goodbye to your car

he’s a write-off mate’ – the dreaded words no owner wants to hear.

I was on the receiving end of this news recently, as my 2003 Honda Jazz made its last road trip to the big Autobahn in the sky.

A steep hill in Belgrave, Victoria pushed old faithful’s transmission one step too far, and it was wrecker-bound from there.

The ‘blue beast’ was coated in that sparkly pale blue that was only pretty in the early noughties, but had some nifty aftermarket gear installed in it by its previous owner – a carefree hippy from Far North Queensland.

To quote Han Solo: “she may not look like much, but she’s got it where it counts.”

Roof racks, a subwoofer, a touchscreen and a spoiler for good measure made it ready for almost anything, apart from steep inclines it seems.

Shoutout to Luke from Bosch Car Service in Ringwood for getting the car in on short

notice and giving me the final diagnosis.

Losing your daily driver in this fashion can be like losing a pet or a loved one.

It’s been with you on a daily basis, getting you to special occasions, or just helping you grind through that work commute.

It’s taken you to dates, weddings, funerals, school, footy games, moved you across the country and down the road.

There’s nothing quite like the connection between man and car that you only get with a car that’s been around the block a few times.

Who knows, but I don’t see someone reminiscing about their Tesla in 25 years the way a Holden Monaro owner would.

This edition of Australian Car Mechanic is dedicated to all those good littler runners, fixer-uppers and old faithfuls out there.

Thanks for all the memories.

Harry Murtough – Editor

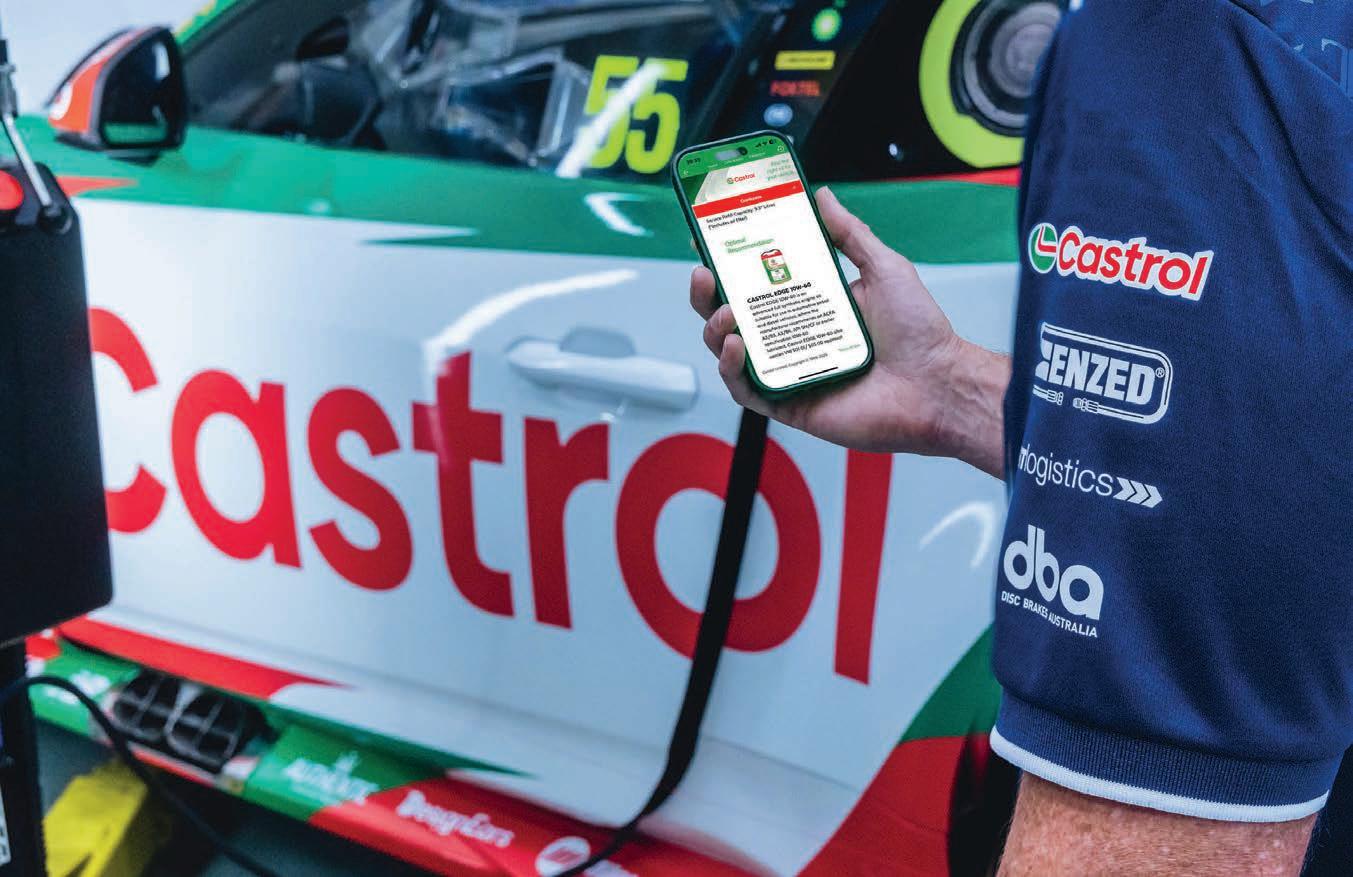

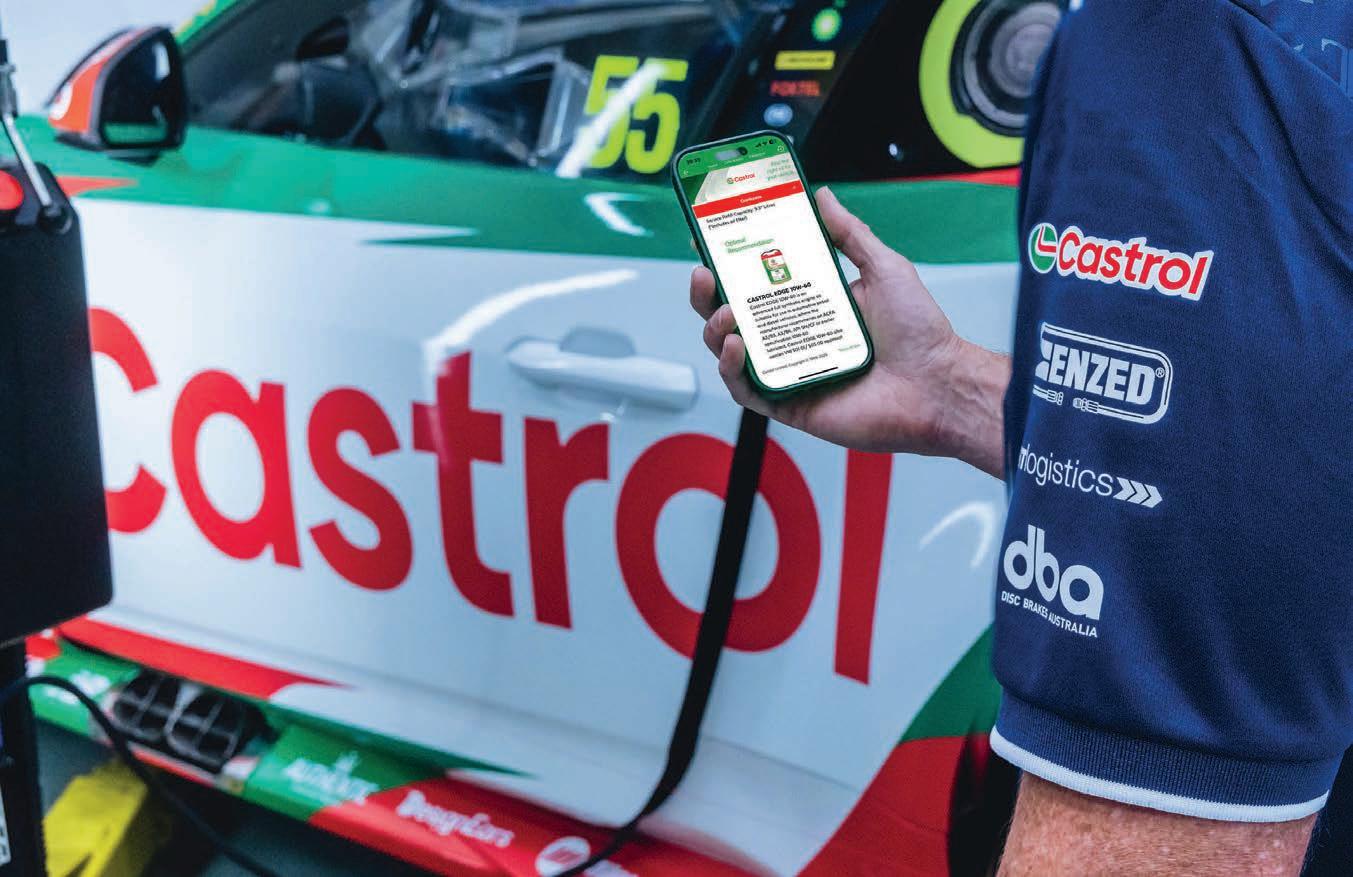

astrol has been one of the biggest names in the auto industry for as long as most can remember. It’s remained at the forefront of oil supremacy thanks largely to its array of technology and resources at its disposal.

We take a look at Castrol’s latest EDGE range of oils, and what makes these products a must for any workshop.

Deadline Aug 20, 2025

Issue 84 • 2025

Deadline Oct 21, 2025

Issue 85 • 2026

Deadline Dec 2, 2025

CEO Christine Clancy

Sales Director

Danny Hernandez

Editor Harry Murtough

harry.murtough@primecreative.com.au

Client Success

Arianna Lucini

arianna.lucini@primecreative.com.au

National Advertising Manager

Michael Ingram

michael.ingram@primecreative.com.au

M. 0423 266 991

Art Director/Design

Daz Woolley

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website www.mechanics-mag.com.au

Background image

Ivan Uralsky/stock.adobe.com

Cover image

Castrol

Copyright

Australian Car Mechanic magazine is owned by Prime Creative Media and published by John Murphy. All material in Australian Car Mechanic magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronicor mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Australian Car Mechanic magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2025

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766

enquiries@primecreative.com.au www.primecreative.com.au

13

22

IAIN CURRY has been a specialist motoring writer and photographer for 15 years, working for a variety of magazines in Australia, United Kingdom, USA, Germany and Sweden. He is former editor of Performance BMW magazine and features writer for GT Porsche magazine, and has been fortunate enough to photograph Formula 1, the Le Mans 24 Hours, World Touring Cars, V8 Supercars and a range of adventure sports.

PAUL MARINELLI is an industry leading PR and Marketing services consultant to automotive aftermarket and motorsport companies across Australia and around the world. His company, Marinelli PR, is celebrating its 30th Anniversary in 2025.

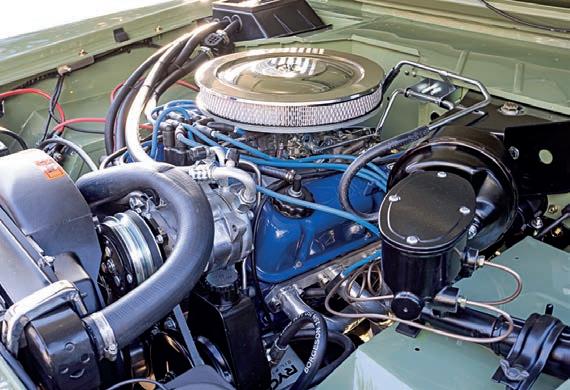

The challenges of advanced engine design

The engine is the heart of the car. Over the past decade, groundbreaking advances in engine technology have boosted performance and efficiency. Now, with tougher regulations and more demanding specifications, the focus for innovation has shifted to engine oils as the critical area where advances can be made.

The challenge is to deliver the best performance for drivers, who still expect peak performance from their cars, while manufacturers navigate increasingly stringent legislative limits.

Every part needs to work in perfect sync to deliver ultimate performance, withstanding more pressure, higher temperatures, greater extremes, kilometre after kilometre.

Countless years of engineering innovation, gathering billions of data points along the way, has enabled Castrol to identify specific factors where engine oil affects car performance and has proven that

Castrol EDGE delivers Castrol’s ultimate performance* across the key factors that impact performance — factors like endurance, wear and high temperature performance.

Nowhere are these factors more important than in the context of Original Equipment Manufacturer (OEM) approvals.

While industry specifications define a baseline for lubricant performance — ensuring lubricants have the right performance level to protect a wide range of engines — OEM specifications typically build on these to dictate exactly how the lubricant must perform within the unique lubrication environment of a manufacturer’s engines.

For this reason, OEM specifications can be among the most stringent of all specifications.

For lubricant manufacturers, obtaining approval can be a challenging, costly, and time-consuming exercise that demands a higher performing lubricant.

Long-standing connections with many of the world’s leading OEMs have ensured Castrol stays at the forefront of technological advancements, providing direct visibility of the latest engine technology and performance requirements. This connectivity is crucial in keeping Castrol at the cutting edge, developing lubricants that perform at the highest level by delivering optimal performance, efficiency, and protection, such that they are reviewed and approved to the stringent specifications demanded by manufacturers themselves.

Indeed, Australia’s portfolio of Castrol EDGE engine oils sees no fewer than 79 OEM approvals held across the range including from the likes of BMW, Ford, Mercedes-Benz, Volvo, Jaguar, and Porsche among others.

The elimination of the table supplied makes this a little empty. Could we add a line instead at the end. Examples include the MB M254 wear test to evaluate the oil’s ability to minimise wear throughout the engine, and the CEC L-109 test to evaluate the oil’s ability to resist oxidation with forced biodiesel contamination.

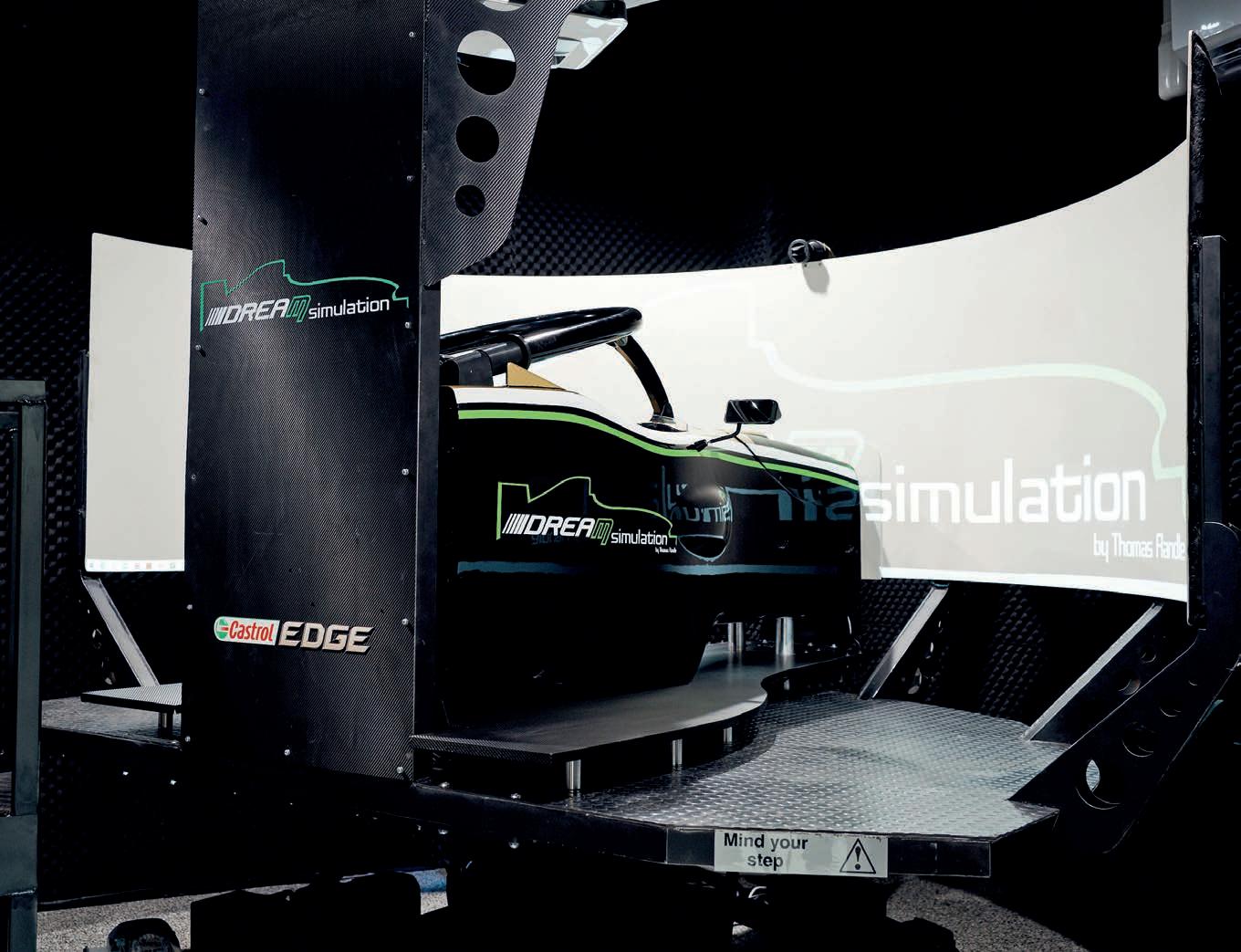

While OEM benchmarks may represent the foundation of ‘ultimate performance’ in a practical sense, to bring ultimate performance to life in a unique manner,

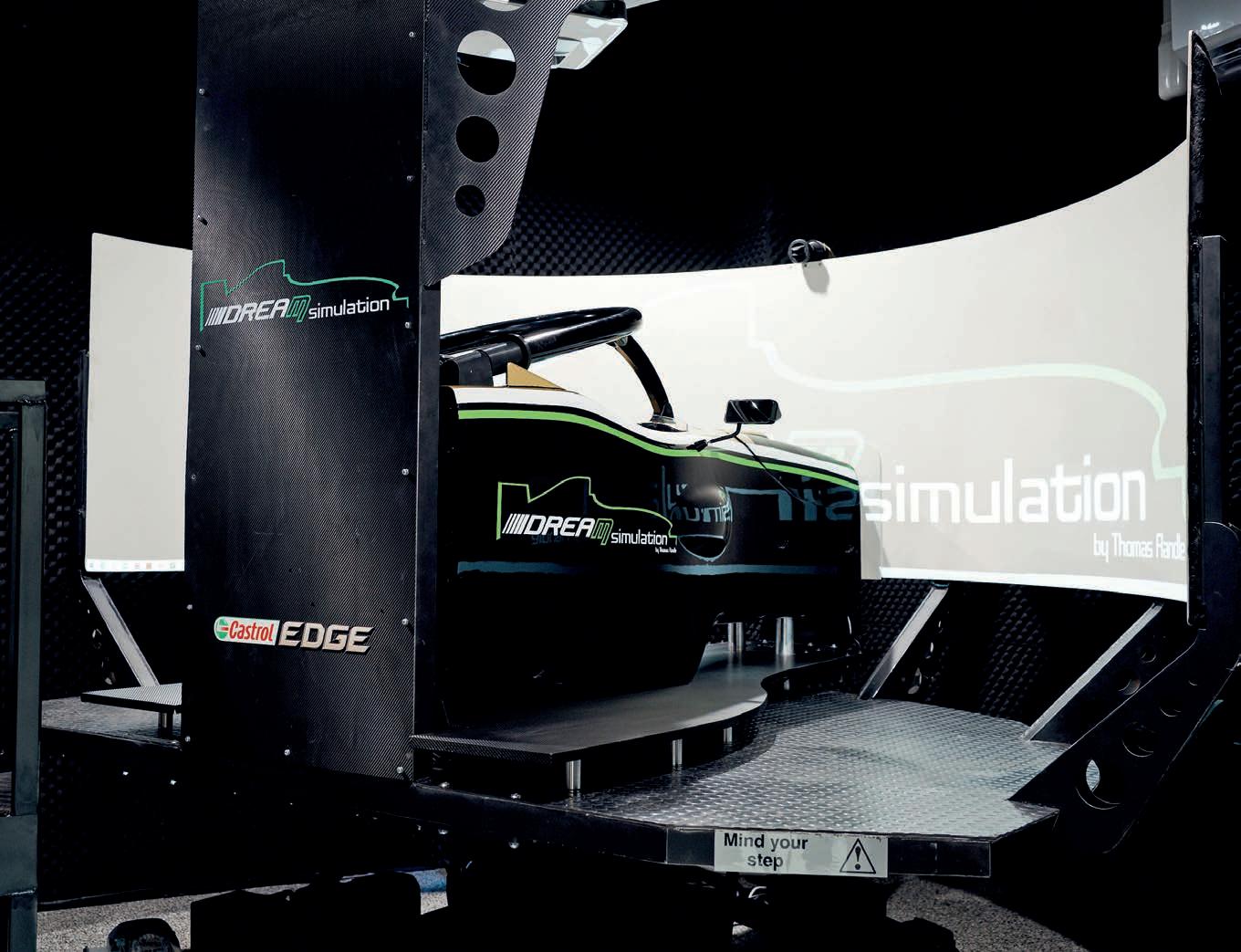

Castrol created drive-cycle conditions far more extreme than an oil would ever experience through day-to-day driving — The Ultimate Performance Demo.

Using world-renowned racing simulator Assetto Corsa, Castrol created a test drive based on a combination of the world’s most iconic racetracks and roads, selected for their ability to challenge the car engine and oil against critical performance factors.

Working together with Tickford Racing Supercars driver Thomas Randle, its Global Technology team collected the simulator data, logged in real time, on the speed, acceleration, breaking and duration of each drive. Then, underpinned by that telemetry data, the team created a real-world drive cycle at ISP, one of the world’s leading providers of testing services, for a real car to run at their state-of-the-art facility Germany.

Running selected Castrol EDGE products – including Castrol EDGE 5W-30 LL - through this grueling demo, data gathered illustrated that Castrol EDGE products were able to consistently withstand such an extreme

endurance challenge, validation that Castrol EDGE products are data engineered, motorsport-inspired and OEM approved.

While many lubricant brands are intentionally vague or ambiguous regarding the approvals held by their oils, Castrol remains black and white.

When you see a manufacturer approval

on a Castrol EDGE product in your workshop, you can be sure you’ve chosen an engine oil that’s data engineered to deliver Castrol’s ultimate performance and validated by approvals from world-leading OEMs.

*Only Castrol EDGE demonstrates Castrol’s ultimate performance exceeding both OEM & Industry specification limits (>80% of Castrol EDGE variants based on 2024 Australian portfolio)

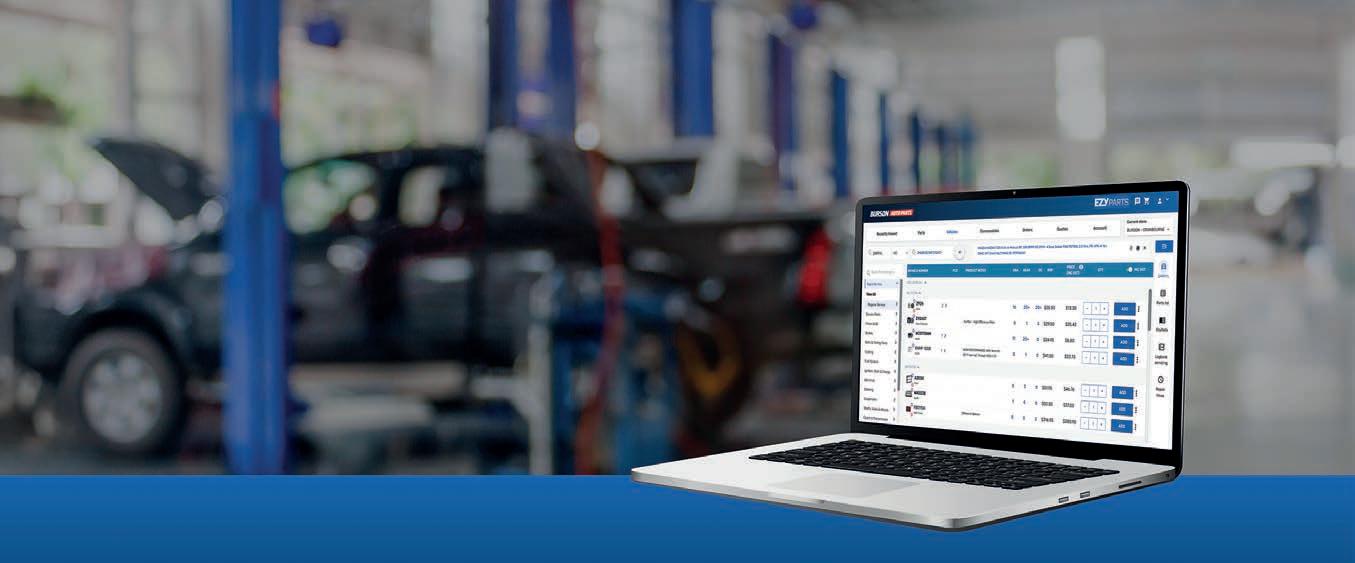

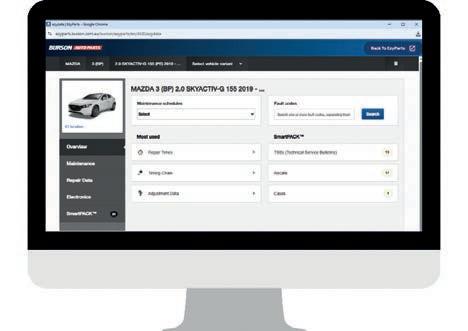

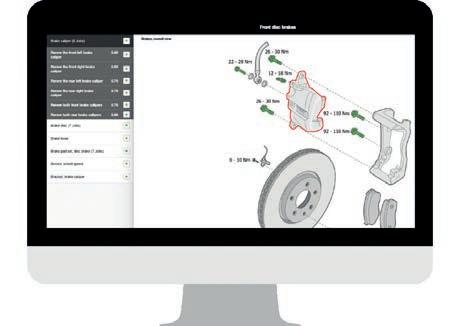

Supporting automotive professionals with the range, pricing & trusted brands they rely on to get the job done.

For nearly 100 years, Penrite Oil has been a trusted partner for the Australian automotive trade.

Being a 100 per cent Australian family owned and operated business that produces the highest quality automotive fluids, Penrite has remained the go to company for workshops and service centres for engine oils, gear oils, transmission fluids, greases, coolants, additives & cleaners used in the automotive trade.

As more Australians than ever, will hit the road this winter season, Penrite Oils and Lubricants will be their trusted partner, providing the highest levels of protection, performance and economy for their vehicles.

For the workshops and service centres that prepare the vehicles for the winter season, it’s the peace of mind knowing that they are using products that were blended right here in Australia that meet the highest of manufacturing and industry standards including selected products with OEM approvals and/or industry licenses.

It’s also knowing that they are using products supplied by a company with nearly 100 years of experience. No other Australian lubricant brand has that heritage of longevity and trust.

Over the last century, Penrite have continued to innovate and bring the latest specification products to the market, so their customers have the ‘Right Product for the Right Application’.

That’s not all

This doesn’t only apply to engine oils. Penrite’s commitment to providing the trade with all of the products they need to complete servicing requirements, mean that they have an extensive range of products that cover — transmission and gear oils, brake, hydraulic & steering fluids, greases coolants, additives and cleaning fluids making them a one stop shop for trade.

Being Australian made, owned and operated, Penrite is employing Australians to keep other Australians in business and employment.

By using Penrite lubricants, workshops and service centres are contributing to

the development of Australia and keeping manufacturing and money in the country to support other Australian businesses and people.

As Australians hit the road again this winter, whether it be on the annual vacation to the snow fields or just back to the everyday grind, Penrite will continue to support the automotive trade with products to cover the oldest to the latest technologies with the service and support that only comes from a 100 per cent Australian owned and operated business.

Join the Penrite family — visit penriteoil. com.au or contact on 1300 736 748

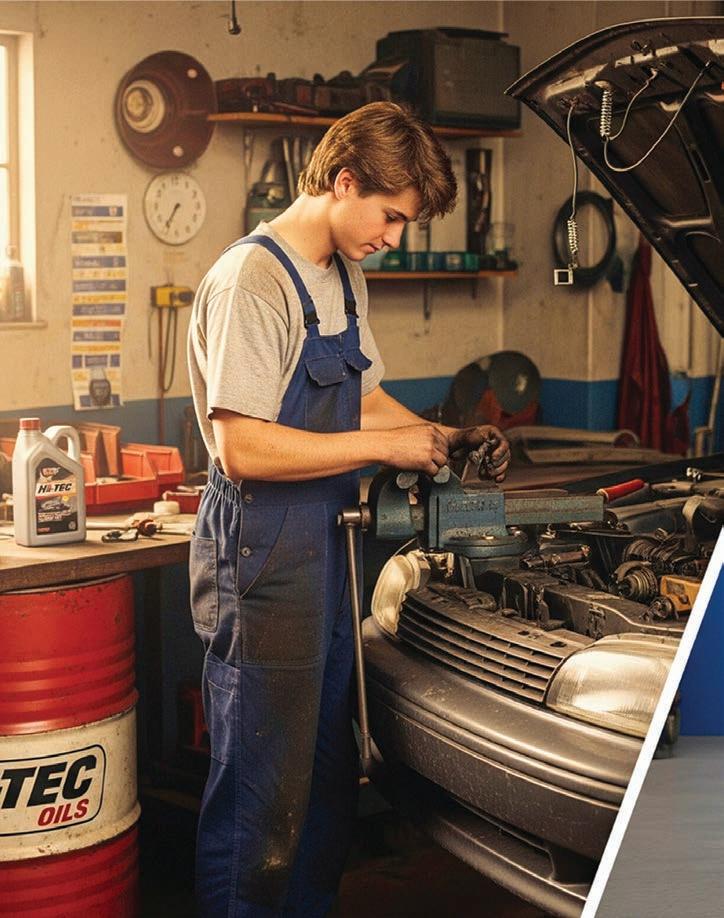

In the world of automotive servicing, precision, reliability, and consistency are essential.

At Roving Mechanical, a Land Rover specialist based in Peakhurst and Barden Ridge, NSW, these values are at the core of everything they do.

For close to 20 years, Hi-Tec Oils & Batteries has been a trusted partner in helping them maintain these high standards.

Founded by a team of passionate Land Rover experts, Roving Mechanical has built a solid reputation in Sydney’s southern suburbs for their deep mechanical expertise, personalised service, and commitment to using only the best parts and lubricants.

Their clientele includes a mix of off-road adventurers, family SUV owners, and enthusiasts who trust them to keep their vehicles in top shape.

“I started working with Land Rover products when I was 16,” Workshop coowner Glen Wickens said.

“Peter [Davis, co-owner] and I worked together early on, and eventually set up this

workshop to focus purely on what we know best — Land Rovers.”

Land Rovers are no ordinary vehicles. With their sophisticated systems, servicing these vehicles presents unique challenges not every mechanic is equipped to handle.

“Working with Land Rovers is not like working on just any car,” Glen added.

“The engines are complex, the systems are advanced, and the expectations are high.

“We can’t take chances with the oils we use.

“That’s why we’ve relied on Hi-Tec Oils for so many years—it simply works, every time.”

“We’ve used Hi-Tec Oils & Batteries for years because they’ve never let us down,”

“It’s a complete solution for us — one supplier we trust, with consistent quality across the board.”

20

Hi-Tec isn’t just a supplier — they’re a partner. From technical advice and training to promotional support and easy-tomanage supply chains, they understand what workshops need on the ground.

Roving Mechanical has been using Hi-Tec Oils for over more than 20 years – spanning

both their mobile and workshop operations

“With Hi-Tec, we’re not just getting drums and batteries dropped off,” Glen said.

“We’re working with a company that is actually supportive of our business.

“That’s rare in today’s market.”

Why the loyalty?

“It’s simple,” Glen explained.

“When everything’s working well, there’s no reason to change.

“Reps from other companies drop in all the time — we’re not even considering it.”

Beyond quality, what has sealed the deal for Roving Mechanical is the relationship and technical support – especially from their long-time sales rep. Their local Hi-Tec sales representative, plays a crucial role in ensuring things run smoothly.

“He has been our rep for decades,” Peter said.

“He knows our needs inside-out. If something urgent comes up, he’s either organising it instantly or delivering it himself.

“You can get reps from other companies coming in all the time — we don’t even look. You just brush them away.”

Hi-Tec’s supply chain efficiency has

also helped Roving Mechanical maintain workshop momentum.

“We’ve had batteries delivered the same day,” Peter said.

“When we use one, it’s back in stock the next day. That kind of turnaround keeps our workshop efficient.”

Hi-Tec’s modern features are just as valuable to the team. Roving Mechanical use LubeSearch & RegoLink daily on their website to identify the exact lubricant specs based on vehicle registration plates.

“It’s brilliant. Especially when we’re working on non-Land Rover cars — Hondas, Toyotas, you name it,” Peter said.

LubeSearch gives you 100 per cent accuracy.

“It saves time and ensures we’re always putting the right oil in.”

For a workshop that prides itself on getting it right the first time, reliability is nonnegotiable.

You grow your business because you’re good at what you do,” Glen explained.

“You can’t afford failures. Hi-Tec helps us deliver that reliability.

“If we used cheap oils, we’d risk comebacks — and we’ve built this workshop by making sure that never happens.”

When Roving Mechanical opened its doors, Hi-Tec Batteries came on board from day one. “They gave us the perfect setup — a stand with all the batteries we’d need for Land Rovers, and even stock for walk-in customers,” Glen said.

The speed of service is another major benefit.

“We fitted a Hilux battery yesterday — it was back in stock the next day. Sometimes, it’s the same day,” Glen noted. “That’s great efficiency for us, especially when you get last-minute jobs.”

And while customers rarely mention battery performance unless something goes wrong, Glen is clear:

“We use Hi-Tec batteries in all our cars — Land Rovers and others. They’re great. No failures.”

For Roving Mechanical, staying with Hi-Tec is a no-brainer.

In their experience, Hi-Tec’s strength lies in:

• Australian-made

• Fast, reliable product availability

• Unmatched technical support

• Product compatibility with premium vehicles

• Personalised service from sales reps

Peter and Glen don’t hesitate when asked what they’d tell other mechanics considering a switch.

“It’s simple — do it. It’s not even a debate,” Glen said.

“Hi-Tec Oils is Australian-owned, Australian-made, and the support is second to none.”

Their trust is absolute. Their results, undeniable. And their message clear:

“We’ve had a great experience with Hi-Tec — and we’re not just saying that. It’s been nothing but positive. We’re loyal because they’ve earned it.”

Want to experience what Hi-Tec can do for your workshop? Roving Mechanical’s story is a testament to the power of genuine product performance and strong supplier relationships. Hi-Tec Oils isn’t just a lubricant supplier for them – it’s an integral part of their workshop’s success story.

With over 30 years of Australian manufacturing heritage and a product portfolio covering automotive, heavy-duty, marine, and industrial applications, Hi-Tec Oils continues to be the go-to lubricant brand for workshops that take pride in their work.

To find out more about becoming a Hi-Tec Oils partner or to explore its full range, visit hi-tecoils.com.au or call 1300796009

GMB ensures peak lubrication in its steering and suspension products, ready to tackle demanding Australian conditions.

GMB stocks a large range of over 2600 quality Steering & Suspension components in their Sydney DC.

The GMB range continues to expand each year enabling Mechanics to easily access this quality range through spare parts stores Australia wide.

The current range includes:

• Ball Joints

• Control Arms

• Rack Ends

• Stabiliser Links

• Steering Joints

• Tie Rod Ends

When it comes to smooth handling and a responsive drive, steering and suspension components do more than just connect the driver to the road — they ensure every turn, bump, and correction happens seamlessly. But no matter how tough the hardware, without the right lubrication and high-quality materials, performance can degrade quickly.

That’s where GMB steps in — bringing OEquality engineering and lubrication insight to every corner of your customer’s vehicle.

At the heart of GMB’s Steering and Suspension range are parts designed to withstand harsh Australian conditions and the demands of modern motoring.

From control arms and ball joints to rack ends and tie rod ends, GMB’s components are engineered for precision, durability and the kind of reliability mechanics can stand behind.

But beyond the raw strength of each part lies something more refined attention to lubrication and material science that protects from the inside out.

High-load pivot points, like those in ball joints and stabiliser links, rely heavily on internal greases to keep things moving freely.

GMB’s internal greasing processes use proprietary, high-temperature, waterresistant formulas to prevent dry-out, washout and metal-on-metal contact.

This is essential in environments where dirt, salt and road grime threaten component longevity every day.

Many aftermarket suspension components

on the market use low-grade lubricants and seals that quickly degrade, inviting noise, premature wear, and eventual failure. GMB takes a different path.

Their use of premium rubber compounds in boots and seals — combined with precision-machined housings — creates a sealed, maintenance-free system that resists contamination and retains lubricant under extreme pressure and heat.

Control arms and tie rod ends are critical wear items, and when they go, vehicle handling and tyre wear follow.

That’s why GMB tests every component for articulation, load endurance and seal integrity. It’s not just about getting the fit right — it’s about keeping internal grease where it belongs, even under the strain of high cornering loads and rugged terrain.

Mechanics across Australia trust GMB not just for the parts themselves, but for what’s inside — because real protection starts with precision lubrication.

Explore the full range at gmb-oceania.com or call 1300 007 132 for your local distributor

Whether you’re on the racetrack or the highway, Ryco SynTec Oil Filters are the perfect upgrade when your customers need the best in filtration.

Derived from Supercars technology, they prevent contamination with 98.9% efficiency and are designed to withstand all conditions.

So when your customers need the power of performance filtration, be Ryco Ready.

When it comes to vehicle maintenance, oils and lubricants are rightly considered essential.

They reduce friction, protect moving parts, and ensure reliable performance.

But while we often focus on what’s happening inside the engine, we overlook one of the most crucial systems responsible for keeping it all together — the cooling system. Overheating is a silent killer of engines, and without effective diagnostics, flushing, and sealing solutions, even the best lubricants won’t save a motor from damage.

That’s where Irontite Cooling System

Sealer, Tee-Kay Head Check Combustion Leak Detector, and Irontite Thoro-Flush step in — three essential workshop-grade products designed to keep your cooling system operating at peak performance.

permanent protection

Available in 150ml and 375ml sizes, the Irontite Cooling System Sealer offers a fast, reliable way to seal leaks in radiators, heater cores, head gaskets, and other cooling system components.

Unlike conventional sealers that may clog small coolant passages or break down over time, Irontite uses non-vegetable-based synthetic fibres that form a permanent seal on contact with air or combustion gases — without the risk of blocking the system.

Critically, Irontite’s sealer contains no soluble oils, protecting rubber hoses, water pump seals, and cylinder liners from premature wear. Its anti-corrosive properties help prevent rust in systems composed of cast iron, copper, bronze, or aluminium, extending the life of the engine.

Modern engines run hot and lean, and their cooling systems need to be efficient and leak-free. Irontite’s advanced formulation ensures you don’t just plug a leak — you restore confidence in the entire system.

Sometimes, the source of an issue isn’t visible.

A cracked cylinder head, failing head gasket, or a porous engine block can cause coolant loss, overheating, and hard starts — but these faults can be difficult to confirm without disassembly. The Tee-Kay Head Check Combustion Leak Detector solves this with speed and precision.

By analysing gases in the air pocket above the radiator coolant level, the

detector reveals the presence of CO2 — turning the test fluid yellow in petrol engines and green in diesel engines. This colour change gives you a clear diagnostic result without having to tear down the engine.

Ideal for post-repair verification, routine diagnostics, or pre-tune-up checks, the Tee-Kay Head Check is compatible with petrol, diesel, and LPG engines, and is supported with available spare parts to keep it operational in busy workshops.

A compromised cooling system doesn’t always result from a leak. More often, it’s rust, scale, grease, and sludge that slowly choke performance. The Irontite Thoro-Flush (455ml) is an industrial-grade cleaning agent that aggressively removes internal build-up without damaging plastic or aluminium components.

By restoring proper coolant flow and

The Tee-Kay Head Check is ideal for tasks like post-repair verification, routine diagnostics, or pre-tune-up checks.

heat transfer, Thoro-Flush helps prevent localised overheating, a major contributor to head gasket failure and engine distortion.

It’s ideal for use during routine service or prior to applying the Irontite Sealer to ensure maximum system cleanliness.

While oils and lubricants keep engines running, it’s a clean, sealed, and wellmaintained cooling system that keeps them alive. Products like Irontite Cooling System Sealer and Thoro-Flush work proactively to prevent failures, while the Tee-Kay Head Check provides the clarity needed to make confident repair decisions.

In an age of high-performance engines and tighter tolerances, proactive cooling system care is no longer optional — it’s essential. And with the Irontite and Tee-Kay solutions available through Warren & Brown Tools, professionals and enthusiasts alike can take that extra step to protect what powers their passion.

Protect the engine. Diagnose the hidden. Clean the system.

That’s smart motoring — beyond oils and lubricants.

Check out wbtools.com.au for more tools and info

If they’re good enough for Supercars, they’re good enough for the average Aussie motorist.

Ryco SynTec Oil Filters remove a near-perfect 99.8 per cent of contaminants.

When it comes to upgrading your service, no one does it better than Ryco, with filter technology derived directly for their work with Supercars.

Ryco’s SynTec technology is put to the test every race weekend, and they’re what Supercars trust for their vehicles.

Having proven effective on the racetrack, Ryco know that drivers looking for the best will want to take this technology straight into their everyday.

But what makes Ryco SynTec the best in oil filtration?

To put it into perspective, standard Ryco Oil Filters have a 35-micron rating, which is a great rating and comparable to most OE oil filters.

The Ryco SynTec Oil Filters however have a 20-micron rating, which filters finer dust and dirt.

This means that between services, your customer’s engine is better protected with more contaminants being filtered.

This is because Ryco SynTec Oil Filters incorporate high efficiency media designed to remove 99.8 per cent of contaminants while ensuring maximum oil flow.

This exceeds OEM specifications which will help keep an engine running smoothly until the next scheduled service.

Engineered, developed, and tested in our dedicated filtration laboratory, the Ryco SynTec Oil Filters offer a premium upgrade

delivering high efficiency filtration without compromising flow.

The future of filtration is exciting with Ryco, as the team has built on filtration developments made with Supercars, with new passenger vehicle applications always being added to the extensive range.

For more information head to the Ryco website rycofilters.com.au and use the filter finder to find the fight Ryco SynTec for your customer’s vehicle

Tighten with Total Confidence with WB Tools’ Precision Screen Micrometer Torque Wrenches Unmatched Accuracy. Exceptional Visibility.

Transform the Way You Work

WB Tools’ Screen Micrometer Torque Wrenches bring clarity and confidence to every turn. Featuring a precision-engineered convex screen, these wrenches magnify your torque setting—displaying a single, easy-to-read value. That means no guesswork, no secondguessing—just precision you can count on. Whether you’re in automotive, aviation, manufacturing or heavy industry, this is the gold standard in torque accuracy, usability, and durability.

Why Trades Rely on WB Tools’ Screen Micrometer Torque Wrenches:

• Unmatched Accuracy

• Precision tolerance of ±4%, built to meet international torque standards

• Convex Screen for Enhanced Visibility

• A magnified lens gives a crystal-clear reading—virtually eliminating setting errors

• Secure Locking Mechanism

• Lock in your setting to prevent accidental changes during use.

• Durable Ratcheting Head

• Built for clockwise tightening—reliable, e cient, and made to last

•

Ergonomic Grip

• Comfortable, non-slip handle designed for long shifts and repetitive use

Last year, Supercheap Auto celebrated a milestone, ten years of Best Performing Oils. A decade of performance, protection, and a whole lot of engine-loving energy.

When the campaign launched back in 2014, Supercheap Auto set out to do something different. The goal wasn’t just to talk about oils, it was to celebrate them.

The result?

Best Performing Oils. A campaign that has since become a mainstay on the calendar for mechanics, car lovers, and motorsport fans alike.

The mission was simple: bring together the highest-performing oils across Australia’s most trusted brands and show how good they really are. But from the very beginning, the intent was never just about specs and viscosity charts.

It was about making oil fun, memorable, and worth talking about.

And over the years, they’ve done just that.

Who could forget the adrenaline-pumping antics of ‘Country Club Chaos’, where five

cheeky valets raced, drifted, and jumped high-performance cars around the fictitious Redline Country Club. This high-octane film featured appearances from Supercars drivers like Russell Ingall, Shane van Gisbergen, and Chaz Mostert, as well as rally driver Molly Taylor, DJs Carl Cox and Bombs Away, and YouTube personalities Marty & Moog from Mighty Car Mods.

Stardom

Rewinding to 2017, Supercheap Auto went full Hollywood with “Octane Island,” a cinematic spectacle featuring 12 race cars, eight months of production, and even a cameo by Hollywood star Danny Trejo.

Shot across three countries, this actionpacked campaign showcased the best performing oils in a high-octane adventure that set a new benchmark for automotive advertising in Australia.

And just last year, the campaign took a scenic turn with “Lake Redline Holiday Park,” transforming a lakeside track into a battleground for the best camping spot.

Supercars stars like Broc Feeney, Al Butler and Will Brown joined forces with

icons such as Craig Lowndes and Grant Denyer, bringing the holiday hijinks to life with drifts, jumps, and a whole lot of engine revving.

These campaigns weren’t just entertaining; they were backed by the real deal.

Best Performing Oils has always featured high-quality, top-selling oils from brands like Castrol, Penrite, Nulon, Mobil and Valvoline.

Over the years, these brands have consistently brought their A-game, whether it’s new-generation synthetics, dieselspecific blends, or everyday oils built to handle the demands of modern engines.

But behind all the characters, high-stakes challenges, and tongue-in-cheek humour, there’s a serious message that’s never changed: the right oil matters.

From trade-sized quantities to easy ordering with their barcode scanner or handy website reordering tools, Supercheap Auto Trade make it simple to get the right oil quickly, so you can spend less time sourcing stock and more time servicing your customers.

Over time, Best Performing Oils has

become more than just a campaign. It’s evolved into a platform for education, product discovery, supplier collaboration, and most importantly, super deals on some of the most trusted oils in the market. It’s helped mechanics and workshop teams navigate changing specs, choose the right oil for every job, and stock up with confidence.

Over ten years, the Best Performing Oils campaign has grown from a clever idea into an annual event. It’s driven awareness, sparked conversations, and helped customers understand the real-world value of premium oils. And it’s also become a powerful platform for our suppliers to showcase innovation and reinforce trust, while having a bit of fun along the way.

Of course, none of this would be possible without the support of Australia’s automotive community. You’ve watched the stories unfold, engaged with the content, stocked up on the featured oils, and helped shape the campaign into what it is today.

After ten years, it could’ve been the

Adrenaline-pumping action has been at the heart of Supercheap Auto’s messaging when it comes to oils.

For decades, Supercheap Auto has had the best in oils at motorists’ fingertips.

perfect moment to take a victory lap. But that’s not how Supercheap Auto operates.

Year 11 is already revving up, and something new is in the works.

Expect new faces, new challenges, and the same commitment to championing quality oils that perform when it counts.

So, whether you’ve been following since year one or only caught on during last

year’s chaos at the caravan park — now’s the time to get ready.

Because Best Performing Oils is far from over.

Keep your eyes on the dipstick. The next chapter kicks off soon.

Check out the full oil range at trade.supercheapauto.com.au

ealed Performance Batteries (SPB) is powering up its national expansion, setting sights on tropical North Queensland.

SFollowing the recent opening of a new branch in Perth, SPB has expanded with the acquisition of the Casey’s Battery Centre Group, which includes Casey’s Battery Centre Cairns, CTI Batteries in Townsville, and CTM Batteries in Mackay.

This significant milestone not only marks a new chapter for SPB but also promises enhanced service and access to premium battery solutions for the communities of North Queensland.

For 27 years, Mike and Jenny Casey have built a highly regarded name in the region, establishing a reputation for exceptional service and strong community ties in Cairns, Townsville, and Mackay. SPB is proud to announce that this acquisition — effective July 1 2025 — will continue Casey’s Batteries’ renowned service model, ensuring a seamless transition and the consistent, reliable support that customers have come to expect.

Furthermore, SPB has employed all existing staff across the three sites, guaranteeing that local expertise and familiar faces remain to provide the ongoing, excellent service customers are used to.

“Mike and Jenny have done an incredible job building Casey’s Battery Centre Group, and we are incredibly excited to welcome Casey’s Batteries into the SPB family,” SPB Managing Director Greg Roberts said.

“Their outstanding reputation for service and deep community ties over the past 27 years aligns perfectly with our own values.

“Our priority is to ensure a seamless transition for customers, and by retaining all existing staff, we guarantee that the local expertise and familiar faces customers trust will continue to deliver the excellent service they’ve come to expect.”

For local auto businesses and their customers, this acquisition means greater access to globally recognised battery products, such as ACDelco, Energizer, and Invicta, right at their doorstep, and all with the advantage of dealing with a familiar face from Casey’s Batteries.

SPB’s approach is more than just about logistics; it’s about building relationships. Its long-standing mission has always been rooted in providing tailored support and dependable service through a knowledgeable, adaptable team. That ethos is coming to life in North Queensland, where local staff, including those who previously served at Casey’s Batteries, will bring SPB’s values — respect, reliability, and excellence — to each interaction.

“Our investment in North Queensland is about more than just expanding our footprint; it’s about strengthening relationships and empowering communities,” Roberts added.

“We believe in providing tailored support and dependable service, and by embedding ourselves in these regional centres, we’re ensuring that North Queenslanders have constant access to the latest battery technology and expert advice, right at their doorstep.”

The decision to invest in the north also reflects SPB’s commitment to supporting Australian regions that are often underserved by large-scale distributors.

It’s an investment not only in infrastructure but in people — local jobs, partnerships, and customer success.

By embedding itself into these communities, SPB is ensuring that regional customers are no longer on the fringe of innovation and quality — they’re at the centre of it.

As the energy storage industry continues to evolve rapidly, SPB’s expansion signals a commitment to staying ahead of the curve while staying close to the customer. North Queensland now joins a growing network of SPB branches in Brisbane, Sydney, Melbourne, and Perth, that are reshaping how Australians access battery technology — from coast to coast. With quality products from ACDelco, Energizer, and Invicta, expert advice, and a dedication to service, Sealed Performance Batteries is set to power North Queensland forward — one connection at a time.

Sealed Performance Batteries can be found in the following North QLD locations: Cairns - 24 Donaldson St, Manunda QLD 4870 Townsville - 608 Ingham Rd, Mount Louisa QLD 4814 Mackay - Unit 5/38/42 Margaret Vella Dr, Paget QLD 4740 Contact us at 1300 001 772 | sales@spb.net.au | spb.net.au

Tested, proven and trusted, our lighting solutions are fit for purpose and offer reliability in all environments and conditions. We’ve sourced quality ranges and partnered with industry leading brands to ensure you can get the right parts. From driving lights, directional, clearance, beacons, truck and trailer lights, to workshop, utility, inspection lights and globes, we have everything you need to complete the job. NAPA IS YOUR SINGLE LIGHT SOURCE

More than parts, NAPA powers your performance. We make it our business to drive yours. Visit napaparts.com.au

As the auto industry’s leading member organisation in NSW and the ACT, MTA NSW takes great pride in providing the very best industry training for both new starters and stalwarts alike.

As one of MTA NSW’s expert trainers, program coordinator Alex Colvin stands as a leading example of the important part educators play in driving continued growth and success for Australia’s auto sector.

MTA NSW nominated Alex as NSW VET Teacher/Trainer of the Year at the NSW Training Awards, and recognises his

hard work and passion for training, which also includes a strong focus on training apprentices with special needs.

MTA NSW Operations Manager – RTO, Peter Klaack, explained why Alex’s story is so significant—and why MTA NSW has nominated the inspiring trainer and mentor for the industry’s highest honour.

“Alex joined MTA NSW in 2022 as a trainer for our automotive mechanical apprentices, and since then, he’s shown an incredible passion for both technical knowledge and mentoring,” Peter said.

Peter also noted that Alex has gone above and beyond to support students with learning difficulties.

Under his guidance, one student in particular, has achieved remarkable success; consistently completing their work and ultimately gaining their qualification.

As it turns out, this story is not uncommon when it comes to Alex.

Several other students with learning difficulties have also benefited from Alex’s mentorship; something that MTA NSW is keen to see recognised by the wider industry.

“Alex is an outstanding candidate for the NSW VET Teacher/Trainer of the Year award. “We are proud to have Alex as part of our team at MTA NSW and believe he is a great example of what passion, dedication, and commitment look like in the industry,” Peter continued.”

Australian Car Mechanic got the chance to talk to Alex and pick his brain about the current state of industry training, and his own personal philosophies when it comes to growth, development and excellence in the field.

Alex recently received the Award for the VET Trainer/Teacher of the Year in the Southern and South Western Sydney Region.

ACM: Thanks for chatting with us, Alex. As someone who has worked in the automotive industry for some time, how important is training to newcomers and established professionals alike?

Alex : One of my core beliefs as a trainer is that education should be personalised and engaging, which is why I’ve developed an approach that integrates my students’ personal interests into their learning.

For example, one of my students was passionate about playing guitar, so I connected mechanical concepts to guitar components, making the information more relatable and easily understandable.

By finding real-world connections that resonate with each student, I hope to make complex automotive concepts easier to understand and apply.

ACM: One of the core tenets of MTA NSW’s training approach is through engaging with apprentices one-onone in their employer’s own workshop. What impact does that have on training outcomes?

Alex : One major advantage of workplacebased training is that students feel more comfortable in their own environment rather than in a classroom.

This familiarity reduces anxiety and allows them to focus on their learning.

Additionally, I work with students who have learning difficulties, such as dyslexia, by adjusting my methods to suit their needs.

Whether that’s using more verbal instruction, breaking tasks down into smaller steps, or providing additional practical demonstrations, I always aim to create a learning plan that suits the individual learning styles and needs of each student.

There is no one-size-fits-all approach to learning, so when you tailor education to each student’s strengths, they are more likely to thrive.

ACM: How do you stay up to date with the latest technologies and training methods?

Alex : As a trainer, I am passionate about staying up to date with new training methodologies.

The quality of training my students receive directly impacts their careers, so I’m always looking for new ways to improve their experience and relationship with learning. This leads me to research

new approaches and consider how I can take my teaching to the next level.

At MTA NSW, we have a continuous improvement team dedicated to keeping training relevant.

I work closely with this team to ensure that the content I deliver is accurate, practical, and aligned with industry advancements.

I also share my knowledge with my colleagues, presenting at internal training events and mentoring other trainers.

Professional development is a core value at MTA NSW. This means that I often have opportunities to learn new skills or qualifications, refine existing expertise, and focus on areas where I want to expand my knowledge.

The automotive industry is incredibly broad, and as much as we may think we know, there is always more to learn.

ACM: In your opinion, what are some of the biggest challenges facing the industry right now?

Alex : One of the biggest challenges in the automotive sector is the rapid evolution of technology.

The progress is so fast that if you were to take some time off and return to the workplace, it would feel like you were entering a new world.

New advancements, particularly in electric vehicles and safety systems, mean that mechanics need to continuously upskill. This is where great training becomes invaluable. My training programs help address this by focusing on the latest industry developments and ensuring that apprentices are equipped with the necessary skills to work on modern vehicles.

As an organisation, we conduct research and ensure we have the right people guiding us so we can provide accurate information to both learners and employers.

This includes verifying the correct training and licensing requirements to keep our programs up to date.

At MTA NSW, we have a team of 42 trainers who continuously share feedback with our continuous improvement team and with each other to identify and fill any gaps in our training.

Every day, there is something new to learn, and there always will be. That is the exciting part of working in this industry.

ecord crowds have witnessed the best young trade skills do battle in Brisbane as the national competition wrapped up on the weekend.

The 2025 WorldSkills Australia National Championships & Skills Show has awarded the nation’s best young apprentices, trainees and students with more than 35,000 visitors in attendance and 600 competitors participating in 60 skill categories. These included auto mechanics, heavy mechanics, autobody repair and motorcycle mechanics.

The 2025 event was a high-energy celebration of vocational excellence — shining a national spotlight on the vital role trades and skills play in Australia’s economic future.

WorldSkills Australia CEO Trevor Schwenke thanked the partners including the Queensland Government, TAFE Queensland in raising he profile of vocational education nationally.

“This has been one of the biggest and best National Championships in our history — and a true celebration of what’s possible when young people, educators, government, and industry come together to back skills,” he said.

“Brisbane was an incredible host and it was fantastic to walk the floor and witness the outstanding level of competition, as the nation’s best young skills talent gave it their all. Their passion was inspiring and I’m sure many visitors are now considering where a vocational career could take them.”

Minister for Finance, Trade, Employment and Training Hon Ross Bates was also celebrating its success.

“I thank all whose collective effort ensured the tremendous success of this

event- further elevating the status of training and skills nationwide,” Bates said.

“I congratulate our latest medallists and all competitors who gave up their free time to hone their skills, and who put themselves forward to compete at the highest level, on the country’s biggest skills stage.

Blues win this round

New South Wales was crowned the overall winner, topping the medal tally with outstanding results across multiple categories.

Competitors who excelled in WorldSkillsrecognised international categories may now be selected to join Team Australia (“The Skillaroos”), representing the nation at the 48th WorldSkills International Competition in Shanghai, 2026.

Adelaide earmarked for 2027

The City of Churches has already been secured as the host for the 2027 WorldSkills Australia National Championships and Skills Show.

South Australia’s Education, Training and Skills Minister Blair Boyer said he had seen the International WorldSkills competition first-hand in 2024 which opened his eyes to just how significant this event is.

“These young people may not have had the chance to ever travel before and being part of a team, that recognises and values the work they do, is a fantastic opportunity,” he added.

“Hosting the 2027 WorldSkills National Championships and Skills Show is a huge vote of confidence in South Australia’s training sector.”

Lachlan Severn

Archie Babich

FEATURES & BENEFITS:

Significantly increased seal temperature resistance

(-60°C to 200°C & peak of 300°C)

Extensively lab and track tested

Manufactured in Europe according to IATF16949

Maintains seal integrity under challenging conditions

Superior longevity over standard repair kits

More cost-effective and sustainable over time

Less time spent rebuilding calipers

Extra peace of mind in racing or track-day situations

An automotive loss assessor (also known as a motor vehicle damage assessor or motor claims assessor) is a professional responsible for evaluating the damage to vehicles following accidents, determining fear and reasonable repair costs, and helping to resolve insurance claims.

This role is crucial in the automotive insurance industry. The assessor’s job involves inspecting vehicles, preparing detailed reports, and advising insurance companies on the extent of the damage sustained and the costs involved in repairing and/or replacing the vehicle should the vehicle be an uneconomical proposition to repair.

In certain countries, there may be slight variation requirements to be an automotive

Background and skills needed:

1. Automotive knowledge:

• In-depth understanding of vehicle construction, repair processes, and mechanical systems.

• Familiarity with the latest vehicle technologies, including electric and hybrid cars, is becoming increasingly important as these vehicles require different approaches to damage assessment and repair.

2. Insurance industry knowledge:

• Understanding of how the insurance industry works, including the terminology and processes around claims and liability.

• Knowledge of different types of insurance policies (e.g., third-party, comprehensive, etc.) and how they relate to vehicle damage claims.

3. Attention to detail:

• A key skill for an automotive loss assessor is being able to thoroughly inspect and document vehicle damage. This includes taking accurate notes, photographs, and sometimes even measurements of damage to ensure that the claim is processed fairly.

4. Communication skills:

• Ability to communicate clearly with all relevant parties: insurance companies, clients and repair facilities. This includes writing detailed reports and, at times, explaining complex damage assessments

Being able to clearly and accurately identify damage to a vehicle is a must-have trait of any automotive loss assessor.

to people who may not be familiar with automotive terminology.

5. Problem-solving:

• Assessors need to determine the full scope of damage and repair requirements. This might include identifying hidden or less obvious damage, which can sometimes require investigative skills.

6. Technical skills:

• Many automotive assessors use specialised software to estimate repair costs, determine parts pricing, and compile reports. Familiarity with these tools is important.

• The use of diagnostic tools for assessing vehicle damage, such as digital imaging or other technologies, is often required.

The educational path can vary depending on the region or country, but typically it includes:

1. High school diploma (or equivalent):

• While a high school diploma is typically the minimum educational requirement, a strong background in mathematics, physics, and technical subjects related to automotive systems is helpful.

2. Automotive qualifications:

• Many assessors have formal training in automotive technology or mechanical engineering. This could include a vocational qualification, certificate, or diploma in motor vehicle mechanics, automotive engineering, or a similar field.

• In some cases, a more specialized qualification such as a National

Vocational Qualification (NVQ) in vehicle damage assessment may be required (this is common in the UK).

3. Insurance industry training:

• Some automotive loss assessors may pursue courses or certifications related to the insurance industry, such as a CII (Chartered Insurance Institute) qualification, which is highly valued in some regions.

• There are also specialized courses in insurance adjusting and claims assessment that can complement automotive training.

4. Additional Certifications:

• Depending on the region, there may be additional certifications or licenses required to practice as an automotive loss assessor. For instance, in the UK, there is a certification body called the Institute of Automotive Engineer Assessors (IAEA), which offers training and certification for automotive damage assessors.

• Work experience: Many loss assessors start with experience as an automotive technician or in a vehicle repair shop to gain practical knowledge of how vehicles are repaired and the cost of repairs.

• On-the-job training: Some companies or insurance firms offer apprenticeships or entry-level roles where you can learn how to assess damage under the guidance of more experienced professionals.

• Specialised training: Continuing education or professional development may be needed to keep up with the rapidly changing automotive technologies and the evolving insurance industry standards.

• Vehicle damage assessment software: Software like Audatex and Glass Mate are commonly used for estimating repair costs and creating reports.

• Diagnostic tools: In some cases, assessors use diagnostic tools that can scan vehicles for mechanical and electrical issues, especially with modern vehicles that have complex electronic systems.

• Photography and documentation tools: Since much of the assessment work involves visual inspection, good photography skills and tools to document the damage accurately are crucial.

• Work environment: Automotive loss assessors typically work in offices, insurance company claims departments or may work remotely. However, the role often involves fieldwork, visiting accident

sites, workshops, or car dealerships to inspect vehicles.

• Job prospects: With the increasing complexity of vehicles, the demand for qualified loss assessors is expected to remain steady. Assessors with expertise in emerging vehicle technologies (electric vehicles, autonomous vehicles, etc.) may find additional opportunities as the automotive industry evolves.

tasks of an automotive loss assessor:

• Inspect vehicles to assess the extent of damage from accidents and/or natural disasters.

• Prepare detailed reports outlining the damage and repair costs.

• Liaise with insurance companies to provide necessary documentation for claims.

• Advise on whether a vehicle should be repaired or written off.

• Calculate repair costs and suggest the best course of action to both the insurance company and the vehicle owner.

• Ensure that the claims process is completed efficiently and fairly for all parties involved.

In summary, becoming an automotive loss assessor typically requires a combination of technical automotive knowledge, industry-specific insurance training, strong communication skills, and attention to detail. It’s a role that combines technical expertise with customer service, making it an essential part of the insurance and automotive industries.

The role of an automotive Loss Assessor

In Australia and New Zealand, the role of an Automotive loss assessor (or motor vehicle damage assessor) shares many similarities with other regions but also has some country-specific considerations. Let’s break down the requirements for both countries, along with the role’s involvement in legal court proceedings.

Automotive Loss Assessor in Australia and New Zealand

While the specific qualifications can vary depending on the region and employer, here are the general requirements for becoming an Automotive Loss Assessor.

Australia:

• Year 12 completion (HSC, VCE etc): A strong foundation in subjects such as mathematics, physics, and technical studies is advantageous.

• Vocational Education and Training (VET): Completion of a VET qualification, such as:

– Certificate IV in Motor Vehicle Mechanical Technology or

– Certificate IV in Insurance Broking (for those entering the claims side of the business).

For assessing vehicle damage, Certificate IV in Insurance (General Insurance) or Certificate IV in Automotive Mechanical Diagnosis might be required to gain industry-specific knowledge.

• Automotive Qualifications: A qualification in Automotive Cert III, in Automotive Body Repair and Refinishing Technology, Automotive Technology or Mechanical Engineering is beneficial to understand the mechanics of the vehicles you’re assessing.

• Insurance Industry Training: Many assessors also pursue additional training in insurance, including qualifications from the Australian and New Zealand Institute of Insurance and Finance (ANZIIF). For example, the ANZIIF Certificate in General Insurance or the Associate of the Australian and New Zealand Institute of Insurance and Finance (ANZIIF) can be helpful.

New Zealand:

• Secondary Schooling: Like in Australia, a good foundation in technical subjects is helpful, especially those related to automotive systems and mathematics.

• New Zealand Qualifications Framework (NZQF): You can pursue certifications in automotive and mechanical fields, like the New Zealand Certificate in Automotive Engineering (Level 4). Specific qualifications focused on vehicle damage assessment can help.

• Insurance Qualifications: The NZ Institute of Insurance and Finance offers certifications that focus on motor claims and insurance adjusting, such as the NZ Certificate in General Insurance.

• Many assessors start their careers in vehicle repair or mechanical work, where they gain the practical knowledge needed to assess damage accurately.

• Some companies offer on-the-job training, apprenticeships, or internships where you can develop your skills under the supervision of experienced assessors.

• Automotive knowledge: Familiarity with vehicle repair processes, automotive technology, and how to identify the cost and extent of damage.

• Insurance understanding: Knowledge of insurance policies, claims processes, and regulations governing motor insurance.

• Attention to detail: Ability to document damage precisely and create reports that

reflect all aspects of the damage.

• Communication skills: Being able to clearly explain the details of a claim to clients, insurance companies, and repair shops.

• Technical proficiency: Proficiency with assessment software like Audatex, Estimage, iBodyshop and Crashzone are tools for assessing vehicle damage.

In both Australia and New Zealand, an automotive loss assessor might be involved in legal proceedings, especially when claims become contested or there is a dispute regarding the extent of damage, repairs, or insurance payouts.

• Expert witness: In legal disputes involving motor vehicle damage, automotive loss assessors may be called upon as expert witnesses. In this role, they would present evidence about the damage, the cost of repairs, and whether the repairs are consistent with industry standards. This could happen in civil court or small claims tribunals and district court subject to claims value, when the parties involved cannot resolve the issue amicably.

• Court-ready reports: The assessor may need to provide a detailed, objective, and independent report, which can be used in court to support an insurance claim or counterclaim. The report should be thorough and contain clear explanations of the damage, repair estimates, and relevant industry standards.

Legal and ethical standards:

• Assessors must follow strict ethical guidelines to ensure their reports are unbiased and based solely on facts.

• They must ensure that they are compliant with the Australian Consumer Law (ACL) when assessing damage, particularly regarding fairness in evaluating repairs and costs.

• Insurance fraud: If an assessor detects potential fraud in a claim (e.g., exaggerated damage or staged accidents), they are ethically bound to report it, and they may be called to testify in an investigation.

3. Insurance code of practice:

• In Australia, insurance assessors and claims handlers are required to adhere to the Insurance Council of Australia’s Code of Practice, which governs how insurers should handle claims, including motor vehicle damage assessments.

While a foundation of automotive knowledge provides the framework of an assessor, there are many other certifications required.

4. Certification & regulation:

• Motor Vehicle Assessors’ Certification: In some states, automotive loss assessors may be required to hold certifications specific to their role, and they may need to renew these certifications periodically.

New Zealand:

1. Role in legal court proceedings:

• Expert witness: Similar to Australia, assessors may be called to court as expert witnesses in cases involving motor vehicle damage claims. They can provide independent, objective opinions on the extent of damage, repair costs, and whether the damage is consistent with the reported cause of the accident.

• Tribunal disputes: If a dispute arises between a vehicle owner and an insurance company, assessors may be asked to provide reports or testimony in front of a disputes tribunal (for smaller claims) or in higher courts for more complex cases.

2. Legal standards:

• Fair Trading Act 1986: In New Zealand, automotive loss assessors are expected to adhere to consumer protection laws under the Fair Trading Act, which prohibits misleading and deceptive conduct in business dealings.

• Privacy Act: Assessors must also ensure that any personal or vehicle information they collect is handled in compliance with the Privacy Act 2020.

3. Insurance Code of Practice:

• The Financial Services Complaints Limited (FSCL) provides guidelines on how claims should be handled fairly. Automotive assessors must be familiar

with these codes to ensure their assessments comply with the standards set by both insurers and regulatory bodies.

• In New Zealand, assessors may be accredited by bodies such as the Insurance Council of New Zealand (ICNZ) or the Motor Trade Association (MTA) to confirm that they meet industry standards for damage assessment and insurance reporting.

Australia and New Zealand both have similar educational, experience, and certification requirements for becoming an automotive loss assessor. The role involves both technical and insurance expertise, and assessors must often engage with legal processes when disputes over vehicle damage arise. They may be called as expert witnesses in legal proceedings, particularly in civil court or insurance disputes. Therefore, assessors must not only be knowledgeable about Automotive Cert III, in Automotive Body Repair and Refinishing Technology, Automotive Mechanics and insurance claims but also understand the ethical and legal responsibilities that come with the role, including adherence to consumer protection and privacy laws.

If you’re aiming for a career in this field, pursuing the relevant automotive qualifications, insurance industry certifications, and gaining experience with damage assessment software will be essential.

Note: If you wish to advance your qualifications to achieve a “Cert IV in Vehicle Loss Assessing” Qualification, you may apply to the IAME (Aust) who is qualified to perform a process via “Recognition of Prior Leaning” (RPL).

- Built for every garage, engineered for every challenge

Launch’s Powerlift Tyre Changer Series steps into demanding workshops with three standout models - the PLC-501, PLC-502A, and PLC-602ADL - each designed to meet the distinct needs of workshops, from entrylevel garages to high-performance tyre centres.

This piece of equipment is a powerhouse tailored for high-volume, high-performance shops. Engineered with a leverless system, this model minimises operator fatigue and damage risk to modern RSC and run-flat tyres.

It boasts a rugged build with a 5mm steel plate column, reinforced hexagonal shaft, and a class-leading 2800kg bead breaker force.

Dual-speed turntable rotation and an assist arm system with three-point pressing ensure fast, safe mounting and demounting even under demanding workloads. The PLC602ADL is also future-proof.

With optional tyre lifters and assist arms designed for maximum ergonomics and efficiency, it’s a serious investment in productivity. Despite its advanced features, it retains a sub-70dB noise level, reinforcing Launch’s commitment to workshop safety and comfort.

The PLC-502A raises the bar. It adds a tilt-back column with an assisting arm, enhancing ease of use with larger and stiffer tyres. With expanded clamping capabilities - handling rims up to 23” inside and a wheel diameter of 1120mm - it’s designed to cater to a wider range of vehicles. The improved rotation speed (6.5rpm) and dual voltage support (220V/380V) make it a more flexible and productive option for growing operations.

This tyre changer is the perfect entry point for workshops looking for reliable functionality without sacrificing safety or performance.

Designed with thoughtful details like turntable protective covers, a robust 2500kg bead breaker, and a mounting head built from special steel with a lifetime warranty, the PLC-501 brings professional features to the entry segment.

The precision of its pedal control system, along with reinforced safety components like wearable washers and rim guards, makes it a dependable asset in any setting.

What unites the entire Powerlift series is Launch’s consistent focus on durability, operator safety, and smart engineering.

Whether it’s the entry-level PLC-501 or the professional-grade PLC-602ADL, each machine reflects a deep understanding of the needs of the modern mechanic.

In a market crowded with tyre changers that overpromise and underdeliver, the Launch Powerlift series stands tall - not just as equipment, but as a strategic upgrade for any serious tyre service business.

For more information, check out

Unleash your vehicle’s potential with Penrite - trusted by Penrite Racing Supercars Team for unparalled reliability and performance on and off the track.

Needing power on the move? The DT4X4 may be the right solution.

l 1,512Wh LiFePO4 Battery (97Ah)

l 2,400W Pure Sine Wave Inverter (3,600W surge)

l Colour Touchscreen Display

l Wireless App Control with Wi-Fi Updates

l Turbo Boost Charging (up to 3,000W via 240V AC)

l Fusion Mode: Connect Two Units

l DC input via 15A socket, Solar, or Vehicle

l Solar Input: Up to 600W / 40V

l Flame-retardant UL94-V0 Housing

t’s no secret that NAPA is a go-to for specialist automotive needs in Australia.

With a vast product range, deep industry knowledge, and commitment to quality, NAPA ensures that you get the right parts, tools, and solutions for the job, every time.

With over 90 years of Australian heritage in automotive electrical and air conditioning expertise, NAPA has expanded to offer a complete aftermarket solution.

Whether parts for Air Conditioning, Electrical, Braking, Clutch & Driveline, Engine Cooling, Servicing & Consumables, Steering & Suspension, Tools, or Workshop Equipment, NAPA partners with leading and own brands to provide reliable, quality OE alternatives.

Combining these values is Drivetech 4X4 (DT4X4), offering a comprehensive range for off-road adventurers.

DT4x4’s lineup includes suspension lift kits, recovery gear, battery management, solar lighting, electrical solutions, and more. Developed in Australia, DT4X4 products withstand harsh conditions, delivering quality and durability.

DT4X4’s latest innovation is the Portable Lithium Battery Pack, designed for portable power needs. Featuring a 1,512Wh LiFePO battery with a 2,400W inverter (3,600W surge), it powers lighting, fridges, induction cooktops, or coffee machines. Whether deep in the outback or making remote repairs, this pack keeps your gear running.

Charging is adaptable: plug into 240V AC with a 3,000W Turbo Boost for rapid top-up, or charge on the go via DC-DC, solar panels (up to 600W), or a vehicle’s cigarette lighter. This ensures you’re never without power. Prefer to stay by the campfire? A dedicated app lets you monitor and control appliances wirelessly, and automatic over-the-air updates keep your unit current.

From remote technicians to serious 4X4 tourers, DT4X4 is more than a battery –it’s a campsite command centre. It’s one of many quality products at your local NAPA.

More than parts, NAPA powers your performance – visit napaparts.com.au for all the latest products

Your super partner in the motor trades Across the motor trade. Around Australia. For every workshop, team and business. We’re your Australian fund who cares about you, your business, and employees. Supporting you every super step of the way.

Scan the QR code to learn more

WORDS AND IMAGES: IAIN CURRY

A spectacular modified duo of Chevys, one on top of the other, shows the extreme talents of Queensland’s Dion Domin.

Summernats is the Big Dance for Australian car modifying, tuning and street machines, and the selfproclaimed “world’s largest horsepower party.”

Every Aussie in the car business should see our country’s largest automotive festival at least once, where you’ll experience some of the most spectacular high-dollar car builds imaginable, often in scorching Canberra summer temperatures. It takes a lot to stand out at this show. But Maryborough’s Dion Domin expertly

found a way with 8.5 metres of modified brilliance; his outlaw 1955 Chevrolet 210 Handyman wagon piggybacking on an equally madly modified tow truck – a giant 1977 Chevrolet Scottsdale dually (dual rear wheels) with modified 1949 Chevy pickup cab.

The scale of work here is off the charts. Both truck and car have been treated to full rebuilds, custom body work, highhorsepower engine modifications, air suspension and bespoke and brightly finished interiors.

“We ended up getting in the Summernats Elite Pavilion this year, and it had a bit of a crowd, which was really nice,” Dion said about his standout duo of vehicles. More than that, the two Chevys snared Top Exhibition award at Summernats 37; and such is the calibre of car build at this show, coming away with any sort of silverware is special indeed.

We caught up with Dion at Cooly Rocks On, another giant car festival on the NSWQueensland border, and his setup once

again proved quite the crowd pleaser. Let’s just say there was no way of getting people out of frame during our photoshoot – the truck and car were constant attentiongrabbers for festival-goers.

Starting with the tow truck, its face is hugely different to the late 70s Chevy hauler it’s based upon.

“It’s a C30 chassis that I bought from Portland Oregon, and they come out with more or less a square body,” said Dion. It’s far more curvaceous now, with beautiful

Legend on board: Outlaw 1955 Chevrolet 210 Handyman wagon piggybacks a modified 1977 Chevy Scottsdale dually with modified 1949 Chevy pickup cab.

lines for the rear wheel guards, tray ends and then, of course, to the immediate postwar front end.

The ’49 pickup’s chrome front end is a standout, but then so’s the colour scheme here. “I’m particular about colour and wheels; everything’s got to be right or it just won’t flow,” said Dion. His choice of hues may not be for everyone – for both truck and car – but Dion makes an important point about not being a sheep and sticking to your beliefs.

“I don’t take anyone else’s opinion; when it comes to cars it’s your own thing and you should stick to your decisions,” he said.

The pickup’s cab, doors, and bonnet colours match the tray’s, but bright yellow’s been used for the front and rear wheel guards. The interior? Well, that’s Fire Engine red. “That’s from a Dulux Duramax rattle can,” said Dion, “and I’ve used the same but in orange for the wagon. So of you scratch it, you’ve got a good chance of being able to quickly patch it up.”

It’s obvious Dion’s something of a perfectionist, and while exterior and interior paint looked exceptional to my eyes, he was still picking holes in it for not being 100 per cent. Little wonder it took around four years to complete the Chevy wagon’s build, and another three to do the pickup.

A huge amount of work went into the

Handyman’s immaculate body has been coated with Toyota colours: a Camry’s Sky Blue with Toyota Prius white for the pillars and roof.

front guards to have the giant wheels fit; the bonnet’s been completely hand modified, and the whole vehicle’s chassis was extended by around a metre.

“It’s got about a two-and-a-half metre overhang on the back, so all up it’s about 8.5 metres long including the bumpers,” explained Dion.

With the Chevy wagon on the back, the combined weight is about 5.8 tonnes.

To ensure the pickup could cope on modern roads, a 2006 Chevy Silverado 6.6-litre Duramax diesel engine’s been employed, mated to a six-speed Allison 1000 transmission and 14-bolt differential.

There’s a healthy 330 horsepower and chunky 660lb ft of torque to help with hauling.

Inside are SASS seats modified to fit and a half roll cage, while the tilt tray features beautiful wood-panelled built-in storage boxes.

There’s a winch to safely haul up the car, while the tilt tray neatly seesaws until the precious cargo is sitting flat.

Said cargo is the 1955 Handyman, finished in Sky Blue paint from a humble Toyota Camry, while the roof is Toyota Prius white. Setting it off are the acres of chrome for the grille, bumpers and trim, and you won’t miss the hefty 22-inch deep-dish wheels on the back, joining 20-inch ones up front.

Mad orange interior is very drag car-like using a B&M shifter and Racepak digital driver display. Seats are Nissan Skyline up front and folding Mitsubishi Pajero out back.

Brembo big brakes with six- and fourpiston calipers from a Porsche Cayenne sit behind, while it uses Ridetech bolt-on four-link suspension, replacing the ancient old cart springs.

Not only does it ride and handle properly now, but the lowered stance is deeply impressive.

“The car came from Arizona, and I bought it from an importer on the Gold Coast,” said Dion. “I bought it for my wife, and it’s set up like a drag car, but it’s a street car really so it’ll go around corners.”

Why the Chevy 210 Handyman? “We used to watch Home Improvement on television, and Tim had a Chevy Nomad,” said Dion. “I couldn’t afford a Nomad wagon as they’re way to expensive; the Handyman’s the more down-to-earth wagon.”

The work to turn it into an Australian outlaw-style high-performance standout has been phenomenal. The beautiful curved body is one thing, but move inside and the drag car inspiration’s clear with the roll cage,

metal door trim, B&M shifter, Racepak digital driver display and gauges in the driver’s door.

Dion’s completed a full right-hand-drive conversion, and the firewall incorporates a 1950’s fridge door “because fridges of this era have a really nice contour to them,” he said. The bright orange cabin’s roof has been signed by numerous well-respected modifiers and racers, while seats are modified 1992 Nissan Skyline chairs up front, and folding Mitsubishi Pajero ones in the rear to maintain the wagon look and practicality.

Where does he come up with such ideas? “It’s trial and error coming from my plans,” Dion said. “We used to be able to walk around the wrecker’s yard with a measuring tape, and just work out what might work and fit.” Hence why this Chevy now has a VR Commodore’s steering rack… it was one of the parts that worked.

The engine is a 388 cu in small block Chevy with Dart block and Holley Sniper Super Stealth injection. “That’s good for about 800 to 1250 horsepower,” said Dion, “the block’s good for about 1200

horsepower and the Garrett T38 turbos are good for about 1000 horsepower.” Massive numbers, but Dion’s not yet put his Handyman on the dyno to see what she’ll do, but he’s hoping for 650 horsepower at the rear wheels.

The hardware’s mighty. A forged bottom end, SCAT crank, Pride pistons, CNCmachined Aeroflow alloy heads, Edelbrock manifold, mandrel-bent three-inch exhaust with a crossover, Turbo 400 transmission and Ford nine-inch diff with 4.11 gears.

And to work with the airbag suspension and giant wheels, he had to raise the engine, transmission and diff up 100mm to keep things legal.

Yep, big dollar build here, but Dion’s been able to do the vast majority of the work himself. In fact, the ’55 Chevy never left his shed during its restoration and modification.

“I do all the stuff myself, because number one, I really can’t afford to spend $100 an hour for somebody else to do it,” Dion explained.

Impressive for a self-taught mechanic whose varied working life has seen him be

a baker, work in underground mines and for trucking companies. Seems he’s the kind of person who can turn his hand to most things.

While this Chevy Handyman’s performance is exceptional, Dion’s not about to hit the burnout pad at the likes of Summernats.

“I don’t like breaking stuff or thrashing cars,” he said.

“I like good acceleration, so I may take it to the track to see what it does over the quarter mile.”

After all the years of hard work, little wonder he’s not keen on damaging this incredible Chevy that’s hauled by an equally incredible tow vehicle.

“You’ve got to be addicted to this sort of work,” he said. “It absolutely fuels me, and I’m in the shed working most days.” As you can see from the results, it’s all been worthwhile.

The 30th Anniversary of Italy’s largest automotive aftermarket trade fair, Autopromotec, can best be described as an incredible success in showcasing Italian automotive equipment and accessory manufacturing and design expertise to the world.

After 60 years of growth for this primarily Italian manufacturer focussed, biennial trade fair, it is more than fair to say that as of May 21 to 24 this year, this show has now become one of the global leaders of our industry.

Rather than showcasing the brilliance of Italian design and engineering to a primarily Italian or European marketplace, this year’s Autopromotec trade fair saw more of the world take notice, with visitor attendances, global buyer and exhibitor participation and worldwide trade media taking part at record levels.

This four-day trade fair included a bumper schedule of industry leading seminars and training events, which saw several senior European and international automotive aftermarket industry identities take part.

The statistics following this year’s Autopromotec trade fair are very impressive. This 30th Anniversary event

became the biggest and best in the sixdecade history of this highly respected Italian trade show.

A total of 97,348 registered attendees took part, all making the trip to Bologna from 131 countries.