpose, flat floor, heavy duty rock, coal and light material to meet any application.

The Cat 980 GC wheel loader has a static tipping load with tyre deflection of 18.9 tonnes.

Field proven, the Cat Z-bar loader linkage with cast crossmember and tilt-lever provides strong digging efficiency and high breakout forces for superior production capabilities. Load-sensing hydraulics produce flow and pressure for the implement only when needed, improving machine productivity and resulting in low fuel consumption.

The new 980 GC can be equipped with the Cat Fusion quick coupler and controls, and combined with optional third-function hydraulics, the coupler allows use of a wide variety of work tools.

Cat VisionLink, standard for the new 980 GC, allows fleet managers to track critical loader operating parameters like machine location, hours, fuel usage, diagnostic codes and idle time to improve productivity and lower operating costs.

Also optionally available, Cat Payload weighs material while

Features focused on fuel efficiency include engine idle management and load sensing hydraulics

moving to the truck and lifting for on-the-go weighing (not legal for trade), so the operator can load to exact specification, load more trucks and avoid over- or under-loading.

The Cat Payload for Trade option for Cat Advanced Payload allows you to integrate the scale data directly into your business processes. It is type approved by the International Organization of Legal Metrology, while retaining all the features of the standard version of Cat Advanced Payload.

Providing a comfortable working environment throughout the shift, the 980 GC’s spacious cab design features easy, intuitive controls and excellent visibility. Pilot-operated hydraulic controls deliver low-effort, comfortable operation and include a remote transmission kick-down switch for operating comfort.

For safety, ladders are standard on both machine sides, providing easy access to the cab from the lefthand side and to service points from the right-hand side. Extended windows with wide, flat, and distortion-free front windshield combined with rearview mirrors with spot mirrors offer clear visibility to the jobsite.

A rearview camera is standard, and a windshield guard option is available. Air conditioning with louvered vents allows the operator to direct airflow, while the suspension seat can be adjusted.

The new loader features convenient service points, one-piece tilting hood with swing-out radiator, and sight gauges for quick and efficient daily maintenance.

Hard-to-reach pins have remote, conveniently grouped grease fittings for easy preventative lubrication.

For more info on the Cat 980 GC wheel loader speak with your local Cat dealer or visit: www.cat.com

MCCLOSKEYS2503D 2024,Usedmachinewithdemohoursonly,fullminespec, magneticheaddrum.SM337. TA1284860.

MCCLOSKEYJ50V2 1270x735jawopening,Catengine,hopperwings,magnet, sidebelt.S157. TA1188902.

MCCLOSKEYR155

R155,16'x5',Hardoxapronfeeder.SM289. TA878996. POA

MCCLOSKEYS130

14'x5'twodeck,100mmremotetippinggrid,Cat130hpInstocknow.SM248. TA908181. POA

MCCLOSKEYTS4080 24mtrackedstacker,1000mmbelt,hydraulictailandtop fold.CM171. TA908173. POA

MCCLOSKEYS190 2020,20'x5'twodeck,100mmgrid,readyforwork condition.SM237. TA1203702.

$335,000+GSTExMSCdepot

MCCLOSKEYC3 MC300cone-directdrive,CaterpillarC13.KM109. TA1059683. POA

MCCLOSKEYS130 2020,14'x5'doubledeck,Catengine,15'hopper.SM238. TA1198773. $280,000+GSTExMSCdepot

MCCLOSKEYS190TRIPLEDECK 20'x5'tripledeckdeck,100mmremotetippinggrid,Cat C4.4130hp.SM284. TA1122980. POA

As South Australian contractor SC Heinrich has grown over the decades, so has its love for Caterpillar® machinery

Based out of Stanley Flat in South Australia’s Clare Valley, family business SC Heinrich has built a well-respected earthmoving, quarrying and transport business over the decades.

Handling everything from largescale roadworks and mining infrastructure to dam construction, windfarm development, agricultural land care and local council contracts, the company also hires out trucks,

scrapers, excavators, dozers and a mobile crushing plant.

In addition, SC Heinrich produces a broad range of quarry products from a series of quarry sites located across the Clare Valley and the Mid North area of SA.

The power of three

Set up over 60 years ago, SC Heinrich is currently run by managing director Malcolm Heinrich, with

help from his son, Alex, as operations manager, and his brother, Andrew, as leading hand and operator.

“We are a family business of friendly, hard workers whose aim is to not only deliver a quality service, but to also exceed customer expectations,” Malcolm says.

The family tradition began three generations ago in 1954, when Stanley Clarence Heinrich, along with his wife Yvonne, started off a transport business with just a truck and a shovel.

“Stan sold his motorbike to buy the truck from his then-employer Merv Hentschke,” Malcolm says.

“He started carting sand and gravel by loading the truck with the shovel and unloading with the same shovel.

“It was hard work. Sometimes he would get the truck bogged in the sandpit and have to unload, dig the truck out and then reload.

“He also carted grain, grapes, fertiliser, all manually loaded and unloaded. He also did earthmoving, cleaning out and building dams, and any other jobs that came along.

“Mum was always by his side doing the books, making food, sewing and

Years later, Stan added a D7R to his lineup

playing the piano accordion when the beers came out!”

As the years progressed, the Heinrich family was able to update to more modern machinery, with a Cat RD4 bulldozer joining the fleet.

“From there on they increased the amount of machines and trucks and, by the 1960s, were employing several workers, with me and my brothers coming on board in the 70s,” Malcolm says.

“We were always expected to perform in the company, but that was an easy task as we all grew up loving trucks and earthmoving machinery.

“I left school on my 15th birthday as I thought there wasn’t much more I could accomplish there.

“Dad was always surrounded by friends and relatives in the same industry, especially the outback mailman Tom Kruse, who was mum’s uncle and famous for the Back and Beyond film.

“From Matchbox and Tonka toys through to the big boys’ toys like our Caterpillar, it was in our blood. It was a no brainer to take over the reins from dad.”

Stan retired after 50 years in business and remained actively involved for a further six years before he passed away in 2010.

“There’s nothing greater than a three-generation family business,” Malcolm says.

“I have worked in it since I left school in 1973. Various other family members have been involved for many decades and now my son is part of the team.

“We work to the strict values that mum and dad had.

“Do an honest day’s work for an honest day’s pay. Don’t be dishonest and remain truthful at all times. You don’t necessarily have to be the cheapest or the dearest – all you have to do is a quality job and that will get you the next job.”

Also paramount is how the business treats its employees, with permanent staff currently numbering between 35 and 40.

“Many of them are like members of the family,” Malcolm says.

At the heart of SC Heinrich and Co’s operations is a deep commitment to dependable, high-performing machinery. Malcolm says that is a key reason why Caterpillar equipment remains a cornerstone of the company’s fleet.

The current line-up includes more than 300 machines, plus attachments: a mix of mobile crushing equipment, dozers, excavators, graders, rollers, scrapers, skid steers, trucks, dollies and light vehicles.

Of these, about 100 machines bear the yellow brand.

“The prime services that we provide are transport, earthmoving and quarrying,” Malcolm says.

“We do lots of local, state and federal government jobs and council contracting, anything earthmoving-related.

“Since 2001, we have been using Caterpillar exclusively. Prior to that, we had a mix of Caterpillar and another brand or two.

“Caterpillar equipment always shone out and we would not change brands from Caterpillar now.”

In short, all the earthmoving equipment is made by Caterpillar, and all the crushing and screening plants are Caterpillar-powered.

The fleet now includes: eight 30-tonne and 40-tonne dump trucks; thirteen D7R to D11T dozers; 26 305 to 374F excavators; five 12M to 140M graders; 30 922B to 986 loaders; 10 two-tonne to 17-tonne rollers; two scrapers and nine CTL 255 to 299D3 skid steers.

Malcolm remembers with fondness the first new Caterpillar the company bought.

“In 1968 we bought a brand-new Cat 922B wheel loader,” he says.

“It was a very proud moment, taking delivery of that machine. We always referred to it as the big loader.

“Until a 936E come along and then that become the big loader, and so on over the ages as things multiplied and enlarged.

“We still have the 922 and will

restore it one day when time permits.”

Malcolm says that a D7R tracked dozer bought in 2001 became Stanley’s pride and joy.

“That dozer was our first new Cat purchase for some time, and it was a sign that we were going the right direction,” Malcolm says.

“We still have that machine as well, fondly referred to as Stan’s dozer.”

Malcolm says the innovations that Caterpillar has brought in over the years have been of significant advantage.

“Technology on Caterpillar machines is leading edge and impressive,” he says.

“The range of machines is huge, with basic models up to the top shelf with the lot.”

Even something as basic as air-con was a welcome move.

“It may be standard now, but the introduction of air-conditioned cabins has been a godsend,” he says.

“Most of our 60’s and 70’s machines had no cabins and loud exhausts. It has been such a fantastic experience to be on a tractor with an enclosed cabin.

“Also, there are other improvements like the mechanical levers changing to electric-overhydraulic controls, which make operation so much easier.

“The electric control modules and computer systems in the machines make servicing and storage of data much faster.

“And then there are the machine guidance, control and 3D systems. The tractor basically tells us what to do now.”

As the official Cat dealer in South Australia, Cavpower now supplies Heinrich with its range of machines. But all those years ago, when the business bought its first Caterpillar, it was from its predecessor.

“I always remember when I was a young fellow in the 60’s, I would go there with dad and I was always amazed at the Caterpillar tractors everywhere,” Malcolm says.

“Then Cavpower took on the Caterpillar franchise, and we continued to be well looked-after.

“The Cavpower team have become like a part of us. For a CEO, Jo Jones is very hands-on. Mark Taylor is our direct sales manager and, as a result, is now a direct family friend who has served us for decades.

“There are many others, like Luke Drogemuller in used sales, and Simon Lyall in product support.

“There are always a few twists and turns running a big business but we have a relationship that flows effortlessly, from new sales to backup and maintenance.”

Taylor says he has been working with the Heinrichs for close to three decades, and over that time has sold the company well over 50–60 machines: “Graders, loaders, dozers, excavators, skid steers, rollers, dump trucks, you name it,” he says.

“They are really like part of the family. With Alex now heading up the business on a day-to-day basis, we are doing business with him frequently as well.”

As Caterpillar celebrates its 100th anniversary this year, SC Heinrich is

also aiming to create a lasting legacy of its own.

“We aim to carry on the father’s and grandfather’s names in the business and hopefully the tradition will flow to our children and maybe their children to make four generations,” Malcolm says.

SC Heinrich is already making a mark when it comes to community projects, including support for a number of sporting and Rotary clubs.

“We do support community in lots of ways, financially and in kind,” Malcolm says.

And it’s always done with Caterpillar at front of mind.

“There’s nothing better than rolling up to a working bee with a Cat machine, which is usually a bit bigger than the task requires,” Malcolm says.

“Our loyalty to the Cat brand is wellknown. We have Cat hats, Cat clothes, Cat socks and even a Cat shovel.”

With family at its core, SC Heinrich continues to grow its reach with passion for earthmoving and a love of Caterpillar machinery.

“Some of our family members are off doing their own thing at the moment, but as time passes they will gravitate back to their grassroots and benefit from the legacy that will ensue,” Malcolm says.

“If Stan could see where we are today, he would have a big smile on the face.

“So many people tell us how well we’ve done, and how much Stan and Yvonne would be astonished and astounded by it all.

“We’ve gone from D7 to D11 dozers, and 922B to 982M loaders and bigger, 305 mini excavators up to heavy duty 374F excavators. Dad would be absolutely amazed. I wish he could see it all now.

“And if I was ever in doubt about buying another machine, he would say ‘If I was your age boy, I’d just go ahead and buy it’. And so the story continues, and hopefully with no end.”

For more information on the Caterpillar range from Cavpower, visit: www.cavpower.com © 2025 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

"It's transformed the way we process waste, making it quicker and more precise"

Joshua

Berardinelli – General Manager, Austip

Recycling

Joshua Berardinelli leads Austip Recycling, a Sydney-based, family-run plant driven by a mission to reduce landfill waste and turn used materials into new, reusable products. Operating daily from 7am to 6pm, their high workload was beginning to push their previous screening equipment to its limits.

Looking for a more efficient, space-saving solution, Austip turned to Screenmasters Australia and the Keestrack K6. “With the K6, we can achieve a three-way split instead of two, which means less material to landfill and more valuable by-products,” Joshua explains. The switch has not only increased production but also reduced costs and downtime.

For Austip Recycling, the results speak for themselves.

You too can count on SMA

Call : 1800 571 464

www.screenmasters.com.au

Proudly partnered with

The winners of the 2025 Civil Contractors Federation Queensland Ltd (CCF QLD) Earth Awards, People’s Awards and Industry Training Awards were announced in August at the Excellence in Civil Construction Awards.

Held for the first time at The Star Brisbane’s new Event Centre, this year’s event welcomed a record crowd of almost 500 attendees.

The evening was officially opened by special guest The Hon. Brent Mickelberg MP alongside CCF QLD CEO Damian Long, who highlighted the significance of the event as CCF QLD celebrated 32 years of the Queensland Earth Awards.

The CCF QLD Earth Awards recognise excellence in civil construction across projects such as roads, bridges, railways, marine structures and utilities. They showcase the innovative engineering achievements of Queensland’s civil construction industry over the past year and are held in the highest regard across the sector.

Awards were presented in six categories based on project value:

• P rojects valued up to $2 million: POTL Eastern Breakwater Modification – CivilPlus Constructions Pty Ltd

• P rojects valued $2 to $5 million: Yungaburra Raw Water Intake

Replacement – CivilPlus Constructions Pty Ltd

• P rojects valued $5 to $10 million: Brisbane Airport A1 and A9 Thresholds Reconstruction Project

– BMD Group

• P rojects valued $10 to $30 million: DRFA Gympie Package 02 –Durack Civil

• P rojects valued $30 to $75 million: Loganlea Road Upgrade Project –SEE Civil Pty Ltd

• P rojects valued $75 to $150 million: South Coast Region Natural Disaster Program – McIlwain Civil Engineering Pty Ltd.

Introduced in 2018, the People’s Awards have become highly regarded within the industry. They celebrate the achievements of individuals and teams working across QLD civil construction. The 2025 winners are:

• Site Supervisor of the Year: Jure Starcevic, Abergeldie Complex Infrastructure

• Work Health & Safety Champion of the Year: James Huurdeman, GRC Civil

• Plant Operator of the Year: Patrick Flannagan, JF Hull Holdings

• Environmental & Sustainability Champion of the Year: Michael O’Grady, BMD

• Civil Engineer of the Year: Matthew Lacey, JF Hull Holdings

Jure Starcevic was named Site Supervisor of the Year. Image: Warrington Photography

• Support Champion of the Year: Alannah Kubacki, Fulton Hogan Construction

• Construction Leader of the Year: Luis Rodrigues, Haslin Constructions

• Collaborative Project of the Year: Toowoomba Regional Council 2022 Flood Recovery Program, Georgiou Group, Toowoomba Regional Council and Golding.

The CCF QLD Industry Training Awards recognise emerging talent in Queensland’s civil construction sector who are undertaking, or have recently completed, studies with Civil Train (RTO #5708).

“Our industry thrives because of the skilled individuals who choose to be part of it,” CCF QLD CEO Damian Long says.

“Celebrating their dedication to training and skills development is essential, and events like this give us the chance to do just that.”

The 2025 winners are:

• Certificate II in Civil Construction Student of the Year: Mark Harden, Get Group

• Certificate III in Civil Construction Student of the Year: Jak Nicholls, CC P & C

• Certificate IV Student of the Year: Chloe Kirby, Bielby Hull Joint Venture (BHJV)

• Diploma Student of the Year: Richard Singh, Albem Operations Pty Ltd

• E ncouragement Award: Jaden Reid, CC P & C

• Outstanding Commitment to Training and Skill Development (Individual): Jeffrey Hughes, Albem Operations Pty Ltd

• Outstanding Commitment to Training and Skill Development (Employer): BMD Group.

CCF QLD congratulates all finalists and winners. Nominations for the 2026 awards series will open in January 2026 via www.ccfqld.com, with expressions of interest to join the waitlist welcome via email at qldevents@ccfqld.com.

CASE Skid Steer and Compact Track Loaders pack serious performance into a compact footprint. With powerful breakout force, precision control, and the durability CASE is known for, they’re built to handle Australia’s toughest jobs — even in the tightest spaces.

Inside the cab, operators get 360-degree visibility and premium comfort, with intuitive controls that keep you productive all day long. Ready to see what compact muscle really feels like? Scan the QR code to learn more.

Breck Con Excavations relies on Jetland loading ramps to safely load and unload equipment

A positive experience using Jetland loading ramps has led Victorian-based Breck Con Excavations to procure a second set

Luke Breckon of Breck Con Excavations was destined to start up his own business, having grown up in and around heavy machinery from a young age.

His father owned various types of earthmoving equipment and trucks and Luke is following that path with his own machinery fleet, including 1.7-tonne and five-tonne excavators, a compact track loader and two tipper trucks.

Since establishing Breck Con Excavations around five years ago as the owner and operator, Luke has been no stranger to hard work, offering a host of earthmoving services such as site cuts and foundational digging.

Based in Melbourne’s Mornington Peninsula, Luke operates across the city’s southeastern suburbs, meaning safe transportation of his machinery fleet is essential.

For that reason, Luke relies on Jetland’s high-quality and heavy-duty loading ramps, which give him the confidence to safely load and unload his equipment.

The positive relationship with the Australian-owned loading ramp supplier has been in place since the inception of Breck Con Excavations, when Luke only had one tipper

truck and one piece of machinery.

Looking to procure a set of loading ramps, Luke says Jetland’s warehouse location – also based in Melbourne’s southeast in Mordialloc – meant that it would be the perfect partner for Breck Con Excavations.

Luke adds this thinking was only reinforced by Jetland owner Jimmy Fang, who made the process easy.

“When I was looking around the loading ramp market Jimmy was really good to deal with,” he says.

“The price-point was appealing, and the ramps were ready-to-go at the warehouse.”

Since the products were readily available, there was no waiting time for the ramps to be made or imported, so Luke could get straight to work without losing valuable time.

While Breck Con Excavations benefited from the proximity, other businesses across Australia might not be as lucky, so Jetland will soon be expanding with a new Brisbane facility to reduce delivery times.

The new warehouse is expected to open around November, helping to better serve customers along the East Coast.

This is complemented by the business’ free delivery across Australia policy, which helps to make the purchasing process hassle-free.

There are various features on Jetland’s loading ramps that have not only increased safety for Luke but also the efficiency of his business.

Anti-slip surfaces ensure maximum traction for his machinery during loading and unloading, while specially designed and tested locking pins eliminate the chance of the ramps moving once locked.

“I don’t have my own workforce, so

I jump in between all the different gear,” Luke says.

“The ramps have increased the safety aspect for me, and I can rely on them as they’re a quality build.”

Having been left impressed with his overall experience using the Jetland loading ramps, Luke has since procured a second set for his other tipper truck.

Instead of using one set of ramps that would have to be changed depending on the truck used, having two sets of ramps means Luke wastes no time when transporting machinery.

“Jetland’s ramps have been awesome in helping to get my machines up and off the trucks with increased safety,” he says.

“Jimmy always looks after me, so the aftersales experience has also been really positive.”

Like many other Jetland customers, Luke was spoilt for choice when deciding on what set of ramps to purchase, as the business offers a comprehensive

range of products in various sizes.