THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / AUGUST 2025

THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / AUGUST 2025

For over 50 years, UAA’s award-winning Mobile Plant and Machinery insurance solutions have powered the cranes and lifting industry - trusted by professionals who keep Australia moving.

We

Our seasoned claims team has access to a network of experienced industry repairers, assessors, and

We pride ourselves in creating insurance solutions that are handcrafted and can meet the varied needs of different businesses.

To learn more about UAA’s Industrial Special Plant products, we invite you to reach out to an insurance broker or visit our website uaa.com.au

57 LGH oba eade and in .

61 Dynamic Rigging Hire e c e t at ift t em a .

64 Global Lifting Group oca fo oca .

67 Erne Safety Supplies e ita oad a i ato tec no o a nc ed.

70 Reid ma te a to ift.

73 Xtreme Engineering ni e mi ift.

FOCUSING ON THE IMPORTANCE OF RIGGING AND LIFTING EQUIPMENT

76 Crane Auctions Australia e a oac to c ane a ction a i nificant cce .

Manitowoc

e i e o e maintenance.

30 Boom Logistics m o tance of menta e bein .

Complete Crane Solutions o en in dne . 34 Franna- A Terex Brand d ee ane o o e anna. 38 Manitowoc Crane Group

79 Liebherr ieb e anno nce ex an ion an .

80 Alliance Engineering Consultants iftin t e im o ib e.

84 CONEXPO on x o feat e ne e e a a d .

86 Zoomlion Australia et ane i e c a e mo e oom ion .

89 Pace Cranes eada mode ade .

92 DRA Group n inee ed in t ted o d ide.

94 Lift of the Month at o ind t doe be t.

LEEA

of com aint iftin

48 Lifting Gear Hire & Sales

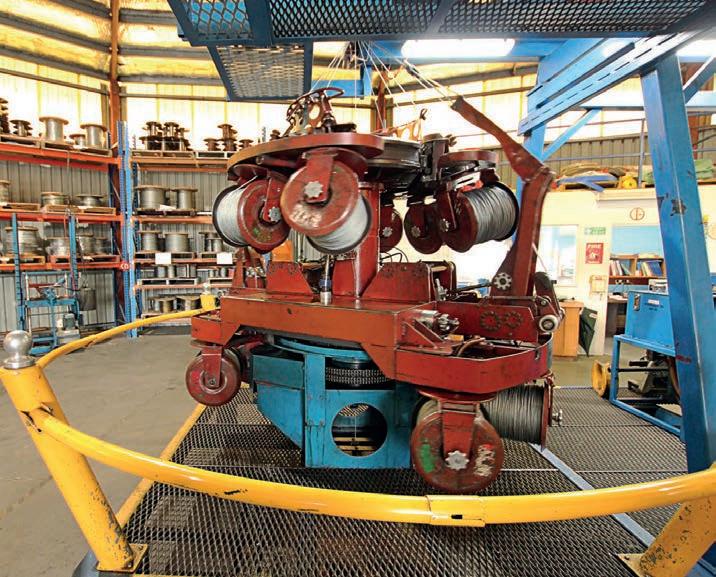

All Lifting & Safety a t o e e o do ntime.

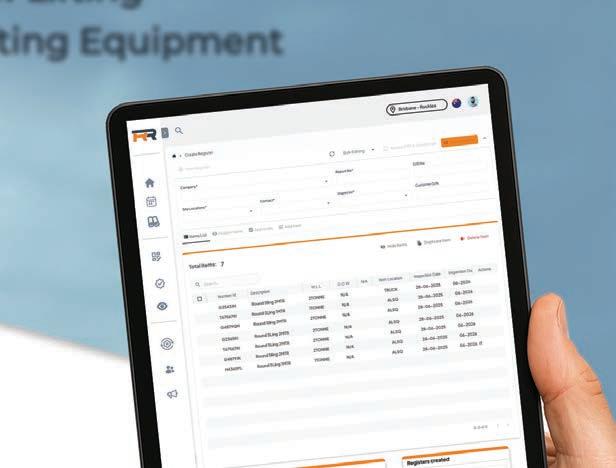

54 Regatta Registers i t b i e oft a e t at ea c ane.

THE CRANE INDUSTRY COUNCIL OF AUSTRALIA (CICA) con nues to develop and implement important ini a ves on behalf of our indus y. One that con nues to be of the utmost importance – CICA Ar culated Crane Drive On-Road.

CICA has developed a comprehensive aining ini a ve aimed at ensuring every ar culated mobile crane driver is properly educated on the dis nct handling characteris cs of these machines. e course is ee to a end and is being implemented by CICA’s Sharon Pearce, who is a super experienced ar culated pick and carry crane operator and ainer. Sharon is avelling the coun y with the course and companies that have put personnel through the aining can’t speak highly enough about the results.

e CICA Ar culated Crane Drive On-Road has received s ong support om the Na onal Heavy Vehicle Regulator (NHVR) and the team at Cranes and Li ng is encouraging all crane hire companies to contact CICA, nd out when the course is being conducted in your neck of the woods and enrol your operators. CICA is encouraging enrolment by awarding one lucky par cipant with an ‘all expenses paid cket’ to this year’s Na onal Conference in Brisbane.

in the li ing indus y for many years and his story provides a wonderful insight into the way he thinks and how he has helped grow Andromeda Indus ies into a li ing powerhouse.

You will read with interest how Joyce Kranes con nues to embrace Liebherr innova on, having recently taken delivery of the rst LG 1800-1.0 to arrive in the coun y. We also encourage all crane hire companies to consider entering e CICA Li of the Year compe on. En ies will be accepted up un l the middle of August.

Between Hook and Load is a regular sec on within the magazine focusing on the vital role the li ing equipment and rigging indus y plays. ere are insigh ul ar cles in this sec on.

As always, the team at Cranes and Li ng has worked hard to provide what we hope is an informa ve and interes ng issue and we hope you enjoy the read.

BOOMS UP!

Published by:

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman John Murphy E: john.murphy@primecreative.com.au

CEO

Christine Clancy E: christine.clancy@primecreative.com.au

Publisher Sarah Baker E: sarah.baker@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Assistant Editor

Danny D’Cruze

E: danny.dcruze@primecreative.com.au

T: 0429 187 751

Business Development Manager Emily Schlegel

E: emily.schlegel@primecreative.com.au T: 0466 317 555

Client Success Manager Louisa Stocks E: louisa.stocks@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

The GMK4080L is an outstanding four-axle taxi crane that, with its 60-meter-long boom, offers both the longest boom and the lowest gross vehicle weight in its class. Within 10 t per axle, the crane can carry 5.2 t counterweight and even 13.3 t counterweight with 12 t axle load.

•60 m boom length and capacity matches the 90-100t class (4.8 t @ 60 m)

•Main boom: 11,3m - 60m, 7-section

•Bifold swingaway jib: 8,7 m /15 m (optional)

•Minimum width 2,55 m and overall length 12,82 m

•Carrier cab: Latest generation of Grove carrier cabs

•Increased safety and flexibility with MAXbase variable outrigger system

•Faster Intuitive set-up with CCS (Crane Control System)

•Engine: Mercedes-Benz OM470LA, 300kW

MAXbase Equipped

•Capacity: 80 t

•Main boom: 60 m

•Maximum jib: 15 m (0°-40° luff)

•Maximum tip height: 77 m

•GVW: 48000 kg

Joyce Krane has built a reputation for being early embracers of crane innovation and this has been reinforced with the L LG . . James Joyce, Joyce Krane General Manager discusses the reasons behind the purchase.

“FOR MANY YEARS, LIEBHERR HAS BEEN our ‘go to brand’ when it comes to large capaci all terrains,” James said.

“We purchased the LG 1750 in late 2010 early 2011. At the me our largest capaci Liebherr was a 400 tonne all terrain. We were receiving enquiries for li s which we couldn’t handle, and we were hiring in cranes for this work. With everything ge ng larger and heavier, we knew we had to have a large capaci all terrain in our eet, and we needed to look a er our own back yard, so we invested in the LG 1750. At the me this was a ground-breaking crane being a la ce boom on a mobile carrier.”

Ini ally, the work for the LG 1750 was quite sporadic. Joyce Krane had work in the oil and gas, mining and in as ucture sectors but it wasn’t un l the emergence of the renewable energy sector, that the crane really hit its s aps.

“For us, the LG 1750 has realised its full poten al towards the end of its working life and s ll con nues to be a well u lised asset in the wind farm cons uc on and maintenance sectors,” said James. “Liebherr did release the SX boom system which was designed to upgrade performance in terms of hoist height and li ing capaci , but because our crane was one of the earlier designed LG 1750s,

upgrading it to the SX boom system would not have been commercially viable, which is why we didn’t undertake the upgrade.

“We did look at the LG 1750 SX3, but at the me we felt this model was nearing the end of its design life and we had heard that Liebherr was working on a signi cant upgrade to the model with the 800 tonne capaci LG 1800-1.0. So, we waited for the release of the model and moved as soon as we could.”

Liebherr released details of the LG 1800-1.0 in late 2023. It is the successor to its highly appraised LG 1750 – a crane that came in for high acclaim thanks to the

design’s combina on of the mobili of a mobile crane and the load capaci of a crawler crane.

e LG 1800-1.0 possesses a maximum li ing capaci of 800 tonne and, akin to its crawler rela ve in the Liebherr range, the LR 1800-1.0, holds a main boom op on of up to 180 me es long and a main-boomplus-lu ng-jib combina on providing a maximum hook height of 208 me es. e crane features a chassis width of three me es and is capable of climbing up

gradients of 25 per cent making the crane “ideal” for the wind indus y, according to Liebherr.

Further op mising the crane for the wind indus y is the machine’s enhanced wind power boom systems that make it possible to work with a boom of 174 me e and an 18 me e long la ce- pe xed jib at hub heights of 180 me es, as well as the wind speed load charts with di erent permissible wind speeds of up to 13.4 me es per second.

Liebherr’s LG 1800-1.0 has also been designed to facilitate easier ansport. Labelling the crane as “suitable for all markets” worldwide, Liebherr says the nine-axle vehicle features an axle-load of ten tonnes with all four supports, meaning the crane is accessible to public roads. Addi onally, ansport of the mobile la ce-boom crane is possible with only two supports and a total weight of 70 tonnes, as well as completely without supports at around 50 tonnes. e

Liebherr says the nine-axle vehicle features an axle-load of 10 tonnes with all four supports, meaning the crane is accessible to public roads.

crane comes with the latest in Liebherr technology too, such as V-Frame, VarioTray, ZF Traxon Torque ansmission with EcoDrive, and the aforemen oned Windspeed Charts.

One of the major di erences between the LG 1800-1.0 and the LG 1750 is that the folding beams on the new 800-tonne machine are not telescopic. e required support base of 13x13m is su cient for the LG 1800-1.0 to achieve enormous load capaci es with the derrick system, and “very good” erectable lengths without the derrick system, according to the manufacturer.

Joyce Krane was impressed with what it saw on paper and the new LG 1800-1.0 has impressed in real life.

“Liebherr has redesigned the crane with shorter boom sec ons, be er boom con gura ons and with counterweights that are 10 tonne rather than 12.5t. ose

three features make the crane far more ansportable and easier to build and con gure for di erent applica ons,” said James. “Our LG 1750 was ideal for oil and gas, mining and in as ucture wind farm work, this machine is doing all that pe of work and much more. e LG 1800-1.0 has a much higher boom reach and li ing capaci which means it will remain contemporary for the cons uc on of wind turbines as they get taller and the componen y gets heavier.

“When it comes to large capaci cranes like this, ansporta on is one of the biggest issues. Liebherr has designed the LG 1800-1.0 with shorter boom sec ons which means we are able to nest more sec ons on a ailer and the 10t counterweights are easier to ansport. e supers ucture is easy to li , and the carrier is too. All in all, it is a pre good package.”

Joyce Krane was also one of the rst

importers of the LTM 1750-9.1, 800t all terrain crane into Aus alia. With the investment in the new LG 1800-1.0, the company con nues its pioneering role in developing markets for new large crane models in Aus alia.

Joyce Krane has been working with Liebherr for many years and is happy with the product as well as support and service.

“We work well with Liebherr, we have a s ong rela onship with the brand and the people that work behind it,” said James. “Our eet of all terrains are all Liebherr’s, and capaci es go right through to our two 800t LTM 1750-9.1s.

“Service and support are cri cal for any crane hire business, and we are no di erent. We receive great support om Stefan DeSilva and his team. Whatever the issue they are on to it and have it resolved as quickly as possible. We couldn’t want for anything more in a partnership.”

From heavy industry and mining in the Pilbara to marine and infrastructure projects on the East Coast, our team of expert technicians and parts specialists deliver around-the-clock, on-site support you can count on.

We’re more than a service provider — we’re a true partner in keeping your operations moving. OUR SERVICES

Mobile crane repairs & diagnostics

With operations based in Karratha (WA) Perth Metro (WA) Sydney (NSW) & SEQ (QLD), we offer rapid mobilisation and local expertise to meet the demands of Australia’s most challenging worksites.

NEW DIRECTION. EXPANDED CAPACITY. SHARPER FOCUS. As CCS enters a new chapter of national growth, we’re investing in the people, systems, and scale to support major projects, port authorities, and private fleets across Australia.

Karratha Workshop - WA

Region - WA

Welcome to the August issue of Cranes and Lifting magazine. It’s always a pleasure to connect with you through these pages, and I want to acknowledge and thank Cranes and Lifting for its valued partnership in helping us share industry news, ideas, and stories.

IT HAS BEEN ENCOURAGING TO SEE THE s ong numbers of people a ending CICA mee ngs recently. In this issue, you’ll read about the Mudgee regional mee ng, the turnout, generosi , and support shown by our members is something I am genuinely proud of. Camaraderie and generosi have long been hallmarks of

our membership, and it’s a privilege to be part of a communi that embodies these values so s ongly.

You may also have come across the CICA Crane Simulator and Trailer in recent months. is cu ng-edge, mobile resource is designed to bring an exci ng and realis c experience of

crane opera on to careers expos, high schools, and other events, in a safe, engaging, and interac ve way. e simulator gives par cipants a feel for what it’s like to operate a crane, without the risks, and it’s a fantas c way to inspire the next genera on to explore whether a future in our indus y is the

“CICA is urging both Federal and State governments to implement a dual approach: prioritising skilled

and investing in local training and development programs.”

right t, and discover where a career in our indus y might lead.

On the topic of skills and aining, this issue also features e Case for an Advanced Crane Licence. is is a crucial discussion for our indus y’s future, and we want to hear your thoughts. I encourage you to complete the accompanying survey to share your views.

CICA will con nue to focus its advocacy to support the crane indus y’s growth and e ciency. Addressing the skills shortage in the crane indus y is a priori for CICA. CICA is urging both Federal and State governments to implement a dual approach: priori sing skilled migra on to ll urgent vacancies and inves ng in local aining and development programs. is s ategy aims to build a sustainable pipeline of quali ed crane operators to meet growing indus y demand.

Looking ahead, our annual CICA Na onal Conference and Crane Display is fast approaching, and ckets are selling quickly. If you haven’t already secured yours, I encourage you to book soon to avoid missing out. is year’s theme, Are You Invested?, promises to be both challenging and inspiring. With the busyness of our day-to-day lives, it can be easy to lose sight of the bigger picture. My hope is that this theme encourages all of us to pause and re ect: How am I invested? Are there ways I can invest more – in my health, my family, my business, our indus y, and in future genera ons?

ank you, as always, for your support and for the incredible work you do for our indus y. Enjoy the read, and I look forward to seeing many of you at upcoming events.

Warm regards,

Ben Pieyre CICA Board President

Ben Pieyre – President

Marcus Ferrari – Vice President

Danny Adair – Director

Danny Black – Director

David Solomon – Director

Karli Sutherland– Director

Anthony Grosser – Director

Andrew Esquilant-Director

Brandon Hitch ief xec ti e ce 0428 228 048 ceo@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CICA Site Operations Advisor 0488 004 274 pat@cranesafe.com.au

Sharon Pearce ane e om etenc ce 0491 134 533 sharon@cica.com.au

Damien Hense

CICA Road Policy Advisor 0488 007 575 damien@cica.com.au

Thomas Webber Communications Coordinator thomas@cica.com.au

Kate Galloway Traineeship & Industry Engagement Coordinator

0491 047 118 kate@cica.com.au

Michelle Verkerk Communications and Special Projects Advisor michelle@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626 justina@cica.com.au

Ashleigh Gould ce e ation oo dinato 0490 356 041 ashleigh@cica.com.au

Shane Coupe

CraneSafe & CrewSafe Administrative i tant ce 0491 047 134 shane@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

In late May, the vibrant town of Mudgee in the Central West of New South Wales played host to 50 plus members of the Crane Industry Council of Australia (CICA). The NSW CICA Regional Meeting attracted crane hire businesses and crane manufacturers with local businesses Strait Up Cranes and Mudgee Cranes ensuring all were made to feel welcome to their part of the world.

THE PROGRAM OF SPEAKERS WAS FULL and the topics interes ng. Stephan Becherand, CICA NSW/ACT Branch Chair hosted the event and Dean Bassed om PNO Insurance was the rst to present. He explained the importance of crane hire companies having the right levels of insurance and indemni es and what can happen if they don’t. Dean’s presenta on was followed by the Regional Crane Owners Panel which included Jess Tuck-Lee om Mudgee Cranes, Grant Gjessing om S ait Up Cranes, Brad Harold om Boom Logis cs and Edward

It is always interes ng to get a di erent perspec ve on the indus y with these regional opera ons facing similar challenges to their big ci cousins. A ac ng the right calibre of individuals to the region and then to the crane indus y is a major issue, especially when they are compe ng with the local coal mining sector.

e ansi on to renewable energy is posi vely impac ng the region and local crane businesses are working hard to get their fair share of the spoils. As always it was a vibrant conversa on enjoyed

A er lunch, the event’s keynote speaker Ma Formston took the stage, and his presence was felt immediately. Ma is no ordinary athlete. With less than three per cent vision he’s a world champion surfer, Aus alian Paralympian cyclist, author, Invictus Aus alia Ambassador, execu ve coach and interna onal keynote speaker. Ma ’s ex aordinary journey includes sur ng giant waves as a blind athlete, documented in the feature documentary e Blind Sea, and running clinics for visually impaired children to embrace the

launching the award-winning children’s book Sur ng in the Dark and winning pres gious sur ng awards, including a Guinness World Record for sur ng the largest wave. His next project is to ee dive to the greatest depth achieved by a sight impaired athlete. Ma is a relentless force, breaking barriers and inspiring worldwide.

With the tough task of following Ma ’s presenta on, Josh Kent om Safework NSW did an admirable job. His interes ng presenta on focused on some of the common incidents Safework is required to inves gate.

Sharon Pearce then launched the On-Road Ar culated Cranes Course Video. e ming of the launch was very topical as within a week, an operator lost con ol of a pick and carry in one of Sydney’s busiest tunnels causing hours of disrup ons. Luckily no one was seriously injured.

Following the a ernoon tea break, Tadano Oceania’s Genevieve Mustafa, Marke ng Manager and O ce Opera ons, shared her passion for marke ng and some of her experiences working with some major brands. Genevieve explained that marke ng campaigns come in many shapes and forms and how important it is to ensure the messaging is carefully thought through so as not to damage the brand. She explained how social media provides great marke ng pla orms, but they are not without their pi alls. Not being able to manage comments and feedback being the main issue.

Sco Greenow, Execu ve Director Freight at Transport for NSW, dialled in to the mee ng with an update and Brandon Hitch CICA Chief Execu ve O cer presented the John Gillespie Na onal CICA update which included details of CICA’s work on ISO standards and highlighted the changes that are coming to high-risk licensing. Stephan Becherand wrapped up proceedings with an NSW/ACT Branch update.

Early in the evening, everyone gathered for dinner which included the all-important fundraising auc on for the chosen chari , Invictus Aus alia.

families to spor ng communi es across Aus alia. Whether at a grassroots level or on the interna onal stage, Invictus Aus alia leverages the power of sport to proac vely foster posi ve health and wellbeing.

By partnering with spor ng bodies, ex-service organisa ons, government, businesses, and the communi , Invictus Aus alia provides the defence communi with a range of spor ng opportuni es, not just for par cipa on, but specta ng, coaching and volunteering too. Being involved in sport can o er people a sense of connec on and purpose, helping to posi vely in uence physical, social and emo onal health, par cularly for those experiencing challenges associated with their service or when making the

across Aus alia, working hard to make a di erence.

Rodney Co am, known as Rocket to his iends, in oduced the audience to Invictus Aus alia and later to his business Run Rocket Run, a professional coaching business which works with people and businesses to enhance their performance personally and in the workplace. Rodney is an ex-military man of the 3rd Ba alion, Royal Aus alian Regiment, Aus alian Army, having served over four years, and running is his tonic.

In 2004 he was on his way to barracks in Sydney when he was in a motor vehicle accident which le with a number of serious injuries, as well as a long-term condi on called Brachial Plexus Palsy that permanently paralysed his le arm. In the

SCAN QR CODE FOR MORE INFORMATION

The course instructors are seasoned professionals who will mentor course participants through real-life scenarios, preparing them for the challenges and responsibilities of a Crane Lift Supervisor.

Crane Lift Supervisors are in high demand globally. Completing this course enhances employability and opens doors to a wide array of job opportunities and career growth.

The curriculum covers a wide range of topics, including lift planning, load calculations, safety protocols, communication strategies, and legal compliance.

Scan the QR code to book in now

Brisbane 10-11 July 2025

Perth 16-17 July 2025

Hunter Valley 22-23 July 2025

Melbourne 21-22 August 2025

Sydney 17-18 September 2025

Adelaide 1-2 October 2025

* Dates Subject to Change – See CICA Website for Latest Information

blink of an eye, he went om being an elite soldier, in the best physical shape possible, to losing all movement and feeling in his le arm, om shoulder to nger ps. His military and prior high-level spor ng experiences had already ins lled a sense of resilience in him, which at this de ning moment helped him make a crucial decision: to accept what had happened, move on and con nue to live his best life. Ma Formston is a ‘Brand Ambassador’ for Invictus Aus alia and spoke about his work with the chari .

Before the auc on began, auc oneers Andrew Esquilant, Chief Execu ve O cer Borger Crane Hire, and Anthony Heeks, Managing Director Pace Cranes, revealed a ne system has been secretly in oduced and o ences such as individuals falling asleep during presenta ons, wearing sunglasses to disguise the fact that they were falling asleep, working on laptops during presenta ons were penalised. e generosi of crane manufacturers and dis ibutors including Liebherr, Manitowoc, Tadano and Pace Cranes know no bounds with all dona ng models, merchandise and sourcing spor ng memorabilia for the auc on. As always, the bidding was fast, furious and generous. Rod and Chris om Run Rocket Run donated their coaching services which secured the auc on’s single largest dona on om Preston Hire.

Jus na Blackman, CICA’s Member Events and Engagement who was congratulated for organising a rst-class event, con rmed that $26,000 was generated on the night but when the nes were nally accounted for and voluntary dona ons made to the chari the amount was closer to $30,000.

At the end of the evening Rod was presented with a Sennebogen model to thank the Invictus Aus alia team for the wonderful work they do with defence veterans and to remind them of how generous our indus y is.

Fines were awarded for wearing sunglasses which disguised the fact that some were snoozing during presentations.

Recently, Universal Cranes’ Gladstone operation put a number of operators through the CICA Articulated Crane Drive On-Road course. Branch Manager Luke Brushe was impressed with the content and the outcomes.

“WE SIGNED UP FOR THE COURSE TO ensure our operators are fully quali ed and competent when opera ng ar culated cranes on public roads,” Luke said.

“When operators are ained and assessed for CN HRWL classi ca on, the focus in on site work, li ing and aversing with loads. ere is no real focus on the speci c steering characteris cs when avelling at road speeds. We think this is a great ini a ve om the Crane Indus y Council of Aus alia (CICA), in line with our ongoing commitment to improving safe and compliance with road ansport regula ons.”

e Universal Cranes’ team found the course very informa ve and well-s uctured. It covered both the prac cal and theore cal components clearly and at a pace that suited everyone. e prac cal component gave a good understanding of the machine’s mechanical func ons said Luke.

He goes on to explain there were some areas in the theory element of the course that the operators found di cult.

“Some team members ini ally found some of the references to speci c models of pick and carry machines a challenge because they hadn’t actually operated them, but with the help of their fellow colleagues they were able to work through these. It was also noted that the course wording could do with some simplifying and be set down in more layman’s terms.”

Having many years of experience as a crane operator, Sharon Pearce joined CICA as the Crane Crew Competency O cer. She is avelling the coun y conduc ng the course. e Universal Cranes’ operators were impressed with Sharon’s approach.

“Sharon was ex emely knowledgeable, professional, and approachable. She

explained the topics in a simple, prac cal way and answered all our ques ons thoroughly. Being an operator herself, it was easy to relate to Sharon,” said Luke.

He said key takeaways for Universal Cranes’ operators included the e ects of avel speed, importance of legal responsibili es when driving on-road, and par cularly the correct procedures for safe steering of ar culated cranes in a c environments.

“ e course was absolutely very bene cial. It increased our team’s con dence and competence in opera ng pick and carry cranes safely on public roads. Our employees believe it is bene cial for experienced operators and beginners alike, if there was anything that you are unsure on, the course provides a safe space to ask ques ons and learn.”

e team learned about road compliance, load res aint techniques, legal responsibili es of crane operators, and prac cal skills for manoeuvring ar culated cranes on-road.

pick and carry cranes play an important role for Universal Cranes’ Gladstone opera on, equently used for a varie of tasks due to their versa li and e ciency.

“We currently run 17 pick and carry cranes om the Cen al Queensland branches, and these are spread across eight di erent models including the AT40, MAC25 SL, MAC25, AT22, AT20, AT18, FE420e, AT15. Seven pick and carry cranes, including AT40, MAC25 SL, MAC25, AT22, AT20, FE420 e AT15 are in constant use across di erent projects.

“Safe opera on is paramount to Universal Cranes. It not only protects our employees and the public but also maintains our reputa on for professionalism and safe in the indus y.

“ e course was surprisingly enjoyable, content was thorough and highlighted the importance of our safe on the road.

“I believe the peer-based rollout will provide a comfortable environment for ques ons to be asked and informa on to be passed on,” said Luke.

Regulators and industry groups, such as CICA, have been engaging in active discussions about how to improve crane licensing.

Why it’s time to take a closer look at how we license our lifters.

EVERY DAY ACROSS AUSTRALIA, cranes move massive loads over busy cons uc on sites, remote mine sites, and everything in between. And si ng in the cab, at the cen e of it all, are the operators, tasked with keeping both loads and lives safe.

Crane opera on is classed as high-risk work under Aus alian law, to get behind the con ols, operators need a High Risk Work Licence (HRWL), issued in accordance with Work Health and Safe (WHS) legisla on. e idea is simple: if you’re moving heavy things through the air, you need to know exactly what you’re doing.

But here’s where things get a li le more complicated, and where the case for an advanced crane licence starts to gain momentum.

ONE SIZE DOESN’T FIT ALL

Crane licences in Aus alia follow a ered system. For example, someone holding a CO licence (for slewing mobile cranes of any capaci ) is legally permi ed to operate smaller crane pes, such as C6 (slewing cranes up to 60 tonnes) or even non-slewing cranes. is concept, known as “encompassment,” is intended to s eamline licensing. But increasingly, indus y voices are asking: is that s ll t for purpose? e reali is that di erent cranes behave in very di erent ways. A vehicle-loading crane has a very di erent risk pro le to a 100-tonne crawler, and both require speci c knowledge, especially when things don’t go to plan. Yet, under the current system, someone could technically operate either with just one licence pe in their pocket.

Regulators and indus y groups, such as CICA, have been engaging in ac ve discussions about how to improve crane licensing. One op on on the table is to in oduce more specialised and advanced licence categories that be er re ect the diversi of equipment in use today.

ere is talk of removing encompassment altogether, requiring operators to be ained and licensed on each speci c pe of crane they use. While some might see this as adding red tape, it’s a necessary move to li safe standards and keep up with modern equipment and work prac ces.

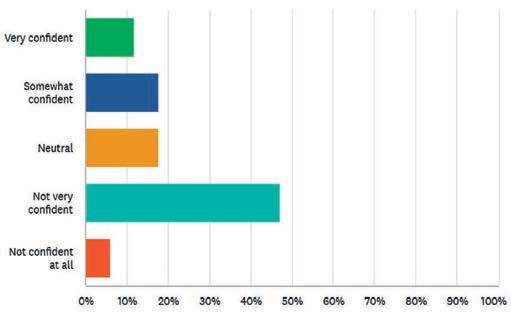

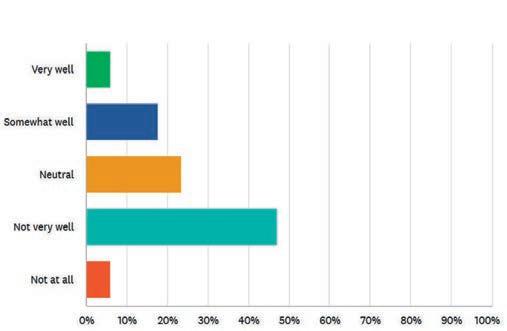

A recent survey that went out to recipients of the CICA Safe Bulle n yielded some interes ng results.

As employers, operators, or site managers, there are realworld advantages to encouraging advanced licensing.

• S With advanced aining, operators are be er equipped to handle complex li s and respond e ec vely in emergencies. at’s good for people, proper , and projects.

“There is talk of removing encompassment altogether, type of crane they use.”

• S Certain high-capaci cranes legally require higher-level licences. Ge ng it wrong can mean serious penal es, not just for the operator. e Chain of Responsibili (CoR) legal amework under the Heavy Vehicle Na onal Law (HVNL) extends safe and compliance obliga ons beyond just the crane operator or driver to all par es involved in the opera on, management, and scheduling of heavy vehicles, including cranes.

• Skilled operators make be er decisions, work more e ciently, and help keep projects on ack, especially on complex or mesensi ve sites.

• For operators, advanced licences open doors. ey signal a level of professionalism that’s valued across sectors, om civil cons uc on to energy and mining. Be er aining can mean be er pay and more opportuni es.

e crane indus y is constantly evolving, and so should the way we

license the people. While regulatory change always takes me, there’s growing recogni on that more tailored, prac cal aining and licensing would be a win-win for safe , compliance, and career growth.

Advanced licensing is about recognising the complexi of modern crane work and giving operators the tools (and the creden als) they need to do the job well.

Choosing OEM service means choosing safety, quality, and peace of mind.

Only Tadano-trained technicians, engineers, and technical support teams have the expertise, tools, and access to the latest factory updates to ensure your crane is repaired to original speci cations.

We use genuine parts, follow certi ed procedures, and o er full technical support, so your equipment performs as it was designed to.

Built by us. Backed by us. Protect your investment with the people who know it best.

With over 45 years in the insurance industry – spanning underwriting, broking, and portfolio leadership – Gary Woodhams, recently appointed National Underwriting Manager at UAA, has had the privilege of working with some of the most respected names in the business.

“MY CAREER HAS ALWAYS BEEN GROUNDED in the heavy motor and mobile plant sectors, where I’ve developed a deep apprecia on for the people, machinery, and risks that de ne this space. Now, in my new role with UAA, I’m excited to bring that experience to the fore ont –suppor ng brokers, building technical capabili , and helping shape the future of plant and equipment insurance. At heart, I’m s ll that curious, hands-on professional who enjoys solving complex challenges and building las ng rela onships in an indus y that never stands s ll,” said Gary.

“Aus alia has been enjoying a sustained period of growth across the ansport and civil cons uc on sectors. We are also seeing considerable cons uc on ac vi in mining civil cons uc on in response to the growing global demand for cri cal minerals. Similarly, we see growth in the general cons uc on sectors (i.e. residen al, commercial, ins tu onal, health),” he said.

WHAT HAS BEEN DRIVING THIS?

e key drivers for this growth came ini ally om bullish State and Federal government s mulus spending in response to the COVID pandemic. is con nues to be pushed along in response to s ong popula on growth pressures to ensure our urban and regional environments have the facili es to cope with this persistently increasing demand.

“ is creates a pipeline of available work opportuni es for crane hire companies –probably for at least the next ve years. UAA’s view on the outlook for the crane

indus y is de nitely very posi ve,” said Gary.

In this environment, there are many risks and challenges in business which need to be iden ed and mi gated. We all know the harsh reali is that all projects come with human, material, legal, nancial, environmental and regulatory risk. As a crane hire business, naviga ng the complex world of con actual obliga ons and insurance requirements, is just as important as managing physical equipment and site based opera onal risks.

How do we go about naviga ng the world on Con act Management and Insurance? It is impera ve to maintain a consistent approach and engage the experts.

Navigating Contract Management and Insurance –

1) Obtain quality legal advice

It is well known that con actual wording can be complex and aught with risk for the unwary. Engaging a lawyer who has experience and exper se with crane opera on con acts is a smart risk management investment. ey can help you navigate complex indemni clauses and: - ensure they are workable om your standpoint, - align with your insurance coverage, and - do not leave you with uninsured and unmanageable exposure.

Experienced lawyers understand the prac cal reali es of crane opera ons. ey can iden fy uninsurable risks in con act terms (which may be required to meet con act requirements) and assist you to nego ate reasonable con actual terms.

ey can also help you liaise with your insurance broker to convey your insurance requirements for a given con act.

Before making any contact and engaging in nego a on, your lawyer will need to understand your risk pro le to support the nego a ng posi on and insurance requirements, including:

• Your safe record

• Equipment condi on

• Operator quali ca ons

• Financial stabili

• Provide documenta on on opera onal procedures, safe management systems and any other documenta on to support risk management processes.

• Speci c site risks

• Copy of insurances and extensions

An indemni clause ansfers risk om one person to another. It can be speci c (eg. a promise to hold a person harmless in

Gary Woodhams, National Underwriting Manager at UAA.

“There are many risks and challenges and mitigated.”

rela on to an occurrence om a par cular event) or broadbrush (eg. to allocate risk of loss, damage or liabili om certain events). Your insurance coverage needs to align as closely as possible to the requirements of such indemni clauses. Importantly, you will also need to iden fy uninsured risks required by the indemni clauses which you will have to manage in other ways.

e indemni clause may enforce a legal requirement on the con actor (i.e. crane operator) to indemnify the principal (i.e. your client), om any direct or vicarious liabili es to third par es that may arise om your ac vi es. In some cases, the indemni in favour of the principal may require you to assume liabili that is beyond normal legal requirement.

Public liabili policies pically cover the insured against legal liabili it may have to third par es for loss or damage to proper , loss of use of undamaged proper , or personal injury which arises out of an insured par ’s ac vi es. erefore, a con actor’s liabili under an indemni in favour of the principal, against third par claims caused by the con actor’s ac vi es, is likely to be covered under a public liabili insurance issued to a crane operator. For this reason, a con actor’s lawyer should seek to nego ate and limit these indemni es as closely as possible to loss or damage arising om negligence of the con actor (i.e. s ictly fault-based indemni es).

Mutual (fault-based) indemnification clauses require each par to the con act to assume responsibili for losses arising om their own negligence. is is a reciprocal obliga on where both par es indemnify each other with the aim of helping to reduce the likelihood of disputes between par es to the con act by keeping each par ’s s ict legal liabili obliga ons separate and clear.

It is impor nt to no indemni ca on clauses need to be carefully reviewed to ensure they are enforceable and as far as possible, insurable. It is even more impor nt to iden fy uninsured risks so other forms of risk management can be applied. Once we s rt going beyond faultbased indemni es, we become open to po n al for uninsured loss. It is cri cal to remember that insurance policies are limi d to their rms, condi ons and exclusions and can only be ex nded to meet con actual indemni es within the insurer’s res aints. Most policies con in a con actual exclusion (unless the liabili would have been incurred even in the absence of the con act).

Blanket Hold Harmless Clauses Put simply, a Hold Harmless Clause is a provision within a con act where the con actor agrees to indemnify, and assume responsibili for, liabili – even if another par (usually the principal/client) is at fault.

Typically, these clauses contain allinclusive words, such as “all claims”, “all

damage”, “any” loss,” “any person”, “any reason”, “howsoever caused”, “in connec on with”. We have seen cases with a requirement for the con actor’s public liabili policy to be extended to include “blanket con actual liabili cover”.

To further move a con actor’s exposure and responsibili for principal’s/client’s risk, con actual insurance clauses may require the client to be added as a “named” or “joint insured” – thereby allowing the client full access to the con actor’s insurance policy.

A er you have reviewed the indemni clauses, the insurance clauses need to be carefully reviewed. e pe of insurance you have (or will require!) needs to match, as far as possible, the insurance clauses in your con act. (Note: Non-insurance people o en confuse “indemni ” with “insurance” in a con act, believing them to be the same thing. ey are not the same. As you will now know om this ar cle, they are two dis nctly di erent facets of con actual requirement).

TYPICAL EXTENSIONS REQUIRED CAN INCLUDE

Named or Joint Insured – is provides the client full protec on under the policy. As an insured, this will allow the client to enforce the policy directly against the insurer and lodge claims – and not necessarily arising om the “policy owner’s” acts.

is requirement is pically required with Hold Harmless indemni clauses but can also be seen in fault-based indemni es. (Aus alian Standard cons uc on con acts contain this requirement).

Cross liability – “Cross liabili ” is insurance jargon. It is an automa c bene t under most quali public liabili policies. e clause allows one insured par under a policy to claim against another insured par under the same policy – as if they were two separate par es.

Naturally, the risk of such a claim being made against a con actor’s policy is increased when a con act requires external par es to be “named” or “joint insured’s”.

Waiver of subrogation – “Subroga on” is insurance jargon. is provision is where one par agrees to give up their right of recovery to seek compensa on om the

par responsible for the loss or damage. Normally your insurer will pay for damage to your proper and will then have the right to pursue the par responsible for the damage to recover the cost of the claim as if they were you seeking such recovery. With a subroga on waiver requirement in a con act, your insurer must agree to not pursue compensa on om the par named.

ere can be other requirements depending on the policy class involved. ere could also be requirements for cer cates of currency, cancella on no ces, loss payee clauses to name a few others.

2) Speak to your insurance broker “ ey are your professional risk advisors supported by UAA’s understanding of con act management complexi es through insurance. Our recommenda on is to engage your broker early – om the

commencement of the tender process. In collabora on with your lawyer, your broker will provide those cri cal inputs at the right me on insurance coverage, limita ons, and gaps. ey will explore extensions or other policies to ensure you are covered as far as possible for any outstanding coverage requirements and should explain where you are not covered,” said Gary.

“Brokers who understand crane opera ons’ unique risks can s ucture coverage to match con act requirements and iden fy gaps before they become an issue.

“Never leave it to the last minute to engage your broker or – worse – a er you have signed the con act. At the end of the day, professional guidance is essen al for you to be fully aware of the risks involved and to allow you to make an informed decision before commi ng yourself to any con act,” he said.

Manitowoc Australia 0417 674 019

infoANZ@manitowoc.com New Zealand 0800 878 695 cranes@trt.co.nz

Manitowoc Australia 0407 967 444

infoANZ@manitowoc.com

New Zealand +61 407967444

infoANZ@manitowoc.com

At CANZ, we work every day to ensure the voices of our members are heard – in boardrooms, policy discussions, and now, at the very heart of the vocational education system. And today, we’re proud to share a success that shows just how powerful that advocacy can be.

wasn’t guaranteed. In fact, we fought to ensure this wording was included.

Why? Because names ma er. Representa on ma ers. And when a sector like ours is formally included in the naming and scope of a governance s ucture, it has a direct impact on how aining is shaped, how funding is allocated, and how our workforce is understood and supported.

is change didn’t happen by accident. It’s the result of collabora ve, s ategic advocacy – the kind that CANZ priori ses every day on behalf of our members.

THAN S TO S STA NED E ORTS O RS and those of our allies – the government has con rmed that one of the newly formed Indus y Skills Boards (ISBs) will be named the Cons uc on and Specialist Trades ISB. at name change might seem like a small tweak, but make no mistake: this is a huge win for the crane indus y, for specialist ades, and for our members.

Historically, aining s uctures in Aotearoa have not always re ected the unique needs of indus ies like ours. Cranes, rigging, and heavy li ing have long operated as specialist disciplines within the broader cons uc on environment – essen al to progress but not always recognised in formal s uctures or funding models.

at’s why we’ve pushed hard for reform. As part of a broader overhaul of voca onal educa on, the government has commi ed to moving away om the cen alised Te Pūkenga system in favour of indus y-led models. From 1 January 2026, eight new Indus y Skills Boards will assume responsibili for aining standards, program endorsements, and modera on.

Crucially, one of these boards will now formally include Specialist Trades – explicitly acknowledging the cri cal con ibu on of crane operators and other highly skilled, high-risk ades. is

Gone are the days when e ec ve lobbying meant marching up the steps of Parliament. Today, it’s about building usted rela onships, aligning with likeminded sectors, and advoca ng through smart, persistent channels. at’s what we’ve done here.

CANZ worked closely with the Specialist Trade Con actors Federa on (STCF), an umbrella body represen ng a range of indus ies o en overlooked in broad “cons uc on” categories. eir leadership in these reforms has been outstanding – and as a proud STCF member, CANZ added our weight and voice through formal submissions, targeted engagement, and direct dialogue with o cials.

Together, we made the case that cranes and heavy li ing are not side notes – they’re integral to New Zealand’s in as ucture, produc vi , and safe . e inclusion of Specialist Trades in the ISB tle is a powerful con rma on that our message got through.

For our members, this win is more than symbolic – it’s prac cal.

From 2026, the Cons uc on and Specialist Trades ISB will oversee how aining is designed, delivered, and assessed across our sector. at means:

• Standards will be er re ect real-world work, rather than academic theory.

• Training providers will be held to

account, ensuring they deliver job-ready graduates with skills employers uly need.

• Crane sector exper se will have a seat at the table, shaping the workforce of tomorrow.

And while the ansi on is s ll 18 months away, the groundwork is already being laid.

CANZ is ac vely preparing to support this change, ensuring there is no disrup on to current appren ces or ainees, and working closely with providers who share our commitment to quali and safe .

MANY is achievement re ects the s ength of working with others – and the importance of never advoca ng in isola on. e Specialist Trades voice is s onger because it speaks with the weight

of many: crane operators, sca olders, roofers, plumbers, steel manufacturers and more.

By embedding ourselves within the STCF, and by maintaining s ong connec ons with other associa ons and sector leaders, CANZ has helped amplify our indus y’s needs at the highest levels. And it’s paid o .

clear guidance for employers and ainees.

• Con nue championing high standards, safe prac ces, and relevant quali ca ons across all li ing opera ons.

But today, we pause to celebrate a step forward. One that proves advocacy – when done right – works. It takes

“The inclusion of Specialist Trades in the ISB title is a powerful .

Our work isn’t nished. As the ISBs begin to take shape, CANZ will:

• Push for fair representa on of the crane sector on the Cons uc on and Specialist Trades ISB.

• Maintain open lines of communica on to ensure

me, e ort, and collabora on. And most of all, it takes the support of a s ong, united membership.

ank you to all our members who have shared your insights, supported our submissions, and stood with us in calling for be er aining and be er recogni on. is win is yours.

When opportunity knocks, you need the power to act fast. Manitowoc Finance helps you acquire your crane without tying up your capital. Whether you‘re expanding your fleet, upgrading equipment, or taking on bigger projects, our flexible financing options and payment schedules are adaptable to virtually any business need.

With Manitowoc Finance, you get: – Competitive rates and flexible terms – Fast approvals and simple paperwork –Financing for new and used cranes – Support from experts who understand your industry

Don’t let budget constraints hold you back. With Manitowoc Finance, you can invest in the future, today.

Ready to elevate your business?

Reach out to Kirk Purchase via the contact details below:

Kirk Purchase

Mobile: +61 414895065 kirk.purchase@dllgroup.com

When a crane owner decides to add another Grove all terrain or Potain tower crane, the cheque book is rarely the only hurdle.

Manitowoc Finance is bridging the gap between crane ownership and tailored financin foc in on t e ni e need of t e iftin ind t .

THE TRUE CHALLENGE IS FINDING A LENDER that understands how project cycles, equipment asset value and ancillary gear shape a crane business – and that is precisely where the nearly 24-year-old partnership between DLL and Manitowoc through Manitowoc Finance, stands apart.

Since the program’s global launch in 2002, Manitowoc Finance has wri en nance for an es mated AUD $10 billion-plus worth of li ing equipment worldwide, funding roughly 60 per cent of Manitowoc crane sales globally and even more in Aus alia.

A FINANCE SOLUTION BUILT AROUND CRANES, NOT SPREADSHEETS

“ e biggest perk is that DLL understands cranes. It’s not like a big pillar bank that just knows a payment is due on the 15th,” said John Stewart, General Manager Manitowoc Cranes Aus alia, about the partnership.

Crane indus y insight ma ers. A customer’s historical cash ow won’t always re ect what is required to get into the next size crane. Manitowoc Finance will work with the customer to understand what is coming up and not just what has

happened in the past. John’s team and Kirk Purchase, Senior Account Manager DLL, can res ucture exis ng con acts or re nance other con acts to get the operator into the equipment they need.

SCALE THAT STILL FEELS PERSONAL Manitowoc Finance underwrites “through-the-cycle”: the DLL credit team looks past the current P&L to the pipeline, new customers, dry hire expenses, order backlog and the Manitowoc factory’s view of a customer’s ack record to build a case for the successful acquisi on of new

equipment. at people- rst approach goes both ways. John o en drives out to a prospect’s yard while Kirk will sani -check with a quick site visit to understand the business and the people behind it. at joint due-diligence is something pillar banks simply don’t have the bandwidth – or the indus y knowledge – to replicate.

crane indus y condi ons. is leads to real-world approvals for businesses that mains eam lenders may classify as not quite ready.

Whether you run a single 60-tonne taxi crane or a na onal tower crane eet, Manitowoc Finance’s proposi on is s aigh orward:

• Indus y DNA: 23-plus years embedded in crane nance; dedicated account managers who know jib charts as well as term sheets.

• Whole-of-li funding: Cranes (new and used), a achments, ansport and even refurbishments under one facili .

• Flexible s uctures, including interestonly periods and re nances to suit market condi ons and cash ow your new Manitowoc eet acquisi on.

A modern li rarely stops at steel and hoist rope. Ou igger pads, spreader beams, ba ery packs for tower cranes or even a dedicated ailer can add hundreds of thousands of dollars to the purchase. Manitowoc Finance can roll all of it into a single package, so operators avoid mul ple loans and mismatched maturi es. “We can supply a tower crane with a ba ery and a personnel li – 40 per cent ancillary equipment, 60 per cent crane – and wrap it in one nance deal,” John said.

e same logic applies to second hand machines. Manitowoc’s new Seven Hills facili is ki ed out to refurbish used cranes, and DLL nances those units on the same terms as new stock – closing the loop for customers ading up or diversifying their eet.

cons uc on equipment. It o ers payment plans tailored to the business’ cash ow, nance approvals for cranes being built, and master lease lines so the business can easily add more Grove equipment. As DLL is part of the Rabobank Group, the backing of Rabobank gives the program the balance-sheet s ength of a global lender while keeping all decisions with a crane indus y-focused team.

- Longer term higher balloons using cha el mortgage

- Opera ng (fair-market-value) leases with terms om 24 to 84 months

- End of lease op ons: extension, re nance or purchase

For operators nervous about today’s high interest rates, Kirk o en s uctures a short ini al term and plans a lower-cost re nance once the rate cycle turns.

CERTAINTY AND A SEAT AT THE TABLE

Because DLL sits alongside Manitowoc’s sales team, credit decisions are quick and collabora ve. If a bank hesitates over a tower crane, Kirk understands the resale value, service history, rental rates and

• Products that grow with you: From two-year opera ng leases to sevenyear cha el ownership paths, with the abili to ade up when appropriate.

“In the end,” Kirk said, “our job is to build a nance case that lets a customer win the con act their crane is designed for. You want to talk directly to the lender and through Manitowoc Finance you can do exactly that.”

For crane businesses looking to scale in a world of ght margins and increasing equipment costs, that beats a bank every day of the week.

Ready to li your business to new heights with nancing through Manitowoc Finance? Reach out to Kirk via the contact details below.

Kirk Purchase Senior Account Manager DLL E

CHECK IT OUT HERE

greater e ciency in crane opera on. S ess-tested in Manitowoc’s own Product Veri ca on Center (PVC), the kit comprises a rope lubrica on system in the form of a metal sleeve that quickly clamps around the rope and is supplied alongside a Portable Grease Transfer System featuring a hydraulic hose with grease pump.

PROVING THAT GOOD THINGS COME IN small packages, one of Manitowoc’s most important product launches at bauma 2025 – the rope cleaner – literally ts inside a briefcase. e system is supplied in a sturdy hardcover case. It comes complete with all necessary s aps and shackles, providing customers with a simple, fast, and e ec ve solu on for regular wire rope maintenance on all Grove all terrain cranes. Using the rope cleaner o ers several bene ts, including an extended working life for the rope, as well as greater li ing e ciency and reduced expenditure on consumable parts.

“Our innova ve a ermarket solu on can extend the working life of the rope by reducing ic on and adding e ec ve corrosion protec on that pene ates all the way to the core,” explains Pa ick Stelter, Grove’s parts and service product and marke ng manager. “ e whole cleaning and greasing procedure can be carried out in as li le as 90 minutes, which is not only much quicker but far less tedious than adi onal methods that use a wire brush or compressed air. It ees up the technician’s me that would otherwise be spent manually cleaning rope, and delivers signi cant reduc ons in planned down me, so owners will bene t om a no ceable increase in opera ng me too.”

e system automates cleaning and lubrica on by feeding the wire rope through an aluminium housing equipped with inserts that are easily clamped around it. e inserts and scrapers are currently available to suit 16, 17, 19, 22, and 24-millime e rope diameters. Further diameters can be made available upon request. It delivers signi cant savings in down me and technician hours, plus

Once the technician has chosen and ed the correctly sized inserts into the sleeve, the lubrica on system is a ached to the hoist rope and secured with the shackles before the separate cleaner device is clamped below. Available to suit ve diameters of rope between 1624 millime e, the compact cleaner is cons ucted om a tough material and precisely designed to allow the s ands to pass through with just the right amount of resistance required to remove dirt without causing de imental abrasion.

With one hose connected to the Portable Grease Transfer System and another to the crane’s air pressure system, the technician can then adjust the levels to deliver the required quan of grease. e hoist is lowered, removing dirt and grime om the rope before esh lubricant is automa cally added to maintain it in op mum condi on. e procedure is then repeated on the rope below the boom head, using the hook block as an anchor and de ec on point to maintain tension on the rope as it is raised upwards.

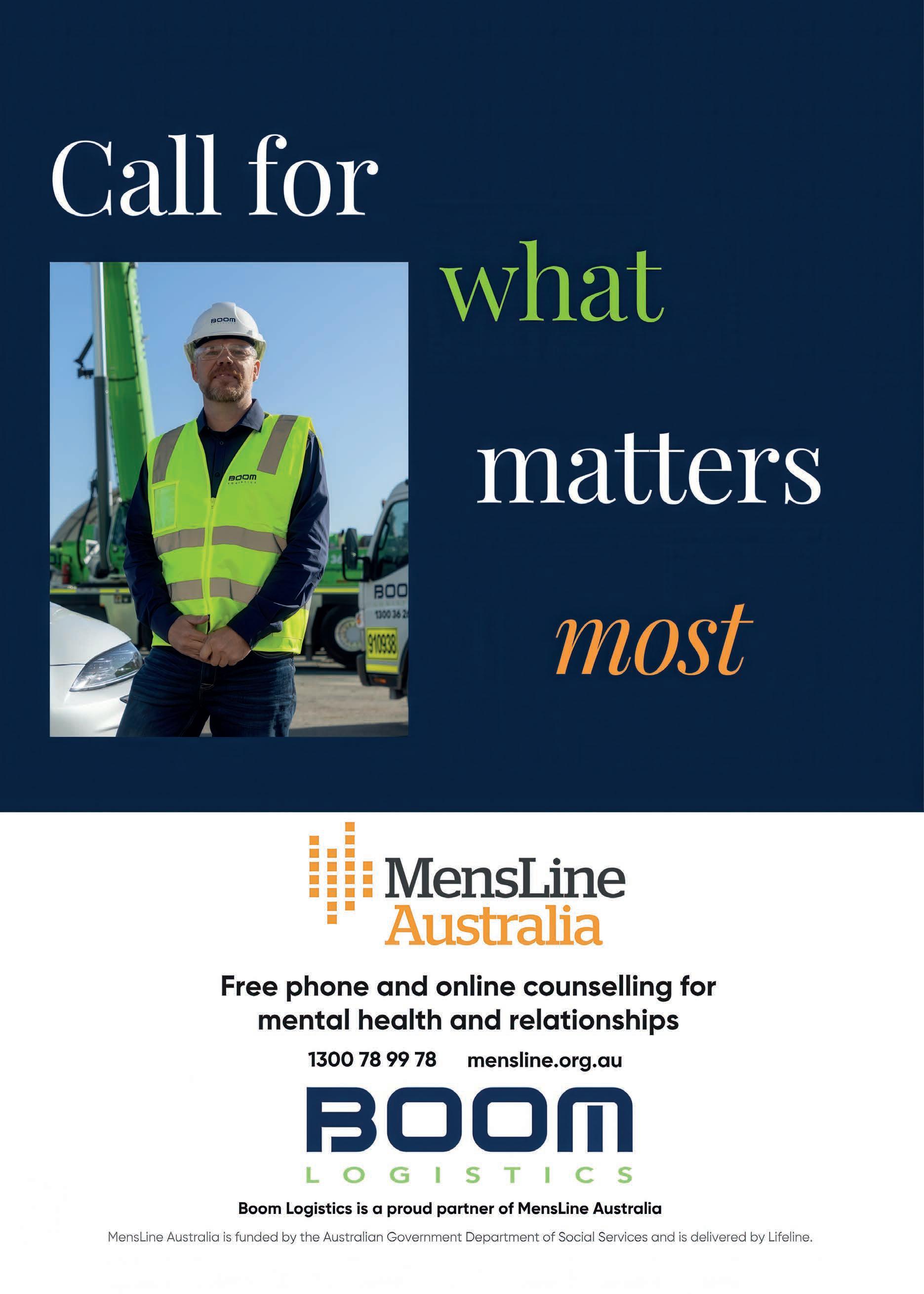

Earlier in the year Boom Logistics announced an inaugural partnership with MensLine A investment in supporting the wellbeing of the broader community. Elaine Buchanan, Boom Logistics General Manager, HR and Industrial Relations, discusses the initiative.

MENSLINE AUSTRALIA IS A FREE NATIONAL telephone and online counselling service delivered by Lifeline that supports men at risk of suicide, experiencing emo onal dis ess, or having rela onship di cul es.

“With over 750 employees our management team at Boom Logis cs understands the importance of mental wellbeing throughout its workforce. e leadership teams meet regularly with everyone om the ground up to understand how they are avelling and to reinforce that they are never viewed as ‘being a number,’ in the business,” said Elaine.

e partnership with MensLine Aus alia commenced o the back of Boom Logis cs Chief Execu ve O cer and Managing Director Ben Pieyre’s successful

FebFast par cipa on in which he raised over $17,000 – the highest amount by an individual in the campaign by a large margin – to help reduce substance addic on and the risk of suicide.

Boom Logis cs’ commitment will go towards a 0.8 FTE MensLine Aus alia counsellor capable of delivering 50 telephone or virtual counselling sessions a week. is will enable anyone who seeks help to receive the support they need during di cult mes.

e FebFast fundraising characterised Ben’s personal value of taking ac on over words. He said that it’s impera ve to lead by example.

“It’s not enough simply to talk about mental health, we must actually invest in

the people who are doing the hard work on the ground. e vast majori of people in our sector are men, and it’s clear that more needs to be done to encourage and support anyone going through s uggle with mental health.

“I’ve seen rst-hand the impact of mental health crises on my sta , and agically, one person took their own life in the past year. Boom Logis cs is s ongly communi -minded and are con dent our commitment will go where it’s needed most.

“Boom Logis cs prides itself on its values and is commi ed to being a workplace and services provider that puts safe rst. We have a du of care to our people, their families and the

broader communi , and we take that very seriously,” said Ben.

Having completed her Commerce Degree in HR Indus ial Rela ons, Elaine has spent the 20 plus years in HR. She has a s ong background in cons uc on having spent 14 years in the cons uc on indus y working with employees in remote loca ons and away om their families.

“During my career, I’ve seen the in oduc on and development of mental health help in the workplace and I’ve also seen the ansforma on, par cularly for men, to actually seek the available help with companies embracing employee assistance programs,” said Elaine.

However, current sta s cs s ll show men are less likely to seek help when they are experiencing emo onal dis ess than women, and three mes more likely to die by suicide. Male suicides make up threequarters of all suicides. In 2023 suicide was the 11th leading cause of death for males and the highest ranked external cause of death in males.

Boom Logis cs is very aware of its responsibili es.

“We have a du of care to our people, their families and the broader communi , and we take that very seriously. e MensLine Aus alia partnership aligns closely with our value of ‘safe always’ and although we are gradually seeing increased diversi in the sector, more than 90 per cent of our workforce iden fy as male. is partnership is par cularly close to my heart,” said Ben.

Lifeline Chief Execu ve O cer Luke Lindsay said the partnership will deliver a vital boost to the na onal service.

“When someone calls MensLine, they are given a safe and private place to talk through whatever it is that is on their mind. is funding will support us to o er mely, professional counselling support for Aus alian men anywhere, any me, in the way which suits them best,” he said.

MensLine Aus alia is delivered by Lifeline, and o ers a na onal telephone and online support, informa on and referral service for men with mental health, family and rela onship concerns. e ee service is available na onwide and is sta ed by professional counsellors experienced

commitment will go towards a 0.8 FTE Mensline Australia counsellor capable of delivering 50 appointments of telephone or virtual counselling sessions a week.

Complete Crane Solutions (CCS) expansion plans continue with the recent opening of a workshop in Western Sydney’s Wetherill Park. National General Manager Mitch Smidt and Workshop Manager Nathan Demanuele explain how

“I’VE BEEN WORKING WITH JOSH JOHN FOR a couple of years and prior to joining CCS, I was working with Primero in the Pilbara where he and the team were servicing our cranes and heavy equipment,” said Mitch. “A er joining CCS, I started in the Karratha opera on, but I’m originally om Sydney, When Josh spoke to Nathan about the opportuni es here and we decided to open this opera on, I put my hand up to move back.”

He said the new facili is viewed as Na onal Headquarters.

“ ere have been a number of exci ng changes within the business. We’ve grown om servicing Karratha and the surrounds, to having opera ons in Perth, Queensland, Sydney and Victoria with a na onal management team now based in Sydney.

“Our inten on has been to let everyone know we are here. e workshop is highly visible in a busy part of Wetherill Park, which is exactly what we needed. We have entered a saturated market with the crane original equipment manufacturers (OEMs) and third par service providers and repairers well established. But we are con dent in what we o er. Our s ong focus on eld service and responsiveness will be hard to compete with. We know we

have to build our reputa on in Sydney, and we are con dent we will,” said Mitch.

A focus on service and a s ong eld presence will be the ini al focus.

“In terms of capabili es we are aligned with the indus y standard, it’s just that we are the new kids on the block and we have to make some noise to get no ced,” Mitch said. “We provide a 24/7 service, with our workshop opera ng om 5am un l 7pm. We o er 24 hour call out, working on a at rate even when it’s a public holiday. We work with customers providing mes to service their cranes that suit them and their business. Given the market’s posi ve response, it appears likely we will outgrow this facili fairly quickly.

“When I was a client of CCS I knew if there was a problem I could call Josh, Ryan or Luke and one of them would pick up and do whatever it takes to get things sorted. at’s always been the culture of the business and that’s why it’s a great place to work,” he said.

CCS has been quick to build an experienced team to service the Sydney market. Nathan has 25 years of experience

managing the servicing and repairs for a major European OEM and has helped recruit a number of experienced technicians.

“It is not o en that you open a new opera on with a team as experienced and dynamic as ours,” Mitch said. “Nathan has helped build a formidable team by combining experience and a ac ng young and enthusias c appren ces who share our vision.

“ e team has experience with every leading brand including Liebherr, Tadano, Grove and Franna but more importantly everyone is commi ed to do whatever it takes to get the customer’s crane back up and opera ng. Across the company we have close to 50 sta who have experience with every crane OEM, they’ve worked all over the globe and have mul ple years of experience which is shared across the en re organisa on,” he said.

“CCS is a service-driven business and we understand the challenges crane hire companies face, especially when they are opera ng remotely or in regional parts of the coun y. Servicing cranes in remote loca ons is a real issue, one that we are

here to address. We’ve already engaged with mul ple crane companies, and we have entered into service agreements with certain OEMs and have s ong alliances with others.

“OEMs see the bene ts of working with CCS because they have the con dence that a er-sale service commitments will be met with full delivery. Our sole focus is repairing broken cranes, and we’ve built our business doing that. We’ve invested in service vans and ailers so we can get out there. Crane hire companies s uggling to nd the right service partner can talk to us, and they will understand they do have op ons.”

Nathan explains the approach to work in regional areas.

“When we get a call om a regional customer, we will ring other businesses in that area to let them know we will have a service technician there for a few days. We then split the cost of the me, accommoda on and ansport between two or three customers and instead of being there for a day, we’ll spend a week servicing the cranes.

He goes on to explain what customers can expect om CCS when it comes to larger repairs and signi cant works such as major inspec ons.

“ e one stand-out customers can expect om us is ansparency. Technically we know we have the best guys, so managing the job is s aight forward. Tailoring the job to the customer’s speci c needs is the key. ere are di erent levels of major inspec ons which depend on what a customer requires om their asset. Do they want to spend hundreds of thousands of dollars on completely s ipping it down and rebuilding it? Or do they want to comply with OEM or the Crane Indus y Council of Aus alia’s CraneSafe requirements?

“We discuss how valuable the asset is to the business, what they are ying to get out of the asset and build the right major around all of the informa on. We quote to the job as we see it and if we can get the cost right at the start there shouldn’t be any major surprises. ere may be discrepancies depending on what we nd, but these are immediately relayed to the client, every step of the way,” said Nathan.

“When you look at the service and repair businesses in the crane sector, par cularly in Sydney, they are mature businesses and many of their sta have been with them for a long me. Obviously, they have signi cant experience but maybe not the levels of passion for the indus y they once had.

“When you are building a business, you need one or two guys with the experience managing young guys who are hungry, who want to do the big hours, who want to go out and set a tone, make noise and make their mark in the indus y. Over the years, I have established good rela onships with third-par repairers who are happy to build rela onships with us and expose our guys to their environment. ese rela onships include hydraulic workshops where our guys learn to service and x cylinders, auto elec icians and pump repair businesses. It’s about exposing our team to various areas of the business and ensuring they receive aining and experience in every facet.”

Mudgee Cranes began life in 1976 when Richard Hooper

Richard changed the name of the business to Mudgee Cranes . T

PA T C EE JO NED THE S NESS as a 17 year old appren ce in 1982 and obtained his rst paper crane licence back in 1986 when opera ng an old 15 tonne Koehring. Paul purchased the business in 2011. Mudgee Cranes’ Manager Jess Tuck-Lee takes up the story.

“Mudgee Cranes has a rich li ing heritage da ng back almost 50 years and we remain a family-owned business servicing the mid-west regions of New South Wales. My father Paul Tuck-Lee has been working in the business since he was 17 years old, my brother started in the business in 2015, and I joined in 2016.

“Being a family business we are very focused on our team of people. We have 14 operators including two women. Our workforce is a mix of Indigenous and mul cultural backgrounds, and we have a ainee learning the ropes. Our team varies in experience with some members having 10 years and others over 40. Our teams are very service cen ic, and we s ive to ensure the customer is sa s ed with everything we do. We are servicing a rela vely small business communi , and our reputa on counts for everything,” said Jess.

Servicing the local mining sector is important for Mudgee Cranes.

“Typically, servicing the mining sector is our bread and bu er and we work on a number of mining con acts,” Jess said. “We also have a lot of day-today work within the local communi and this involves working with local builders helping to cons uct new homes and

renovate and extend others. We help put people’s pools and spas in and recently we have been busy li ing containers into place which are then turned into homes.

“We will go as far as anyone’s willing to pay us to avel. We’ve done a bit of work out at Warren, which is a fair few hundred kilome es away, and we also do a bit of work in Dubbo, Gulgong and Coolah. We are not a aid to avel if the work is there.”

Mudgee Cranes currently operates six Frannas, two all terrain slew cranes and one uck-mounted slew crane. Li ing capaci es start with a 14 tonne Franna through to a 160 tonne Terex Demag.

“We s ll operate one of Richard Hooper’s original Frannas. It’s a 1991 4WD16 which we use as our ‘workshop Franna’. It’s an old manual and very humbling to drive but it s ll goes to work every day and is testament to the longevi of Frannas and how well engineered they are,” Jess said.

“Over the years, we have been adding Frannas to our eet and they really are the ‘work horses’ for our business. Last year we invested in a new, 2024 model Franna AT40 and this has proved to be a really valuable asset. e operators enjoy driving and li ing with the AT40.

“ e Frannas really come into their own with the mining work. We manage a couple of di cult jobs like ‘Pump Alley’ which is a really ght alleyway that they have to get into and li various products during mine maintenance

programs and shutdowns. But they are equally comfortable in town here, we use them every day for li ing roof usses, containers spas and pools.

ey are de nitely the workhorses of the business.”

All Mudgee Cranes are MDG15 compliant and undergo three-monthly mines-speci c inspec ons as well as annual CraneSafe and non-des uc ve tes ng (NDT). All li ing and rigging equipment is inspected every three months.

Jess and the Mudgee Cranes’ team have been impressed with the a er sales service and support they receive om Terex Franna.

“In our opinion, any new crane can prove to be di cult because they are fairly complex machines. We had a few minor issues when we rst took delivery

of the AT40, we reported them to Terex Franna and to their credit, they had a technician out here the next day to x them,” said Jess.

“A li le later in the piece we had a couple of other minor issues, and again the technician was out the next day and got everything sorted.

“Like any crane hire business, an asset that isn’t working is cos ng money and with Mudgee being a good three and a half hours om Sydney, we rely on the a er sales service and support provided by our suppliers. Terex Franna has always provided rst class support. We’ve operated Frannas for many years and they have been the ‘back bone’ of the business since its incep on.”

Jess goes on to discuss how the team at Mudgee Cranes engages with the local communi .

Last year Mudgee Cranes invested in a 2024 model Franna AT40 and this has proved to be a valuable asset.

More than just a pre-start checklist

More than just a pre-start checklist

StartSafe is comprehensive tool designed to streamline your crane operations, enhance safety, and ensure accountability.

StartSafe is comprehensive tool designed to streamline your crane operations, enhance safety, and ensure accountability.

“Obviously we live with the local communi , we know them, we engage with them, and we support them in any way we can. We sponsor a number of local spor ng events and teams including

Mudgee Basketball, Kandos S eet Machine, Mudgee Cranes O -Road Racing Team, Mudgee Spor ng Clays, Skillset’s Try-A-Trade at Mudgee High School and Mudgee Rugby League.

More than just a pre-start checklist

and Cabin

“When it comes to the business communi , we are focused on customer sa sfac on. Pre much every job crosses my desk, and I work on the li studies. We visit every site prior to the job to ensure we are prepared, that we are deploying the right crane and that the team knows what to expect. We don’t charge for these site visits, as they are part of our service.

Attatchment - Security

Charts

“When you are opera ng a crane business in a rela vely small regional cen e like Mudgee, customer sa sfac on and your reputa on are everything. Recently, we have no ced clients have come to us because their incumbent craneage provider hasn’t been able to provide a solu on or hasn’t delivered to their expecta ons. We are always examining how we operate and wherever possible, we are implemen ng ways of simply doing things be er. In a small regional cen e, that gets no ced.”

More than just a pre-start checklist

Machine specific checklists are in line with the CraneSafe program.

Machine specific checklists are in line with the CraneSafe program.

StartSafe is comprehensive tool designed to streamline your crane operations, enhance safety, and ensure accountability.

Photos tell the story.

Photos tell the story.

StartSafe is comprehensive tool designed to streamline your crane operations, enhance safety, and ensure accountability.

StartSafe streamlines the process for collecting pre-start information, with instant data retention to a central location for the crane owner to access.

StartSafe streamlines the process for collecting pre-start information, with instant data retention to a central location for the crane owner to access.

Machine specific checklists are in line with the CraneSafe program.

Machine specific checklists are in line with the CraneSafe program.

Photos tell the story.

When a faulty item is recorded by the operator, the maintenance team is notified of the issue by email, which includes photo evidence of the fault. This also assists with gathering major inspection data.

StartSafe streamlines the process for collecting pre-start information, with instant data retention to a central location for the crane owner to access.

StartSafe streamlines the process for collecting pre-start information, with instant data retention to a central location for the crane owner to access.

When a faulty item is recorded by the operator, the maintenance team is notified of the issue by email, which includes photo evidence of the fault. This also assists with gathering major inspection data.

TAILORED VISIBLE

When a faulty item is recorded by the operator, the maintenance team is notified of the issue by email, which includes photo evidence of the fault. This also assists with gathering major inspection data.

Photos tell the story.

When a faulty item is recorded operator, the maintenance team notified of the issue by email, includes photo evidence of the This also assists with gathering inspection data.

Compact structure with a small footprint,5.94m slewing radius, suitable for operation in narrow spaces

Max. luffing jib configuration: 52m + 46m; optional folding luffing jib. Requires only 68m max. luffing space.

Integrated boom and jib design cuts parts procurement by 26% and reduces idle time.

Main unit transport weight: 32.5t, width: 3m (fits standard flatbed trucks). Boom: 3-layer nesting, full configuration requires 5 truckloads

Multi-stage counterweight, customizable variable-gauge crawler chassis for diverse working conditions

Brothers Chris and Tony Farley have been operating Western District Crane Service (WD Crane Services) for over 16 years, servicing customers in Southern Victoria. Grove is their chosen brand of all terrain and they recently added a Grove GMK5150L-1 and GMK3060L-1

C T .

CHRIS AND TONY STARTED WORKING IN the indus y back in 1985. ey worked in cons uc on and crane hire for various companies around Aus alia and Chris worked overseas in the Sco sh oil and gas sector.

“We both started in the cons uc on

we were pu ng cranes out on dry hire, one at a me and seeing an opportuni , we brought them back in and started our own business,” said Tony.

“In the early days, we bought two Franna MAC25s and then we bought a Liebherr LTM 60 tonner and we had them

GMK3060L and a GMK 4100L-1 and our recent purchases have been the GMK5150L and the GMK3060L. Basically, we’re running six Grove all terrains om 60t capaci through to 250t capaci ,” he said.

T WD C S

• 1 x 250t GMK5250 L all terrain crane.

• 1 x 150t GMK 5150 L - 1 all terrain crane.

• 1 x 100t GMK4100 L-1 all terrain crane.

• 1x 100 t GMK4100 all terrain crane.

• 1 x 60t GMK3060 L-1 all terrain crane.

• 1 x 60t GMK3060 all terrain crane.

• 3 x 25t MAC Franna mobile cranes.

• 2 x 20t Franna mobile crane.

• 1 x 2.5t Manitou all terrain fork Li .