INSIDE Official Media Partner FEATURES EMPIRE CRANES STRIKES NEW DEAL LIFTEX A MAJOR SUCCESS FOR LIFTING SECTOR TRT’S BIG BIRD TAKES FLIGHT THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / JULY 2023 LIEBHERR DELIVERS FOR AUSTRALIAN DEFENCE FORCES

BUILT TO LAST THE EXPERTS IN PLANT AND CONSTRUCTION INSURANCE For more information about UAA’s insurance products please contact your insurance broker or visit www.uaa.com.au

dedicated local claims teams specialising in both Mobile Plant and Contract Works claims, providing a one stop, end to end, award winning claims service.

With

When things go wrong UAA and MECON will help make it right For more information about Mecon’s insurance products please contact your insurance broker or visit www.mecon.com.au

ENGINES/ GEARBOXES DIFFERENTIALS/ TRANSFER CASES BARE/GLAZED CABS UPPER AND LOWER SERVICE EXCHANGE HYDRAULIC CYLINDERS BOOM SECTIONS/ FLYJIBS BEN BADEN SERVICES PTY LTD | PH (02) 9679 8333 | 43 HOLBECHE ROAD ARNDELL PARK 2148 MECHANICAL STRUCTURAL PAINTING MACHINING AND LINE BORING ENGINE AND TRANSMISSION OVERHAULS CASAR WIRE ROPE DISTRIBUTOR BEN BADEN SERVICES NO DOWNTIME! MOBILE CRANE REPAIRS COMPONENTS EXCHANGE PROGRAM DRY HIRE AVAILABLE WHILE YOUR CRANE IS BEING REPAIRED!

44 Universal Cranes A detailed exploration on Smithbridge group and its services.

46 TRT

TRT’s ‘Big Bird’ delivers on major infrastructure project.

50 Bruce Carden

Structural changes abound at TRT.

52 Paramount Safety

Paul Bozkurt discusses expansion strategies and untapped markets.

56 Andrew Gray

With retirement imminent, Manitowoc’s Andrew Gray reflects on his career and where he sees the industry heading.

61 UA A

Marc Crossman takes a ‘deep dive’ into the directions UAA is headed.

64 WATM

Adrian Wilkes details WATM’s relationship with Manitowoc, logistical processes in aiding remote clients and highlights the delivery of new Grove Rough Terrains.

68 Pace Cranes

Pace Cranes delivers Maeda to SouthWest Spider Cranes.

72 Franna

Billing Cranes’ Darren Ling discusses the features of his new AT40.

76 Tutt Bryant

Director of BridgePro Engineering, Aaron Brimfield, elaborates on Japanese engineering, sustainability, community, and the new HSC 275-tonne crawler crane.

81 XCMG

Regional Manager Stephen Broomfield discusses the company’s expansion plans into the ANZ market.

84 Gleason Cranes

NR Cranes have taken delivery of a Zoomlion ZTC251V to help them kickstart their business.

87 Tadano

Wilson Lift chose the Tadano AC 4.080-1 to expand its operations –hear from director Danny Wilson on the features of his new all-terrain crane.

22 8 Industry News

Liebherr Up Front Liebherr delivers for the Australian Defence Forces.

CICA President’s Report Perth to host the CICA

Conference and Exhibition. 18 CICA Member Profile Keeping pace with cranes, planes, trains and automobiles. 22 EMPIRE CR ANES Empire Cranes looks to expand operations by advancing its fleet. 28 Hoisting Equipment Specialists HES explores all things safety and introduces a new Road Plate lifting device . 32 Lif tEx LEEA makes a major announcement during Lif tEx in Sydney. CANZ Section 38 CANZ CEO Report

Adam’s

12

16

National

40

Crane

his business

The Nelson-based crane operator explores

and his Grove crane.

cranes_and_lifting

SCAN THE QR CODE TO SUBSCRIBE TO OUR NEWSLETTER 76 July 2023 CAL / 5 www.cranesandlifting.com.au

IN THIS ISSUE Cranes and Lifting Magazine

Cranes and Lifting

FROM THE EDITORIAL TEAM

WELCOME TO THE JULY ISSUE OF CRANES AND LIFTING.

TOWER CRANE NUMBERS ACROSS AUSTRALIA PEAK.

According to April’s Rider, Levett Bucknall (RLD) release of the Q1 2023 RLD Crane Index®, crane numbers across the country have peaked.

While the 835 crane numbers across the country continue to be strong, posting the second highest number of cranes seen since the inception of the RLB Crane Index® in 2012, this represents a 3.8% fall from the record 868 cranes seen in the last edition.

The past six months has seen 292 new cranes added to new development sites, and 300 were removed from projects nearing completion, resulting in 33 fewer cranes.

The Q1 2023 RLB Crane Index® found national crane numbers fell in the past six months with all sectors except civic, civil and education. The residential index recorded an index level of 171, fractionally below the peak of 172 recorded in Q3 22 and Q1 19.

Looking around the country, Sydney continues to be the main driver of the crane count. Of the 836 cranes sighted across Australia, 365 were in Sydney, 189 were in Melbourne, 77 were in Brisbane, 56 on the Gold Coast, 51 were in Perth, 20 in the Sunshine Coast, 18 in Adelaide, 17 in Canberra, 16 in Wollongong, 13 in the Central Coast, 9 in Newcastle, 4 in

Darwin and one crane in Hobart.

In this issue, we talk to a straight talking industry stalwart about his imminent retirement, we examine the career of an industry legend responsible for introducing mini crawler cranes to the local crane sector (below) and report on Empire Cranes latest additions.

The CICA National Conference and Exhibition will be in Perth from the 26th to 28th of October. The team at Cranes and Lifting encourage all to submit entries for the CICA Lift of the Year and also the CICA Photo of the Year.

The issue also includes details relating to the successful LiftEx event organised by the Lifting Equipment Engineers Association and we have prepared a second focus on the New Zealand market which coincides with the CANZ Conference, July 24th to 26th Te Pae, Christchurch.

The team at Cranes and Lifting works hard to deliver what we hope is an interesting read and, as always, we welcome your feed back.

Published by:

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766 www.primecreativemedia.com.au

CEO John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Journalist

Jack Alfonso

E: jack.alfonso@primecreative.com.au

Business Development Manager Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager

Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

6 / CAL July 2023 www.cranesandlifting.com.au

Simon Gould Editor, Cranes and Lifting

EXPERIENCE THE VERSATILITY, DURABILITY AND COST EFFICIENCY OF A TEREX ROUGH TERRAIN CRANE BACKED BY FRANNA’S DEDICATED AUSTRALIA WIDE SERVICE AND PRODUCT SUPPORT TEAM

FRANNA IS THE EXCLUSIVE PROVIDER AND AFTERSALES SUPPORT VENDOR FOR TEREX ROUGH TERRAIN CRANES IN AUSTRALIA

To learn how a Franna or Rough Terrain Crane can assist you on site or to request a quote, scan the QR Code

For more information contact the Franna team today: T: 1800 837 395 E: franna@terex.com

www.terex.com/franna

OF A

DAWN

NEW AGE

THE

LIFTEX SYDNEY A MAJOR SUCCESS

LEEA regional manager Australia and New Zealand Justin Boehm launched the 2023 LiftEx Regional to a strong showing of lifting and rigging experts at the Australian National Museum, Sydney, in mid-May.

“LiftEx Sydney will serve as a platform for excellence and innovation in the lifting and rigging space,’ Justin told attendees.

“Sydney promises to be a melting pot of ideas, collaboration and innovation and we aim to ignite a renewed passion throughout the industry.

“As we embark on this journey together, lets embrace the opportunity that this event can present for all of us to learn and grow.

“LEEA’s vision is to assist the lifting and height safety industries in eliminating accidents, injuries and fatalities. This is achieved through education and influence, thus ensuring best practice is an everyday action,” he said.

Day One included presentations from futurist Charles Brass and mindset and behavioural expert Alison Earl. Day Two saw Justin announce the launch of Certificate IV in Lifting

Equipment Testing and Inspection - a long-held industry goal.

LiftEx also had an international theme with Justin welcoming LEAA chief executive officer Ross Moloney, Deputy Chief Executive Andrew Wright - both from the UK.

They also welcomed Sarah Toase, Chief Executive Officer of the Cranes Association of New Zealand, who had crossed the ditch especially for the event.

INDUSTRY NEWS 8 / CAL July 2023 www.cranesandlifting.com.au

“The mission we have as LEEA is to educate, influence and enable, so that best practice permeates from what we do, all the way through the industry,”

(L to R) Andrew Wright, LEEA ‘s Deputy CEO, Justin Boehm, LEEA Regional Manager Australia and New Zealand, Sarah Toase, CEO of CANZ and Ross Moloney , LEEA’s CEO.

BUILDING A SUSTAINABLE

� Home of Australia’s

QUBE RENEWABLES – END TO END LOGISITICS

first purpose built

Contents TableofContents 1 EXECUTIVESUMMARY 2 QUBEHoldings 3 2.1 Qube 3 Experience 4 3.1 Previous WindFarm Projects 4 3.2 Componentshandled, stored, and delivered 4 3.3 CurrentWind FarmProjects 4 SUPPLYCHAIN 5 4.1 BreakBulk andContainerHandling 5 4.2 Stevedoring 6 4.3 Distribution and Storage 7 4.4 CraneHire forPort andSite Lifting Services 8 4.5 Heavy Haulage and Logistics 9 4.6 Post Construction andMaintenance Solutions 10 4.7 Export Logistics 11 CONTACT 12 5.1 Andrew McGaw 12 5.2 Angus Gillespie 12 RELIABLE ADAPTABLE

Table of

Western Australian heavy-lifting machinery company MCT equipment has officially unveiled its new workshop and office in Henderson, in Perth’s southern suburbs.

Equipped with state-of-theart machines and equipment, the new facility will better enable the company to serve customers in construction, mining, infrastructure, and marine lifting settings.

“We are excited to make our mark at our new facility and we believe that it will enable us to continue providing innovative solutions to our clients,” said Anthony Grosser, Managing Director of MCT Equipment.

“At MCT Equipment, we strive to Think Different, Lift Different, and we are confident that our new location will help us to do just that.”

MCT held an official ribbon-cutting ceremony, attended by partners, clients, and supporters of the company, to express its gratitude to everyone who contributed to the facility.

In particular, MCT noted the efforts of its partners Magni TH, JMG Electric Cranes and Italy-based Cimolai Technology – which will be partnering with MCT to distribute its construction machinery and custom products.

MCT says the support of these groups was pivotal to the Henderson facility becoming a reality.

“We are grateful for the partnership and support and we look forward to cotinuing our collaboration to achieve greater success in the future.”

Under a key focus of innovation, safety, and efficiency, the new Henderson facility marks the beginning of a new era for MCT Equipment in its labours of supplying and maintaining both used and new lifting products to customers across Western Australia and the Northern Territory.

MCT OPEN NEW WA FACILITY

The ribbon cutting ceremony at the official opening of MCT’s new facility.

MCT OPEN NEW WA FACILITY

The ribbon cutting ceremony at the official opening of MCT’s new facility.

INDUSTRY NEWS 10 / CAL July 2023 www.cranesandlifting.com.au

“We are excited to make our mark at our new facility and we believe that it will enable us to continue providing innovative solutions to our clients.”

LIEBHERR MOBILE CRANES TO SERVE AUSTRALIAN DEFENCE FORCE

Liebherr Mobile Cranes recently delivered the first 10 of 24 all-terrain cranes to Ventia and the Australian Defence Force (ADF). The Liebherr LTM 1060-3.1 cranes are a significant element of a contract awarded to Ventia for Project Land 8120 – bringing best value manufacturing, engineering, and logistics support capability to the ADF.

PROJECT LAND 8120 PHASE 1 SEEKS TO provide a replacement capability effect for the ADF’s earthmoving and material handling equipment engineer support platforms. Platform tasks in Australia and on deployment include construction, demolition, development of protective earthworks, route development and maintenance, airfield and port construction and repair, port operations, supply and distribution, humanitarian assistance and disaster relief and beach recovery. Platforms include cranes, excavators, front-end loaders, dozers, rollers, graders, skid-steer loaders and telehandlers.

When the ADF sent out a Request for Information in 2017, Liebherr sent out the initial details about the machines it was planning to submit, in particular the Liebherr LTM 1060-3.1.

John Stach, Mobile Crane Sales Manager Victoria and Tasmania for Liebherr Australia takes up the story.

“In 2019, the process went to a Request

12 / CAL July 2023 www.cranesandlifting.com.au

UP FRONT / LIEBHERR MOBILE CRANES

for Tender. At that time, we submitted information to five prime tenderers. When Ventia was announced as the preferred tenderer, we commenced contract negotiations which went for approximately nine months.”

“During this time Liebherr submitted all the technical information relating to the cranes. With the initial tender, Ventia was looking for 60t and 80t capacity cranes but the ADF decided not to proceed with the requirement for 80t machines.”

“Obviously, the LTM 1060-3.1 was the ideal machine in the 60t capacity range. The LTM 1060-3.1 were off-the-shelf machines, and the availability of spare parts was an important element of the commercial side of the tender,” said John.

John explains how a contract this size works with the factory in Ehingen, Germany.

“Over the five year period, I worked very closely with Hans Joerg Nothacker, Manager of Sales for Australia and New Zealand along with the Australian Technical team, and during 2020, we were gaining in confidence that we may win the contract, so we put forward orders into the factory to be able to meet the April 2023 delivery dates.”

“To be able to equip the ADF with these units provides our team with enormous pride and we’d also like to thank the team at Ventia for putting together the successful bid,” said John.

With Liebherr in the middle of the delivery period, John is working closely with Dino Mosca, Product Support Manager Mobile and Crawler Crane Division.

Dino explains more about his role within the project. Having recently started this new role, his initial responsibility has been the military project and the delivery of the 24 machines to Ventia and the ADF.

“I project manage the delivery of the machines to a set deadline and then support and manage the project moving forward. Once we’ve delivered the machines, we’ll offer the MyLiebherr digital package which provides the customer with an extensive range of services, including digital services and application software. MyLiebherr also provides access to a components and parts package, enabling the customer to manage all of that,” Dino says.

“This project has meant a lot of work for the Mobile Crane and Crawler Cranes team, but it’s a significant contract, and it is the beginning of a relationship with the

July 2023 CAL / 13 www.cranesandlifting.com.au

Equipping the ADF with these units provides the Liebherr Mobile Crane team with enormous pride.

As an off-the-shelf machine, the LTM 1060-3.1 was ideal in the 60t capacity range, as the availability of spare parts was an important element of the commercial side of the tender.

Commonwealth, so it’s a step in the right direction for Liebherr,” he said.

Ventia is one of the largest essential service providers in Australia and New Zealand specialising in the long-term operation, maintenance and management of critical public and private assets and infrastructure.

Ventia secured the contract with the Department of Defence, Capability Acquisition and Sustainment Group (CASG), to deliver engineering support platforms to the ADF, under Project Land 8120 Phase 1.

The contract will generate revenue to Ventia of $158 million over five years. Ventia has brought together a team of equipment partners including JCB/CEA, Manitou, Liebherr Mobile Cranes, Komatsu and ECLIPS, and systems engineering specialist QinetiQ to offer the full breadth of services sought by the ADF.

Ventia Group Executive, Defence & Social Infrastructure, Derek Osborn, said that Ventia’s selection was testament to its strong engineering and project delivery capability, and 30-year history as a Defence Industry partner.

“Ventia applies a client-focused, innovative and sustainable approach to essential infrastructure services, and we are excited to bring this to Project Land 8120,” Derek said.

“We are very proud to be taking this next step in our relationship with the Department of Defence. We look forward to working with CASG, and our contract partners, to deliver this essential capability for the ADF.”

Phase 1 involves Ventia leading a team of equipment manufacturers and local engineering specialists to supply approximately 300 earthmoving and material handling vehicles. Minor modifications will occur to meet specialist

requirements such as air transportation. Vehicles will undergo a rigorous verification and validation process to ensure that specific Defence requirements are met. Where required, specialist testing will be undertaken at the Australian Automotive Research Centre proving ground near Anglesea in regional Victoria before introduction into service.

Ventia will also provide vital integrated logistics support, technical documentation and deliver operator training at Defence sites nationally.

With a maximum load capacity of 60t and a 48m telescopic boom, the Liebherr LTM 1060-3.1 is one of the most powerful and capable cranes in its class. Safety and comfort configurations ensure greater operability and the hydro-pneumatic axle suspension and pneumatic disc brakes provide greater control and stability. Its five steering programs enable the operator to adapt to different environments with the touch of a button. Both the driver’s cab and crane cab are modern, spacious and dependable and ergonomic features help prevent operator fatigue.

Other key features with the Liebherr LTM 10603.1 include:

• VarioBase which is designed to make the crane’s support system variable. It enables each outrigger to be extended to a different length. This enhances safety – especially in constricted spaces. The crane’s lifting capacities are significantly increased particularly over the outriggers and depending on the configuration.

• ECOmode minimises both fuel consumption and noise emissions when operating the crane superstructure. The crane operators can set the required working speed using the control lever. The LICCON2 control system calculates the perfect engine speed for the diesel engine.

• ECOdrive makes the mobile crane significantly more comfortable and quieter by reducing the engine speed. Faster gear shifting delivers greater dynamic and traction off-road. On the road, the torque from the Liebherr diesel engine is used efficiently to minimise fuel consumption.

UP FRONT / LIEBHERR MOBILE CRANES 14 / CAL July 2023 www.cranesandlifting.com.au

“This project has meant a lot of work for the Mobile Crane and Crawler Cranes team, but it’s a significant contract, and it is the beginning of a relationship with the Commonwealth, so it’s a step in the right direction for Liebherr.”

When the machines are delivered, Liebherr offers the MyLiebherr digital package which provides the customer with an extensive range of services, including digital services and application software

The jewel in your fleet

The LTM 1150-5.3

Capable of carrying nine tonnes of ballast with an axle load of 12 t, together with a powerful 66 m boom. That reduces the number of transport vehicles required. Global mobility and convenience thanks to ECOmode, ECOdrive, Hillstart Aid and VarioBase. It does not get more economical than that!

www.liebherr.com

Mobile and crawler cranes

Mobile and crawler cranes

PERTH HOSTING THE CICA NATIONAL CONFERENCE AND EXHIBITION

WELCOME TO THE JULY ISSUE OF Cranes and Lifting magazine. The 2023 CICA National Conference and Crane Display is being held in Perth this year from Thursday 26 – Saturday 28 October. Registrations are currently open, and early bird pricing is finishing at the end of July. The CICA Conference features renowned experts and thought leaders from our industry. Listening to their presentations, participating in Q&A sessions, and engaging in discussions can provide valuable insights and practical advice. You’ll gain new perspectives, learn from their experiences, and be able to apply this knowledge to your own business endeavours.

It also provides a platform to network and connect with like-minded individuals, potential clients, customers and suppliers. Building relationships and expanding your professional network can lead to new business opportunities, collaborations, partnerships, and valuable contacts.

The theme of this year’s conference is ‘The Next Generation’ and will address some of the issues the crane industry in Australia currently faces that impact its operations and growth. Some of these key issues are:

SKILLED LABOUR SHORTAGE

Finding skilled and experienced crane operators remains a significant challenge for the industry. The demand for cranes has been increasing in various sectors, such as construction and infrastructure, while the supply of qualified operators remains limited. This shortage of skilled labour is something that CICA is working hard to ameliorate, with initiatives to

turnover of less than $10m.

More than 700 infrastructure projects set up by the former government also face possible cancellation as the federal Minister for Infrastructure has ordered a three-month investigation into the projects promised by the former Coalition Federal Government. As an announcement from Minister for Infrastructure, Transport, Regional

attract talent to the existing traineeships and presenting at schools and attending trade shows.

PROJECT PIPELINES

The 2023 Albanese Government Federal Budget was not hugely beneficial to the crane industry. The Albanese government has overhauled the instant asset writeoff scheme, decreasing the amount businesses can claim for new equipment down to $20,000, and it has been restricted to businesses with an annual

Development and Local Government

Catherine King states, “This process will allow all levels of government time to consider the projects that are actual priorities and assess their cost and deliverability in the current climate.”

The level of infrastructure investment and government policies play a significant role in driving the demand for cranes. Fluctuations in government spending on infrastructure projects and changes in policies related to construction and development have a marked impact on

16 / CAL July 2023 www.cranesandlifting.com.au

CICA PRESIDENT’S REPORT

“The theme of this year’s conference is ‘The Next Generation’ and will address some of the issues the crane industry in Australia currently faces that impact its operations and growth.”

our crane industry, with the delay in delivery times a concern, many crane companies order cranes in anticipation of fulfilling infrastructure project needs. A stable and supportive policy environment will be essential for the industry’s growth and stability and CICA will continue to advocate for this.

COST PRESSURES

Wages, equipment maintenance and insurance premiums for crane operations can be substantial. Accidents or damage to property can result in significant financial liabilities, so while rising costs can put additional financial pressure on crane companies, particularly smaller operators who may struggle – it is important to ensure that adequate crane maintenance and insurance coverage is upheld.

When payments are not received on time, it can disrupt cash flow and create financial strain. This can impact your ability to pay bills, purchase materials, and cover expenses. Chasing payments requires investing time and effort in following up with clients, sending reminders, making phone calls and potentially engaging in legal processes. This can divert your attention from other important aspects of your crane business, such as bidding on new projects or managing ongoing work.

While chasing payments can be challenging, ensuring you are compensated for your work is important. Consider implementing strategies such as setting up regular payment milestones, requesting upfront deposits, or using construction-specific payment tools and platforms to streamline the payment process and minimise potential inconveniences.

Addressing these issues requires a collaborative effort among industry stakeholders, government bodies and training institutions. Promoting safety, investing in training programs, attracting and retaining skilled labour, maintaining the crane fleet, managing finances and ensuring a favourable policy environment are key factors for the sustainable growth of the crane industry in Australia.

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Tom Smith – Director

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 03 8320 0444 0428 228 048

ceo@cica.com.au

Paul Arztenhofer Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

Damien Hense CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant / Office Manager 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship Coordinator 0491 047 118

Kate@cica.com.au

Ashleigh Gould

Cranesafe and Crewsafe Administration Officer

Phone: 03 8320 0466

Email: ashleigh@cica.com.au

Michelle Verkerk Marketing Communications Officer 0404 938 714 michelle@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626

justina@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

July 2023 CAL / 17 www.cranesandlifting.com.au

CRANES, PLANES, TRAINS AND AUTOMOBILES

For close to 45 years, Paul Heeks’ name has been synonymous with the growth and advancement of the crane industry, and he is seen as the pioneer of the mini crawler crane market.

PAUL IS RECOGNISED FOR HIS CONTINUED contribution to the crane industry. He makes a point of attending CICA’s National Conference and Exhibition where he has been the Master of Ceremonies on many occasions, and he remains involved with CICA NSW co-hosting its successful fundraising auctions. But he nearly didn’t have a career in cranes.

After an unimpressive school record, his first trade was toolmaking, moving onto work as a design draughtsman while studying, before eventually moving into engineering sales.

In the early 1970s he started work at Rheem as a sales engineer in the Engineered Products division, where he had a career path that involved taking increasingly intensive management training courses.

Paul then ventured into the world of cranes and went to work with Favco Cranes, a division of Aquila Steel.

“Favco Cranes was the start of my love affair with cranes. I started as sales engineer, then sales manager, and then finally marketing manager. Primarily, we were working on tower cranes and construction work around Australia. Then the business

developed, as did the products, and we moved into offshore platform cranes - and that’s where the real fun started,” he said.

“This was in the early 1980s and the oil industry was going berserk. Favco were making cranes in Liverpool, NSW at that time, and we were selling cranes for oil and gas platforms around the world including New Zealand for the Maui A platform, the Middle East and the North Sea. We had a joint venture operation in Newcastle in the UK, an office in London, one over in Vancouver and another JV in Singapore for the vast SE Asian market. The job involved a lot of hard work and travel, but a lot of fun. It was terrific, until after a stint in India for three weeks looking for another JV partner, I had just arrived home and then suffered a heart attack in late 1982,” said Paul.

“I was told by my specialist I needed a job with less stress (travel) or I would be dead!

Paul says he was on “gardening leave” from Favco when he was was offered the job of state manager at Australian Crane and Excavator Co. - which at the time was the distributor for Manitowoc and Grove Cranes.

18 / CAL July 2023 www.cranesandlifting.com.au

CICA MEMBER PROFILE

Paul Heeks and part of his collection of model cranes, planes, trains and automobiles.

Australian Crane and Excavator Co. was part of the Tutts Group which was a subsidiary of Bowater Scott

A couple of promotions later he became state manager of the Tutts Group, NSW

“It was a good job, a good company full of challenges and I was enjoying it,” he says.

Paul recognised that working for a large multinational organisation had its benefits, but he really wanted to back himself and give his own business a go.

“And so, in 1987 I started PA Construction Equipment working from a desk in my rumpus room at home and that was about the size of it. I started buying and selling used cranes using the old network of contacts from my Favco & Tutts days and with a lot of help from my mechanic, friends Paul Flood and Patrick Mardaymootoo doing field service work and selling spare parts.

“In 1988, I found a little factory in Mortdale which we rented to refurbish older used cranes and carry out light repairs.”

“I had a few overseas contacts from my travelling days, and I was in touch with guys like Stuart Anderson in the UK and many

old friends around Australia and Singapore,” he said.

“This was before the internet and if anybody in those days was in the market for a crane, they had to rely on their own contacts or maybe use a magazine called “Plant and Equipment” which was about the only way you could even check if there were any suitable cranes for sale.

“I always enjoyed the personal side of the business and dealing with industry friends like John Farrier. He would occasionally call and ask what we had in say a 25t RT, I would check our listings and quite often they were available in Japan, so off we’d go to Japan, we’d view the cranes and he’d pick the one he wanted. We would then bring it back, carry out a full inspection and service and ensure it conformed with Australian standards. I did that for quite a few years for many customers,” said Paul.

He was also traveling domestically, talking to crane owners to see which cranes might be coming up for sale and what they might be needing in the future, and then putting deals together.

As time went on, Paul decided he wanted to represent crane OEMs with new cranes and then he was introduced to Maeda.

“Back then nobody had heard of mini crawler cranes, there was no such thing in Australia (or in fact anywhere else outside of Japan). The whole idea of a small mini crawler crane was a completely alien concept. Regardless, Maeda asked if I would like to visit the factory and have a look at the product, so I flew to Japan, and the rest as they say, is history,” he said.

This was in 1991 and Paul agreed to represent the brand. Initially, he bought a small model and was keen to see how the market responded. The initial response wasn’t promising.

“Nobody wanted it. I was told it was too small and just a toy, ‘who wants to own a crane that size?’ ‘They’re silly little things and there’s no use for them’. But I had bought one for stock and I was trying to promote the concept around the country, and nobody wanted it,” said Paul.

“Then one day, I was having a conversation with Bob Smith at Brambles,

July 2023 CAL / 19 www.cranesandlifting.com.au

With the Maeda brand, unquestionably, Paul was responsible for developing the market for mini crawler cranes in Australia.

and they had a job out at Penrith. He said, ‘I think I can use that little crane of yours.’ I took it to site for a demonstration and it worked very well. The job involved lifting air conditioning ducts down and out of the ceiling. Instead of using two access platforms with two blocks and tackles which would take about two hours to lift one duct down, we put this little crane in and we had them down in about 20 minutes. Everyone was impressed,” said Paul.

“I said, ‘Okay Bob, do you want to buy one?’ he said, ‘No, but can you leave it here for a while?’ I then said, ‘Do you want to hire it?’ because at that stage I was thinking to myself if I can’t sell these cranes, maybe I can hire them and sell the concept. Maybe even make a small return on the investment.

“And that’s exactly what we did. I bought a few more which I offered for sale, but

hire was the way people were going because nobody wanted to own these tiny cranes as they couldn’t see a market for them.

“We were hiring them for a couple of years and then customers finally started seeing continuous applications for the Maedas and they were getting ongoing work, and that’s when they started to buy them.

“This would have been around 1993 and that’s when we really kicked off with the Maeda brand,” he said.

The Maeda product went well for Pace Cranes for the next 10 years. The mini crawler concept became popular, and a lot of small builders, glaziers and crane hire businesses wanted at least one in the fleet.

They are very suited for small scale work including window installation, commercial glazing, air conditioning installation and tasks of that nature.

“We started by bringing in a 2.5t capacity crane and then a 3t, and it stayed at these sizes for some time. Maeda then launched a 5t and 6 t followed by an 8t model, which is the largest they made. I could see the potential for much larger capacity telescopic crawlers and in those days, there weren’t many brands represented locally,” said Paul. (There were a few very old Kato NK160s.)

Paul started looking at the larger telescopic crawler manufacturers around the world and eventually discovered Sennebogen, which at the time was another unknown brand in Australia.

At this time, Paul’s son Anthony was becoming more and more active in the business. He was initially more interested in the servicing and maintenance of the equipment and although he completed management studies, he preferred being on the workshop floor rather than selling. In fact, Anthony became the first Cranesafe Assessor for CICA in NSW.

He was deeply involved in the decision to take on Sennebogen and he basically took the ‘business reins’ at that stage.

“We contracted a succession consultant to enable a successful transition and he provided sound advice over a 12-month period as I backed out and Anthony took over. He now runs the business, probably better than I ever did,” said Paul.

Anthony is closely associated with CICA as Chair of CICA NSW - which was a position Paul held many years ago.

He was involved with the National Crane Association right at the start, attending the very first national meeting of the Crane Association at the Broadbeach Hotel in 1979. Since then, he has been to every national convention, and every CICA “bauma” European bus tour. He has had various roles within the Crane Industry and was the President of the Crane Industry Association (CIA, NSW), and has also served on the CICA board,

In 2015 he was awarded the CICA “Con Popov Memorial Award in recognition of outstanding contribution to the Australian Crane Industry”.

He has been the MC for the national convention many times, and is still active with the NSW division, although in minor activities.

20 / CAL July 2023

CICA MEMBER PROFILE

‘Paul’s Shed’ enabled him to realise a child hood dream of building his train set.

He recently enjoyed the Canberra Regional meeting where he stood in for Anthony and welcomed Sarah Brookes and her father Jon, the recipients for the fundraising auction conducted by Jeff Wilson from Finlease. The auction generated $48,000 for Sarah’s Charity for the fight against children’s cancer, with all funds going to the Sydney Children’s Hospital.

“Our industry is so generous towards this type of cause, and I like to be involved wherever I can,” Paul said.

On a personal note, Paul was made a “Life Member” of Lions International service Clubs in 2007 after many years’ service and chairing the “Lions Children’s Hospital Eye Clinic Appeal”, raising over $1,000,000 over six years from Lions clubs in the Sydney District.

He also received a much cherished “Cook Community Award” from Scott Morrison in 2017.

Paul very much enjoys staying involved with the family business, so much so he has a permanent base in the Pace Cranes yard. He bought a demountable building from Terry Whyte from Whyte Cranes while they were building a new office and workshop in Peakhurst.

“I now use this “shed” to house my collection of crane models that I have collected for over 40 years. I’ve never been able to display them previously. So, I bought a few cabinets and now have the models on display with separate rooms for my crane models, a small display of planes, another one for trains and a large collection of classic Jaguar car models as well as trucks. (Craig Membrey’s vehicles feature here as well as a beautiful 1933 Bentley Blower donated by John “Shades” Shevlin)

“I enjoy cars and motoring and have participated in a couple of Variety Club Bashes around Australia, including one

from “Bondi to Broome” What a great fun drive in the bush!”

“The shed is popular with old mates, and we frequently entertain local and overseas visitors from the industry to just sit and have a coffee and a chat – All are welcome,” he said.

Paul’s wife Faye was also involved in the business from scratch and is also well known in the industry’ attending many of the functions, home and away. They have been married now for 58 years and still enjoy travelling together around the world.

Iceland and Norway are next on the agenda later this year, followed by the long-awaited trip to Antarctica. Paul’s career has been long and distinguished. Like so many industry stalwarts he has repaid his good fortune with time and generosity. Without the contribution of the likes of Paul, the crane sector wouldn’t be the powerhouse industry it is today.

www.crewsafe.com.au

CrewSafe is the standardised VOC assessment tool for the Australian crane industry.

CrewSafe provides machinespecific, impartial, peer assessment with documented evidence of competency.

EMPIRE CRANES STRIKES NEW DEAL

Founding directors of Empire Cranes Jared McDonald and Jarrod Belsey sat down with Cranes and Lifting to discuss their recent trip to the Sany Global Crane Conference in China, the recent major expansion to their national fleet, and the driving forces that have motivated them in their crane purchases.

ALTHOUGH THE BUSINESS ITSELF HAS ONLY been around for just over four years, both directors are no strangers to the industry.

“Jared number one” – as Belsey calls his business partner – “has been in cranes his whole life.”

With his father owning a small owneroperator business in Melbourne for years, Jared has gone on to work at some of the most widely known engineering and crane hire companies in Australia and around the world. Belsey, on the other hand, has been in construction hire for over 20-years and worked at a national sales level around the country.

With their new head office located in the outer Melbourne suburb of Pakenham,

Empire Cranes’ operations have ventured anywhere but local. Employing a “longterm dry-hire” business model, and utilising their strong national network, Empire Cranes fleet is currently spread across the country on projects from Melbourne’s Metro Tunnel Project through to mining projects out in the Pilbara.

“The business is sound,” Belsey says. “Our long-term dry hire lease model is ‘slow and steady’; nothing dramatic changes day to day for us, giving us more time to focus on the most important thing, our customers. Without them, we would not have a business at all.”

Speaking to the expansion of their

current fleet, McDonald announces that Empire Cranes have “purchased five new cranes in recent months.”

“We have always had an aggressive attitude towards growing our fleet, and we are committed to meeting the demands of our growing customer base,” Belsey says.

Recently accompanying Australian distributor of Sany products Tutt Bryant to the 2023 Sany Global Convention in China, Belsey says he was “blown away” by the magnitude of the event. Treated to multiple factory tours in Changsha and Shanghai, Belsey added that the Chinese manufacturers “really looked after their global distributors and customers from all over the world.”

22 / CAL July 2023 www.cranesandlifting.com.au IN FOCUS / EMPIRE CRANES

Citing the reception as “incredible”, Empire Cranes were also able to bear witness to the production lines for Sany crawler crane, mobile crane and tower crane facilities.

“We were given full access to the manufacturing line. We observed firsthand the level of investment Sany is putting into their crane production, their R&D and their QA Systems. We were impressed with the level of quality and precision with which each crane is made,” he said.

And that impression made its mark on Empire Cranes; as a result of what they saw, they made the decision to purchase three new cranes from Sany: a 60-tonne and 90-tonne rough terrain crane, and a 100-tonne telescopic boom crawler crane.

“We’ve taken possession of all of the Sany cranes. They are in Australia, ready to work, and we couldn’t be happier with them,” says Belsey.

Featuring a Stage III emission standard Cummins engine, the Sany SRC600T offers a lighter, slightly more transportable, and cost-effective version

July 2023 CAL / 23 www.cranesandlifting.com.au

Having seen the Sany product stand up in environments such as the Pilbara, Empire Cranes needed no extra convincing to purchase three new cranes from the Chinese manufacturer.

“We’ve taken possession of all of the Sany cranes. They are in Australia, ready to work, and we couldn’t be happier with them.”

The team at Empire Cranes recently visited the Sany factory in China as they look to expand their current fleet.

Able to witness the level of investment first-hand, Belsey and McDonald were both deeply impressed by the procedures Sany had in place.

compared to its 90-tonne counterpart, the SRC900T. Not to be outdone, however, the 90-tonne rough-terrain crane offers more versatility with its heavier loads and complements Empire Cranes’ current fleet as they expand further into the rough terrain market.

“We believe the new Sany purchases will add to the overall fleet mix and give our customers more options on their future projects,” says Belsey. “We are seeing a real demand for rough terrains and mid to large size telecrawlers recently, so we had to invest. We are listening to our customers’ needs and working fast to fulfil them.”

The 100-tonne teleboom crawler crane, also features a four-stroke Cummins diesel engine, possesses a boom length of up to

90 metres, a maximum lifting moment of 378 tonne-metres, and is easily assembled counterweight of up to 32 tonnes.

“We’ve seen the Sany product in the harshest of environments in Western Australia and we are confident in their quality and ability to perform consistently, but probably the biggest push for us in considering Sany was the partnership they have with Tutt Bryant Equipment,” Belsey stated. “With a national brand like Tutt Bryant working closely with Sany on meeting and exceeding the highest Australian safety and quality standards and spare part supply minimums, it really reaffirms our decision to go with Sany.”

Empire Cranes is also quick to acknowledge the role Phil Chadwick, Tutt Bryant Equipment Sales Manager for

“We have a great relationship with Phil,” says Belsey. “He has worked hard on promoting the Sany product to us – even inviting us to the Archerfield yard to touch and play with the cranes all afternoon, which allowed us to get a better feel for the crane.”

“Our relationship with Phil provided Sany with a foot in the door. It enabled us to experience first-hand what they were capable of and, as mentioned before, we are so impressed with the quality of the cranes they are producing, and we look forward to sharing this with our clients,” he adds.

Discussing the other new additions to the Empire Cranes fleet outside of the Sany purchases, Belsey and McDonald speak of their “excitement” in announcing the purchase of a Liebherr LTR1220 telecrawler crane; as they put it, “the new flagship of our growing fleet.”

Set to be delivered in August this year, the team at Empire Cranes are confident the 220-tonne telescopic crawler will

IN FOCUS / EMPIRE CRANES 24 / CAL July 2023 www.cranesandlifting.com.au

the southern region, played in opening the door for Empire Cranes to the Sany product.

Belsey says Sany “really looked after” their customers and global distributors.

be a highly sought after product. With a maximum load capacity of 220 tonnes, the telescopic crawler crane features a boom length of up to 60 metres as well as a lattice jib extension of up to 43 metres. As a telescopic crane, it requires a shorter set-up time compared to its lattice-boom compatriot and holds more versatility and transportability thanks to its automated boom system.

Featuring a Liebherr, 4-cylinder diesel engine, the LTR 1220 holds a maximum hoist height of 101 metres in tandem with a radius and has proven itself equally adept on mining sites or civil construction projects.

“We are proud to put this crane in our fleet,” says Belsey. “It is perfect to assist with the wind farm, mining and new construction projects starting around Australia at the moment. We have already had a lot of interest in this crane as soon as

it lands in the country.”

With the fifth new crane added to their fleet being the Japanese manufactured 8-tonne Maeda mini-crawler – only the second of its kind in Australia – Belsey and McDonald were keen to point out the shifting power dynamics in the heavymachinery market, highlighting the rising quality coming from Asia.

“The quality keeps consistently improving. It’s been especially notable over the past few years, and we were lucky enough to witness it in person on our trip to Sany’s factory,” they say. “The amount of time and investment they’ve made into making those cranes meet the high standards that we have here in Australia must be underscored.”

“We feel that the market is turning to other players, and we really believe the Sany brand is going to go from strength to strength here,” Belsey continues. “With

this round of purchasing, we’ve identified some key areas in which we’d like to grow our fleet that are in line with what the market is telling us now. We are very keen to get them out there and working!”

Having grown their fleet from one MAC25 Franna crane in 2019 to over 20 cranes in 2023, consisting of pick & carry, all-terrains, rough-terrains and crawlers of all sizes, business is escalating at a rapid rate for Empire Cranes.

Putting their success down to a customer-centric approach, Belsey says Empire Cranes “want to ensure our product and service to our clients is always of the highest quality.”

“With this focus front of mind, we are committed to continuously updating our cranes, and reducing the age of the fleet as well; we want the best for our clients, and we believe they notice the difference in our level of customer service.”

July 2023 CAL / 25 www.cranesandlifting.com.au

“We are seeing a real demand for rough terrains and mid to large size telecrawlers recently, so we had to invest. We are listening to our customers’ needs and working fast to fulfil them.”

The team at Empire Cranes believe the market is shifting, and there is a rising level of quality coming from the East.

EMPIRE cranes MINI CRANES • PICK AND CARRY • CRAWLER CRANES CONTACT OUR TEAM FOR A QUOTE 1300 986 955 sales@empirecranes.com.au WEBSITE

NATIONAL DRY-HIRE CRANE SPECIALISTS

TELECRAWLER CRANES • ALL TERRAIN • ROUGH TERRAIN

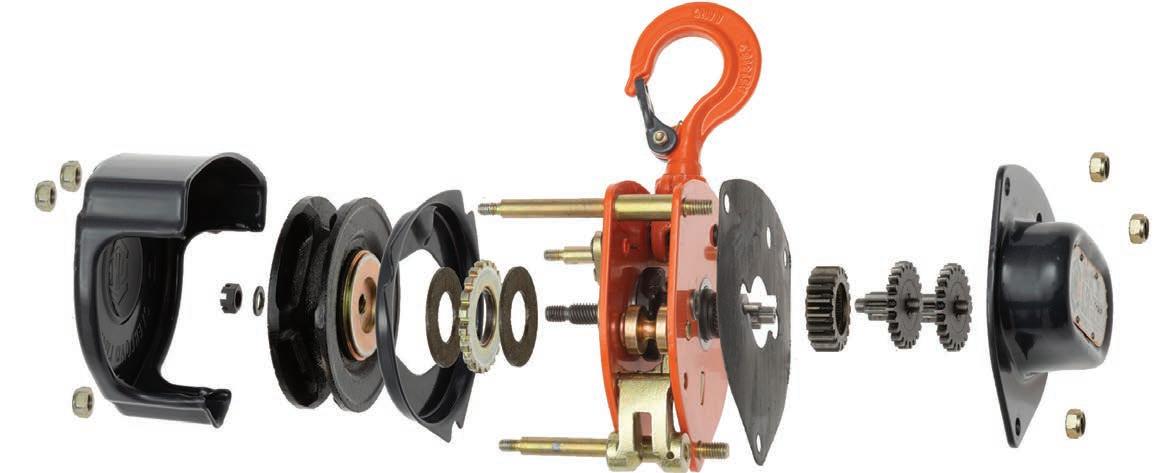

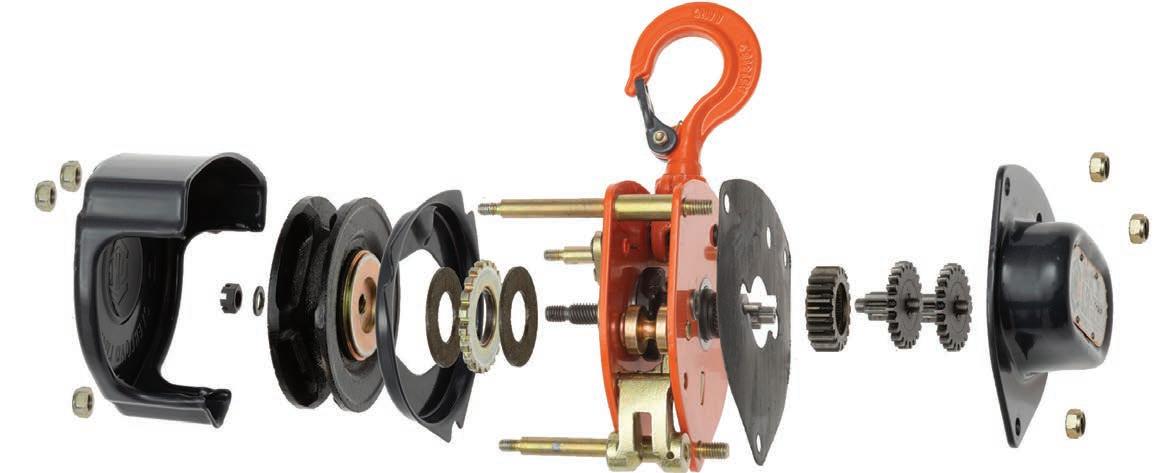

HES HITS THE ROAD WITH NEW LIFTER

In operation for over 40 years, Hoisting Equipment Specialists (HES) holds a tight focus on supplying lifting products and customer service for lifting, lashing, rigging, materials handling and height safety applications. The company’s latest new product release ticks all those boxes.

WORKING WITH HES FOR JUST OVER two years and moving to his current position just six weeks ago, sales manager Greg Francis has been on a steep learning curve to understand the contribution HES has made to the lifting sector over the years.

“It’s been a sharp learning curve for me since I started. We’re a small-tomedium business, we employ a small but specialised team and we’re growing. We have an office in Brisbane and a Sydney one, and while we do operate mainly out of those two areas, we also

IN FOCUS / HOISTING EQUIPMENT SPECIALISTS 28 / CAL July 2023 www.cranesandlifting.com.au

The OzBlok Road Plate Lifter is designed to lift road plates and other sheets of metal.

have a distributor network in each state – excluding Northern Territory and Tasmania.”

“We opened up our Brisbane office over 5 years ago, and that’s proving to be a growing market for us,” he said.

Supplying a mixture of both their own OzBlok products and those sourced from local suppliers, Greg says HES is selling and supplying products right across the construction and lifting sectors.

“With the construction sector being a major focus for the business, you are likely to see our products on any construction site - with lifting and rigging being our main areas of expertise,” he said.

As the newly appointed sales manager at HES, Greg is across all product-related releases coming from the company and, under its ‘OzBlok’ brand, he reveals HES will launch a new product that will hit the shelves of lifting and rigging specialists’ on July 1.

Stating it to be a Road-Plate Lifter, Greg says the product does exactly what it says it will.

“Essentially, it will be used for lifting road plates and other sheets of metal,” he says.

“We believe it’s the best in the marketplace. It comes with its own serial number and its own certificate, as opposed to other brands that need to be load tested. Ours can be bought straight off the shelf and put straight into action,” he said.

In tandem with its quality, Greg says, the five-ton capacity device is priced

July 2023 CAL / 29 www.cranesandlifting.com.au

Greg Francis, Sales Manager for Hoisting Equipment Specialists.

“Essentially, it will be used for lifting road plates and other sheets of metal. We believe it’s the best in the marketplace. It comes with its own serial number and its own certificate, as opposed to other brands that need to be load tested.”

to be competitive in the marketplace, offering the utmost value for money. Speaking to its components and functionality, he adds there are “two components” that ensure the product works effectively.

“It has a base which is welded into a plate, and then there’s a lifting component which fits into that plate, and then a shackle or a hook will slot in and then you just lift it. So, when you see road plates on roads and things like that, covering holes – it’s designed to enhance the productivity of the installation and removal processes of the road plates, facilitate easier access in and out for construction workers and enhance the safety of the workers handling the plates.

Speaking to the conception of the product, Greg says there will “definitely be local demand for it”.

“We saw the Road Plate Lifter concept in Australia and thought that

if we could create something similar it would complement our existing OzBlok range of products. We expect big things from the launch, and we are confident the local construction and civil sectors will quickly realise the benefits of our OzBlok Road Plate Lifter.”

Aside from its array of products, HES also offers a plethora of services to keep those operating in the construction industry safe and in business.

“With our facilities we’ll test anything from chains and wire ropes, to height safety gear, wire rope pullers - basically anything you might see on a construction site or in the rigging and lifting sectors,” says Greg.

Providing the option for customers to have their gear inspected and certified on site, he also specifies that people can bring their products into a HES workshop to get tested on the spot.

“We’ve had a good last couple of years,” he says. “We are very busy in both departments; selling merchandise, and testing and certifying equipment.”

“With people needing to have their height safety or their lifting gear checked on a regular basis to prevent any mishaps, we make sure we’re available to offer that service to them as well. Sometimes, depending on what the item is and how often it is used, it might need to be checked every three months, so we’re always open to managing these types of check-ups for people.”

With HES set to acquire its credentials from the Lifting Equipment Engineers Association (LEEA), the implications of the job are not lost on Greg as the conversation turns to safety in the industry.

“Getting accreditation from LEEA is a very important milestone for us; it will give us recognition that the industry will resonate with. LEEA accreditation

says we are a safe tester and certifier. It gives people who get their gear tested confidence that you’re following the right safety guidelines – which is critical,” he says.

“Lifting is all about safety. Everyone in the height safety, rigging and lifting sectors must ensure the equipment is fully compliant and that safe work practices are adopted at all times.

“Ultimately we are talking about people’s wellbeing here and the team at HES wants to make its contribution to ensure everyone is able leave home for work with the expectation they will go home safely at the end of the day,” said Greg.

IN FOCUS / HOISTING EQUIPMENT SPECIALISTS 30 / CAL July 2023 www.cranesandlifting.com.au

HES is confident the local construction and civil sectors will quickly realise the benefits of the OzBlok Road Plate Lifter.

“Lifting is all about safety. Everyone in the height safety, rigging and lifting sectors must ensure the equipment is fully compliant and that safe work practices are adopted at all times.”

ROAD PLATE LIFTER

CAPACITY: 5.0T

Manufactured and certified to AS4991

Individual serial number on each unit –not batch number

Individual test certificate

Rated to a minimum safety factor of 5:1

Lift and position road plates safely and securely with the NEW OzBlok Road Plate Lifter. Robust and easy to use, the OzBlok Road Plate Lifting System is the only one on the market that is ready to use from the box with an individual serial number on each unit (not just a batch number) eliminating the need to individually tag each unit.

1300 692 565 | OZBLOK.COM.AU

NEW

LEEA’S CERTIFIED SAFETY

During LiftEx, the Lifting Equipment Engineers Association’s (LEEA) Regional Manager for Australia and New Zealand, Justin Boehm, announced that LEEA has officially launched its Certificate IV in Lifting Equipment Testing and Inspection.

MAKING THE ANNOUNCEMENT IN A speech to a strong crowd on May 25th at the Australian Maritime Museum –where LiftEx was being held – Justin said the certification represented a “milestone” in the industry, labelling the certificate a “real gamechanger”.

“We’ve worked hard to achieve this, as a testament to the dedication, expertise and unwavering commitment of the professionals who strive for excellence in their craft – our technicians,” he said. “The Certificate IV in Lifting Equipment Testing and Inspection stands as a symbol of industry knowledge, competence and proficiency in ensuring safety in the lifting equipment industry.”

Boehm also highlighted that the Certificate IV was developed in

collaboration with “industry experts, regulatory bodies and educational institutions”, stating that it will “set a new standard for excellence in our field”.

“It equips our professionals with the necessary skills and knowledge to assess, test, and inspect lifting equipment, ensuring compliance with stringent safety standards and regulatory requirements,” he said.

The new qualification was recently accredited by the Australian Skills Quality Authority – the body responsible for regulating around 90 per cent of vocational education and training providers.

Boehm says the Certificate IV in Lifting Equipment Testing and Inspection is both broad and comprehensive in its content.

IN FOCUS / LEEA 32 / CAL July 2023 www.cranesandlifting.com.au

Justin Boehm and the LEEA Regional Council celebrate Certificate IV in Lifting Equipment Testing and Inspection.

“It covers a wide range of topics, including equipment maintenance, calibration, load testing techniques, inspection protocols, risk assessment, and documentation procedures,” he said.

“It offers a holistic approach to the inspection and testing process, empowering professionals to identify potential hazards, prevent accidents, and enhance workplace safety.”

The course was developed to meet the requirements of the industry, as the association sought to fulfil a long-time request from members in adding more veracity to their accreditation.

“This certification program recognises the vital role that professionals play in the lifting equipment industry, and it celebrates their expertise, dedication, and contribution to ensuring the safe operation of equipment that is integral to our clients,” Boehm said.

“By earning the Certificate IV in Lifting Equipment Testing and Inspection, professionals demonstrate

July 2023 CAL / 33 www.cranesandlifting.com.au

There was plenty of interaction between attendees and exhibitors.

LiftEx attendees were highly engaged over the two days.

their commitment to continuous learning, professional development, and maintaining the highest standards of safety and quality.”

“This certification is evidence of high-level competence, allowing them to provide valuable services to organisations, enhancing operational efficiency, and minimising risks.”

Justin says the new Certificate IV represents success for the industry.

“The approval of program is evidence of the lifting equipment industry’s

continuous progress, innovation, and unwavering commitment to safety,” he told attendees.

NSW Minister for Skills, TAFE and Tertiary Education Tim Crakanthorp congratulated LEEA, as did Member for Woollongong Paul Scully.

The Minister said the development of the new certificate was a great achievement.

“I would like to congratulate the Lifting Equipment Engineers Association, and all involved on the

development of the Certificate IV in Lifting Equipment Testing and Inspection,” he said.

“These things aren’t easy to create. It takes technical expertise, industry understanding and a whole lot of hard work, and that’s before the Australian Skill’s Quality Authority takes a look.

“To have ASQA endorse the course is a massive achievement and is testament to the personnel in your industry and your association.

“I’m sure a nationally accredited training package will be a gamechanger, not just for you, but for the industries you service.

“Everyone who goes to work needs to return home safe as well, so it’s critical that equipment being used on work sites across the state is inspected to the highest standard. Congratulations again on this achievement,” he said.

IN FOCUS / LEEA • MCH175A: 10t max lift & 55m Jib Length • MCH125A: 8t max lift & 50m Jib Length • Standard 1.6m masts • 2m masts up to 58.5m height • Fast erection < 4 hours • Reduced Out of Service radius at 10m Manitowoc Australia Tel: 02 8822 4000 Mob: +61 409 757 451 infoANZ@manitowoc.com www.manitowoc.com New Zealand TRT NZ Tel: +64 7 849 4839 trt@trt.co.nz

“By earning the Certificate IV in Lifting Equipment Testing and Inspection, professionals demonstrate their commitment to continuous learning, professional development, and maintaining the highest standards of safety and quality.”

A huge thanks to our supporters & attendees in joining us for LiftEx Sydney 2023, and we’re looking forward to seeing you again for a bigger event in 2024!

liftex.org/liftex-australia

P.A. Construction Equipment Pty Ltd (Pace Cranes) was established in 1987 to provide the construction industry with an independent Australian owned and operated crane sales, crane service and crane spare parts organisation.

For over 30 years Pace Cranes have offered premium quality equipment to the Australasian market with a dedicated and unrivalled service, supported by specialist technical advise across the full range of equipment sold.

Mini Crawler Cranes Crawler Cranes

Electric Cranes

Mobile Cranes Telescopic Crawler Cranes

Duty Cycle Cranes

Glass Lifting Devices

Tracked Carriers

Crawler Cranes

Knuckle Boom Cranes

Electric Pick & Carry Cranes

Glass Manipulators

Mini Crawler Cranes Crawler Cranes

Electric Cranes

Mobile Cranes Telescopic Crawler Cranes

Duty Cycle Cranes

Glass Lifting Devices

Tracked Carriers

Crawler Cranes

Knuckle Boom Cranes

Electric Pick & Carry Cranes

Glass Manipulators

pacecranes.com.au +61 2 9533 5411 sales@pacecranes.com.au

Bi-level Multi Loaders

NAU MAI HOK MAI

WELCOME BACK

PARTNERSHIPS: THE SECRET OF OUR SUCCESS

At the time of writing I’ve just returned home from a trip to Nelson. I met with our new virtual support team On Cue and I took the opportunity to swing by the “Adam’s Crane” yard.

I WAS FIRST IN TOUCH WITH ADAM Gausel in his previous role at a development/construction company. Adam informed me that he was about to buy a crane to start up his own business and would, in time, join the Crane Association of New Zealand as a member in his own right.

So it was great to roll up to the yard and see the fantastic yellow Grove in all its glory, after watching the business get up and running over the past couple of years.

This word “partnership” features in the Adam’s Crane logo. It also features in the way he does business.

So when I sat down to review this second instalment of the “New Zealand Feature” and saw his article that follows in this section, the idea of partnership once again came to mind.

NOT JUST AN IDEAL

Partnership and collaboration are easy words to throw around, but the success the Crane Association of New Zealand (CANZ) has enjoyed over the past few years, wouldn’t be possible without holding tight to these two ideals.

Partnership is what has made this New Zealand Feature possible. The team at the Cranes and Lifting publication have put in an incredible amount of work to make this a possibility.

The association has limited resources so by coming to me with an idea and the resources to make it happen, together we have been able to partner to create this feature. In return we’ve provided our knowledge of industry and stories of the great work being done across the motu (country/land/nation) and the connection with the incredible people who are making it all happen. That’s you!

This feature highlights the passion, innovation and success of our members. CANZ is the voice of the industry, and through this partnership with Cranes and Lifting we’ve been able to use that voice to highlight your businesses and your success.

38 / CAL July 2023 www.cranesandlifting.com.au

Sarah Toase, CEO of The Cranes Association of New Zealand.

BIGGEST PARTNERSHIP IN OUR HISTORY

We work closely with other associations to identify common streams of work where we can share ideas and resources to create a partnership that benefits both industries.

The perfect example of this is when the Port Industry Association and CANZ sat down over a drink in January 2021. In looking to reestablish the relationship between the two associations we identified that both industries with feeling underserved by the new vocational education framework promised by the Reform of Vocational Education (RoVE). We quickly realised that there was an opportunity for our industries to create a partnership. One which would provide high quality industry training and remove the bureaucracy which would place our niche industries under the behemoth of the post-RoVE model.

We spoke about our vision of creating better outcomes for learners, employers and industry.

This partnership has now come to fruition with the registration of the PTE to be known as PCANZ being confirmed in May 2023.

The success of the PTE is going to require even further partnership as we navigate a once-in-a-generation change to the vocational education sector in New Zealand.

We may need to traverse some rocky water with current providers, trainers and assessors in our industry as we all find our place in the postRoVE world.

I am confident that because we share a vision of an industry which is better served by quality training, we will be able to work through whatever challenges arise.

We will need to rely on that shared vision to create a strong partnership that we can lean on when the waters get a little rough. However, nothing great comes from staying exactly where you are. I know that by moving

forward and moving forward together we will be able to achieve CANZ’s vision to ‘provide world class-training in our own backyard’.

CONFERENCE A CELEBRATION OF PARTNERSHIP

You may well be reading this at the annual CANZ conference being held at the fabulous Te Pae Convention Centre in Ōtautahi, Christchurch. Let me assure you that this oncea-year coming together of the New Zealand crane industry would not be possible without partnership at every level.

Our loyal sponsors partner with CANZ to showcase their products and services and by doing so make this conference the premier event for the Kiwi crane industry.

Our delegates are leaning on partnerships both at home and at work to be here and indeed the company owners who allow their

genuinely increase the benefits to our members and to the wider industry.

Our supplier partnerships are mutually beneficial. An example of this is the printed material you see here at the conference is which sponsored by our printing partner Excel Digital. They print and deliver all of the products that are available in the Crane Training NZ shop.

Another example is how invested our consultant has become in the success of our PTE. The incredible team at SAARA were so invested in getting our registration across the line that when they could see the billable hours mounting up, one of their staff members chose to do work in his own time.

Those two examples demonstrate how vital it is to develop and maintain partnerships with the right people and this is something that the association has focused on. This helps us to achieve our purpose

staff to attend the conference are showing true industry partnership.

I look forward to celebrating partnership at the gala awards dinner taking place on the final night of our conference. This sees our members, who are often fierce competitors, coming together to nominate each other or to nominate a project collaboration for one of the awards.

SUPPLIERS COMING TO THE PARTNERSHIP PARTY

As I mentioned earlier, CANZ does have limited resources – but through supplier partnerships we are able to deliver for our members.

I have been so grateful of the support of our suppliers as we work to

and work towards our vision, not just with suppliers, but with all key stakeholders.

Our key partners of course are our members - the people the crane association is here to serve. There is such a rich history in our industry and so many of your stories are woven together in tales of partnerships (past, present and most certainly - future.)

Adam, of Adam’s Crane shared with me yesterday that two of the association’s life members have (each independently) supported him to get his business off the ground and make it a success.

I can’t think of a better example of partnership, for the success of the kiwi crane industry, than that.

July 2023 CAL / 39 www.cranesandlifting.com.au CEO REPORT

“I have been so grateful of the support of our suppliers as we work to genuinely increase the benefits to our members and to the wider industry.”

ADAM’S CRANE LIFTING TO NEW HEIGHTS

Driven by a strong passion for his local community, his family, and the industry he works in, CANZ member Adam Gausel opens up on his history in the industry, his business and his Grove GMK3060L-1.

FOR NELSON LOCAL ADAM GAUSEL, engineering and the construction industry have consistently been at the centre of his professional career.

“I’ve always had a passion for cranes and machinery,” he says. “Before starting my own company, I’d worked my way up to management at a small crane hire company that was a subsidiary of a developmentconstruction company. A change in the business provided the timing to give ownership a go.”

Having been in the construction industry for 23 years, being owner and

40 / CAL July 2023 www.cranesandlifting.com.au

The Grove can be controlled by remote, something Adam says is beneficial for working closely with his clients.

operator of the Nelson-based crane hire company is turning out to be what he’d “hoped it would be”.

“The business is ticking along well,” he says. “I’m established now and have a good core clientele who I’m focused on providing with a high level of service. The casual crane hire is increasing at a pace that is manageable, so I’m happy with how the first couple of years have gone.”

Out of many, one of the things Adam enjoys about working in the crane hire business is that there are a multitude of different aspects to the job. Constantly needing to adapt to other people’s projects at pivotal moments and being kept on his toes is a challenge that Adam regularly embraces through his business.

“Crane hire is always interesting as you never really know what you might end up doing next,” he explains. “My work is mostly construction and industry based, but I also have construction projects within other industries as well as ongoing work for a provider to central government.”

Aiding him in his conquests around the region is Grove’s GMK3060L-1, a

60-tonne capacity crane possessing a 48-metre boom length and a 65-metre maximum lifting height. Coming up to two years since purchasing the crane, Adam says the Grove is “great to use”, reserving special praise for Tidd Ross Todd Limited (TRT), which was where he acquired the crane.

“I enjoy a really good relationship with TRT; they’ve been very good to me considering I’m just a small entity,” he said. “I appreciate the product support from their team; it’s one of the main reasons I purchased a Grove.”

On top of the aforementioned specifications, Adam’s main sellingpoint for the GMK3060L-1 is its radio control feature. Allowing the operator to

control the crane from outside the cabin, having an enhanced vantage point and the ability to work alongside his clients are some of the major positives for him.

“Half of my background in cranes is working with knuckle boom cranes,” he says. “I got very familiar with radio control and can see the advantages especially for a small business starting out where it’s hard to justify rigging staff. The radio control was something I really wanted to try with a mobile crane.”

Being able to do all the functions from outside the crane allows the operator to position themselves in what they deem to be the best possible place and also allows for optimal

July 2023 CAL / 41 www.cranesandlifting.com.au

ADAM’S CRANE

The GMK3060L-1 possesses a 48-metre boom length.

Adam’s Crane, operating out of scenic Nelson, NZ.

communication between client and operator. However, there are instances where Adam won’t use radio control, as he explains.

“Not being in the machine and being able to feel how it is behaving is always a consideration,” he says.

“I’m fussy with blocking under the outriggers and I optioned the crane with outrigger point load sensors so I can keep track of the stability of the crane. It goes without saying, configuring the crane correctly and operating it safely is critical.”

“There are situations where I don’t use the radio control, like tree removal

with arborists or if I feel it’s safer to be in the crane.”

Overall, though, the radio control feature of the Grove – a first in Nelson – is something Adam says he “couldn’t” go back on.

“With a mind on not having the feel from being in the seat, being at the load makes a massive difference for how I interact with my clients,” he says. “I feel it’s a positive step forward, and I don’t think I could go back to operating a crane of this size conventionally.”

Having been born and raised in Nelson, Adam and his family feel a strong sense of connection to the

local community and surrounding environment. Having purchased the latest model Grove with a EUROMOT 5/Stage four engine as well as a counterweight trailer to eliminate the need for a support truck, Adam says producing fewer emissions and cutting fuel consumption and end of life waste are a step in the right direction.

“It’s good to see hybrid cranes starting to come through,” he says. “At the time of purchase the hybrid wasn’t an option but the Cummins engine is a good little runner and a step forward on previous models in terms of emissions.”

42 / CAL July 2023 www.cranesandlifting.com.au ADAM’S

CRANE

“I’m fussy with blocking under the outriggers and I optioned the crane with outrigger point load sensors so I can keep track of the stability of the crane. It goes without saying, configuring the crane correctly and operating it safely is critical.”

With a counterweight trailer and a stage four engine, Adam is doing what he can to reduce his environmental footprint

The TIDD Pick and Carry Crane, manufactured by TRT, prioritises safety and performance. Standard on all TIDD Cranes is the exclusive Slew Safe® system specifically designed to prevent rollovers. The TIDD Crane is Australia’s only pick and carry crane with this level of safety.

Construction Equipment & Engineering TRT Australia TRT New Zealand QLD, NT, VIC, TAS, NZ PNG, & Asia Pacific 07 3890 8800 cranesales@trtaust.com.au www.trtaustralia.com.au The Baden Davis Crane Connection NSW & ACT 02 9672 1682 anthony@craneconnection.com.au www.craneconnection.com.au Ronco Construction Equipment & Engineering WA 1800CRANES TIDD@ronco.com.au www.ronco.com.au RMB Service Group SA 08 8268 1300 cheryl@rmbservicegroup.com.au www.rmbservicegroup.com.au

Australia’s safest Pick and Carry Crane SCAN TO WATCH

SMITHBRIDGE GROUP CELEBRATES MULTIPLE MILESTONES WITH THREE ANNIVERSARIES

Smithbridge Group is set to celebrate the 30th anniversary of Universal Cranes in 2023, the 30th anniversary of Smithbridge Guam in 2022, and the 60th anniversary of the entire Smithbridge Group in 2024.

WITH A RICH HISTORY DATING BACK

to 1964, Smithbridge Group is a 100% family-owned crane and construction business now entering its third generation of family ownership and management. The company’s brands Universal Cranes in Australia, Auckland Cranes in New Zealand and Smithbridge Guam in the Micronesian Islands have each earned reputations for industry leading engineering and construction services. These milestones further highlight the enduring success and commitment of

Smithbridge Group to excellence and industry leadership.

“As a family-owned business we take immense pride in our team of experienced and skilled employees who ensure every job is done right,” says Albert Smith, Managing Director of Smithbridge Group.

“Back in 1964 my father, John Smith founded John C Smith Contractors, and I’m proud to say we have continuously evolved this business to meet the diverse needs of the construction industry. From a small site in Rangiora, New Zealand, we now have

locations across New Zealand, Australia and the Pacific Region including Guam.” Over six decades, Smithbridge Group has experienced remarkable growth, expanding its service offerings, acquiring subsidiaries, and garnering recognition for its contributions to the industry and the communities it serves.

SMITHBRIDGE GUAM