26M A-DOUBLE FARM PICK UP COMBINATION

26M A-DOUBLE FARM PICK UP COMBINATION

For nearly 50 years, Byford Equipment has delivered reliable liquid transport solutions trusted by operators across Australia.

Designed with performance in every detail, our tankers are engineered from concept to completion to meet the demands of diverse industries.

With a commitment to quality and innovation, we provide solutions that work as hard as you do, every day and in every environment.

CHAIRMAN

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

EDITOR

Peter White peter.white@primecreative.com.au

JOURNALIST

Sean Gustini sean.gustini@primecreative.com.au

CONTRIBUTORS

Paul Lancaster paul.lancaster@primecreative.com.au

William Craske william.craske@primecreative.com.au

ADVERTISING

Adrian Kos: 0413 777 670 adrian.kos@primecreative.com.au

Ashley Blachford ashley.blachford@primecreative.com.au

DESIGN

Alejandro Molano

HEAD OF DESIGN

Blake Storey

CLIENT SUCCESS MANAGER

Ben Sammartino ben.sammartino@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher. Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

O cially endorsed by the VTA

The freight industry isn’t just critical to our economy – it’s the foundation of our livelihood. Transport and supply chains support every aspect of our lives, whether it be with food delivered to supermarkets, clothing and goods to retail stores or petrol to service stations. But the industry is facing growing pressure as it struggles to align with Australia’s sustainability targets and increased consumer demand.

With the sector still being heavily reliant on diesel-powered transport, UNSW School of Civil and Environmental Engineering Senior Lecturer, Dr Elnaz Irannezhad, is warning that the industry will risk becoming a roadblock to Australia’s path to net zero without urgent innovation and coordinated policy action.

“From our ports and rails to our intermodal terminals, where containers are moved between different modes of transport, almost all our freight fleet currently runs on diesel fuel,” she said. “There is a huge opportunity to decarbonise the freight and logistics sector – and it starts with collaboration between industry, researchers and government.”

Transport accounts for 21 per cent of Australia’s total greenhouse gas emissions, and the Australian Government’s Emissions Projects 2024 report claims that truck emissions are expected to increase by 16 per cent (four Mt CO2-e) by 2040. It’s therefore clear that further adoption of electric vehicles will be needed if sustainability targets are to be met. But several challenges stand in the way.

Australia's lack of charging infrastructure, unique freight challenges and different policies make electrification more complex. Inconsistencies in regulations

between states is also an issue. While most Australian transport authorities have increased axle mass limits for new zero emission heavy vehicles to accommodate heavier battery loads, there is still a lack of harmonisation. As Irannezhad noted, EVs which comply in one state can become noncompliant once they cross the border.

In last month’s Food supply chain special report, we investigated the ways that supply chains are shaped by consumer trends, market demands and other factors. Following the surge of e-commerce in recent years, it’s clear that as consumer demand continues to grow, businesses will struggle to keep up.

The answer to all this pressure is not an easy one. But it’s widely accepted that more investments in infrastructure, a solution to the labour shortage, the introduction of better regulatory policies and the innovation of smarter technology is needed.

Peter White

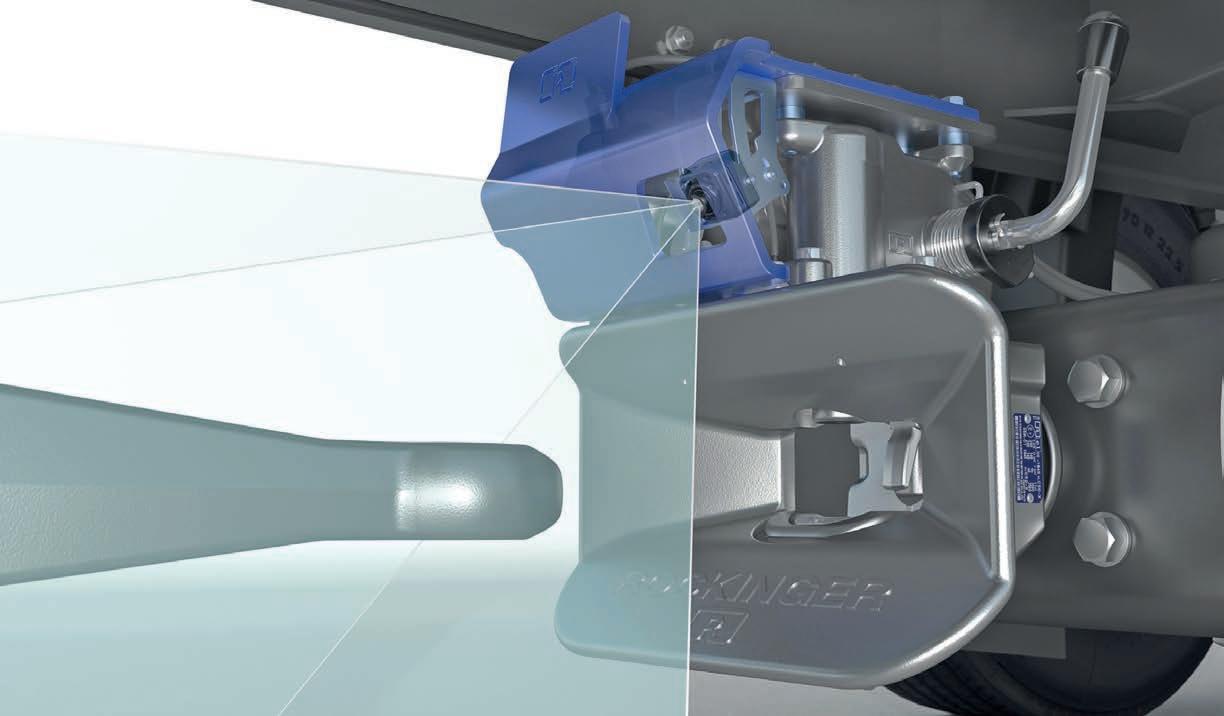

+ No Ubolts

+ More uptime

+ Low maintenance

+ Patented composite rotor

+ Frame bracket symmetry – no shocker bracing needed + SAF drum brake with quick release spherical anchor

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

SAF-HOLLAND (Aust.) Pty. Ltd

+ Long life disc brake technology SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

www.safholland.com.au

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Email: sales@safholland.com.au www.safholland.com.au

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

(Aust.) QLD

(61-7) 3375 7033 Fax: (61-7) 3375 7044

Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044

(Aust.) WA

(Aust.) WA

Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730

2025 24 30

Business partnerships, people movements, developments that bolster freight productivity and more.

22 Economy

The Western Australian Government is seeking to strengthen the state’s economy with over $1 billion of investments to be delivered through the 2025-26 State Budget.

24 Modern road tankers

See the industry’s latest tanker technology.

30 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

34 Tippers

FortySeven Industries has taken delivery of a new Hamelex White Performance-Based Standards combination.

36 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

42 Metal special

Capral Aluminium, SSAB and Calibre Steel put the pedal to the metal.

48 ALRTA

The Australian Livestock and Rural Transporters Association remains committed to the future of a productive and e cient supply chain.

50 Safety insight

Hannah’s Haulage invests in the industry’s latest technology, regularly replaces all of its prime movers and trailers and relies on experienced drivers.

52 Infrastructure spotlight

What you need to know about Australia’s biggest road projects this month.

54 World map

Logistics companies face a daunting time ahead with several impactors, particularly cyber security threats.

57 Fleet of the month

XFM has added three new B-double combinations to its fleet on the back of its recent rebranding.

58 What’s on Upcoming shows and field days.

Followmont Transport has added 10 new Maxi-CUBE refrigerated trailers to its fleet.

The delivery consisted of six 12-pallet A trailers and four 22-pallet B trailers.

These units have been configured to support a range of combinations including BAB and ABB quads, B-triples, road trains and B-doubles.

Followmont Transport CEO, Ross Longmire, told Trailer the investment was driven by continued fleet expansion and the need to meet new customer requirements.

“As our network grows, we’re committed to aligning our fleet with the needs of our partners,” he said.

“That means reliable, high-capacity equipment that’s ready to meet demand.”

Operating under both PerformanceBased Standards (PBS) and Concessional Mass Limits (CML), the trailers will enable Followmont Transport to move greater volumes more efficiently while upholding safety standards and compliance.

The Gross Combination Masses (GCM) for these units range from 65 to 130 tonnes, with payload capacities between 35 and 70 tonnes.

Longmire explained that the wide payload ratio allows the fleet to cater to varying customer needs.

“These refrigerated vans were purposebuilt to support our cold chain operations with high-volume capacity and dependable temperature control,” he said.

“The flexibility of these setups allows us to optimise vehicle use depending on route requirements and freight types, while also maintaining compliance across state and territory regulations.”

A standout feature of these latest trailers are their lighter tare weights.

Followmont Transport General Manager Linehaul, Rob Dummer, said this factor alone allows the fleet to increase payloads without compromising on compliance.

“Combined with their build quality, this results in better fuel efficiency and stronger return on investment,” he told Trailer “These are both key considerations as we scale our operations.”

Each unit is also fitted with a Thermo King A-500 fridge motor – the fleet’s trusted choice due to its exceptional fuel economy and long-term reliability.

“These systems play a key role in ensuring consistent temperature performance across our network,” Dummer said.

“Together, the build quality of Maxi-CUBE and refrigeration technology from QTK

Group help us deliver quality, efficiency and reliability to our customers every day.”

Followmont Transport’s Maxi-CUBE combinations will support the fleet’s movement of general freight, fresh produce and chilled and frozen goods.

They will span the entire east coast, operating with a strong presence in Queensland as well as in extended runs into the Northern Territory.

Although the trailers have just been deployed, Followmont is confident they will perform to expectation due to the build quality of Maxi-CUBE units.

“Maxi-CUBE trailers are known for their durability, consistent performance and capacity to handle the rigours of Australian transport conditions,” Longmire said.

Dummer believes they are the perfect fit for Followmont Transport’s applications.

“The combination of temperature control and payload flexibility on these trailers makes them ideal for long-haul refrigerated transport across regional and metro corridors,” he told Trailer

“Based on our experience, we’re confident they’ll deliver the reliability and efficiency we need across a range of freight types and long-haul routes.”

Lindsay Australia’ latest milestone deal is expected to create a national refrigerated logistics operation which will generate combined annual revenues of more than $1 billion.

Lindsay Australia acquired SRT Logistics

practical, forward-looking legal solutions.”

On 13 May 2025, SRT Logistics confirmed the $108.2 million transaction.

“The combined experience, expertise, and financial strength of our businesses, along with our shared focus on safety and

customer service while enhancing operational efficiencies and expanding our geographic footprint,” he said.

“I look forward to leveraging the combined expertise to deliver further value to our customers and employees.

“At last Tasmanian producers will benefit from a locally based logistics operator with a fully integrated road, rail and sea network with nationwide reach.”

Under the agreement, Lindsay Australia acquired the shares of SRT Logistics.

Barker Trailers has completed a significant leadership restructure aimed at enhancing operational efficiency and fostering innovation.

The strategic realignment will allow Barker Trailers to adapt and thrive in an ever-changing marketplace, ensuring that it continues to deliver exceptional quality and service to customers.

Now at the helm of the organisation is CEO, Stuart Scanlin.

With over 30 years of commercial and finance experience across various sectors, Scanlin is a seasoned professional with expertise in strategic business planning, performance management and financial control.

His background includes extensive work in fast-moving consumer goods (FMCG), manufacturing and service industries.

Scanlin’s leadership philosophy is rooted in integrity and collaboration, with a commitment to fostering a culture of transparency and innovation.

Under his guidance, the team will focus on sustainable growth and operational excellence, ensuring that every initiative aligns with the overall vision of the company.

“As we settled into the new structure, our leadership team quickly started to identify and capitalise on opportunities for growth and improvement,” Scanlin said.

“Their collective expertise and vision are vital in positioning Barker Trailers as an

industry leader in both product quality and customer relationships.”

Scanlin is joined by Barker Trailers Plant Manager, Martin Merry, who oversees production, safety and facilities maintenance with a keen eye on technology and innovation.

His role is pivotal in integrating cuttingedge solutions that enhance operational efficiencies.

Merry’s capability also extends to stepping in as acting CEO when necessary, providing a seamless leadership presence.

As Barker Trailers’ Sales and Operations Planning Manager, Aaron Tindal is responsible for all key customer-facing operations including new trailer sales, repairs, spare parts, delivery and warranty support.

His approach centres around enhancing customer satisfaction by aligning these functions seamlessly.

Meanwhile, Barker Trailers HR Manager, Rachel Mostacci, will play a pivotal role in overseeing staff welfare and company culture.

With a strong background in operations and project management, she serves as a trusted advisor within the organisation.

Mostacci is committed to fostering collaboration and ensuring that all projects align with Barker Trailers’ organisational goals.

Lastly, Financial Controller, Kylie Gray, joins the Barker Trailers leadership team

with a wealth of knowledge in financial and management accounting.

As a chartered accountant, she is responsible for finance, payroll, insurance and legal matters.

Her contributions are crucial for advancing Barker Trailers’ initiatives and achieving financial success.

“Looking ahead the restructuring of our leadership team represents more than just a change in roles – it signifies a renewed commitment to excellence at Barker Trailers,” Scanlin said.

“With this capable and driven team guiding the organisation, we are confident in our ability to navigate challenges and seize opportunities in the future.

“Together, we are poised to uphold our reputation for high-quality, custom trailers while continuing to innovate and strengthen our customer relationships.”

Fulton Hogan has been appointed to the Australian Government’s Defence Infrastructure Panel – Major Construction 2025-2030.

Defence Infrastructure Panel – Major Construction 2025-2030 is a national major construction and capital facilities contract panel for projects valued over $200 million.

It allows the Australian Government to engage industry partners in delivering complex Defence infrastructure, maintenance and specialist project solutions nationwide.

Fulton Hogan CEO – Construction, Brett Smiley, said the company is proud to be among industry partners.

“Being selected for the panel is a great recognition of our experience and the quality of work our teams deliver,” he said.

“We believe delivering Defence projects represents more than just building infrastructure – they’re about reliability, responsiveness and contributing to the security of Australia.”

Fulton Hogan has several years of

experience supporting Defence projects, having successfully delivered major infrastructure, specialist facilities and asset maintenance solutions nationally.

“Our appointment to this Defence infrastructure panel reinforces our reputation for excellence and security,” Smiley said.

“We look forward to working with Defence to deliver high-quality infrastructure solutions that support Australia’s Defence capability across the country.”

Capral Aluminium, Sims Metal, and Rio Tinto have teamed up to create a lowcarbon aluminium recycling loop that boosts domestic manufacturing and cuts emissions.

Post-production aluminium scrap will be taken from Capral’s Bremer Park facility, processed and sorted by Sims Metal, and delivered to Rio Tinto’s Boyne Smelter in Gladstone for remelting.

This scrap will be used to produce 1,000 tonnes of aluminium with a minimum 20 per cent recycled content, which will be supplied back to Capral’s Bremer Park manufacturing site in Southeast Queensland for extrusion operations, creating a domestic, local recycling solution.

Capral and Rio Tinto will leverage

Sims Metal’s expertise in processing and sorting aluminium which will deliver improved production efficiencies allowing larger volumes of scrap to be remelted at BSL, increasing scalability while maintaining agreed recycled content percentages.

The aluminium in this process is part of an entirely local Queensland supply chain. Rio Tinto mines the bauxite in Weipa, then refines it into alumina and smelts it to become aluminium in Gladstone, before being extruded by Capral at Bremer Park. After processing and sorting by Sims Metal, Rio Tinto remelts Capral’s post-production scrap to make the recycled billets at Boyne Smelter.

The initiative supports ongoing efforts

to establish commercially viable onshore recycling of aluminium in Australia and contributes to reducing emissions associated with aluminium production. It will also assist Capral in reducing its Scope 3 emissions and provide Capral’s customers across a diverse range of Australian manufacturing industries, including construction, marine, transport, renewable energy, and general fabrication, with products aligned with their sustainability goals.

“This project represents a practical step forward for Capral in reducing our operational emissions and increasing the recycled content of the aluminium we use,” said Capral Managing Director and CEO, Tony Dragicevich.

“Building on our successful 2024 trial with Rio Tinto, working together enables us to offer our customers extruded aluminium options that support circularity, strengthen local supply chains and reinforce the role of Australian manufacturing in a low-carbon future.”

When it comes to trailer and truck body manufacturing, one size doesn’t fit all. That’s why Calibre Steel offers a comprehensive range of steel plate products to suit every application—from heavy-duty haulage to lightweight transport solutions. Whether it’s TRU-SPEC® steel for consistent flatness or BISALLOY® steel for high-impact performance, our steel plate product range is engineered to meet the most demanding fabrication and performance requirements. Combined with our processing capabilities, we help manufacturers build truck bodies and trailers that are stronger, lighter, and built to last.

Visit calibresteel.com.au to see how we can support your next project. Scan to download the Calibre Steel capability statement. Proud suppliers of:

Ken Buchanan has announced his departure from the transport industry after more than 40 years of service.

Buchanan joined Krueger as Area Manager in 1988 following a 13-year tenure at Fruehauf Trailers.

He was entrusted with managing the regional Victoria area which covered suburbs such as Shepparton, Mildura and more.

Buchanan quickly built strong relationships within his dedicated parameter and even extended his influence beyond it – earning the trust and respect of many across the broader network.

Speaking to Trailer, he said the main highlight of his time at Krueger has been seeing how far the business has come.

“The difference from what it was when I first joined to what it is now is

unbelievable,” Buchanan said.

“The customer base has probably been the biggest improvement overall.

“Every day was a challenge in terms of building relationships and helping people in the company to make it grow, and that’s what I enjoyed. I liked the challenge.”

Krueger National Sales Manager, Grant Krueger, told Trailer that Buchanan was well-liked, deeply knowledgeable as well as highly sociable – a quality that has been his greatest strength at the business.

“Ken’s talent for building genuine relationships with customers is exceptional,” he said.

“It’s no surprise that people wanted to buy from him because his personal touch made all the difference.

“Ken is one of the true gentlemen of the industry. He was very social and was always good for a laugh.”

Krueger said Buchanan’s greatest contribution to the family business was his unwavering loyalty.

“He was very loyal, and not just to the brand but to our family as well,” he told Trailer

“Ken was there during the early days when my father, John Krueger, was running the business and was actively

Toll Group has announced the appointment of Thomas Knudsen as Executive Chairman.

The appointment follows the departure of Toll Group Managing Director, Alan Beacham, and will see Knudsen take on the role in an interim capacity.

Knudsen has more than three decades of experience in global logistics and leadership across Asia, Europe, the Middle East and the United States.

Having joined Toll in 2018 as President of Global Forwarding, he later served as Managing Director from 2020 to 2022 and most recently as Non-Executive Chairman from 2022 to 2025.

“Toll has a proud history and a strong future,” Knudsen said.

“I’m honoured to step into this role at a pivotal time and continue working alongside a talented leadership team

committed to delivering for our customers, people and partners.

“My focus will be on stability, execution, and momentum as we transition into our next chapter.”

As Executive Chairman, Knudsen will provide executive oversight while continuing to work closely with the Toll Board and executive leadership team to ensure continuity of operations and a

involved across all areas, especially sales.

“After 37 years with the company, it’s that loyalty along with his dedication, experience and consistency that stands out as one of the most valuable things Kenny brought to Krueger.

“On behalf of my father and the family at Krueger Transport Equipment, we thank Ken for all of his time and loyalty given to the company. We wish him the best in the next stage of his journey.”

Reflecting on his time in the entire transport industry, Buchanan said meeting new people has also been very rewarding.

“I’ve made a lot of friends in the industry,” he told Trailer

“You’re meeting new people all the time which is great.”

Buchanan joined Krueger during the period when founder, John Krueger, was running the business full-time.

He expressed his gratitude to Krueger for the opportunity to work for his business.

“I’d like to thank John Krueger,” he said. “He’s been very good to me over the years.”

Buchanan is looking forward to travelling and spending time doing some work around the house in his retirement.

sharp focus on business performance.

In addition to his extensive experience with Toll, he currently advises several private equity and investment firms –bringing strong commercial insight and a global perspective on capital strategy and business transformation.

Knudsen has played a significant role in strengthening Toll’s global operations over the years, including navigating the business through the challenges of the Covid-19 pandemic and driving key innovation and efficiency initiatives.

Originally from Denmark, he has been based in Singapore since 2010.

He holds an Executive Master of Management in Supply Chain from IE Business School in Madrid and has completed executive programs at Harvard Business School, INSEAD and Cranfield School of Management.

Direct Freight Express has expanded its operations in Dandenong, Victoria.

The company has launched a brandnew 6,500-square-metre time slot distribution centre.

In a statement online, Direct Freight Express said the opening of the new depot contributes to its objective of being one of Australia’s most reliable and

respected road freight services.

“This expansion represents a key milestone in our ongoing commitment to providing reliable, high-quality freight solutions across Australia at the cheapest possible price,” the company said.

The location also features a convenient underground car park with more than

140 spaces, offering improved access for staff and visitors.

The Dandenong facility joins three other depots that were opened earlier this year.

The “triangle” expansion covered Warrnambool, Portland and Hamilton as part of Direct Freight Express’ strategy to bolster its presence further in the southwest of the state.

The 2025 Women in Industry Awards have recognised and celebrated some of the most inspiring and accomplished women working across Australia’s manufacturing, mining, engineering, transport, energy and construction sectors.

Presented at a gala evening on Thursday 19 June at The Carousel in Melbourne, the awards brought together industry leaders, innovators and advocates to honour the women driving real change in traditionally male-dominated sectors.

This year’s winners represent a broad cross-section of industry, united by their excellence, leadership and commitment to creating more inclusive and forwardthinking workplaces.

The 2025 Women in Industry Awards winners are:

• Woman of the Year: Tammy O’Connor –KingKira Group

• Business Development Success of the Year: Tammy O’Connor – KingKira Group

• Industry Advocacy Award: Eileen Breen – NTEX

• Safety Advocacy Award: Mandeep Singh – Ego Pharmaceuticals

• Rising Star of the Year: Jennifer Clements – Consultex

• Excellence in Transport: Kirryn Crossman – SMEC

• Excellence in Engineering: Stacey Daniel – Board Presence

• Excellence in Manufacturing: Naomi Elliott – Concept Labs

• Excellence in Construction: Isolde Piet –Suburban Connect

• Excellence in Energy: Suzanne Shipp –APA Group

• Excellence in Mining: Becky May

Felstead – Strong Minds, Strong Mines KingKira Group founder, Tammy O’Connor, was named Woman of the Year at the 2025 Women in Industry Awards – the biggest honour of the night.

O’Connor’s leadership, vision and impact are redefining what’s possible for women in the mining and civil construction sectors.

On top of this prestigious title, she also took home the Business Development Success of the Year award, recognising her relentless drive to grow, innovate and lead from the front.

“The first time was scary, but the second time is even scarier,” O’Connor said when accepting the award.

Speaking about the importance of women leading differently, O’Connor said it was important to drive change and inspire future generations to break traditional boundaries.

“I think it is important that women lead the industry, and I think we do things a lot differently,” she said.

“I’m standing up here for the next generation because back in the day growing up my mum didn’t work, my grandmother didn’t work either, and now we see other women in the industry, in leadership, and they can see women can do more than the things we are told we should be doing.”

Prime Creative Media CEO, Christine Clancy, said the awards continue to play a vital role in recognising the achievements of women who are breaking down barriers and paving the way for future generations.

“These awards celebrate not only technical excellence but also the courage,

Interstate fuel distributor, Refuel Australia, is celebrating its 25th anniversary.

Twenty-five years ago, Ian and Monique Burrows assumed control of Geraldton Fuel Company and drove it to become something bigger.

The local operation eventuated to what is now known as Refuel Australia.

Delivering over 200 million litres a year across the Pilbara, Midwest, Gascoyne and Murchison regions, Refuel Australia has become one of WA’s and the Northern Territory’s key fuel suppliers.

“We’ve grown. We’ve rebranded. We’ve rolled out roadhouses, retail and remote fuel services across some of the toughest

resilience and leadership it takes to create lasting impact,” she said.

“Each winner is an inspiration and a powerful reminder of what’s possible when diversity is embraced.”

The Women in Industry Awards are hosted by Prime Creative Media and are proudly supported by a range of industry partners and sponsors committed to advancing gender equality and innovation across the industrial landscape.

country in Australia,” Refuel Australia said.

“But the goal’s always been the same: keep the regions moving, with service you can count on.

“Here’s to 25 years of Refuel Australia as we know it – built on big kilometres, local knowledge and a crew that gets the job done.”

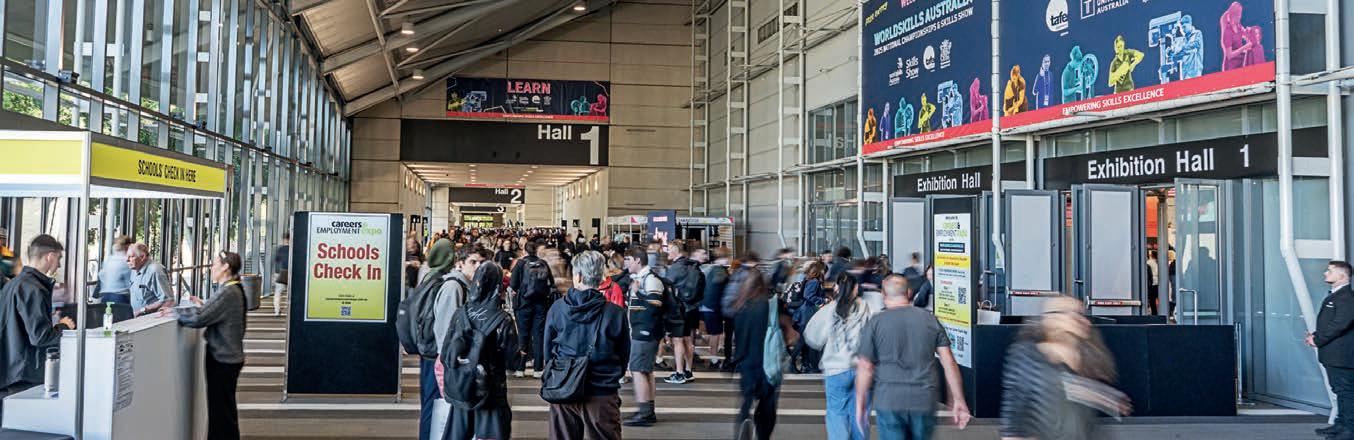

The 2025 WorldSkills Australia National Championships & Skills Show recently wrapped up in Brisbane.

Held at the Brisbane Convention & Exhibition Centre from 12-14 June, the event drew record crowds while celebrating vocational excellence and the vital role of trades and skills in Australia’s economy.

The event brought together more than 35,000 visitors who witnessed over 600 competitors from every state and territory go head-to-head across more than 60 skill categories.

These ranged from Cyber Security and Cabinetmaking to Cookery, Floristry and Plumbing.

WorldSkills Australia CEO, Trevor Schwenke, said the show was one of the largest National Championships in WorldSkills Australia’s 44-year history.

“This has been one of the biggest and best National Championships in our history – and a true celebration of what’s possible when young people, educators, government and industry come together

to back skills,” he said.

“Brisbane was an incredible host and it was fantastic to walk the floor and witness the outstanding level of competition, as the nation’s best young skills talent gave it their all.

“Their passion was inspiring and I’m sure many visitors are now considering where a vocational career could take them.”

New South Wales was crowned the overall winner, topping the medal tally with outstanding results across multiple categories.

The top awards presented were:

• Best of Nation – Lily-Grace Toohill, Victoria – Jewellery recognised as the highest-performing competitor across all categories;

• VETiS Shield – NSW, awarded Best Performing State for Vocational Education and Training in Schools; and

• Evatt Shield – Melbourne East Region, awarded Best Performing Region.

Competitors who excelled in WorldSkills-recognised international skill categories now have the potential

The specialist carrier, which commenced operations in Mascot, New South Wales, in 1993, celebrates 32 years of business.

“From humble beginnings in a small shed in Mascot to now operating 68 companyowned depots across the country – it’s been an incredible journey of growth, commitment and service,” the company said.

“Thank you to our dedicated team, loyal customers and valued partners for being part of the ride.”

Direct Freight Express was an early adopter of the latest technology running single, B-double and B-triple combinations across the country multiple times a day.

It is also committed to the PerformanceBased Standards (PBS) high productivity scheme.

In 2019 it launched a 42-metre-long B-triple which was approved for Level 3 access developed specifically for a transit lane between Perth and Adelaide.

The carrier has always prioritised cost savings and fuel usage with the heavy

opportunity to be selected to join Team Australia (The Skillaroos) at the 48th WorldSkills International Competition in Shanghai, 2026.

The 2025 WorldSkills Australia National Championships & Skills Show was also proudly supported by the Queensland Government, TAFE Queensland and a nationwide network of industry, education and community partners.

Federal Minister for Finance, Trade, Employment and Training, Ross Bates, praised medallists for their exceptional performance.

“I congratulate our latest medallists and all competitors who gave up their free time to hone their skills, and who put themselves forward to compete at the highest level, on the country’s biggest skills stage,” he said.

“I thank WorldSkills Australia, TAFE Queensland, expo exhibitors, and all whose collective effort ensured the tremendous success of this event –further elevating the status of training and skills nationwide.”

vehicles it invests in for transporting palletised freight.

Direct Freight Express is driven by service while striking a balance between outlay, innovation and upkeep.

In February this year the business announced the opening of three new depots in Victoria – Warrnambool, Portland and Hamilton.

Direct Freight Express Managing Director, Joe Catania, said this expansion strengthened the company’s national footprint.

“These new locations will enhance our ability to provide top-tier logistics services across Australia,” he said.

In November last year, the carrier developed a new facility in Kenwick, Western Australia.

Tough, thermally efficient and engineered for the long haul, Thermaxx bodies are built to perform in Australian conditions. Available in-stock or customised to your specifications.

✓ Lower Tare Weight

✓ igh Thermal fficiency

✓ Long-Term urability

✓ educed ost of wnership

✓ urpose- uilt in Australia

Treasurer of Queensland, David Janetzki, said the 2025-26 Budget includes a historic 80:20 funding deal for $9 billion of upgrades for the Bruce Highway.

In addition to the 16 projects already in planning or under construction for the Bruce Highway, other key initiatives of the $41.7 billion Transport and Main Roads Budget include:

• The Safer Roads, Better Transport Plan including Barron River Bridge, the Bribie Island Bridge, the Caloundra Congestion Busting Plan and Mooloolah River Interchange.

• The Wave with seamless public transport all the way to the Sunshine Coast Airport – with heavy passenger rail to Birtinya and metro all the way to the Sunshine Coast Airport through Maroochydore CBD, with an additional $40 million to accelerate planning for stages 2 and 3 in this year’s Budget.

• Faster Rail between Logan and the Gold Coast with $5.75 billion jointly funded with the Australian Government.

• $100 million Country Roads Connect program to boost the safety and flood resilience of regional unsealed roads.

• $27.5 million for the Schools Transport Infrastructure Program to improve the safety and operation of schools across Queensland.

• $15 million for the Keeping Our Waterways Safe program (formally War on Wrecks), with a focus on action and enforcement activity.

• $2.2 million to remove the fee for a new Disability Parking Permit to deliver on our election commitment and provide cost of living relief.

Janetzki said the Budget was about delivering a plan for Queensland’s future.

“We promised a fresh start for Queensland and that’s exactly what this Budget delivers,” said Janetzki.

Meanwhile, Minister for Transport and Main Roads, Brent Mickelberg, said this year’s Budget is helping deliver a transport network that meets the needs of a growing population, supports the economy and connects communities.

“Whether it is the Barron River Bridge in Cairns, the Caloundra Congestion Busting Plan or the Bribie Island Bridge, we are progressing these important projects for Queensland’s future,” he said.

“We are delivering to ensure Queensland is well positioned to meet the challenges of hosting the 2032 Games, while also preparing for the significant transport demand that comes with a growing state.

“We’re working across multiple levels of government and with industry bodies to explore innovative products and delivery

options to drive value for money and manage project cost pressures.

“These include improving design quality, conducting earlier investigations to manage risk, and engaging with industry early to ensure better outcomes.

“This is about managing a decade of mess and mismanagement left by the former Labor Government to deliver the generational infrastructure needed to protect our way of life for the future.”

The Budget is also delivering targeted industry investments including a manufacturing hub in Toowoomba and an additional hub on the Sunshine Coast for $10 million. Also, a $79.1 million program aims to facilitate pathways for export opportunities and enable reshoring and onshoring by Queensland manufacturers.

Primary producers are expected to benefit from a $817.2 million allocation and 25-year blueprint which is projected to boost primary production output by $30 billion by 2030.

The blueprint includes five-year action plans to drive investment, create jobs and unlock opportunities for the sector, supported by a $30 million Sowing the Seeds of Farming Innovation Fund.

It also includes funding to boost biosecurity which will see the first of 100 new biosecurity officers across the state.

Road Tanker Load Calculator (RTLC) is a cloud-based SaaS tool tailored for the fuel and lubricant logistics industry,

helping fleets optimize liquid deliveries. It ensures each load is legally compliant with maximum volume.

Advanced optimization

Using linear programming

Device-agnostic

Mobile/Tablet/Desktop

Fleet versatility Supports any combination from Tanker Trucks to Road Trains

Workflow integration For Planners, Drivers, and APIs

We use Road Tanker Load Calculator because we know our trucks leave the terminal or depot with legal weights while maintaining maximum efficiency every time. The program is user friendly and makes scheduling easier while helping us meet Mass Management requirements.

Haydn Simpson, Operations Manager, Simpsons Fuel

• A 5% efficiency gain delivers millions of additional litres fleet wide.

• Smart OBM without the hassle of actual hardware.

• Helps cut costs and boost margins. Get the most from your fleet.

• Drivers love it. Planners rely on it. Auditors trust it.

• We help you make every litre count!

Email sales@roadtankerloadcalculator.com for a Free Trial

The results of a recent road safety operation should serve as a wake-up call for all road users.

As part of a week-long initiative

‘Operation Omega II’, the National Heavy Vehicle Regulator (NHVR) intercepted almost 3,000 heavy vehicles to combat the dangers of fatigue during Easter.

NHVR COO, Paul Salvati, said these road safety operations are crucial to protecting lives on Australian roads especially during ‘high-risk’ holiday periods.

“Fatigue continues to pose one of the most serious safety risks in the heavy vehicle industry and is a known contributor to road trauma,” he said.

“It only takes a momentary lapse in concentration for lives to be lost or forever changed.

“That’s why NHVR Safety and Compliance Officers (SCOs) conducted 426 intercepts each day during Operation Omega II, ensuring drivers both understood how to manage their fatigue and were compliant with the law.

“Of the 2,985 intercepts conducted throughout the week-long safety operation, 131 were found to be noncompliant with fatigue requirements in some way.

“To put it simply, that’s 131 instances where we could have seen potential tragedy occur on our roads, had our SCOs not intervened.”

Salvati said 172 fatigue-related offences were issued during Operation Omega II, with 46 classified as either critical fatigue breaches, or breaches due to drivers

making false and misleading entries in their work diary to hide a fatigue offence.

“This is a concerning figure and shows an increase in the number of breaches of this severity in comparison to the previous Operation Omega, which ran in the lead up to Christmas,” he said.

“Already this year, there has been 60 fatal crashes involving a heavy vehicle across Australia, which is not only tragic, but preventable.”

Salvati said the positive outcome of the operation was to see many operators are implementing the appropriate measures to prioritise rest and alertness for drivers.

“The fantastic takeaway is how many professional drivers and companies understand that no freight task is worth more than a human life and we commend them for putting safety first,” he said.

SCOs, according to Salvati, also delivered 407 education sessions

Waste management specialist, Cleanaway, has acquired Citywide Service Solutions (Citywide Waste).

The acquisition has expanded Cleanaway’s solid waste services business by an additional 100 fleet units and 200 staff members.

As part of the agreement, Cleanaway has also acquired Victoria’s secondlargest waste transfer location, the Dynon Road Transfer Station.

The business will now invest $35 million

into the station to transform it into a modern and efficient post-collection hub.

Cleanaway Executive General Manager Solid Waste Services, Tracey Boyes, said the business is delighted to welcome the Citywide Waste team to Cleanaway.

“Together, we’ll continue delivering essential services to Melbourne’s communities while enhancing resource recovery outcomes across the CBD and surrounding areas,” she said.

“The Citywide team has built a

specifically centred on fatigue and work diaries, accounting for almost 97 hours.

“When drivers are impacted by fatigue, they’re at risk of impaired judgment, slowed reaction times and an increased chance of being involved in a catastrophic collision,” Salvati said.

“Throughout Operation Omega II, SCOs took the time to engage with drivers, providing education and raising awareness about the serious risks of driving tired, with the aim of encouraging voluntary compliance with the law.

“An additional 253 education sessions were provided to drivers on other Heavy Vehicle National Law requirements, such as vehicle standards, loading, and mass.”

During the operation, a number of additional compliance issues were also identified, with mechanical noncompliance proving to be the primary area of concern.

successful business and brings deep experience in servicing Melbourne’s inner city.

“Now, as part of Cleanaway, we’re excited to continue serving residents of the City of Melbourne and other major councils, as well as the many commercial and industrial customers who rely on the Dynon Road Transfer Station.”

The potential acquisition was first announced earlier this year.

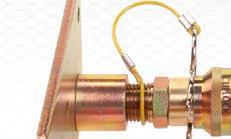

By popular acclaim, the SWIFT Delivery System from Liquip is the industry’s simplest, lightest, smartest and – yes –fastest fuel-delivery solution.

The SWIFT’s innovative metering delivery system uses level gauging to accurately and conveniently deliver multiple products through a single pump – whether the method of delivery is gravity-fed, bulk-drop or hose reel.

Make the SWIFT Delivery System the star of your fuel-delivery production!

The Western Australian Government is seeking to strengthen the state’s economy, with over $1 billion of investments to be delivered through the 2025-26 State Budget.

Western Australia boasts a unique set of conditions which have long made it an economic powerhouse in the nation.

According to the Western Australian Treasury Corporation, WA notably enjoys an abundance of natural resources when compared to other states and strong economic resilience as a result. Because of this, WA accounts for roughly half of Australia’s goods exports, producing over 50 mineral and petroleum products through its massive mining and gas industries.

This economic performance is being further built upon with a $1.4 billion investment as part of the WA Government’s 2025-26 State Budget. This figure is headlined by a $500 million investment into the state’s Strategic Industries Fund and also includes $38.5 million to support defence, mining and exploration and hospitality sectors; $209.4 million to boost local manufacturing of buses, batteries and ferries; and a $331 million investment in training initiatives including $122 million extension of popular fee-free TAFE and additional provision of construction courses.

According to WA Premier Roger Cook, the government wants to continue the support and incentivisation of hard work by creating more opportunities for it within the economy.

“Our economy has been made strong through the hard work of generations of Western Australians,” he said.

“We’ve created hundreds of thousands of jobs, overseen a massive surge in apprenticeship starts, and seen businesses investing in WA like never before. We want to build on that record, make more things here, power WA on clean energy, supply the materials required for the world’s clean energy transition, and diversify our economy by leveraging our existing strengths.”

Elsewhere in the budget, the state’s manufacturing space will receive a significant boost of $208.4 million via several smaller investments into electrifying public transport, encouraging the use of new technologies through the

Housing Innovation Fund, support for the Local Battery Manufacturing Program and more.

WA Deputy Premier and Treasurer, Rita Saffioti, praised the state’s multi-faceted economic future.

“Protecting our economy and creating more jobs for Western Australians will always be a key focus for our government, and our Made in WA plan will help deliver on that,” she said.

“Western Australians have an entrepreneurial spirit – and we have incredible capacity within our State to build the things we need to take WA forward.”

The Freighter Group network is here and ready to support all your spare trailer parts needs. With a wide selection of high-quality, genuine spare parts for all Freighter Group OE trailer brands, available now and ready to order, you can easily find the right part without the hassle. It is all part of our unwavering commitment to keep you moving by supporting your business for the full life of our products.

freighter.com.au

Fonterra’s new Byford Equipment Performance-Based Standards rigid tanker and dog is the forerunner of a new fleet of highly productive and efficient combinations.

Transporting 55 million litres of milk in a year is a task on its own. But dedicating this responsibility to a single tanker combination is something entirely different. National dairy company, Fonterra, is carrying out this monstrous freight task with its new Byford Equipment Performance-Based Standards (PBS) fiveaxle rigid tanker and dog combination – a unit that will act as a prototype before the fleet’s makeup fully evolves to a new trailer configuration.

The maths behind the transport objective is as follows. With a Gross Combination Mass (GCM) of 63 tonnes and payload of 42.6 tonnes, the Byford unit can deliver 38,000 litres of milk per trip. It completes two trips per shift and two shifts a day, tallying up 152,000 litres. Multiply that figure by 365 days a year and you end up with 55,480,000 litres of milk delivered annually.

All of this milk is collected from hundreds

fleet transitioning from standard A-doubles and B-doubles towards rigid tanker and five-axle dog applications.

“We wanted to trial a set from Byford,” he says. “Being an Australian-made manufacturer, they gave us great input into the design, construction, materials and componentry that they used. We did that purely with the five-axle dog so that we could get a higher volume over our four axles, not be incumbent by On-Board Mass regulations and still stick within our Performance-Based Standards (PBS) Tier 1 constraints.”

The tanker set is now the most critical unit in Fonterra’s fleet due to it being the first of its kind.

“This combination is driving us towards a five-axle truck and dog fleet, so it’s the one we’re watching the most,” says Fonterra National Fleet and Equipment Manager, Cameron Nicholls. “We want to push the envelope for weight purposes

in a way that would tailor their operational needs and allow the PBS combination to serve its purpose of being a role model for future instalments. The design covered axles, braking systems, rims and tyre sizes, the amount of manway in inspection ports, pipe work, venting and more.

“We had complete design selection,” Cameron says. “We worked with Byford through the design specs and the things that are specific to us so that the product would be built how we wanted it to be. The end result is the furthest we’ve gotten in developing a tanker that works for us, our sites and our collection process.”

The rigid tanker on the front of the combination has a 13,000-litre capacity, while the five-axle dog at the rear has space for 30,000 litres. The entire PBS combination has network access under the National Heavy Vehicle Regulator’s (NHVR) National Class 2 PBS Level 1 & 2A Truck and Dog Trailer notice. Being under 20

this vehicle out compared to the others because it can pick more volume up.

“It performs really well. It’s actually more stable on the road than a four-axle dog because of the five axles and longer trailers. It’s got a really good drawbar system as well which makes it steadier.”

The five-axle truck and dog has a swept path of 5.6 metres on a 90-degree turn, similar to a single tri-axle trailer, meaning access and turning angles are never a problem. This is critical for Fonterra’s tankers which often find themselves in tight and narrow spaces on farms.

“The truck and dog combination has been really good for access on farms,” Cameron says. “There hasn’t been any sacrifice with five axles over four. I don’t know of any farms that this one can’t go to that a fouraxle can.”

The versatility of the unit has given Fonterra a major advantage. By sticking to PBS Tier 1, it has very minimal restrictions and can be operated wherever required without needing additional permits to comply with tier levels and road and bridge restrictions.

“It allows us to go everywhere we need to go as one of the most productive trucks that we’ve got,” Cameron says. “If we tried to be any trickier with PBS, we would be doubling up on sending trucks back to farms that were next door to ones we’d already been to. So, it’s walking a nice line between getting enough volume on board and not being too restrictive by road access.”

The entire combination is also extremely fuel efficient. With a 540hp Volvo FM prime mover it has an average consumption rate of 2km/l.

“We’ve seen some pretty good productivity gains, particularly with the latest Volvo,” Cameron says. “It has increased our fuel efficiency significantly by greater than five per cent.”

Fonterra’s latest PBS tanker application joins 30 Byford trailers at the business – a fleet of older units which will now be gradually replaced with five-axle rigid tankers and dogs using the same formula that was perfected with this latest order. The company is extremely confident about this new venture due to the quality seen with the existing equipment in the fleet and the relationship established between both businesses.

“We’re only completing standard maintenance procedures on our Byford equipment,” Matthew says. “We service

them every 15,000 kilometres, so they’re getting inspected every three weeks. The maintenance is key to keeping our trailers on the road and it increases the reliability of our fleet due to minimum downtimes.”

“Fonterra and Byford really value each other,” Cameron adds. “If there’s an issue, there’s no finger-pointing. It’s just about solving the problem.

“That’s something I enjoy about my role and working with a company like Byford on behalf of Fonterra. Gary Byford is very aware of his reputation, and he wants a good outcome for his name on the door. You can’t ask for much more than that.”

Contact Byford Equipment

Ph: 03 5482 0666

Web: www.byfordequipment.com.au

Liquip is used to fielding requests that are a bit different from the usual, so when working with Freight Lines Group, a custom request spurred the further expansion and innovation of the Swift delivery system.

With an install base of over several hundred systems, the team at Liquip are certainly on to a winning formula with the Swift delivery system. The Swift system can accommodate a range of tanker designs including rigids, single trailers and B-double road trains, but every now and again a request comes along that challenges this winning formula.

When Freight Lines Group came to Liquip with a requirement for a triple road train that would have the ability to pump and meter from the front, middle or rear trailer (via a delivery system installed on the middle trailer), it wasn’t a standard configuration for the Swift range. It was a case of thinking outside the box – taking a recipe and expanding on it to create a working delivery system and a very happy customer.

“Liquip’s engineering team thrives on complex challenges and it excels at finding simple, standardised solutions,” says Liquip International National OEM Account Manager, Joel Cork. “When we first sat down to work through the initial scope, it was clear this wasn’t going to be straightforward. But I had full confidence in the team and they absolutely rose to the occasion.”

Liquip Victoria Managing Director, Jeff Borg, explains that the Swift system had only ever been designed for up to two trailers.

“When the customer required one for a triple combination, we had to go and design the system so that it could communicate and work across three trailers,” he says. “There was a lot of research and development that had to be done for the customer’s order without delaying delivery. To bring this solution together, engineers from Liquip International and Liquip Victoria worked together to design and verify the solution.”

The Liquip engineers took a standard Swift configuration and, with the addition of only one control box, were able to expand the functionality of it. The end result was a first-of-its-kind triple road train Swift, affectionately called the Swift ‘Piggy-in-theMiddle’ configuration.

“We had to develop some way of switching between trailers,” Jeff says. “The solution was reached by keeping the standard functionality the same across all three trailers and developing a switching methodology between the first, second and third whilst maintaining the original look and feel of Swift.

“It was a challenge to do it without modifying the way that Swift is used. So, the project shows how our team uses its manufacturing expertise and demonstrates its ability to come up with a unique solution.”

The same outcome could have been achieved through the inclusion of a multitude of control units, complex software and additional wiring. However, by critically analysing the customer brief and investing significant hours up front in the design and testing phases, the final product was able to meet the brief while using mostly existing parts.

Freight Lines Group is a large Western Australia-based freight company which specialises in bulk grain, fertiliser, lime and gypsum as well as general and fridge and freezer freight. The new road train, based in Albany, WA, has been dedicated to its sister company, Western Fuels Group, and will be used to transport Dangerous Goods (DG) throughout the Great Southern and Goldfields-Esperance regions.

Western Fuels Group’s Jim Raszyk explains that the majority of the combination’s work will include multidrop deliveries as well as linehaul work for retail sites and large commercial accounts. The

Swift delivery system, as a result, needed to be faultless, flexible and capable of continual use without breakdowns.

“The combination is licenced to carry petrol and diesel, and it has dedicated hose reels so that both products can be metered,” he says.

Jim adds that the new configuration needed to be flexible with linehaul work to maximise payloads.

“The road train is our third Tieman Tankers setup in the fleet,” he says. “For this one, we put a full Liquip Swift delivery system on it because of the weight saving of around 500 kilograms compared to traditional pumping systems.

“The other reason we went with the Swift system is because of the deliveries these trailers are doing. They’re doing a lot of multidrops, and with full three-trailer loads they could do up to 10 deliveries in a run based on our schedule.”

With the road train boasting a 90-tonne payload with capacity for approximately 100,000 litres, Jim needed a system that would save on weight but deliver on accuracy.

underground tanks a lot easier, especially when split deliveries are needed.”

While the road train features the bespoke Swift system, it does include all standard, modern-day specifications such as Antilock Braking Systems (ABS) and Electronic Braking Systems (EBS).

“It’s also been made to be used as a standard B-double or a pocket road train at 27.5 metres,” Jim says. “This gives us a lot more flexibility, and that flexibility also allows us to deliver metered product from any of the trailers.”

Jim adds that the Swift system’s accuracy ensures peace of mind for his customers, knowing they are receiving an accurate amount of fuel each delivery especially when delivering petrol.

“It’s also the ease of operation for the drivers,” he says. “The system is very intuitive and user-friendly. This is essential when you have different drivers using the system.”

Since the launch of the Swift delivery system, the Liquip enigneers have been working diligently to expand the product to cater for a range of configurations.

“Our R&D doesn’t stop there,” Joel says. “We have some exciting nextgeneration developments on the horizon, particularly in metering and delivery system technology.”

push for increased payloads and greater operational efficiency, Liquip is not only adapting the Swift system to meet changing market demands – it’s at the forefront of the industry’s evolution.

“Our focus remains on delivering consistent, reliable functionality,” Joel explains. “As fleets move towards delivery systems for triples and quad configurations, system complexity naturally increases. That’s where Liquip’s greatest strength lies. In our people.”

With a dedicated local team spanning R&D, and manufacturing and product specialists working directly with operators and system installers, Liquip is wellpositioned to solve intricate challenges with intelligent, fit-for-purpose solutions.

“We’re able to implement innovative and often highly technical processes while maintaining system familiarity,” Joel says. “And most importantly, we actively incorporate feedback from the people who use the equipment every day, the operators.”

“We deliver petrol to agricultural and other businesses, hence the need for a system like this,” he explains. “A key feature of the Swift system is the automatic inclusion of Liquip’s level gauging which makes delivering into Contact Liquip

As the transport industry continues to

148 Newton Road

Wetherill Park, Sydney

NSW 2164

Ph: 02 9725 9000

Web: www.liquip.com

Road Tanker Systems’ cloud-based Road Tanker Load Calculator provides an easy way to increase payload capacity and efficiency while ensuring full compliance within legal weight limits.

Road Tanker Systems’ story dates back to 2004. What started as manual calculations and Excel spreadsheets turned into a side hustle and, from there, developed into what is now known as the company’s flagship tool – the Road Tanker Load Calculator (RTLC).

The RTLC is a mass management system specifically designed and built for the bulk fuel and lubricants logistics industry which allows operators to calculate axle weights and overall combination weights for different load configurations. The calculator, which was established in New Zealand and later expanded across Australia and into Canada, is what Road Tanker Systems considers to be equivalent to a Smart OnBoard Mass (OBM) system, but without the hardware.

“We can deliver the same results, predicting optimal loads before drivers hit the terminal using real-time density data,” says Road Tanker Systems Sales Manager, Simon Lytollis. “We can help planners or drivers figure out how much to load on each combination to achieve optimum legal delivery volume. So, we can essentially tell users the results before they’ve even started the truck.”

The RTLC’s main objective is to ensure that every load out of the gate is legal but maximises delivery volume, and it allows operators to optimise their fleet in three ways.

Firstly, it helps them to start planning how they can load efficiently. This provides the biggest delivery volume uplift. For further efficiency gains, a daily product density feed from the terminals helps optimise batch and temperature variations throughout the year. Lastly, fleet modifications such as fifth wheels or different unit combinations can be tested. The goal is to see every axle group loaded to its legal maximum to know the operator is being as efficient as possible.

“We see more and more fuel logistics companies modernising and becoming aware of the value of efficiency in every

area of their operations,” Simon says. “With changing densities, every load is different. So, it becomes difficult to know when and how to squeeze out that last few per cent that can mean the difference between profit and loss. This is the exact problem that we solve.”

The RTLC’s load calculator eliminates the guesswork out of load planning. This saves costs, avoids fines and maximises every trip. Its advanced ‘Auto Optimise’ functionality uses linear programming to solve compartment volumes and automatically balances axle and combination weights to stay within legal weight limits – resulting in more efficient deliveries and improved productivity. Due to its proven methodology, the calculated results are impressively accurate (calculated within 2.5 per cent on any axle group).

The concept of calculating fuel tanker axle weights has also been used by the RTLC’s architect for more than 12 years in similar systems built for BP and Linfox. Road Tanker Systems claims tanker manufacturers also use the same mathematical principles for their design calculations.

The RTLC system itself has been quietly operating since late 2016. In that time, its users have completed nearly 250,000 calculated loads to help shape the calculator into final product that Road Tanker Systems has today.

“By using this tool, users can transport more fuel in less time while giving them the peace of mind that their fleet is loaded safely and legally,” Simon says. “Our existing clients have typically seen between a three- to six-per-cent uplift in delivery volumes across their fleets. From DEF Group to Simpsons Fuel, RTLC has proven to increase payload capacity and simplify compliance while delivering Return on Investment through smarter logistics.”

Other features include support for High Productivity Freight Vehicle (HPFV) permits which allows users to configure override for axles, gross combination weight limits or specific states/routes; ‘Multidrop Checks’ which ensures a run with multiple farm or small drops stay legal at all times as deliveries are made and the compartment volumes change; ‘Saved Loads’ which allows regular delivery runs to be set up for repeat use; and ‘Audit Loads’ which save the finalised loads to a date time stamped audit log.

This log can’t be changed once the load is committed as the audit trail is locked down and ready to retrieve any load at any time, on screen or downloaded as a PDF.

In addition, the RTLC’s ‘Fleet Management’ interface has been refined with extensive testing to fit real-world conditions. It has scaled unit diagrams and features to correctly calibrate fleet equipment during onboarding.

“We pride ourselves on offering comprehensive support for a wide range of transportation units and configurations,” Simon says. “Our expertise ensures that no matter the combination or complexity of a fleet, we can keep its operations running efficiently.”

Looking ahead, Road Tanker Systems intends to build on the RTLC by launching a planning tool later this year. An in-cab app for completing deliveries onsite is also in the pipeline to follow that, along with a few other connected experiences around driver and maintenance management as well.

“The future of fuel logistics is about moving smarter,” Simon says. “RTLC solves today’s loading headaches while building toward tomorrow’s connected fleet.”

Contact

Road Tanker Systems

E: contact@roadtankersystems.com

Web: www.roadtankerloadcalculator.com

Barker Trailers, in collaboration with Polyweld, has developed an innovative freight solution which addresses driver safety, efficiency and return on investment – all paramount operational considerations.

When anyone has health issues, they consult a doctor or health professional. The same applies to the issue of drivers’ health and safety when operating heavy vehicles.

That was the approach Barker Trailers took when it approached Polyweld for an innovative curtainsider semi-trailer solution.

The end result is the highly efficient meshbased Load Restraint Gate System –an alternative gate system that is time efficient, user-friendly, easy to operate and most importantly, safe.

“The Load Restraint Gate System works very much along the lines of a load restraint-rated curtain,” explains Barker Trailers Engineering Solutions Specialist, Ian Brownlee. “It’s hung from rollers, similar to the rollers that would be used on a load restraint-rated curtain. The curtain would ordinarily be the full length of the trailer, but in this case the gates are broken into sections which fit between the roof support posts.”

Ian explains how the Load Restraint Gate System makes the operation of the curtainsider a quick and easy task.

“With side gates, whether they’re supported or unsupported, you have to lift them out of slots in the coaming and manually manoeuvre them out of the way or onto the ground,” he says. “But with this, the mesh system hooks into a customised coaming rail which has a latching system incorporated into it.

“The mesh gate strap attaches to a pin plate that hooks into the coaming rail or the

gate pockets. This arrangement is not only faster than a traditional buckle, hook and strap, but it is also only a few millimetres thick meaning it doesn’t interfere with the function of the vinyl side curtain. The gate is then strapped in, forming the internal load restraints behind the main trailer curtain.”

For Barker Trailers, achieving Dangerous Goods (DG) certification and the load restraint rating was an ultimate goal of the system’s development. The end product is a unique mashup of Barker Trailers’ low buckle curtain system and Polyweld’s inventiveness.

“This mesh system works well in combination with our low buckle curtain,” Ian says. “It was really a case of mimicking what a normal load restraint curtain would do in terms of straps per pallet space and then connecting it with some kind of webbing.”

The system, rated to 2,000kg per pallet space, is highly effective. Due to its open mesh webbing design, the operator can open the main trailer curtain and see through the system to assess any freight movement on the inside. This then eliminates the need for handling heavy metal gates, reducing tare, costs and the possibility of injuries.

“An open mesh-type webbing seemed to be the best solution because you can see through it,” Ian says. “It’s really just there as a carriage for the main load restraint straps to keep them all together as a unit.”

A key factor to the successful creation of the product was also Barker Trailers’ longstanding relationship with Polyweld.

“Barker Trailers have always been a premium brand, and their equipment certainly reflects their commitment to quality,” says Polyweld Managing Director, Stuart Donaldson. “We have long been supporting this commitment.

“More than that, the Donaldson family and the Barker family have worked together for decades. Even now, the first generation has passed on this bond and these values have been adopted and reinforced by the second generation.”

During the development of the product, Stuart was also acutely aware that safety is always a paramount consideration.

“A seat belt will only save your life if you put it on,” he says. “The same is true of load binders. The mesh curtains are more like airbags.”

The Load Restraint Gate System was originally thought of as an idea to replace heavy metal gates when operators wanted new ways to improve driver safety. In 2021, Stuart proposed Polyweld’s Axitex mesh curtains as an option at the Brisbane Truck Show.

For Barker Trailers’ latest application, it was a case of bringing the idea to life for Adelaide-based transport company, Energy LogistiX. Ian explains that the curtain system, produced in accordance with the fleet’s needs, would focus on time efficiencies and traditional

curtainsider operational issues.

“You hear that a lot of injuries occur to shoulders around shifting trailer gates out because it’s all done above shoulder level,” he says. “This completely alleviates that, so I think it would pay dividends when implemented on a large scale. Most businesses replace trailers over time, so it could just form part of a new spec that gets incorporated into new trailers.

“The cost benefit would be there in terms of cumulative time saved per trip. It might not be a huge amount per trip, but over the life of a trailer, it would be substantial.”

Barker Trailers has already experienced a wave of positive interest in the mesh curtain system. It now sees ample opportunity for a greater market share.

“There were some systems put out on a couple of trailers in South Australia a few years ago, and they’ve given us the confidence to move into a larger fleet like Energy LogistiX,” Ian says. “It has garnered a fair amount of interest and the feedback from those who have seen it has been very positive.”

For Stuart, helping to develop something as innovative and practical as the Load Restraint Gate System was an opportunity to help heavy vehicle truck drivers in what he describes as “the most dangerous job there is”.

“I often think of how many times someone is operating a curtain or loading a truck,” he says. “I’m proud to be able

Windella Agricultural Company has revamped its cotton carting abilities with a new delivery from Moore Trailers.

Cotton harvesting is a huge business in Australia’s east. According to Cotton Australia, the Australia cotton industry – primarily based in New South Wales and Queensland – generates over $3 billion in export revenue and employs over 7,000 people. Approximately 90 per cent of these labourers work on family farms which are passed down through generations, as seen with family businesses such as Windella Agricultural Company.

Windella Agricultural Company, a century-old dry land and irrigation cropping farm located near Rowena, NSW, grows an assortment of wheat, chickpeas and broad beans in the winter and cotton during the summer. For many years, the farm has implemented builds from Moore Trailers to assist in this harvesting. This has cultivated a strong partnership between the two companies according to Windella Agricultural Company owner and fourth generation family member, John Stump.

“We’ve had a good, long history with Moore,” he says. “We’ve got 18 of their trailers, and they’re great to deal with.

“If you go to them with an idea or vision, they’re happy to do certain things to accommodate that. They will build a custom-built trailer much more than just a stock standard trailer.”

Windella Agricultural Company has just taken delivery of two new nine-bale flat tops from Moore Trailers – something which has been in the works for a considerable amount of time.

“We’ve been carting cotton with our Moore Trailers 45’ flat tops for a long time,” John says. “I’ve been talking to them on and off about building a new set for three or four years and we both decided to go ahead with it last year.”

The new combination is made up of two trailers which are currently travelling between Windella and a cotton gin 75 kilometres east of the area. Each of the trailers have the capacity to carry nine bales of cotton – a total of 18 on the entire unit –and provide a significant increase in productivity compared to previous 12bale units in the fleet.

“We’re now getting 50 per cent more cotton on per load,” John says. “We typically do four loads a day, so we pick up an extra full day of carting every two days with these trailers compared to our other units. This gives us huge productivity benefits and fuel savings as a result.”

This enhanced efficiency is coupled with a user-friendly design which enables more cotton to be transported easier.

“The usability of these trailers is just great,” John says. “We’ve got toolboxes

up at the front, a flush mounted winch at the front, and a system where we have a pole on the back of the trailer to pull a ski rope across the top of all the bales. You then pull the 100mm strap across it.”

Additional features on these trailers continue to ensure efficiency for Windella Agricultural Company’s operations.

“We’re often picking up mud and cotton stalks with the bales, and that ends up in the trailers,” John says. “So, we have a grain shovel that lives on there and a set of steps so that we can safely reach the top and bottom decks and clean them out when required.”

Meanwhile, the builds have provided other benefits on the financial side of the business.

“Savings on fuel, labour, repair and maintenance are through the roof,” John says. “There aren’t many things that you can pick up that amount of efficiency with.

“We’ll be travelling 33 per cent kilometres less each year because of the efficiency gain. The workmanship and the quality of these trailers have blown us away. Moore Trailers has been flawless and they haven’t let us down at all.”

Contact Moore Trailers

Ph: 07 4693 1088

Web: www.mooretrailers.com.au

enhancing performance and extending the life of your engine.

www.castrolvecton.com.au New Kenworth trucks come with the reassurance of

FortySeven Industries continues its exponential growth by taking delivery of its latest Hamelex White Performance-Based Standards truck body and dog tipper combination from Freighter Group.

‘FortySeven Industries’ is a name that is not only intertwined with transport, but also racing. The company is a truck and dog tipper business which was formed by co-owner, Brendon Claridge, and his wife, Tatum, on the back of their previous fuel company named Claridge Transport.

After purchasing a new truck and starting their second transport business in March 2021, it was time to form the organisation’s identity. For the name, Brendon and Tatum, together with their two children, Lamiah

and Kinser, decided on ‘FortySeven Industries’, a tribute to their family sprint car racing team.

“We have a sprintcar team called Claridge Racing and our number is 47,” Brendon explains. “It’s the same number that my dad always had in racing, so we named our new business after that.”

From just one truck and dog combination to eight prime movers and 17 truck and dogs, FortySeven Industries has grown exponentially. As it stands, the fleet is not

slowing. In fact, it’s growing at a rapid rate with Freighter Group and the Hamelex White product.

“Our 12 Hamelex White truck and dogs are currently contracted to major companies in southeast Queensland, and we’ve got another one on order to arrive at the end of the year,” Brendon says. “We mainly cart quarry aggregates, sand, mulch and landscape materials. Anything you can put in the back of a truck and dog, we put in there.

“We’ve had nothing but a great experience with Hamelex White. They’ve been perfect, and I couldn’t have asked for anything better.”

FortySeven Industries’ latest Hamelex White delivery arrived in the form of a rigid body fitted to a Mack Super-Liner prime mover and a Performance-Based Standards (PBS) four-axle dog on the rear. The rigid unit includes truck and dog hydraulics, grain locks, a Right Weigh digital gauge, mesh tarp and Ringfeder coupling among many other standard specs. Meanwhile, the four-axle dog features E-Plas QuickSilver flooring, Hendrickson INTRAAX suspensions and disc brakes, grain locks and a paver chute to name a few. Both Hamelex White bins were also spec’d with extra features including additional lighting on the tops and sides.

With a Gross Combination Mass (GCM) of 57.5 tonnes and a payload of around 39.8 tonnes, the new PBS combination gives FortySeven Industries a tare weight of 17.5 tonnes. This has been seen to improve efficiency and the business’ bottom line.

In its operations of quarry aggregate, landscape material and paving applications, the new Hamelex White build has also continued to deliver in performance and reliability.

“The quality and reliability of the Hamelex

White product has been amazing so far,” Brendon says. “We haven’t had any issues with it. It’s great for me because I don’t have to worry about it. The truck just goes to work every day and the trailers do their job, so we don’t need any maintenance and we aren’t having breakdowns on the side of the road.”

With FortySeven Industries being a local business based in the South East Queensland region, the truck and dog unit often finds itself in Toowoomba, Gympie and near Lismore, New South Wales. Operating throughout a 200-kilometre radius from its home base has been a breeze.