PRESTIGE Truck Bodies was ned $225,000 and convicted in the Melbourne County Court last month after pleading guilty to a single charge of failing to provide or maintain safe systems of work, so far as was reasonably practicable.

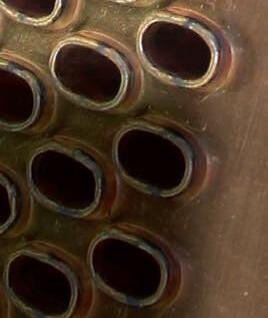

e court heard that in its production process, the Carrum Downs company used breglass and particle board panels that arrived at the workplace in shipping containers, packed in a manner that meant they could only be unloaded manually.

In January 2020, ve workers, including the manager Kevin Smith, 56, were emptying stacks of panels weighing more than 3.5 tonnes in total from a container. e panels had not been securely packed and had become loose in transit.

As the rst panel was being removed, several others fell and fatally crushed Smith against the container wall.

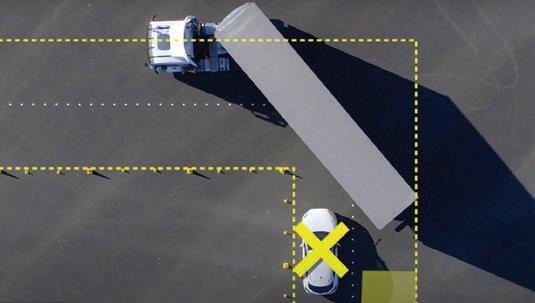

e court heard that it was reasonably practicable for Prestige Truck Bodies to have implemented a system of work that required the supplier to pack panels in a manner that would allow them to be unloaded

using machinery, such as a forklift, and to return any containers that were not packed in this manner.

In a WorkSafe Victoria media statement, executive director of health and safety Narelle Beer said the risks of removing heavy loads from shipping containers were well known and employers must ensure they have a safe system of work in place.

“Once a load begins to fall, there’s often no opportunity to escape for anyone inside a container, and the consequences are all too often deadly,” Dr Beer said. “Duty holders should never allow workers to attempt to unload a shipping container that has not been safely packed, and WorkSafe will continue to prosecute those who put workers in harm’s way.”

In sentencing the business, Judge Peter Lauritsen said Smith was a “greatly loved and admired man”.

He also said the death of Smith has had a “profound” impact on the Prestige Truck Bodies’ founder and director, Paul Williams, who he said was unable to enter the plea himself due to his distress.

Judge Lauritsen said Williams su ered “recognised

psychological disorders” as a result of his oor manager’s death and undergoes regular counselling.

e judge also said the company had made “increased e orts to safeguard its employees” since the accident, including the hiring of a full-time health and safety adviser and regular external audits.

Prestige Truck Bodies did not wish to comment.

A consignor of timber goods has pleaded guilty to one category two o ence under the Heavy Vehicle National Law (HVNL) and was convicted and ned $75,000 at Melbourne Magistrates’ Court.

e consignor had breached its safety duty by exposing drivers and members of the public to the risk of death or serious injury by failing to comply with section 26G of the HVNL.

e NHVR rst charged the Victorian-based compa-

ny with this safety o ence after a truck rolled over onto a pedestrian island crossing. e heavy vehicle was loaded with a 40-foot shipping container carrying 26 tonnes of imported timber plywood products when it rolled in 2019.

e regulator said that its investigation revealed that the consignor had failed to:

• Comply with its own CoR policy.

• Provide overseas suppliers with instructions regarding

compliance with Australian safety regulations.

• Require records and photographs of the container’s load and restraint to be provided prior to shipping.

• Advise the driver and operator of the vehicle on how the load was restrained.

Unsecured or inappropriately packed freight in shipping containers transported by road poses a signi cant safety risk to drivers, workers, other road users and the community, the NHVR said

in a media statement.

NHVR executive director statutory compliance Ray Hassall stated that all parties in the chain should take note of this court outcome.

“ is is a signi cant decision that should be heeded by all duty holders under the HVNL, but particularly those involved in the consignment of imported goods,” said Hassall.

“ ese obligations are in place to ensure all parties in the CoR manage the safety of their transport activities

and can’t simply delegate responsibility to drivers and transport operators.”

e NHVR added that consignors and consignees have the best opportunity to in uence how shipping containers are packed and loaded at the point of origin through contractual and commercial relationships.

“ ey must communicate with suppliers, manufacturers, packers and loaders to ensure processes are carried out to meet safety requirements.”

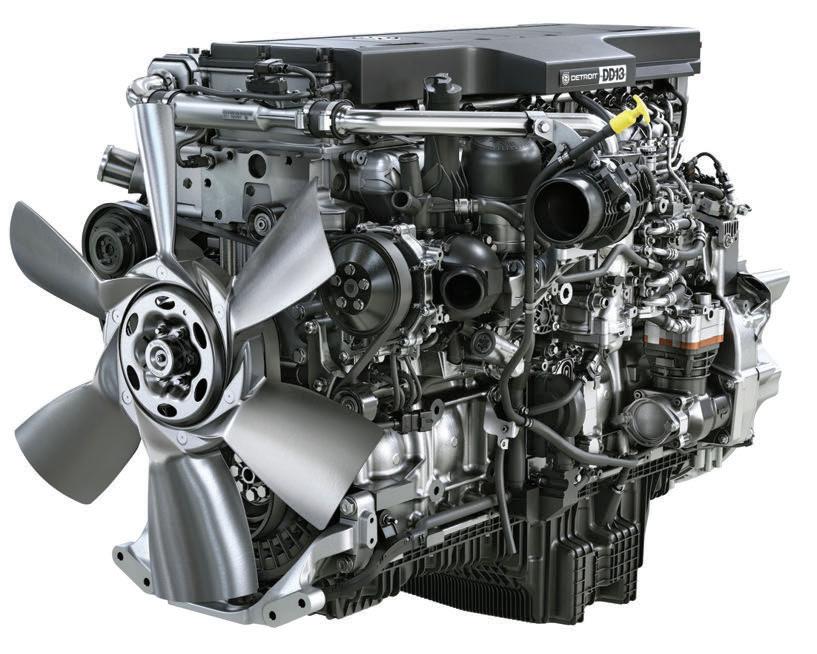

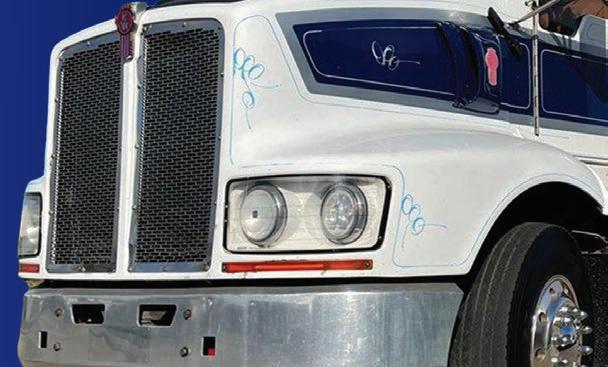

THIS is a perennial question argued about for many hours in truck stops across Australia. In fact, you will never get a de nitive answer, because everybody has a di erent opinion.

In many cases, it’s simply a matter of taste. Some people are Kenworth, International, Freightliner or Western Star fans, while others love their Volvo, Scania, Benz or MAN.

e fact of the matter is that merely mentioning choosing the best truck on the road always provokes plenty of discussion and argument when the subject comes up.

e teams at PowerTorque magazine in Australia and TruckingNZ in New Zealand have decided to get involved in this age-old argument and present an award for the best truck on the market.

At this year’s Brisbane Truck Show (BTS), from May 18-21, one lucky truck manufacturer will be taking away the Truck of the Year Australasia (ToYA) 2023 Award for their latest model. e editors of the two

magazines, Tim Giles and Dave McCoid, are associate members of the International Truck of the Year (IToY) jury, which presents a similar award every year in Europe.

e thinking behind the award is simple. What the jury of ve are looking for is the truck which has been introduced in the last year or so, which has contributed to and improved the standards of safety and e ciency of the transport of goods by road in Australasia.

Any truck which ful ls this and which has a gross vehicle mass 4.5 tonnes or above is eligible. e truck must contain considerable technological improvements. A minor facelift etc. does not make a truck eligible. e truck nominated must be reasonably new, shall be produced in series and shall be ordered, according to an o cial price list.

Australasia presents truck makers with challenges unlike those it faces elsewhere in the world, and also considerably tougher. Trucks are working in the harshest conditions, extreme heat, sub-zero temperatures and

mountainous topography at weights up to and over 200 tonnes, in some cases, and the trucks are running at higher speeds than most of the rest of the world.

Unlike the other regions in the world, Australia and New Zealand utilise trucks from Europe, North America and Asia, and loading these trucks to much higher weights than they are designed for in their domestic markets.

In no particular order, the trucks in the running for this year’s ToYA are: the MAN TG3, the Kenworth K220, the Iveco S-Way and the Fuso Shogun 500, all of which have arrived with something new to o er Australasian truckies.

e Fuso Shogun 510 is a completely new concept for our trucking industry, a Japanese truck which actually has some real power. Okay, it’s only a 13-litre engine, but it does knock out genuine power, and torque to match. Anyone getting into this truck will be surprised at how it performs and how good it is to drive.

e Iveco S-Way is a

complete renewing of what the Iveco brand has on offer in Australasia. It comes at a point where the whole Iveco organisation has gone through a massive change and is virtually starting again. e new range is based upon a tried and trusted formula for Iveco, with the latest version of the Cursor engine, an AMT made for Iveco by ZF and the stylish Italian design we have come to expect from the brand.

e introduction of the

K220 by Kenworth may be contentious for some, but the changes introduced in the new model had to happen, to keep the model abreast of the new regulations coming through. It is a delicate balance for the designers to try and maintain the traditional look and feel of an industry favourite, while also bring the K-Series into the 2020s.

MAN is a truck brand which has struggled to make headway in the Australian market, despite being regard-

ed as a quality truck brand and selling well in Europe.

e driveline is up to the kinds of tasks we would use a truck like this for and is a development from a driveline which has shown its durability in the past. e new design elements in the cab are well thought out and are clearly designed after driver feedback.

For more on the contenders for the top honour, check out our bumper BTS liftout from page 17.

BY JAMES GRAHAM

BY JAMES GRAHAM

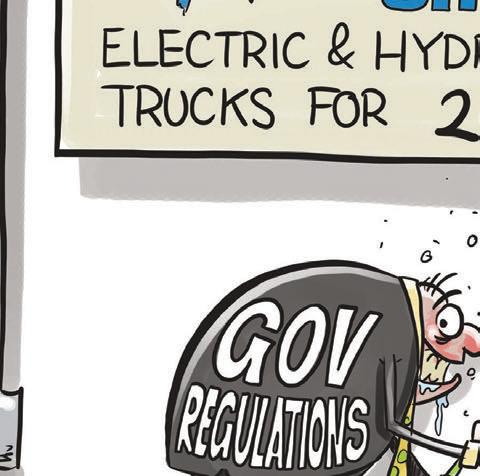

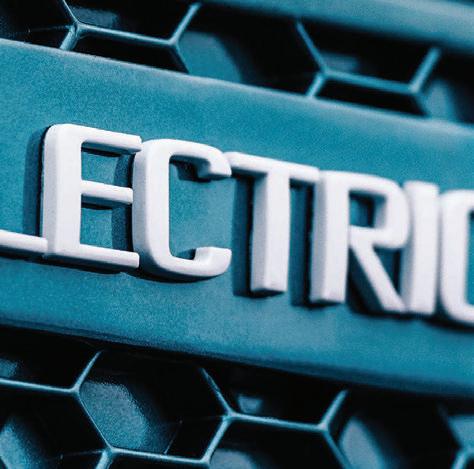

INDUSTRY bosses are calling on federal and state governments to fast-track alignment of legislation and incentives with the burgeoning electric truck technology and emission-free vehicle uptake.

e biggest display of zero-emission trucks ever seen in Australia goes on show at the Brisbane Truck Show from May 18-21 [see this edition’s special liftout from page 17].

But in the lead-up to the event, many industry heads and experts have vented their frustrations over the red-tape failing to keep pace.

Heavy Vehicle Industry Australia (HVIA) chief executive Todd Hacking used the launch of Heavy Vehicle Industry Week to highlight the fact that current truck axle load limits are too low for electric vehicles.

“If not addressed, they will completely strangle e orts to decarbonise the industry, preventing it from contributing to Australia’s mandated emissions reductions targets,” he said.

At the same event, Volvo

Group Australia president Martin Merrick also sent a clear message to Canberra to get on board with how fast industry and eets are already embracing the technology.

“Volvo Trucks now have a full range of heavy-duty electric vehicles that we intend to launch in Australia this year, with a view to manufacturing these vehicles right here in Brisbane by 2027,” Merrick said.

“However – let me be clear – these targets will not be met, unless we have all levels of government working together to change legislation that will

allow these vehicles to operate here in Australia.”

Merrick said that the lack of political decisiveness on the issue is hindering investment decisions, and needlessly shackling Australia’s economy.

“ e stakes are too high to ignore this issue any longer,” he said.

“I call on all levels of government to create a taskforce to deal with this issue as a matter of urgency.

“ is is not a Volvo problem; this is a zero-emissions future problem; this is an industry-wide problem.”

Hacking echoed Volvo’s

position with insights gained directly from other HVIA members.

“ e heavy vehicle industry wants to transition the eet to zero emissions vehicles, and the technology is available right now,” he said.

“Australia has everything it needs to meet emissions reductions targets, creating more local jobs and investment in the process.

“ e only missing piece is the regulatory framework to support us.

“HVIA urgently calls on government at all levels to accelerate truck axle mass regulatory reform,” Hacking added.

“ e ongoing contribution of the industry to Australia’s economy and emissions reduction targets is at stake.”

HVIA’s chief technical ocer Adam Ritzinger proposed four practical actions that can be implemented by regulators right now: classify roads based on structure type, strength, and durability; develop road maps suitable for ZEVs; utilise telematics; and seal pavement research to support higher axle loads.

“We are on a path to be-

coming the highest emitting industry in Australia if nothing is done,” he said.

He called on road managers to urgently classify roads based on their current structural capacity, leading to the development of networks that can support the heavier axles of zero-emissions trucks.

“Australia has been ‘sweating the road asset’ for many years to meet productivity demands. It is time to refocus on the environmental demands and sweat the asset from that perspective.

“Australia has the capability and technology to resolve this problem and must urgently

act to do so.”

e Australian Trucking Association (ATA) has also been lobbying Canberra for change.

It’s zero emission truck plan includes:

• Australia signing the global zero emission truck memorandum of understanding in which leading countries commit to working together to enable 100 per cent zero-emission new truck and bus sales by 2040 with an interim goal of 30 per cent by 2030, to facilitate achievement of net-zero carbon emissions by 2050. e US, Canada, UK and New Zea-

land are already signatories.

• Fixing vehicle design rules, including 7.5 tonnes steer axle mass and increasing width for trucks and trailers.

• Investing in electrical recharging and hydrogen refuelling infrastructure for trucks.

• Delivering a purchase price incentive.

• Exempt zero emission trucks from curfews.

In line with the association’s recommendations, the ATA said that Australian Government has committed to mandating Euro 6 and equivalent emissions standards and has begun to increase funding for deploying zero emission trucks and infrastructure.

But Sam Marks, the ATA’s sustainability and future transport manager, told Big Rigs that the wheels aren’t turning fast enough.

For example, there wasn’t a single reference to trucking in the recently released National Electric Vehicle Strategy.

“It was disappointing,” said Marks. “And it means as other markets in Europe and North America are now starting to move ahead in this space, that Australia is now in a position where we will fall behind.

“Leadership is happening overseas. e US has incentives. ey’ve also already got some vehicle design rules, and they’ve also got clear statements of intent as well in terms of where they’re going, and we don’t have any of that yet.”

Marks said the solutions come back to xing the regulatory barriers, providing

the alternative energy infrastructure, whether it’s EVs, or hydrogen, and also have some sort of temporary purchase price incentive.

“ e cost of these zero emission trucks will come down in time, but if we want to accelerate the transition, which makes for a smoother trajectory, and reduces the amount of emissions we produce over the next couple of decades, you need some sort of incentive to bring that whole transition forward.

“Australia has now legislated commitment to net zero [by 2050], but for trucks we have no plan to get there.

“Europe has wider trucks and narrower tra c lanes so there’s not a good argument for not doing it, it’s just a matter of bureaucracy catching up with modern needs.”

e ATA has now joined forces with HVIA, the Electric Vehicle Council and the Australian Hydrogen Council to lobby for the federal government to develop and implement a National Zero Emission Truck Strategy.

A media release from the newly formed consortium says the freight industry contributes 38 per cent of Australia’s transport emissions.

At the ATA’s recent Trucking Australia conference on the Sunshine Coast, Transport Minister Catherine King told attendees that she was aware that they were up to the challenge of decarbonising transport.

“With our commitment to net-zero emissions, we need to

drive these down – whether it be through hydrogen highways, electric trucks, or cleaner fuels.

“I know that industry is ready and wanting to do your part.”

“ is ingenuity is why I am con dent that Euro 6 emissions standards can be phased in for new trucks and buses, from November next year.

“ is will bring Australian noxious emissions standards

closer to those already in place in the UK, Europe and elsewhere.”

In making this change, King said she was conscious of the development costs faced by industry to meet steer axle mass and vehicle width limits when introducing low and zero emission heavy vehicles to their eets.

“ at’s why our government is working closely with the heavy vehicle industry through the National Trans-

port Commission and the National Heavy Vehicle Regulator to settle any outstanding concerns before the implementation of Euro 6.

“We have to take these steps – even when they might be di cult – because the alternative is too damaging.”

A spokesperson for the Department of Infrastructure, Transport, Regional Development, Communications and the Arts told Big Rigs that plans to further reduce emissions across transport, including in the heavy vehicle sector, will be led by a newly established net zero unit.

“We expect to have more to say following the budget [on May 9],” the spokesperson said in a statement.

Meanwhile, the spokesperson said the government would continue to “support the decarbonisation” of heavy vehicles via investments such as the Team Global Express (TGE) EV trial. TGE received $20.1 million in funding from the Australian Renewable Energy Agency to deliver the largest battery electric vehicle eet of its kind in Australia.

“As well as investment into hydrogen highways to help industry eets acquire heavy hydrogen fuel cell vehicles and construct renewable hydrogen refuelling stations on major freight routes across Australia, starting with the Hume Highway.”

e new ADR which will phase in Euro 6 noxious emissions standards for new heavy vehicles from November 1, 2024, will also provide

a “pathway” for electric and hydrogen fuel cell vehicles to operate at the same mass limits as new diesel trucks under the Heavy Vehicle National Law, the spokesperson added. “ e department understands the concerns of the heavy vehicle industry regarding barriers to the uptake of heavier low and zero-emissions trucks in the Australian market, including axle mass limits speci ed in the Heavy Vehicle National Law.

“ at’s why we are working, through the Infrastructure and Transport Ministers meeting, with the NHVR, National Transport Commission and industry to consider options to ensure operators can purchase and safely utilise more low and zero-emissions trucks.

“ is also includes discussions with industry partners about how Australian heavy vehicle manufacturing can be supported with the low and zero-emissions transition.” e department has also prepared a Regulation Impact Statement - released in 2021 - on options to increase the width of heavy vehicles that include certain safety updates and technologies. “We are nalising advice and recommendations for the government on this package of safety technologies, which would be regulated through the national road vehicle standards.

“Should the government agree to the recommendations, we expect the package to come into e ect later this year.”

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164

Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110

Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020

Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110-120 Maggiolo Drive, Paget QLD 4740

Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Road, Welshpool WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Everyday demands are increasing, Safety is important. To achieve Safety you require comfort. Make sure you have an ISRI Seat.

Ph. 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au

www.isri.com.au

comfort equals Safety.

THE National Road Transport Association (NatRoad) has voiced its opposition to tolling giant Transurban swallowing another operator in a submission to the country’s competition regulator.

NatRoad was asked by the Australian Competition and Consumer Commission (ACCC) to contribute to its review of Transurban’s proposed majority acquisition of Horizon Roads in Victoria, which operates the 39km EastLink motorway in Melbourne.

Horizon Roads, through ConnectEast, holds a conces-

sion from the State of Victoria to operate the EastLink toll road until November 2043.

NatRoad has opposed the deal, reported to be worth $2.5 billion, which it says will have a negative impact on competition and open the way for higher toll charges for road freight operators.

EastLink is the second-busiest tollway in the country, with around 250,000 users each day, and serving 40 per cent of Melbourne’s population.

According to the EastLink website, truckies currently pay $17.91 per trip in one direction.

“In our opinion, the proposed acquisition will increase Transurban’s bargaining power and therefore result in a lack of price competition,” said NatRoad CEO Warren Clark.

“We have strongly recommended that the ACCC consider the potential for increased toll charges and their impact on end consumers.”

Clark says, as in New South Wales, Transurban already operates a signi cant number of toll roads in Victoria.

“Toll tra c data is crucial in competing for toll road development, ownership, and oper-

ation. “ e purchase could also limit the Victorian government’s ability to in uence or control future competitive processes for toll road concessions.

Transurban provides electronic tolling and tag-issuing services under its Linkt brand, and in Victoria has interests in CityLink and the West Gate Tunnel, which is currently under construction. In NSW, it has a near monopoly on toll roads in and around Sydney.

“With the election of a new government in NSW, we are expecting real toll relief

for truck drivers in that state but the creeping rise in tolls is something that needs attention nationwide,” Clark said.

“We have urged the ACCC to carefully consider our submission and to prohibit the

proposed acquisition.”

Transurban is Australia’s largest toll road operator. In Melbourne, it operates the CityLink toll road, and is building and will operate the West Gate Tunnel toll road.

CONSTRUCTION has begun on a new 16-kilometre toll-free motorway – being built at a cost of $2 billion – which will provide a connection to the future Western Sydney International (Nancy-Bird Walton) Airport.

Due to open in 2026, the M12 Motorway is expected to carry 52,000 vehicles per day by 2036. It will have connectivity via Elizabeth Drive to the east and e Northern Road to the west; aiming to meet demand for the airport’s passenger and

freight transport requirements.

“ e M12 is an important part of the $4.4 billion Western Sydney Infrastructure Plan and is jointly funded, with the Australian Government committing over $1.6 billion to the project,” said Federal Infrastructure, Transport, Regional Development and Local Government Minister Catherine King.

“ is road is an essential part of the strategy to ensure Western Sydney International

Airport enjoys good transport connections from the outset.”

Current works are being delivered by contractors Seymour Whyte along the central section and CPB-Georgiou Group Joint Venture through the western section of the future motorway with more than 2000 people being directly or indirectly employed.

As NSW Roads Minister John Graham explained, “It has also been built to accommodate future freight movements and

growing economic zones such as the Aerotropolis and employment zones stretching from Liverpool to Erskine Park and beyond.

“Importantly, the M12 will also take tra c o Elizabeth Drive, giving the road back to the local communities that rely on it for their day to day needs.”

Major construction on the M12 will be complete prior to the opening of the new Western Sydney International Airport in 2026.

Fuel saving - e driver doesn’t need to use the truck to let the parking cooler work because VIESA Kompressor III works only with truck batteries

Longer battery life - e new automotive electronics reduce the charge/discharge cycles. is means that batteries have less stress and increase their life

The reliable, powerful parking cooler for a refreshing rest

e Viesa Internals and Platinums are designed for all trucks, 12 or 24 volt options ey are the same units but the Internal is tted to the external back wall of the sleeper cab and the Platinum is tted to the external roof of the sleeper cab.

• Cheap to t / run (water based)

•Supplied with a remote control

•6 to 8 hours usage time depending on truck batteries

•Quiet to run

•8 speed fan

•Annual servicing is required to keep it running to it’s full potential

•1 year warranty

Fitted Priced From $3,900.00 + GST

e Koolkat is designed for larger sleeper cabs.

e unit comes with 2 x auxiliary batteries and a charger which will charge as the truck is driving. It works exceptionally well in all weather conditions, dry or humid Colour matching extra

National Authorised Installers

Total weight 14 kgs Battery consumption 12.3ah Most efficient on the market

e Ecowind is a diesel powered unit designed for a range of truck types ere are a few di erent tment styles depending on your truck

•Side mount on chassis - Standard tment

•On top of chassis & Rear of chassis - Extra cost

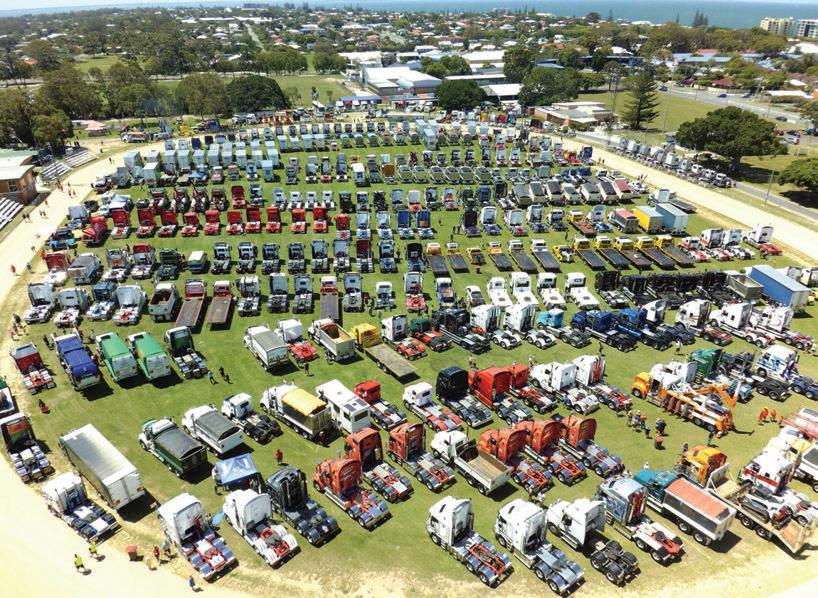

AFTER all the Covid-related uncertainty that plagued the build-up to the 2021 event, what a relief it is to see such a turnout for this year’s Brisbane Truck Show.

Most of the major brands are back on the main floor and with what organisers are calling the biggest display of emission free trucks ever seen in the southern hemisphere.

Hopefully Canberra takes note. The clear message coming through in the build-up was the glaring gap between the industry’s willingness to embrace the new technology and the regulations that are so far failing to keep pace. Factor in the lack of incentives for buyers and charging infrastructure and you can see why the calls for change are growing louder.

As frustrating as it must be for early investors, I’m sure we’ll get there. The government simply can’t reach its net zero goal in 2050 without transport playing its part.

Both Jenny Varcoe and Nick Renowden remarked that the facility was not well planned to begin with and there wasn’t enough consultation done to include all the stakeholders, particularly drivers.

facilities” instead of “consulting with the wrong people”.

TRUCKIES say authorities need to step in and regulate the use of this busy Queensland decoupling facility because too many companies are using it as a trailer depot.

“Place was never planned right, no toilets, not enough parking, simply too bloody small and no input from the people that use it,” Varcoe wrote.

Leanne Dyer agreed that the authorities must “talk to the actual drivers that use these

Eddie Roberts said the government must “keep up with the economy and build bigger pads and amenities, instead of Band-Aid measures keep up with the economic needs of the transport industry.”

Gary Morton agreed with the thought, adding: “The infrastructure needs to get with the times in a growing society with higher freight demands. The state or federal governments need to allocate more land and funds.”

THERE was some interesting response from readers to the first pics and video of the world-first electric triple road train launched in South Australia, a converted Volvo that will cart copper concentrate to the Whyalla port.

Many readers have wondered if it is worthwhile to bring in EV technology to transport, putting further strain on the power supply chain. Peter Hughes said: “100% EV is not the way… hybrid is a better way to go, recharging itself.”

Damien Hedger questioned the logistics of the batteries that will be used. “What do the bat-

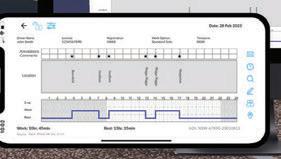

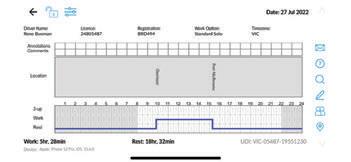

From June 2024, 3G devices will no longer operate and will need to be replaced. Don’t be caught off guard, start planning your 3G migration now.

Refitting your fleet does not need to be an expensive exercise, talk to WHG to understand your options. Refit your fleet with a new telematics device and benefit from the latest technology.

For more information and to start planning your fleet upgrade, contact WHG today.

teries cost? How long to charge given the truck will do about six loads a day and use a full charged battery for each load? How volatile are the batteries if damaged?”

Ian House also questioned how much electricity it would take to charge one set of batter-

ies, and whether it is viable to invest in this technology considering the cost to the broader community. “Electricity prices are at an all-time high Australia wide and here we have a company wanting to put more pressure on an already strained power grid.”

Steven Angel responded: “Ian House, yes, I agree I just do not understand either how can they just jump into something which is only a dream idea” before adding “what about a traineeship program for new and inexperienced drivers first? At least we can fix that!”

The ultimate wheel finish, crafted without compromise.

CHOOSE ARMOURBRITE VISIT US AT THE BRISBANE TRUCK SHOW MAY 18 - 21

forged wheels

gloss

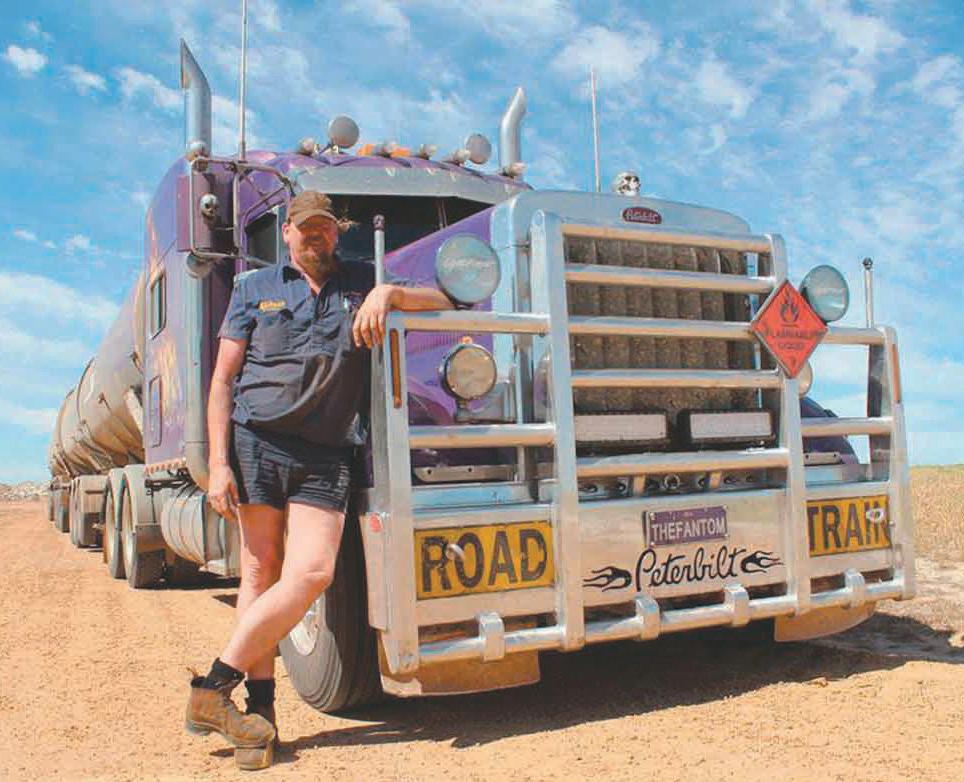

FOLLOWING a horrific motorcycle accident on March 4, that left him with serious injuries, Paul ‘Sludge’ Andrews recently returned home to continue his long recovery.

e popular truckie became well known after his regular appearances on Outback Truckers, alongside his beloved 2008 Peterbilt 379 called ‘ e Phantom’.

Sludge has spent a lifetime behind the wheel and has travelled to all corners of the country. But now it could be a long time before he’s able to get back on the road again.

e accident happened just around the corner from his home. He had headed out on the motorbike, with his 16-year-old son following behind him on a scooter, when the unthinkable happened.

Sludge su ered a fractured skull, eye sockets,

cheeks and ribs, a bleed to the brain, and torn ligaments in his neck, along with back and hip pain. It left him unconscious for several minutes, and he is unable to remember the accident.

Sludge was rushed to Royal Perth Hospital’s trauma unit, where he stayed for two weeks, before being transferred to the Fiona Stanley Hospital, where he was for close to ve weeks.

“ ey also did surgery on his brain to block an artery, to stop any more bleeding on the brain,” said his ancé Wendy Kennedy.

Sludge was discharged in late April so he could continue his rehabilitation from home, with Wendy being his full-time carer.

His rehab will include physiotherapy, speech therapy and continuous doctor and specialist appointments, along with hydro pool therapy several times a week. e recovery is expected to take

6-12 months, but it could be even longer before he’s able to drive a truck again.

ough Sludge is now back on his feet and able to walk short distances, Wendy told Big Rigs there’s still a long way to go. “Sludge is walking now, but very slowly. He couldn’t go to the shops for example without being in a wheelchair. He can walk little distances but then he gets fatigued. It’s good for him to walk though, where he can. So I let him walk and then get the wheelchair out when he gets tired. It can be emotionally trying too though.”

Sludge also opened up about how di cult it’s been. “I’m actually a little over it. It’s not coming along like I thought it would. I’m alright with walking, but still a bit unsteady,” he said.

In fact, just three days after coming home, Sludge had a fall – thankfully he didn’t hurt himself too badly. Wendy explained, “He keeps losing his balance. He’ll be walking and then his leg will give way. He had a nasty fall outside our house. He grazed his head on the pole and hurt the wrist that wasn’t injured, on the concrete. It could have been a lot worse.”

Sludge added, “A fall like that puts me back two or three days, and that annoys me. We’ll get there, it’s just going to take time.”

Unfortunately, it hasn’t been an easy ride for this couple in recent times. Sludge’s motorbike accident came just a week after he had returned to work, following a jet ski accident at the end of December 2022. He had suffered seven broken ribs as a result and was sidelined from work for six weeks.

“No one can give an answer about when Sludge will be able to drive again. With a head injury, this is really fresh, it’s still early days,” said Wendy.

When asked about getting back behind the wheel, Sludge said he was hopeful,

“It’s probably 12-18 months away – it could even be two years before I’m driving again. I need to be able to pass my main medical too, so I might not be able to road train again, I may only be

able to do singles. But you never know. I had a mate who had a stroke and he was set way back, and he’s going again.”

He continued, “From the head injury, I get car sick at

the moment. Every time I get in the car, I have to take medication. I can handle not being able to drive, but this is the one thing I’m really struggling with. I struggle to even go in the car to get to appointments.”

Wendy added, “ e doctors can’t say how long it will take but he won’t be driving a truck for a very long time. What people don’t understand is that we’re not loaded – we’re just an average working couple.

“He nearly lost everything seven years ago and had to rebuild. Everything he does is because he’s passionate about trucks and loves doing it. Now we’re looking long term, because we don’t want to go broke again.”

A friend of the couple, Donna Gell, has created a GoFundMe page to help with the associated costs while Sludge’s business is on hold. At the time of writing (May 3), $15,530 had been raised of the $25,000 goal.

COME AND VISIT OUR UNIQUE STAND AT THIS YEARS BRISBANE TRUCK SHOW AND SEE ALL THINGS KRUEGER AS WE CELEBRATE 25 YEARS OF OUR AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION.

also an upgrade on the Mack.

“I had no troubles with it, with the 44s under it, it could do anything. She hauled some big loads and it never saw a weighbridge in New South Wales,” McGlinchie said with a smile.

“Of course, there was still 600 miles of dirt roads – when I started running out there in 1959 the dirt started at the Kimba turno and nished at Norseman – it was rugged, but the truck stood up to it. I had slept across the seats for 10 years, so it was a step up in comfort. It did 90 per cent of its time running Sydney to Perth, carrying general and then copper tube and loading timber back out of the south-west.”

McGlinchie sold the truck in the mid 1970’s in favour of a Detroit-powered Atkinson, with the DCO a familiar sight around Sydney for a number of years working as a salvage unit for Retriever Towing.

Buying the truck back, McGlinchie started his restoration project, which has resulted in the truck today nished with a white roof, blue cab and gold trims.

a lot more sociable too,” he said.

In between owning the DCO, McGlinchie spent a number of years carting steel between Sydney and Newcastle before nishing his fulltime driving delivering BP fuel for a sub-contractor. In more recent times he worked shifting the Stihl Timbersports woodchopping carnival around the country before the various Covid shutdowns saw him call time on his driving duties.

For older readers he is best known for his 14-year stint as test driver and technical contributor for the much-missed Truck and Bus magazine.

“I would have done that job for nothing – at one time International built us a Big Cam powered Atkinson for a road test between Sydney and Perth, it was nice that they trusted you enough to build a truck for you to do a test,” he said.

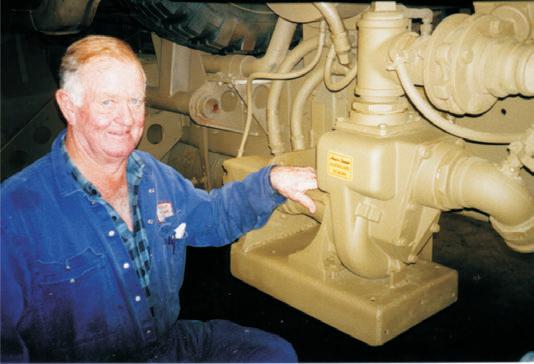

BY DAVID VILELOOKING back through the archives of road transport in Australia and in particular the myriad of makes and models of trucks that have graced our roads, the International DCO-F does not come as readily to mind as other trucks such as a Mack Super-Liner or Kenworth SAR.

e only known DCO-F still on the road in Australia along with its owner, did the hard yards on the Nullarbor between Sydney and Perth when the road was not much more than a dirt track.

Don McGlinchie has twice owned the 1965-model DCO, in the rst instance purchasing the Emeryville, California-built truck with which he ran across ‘ e Paddock’, and other destinations between 1969 and 1974. He once again bought the truck

around 10 years ago and spent four years overhauling and rebuilding it into an immaculate example of the model, which he had on display recently at the Gundagai Tractor Pull and Swap Meet.

“ e DCO-F was the predecessor to the Transtar, there is no documented history of

them in Australia but as near as I can nd out the rst series had a 280 Cummins which was de-rated from a 335. It’s a D-series, the CO is for cabover, and the F denotes a bogie drive,” McGlinchie explained.

Having been running a B-Model Mack east-west, McGlinchie bought the DCO

from Phil Murray, another Sydney-based operator. With the tment of a 15-speed Roadranger and the International rear end swapped out for a 44,000lb Rockwell setup, the International soon proved its worth, and with the sleeper cab somewhat of a rarity at the time, the comfort levels were

“It still had the tow-truck body on it, but the chassis was cracked in a couple of places, I bought an old Kenworth and ogged all the good stu out of it and put it back in this. With the 350 Big Cam Cummins, it runs along nicely, you can sit on 100k and she’s only doing 1300 revs. It also now has air suspension so that’s made it

For now, McGlinchie wheels the DCO out for events such as the Gundagai event and Haulin’ the Hume, where the truck’s rarity makes it somewhat of a talking point.

“I know where there are three others being restored but they are long term projects. ey built 33,800 of them which would have been the best-selling International in the USA until the Transtar came out. But you just can’t seem to nd much history of them here in Australia which is a real shame.”

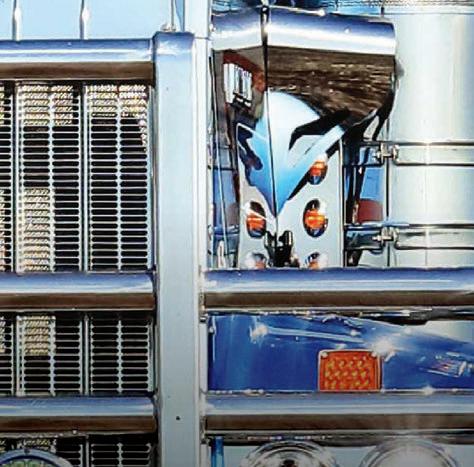

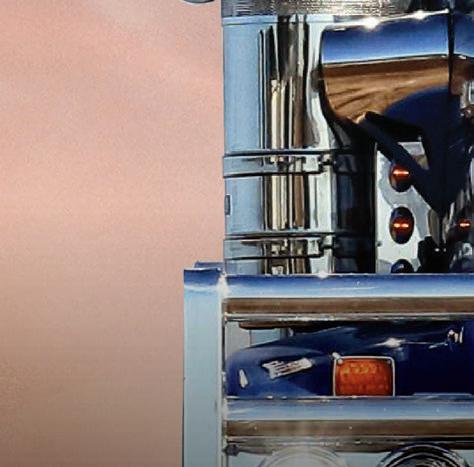

‘A MODERN classic’ would probably be an apt term to describe the 1976 Kenworth which is owned and operated by Matt and Courtney Hambridge.

e 47-year-old Kenworth’s iconic SAR styling is straight out of the 1970s, coupled up to a current era engine and driveline.

Based just south of Sydney at Yerrinbool, Matt and Courtney operate MCH Heavy Haulage, with a eet of predominantly cabover Kenworths, joined last year by the SAR, which has taken pride of place as both a agship vehicle for the business and one which will be part of the Hambridge operation for many years to come.

Coupled up to a Drake quad oat and loaded with a Caterpillar PM620 pro ler, the couple had the Kenworth on display in late February at the Gundagai Tractor Pull and Swap Meet.

With the truck having recently once again become a fully working truck as opposed to an historic one, Matt gave a background to both the unique speci cations of the SAR and its new home as

part of the MCH eet.

“It has the features of a modern truck in an older truck. It actually has a Series 60 Detroit in it and all the running gear out of a K104 Kenworth with an 18-speed ‘box and an airbag rear end,” explained Matt.

“ e 14-litre Detroit is rated at a little over 600 horsepower, so it has no problem getting over the hills! It is a bit of a toy, I just wanted something that I could do up so we got a hold of it and started tinkering.”

Having been on the lookout for an older SAR and having just missed out on another example, a ick through the classi eds on Gumtree late in 2022 soon had Courtney on a plane to Western Australia to check out the truck.

“Courtney found it on Gumtree and went straight over to Perth that afternoon to look at it, she came back and got a bank cheque and we went back over and drove it home,” said Matt.

“It has been converted with all the newer gear over there and the fella needed to buy a set of grain tippers for the harvest season and needed to sell it.

“We were a bit lucky; the truck had been sitting in his

shed for four years, and he had only had it on Gumtree for two days.

“We bob-tailed her home – I am a bit time poor so didn’t have time to get a trailer sorted – there was a bit of hopping and carrying on but with the airbags it wasn’t too bad.”

Having planned to take a couple of his restored GM-powered Dodges on a trailer to Gundagai behind the SAR, Matt’s plans soon changed when one of his clients needed the pro ler picked up out of Wagga to go back to Sydney.

With the truck having been put back on full registration the week before it was an opportunity for the Kenworth to start earning its keep.

“It’s the rst week on the road as a working truck. It had been on vintage plates prior.

“I said to Courtney that it’s a bit of a waste having it sit in the shed and not being utilised so we got it spec’d to 75-tonne and got it back on full rego.

“Coming down here it was a perfect opportunity to take it for a run and still utilise it in the business. We took the

weekend o for the show but this will save two trips.

e MCH operation is run as a family business and undertakes a variety of roadworks and road maintenance projects for companies such as Fulton Hogan.

From their Yerrinbool base the MCH trucks and equipment work throughout the Southern Highlands, and with the recent oods requiring a number of road projects to be undertaken, Matt’s team has been as far a eld as West Wyalong and Narrandera.

e current eet includes ve K200s, a K104 and a K108, and looking to the future Matt is about to put two A-double tipper sets on the road to haul asphalt.

“We built up the business with excavation and heavy haulage. We wound it down a bit through Covid and have found our niche market, the A-doubles we have invested money in to maximise what we can do with our sta and so forth. We are a small family business but we all work together and get through it, taking on the two double setups is a big risk but if you don’t have a go you’ll never know,” he said.

e family ties extend through to the SAR, which has been dedicated to Matt’s great grandmother, Catherine Grace Hambridge, who was better known around the place as ‘Dynamite Kate’.

“I wanted a truck I could do up in honour of her. I was probably a little too young but she drove for TNT on parcel freight for a number of years,” recalled Matt fondly.

“She had a reputation, apparently she used to go o like a recracker at Marulan!” he added with a smile.

Also adorning the sleeper cab are the names of Matt and Courtney’s three children, Katie, Tyler and Chloe, with 13-year-old Katie apparently showing good form already changing gears around the MCH yard.

Matt reckons with the support of Courtney, who is also regularly behind the wheel of a truck, his father Ian, and other family members helping out along the way his business is well poised for the future.

It is the passion for his machinery and work that will keep the MCH name, and the ‘best of both worlds’ Kenworth out on the roads for a long time yet.

“It is old but modern enough that I can still put it to work, and this is something we can hand on down to the next generation,” he concluded.

Editor’s note: Astute readers may recall this story from the previous issue. We’re running it again in its entirety this time after a le error at the printing stage inadvertently deleted the second half.

A quick ick through the classi eds on Gumtree opened up a whole new world for this Yerrinbool couple.Matt and Courtney Hambridge with kids Tyler, Chloe and Katie. The SAR has been dedicated to Matt’s great grandmother Catherine ‘Dynamite Kate’ Hambridge. The best of both worlds, the Kenworth has once again become a working truck.

A key focus for this year’s program is sustainability and

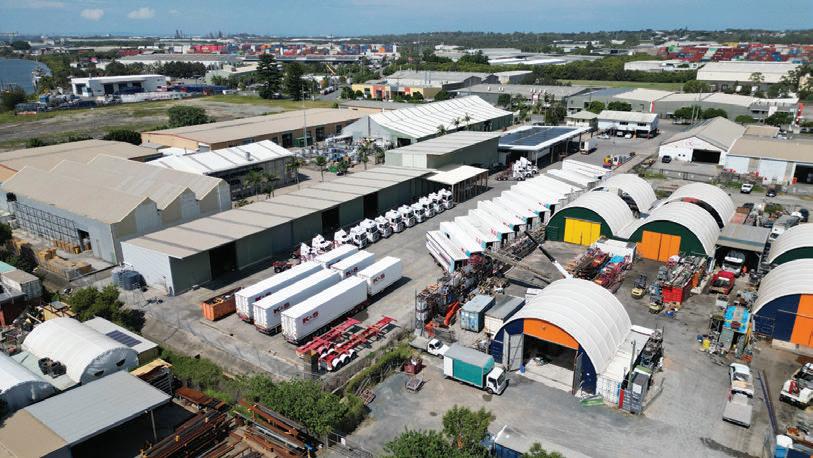

HEAVY Vehicle Industry Australia (HVIA) chief executive Todd Hacking said this year’s Heavy Vehicle Industry Week will be the biggest and the most innovative heavy vehicle events program to be delivered in Australia.

e week-long celebration from May 15-21 also includes the largest display of zero-emissions vehicles in the southern hemisphere, one of the most talked-about features of the Brisbane Truck Show at the Brisbane Exhibition and Convention Centre.

“It is a tremendous honour and thrill to host Queensland’s biggest business-to-business event, which is expected to contribute $40 million to Queensland’s economy,” said Hacking at the o cial launch.

“In particular, I would like to acknowledge the tremendous assistance and support we receive from the Queensland government and Brisbane City Council who work with us to deliver this world-leading industry event.

“With an extraordinary program of informative, interactive and educational activities we expect 40,000 attendees to the Brisbane Truck Show over four days, lling over 70,000 hotel room nights across the city.”

Hacking said that a key focus for this year’s program is sustainability and environmentally friendly transport.

“We will feature the future of heavy vehicle technology including the largest display of zero-emission vehicles in the southern hemisphere including hydrogen fuel cell and battery electric vehicles, hybrids, renewable diesel and much more.”

Volvo Group Australia pres-

ident Martin Merrick said the event is an opportunity for everyone to get a glimpse of the future of transport, a vital industry that lies at the heart of the Australian economy.

“It is no secret that we are on a zero-emissions journey both globally and locally,” Merrick said.

“By 2030, at least 30 per cent of the new trucks we sell globally will be either electric or utilising a zero-emissions power source.

“We intend for that gure to rise to 100 per cent by 2040.

“Electric trucks will bring lower running costs, lower emissions, and more choice for

trucking operators.

“But most importantly they make our cities and urban environment a better place to live and work.

“We are expanding our electric o ering with a view to manufacturing heavy electric vehicles right here in Brisbane by 2027.”

Brisbane City Council Deputy Mayor, Krista Adams said the Brisbane Truck Show was a major business and tourism drawcard for the city, a vital hub for road transport which supports thousands of jobs for locals.

“ e Brisbane Truck Show will also be a massive boost

for the events industry, attracting 40,000 people to the city thanks to an exciting line-up, including free and a ordable events for the whole family,” she said.

e week incorporates the following heavy vehicle events:

• e Brisbane Truck Show, May 18-21 (BCEC).

• South Bank Truck Festival (South Bank Parklands).

• Mack Anthem Truck built by LEGO bricks as a Guinness World Record attempt.

• Rock on Riverside Live @ South Bank concerts.

• Electric Avenue – zero-emission truck display on Little

Stanley Street.

• National Apprentice Challenge at the South Bank Piazza.

• Heavy Equipment and Machinery Show (Brisbane RNA Showgrounds, Bowen Hills).

• Heritage Truck Show (Rocklea Showgrounds).

Program highlights include:

• e largest display of zero emissions heavy vehicles in the southern hemisphere.

• Electric Avenue display on Little Stanley Street, South Bank.

• Complimentary community concerts in South Bank Park-

lands Riverside Green.

• Co-presented by Live at South Bank, Eat South Bank, QMusic.

• e Superjesus and Australian Rock Collective plus many more.

• e Live at South Bank program is proudly supported by the Australian Government Restart Investment to Sustain and Expand Fund.

• Full-scale replica Mack Anthem built from Lego bricks. celebrating 60 years of Mack

• Trucks being manufactured in Queensland.

• e battle of Australia’s best automotive apprentices at the HVIA National Apprentice Challenge, featuring a crowd of almost 2000 students from an anticipated 50 high schools to experience the diverse and rewarding career opportunities.

“ e heavy vehicle industry has shown incredible resilience and tenacity over the last few years, helping to keep the country moving through drought, bush res and the pandemic,” added Hacking.

“Our ability to support the largest accelerated increase in online shopping in the world’s history is a testament to the sector’s character, agility and capacity to scale and deliver in the face of extraordinary challenges.

“ is year we celebrate our achievements as an industry and also demonstrate our commitment to, and embrace of, innovative, sustainable and environmentally friendly transport technology.

“We have also partnered with industry and mental and wellbeing charity, Healthy Heads in Trucks and Sheds, to support the mental health of our greatest asset, our people.”

TRANSPORT Minister

Catherine King and Climate

Change Minister Chris Bowen only need to take a quick walk around the main auditorium to see that manufacturers are more than willing to play their role in helping Australia reach its net zero target by 2050.

Zero-emission vehicles have been the talk of the show in the build-up with all the main players eager to show o their latest o erings.

So big was the hype, some were still under wraps at deadline for this issue, including Volvo’s eagerly-anticipated heavy-duty prime mover, which was set to be revealed to industry media for the rst time on May 17, the day before the covers come at the Brisbane Convention & Exhibition Centre.

Until then, here are more details about some of the other zero emission trucks that we do know will be on display.

Despite the regulatory handbrakes and lack of incentives for buyers (see story on page 4-5), Volvo is an early frontrunner in Australia in the EV truck space.

Early adopters of the Volvo product so far include heavyweight clients such as Australia Post, Linfox, Team Global Express and GEODIS.

Just recently, Volvo Group Australia president Martin Merrick also announced the group’s intentions to build

battery-electric vehicles at its Brisbane facility by 2025, with the heavy-duty model coming on line two years later.

e current models available in Australia include the Volvo FE Electric, a 300hp (225kW) rigid, that runs a dual-motor driveline with a two-speed gearbox with three to four batteries; and the FL Electric, a medium-duty truck designed for city rigid work that’s powered by a single electric motor with a two-speed

gearbox.

e range for the FE is up to 200km and its gross combination weight pushes up to 26 tonnes and comes in 4×2 or 6×2 axle con gurations.

e FL claims a 300km range and pushes out 174hp (130kW) from its single electric motor. e FL also boasts GCW of up to 16 tonnes and has four battery packs at 265kW.

Charging time takes 11 hours with alternating current

and two hours with direct current charging.

Team Global Express has chosen a eet comprising 36 Volvo FL electric trucks tted with 10-pallet van bodies, a GVM of 5900kg, and a range of up to 300km.

Continued on page 22

To nd out more, contact your UDTrucks dealer on 1300 BUYA UD or visit udtrucks.com/australia

When you’re running a trucking business, or you’re out on the road, trust is everything. You need a team behind you that you can rely onpeople you know are always on your side.

At UD Trucks, we have one of the widest networks of sales and service experts dedicated to your success. From local dealership managers to finance specialists, from performance specialists to truck technicians, our people take the time to get to know your business, and they work with you like they’re part of the team.

Find the team and truck Australia trusts at the Brisbane Truck Show - Stand Number 49

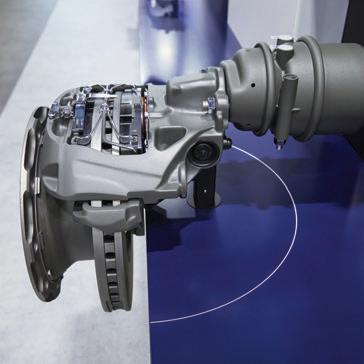

MERCEDES-BENZ Trucks will present the all-electric eActros for the rst time in Australia at the show.

e battery-electric eActros is focused on heavy-duty short radius distribution and development trucks have been working away in select eets in Europe since 2018, impressing customers with its advanced design, strong performance and e ciency.

Mercedes-Benz Trucks will soon begin a local validation program for the eActros in Australia and New Zealand.

Daimler Truck already has considerable experience with electric trucks in Australia. It was the rst manufacturer to launch an all-electric truck

when Fuso introduced the pioneering eCanter locally in 2021.

e eActros validation program is designed to ensure the eActros speci cation is tailored for the unique conditions of Australia and New Zealand and meets the speci c requirements of local customers.

Initially, four eActros trucks will get to work in Australia and one unit will hit the road in New Zealand, with additional units to follow.

As we were going to print, Mercedes-Benz Trucks also con rmed that the all-electric eEconic will also be on display in Brisbane for the rst time.

e Econic, which is best known for waste collection was designed from the ground-up to

work in densely-populated areas and is known for its excellent visibility, practicality and active safety features.

Now, the electric eEconic version will also be known for its near-silent powertrain and zero local emissions.

e eEconic that will feature on the Daimler Truck Stand at the Brisbane Exhibition and Convention Centre will also be part of a validation trial that will take place in Australia and New Zealand after the show.

STAND: FOYER 44

Ph: 1800 033 557

Web: mercedes ben trucks.com/en_AU

THE lightning-fast electric evolution continues with the next-generation Fuso eCanter making its debut in Brisbane.

Fuso Fuso launched the rst eCanter globally in 2017. It was the rst OEM electric truck introduced locally in 2021 and has worked for big brands including Bunnings, Toohey’s, Centurion, Goldstar, Linfox and Australia Post.

e next-generation eCanter moves the needle further with a raft of new technology that demonstrates how quickly electric truck technology is moving.

ese include a state-ofthe-art eAxle electric Power Take O (PTO), advanced safety, connectivity, boosted range and a bigger choice of models that covers di erent wheelbases, weight ratings and a choice of a City Cab or Wide Cab.

e eAxle is big highlight as it delivers big e ciency bene ts and reduces weight. For the existing model, the power is fed through a driveshaft from an electric motor that sits just behind the cab to the drive axle. For the next generation eCanter, engineers have developed a drive axle that also houses the electric motor.

Another smart piece of technology is the electric PTO, which opens up a bunch of new opportunities for the new eCanter. It means

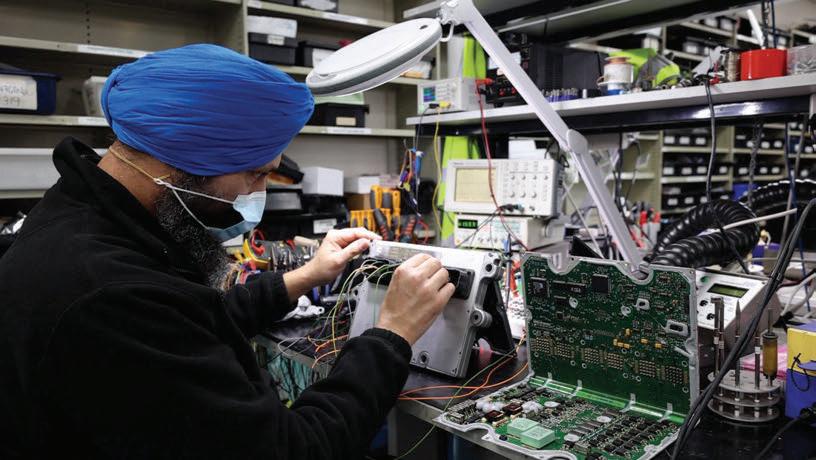

HYZON Motors is showcasing its heavy rigid truck platform, an Australian-designed and built hydrogen fuel cell electric vehicle, at the show.

e company is developing the heavy rigid truck as a global platform, adaptable for international markets, with a multitude of uses, such as garbage compactors, tilt trays and atbed trucks.

Leading the development of the global heavy rigid program in Australia has allowed Hyzon to tap into the rich

resources of highly skilled local engineering and technical knowledge to build a team, process, and product for its global and domestic markets, the company says.

Last year, the US-based company announced development of a purpose-built assembly plant in the southeast Melbourne suburb of Noble Park, to locally manufacture hydrogen-powered commercial vehicles.

Hyzon’s team has designed and built the rst three trucks

over the past year, replacing the diesel engines in new Mercedes trucks with hydrogen gas tanks and a fuel cell.

STAND: PLAZA 297

that the new truck’s electric power can also be used to move things like a tipper body, crane, or fridge body.

e eCanter will come with clever factory connectivity that will allow eet operators to see battery information, including charge level, remotely, along with a vast amount of other information.

ere is a newly-developed eMotor that makes a maximum output of 129kW and 430Nm. e ‘engine brake’ system that slows the truck while harvesting energy at the same time now has four stages for even better control.

is powerful system means that eCanter drivers can slow the truck in tra c, even to a complete stop, without having to touch the service brakes. e energy recouped also increases the range.

Like the existing model the new eCanter can be charged with regular AC charging technology or a faster DC

charging station.

ere are new thermally-controlled battery packs available in three di erent sizes. Australian tests will soon be conducted with a fully loaded eCanter to determine how much the range has improved and to make it t for our market.

Fuso has introduced a new look exterior, while the interior has been given a major freshen-up with a futuristic digital dash and upgraded steering wheel.

Customers will also have more choice, with 14 variants all up. e range will start at 4.5 tonnes and move up to 8.55 tonnes.

Order books open toward the end of the year.

STAND: FOYER 44

1800 033 557

Ph:

A HUGE array of battery and hydrogen fuel cell EVs are set for display at the 2023 Brisbane Truck Show, with Korean brand Hyundai the latest to unveil plans to launch a new EV at the upcoming event.

Hyundai Motor Company Australia will enter the electric commercial vehicle market with the arrival of the 4×2 Mighty electric truck, which will be shown for the rst time in public in Brisbane.

Rated at up to 7.3-tonnes GVM, with a payload of up to

3.5-tonnes and a laden range in excess of 200km, the Mighty is suited for nal-mile deliveries for operators seeking a zero-tailpipe emission vehicle.

It is quiet and smooth to drive and comes with many safety and comfort features, including forward collision-avoidance assist, lane departure warning and electronic stability control.

Trucks displayed at the Brisbane show will include a atbed and a pantech box, with further body options available

once sales commence.

e Hyundai Mighty electric truck is powered by a 120kW, 320Nm traction motor fed by a 114.5kWh battery system with rapid DC charging capability that can replenish the batteries from 10 per cent to 100 per cent in under 70 minutes.

STAND: FOYER 112

MAN’s TGX 26.510 is trucking redefined. Featuring the generous GM cab and powered by MAN’s technologically-advanced 510hp 13L Euro 6 engine with over 390hp of engine braking, the TGX will go the distance. Come and see us in the main hall to learn how our new MAN truck generation boasts excellent driver fit, great efficiency and economy features, optimised uptime, and makes for a strong business partner.

WHILE the anniversary Legend SAR on display in 2021 stepped back in time to pay homage to an icon, the future of Kenworth trucks can be found in the recently released Kenworth K220.

e K220 is the brand’s most technologically advanced truck and will sit front and centre of its popular stand at the 2023 Brisbane Truck Show.

e truck is also one of four nalists for the inaugural Truck of the Year Australasia prize, with the winner to be crowned at the show.

e most noticeable change to its predecessor, the K200, is the operating environment. Stepping inside the K220 cab, you’ll nd a more modern interior tted with a 15-inch high-de nition display as well as a new eight-inch audio-visual navigation unit that has smartphone integration. However, it still feels and looks like a Kenworth inside.

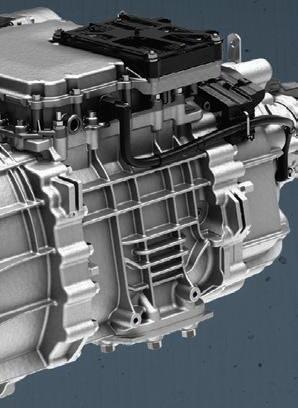

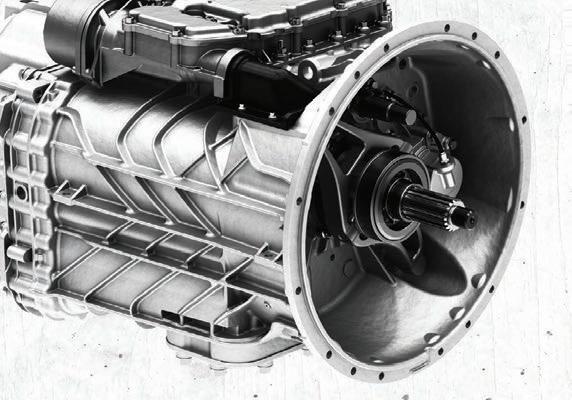

PACCAR Australia has also updated the automatic transmission, with the new K220 swapping out its previous Eaton Ultrashift for the new Eaton 18-speed Endurant XD Pro automated transmission. An 18-speed Road Ranger box is still available.

Safety-wise, the company says the K220 has the largest range of active and passive safety options ever o ered by Kenworth Australia and includes adaptive cruise control, lane departure warnings, side object detection and collision mitigation.

Early adopter Mark Tobin, chief executive at Followmont Transport, has been impressed with what he’s found in the new model and already has plans to buy more. “ e K220s are universal,

they can just handle anything you throw at them,” Tobin said.

“When we purchase eet, we really look for trucks that are durable as we want to get the most out of our equipment, and the K220s really stand up.

“ eir durability makes them the best on market and the trucks speak for themselves. I just love this product.”

Tobin added that a key factor for Followmont is driver satisfaction with any of the trucks they buy.

“Our team love these vehicles and the comfort they provide,” he said.

“ e sleeper is spacious and a big drawcard for our drivers.

“Everyone you speak to wants to look at the K220, it’s becoming Followmont’s newest tourist attraction!”

Our WA writer David Meredith struck the same level of curiosity when test driving a pre-production model late last year from Perth to Coolgardie.

“Everyone in the parkups were drawn to the rig, emblazoned with Kenworth’s “Next Level” marketing message for the K220. And they all wanted a cockpit tour,” he wrote at the time.

e major mechanical upgrade for Meredith was the lighter, smoother Eaton Endurant XD Pro automated manual, which shifted between cogs with its usual e ciency, but with faster changes to smooth out the torque interruption.

“Using the manual mode on the few hills we encountered was easy to manage and allowed me to optimise fuel usage. ere is more room for the driver too, and as with all K Series driver placement is as far to the RHS of

the truck as you can get.

“A new grille optimises cooling and there are LED headlights. e roof and fairings have been smoothed out to reduce drag, and wheel arches changed to reduce spray into the engine compartment.”

Meredith was also impressed with the “acres” of room in the cab.

“Certainly, a life on the road will not be cramped in the K220.”

Meredith was also taken with the massive 15” high-de nition instrument panel that is switchable between displays.

e K Series engine brake was especially e ective, noted Meredith. “Not as good as a retard er, of course, but the combina tion of a driver

who drives well ahead of themselves and the twostage engine brake will minimise service brake use anyway.

“Certainly, the transmission’s connection to the auxiliary brake was helpful, particularly as the rst two

clicks on the engine brake lever were followed by a spring-loaded additional click which instantly dropped down a gear.

“Down the road, an overnight run would be good to assess the new cab, but so far there is no doubt that for Kenworth devotees the changes will be received with enthusiasm. And that’s already happening.”

Also on show for PACCAR will be the legendary T909 with a 50” sleeper, the T610 with a 1400mm sleeper, the T360A and

T410SAR con gured in a low-roof car carrier specication.

DAF fans will also have plenty to take in at the show’s most popular stand with the Kenworth cousin displaying the XF530, CF530, the CF340, and a special preview of what’s coming in 2024, the biggest design project in DAF Trucks Australia’s history.

Zero emission vehicles

Although its diesel rigs are always fan favourites, the 2023 Brisbane event will herald in a new era for PACCAR in cutting-edge design and technology with the rst public appearance of its hydrogen and battery electric models. PACCAR future fuels initiatives include the Kenworth hydrogen fuel cell electric vehicle, the T680, equipped with a 630hp electric motor.

Sixty kilograms of hydrogen gas stored at 10,000psi can supply enough energy to the fuel cell for a range of 480km, with a mere 15-minute refuelling time.

At the lighter end of the spectrum, the 19-tonner DAF LF o ers an ideal zero emissions distribution truck. It has a 260kW electric motor powered by a 282kWh battery pack. e result, says PACCAR, is outstanding performance, and a range of up to 280km.

With undisputable road presence and trusted reliability, there’s no place you’d rather be than behind the wheel of a Kenworth.

kenworth.com.au

beady eye on you as well as the road, and will now report your driving performance, focused on braking use, e cient throttle management and truck road placement.

e bunk area is symmetric so you can pick which side your sleepy head goes and still operate all the controls without getting out from under the doona.

On the road, the truck systems and driveline are a significant upgrade from the X-Way, adding features that help a driver to maximise fuel e ciency no matter what the terrain.

e Cursor 13 engine develops up to 550hp and 2500Nm of torque, and in the S-Way it is further re ned to be as smooth and silent as a car driveline.

BY DAVID MEREDITHFOR some time now Iveco dealers in Australia have been hanging out for a solution to undeservedly low market share in the heavy-duty sector.

Although the X-Way competes favourably with the other European competition in terms of driveability, fuel e ciency and reliability, its spec excluded Iveco from big eet purchasing programs that required trucks with broader weight capacities.

e new S-Way still tops out at 70t GCM, so a full B-double role is its limit. We’ll wait to see if Iveco can develop that spec so that the trend towards B-triples doesn’t leave the brand oundering in the wake of the 110t GCM competition.

In the meantime, Big Rigs took to the road in one of the rst Aussie road tests of the new truck.

In broad terms, the new S-Way is the sum of a myriad of tweaks to an already solid hard-working platform. Few of the changes would warrant a new truck launch, but together

the package delivers a fundamentally di erent driving and operating experience that, in my view, should attract drivers and owners to a better and safer on-road experience.

Add to that a new cab, which explores design opportunities for better air ow, improved cooling capacity and more usable driver space, and S-Way is a signi cant improvement to Iveco’s o ering in the heavy-duty sector.

Every part of S-Way’s exterior has been tweaked for better aero performance and accessibility.

e new high roof, bumper design and door extensions drop fuel consumption by a signi cant 4 per cent. Mirrors and wheel arches have top and side spoilers and a side skirt. e door extensions cover the middle step to make thieving more di cult and minimise movement of mud onto the steps and into the cab.

Lighting now includes cornering illumination, LEDs as standard and a twilight sensor switches the driving lights on for you. A headlamp grill helps

with stone protection.

Under oor storage is boosted by 12 per cent and the access is wider, allowing a couple of 130-litre water cages.

Inside, the audio system screen in the centre of the stack will mirror your mobile, and the options available on the large touch screen will allow the fussiest driver to get set. Voice recognition and DAB radio is standard.

e driver’s seat is lower, but features more movement range.

e shelf is sculptured to increase visibility and the middle side pillar has been removed.

e steering wheel brings mostused functions to the driver’s ngertips as well as improving cab movement with a attened bottom to the wheel itself.

e central dash stack is uncluttered and littered with storage nooks and crannies. e door panels now accept 1.5L drink bottles and the fridge and cooler each have an easy-access hatch so your drink can stay cooled but still at hand.

A new Driver Attention Support system will keep its

JOINING the S-Way on stand in Brisbane will be Iveco’s latest o -road model, the T-Way, which replaces the Trakker range.

T-Way is available in 4x4, 6x6 and 8x4 con gurations and shares many innovations and technology advancements featured in S-Way, including Euro6 (Step E) engines, Hi-Tronix transmissions and safety equipment such as Electronic Braking System (EBS), ABS and ASR (Anti-Skid Regulator) and Hill Holder.

ese models also feature Daytime Running Lamps, LED headlamps (with corner-

ing fog lights), transmission intarder and engine brake, and a tough ECE-R29.03 certi ed cab. An optional Lane Departure Warning System and Tyre Pressure Monitoring System are also available.

e display vehicle is a 4x4 variant that boasts a host of o -road systems including fulltime 4x4, hub reduction to all axles and front, centre and rear di erential locks to provide superior traction in slippery conditions.

A two-speed transfer case also delivers excellent tractability in low range, allowing T-Way to overcome steep ascents and

descents easily and safely.

Further aiding o -road capabilities is a generous 33° approach angle, front parabolic suspension with dampers and stabiliser bar, and rear 3-Leaf parabolic suspension with stabiliser bar, which provides outstanding articulation while smoothing out the bumps.

To experience the new S-Way and T-Way ranges rsthand, visit Iveco at stand 58 at this year’s Brisbane Truck Show.

An additional Iveco S-Way prime mover will also be exhibited at the South Bank Truck Festival in the South Bank Parklands, May 17-21.

e emissions system is Iveco’s patented Hi-eSCR which provides many bene ts compared to EGR and SCR equivalents, including reduced fuel consumption and a lower tare weight.

e ZF designed 16-speed transmission allows various transmission modes to handle loading bays, parking areas, broken surfaces and tricky reversing tasks.

Take a tip from me - read the transmission manual to be clear about all the features and modes available at your ngertips. You’ll save fuel as well as bumps, scrapes and abuse from your mates if you do.

I was pleasantly surprised in my shortish test drive, but I did enough to nd that S-Way is at least on the level of the very best European trucks currently available.

Iveco has increased the warranty period and kms by healthy 50 per cent, to 3-years and 750,000km, plus the service intervals are out to 75,000km, or 12 months for the 11- and 13-litre engines.

In summary, Iveco now has a contender in the sub-70t GCM sector that is as good as the best and better than some.

If you’re in the market for a single trailer or B-double prime

nder oor storage is boosted by per cent and the access is wider, allowing a couple of 30 litre water cages.

mover, or a 6x4, 8x4 or 6x2 rigid tray, curtainsider or pantech, make sure you get behind the S-Way’s newly sculptured steering wheel before any money changes hands.

STAND: FOYER 58

Ph: 03 9238 2200 Web: iveco.com.au

The S-Way’s high efficiency engine, transmission and Fuel Efficiency System continuously evaluates conditions boosting performance.

The fully redesigned cab transforms the driving experience so that you can work, relax and rest to always perform at your best.

And the S-Way’s uncompromised safety means that every journey is a destination that brings you back home. iveco.com.au

THE Fuso Shogun 510 has been announced as a nalist for Truck of the Year Australasia.

Australia’s most powerful Japanese truck is one of four nalists for the inaugural award, which seeks to shine a spotlight on the excellence of the product-hauling freight on our highways.

e Truck of the Year Australasia is judged on criteria used globally by existing International Truck of the Year awards, but also takes into account the particular characteristics of the Australian and New Zealand truck markets.

e other three nalists are the MAN TG3, the Kenworth K220, and the Iveco S-Way, with the winner announced at the show.

Fuso will also present the Shogun 510 as a tipper for the rst time at the show, while a prime mover version of the same truck will also be on hand.

e 510 Tipper speci cation model has the lightest tare weight of any tipper with 500hp-plus in Australia and New Zealand, which is a boost for productivity.

e Shogun 510 was devel-

oped speci cally for Australian and New Zealand customers who asked for an advanced Japanese truck with more than 500hp and a mountain of torque.

Fuso listened and sourced a 13-litre OM471 engine from the Daimler Truck family, creating the ultimate Japanese

truck that belts out 510hp and 2500Nm of torque while meeting Euro 6 emission standards, well ahead of local mandates. e package also includes a smart shifting DT12 fully Automated Manual Transmission (AMT), which is well-suited to the potent engine.

Fuso Truck and Bus Australia director, Alex Müller, was excited the 510 Shogun has been recognised as a nalist.

“We are very pleased to see the Shogun 510 make thenals of the Truck of the Year Australasia award,” he said.

“ e Shogun 510 is a very special truck because it was

developed for the hard working truck drivers of Australia and New Zealand. It is a great example of listening to your customers and giving them exactly what they want.”

Müller said the Shogun 510 combines the robustness of a Japanese truck with the power normally found in trucks from

Europe and North America in a package that also includes the latest generation active safety technology.

“Australian and New Zealand customers love their horsepower and their Japanese trucks. We thought it made sense to combine them both and the Shogun 510 has been huge hit,” he said.

e Fuso Shogun is available as a prime mover that can be used for single trailer or B-double work. A rigid version was also made available recently and is a very popular speci cation for tipper and dog work thanks to its power and torque.

e Shogun 510 was put through an extensive durability testing regime, including an outback Australian test of an initial prototype in 2017. Extensive hot weather durability testing was also carried out in South Africa and a nal production-ready test program was undertaken in Australia and New Zealand.

THE Freightliner Cascadia has proven that comfort is king when your truck doubles as your home out on the road. Its road-focused design and optimum layout means the Cascadia ride quality leads the class, while its premium seats, ergonomic layout and high levels of re nement mean drivers can still feel fresh after a long drive.

e top of the range 126 will be the star of the stand and this imposing machine features a spacious 60-inch cab that turns it into a homeaway-from home.

All 126 models feature the big 16-litre six-cylinder DD16

Detroit engine that pumps out up to 600hp and 2050lb-ft of torque. It can be paired with a 12-speed Automated Manual Transmission (AMT) that is so smart it can use GPS and topographic data to help the truck maximise its coasting and pick the perfect gear for the terrain. Of course, you can also select an old-school 18-speed Eaton manual.

Freightliner will also showcase the shorter 116 Cascadia, which gets the job done with a strong 13-litre Detroit six-cylinder.

e Cascadia has quickly established itself as a fuel economy leader in the convention-

al class thanks to its strong but smart engine and transmission as well as its aerodynamic design. It also features Detroit Assurance safety features and class-leading connectivity.

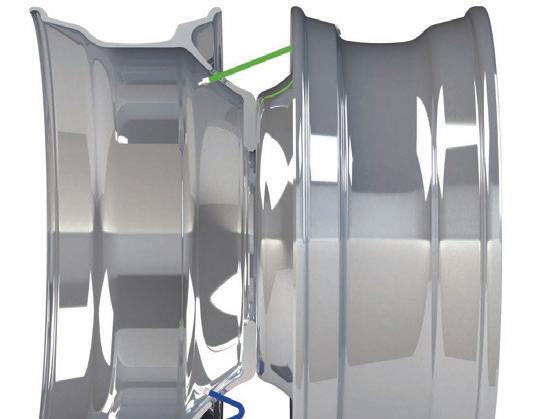

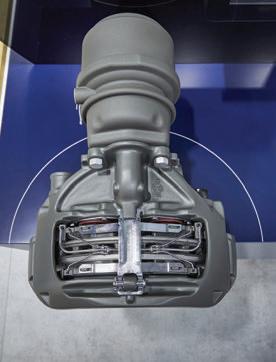

Freightliner has prepared a special cut-away of its largest cab, so attendees can check out the comfort features of the cavernous space including the bunk beds and other elements that turn the Cascadia into a premium mobile motel.

THE Australian Actros is about to become even more e cient as Mercedes-Benz Trucks delivers fuel cuts of up to four per cent with the third generation OM471 engine.

Already known for its excellent fuel economy, the Actros will push further with a raft of minor changes that add up to a major improvement of the 13-litre OM471 powerplant.

Mercedes-Benz Trucks will present the 13-litre engine at the show, and trucks tted with upgraded heart have just started arriving on Australian shores. e fuel saving of up to four per cent is compared to the previous generation OM471.

e OM471 is the middle engine in the Actros line up,

sitting between the 11-litre and 16-litre units.

Several key engine elements have been redesigned to reduce friction and optimise combustion.

Mercedes-Benz Trucks Director Andrew Assimo says the most recent fuel e ciency improvement is clear evidence that Mercedes-Benz Trucks is committed to further developing diesel engines as well as the new battery electric and fuel cell heavy truck technology.

“Mercedes-Benz Trucks and many of our customers are very excited about advanced battery electric trucks such as the eActros, which produces zero local emissions. We also think further advancements of our diesel internal combustion engine

technology will deliver considerable fuel e ciency improvement and emission reductions across many eets,” he said.

Mercedes-Benz has also introduced PowerShift Advanced Automated Manual Transmission (AMT), which enables faster and smoother moving o and acceleration thanks to optimised clutch control. Gearshifts have also been improved and are considerably faster than before, further reducing torque interruption.

THE SMOOTH POWER ON STEEP TERRAIN, THE BUNK SPACE,

TROY HAMILTON, HAMILTON CONTRACTING

WHILE the Mack Superliner may be the most iconic Mack truck to ride the roads in Australia, it’s the company’s new Anthem model that will set its future course.

e next-generation Bulldog is here and the Anthem is that for Mack. Just take a look at its sleeker, more aerodynamic design in comparison to the big,

and muscular, Macks that have come before it.

After years in the US, the Anthem nally arrived in Australia in 2021. Had it not been for Covid, the Anthem would have been on display in full at the previous truck show but will now have its rst major Australian outing at the 2023 event.