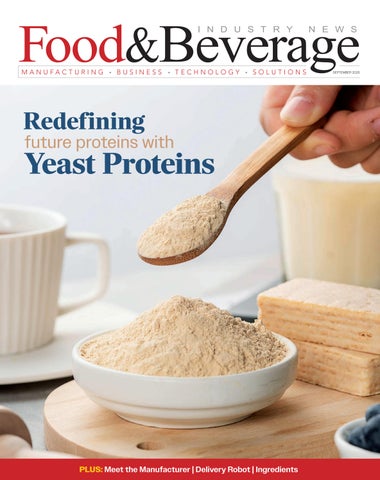

Yeast Proteins future proteins with Redefining

Yeast Protein

Redefining Future Proteins

Complete Protein Protein Content >80% Gluten Free 100% Vegan Natural and Ecofriendly Clean Label

NUTRITION SUPPLEMENT VEGAN MEAT SNACKS

BEVERAGE MIXES

Risk getting left behind

Managing Editor: Mike Wheeler

ur world is moving at a faster pace than ever. I remember moving from a typewriter to a computer back in the day, and before long I wondered how journos of old – any type of writer to be honest – got by. Suddenly there was no tracking back to fix mistakes (unless the typewriter had the functionality) or getting out the Tipp-Ex (you younger readers might have to look that one up).

As with any new technology, a decision has to be made sooner or later – do we join in and go with the flow, or wait and see? When it comes to manufacturing technologies, those who are first adopters get a head start. They usually pay a little more to get new software installed, a production line up and running, or whatever the case may be. This extra cost is down to the technology not being mainstream, so economies of scale come into the equation.

Not that long ago, the Internet of Things (IoT) was a huge buzzword in the food and beverage sector. And while this technology is still in use – and still relevant – other progressions are not only on the horizon, but here to stay. AI is the most obvious, but there are many others, too.

In the latest issue of Food & Beverage Industry we have not one, not two, but four Meet the Manufacturers. Talking to the big and small entities in this space, it has become apparent that

while taking a few risks is par for the course, and making sure quality wins out (and that legacy is an integral part of any food/beverage journey), innovation is not something that should be put on the backburner. While Moore’s law states that the number of transistors on a microchip doubles approximately every two years, and was an observation that has been a driving force behind the rapid advancement of computing technology for decades, the same could be said for manufacturing innovations. Now is the time to get on board or get left behind.

Over the past 12 months, FBIN has covered new innovations in AI, software, robotics and automation. Australia already has a reputation for producing great food and beverages; now it’s time to revolutionise our production lines and processing plants.

This issue has a range of articles to help those wanting to take the next step in their processing journey. From Monash University’s robots and Centric Software’s product designed to help companies navigate the complexities of recent regulations, through to Neogen’s data analytics solutions, Food & Beverage Industry News is at the forefront of keeping the industry up to date on trends and innovations that keep us moving forward.

Have a great month. F

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Ph: 041 557 2106 mike.wheeler@primecreative.com.au

Journalist: Dae Hong david.hong@primecreative.com.au

Art Director: Michelle Weston michelle.weston@primecreative.com.au

Sales/Advertising: Joanne Davies Ph: 0434 785 611 joanne.davies@primecreative.com.au

Client Success:

Cait Pillay

Ph: (03) 9690 8766 caitlin.pillay@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Cover

Image: Angel Yeast

Head Office

379 Docklands Drive Docklands VIC 3008

Ph: +61 3 9690 8766

enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite 11.01, 11th Floor

201 Miller St North Sydney, NSW 2060, Australia

Printed by: Precision Group

83-89 Freight Drive, Somerton Vic. 3062

Ph: (03) 9490 1500

10 Meet the Manufacturer: The Carob Kitchen

After thousands of carob trees were planted, a chocolate alternative was born.

14 Meet the Manufacturer: CJ Foods

Korean cuisine is rising, and CJ Foods is at the forefront of this movement.

18 Meet the Manufacturer: KOOEE Snacks

A company specialising in healthy meat snacks joins the Jack Links’ APAC family.

22 Meat the Manufacturer: Taylors Wines

According to Taylors Wines’ chairman, innovation is at the core of the business.

26 MICE

From Roasters Playground to awards show, MICE 2026 will come back with exciting features.

28 Yeast proteins

To meet food production demands, a vegan protein shows nutritious potential.

30 RTE ingredients

Technical ingredient solutions to meet demands for healthier ready-to-eat meals.

32 Software

EPR regulations can be tackled with Centric Software’s management platform.

34 Biosolutions

Biosolutions can unlock the “magic” of freshness, textures and appearance.

36 WorldSkills Australia

WorldSkills Australia is preparing for the 48th competition in Shanghai.

38 Analytics

Businesses can use analytics to visualise and manage Environmental Monitoring.

42 Delivery robot

Monash University students developed a temperature-controlled delivery robot.

46 Equipment news

A properly spliced belt ensures smooth material flow, reducing operational shutdowns.

48 AIP

Two new innovations awarded at the annual PIDA Awards.

50 New Products

US and Canadian beef cleared for entry into Australia

Following a detailed assessment, the Department of Agriculture, Fisheries and Forestry (DAFF), along with authorities in the US and Canada, has finalised health certification and import permit conditions for beef entering Australia.

Meat & Livestock Australia (MLA) has acknowledged the conclusion of the review into the importation of beef from the US and Canada, and stated that the introduction of these imports is expected to have minimal impact on the local market.

MLA noted it is unlikely the move will significantly affect Australian cattle producers, with demand for Australian beef in the US continuing to grow. In June 2025, Australian beef exports to the US increased by 24 per cent compared to the same period last year, despite the introduction of a tariff in April.

According to MLA, more than 99 per cent of the beef available in Australian supermarkets, pubs and restaurants is domestically produced. Approximately 70 per cent

of Australia’s total beef production is exported to international markets.

The government’s decision to allow imports from the US and Canada follows a comprehensive risk assessment to confirm that all

biosecurity measures and import conditions meet Australia’s rigorous standards.

Although US beef has technically had access to the Australian market since 2019, exports during that time

have been negligible.

MLA has reiterated its support for science-based decisions within Australia’s biosecurity framework, which it says protects the interests of both producers and consumers. F

Aussie wine exports to China begins to stabilise

According to Wine Australia’s recent Export Report, Australian wine exports increased by 13 per cent in value to $2.48 billion and 3 per cent in volume to 639 million litres in the 12 months ending June 2025. Peter Bailey, manager, market insights at Wine Australia, said the latest data shows the impact of the China market reopening in March 2024 is beginning to stabilise.

Bailey explained that the year-onyear increase in exports was “almost entirely driven by mainland China” after the removal of tariffs in March 2024.

“Over 12 months have passed since tariffs in mainland China were removed and the initial surge in exports has eased, resulting in 85 million litres of wine exports to the market in the 12 months ending June 2025, worth $893 million,” said Bailey.

“The quarter ending June 2025 was 35 per cent smaller in value than the same quarter in the previous year.

“This indicates that the level of exports to mainland China may be

normalising after the initial re-stocking phase.”

Exports to the rest of the world declined by 11 per cent in value to $1.59 billion and 6 per cent in volume to 554 million litres. The drop in volume reflects a reduced supply of Australian wine available for export after three smaller vintages, as well as declining demand from key export markets such as the US and UK.

The top destinations by value were:

• M ainland China, up 123 per cent to $893 million.

• United Kingdom, down 1 per cent to $350 million.

• United States, down 12 per cent to $314 million.

• Canada, up 7 per cent to $157 million.

• H ong Kong, down 54 per cent to $127 million.

The top destinations by volume were:

• U nited Kingdom, down 6 per cent to 204 million litres.

• U nited States, down 10 per cent to 111 million litres.

• M ainland China, up 162 per cent to 85 million litres.

• Canada, down 10 per cent to 61 million litres.

• N ew Zealand, down 9 per cent to 25 million litres. F

DAFF has finalised import permit for US beef into Australia.

Australian wine exports increased in value to $2.48 billion.

$173 billion turnover for Australia’s food manufacturing sector

The Australian Food and Grocery Council’s (AFGC) State of the Industry 2023-24 report, based on ABS data, shows growth in employment and turnover in Australia’s food and grocery manufacturing sector.

Turnover rose by 5.3 per cent to $173 billion, while employment increased by 4.4 per cent. The sector now supports almost 300,000 jobs, with more than a third located in regional Australia. Exports grew by 5.2 per cent, reflecting the industry’s expanding global presence.

“This is a sector with enormous potential,” said chief executive officer of AFGC Colm Maguire.

“With the right policy settings and strategic support, food and grocery manufacturing will continue to boost Australia’s economy – driving regional jobs, underpinning Australia as a proud manufacturing nation, and securing our food and grocery supply in an increasingly complex

global environment.”

Key findings from the report:

• Turnover increased by 5.3 per cent to $173 billion, keeping the sector at the forefront of Australian manufacturing.

• Employment reached 294,212, up 4.4 per cent, with 36 per cent of jobs in regional communities.

• E xports rose 5.2 per cent, while imports fell 3.3 per cent, improving the trade balance.

• T he United States overtook China as Australia’s top export market.

• Investment fell by 11 per cent to $3.8 billion, highlighting a need for renewed focus on capital growth.

The AFGC is calling for closer collaboration with government to drive further growth and innovation. Its plan outlines seven key priorities to boost productivity, including reducing regulatory burdens, strengthening supply chain resilience, and ensuring access to affordable, reliable energy. F

New shopping centre backed by $42M investment opens

As part of a $42 million investment by Woolworths Group, the Upper Coomera Shopping Centre has officially opened its doors on the Gold Coast, creating a modern retail hub for the local community.

After 16 months of construction, the centre is now complete, anchored by a new Woolworths supermarket spanning 3,780 square metres. The store has welcomed 110 team members from the region. In addition to Woolworths, the centre includes a BWS, a chemist, and eight other dining and retail outlets.

“I am delighted to attend this official opening of the Upper Coomera Shopping Centre,” said local MP Mark Boothman. “The 42-million-dollar investment made by Woolworths in our local community will offer residents significant convenience in local shopping and create numerous local employment opportunities.”

The Woolworths store includes a large fresh food market with

AFGC is calling for collaboration with government to drive growth and innovation.

Upper Coomera Shopping Centre has opened its doors on the Gold Coast.

Australian-grown fruit and vegetables, along with a bakery, deli, and seafood counter. To meet growing demand, the store offers

eight Direct to Boot bays for online customers collecting groceries without leaving their vehicles. The investment made by

Woolworths aims to offer residents convenience in local shopping and create numerous local employment opportunities. F

v2food expands with new partnership and acquisition

v2food, an Australian plant-based meat manufacturer, has announced a strategic partnership with Ajinomoto Co., Inc, alongside the acquisition of US-based unbreaded plant chicken brand Daring Foods.

“...We are excited to be able to introduce our world-class product range into the USA market,” said Tim York, chief executive officer of v2food.

“Daring has built an incredible, consumer-loved brand with strong reach across the U.S., and combining that with our food technology creates immediate opportunities to accelerate our mission to be one of the global leaders in plant-based protein.”

Daring will continue to operate under its own name in the US market, while serving as a platform to introduce v2food’s product range to American consumers.

The partnership with Ajinomoto Co. further reinforces v2food’s global ambitions. Founded more than 100 years ago, Ajinomoto Co. brings scientific expertise and a legacy of innovation in food and nutrition.

Both companies share a vision of transforming the global food system, underpinned by a mutual commitment to sustainability and innovation.

“This strategic collaboration between Ajinomoto Co. and v2food is focused on our shared commitment to revolutionising the global food system through innovation, sustainability, and co-creation in technology and business development to contribute to the wellbeing of all human beings, our society, and our planet,” said Shigeo Nakamura, president and chief executive officer of Ajinomoto Co.

The collaboration will help fast-track the development of next-generation plant-based products that meet changing consumer expectations for flavour, nutrition, affordability, and ingredient transparency. One of the first initiatives will be a new frozen meal range designed to demonstrate how plant-based foods can be both accessible and appealing. This will address the growing demand for products with cleaner labels and simpler ingredient lists.

“Together, we see an opportunity to shape the future of our space in a way none of us could have achieved alone,” said Jeffrey Gendelman, chief executive officer of Daring Foods.

“With v2food’s technology platform and Ajinomoto Co.’s expertise supporting us, we’re in the best position yet to deliver on our consumer promise

at both pace and scale.”

The partnership also reflects a broader global strategy, with initiatives already underway in Africa and emerging parts of Asia.

The collaboration will seek to deliver both economic and social impact, while pushing the boundaries of what is possible in plant-based food innovation. F

Kombucha brand acquisition boosts portfolio to $1 billion

Generous Brands has announced the completion of its acquisition of Health-Ade, a kombucha tea brand, from private equity firms First Bev and Manna Tree Partners. Both firms will remain as minority shareholders in Generous Brands.

Launched in 2024, Generous Brands has built a diverse portfolio spanning juice, smoothies, kombucha, cold-pressed beverages, protein drinks, coffee, and alternative sodas.

With the inclusion of Health-Ade, the company’s retail portfolio is nearing $1 billion in value. The acquisition brings added scale, strong market reach, and enhanced in-house manufacturing capabilities.

“This is an exciting milestone for Generous Brands,” said Steve Cornell, chief executive officer of Generous Brands.

Originally launched in 2012 at the Brentwood Farmers Market, Health-Ade has expanded rapidly, now generating close to $250 million in annual retail sales. Its products are available in over 65,000 retail outlets across the United States.

The kombucha category has experienced steady growth over the past five years, and Health-Ade is well positioned to continue expanding in this thriving segment by boosting Generous Brands’ retail portfolio close to $1 billion. F

v2food is an Australian plant-based meat manufacturer.

Health-Ade has been acquired by Generous Brands.

Preventing 600 million cases of food poisoning with AI

Led by the University of South Australia (UniSA), a team of researchers have made a research publication to demonstrate how artificial intelligence (AI) can detect food poisoning in fields and factories before it reaches consumers.

With a potential of saving four million deaths annually, the paper published in the journal Toxins describes how advanced hyperspectral imaging (HSI) integrated with machine learning (ML) can identify mycotoxins. Mycotoxins cause a range of serious health issues, such as cancer, compromised immunity and hormone-related disorders.

According to the World Health Organization, foodborne contamination, including from mycotoxins, results in 600 million illnesses and 4.2 million deaths each year. The UN-based Food and Agricultural Organization estimates that about 25 per cent of the world’s crops are contaminated by mycotoxinproducing fungi.

Lead author and UniSA PhD candidate Ahasan Kabir said that

traditional detection methods are timeconsuming, expensive and destructive, making them unsuitable for large-scale real-time food processing.

Kabir and his co-authors in Australia, Canada and India evaluated the effectiveness of HSI in detecting toxic compounds in cereal grains and nuts, both which are highly susceptible to fungi and mycotoxin contamination in warm, humid environments, from cultivation to storage.

“HSI captures an optical footprint of mycotoxins and when paired with machine learning algorithms it rapidly classifies contaminated grains and nuts based on subtle spectral variations,” Kabir added.

Reviewing more than 80 recent studies across wheat, corn, barley, oats, almonds, peanuts and pistachios, findings showed that ML-integrated HSI systems consistently outperformed conventional techniques in detecting key mycotoxins.

“This technology is particularly effective at identifying aflatoxin B1, one of the most carcinogenic substances

HSI captures an optical footprint of mycotoxins when paired with machine learning algorithms.

found in food, according to the project lead UniSA professor Sang-Heon Lee.

“It offers a scalable, non-invasive solution for industrial food safety, from sorting almonds to inspecting wheat and maize shipments.”

The team is now working on refining the technique to improve its accuracy and reliability, using deep learning and AI.

The research was supported by

the federal government’s Research Training Program, with top-up funding from SureNut Australia. The paper is authored by Ahasan Kabir, associate professor Ivan Lee and professor Sang-Heon Lee (University of South Australia); professor Chandra Singh (Lethbridge College, Canada); and assistant professors Gayatri Mishra and Brajesh Kumar Panda (Indian Institute of Technology Kharagpur). F

Analytical Process Division

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field.

Image: University of South Australia

Substitute for sweeter and healthier chocolate

The Carob Kitchen is one of only two commercial carob orchards in Australia and the only one to manufacture its own carob chocolate products.

Director at The Carob Kitchen, Sophie Richards, grew the business with gourmet recipes.

Images: The Carob Kitchen

Carob is experiencing renewed interest as a plant-based, naturally sweet alternative to traditional confectionery. The Carob Kitchen has stayed ahead of this trend through its focus on sustainability, natural ingredients and ethical production.

But before confectionery and sweets, what was carob known for?

Carobs were widely sought for locust bean gum (LBG). In food production, LBG absorbs water and creates thicker, viscous solutions without altering taste. Dairy products and sauces are common examples that rely on thickening agents to enhance texture and consistency. Carob seeds contain galactomannan polysaccharide, known for its functional properties including thickening, gelling and stabilising.

While demand was high, supply was low. To leverage this industry challenge, David and Carol Solomon planted over 3,500 carob trees in Port Elliot, South Australia, in 1997.

According to their daughter, Sophie Richards, who is now director at The Carob Kitchen, one carob tree took 10 years to grow crops. She credits her parents as the pioneers of the commercial carob industry in Australia.

However, with the rise of technological advancements in food, the family business was met with a challenge.

“Fast forward 10 to 15 years, there were synthetic food thickening agents taking over and the market for LBG had died,” recalled Richards.

After a couple of harvests, the family gathered for a business meeting. With all the hard work of tending to the trees over the years, Richards was elected from among the siblings to investigate business opportunities so that their efforts would not be in vain.

From there, The Carob Kitchen was born.

Leading into the next chapter, the business has grown into a vertically integrated operation under Richards’ leadership, developing new gourmet carob recipes with products ranging from kibble and powders to bars and vegan-friendly options.

The Carob Kitchen then developed the Banjo Bear brand to deliver alternative chocolates using real cocoa butter as opposed to palm oil.

So, what does the manufacturing process for carobs look like? Richards described the unique processes used for carob production.

Too

much food, not enough nutrition? Let’s change that.

Consumers are looking for healthier ready-to-eat meal options, and IMCD is here to help food manufacturers develop concepts to combat this growing trend. IMCD combine industry-leading ingredients with technical expertise and the latest market insights to help you innovate with confidence.

Scan the QR Code to discuss formulations customised to your needs.

Carob is gluten, fat, caffeine and theobromine free.

Kibbling

The annual production cycle begins in late summer or early autumn when the carob pods are harvested. A process called “kibbling” – a method of deseeding carobs – takes place.

handled similarly to fruit. The edible part is the outer husk, not the inner seed, and the pods are collected and

temperature-controlled conditions. The specific time and temperature during roasting affect the final flavour and colour of the carob. After roasting, the kibbles are then milled into a fine powder.

“This process takes a whole year of roasting and milling,” said Richards.

The journey from tree to powder is time-consuming but vital for quality control and flavour development before being sent to its comanufacturing partner to create the Banjo Bear chocolate range.

The final product is manufactured interstate by a long-term contract partner, using a formulation developed and owned by the

The plain Banjo Bear chocolate alternative is made from a short list of ingredients: roasted carob powder,

Not only are they substitutes, but they are also healthier alternatives.

“Carob is gluten free, fat free, caffeine and theobromine free,” she added.

Targeting demographics where people struggle with essential nutrients and vitamins, carobs are high in fibre and contain high levels of calcium and iron. According to Richards, carobs are known for nourishing people through droughts, famine and wars.

“Carob has a long history,” she said. “It’s become popular not just for kids but also for adults over the years.”

Ethical, consistent choices

The Carob Kitchen has worked with Banjo Bears and its chocolate-making facility since 2011. After a year of research and recipe development,

The annual production cycle begins after harvest.

Richards’ parents planted over 3,500 carob trees in Port Elliot, SA.

Palm oil, a hydrogenated fat commonly used for its cooking and melting properties, was not considered ideal for the brand’s product positioning. While palm oil is widely used in the food industry, it is highly processed and has higher cholesterol levels. Environmentally, palm oil production is linked to deforestation.

While sustainable palm oil is now more widely available, the company opted to differentiate itself through a simpler, cleaner formulation.

Cocoa butter, on the other hand, is generally considered a healthier option due to its potential health benefits and lower risk of negative health impacts. Richards also stated its overall quality in taste.

“We chose cocoa butter as it gives a better mouthfeel to the palate,” she said.

Product consistency remains a key focus for The Carob Kitchen. Unlike traditional chocolate, carob does not rely on sugar to mask flavour inconsistencies, making roasting and milling precision essential.

Maintaining this consistency at scale has presented numerous manufacturing challenges. Weather variability, especially wet summers,

has also affected tree health and yield.

Nonetheless, recent upgrades – including a new milling system, harvest equipment, ovens and sheds – have allowed the business to meet demand while maintaining quality.

“It’s been a lot of ironing out of problems over the years as well as creating space for growth,” said Richards.

Looking ahead

From modest beginnings in local health food stores in South Australia, The Carob Kitchen now supplies independent supermarkets and health stores across the country.

The company has also expanded internationally, exporting to New Zealand, Japan and Dubai, with new markets under consideration.

Through regular investment in new processing equipment, storage facilities, and machinery to improve production efficiency, The Carob Kitchen has seen growth.

Despite challenges and external threats, the company’s ability to oversee every step of the production process has positioned it favourably in the global market.

It has also allowed The Carob

Kitchen to retain control over quality, sustainability and innovation.

“From a manufacturing point of view, the challenges are one step at a time,” Richards concluded. “The biggest thing is not to get disheartened.”

Looking ahead, the company’s goal is to continue supplying consistent, high-quality products while expanding brand awareness across Australia.

Beyond this, Richards aims to establish a stronger global presence, exporting to more countries and bringing greater recognition to South Australia as a centre for high-quality carob production.

As the global food industry places increasing importance on clean-label, minimally processed products, The Carob Kitchen is well placed to grow further. F

The Carob Kitchen developed the Banjo Bear brand to deliver alternative chocolates.

Korean cuisine’s rise in Australia

With manufacturing facilities across Australia, CJ Foods is expanding the food industry using premium Aussie ingredients.

Australia’s food scene goes beyond a regular BBQ of sausages and steak sizzling in the family backyard. With a multicultural population, Australian cafes, restaurants and supermarkets provide meals and ingredients from all over the world. From Italian, Indian, Thai, Chinese, Vietnamese, and Middle Eastern cuisines, the melting pot of variety keeps the Australian palate excited for more.

In recent years, Korean cuisine has been gaining traction, and its popularity in Australia has surged. The rise of Korean pop culture has helped make Korean food more familiar to non-Korean consumers.

From music to films, awareness surrounding Korean street food has grown. Dishes such as ramyun (noodles) and tteokbokki (spicy rice cakes) are now recognised and sought after by audiences who first encountered them through entertainment media.

Influential to this movement is CJ Group, a South Korean conglomerate holding company comprising businesses in food, bio, logistics, retail and media entertainment.

CJ Foods is at the forefront of growing Korean foods in Australia by shifting to local manufacturing, partnering with Australian farmers, sourcing fresh local ingredients, and

using Australia as a launchpad for global innovation.

Growth is driven by a combination of authentic flavour innovation, strategic retailer partnerships, and investments in advanced manufacturing capabilities that bring Korean food culture closer to Australian consumers.

Leading the company’s operations, managing director and head of Oceania, Eugene Cha-Navarro, described what led to the growth of this cuisine in Australia.

A ‘mosaic community’

Korean cuisine’s presence in Australia is the result of cultural, demographic,

and market trends. Cha-Navarro credited the early Korean diasporic community in Australia for laying the foundation, introducing authentic

products and flavours to local markets. This grassroots presence was an important starting point for the company’s expansion.

She also stated that the Korean population is a contributing factor to the growth of this food. With strong community networks across the nation, Korean supermarkets such as Hanaro Mart, an Asian grocery store based in Queensland, operate in the supply chain to distribute products to local customers.

While initially the products from such groceries targeted Korean or other Asian demographics, this began to shift. Cha-Navarro said these grocery stores and supermarkets

started to attract Australian consumers within the vicinity. Australia’s multicultural environment plays a crucial role.

“The Australian community is like a ‘mosaic community’,” said Cha-Navarro.

The term “mosaic community” is where people maintain their own cultural traditions while embracing those of others. This openness extends to food, with Australians showing a willingness to explore new flavours.

“This way of life applies to the way they taste and experience new flavours,” Cha-Navarro added.

The company has a strong network

The rise of Korean pop culture has helped make Korean food more familiar.

Managing director and head of Oceania, Eugene Cha-Navarro.

of retail partners outside Asian grocery stores and Korean supermarket chains, including Woolworths, Coles, Harris Farm, and IGA. These outlets serve both the Korean community and an increasing number of non-Korean customers who are developing a taste for cuisine.

CJ Foods has also invested in its local manufacturing footprint. The company operates facilities in Queensland, New South Wales, and Victoria, each serving a distinct purpose with a focus on delivering premium products.

Using Aussie ingredients

One of CJ Foods’ most popular products in Australia is bibigo dumplings. As Australia has developed a multicultural palate, ChaNavarro linked the popularity of the product to the familiarity Australians have with Chinese dim sum dishes.

“We use fresh ingredients sourced from Australian pork and beef,” she said.

With locally sourced beef, CJ Foods aims to provide not only freshness and quality but also a point of pride for Australian consumers. ChaNavarro said this sourcing strategy

strengthens the connection between the product and its customers, while also supporting the local agricultural sector.

“Because we use Australian meat, consumers recognise our products as premium quality,” said Cha-Navarro.

Another example is Dasida, a powder seasoning used in traditional Korean soups. After purchasing Australian beef bones, they are brought into the company’s Queensland factory where beef bone broth is produced. This involves boiling and simmering at high temperatures until the broth is extracted into a paste form. The raw ingredient is then used to develop Dasida. This seasoning product can be made into powdered stock, soybean paste, and soup.

Local manufacturing saves the planet

The bone broth extract manufacturing facility is in Queensland, while Sydney hosts the dumpling production facility, and Victoria is home to kimchi manufacturing.

The company’s localisation strategy allows for a decentralised

production model that reduces the need for long-distance transport, lowering carbon emissions and ensuring fresher products. It also allows greater responsiveness to local demand, avoiding delays associated with importing goods from overseas.

Beyond local sourcing, the company is working to reduce its environmental impact through packaging innovation.

“CJ is also decreasing the amount of plastic in our packaging as an effort to be sustainable,” ChaNavarro said.

“We are investing in biodegradable plastics and reducing the amount of plastic used in its products. This effort extends to the wider CJ Group.”

Australia as a test market Looking ahead, CJ Foods aims to

CJ Foods is at the forefront of growing Korean foods in Australia.

The long-term vision is for bibigo to become a household name for Australians.

expand its product lines in retail chains and increase brand awareness among Australians.

The long-term vision is for bibigo to become a household name recognised not only as a Korean brand but as a trusted food choice for all Australians.

According to Cha-Navarro, Australia’s diverse population makes it an ideal testing ground for new products.

“Any new concept or product that we launch can see the initial consumer feedback from multiple communities within Australia,” she said.

This information can then be shared with stakeholders in other countries such as Vietnam and China, helping guide product launches in those markets.

Extending meaningful connection

For Cha-Navarro, the Australian market is both an opportunity and a responsibility.

By combining local manufacturing and sustainable practices, CJ Foods aims to bring authentic Korean cuisine to mainstream Australian dining tables.

By blending tradition with innovation, CJ Foods is contributing to Australia’s food manufacturing sector and sustainable future. As Cha-Navarro sees it, this approach ensures the company’s success while delivering meaningful value to its customers, partners, and the communities it serves.

Having worked for international giants such as Nestlé in Switzerland and Japan before joining CJ Foods,

Cha-Navarro’s career reflects a deep connection to the brands she represents.

“I believe emotional connection with the brand is important,” said Cha-Navarro. “The reason why I love the food industry is because I could associate myself to what I develop and sell.”

Her decision to join CJ Foods was influenced by her familiarity with its heritage brands, such as Dasida, which

she knew from her own upbringing.

As a parent, a leader, and a food lover, she wants more than just to scale a brand, but to bring meaningful stories and cultures into the Australian community.

“As a Korean living abroad, the connection to my own culture was meaningful,” she added. “I work in food and I love what I do. I taste what we make. I feed it to my child. I trust it.” F

We harness and amplify the power of cultures and enzymes in our biosolutions, so you can give people more of what they want and less of what they don’t. Improve quality, cut costs, and maintain the authenticity your consumers love.

Korean cuisine is making its way into mainstream Australia.

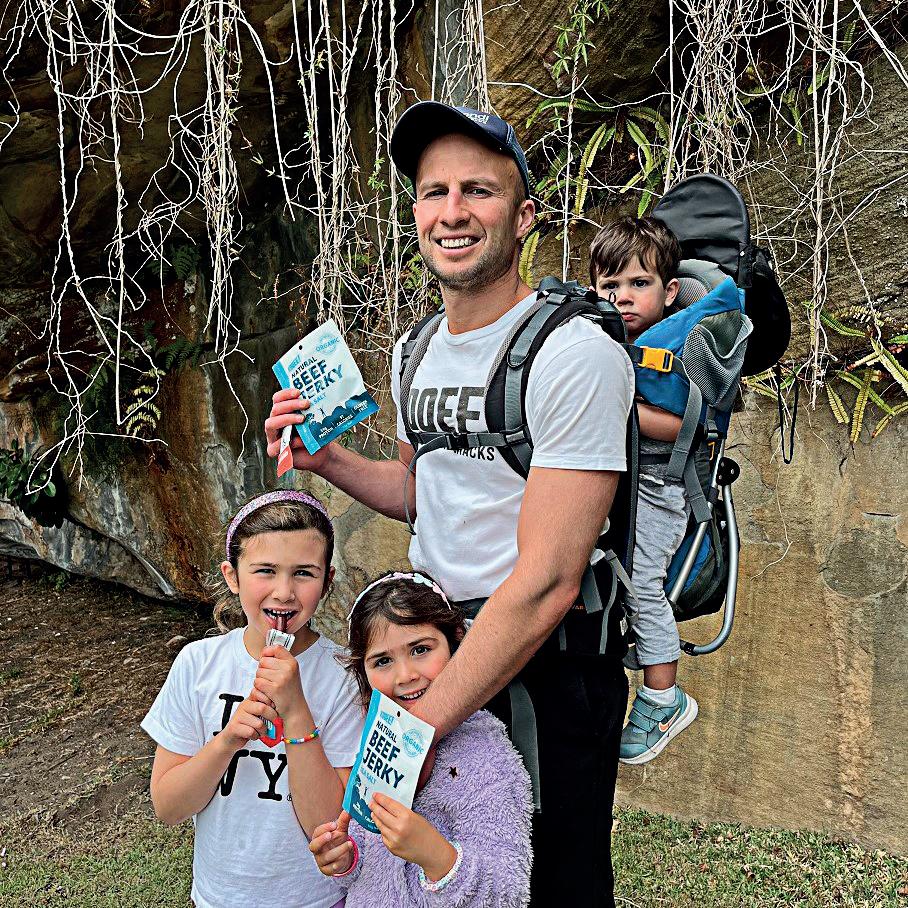

KOOEE powering Aussie health with quality meat snacks

Recently joining the Jack Link’s Asia Pacific family through a strategic acquisition, ‘luck’ is an understatement to describe the journey of KOOEE Snacks.

KOOEE! Snacks was founded in 2014 with a goal of delivering healthy meat snacks.

Images:

KOOEE! Snacks

Are meat snacks the domain of men alone? After 10 years of building his brand, founder of KOOEE Snacks, Shaun Malligan, disagrees and has female customers to prove it.

KOOEE Snacks was founded in 2014 with the mission to make natural, high-protein snack for healthfocused men, women and families, who have long been ignored by the fast-growing snacks category.

Before founding KOOEE Snacks, Malligan worked at Big 4 accounting firm EY as a senior consultant. As an avid trail runner and fitness junkie who was training up to three times a day, he needed ways to fuel himself without consuming sugar, artificial preservatives or empty calories.

After researching different options, he saw that beef jerky was high in protein, low in carbs, and easy to snack on the go. However, the local meat snacks on offer in Australia were full of sugar and artificial ingredients. There were also import restrictions on ordering meat snacks from overseas.

“Because of import restrictions into Australia, you couldn’t actually bring beef jerky products from the US,” said Malligan. “So, I decided to make it myself.”

Purchasing a small dehydrator, he began crafting his own beef jerky at home. As he brought it to his workplace, he noticed the stirring curiosity by his peers.

“People around the office were curious about what I was making,” he added. “Eventually, my Sundays were packed with making beef jerky snacks for people in the office.”

His practical solution for healthier snacking evolved into a paid hobby. Colleagues he had never spoken began reaching out to order more. While the responses were positive, Malligan said it was still “just a hobby”, as he did not yet see the potential for a scalable food business.

It was only when he attended an entrepreneurship class in New York that a strong idea emerged: highprotein snacks not just for men, but for women and children too.

“I felt a magnetism towards launching a food business making something I actually really believed in,” said Malligan.

the traditional “blue-collar male”, but also at women and health-conscious consumers.

Encouraged by a friend, Andy Fist, who would later become his business partner, they decided to launch the business out of Tasmania, drawn by the number of high-quality food brands and, importantly, premium beef. They bought a small factory north of Launceston and began scaling the product commercially.

The making of the product

“People around the office were curious about what I was making. Eventually, my Sundays were packed with making beef jerky snacks for people in the office.”

As a small operation, Malligan described the early days as very hands-on. The factory included commercial dehydrators, vacuum tumblers and meat slicers.

According to Malligan, healthy style beef jerky snacks started entering the US market in the early 2010s, with brands such as Krave and EPIC. These products were not targeted at

Like every other business, starting from scratch was a challenge.

“It took about a year to figure out how to commercialise the product and get equipment,” he said.

The process of making beef jerky started with trimming the fat from the beef and slicing it into strips. These strips are then marinated in a blend of natural spices. The marinated slices are then placed in a vacuum tumbler, a machine that

tenderises meat and helps marinades absorb more effectively.

Following that step, the beef slices are arranged on large trays and dried in the commercial dehydrator so that the product becomes food safe and shelf stable. The slices are then packaged.

After a few years, the KOOEE team decided to launch Australia’s first range of healthy meat sticks. They saw that the sticks sub-category had

The acquisition process took three months.

begun to surge in the US, with the growth of brands such as Chomps and The New Primal and wanted to be the first Australian company to follow this trend. With a fond memory of snacking meat sticks from the local Italian deli, KOOEE! wanted to make something healthy for kids.

However, when Malligan realised that they weren’t going to be able to manufacture this on their own given the equipment and production requirements, they started searching for a contract manufacturer that could make a meat stick using KOOEE’s own recipe

to be individually packaged, which required specialised packaging equipment that only few manufacturers possessed.

After a national search, they found a co-manufacturer that was excited to partner with them on this journey just in time for the Sticks to launch in Woolworths in 2020.

Accelerating the business

Awareness for KOOEE’s meat sticks began to grow from 2020. In 2023, KOOEE Snacks sold its factory and adopted a 100 per cent comanufacturing model. However,

Founder Shaun Malligan is a father of three and an avid trail runner.

Keeping up with demand became an issue for the product.

“Our meat sticks are a premium product, so it needed that extra bit of care,” Malligan added.

“It’s a lot more difficult to make the stick that we make compared to a regular meat stick.”

The company avoided artificial preservatives and instead opted for vegetable powders and natural curing methods. This approach, designed especially with children in mind, drove their commitment to clean ingredients.

As the business grew, Malligan noticed the increasing number of female customers buying the meat snacks, including children who brought them to school.

He also saw celebrities and athletes

enjoying the snacks. Notably, 90 per cent of their online customers were women.

“Almost every other brand was targeting the same customer that already eats beef jerky, which is primarily your male gym goer,” he said. “Women would not eat it, as snacks like these were something so foreign with brands that didn’t cater to the female audience.”

By engaging with women and families through trade shows and on social media, KOOEE Snacks highlighted the importance of protein snacking, by making something that tasted delicious and was convenient to eat on the go. Offering both convenience and functional benefits, the meat snacks “just ticked the boxes”.

KOOEE’s business more than

“The brand initially reflected trail runners and hiking. But as I grew my own family, I realised it reflected my own life in that I wanted to make something my own kids would love and I could trust as a parent.”

KOOEE uses clean ingredients designed to provide healthy snacks for children.

doubled from FY24 to FY25.

According to Malligan, the popularity of the snack sticks was the “real driver” of growth, with the business increasing by 30 per cent in just one month from May to June 2025.

The shift to a leaner and simpler model allowed the business to scale efficiently without the heavy demands of in-house manufacturing.

Jack Link’s Asia Pacific

It was then that the business was acquired by Jack Link’s. Shannon O’Connell, managing director at Jack Link’s Asia Pacific, said the acquisition process was seamless.

“The acquisition process took only three months,” she said.

Describing the deal as “natural”, O’Connell explained the decision to bring KOOEE Snacks into the fold was driven by a desire to expand their product portfolio.

With access to quality beef and price advantages, Jack Link’s APAC plans to drive the growth of betterfor-you snacks in the Australian market. As meat snacks continue to gain popularity worldwide, the company is exploring new export opportunities.

“The Jack Link’s APAC team are keen on growing KOOEE using their resources and know-how,” Malligan said.

To maintain brand identity, no major changes are planned for how KOOEE operates.

Malligan will step back from daily operations but continue as a consultant to the business.

Reflecting on the journey, Malligan noted how the brand’s identity evolved alongside his personal life.

“The brand initially reflected trail runners and hiking,” he said. “But as I grew my own family, I realised it reflected my own life in that I wanted to make something my own kids would love and I could trust as a parent.”

Now a father of three, Malligan said that providing healthy snacks to his family shaped the values behind the business.

Persevering through what he described as a “hard industry”, he highlighted the importance of the little things, including brand identity, trust, and customer service.

“The product is super important,” he said. “But growing the brand, the identity, and connecting with our customers was really important to our success in retrospect.” F

Not just a wine business but a fashion business

Before a mysterious box arrived at Taylors Wines, innovation had not always been at the core of the business. Now, under Mitchell Taylor, the business is expanding its reach and modernising operations.

Chair at Taylors Wines, Mitchell Taylor, recalled a memory as a young boy witnessing chainsaws slashing through a vineyard, cutting down half of his family’s beloved Cabernet Sauvignon. He described the look on his father’s face that he had never seen before.

“I could see the emotion and rawness in my father’s eyes,” he said. While this memory was from many years ago, Taylor mentioned how he could never forget what his father said to him.

“He said, “Don’t worry about it, son. We’re just not in the wine business anymore. We’re in the fashion business”,” said Taylor.

In the late 1970’s, negative health implications surrounding red wine was circulating in Australia. Soon enough, the business established by Taylor’s father and grandfather was being shaken by chainsaws. The traditional wine business was no longer immune to fashionable trends.

From that moment, Taylor understood that tradition cannot be secure without change. As he continued to grow in the business, he made sure that he was earning respect through hard, hands-on experience and not through his family name. Driven by his hunger for knowledge surrounding the business, he started a winemaking degree.

His school holidays were filled with grape picking, and when it was not the right season, Taylor would be directly involved in the bottling line. Although his passion and lifestyle centred on the family business, he later pursued a career overseas in finance markets and stockbroking.

This was until a box arrived at Taylors Wines – one of the very first computers. However, the new technology was not welcomed with open arms by the team.

“The business at the time was very small and everyone was hesitant to plug the computer in,” Taylor said.

Known for his eager-to-learn attitude and years of experience in financial markets, the external

accountant at the time urged Taylor to step in and train the team. According to Taylor, at the time all processes were performed manually, and this small piece of modern technology helped him see the growing need for the business to improve and adopt efficient processes.

What started as a humble IT role of three months evolved into 25 years as the company’s managing director, and recently as the latest chairman. Taylor’s involvement in the winery has been lifelong. He sees the wine business not as a single trade but as several industries combined, from farming, manufacturing, winemaking, bottling, marketing, exporting and distribution.

Taylors Wines produces wines that balance heritage and innovation.

Images: Taylors Wines

Valley

Better innovation to respect the fruit

Taylors Wines has been a fixture in the Clare Valley for years, producing wines that balance heritage with a commitment to innovation. Central to Taylors Wines’ winemaking philosophy is to “respect the fruit”. Preserving the quality of the fruit is essential for consistent and rich flavours of the wine, according to Taylor. With this philosophy at its core, Taylors Wines’ operations revolve around efficiency and quality to best deliver premium products.

Temperature is a crucial factor in winemaking. Taylor provided an example of innovation when it came to fermenting red wine. He linked the popularity of Australian wine to the country’s access to the latest technology and refrigeration. Teaming up with an engineer, they developed a special fermenting vessel that was designed for cooling.

“We could really control and monitor the ferments without losing all the beautiful fruit flavours from the heat,” Taylor said.

Winemakers and has been on the Wine Australia Board for six years.

Taylors Wines’ winemaking philosophy is to “respect the fruit”.

Chair at Taylors Wines, Mitchell Taylor.

This technology improved the sector’s resilience and ability to produce wine despite the hot climate. The fermenters became a well-known technology that was exported around the world to new developing wineries.

Taylor described the experience as a good “test parlour”, and soon enough, he had an idea to operate the business on an estate model.

Coming from a manufacturing point of view to create high-quality wines, this model suggested growing grapes close to the winery to minimise handling time and preserve fruit quality.

“We’d shorten the time for processing and cooling without letting oxygen upset the product,” he added.

Taylor mentioned that oxygen is the “worst enemy for a winemaker”. Oxygen exposure can affect the redox state of the wine, impacting reactions involving acids and other compounds, ultimately affecting the acidity level. Therefore, decisions on harvest timing are guided by scientific measurements of ripeness,

the optimal balance point, ensuring that wines have structure, flavour and the potential to age gracefully.

Modernising the traditional workspace

Although the business now operates on a modern scale, it was not always this way.

“We used to employ over 300 grape pickers over vintage because we did not have any mechanical harvesters,” said Taylor.

While the operation was costly, another challenge in efficiency was bringing in the grapes only during the day. According to Taylor, picking the fruit at the optimum period when ripest is imperative as a winemaker.

Particularly for white wines, grapes are best picked in cooler conditions. By adopting a mechanical harvest technology, Taylors Wines was able to harvest the grapes at any time of the day.

Another manufacturing task the company brought in-house was bottling. Unlike many producers who

carries out this process in-house with its state-of-the-art bottling line. The line is fitted with computer-linked machinery that operates with minimal manual intervention, ensuring precision and efficiency.

With programmable computers on all pressers and bottling lines, the once manual-heavy bottling line monitors itself, starting and stopping independently based on data fed to streamline operations.

While Taylors Wines prides itself on its bottling technique, Taylor admitted that it was not an easy road.

Ditching the cork

According to Taylor, the company received quality corks all the way from Portugal.

“Cork was good traditionally many centuries ago, but it wasn’t the latest nor the best seal,” he said.

Due to cork taint problems coupled with oxidation and leaking issues, Taylors Wines was met with a recall of an entire vintage worth of wine. Seeing the huge loss from the

brought the issue of corks into a meeting as a chief executive officer at Clare Valley Winemakers in 2000.

Alongside other leaders in the meeting, the agreement on the disadvantages of cork grew unanimous. Screw caps were an option; however, the implications of switching from cork to screw caps served as a risk. Taylor mentioned that, at the time, only one winery had tried adopting screw caps and was rejected due to its visual appeal and uniqueness in the market.

Soon enough, they all came to an agreement to trial screw caps on all their Rieslings. This decision was backed by years of winemaking and research from the Australian Wine Research Institute. Taylor said the transition to screw caps was a gamechanger in the quality of the wine and their processes. While initially people remarked that screwcapped wines were “cheap”, the movement was able to demonstrate the ease of opening wine bottles and prove the purity.

Taylors Wines aims to be carbon neutral by 2030.

sulphur in our wines for protection because we now had a perfect seal.”

For Taylor, this collaboration was a special moment for the Australian wine industry to power through a global challenge. The Clare Valley became the first Australian region to adopt screw caps, and Taylors Wines went further by applying them to its entire range.

“What I’ve learned from studying with other winemaking students is if you ever run into a problem, it’s great to talk to your colleagues,” he said. “Even though they’re competitors, we’ve all got the same problem, so let’s get together and work out a solution.”

This revolution was a breakthrough for Taylors Wines, and what originally started with the Clare Valley Winemakers extended its innovation through the entire wine world. As mentioned, Taylors Wines’ philosophy of respecting the fruit was about producing not only delicious wine but a consistent one.

Sustainability and premium positioning

Taylor views the business as a family legacy and sees himself as a custodian for future generations. This long-term perspective underpins

“I want to have a green, clean and responsible industry,” said Taylor.

Solar panels have been installed across all suitable roof space. Water management, waste reduction, and the careful selection of vineyard sites and grape varieties are all part of a strategy to maintain environmental health while producing premium wines.

He stated that the winery aims to be carbon neutral by 2030 and is working and measuring every year to reduce its footprint.

While the vineyard has always produced wines accessible to a wide audience, the business has increasingly focused on the premium segment. Under Taylor’s leadership, the business was able to shift its winemaking process to separate its best wines from the old vines, which has been marked by the creation of the St Andrews range.

Taylor talked about a new premium wine called “The Legacy”. Named after his grandfather and father, this wine has been made from the “very best and old fruit vines”, winning awards around the globe. These wines are designed for both immediate enjoyment and long-term cellaring, representing the pinnacle of Taylors’ craftsmanship.

said Taylor. “Clare Valley is a premium area and it’s about building wines that are not only beautiful to taste but have the ability to be iconic.”

The focus on premium wines is matched by ongoing investment in facilities, including a new cellar door in the Clare Valley that reflects the quality and hospitality the brand aims to deliver.

The business is currently exploring new regions to bring in fruit to expand its wine range. Taylors Wines brings grapes from Adelaide Hills, McLaren Vale, Coonawarra, and is experimenting with wine from Margaret River and the Yarra Valley. Taylor explained that this is a strategic plan to diversify and expand the business.

“Taste preferences are changing,” he said. “So, we as a business must be adaptive by using the latest technology, exploring new grape varieties and understanding what our customers really want.”

Looking ahead

Taylors Wines has grown into a global brand, exporting to key markets including China, the UK, Ireland, Canada, New Zealand, and parts of Asia. The return to the Chinese market was a strategic priority to

rebuild relationships and expand its offerings there to include white wines.

According to Taylor, Canada is a strong market, particularly for the full-bodied red wines that suit its cooler climate. In New Zealand, Taylors Wines’ reds are also well received alongside the country’s dominant Sauvignon Blanc production. The winery also maintains a presence in North America, with the US market presenting both opportunities and complexities.

Across Asia, Taylors sees significant growth potential, building on early export successes and adapting to evolving tastes.

For Taylor, the goal is not only business growth but also preserving the values of quality, sustainability and family stewardship that have defined Taylors Wines since 1969. Through innovative approaches, from AI-driven production planning to advanced vineyard monitoring, the changes and adaptations made in the business are all calculated for future generations to keep the beloved wine industry afloat.

“We are always trying new things and pushing to innovation that will make the business better,” said Taylor. “You have to be in this continuous change to improve in quality.” F

The Clare Valley became the first Australian region to adopt screw caps.

What’s in store for MICE 2026

Following record attendance in 2025, the Melbourne International Coffee Expo (MICE) will come back in March 2026 with new and returning events.

Tbrought together a record number of coffee professionals, enthusiasts and innovators at the Melbourne Convention and Exhibition Centre. More than 31,000 visitors attended over the three days, with 134 exhibitors from across the sector showcasing their products, expertise and innovations.

The show floor was filled with the aromas of freshly brewed coffee as roasters, equipment suppliers and industry service providers engaged directly with café owners, distributors, food and beverage experts, and coffee lovers. The event blended business opportunities, sensory experiences and industry discussion, creating an atmosphere that was both energetic and collaborative.

to include both new and returning activations designed to enhance the visitor experience for MICE 2026.

Drawing the crowd with Roasters Playground

One of the features of MICE2025 was the Roasters Playground, which was developed by an advisory committee with representatives from La Marzocco, San Remo, Service Sphere, Single O, Bombora, ST. ALi, Riverina Fresh and Veneziano Coffee Roasters. The committee reviewed past events and made recommendations to boost value for exhibitors and attendees.

T his area featured a rotating line-up of Australia’s top roasters,

the event. Its success confirmed its place as a central attraction for both trade and public visitors.

Across the three days, crowds gathered to sample coffee from different roasters, participated in interactive sessions and enjoyed the lively atmosphere. The Roasters Playground not only allowed roasters to showcase t heir craft but also encouraged meaningful connections between industry professionals and consumers.

Following its strong debut, organisers have confirmed that the Roasters Playground will return in 2026, with plans to make it bigger and better through the support of La Marzocco and Riverina Fresh.

see the expo remain open late into the evening, giving Melbourne’s café owners and hospitality professionals the chance to explore the event outside standard business hours.

According to Siobhan Rocks, general manager events at Prime Creative Media, some café owners and operators struggled to engage with the event due to time constraints caused by peak hours in the business. The extended hours will allow key members of the coffee industry greater access to the show.

In doing so, MICE aims to bring together all parts of the international coffee value chain in the next iteration of the trade show.

It also creates a unique experience after dark.

Image:

Prime Creative Media

The Roasters Playground will return in 2026.

Trip to Origin

Another addition to MICE 2026 is Trip to Origin, which will welcome coffee farmers, green bean traders, coffee boards and embassies from key coffee-producing regions.

This feature will give visitors insight into the origins of coffee, highlighting the agricultural and trade connections that underpin the industry.

An education stage – built for panel discussions and presentations – offers interactive tasting areas and opportunities for direct engagement will help close the knowledge gap between consumers and origin communities. By recreating the sights, stories and flavours of origin, the new addition will give visitors a taste of what it is like to travel to the source, with a chance to ask questions, hear first-hand experiences and explore the journey of coffee from crop to cup.

Giving credit where its due

While MICE offers networking and innovation opportunities, the event also recognises individuals who have laid the foundations for the growth of the greater coffee sector.

Held in conjunction with the MICE After Party, the Coffee Industry Heroes awards acknowledge the contributions of people growing the coffee industry, particularly those who have displayed commitment and made positive impacts on their craft and community.

The awards include Community Champion, Next-Gen Talent and Lifetime Achievement. The Community Champion award recognises volunteers in charity, community organisations or social service outside of their business.

The Next-Gen Talent award is for anyone under 30 years of age who has contributed to the business they are part of through achievements such as financial growth, social media campaigns, positive client feedback, product innovation or the implementation of new technology. The Lifetime Achievement award is for an individual who has been part of the industry for more than 20 years and has made significant contributions to the Australian and global coffee market.

Sponsors bring creativity

to the show floor

Sponsors played an important role in shaping the experience at MICE 2025.

MILKLAB, an Australian-owned barista milk company, created one of the busiest stands with a chequered dance floor, DJ booth and immersive drink experiences.

Its popular strawberry matcha drink had queues stretching up to 45 minutes.

As a MICE supporter of eight years, the brand also hosted the Royale Tasting Experience, pairing premium coffee roasts with MILKLAB products, as well as daily latte art competitions that drew large audiences.

These high-energy activities contributed to the vibrant atmosphere, reinforcing MICE’s position as a hub for creativity and connection within the coffee sector.

What are you waiting for?

MICE 2026 will return from 26 to 28 March and exhibitor spots are already filling.

The 2025 event demonstrated how industry collaboration can deliver both commercial outcomes and cultural impact.

By bringing together diverse voices and expertise, MICE creates an environment where ideas are exchanged, trends are set and the future of the coffee industry is shaped.

MICE has built its reputation as the meeting place for everyone from

small specialty coffee businesses to large-scale equipment suppliers. Its combination of product displays, hands-on experiences, educational content and networking opportunities makes it a valuable event for the entire supply chain.

With demand already high for exhibitor spots in 2026, organisers expect another year of growth.

For businesses in the coffee sector, MICE represents not only an opportunity to showcase their products but also to engage in the conversations and partnerships that

drive the industry forward.

From its vibrant show floor to its late-night sessions and industry connections, MICE2026 aims to build on the success of 2025 while introducing fresh experiences for attendees.

Whether it is tasting a new blend, discovering innovative technology or forging a new business relationship, visitors can expect an event that celebrates coffee in all its forms and offers a way to keep ahead of all the coming trends within a fast-paced and exciting industry. F

The Coffee Industry Heroes awards are for people growing the coffee industry.

More than 31,000 visitors attended over the three days.

Redefining future proteins

Angel Yeast’s AngeoPro is unlocking the power of yeast protein to meet rising global demands for nutrition, performance, and sustainability.

As global food systems face unprecedented strain, the demand for sustainable, nutrient-rich protein sources is climbing faster than ever.

According to the United Nations, the global population is expected to reach nearly 9.7 billion people by 2025. Feeding this population will require a 70 per cent increase in food production. However, under the constraints of climate change, limited farmland and depleting resources, the industry is met with an obstacle for the future. One of the ways to navigate this complex landscape is to evolve the approach to protein production.

Angel Yeast believes that yeast fermentation is one of the most

dilemma. Founded in 1986, Angel Yeast is a company specialising in baking, yeast extraction, nutrition, health, and biotechnology.

Providing products and services across 170 countries and regions, the company is meeting this challenge head-on with AngeoPro, a yeast protein designed to support human health while protecting the planet.

AngeoPro Yeast Protein

AngeoPro Yeast Protein is a vegan protein developed through the fermentation of Saccharomyces cerevisiae, commonly known as baker’s yeast. Compared to conventional protein sources, it has features that allow it to be a cleanlabel, functional protein with a high

nutritional profile and sustainability.

One of the advantages of AngeoPro is its amino acid composition. Its Protein Digestibility-Corrected Amino Acid Score (PDCAAS) of 1.0 indicates high digestibility and amino acid bioavailability. With more than 80 per cent protein content, the protein contains all nine essential amino acids, making it a valuable dietary protein source for all ages and demographics. Its high concentration of branched-chain amino acids (BCAAs) – which make up over 21 per cent of the protein content – are essential for muscle growth, repair and recovery. For athletes and physically active individuals, AngeoPro offers a powerful tool for muscle support and performance nutrition.

Health benefits

AngeoPro Yeast Protein is a versatile, functional ingredient offering benefits beyond basic nutrition.

As a non-dairy, non-soy protein source, AngeoPro is also suitable for individuals with strict food allergies or intolerances.

According to Angel Yeast, a clinical study in 2024 demonstrated positive effects of AngeoPro on lean muscle mass and strength in adults engaging in resistance training. The product offers developers a unique tool that meets a long checklist of formulation needs, including high protein content, neutral taste, sustainability and functional performance.

The protein offers customisable digestion speeds, with fast-digesting

Images:

Angel Yeast

Angel Yeast delivers solutions across production bases and service centres.

options ideal for post-workout recovery as they aid muscle repair and growth. Slow-digesting options assist with weight management by promoting metabolic health and helping to retain lean muscle during calorie deficits.

Its suitability for clean-label formulations and vegan claims makes it a versatile ingredient for future food trends. As protein continues to play a central role in sports nutrition, elderly care and general wellness, yeast-based solutions will likely become more prominent.

Versatile applications

AngeoPro Yeast Protein can be widely used due to its neutral flavour. Suitable for a range of applications across the food and beverage industry, it can be blended easily with other proteins to customise taste, texture or nutritional values, making it adaptable for product formulators.

Whether it is used in plantbased meats, high-protein snacks, powdered supplements, dairy alternatives or energy bars, AngeoPro can be incorporated without compromising taste.

Its adaptability ensures that manufacturers can meet consumer expectations for both performance and clean-label standards.

With the clean flavour to minimise interference with other ingredients, it removes the need for masking agents or flavour enhancers. This enables brands to formulate products with shorter ingredient lists and greater transparency, which is a growing priority for health-conscious consumers.

The versatility of the yeast protein in food applications includes nutritional supplements, protein-fortified beverages, dairy and non-dairy products, healthy snacks, sports and nutrition bars, baked goods, meat alternatives, and condiments or seasonings.

The product’s vegan credentials also speak to a growing segment of consumers looking for alternatives that do not rely on animal agriculture. For markets with high rates of lactose intolerance or dietary restrictions, yeast protein provides a welcome, inclusive alternative. While its functionality allows flexibility across multiple food types, thinking ahead of sustainability challenges in the food industry is imperative.

Sustainable champion

Unlike traditional animal-based or crop-based proteins, yeast protein production does not require arable land. This eliminates the strain on agricultural land use and allows production to occur year-round, independent of weather or climate.

The production process also uses less water and emits lower greenhouse gases compared to livestock or plant-based protein farming.

According to Angel Yeast, AngeoPro Yeast Protein’s biomass doubles within a matter of hours, making it efficient in terms of output per resource input. The speed and scalability of yeast fermentation also mean that production can be rapidly expanded to meet spikes in demand without the long lead times associated with agricultural harvests.

With mounting global concern around food system emissions, land degradation and biodiversity loss, protein alternatives like AngeoPro Yeast Protein represent a step forward in rethinking food production.

More than ingredients

Angel Yeast’s background in biotechnology, fermentation and protein engineering makes it a major player in the development of sustainable protein systems. However, it also prides itself on its ability to work closely with customers, offering customised solutions and collaborative product development. With numerous ongoing patents and research initiatives, Angel Yeast

remains committed to delivering quality solutions across 16 production bases and 12 applied science service centres.

The company is applying decades of experience to develop scalable manufacturing processes that deliver consistent, high-quality protein at commercial volumes.

As demand increases for nutritious, shelf-stable protein ingredients that meet regulatory and environmental standards, Angel Yeast’s manufacturing infrastructure ensures reliable supply chains and production capacity.

More than that, the company is working towards progressing the food sector through innovative, sustainable and nutritious solutions.

Its solutions, including AngeoPro, are processed in facilities that follow rigorous quality control processes. It is HACCP-certified and holds other international certifications to meet global regulatory standards.

As consumers, manufacturers and regulators all turn their attention to the future of food, the demand for functional, sustainable protein is high. The modern food industry is under constant pressure to innovate while complying with regulatory frameworks, consumer demand and environmental requirements.

Angel Yeast is not only meeting current market demand but also setting a new direction for where food systems need to go. Scalable, nutrient-dense and environmentally sound, yeast protein production represents a positive development in the protein space.

Angel Yeast’s investment in research, product development and global distribution ensures that AngeoPro will continue to evolve in both formulation and application scope. With applications spanning from mainstream retail to specialised clinical nutrition, the future of yeast protein looks bright. F

Angel Yeast specialises in baking, yeast extraction, nutrition, health, and biotechnology.

AngeoPro Yeast is a functional protein with a high nutritional profile.

Tailored ingredient solutions for ready-to-eat meals

IMCD’s Food & Nutrition team is supporting manufacturers across Australia and New Zealand with technical ingredient solutions to meet the growing demand for healthier ready-to-eat meals.

In a competitive and fast-evolving food industry, ready-to-eat (RTE) meals have become a growing segment in Australia and New Zealand. Consumers are seeking convenient options that not only meet their busy schedules but also deliver on health, taste and sustainability.

The RTE segment has grown rapidly due to shifts in work and lifestyle patterns. Today, the market is shifting towards ready-made meals that are fresh, nutritionally balanced and offer a variety of options.

However, meeting these consumer expectations presents challenges for food manufacturers. As demand increases for meals with lower sodium, sugar and fat, as well as

plant-based options, manufacturers are finding it difficult to deliver. At the same time, consumers are seeking high-quality meals that deliver on flavour and texture.

IMCD’s Food & Nutrition Business Group is at the forefront of this shift, offering formulation expertise and a robust portfolio of specialty ingredients to support manufacturers responding to modern consumer expectations.

IMCD’s Amanda Shaffer is the business unit manager for Food and Nutrition in Australia and New Zealand. She describes the company’s role as supporting customers with functional and speciality ingredient solutions.

“Our products and offerings are

designed to inspire and provide our customers with functional solutions to their product development or formulation challenges,” she said.

Having served IMCD in various technical and commercial roles across Australia and New Zealand for more than 13 years, Shaffer said awareness and access to nutrition information is only the beginning.

Shelf-life, simple ingredients, cheaper production

The challenges RTE manufacturers face include balancing nutrition with taste and texture, ensuring shelf-life stability, and meeting clean-label and regulatory standards, all in a cost-effective manner.

The rise of direct-to-consumer delivery models, where consumers order fresh meal kits online, is expanding rapidly in Australia.

“We’re seeing it heading more into the chilled fresh segment and a massive expansion in consumerdirect delivery,” said Shaffer.

Valued at approximately $3 billion in 2024, the market is projected to expand at a compound annual growth rate of around 7.5 per cent over the next five to 10 years.

With the increasing number of chilled or frozen RTE meals, manufacturers seek to preserve freshness and quality for seven days or more. Shelf life must be stable enough to withstand transport and storage, while retaining both visual

IMCD’s staff are trained technologists who understand the science behind formulation.

Images: IMCD

be used as freely.

Shaffer also pointed out cost challenges. Even when manufacturers find solutions for shelf life or artificialfree ingredients, scaling RTE meals in a cost-efficient manner remains a challenge.

“When cost pressures are on, processed and high-cost foods decline in demand,” she said.

As the RTE market continues to grow, IMCD is well placed to support the industry in developing clean-label, nutritious solutions that respond to evolving consumer preferences.

IMCD offers a comprehensive portfolio of specialty ingredient solutions designed to assist customers in reformulating and enhancing products through

enable deep sugar reduction, and fat mimetic ingredients that replicate creamy mouthfeel and textures while reducing overall fat content.

The IMCD approach

By identifying consumer trends both locally and globally, IMCD Australia works with customers to develop food concepts that are a tailored solution by reformulating through modification, fortification or reduction.

“It starts with the customer,” she added. “What are they looking to do? What are the guidelines and criteria? From there, we help look through our extensive portfolio to identify potential solutions.”

Shaffer expanded on a recent case

study that exemplified this approach.

IMCD Australia worked with an RTE meal manufacturer that wanted to improve the nutritional profile of one of its best-selling products.

The goal was to reduce sodium and fat while increasing protein, without impacting flavour or texture. Through a combination of plantbased proteins, natural flavours, and clean-label stabilisers, IMCD helped them achieve a 30 per cent sodium reduction and a 20 per cent protein increase.

The new formulation helped the manufacturer meet consumer expectations for healthier meals while maintaining product quality.

Shaffer described how the team is a key strength of IMCD.