Whatever the job, wherever you are, whenever you need us. ROKBAK has you covered. Our haulers are built to take on the toughest jobs, so you can keep powering on, no matter what. Plus, our triple care package (3 years warranty, maintenance and telematics as standard) gives you the peace of mind you deserve. We take care of you, so you can take care of business. rokbak.com

“The

investment we have made in setting up the plants has paid off with our ability to sell around a million tonnes on a regular basis.”

ISSUE No.5 September/October 2025

05 COMMENT

Having far more in reserve.

06 INDUSTRY NEWS

The latest news and updates from Aggregates Europe – UEPG.

50 EVENTS

All the key events in the quarrying and aggregates world

08 MARKET REPORT

A look at the major players in the Eastern Europe quarrying and aggregates sector.

13 QUARRY PROFILE

How Liebherr GB is supporting UK operation Brookland Sand & Aggregates.

16 INTERVIEW

An in-depth look at how Smiley Monroe is expanding its operations.

20 INTERVIEW

Pablo Zambianchi discusses how Holcim Italy is embracing technology.

24 WATER RECYCLING

McLanahan and SunEnviro open the doors for a major industry open house event.

28 WATER MANAGEMENT

Through its latest case study, CDE showcases how it tailors solutions for the quarrying sector.

30 LOADING

The latest updates and innovations from global loading equipment manufacturers.

34 HAULING

From new haulers to successful case studies, hauling manufacturers take centre stage.

38 CRUSHING AND SCREENING

The latest equipment is unveiled in the crushing and screening market.

40 DRILL RIGS, ROCKBREAKERS AND HAMMERS

Rockbreakers and drill rigs are becoming increasingly prominent –with impressive results.

42 TYRES –2

The unsung heroes of the quarrying operation, the latest tyre developments are here.

44 DIGITAL SOLUTIONS

Volvo CE showcases its range of digital solutions for quarries.

46 FLEET MACHINERY

Develon’s machinery continues to impress.

48 CONEXPO-CON/AGG

The latest updates ahead of the North American trade show’s return in 2026.

HEAD OFFICE

Prime Global Publishing Capitol Square 4–6 Church Street Epsom, KT 17 4NR

EDITOR

Guy Woodford +44 (0) 7879 408 069 guy.woodford@primeglobalpublishing.com

ASSISTANT EDITOR

Adam Daunt adam.daunt@primeglobalpublishing.com

BUSINESS DEVELOPMENT MANAGER

Les Ilyefalvy +61 423 177 966 les.ilyefalvy@primeglobalpublishing.com

CHAIRMAN

John Murphy

CHIEF EXECUTIVE OFFICER

Christine Clancy

GROUP MANAGING EDITOR

Paul Hayes

CLIENT SUCCESS MANAGER

Janine Clements +61 432 574 669 janine.clements@primeglobalpublishing.com

ART DIRECTOR

Michelle Weston

COVER IMAGE CREDITS Rokbak

Holcim Italy Metso

Prime Global Publishing SUBSCRIPTIONS subscriptions@primeglobalpublishing.com

No part of this publication may be reproduced in any form whatsoever without the express written permission of the publisher. Contributors are encouraged to express their personal and professional opinions in this publication, and accordingly views expressed herein are not necessarily the views of Prime Global Publishing. From time to time statements and claims are made by the manufacturers and their representatives in respect of their products and services. Whilst reasonable steps are taken to check their accuracy at the time of going to press, the publisher cannot be held liable for their validity and accuracy.

PUBLISHED BY

Prime Global Publishing

AGGREGATES BUSINESS USPS: is published six times a year.

PRINT: ISSN 2051-5766

ONLINE: ISSN 2057-3405

PRINTED BY: Warners (Midlands) PLC

far

ow best to address declining aggregate reserves, which hinder the supply of vital building materials to infrastructure works, has long been a big topic of debate within the European aggregates industry.

As permitting for aggregate processing sites across the continent becomes increasingly complex, delaying vital new production, the supply of essential construction materials for key projects is becoming more challenging each year.

In August this year, a new report for the UK Government showing declining reserves of aggregates over two decades prompted fresh calls for urgent action if Britain’s ambition to build 1.5 million homes and future-proofed infrastructure is to be realised.

The Aggregate Minerals Survey 2023 (AM2023) is the latest four-yearly study, prepared by the British Geological Survey (BGS) for the Ministry of Housing, Communities and Local Government (MHCLG) that assesses the national supply and demand of aggregate to inform future mineral planning policy.

AM2023 shows that permitted aggregate reserves in Great Britain fell by 46 per cent between 2001 and 2023, which has been a trend also highlighted by the Mineral Products Association (MPA) which represents Britain’s aggregate producers.

The BGS report shows that total permitted reserves of aggregate in Great Britain (including sites worked in the past but still containing reserves and sites that have yet to be opened) at the end of 2023 were 5.106 billion tonnes (Bt). Crushed rock accounted for 90 per cent (4.589Bt) and sand and gravel the remaining 10 per cent (518 million tonnes).The MPA has said the proposed changes to the planning system meant to speed up new housing approvals will do little to halt the decline in permitted reserves of the materials needed to build them, including foundations, oors, walls, roof tiles, driveways, associated services and amenities.

According to MPA, aggregates continue to represent the largest material ow in the UK economy, comprising the vast majority of materials for all construction products and being the only bulk material to be sourced almost entirely domestically.

The MPA has called on the UK Government to renew its commitment to the long-established Managed Aggregate Supply System (MASS) that is intended to ensure a steady and adequate supply of aggregates for construction and industry. Yet the MPA believes consecutive governments continue to take aggregate supply for granted, while reserves continue to deplete.

“Aggregate Minerals surveys are a vital part of the Managed Aggregate Supply System. Failure to respond to the ndings of AM2023 would create a serious and costly risk not just to the minerals sector but also to the construction industry and the wider national economy, especially given that up to half of all aggregates are procured, directly and indirectly, by the government,” MPA executive director for mineral resources Mark Russell said after the publication of AM2023.

“As it stands, areas such as the south-east of England rely heavily on imports of materials from other regions in the country.

“The long-term planning for these supplies, along with the necessary transport and infrastructure for their delivery, is vital to economic development.

“Britain is blessed with a diverse geology, and while we understand the government’s focus on ‘critical’ minerals over recent years, it has undoubtedly taken its nger off the pulse regarding the bread-and-butter minerals that the economy, and in particular the construction sector, relies upon.”

What happens next in the UK will be closely watched by the wider European aggregates community. GW guy.woodford@primeglobalpublishing.com

Aggregates Europe – UEPGpublic a airs o cer Miquel Paris Coderch provides an update on the latest projects and activities from the association.

Every quarry tells a story of transformation. During their lifetime, extraction sites reshape landscapes, provide essential raw materials for society, and, when properly managed, create new habitats. These evolving environments can host a wide diversity of ora and fauna, contribute to ecological networks and support species that might otherwise struggle in highly fragmented agricultural or urban landscapes.

Far from being only industrial spaces, quarries can emerge as biodiversity hotspots and connectors, linking natural areas and reinforcing ecological resilience. To measure this contribution and to ensure it grows over time, clear and practical biodiversity indicators are needed. In this framework, the aggregates sector has a particular responsibility and opportunity: quarries, often overlooked in discussions about nature, can become key actors in delivering biodiversity bene ts.

It is with this ambition that Aggregates Europe launched in 2024 a European-wide

study to develop a framework of biodiversity indicators speci cally adapted to the extractive industry. Such initiative is the product of the cooperation of Aggregates Europe with the ROTATE Project, co- nanced by the EU Horizon Europe Research and Innovation Programme (GA – N°101058651), and led by Asociación Nacional de Empresarios Fabricantes de Áridos – Spanish National Association of Aggregates Business (ANEFA), Spanish Aggregates Federation (FdA), the University of Liège and Fundación Tormes.

The initiative aims to equip quarry operators and sites with tools that are both scienti cally sound and practical, enabling them to monitor biodiversity and ecosystem services, demonstrate progress over time, and ultimately engage with stakeholders.

The framework is structured in a three-level hierarchy: from a simple pre-assessment to more detailed environmental evaluations that require specialised knowledge.

This stepwise approach ensures that all operators, regardless of size or resources, can participate.

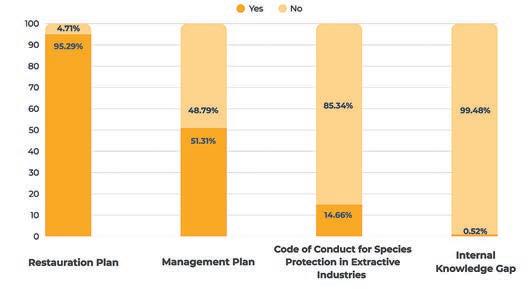

The rst milestone of this journey has been achieved with the completion of the Level 1 questionnaire, yielding exceptional results: 191 validated submissions from 12 different countries.

The Level 1 questionnaire was designed as a simple, practical starting point that any quarry operator can complete without needing environmental expertise.

It gathers basic yet essential information across ve areas: general data about the site; base data such as site mapping and its possible relationship to protected areas like Natura 2000; existing rehabilitation or biodiversity management plans; biodiversity practices including restoration, species inventories, monitoring activities, and invasive species control; and nally, ecosystem services, from agricultural use and forestry to community visits, education, and research projects. By bringing all this information together, the questionnaire provides a clear baseline picture of how quarries interact with biodiversity and their surrounding environment. It helps operators and associations to organise the knowledge they already have, highlight opportunities for improvement and prepare for more detailed monitoring in later stages. In doing so, it demonstrates that quarries can contribute not only as extraction sites but also as valuable spaces for nature, people, and society. For Aggregates Europe, this process is not only about data collection, but also about fostering a culture of biodiversity management across the sector, encouraging quarry operators to identify themselves as custodians of ecosystems as well as producers of essential raw materials. AB

Designed with a unique combination of power and intelligence the TA 230 features market leading technology, an innovative weighing system, automatic traction control, hill start assist, not to mention the superior cabin design to leave your operator feeling good. Simply put, a perfect mix of agility with outstanding performance.

It’s a Liebherr. Job done.

Quarry Manufacturing & Supplies (QMS)' 1000tph aggregate plant for Luscan Com, supplied

Increasing demand for building materials to deliver major infrastructure projects is making Eastern Europe an attractive region for quarrying equipment manufacturers and suppliers of aggregate, cement and concrete.

Metso senior sales manager of aggregates for Germany, Central East Europe and Ukraine Franz Zingl said aggregate demand across Eastern Europe is increasing “year after year”.

“This demand stems primarily from infrastructure projects in the transportation and energy sectors. Regionally, conventional construction, particularly industrial construction, is also noteworthy,” he said.

“Countries with ‘reasonable’ political stability are preferred for investment. Furthermore, project nancing in these countries, especially all fund-linked investments, is very well organised.”

Zingl said that the continuing crushing and screening plant purchases in Eastern Europe had made the region a growth market it is for Metso.

“The reason for investing in crushing and screening plants is the need for aggregates for the respective construction projects. At Metso, and especially we at the Metso Market Organisation for Central and Eastern Europe, are very proud of the sales and service organisation we have built in the eld of crushing and screening technology over the past decades,” he said.

“Absolute customer orientation and a clear focus on solution-oriented applications for our customers have been our goal for decades.

“Our growth year after year is in the double digits, with some countries even exceeding this mark.”

Zingl said that one Eastern European country is a great example of the tremendous business opportunities for Metso and other original equipment manufacturers (OEMs) in the quarrying sector. According to Zingl, the unspeci ed country has 700 kilometres (km) of highways under construction, with a rough equivalent distance being tendered. The same nation has around 300km of expressways under construction, and an additional 300km out for tender. Close to 1200km of railways are also being reconstructed and another approximately 1000km are being tendered.

“Multiple Metso Crushing and Screening equipment is in operation in those projects. Whether stationary, mobile, or portable, our supplied equipment plays a key role in the success of the projects and for our customers,” Zingl said.

Zingl said he is “very optimistic” about the future of the Eastern European aggregates market. “We will continue our current path and, if necessary, even expand further. Our conditions are optimal. Firstly, we have highquality crushing and screening equipment, including both mobile and stationary models. Secondly, our sales and service organisation is in place, allowing us to fully focus on our customers every day,” he said.

As reported in the last issue of Aggregates Business Europe, Metso has con rmed plans to expand its presence in Romania with a new screen manufacturing centre.

The move will expand the Finnish quarrying equipment giant’s production capabilities of stationary screens with a new centre in Oradea, Romania. This will ensure Metso can support customers in Europe, Central East Asia, and the Middle East with capital screening equipment and the supply of wear and spare parts, including rubber screening media.

Metso has estimated the facility will employ 70–80 people by the time the site is fully operational by the end of next year.

Remaining in Romania, Lintec & Linnhoff continues to provide solutions that support road construction ef ciency and environmental responsibility. A key example is the recent installation of a Lintec CSD1510 Asphalt Mixing Plant in Transylvania. Operated by Drumuri i Poduri SA Sibiu, a company specialising in road repairs and maintenance, the plant is playing a critical role in enhancing infrastructure near the historic city of Sibiu in central Romania.

Replacing an older and smaller unit, the new asphalt plant brings state-of-the-art technology and compact design to a site where space constraints once limited production capacity. The Lintec CSD1510, with a capacity of 120 tonnes per hour (tph), was reportedly selected for its proven ability to deliver high-quality asphalt with outstanding energy ef ciency and environmental performance. At the heart of the CSD1510 is its fuel-optimised Screen Drum Technology, which ensures sustainable energy usage without compromising output.

An integrated hot storage tower enables seamless asphalt supply, even in high-demand conditions, while the advanced dust processing system recovers ller material, further reducing waste.

A standout feature of this installation is its 100 per cent electric heating systems for both the tower and bitumen tanks, as well as the accompanying bitumen emulsion plant. Later this year, the system will be connected to a solar panel array, enabling a portion of the plant’s power consumption to be met with renewable energy which is a crucial step toward more sustainable asphalt production.

Drumuri i Poduri SA Sibiu general manager Mihai Lisan said the plant’s performance had been impressive.

“The Lintec CSD1510 has exceeded our expectations, particularly in terms of fuel ef ciency and product consistency. Its innovative features have allowed us to upgrade our operations signi cantly, without expanding our footprint. We’re proud to lead the way in adopting cleaner, smarter road-building solutions,” he said.

This is not the rst time a Lintec asphalt mixing plant has contributed to Romania’s infrastructure development.

At a production site located approximately 100km from Bucharest, a Lintec CSM3000 Containerised Asphalt Mixing Plant was installed in 2021 to replace a long-serving Lintec CSD1500 that had operated successfully for over 12 years.

While the CSD1500 had delivered excellent results with its 120tph output, growing demand prompted the customer to upgrade to the CSM 3000, which offers double the production capacity and ensures continued operational ef ciency.

The success of this project builds on Lintec & Linnhoff’s growing presence in the region, with another 160tph plant recently delivered to the city of Târgovi te. The company’s reputation for quality and technical excellence continues to attract operators looking for future-ready solutions in demanding environments.

Next steps in Poland

Heidelberg Materials has started operations at its new industrial pilot facility for enforced carbonation in Góra d e, Poland. This marks the next step in the large-scale implementation

A VSK Minerals’ site deploying a Metso C130 jaw crusher, VG540-3V scalping screen, an HP300 cone crusher, and four CVB screens.

of Heidelberg Materials’ patented ReConcrete process, which leverages new potential in the production of sustainable building materials by combining circularity and decarbonisation. The new facility in Góra d e processes recycled concrete paste (RCP) recovered at the company’s rst-of-its-kind recycling plant in Katowice, Poland. RCP naturally absorbs and permanently binds CO2, thereby acting as a carbon sink. To accelerate the natural process, the RCP undergoes enforced carbonation.

This process involves exposing the RCP to exhaust gases from the kiln in Góra d e, allowing CO2 to bind within the material chemically. Once carbonated, the RCP can be used as a supplementary cementitious material (SCM), partially replacing energy-intensive clinker in composite cements.

“Scaling ReConcrete is an important step for us in unlocking new ways to reduce the carbon footprint of our products,” Heidelberg Materials chief sustainability and new technologies of cer Dr Katharina Beumelburg said.

“At the same time, it is an excellent showcase of our integrated approach to sustainability – we can now combine circularity and resource ef ciency with decarbonisation, leveraging RCP’s natural ability to bind CO2 .”

The process has the potential to reduce CO2 emissions by approximately 900–1000kg per tonne of RCP used. This total includes 100–150kg of CO2 that is permanently bound during the carbonation of RCP, and an additional 750–850kg of CO2 emissions that are avoided by replacing clinker with carbonated RCP in composite cements.

“I’m proud of our teams for successfully bringing ReConcrete to life, which marks a signi cant milestone on our journey to closing the CO2 cycle in cement production,” said Heidelberg Materials member of the managing board Jon Morrish said. “With the collective strength of our local team and central [research and development] functions, our accomplishment in Poland will serve as a blueprint for similar projects across the Group as we continue to expand our circular and low-carbon product offering for our customers.”

In July 2024, Heidelberg Materials launched the rst phase of the large-scale implementation of ReConcrete by opening an innovative recycling plant for selective separation in Katowice, Poland. This pioneering facility features a proprietary crushing mechanism that enables advanced separation and sorting, allowing for the complete recycling of old concrete into its original constituents. The fractions obtained include sand and gravel of the highest quality, equivalent to that of virgin raw materials, with RCP as the nest fraction.

Heidelberg Materials will now focus on conducting operational trials and evaluating the technology under industrial conditions. The company’s pilot facility is part of the international “Carbon4Minerals” research and development project, carried out by a consortium of leading scienti c, technological, and industrial partners across Europe. The project is co-funded by the European Union and by the Swiss State Secretariat for Education, Research, and Innovation (SERI).

Cemex signs on

Earlier this year, Cemex signed an agreement with EDP Energia Poland to construct solar installations at several of its plants in Poland, with a total capacity exceeding 14 MWp, thereby furthering its commitment to environmental sustainability. This investment is part of Cemex’s global Future in Action strategy to combat climate change.

“Cemex sets ambitious decarbonisation goals, and investing in renewable energy is an important step towards reducing emissions. The concluded agreement is important in this context because it will guarantee us access to green energy in the long term. Additionally, the mentioned contract will enable the diversi cation of energy sources powering our plants,” Cemex Poland Regional Energy Negotiator Michał W glorz said.

Adding to an established photovoltaic (solar) farm at its ready-mix concrete plant in Pruszków, Cemex is building new photovoltaic installations at the Chełm, Rudniki, and Gdynia cement plants and the concrete plants in Mysłowice, Warsaw Annopol, Lublin, Szczecin, and Gda sk.

“The photovoltaic installations are being gradually commissioned in accordance with the formal, legal, and engineering processes. Currently, we have completed four additional installations in the Materials Division and are awaiting two more. Investments at the cement plants will be implemented in 2026 and 2027,” a Cemex spokesperson said.

The project is being carried out in collaboration with EDP Energia Polska under a 15-year agreement. EDP will install and manage

the solar installations, providing clean energy to Cemex’s network of facilities.

“We are glad that Cemex Poland, as a leader in its industry, has chosen photovoltaic solutions from EDP to implement its ambitious decarbonisation goals. This cooperation is part of our mission to support the energy transition and provide clean energy for every type of industry,” EDP country lead for Poland Ireneusz Kulka said.

In the Czech Republic, Cemex recently supplied materials to a restoration project for one of the most important historical monuments in the city of Pardubice.

The work at Pardubice Castle includes the restoration of the northern palace, the construction of a new visitor centre and the creation of a new natural history exhibition of the East Bohemian Museum in the former farm buildings.

Cemex is closely involved in these major modi cations, including supplying cement cast screeds for the oor structures of the future Natural History Museum. The new ballroom is scheduled to be completed by the end of next year, and the visitor centre and nature exhibition are expected to be completed by 2027.

As reported in the May-June 2025 issue of Aggregates Business Europe, demand for Russian aggregates has been relatively healthy despite international economic sanctions and the country’s complex business environment.

According to Aggregates Europe (European Aggregates Association) estimates, Russia’s 1485 extraction sites produced a combined 857 million tonnes of aggregates in 2023, by far the largest single-country volume in Europe, with Germany’s 546 million tonnes produced that year, a distant second.

Russia’s major aggregate companies include JSC LSR. Basic Materials, JSC First Aggregates Company, JSC Bashkiravtodor, JSC Kiembaevsky Mining and Processing Plant Orenburg Minerals, and JSC Sibagropromstroy. Most aggregate production is concentrated in the Russian Urals region. LSR Basic Materials (LSR), a leading player in the Northwest Russia aggregates market, estimates its annual capacities at over seven million cubic metres of crushed stone and more than eight million cubic metres of sand.

Showing con dence in mid- to longterm national aggregate market demand, the company plans to further increase these gures in the coming years by expanding its existing agship quarries and mines, as well as opening new sites.

Heidelberg Materials Kunda AS managing director Riho Iskül and Association of Construction Materials Producers of Estonia Marina Vaganova said Estonia, which borders the Baltic Sea and the Gulf of Finland, has seen a signi cant decline in its aggregate demand.

“While just a few years ago the volume of limestone and dolomite extraction exceeded two million cubic metres per year, by 2024

it had fallen by nearly 50 per cent, reaching around 1.4 million cubic metres,” they said.

A similar trend is seen in gravel and sand extraction, which, though still large in absolute terms (over seven million cubic metres), has not shown growth compared to previous years.

“The main reason is the sharp decline in state-funded infrastructure projects, particularly in road and railway construction. Since the largest consumers of aggregates are major infrastructure developments, the reduction in public investment volumes has directly led to a signi cant fall in demand.”

Iskül and Vaganova said the demand for aggregates in Estonia is likely to increase in the coming years.

“One of the main drivers could be the EU-funded infrastructure project, Rail Baltica, which has fallen behind schedule, but the volumes going into groundwork are expected to grow soon. Additionally, the Government

has promised to allocate €270 million to the road budget, which will mainly be used for two major road sections: Tallinn–Pärnu and Tallinn–Tartu,” they said. “If this kind of annual increase continues, it will certainly stimulate the market. The year 2027 marks the start of a new EU funding period. Nothing is con rmed yet, but we can expect various defence-related constructions and associated infrastructure to emerge as well.”

Iskül and Vaganova said the Association of Construction Materials Producers of Estonia has been raising awareness of the value of local natural resources, while also working on projects that emphasise the use of domestic materials instead of imports, and promoting sustainability and the circular economy, such as via recycling construction waste for use in roadbuilding.

“This work has increased public understanding that aggregates are a strategic

resource and that local production reduces the environmental footprint associated with transport,” they said.

Iskül and Vaganova said sustainability is a top priority for Estonian producers. Estonian producers are also adopting a long-term perspective when planning quarry restoration, aiming to return the land to society with enhanced value, both ecologically and for local communities. To achieve this, extensive collaboration is undertaken with universities and research institutions.

Iskül and Vaganova said that automation and digitalisation in aggregates production have gained “strong momentum”.

“We have national support measures for such projects, which help companies develop a digitalisation roadmap and then begin implementing it,” they said.

“Initially, the focus has been on picking the ‘low-hanging fruit’, such as material dispatching, GPS-based monitoring systems, weighing, and electronic delivery notes, using the drones in surveys.

“We also see a growing need for continuous quality monitoring and remotecontrol solutions. At the same time, it must be acknowledged that when demand for aggregates is low, many investments are put on hold—waiting for better times.

“Certainly, a lot has already been done in this eld, and there are further plans. However, this sector will likely never be ‘ nished’, it will continue to evolve.” AB

Liebherr Great Britain machines are well-proven winners for Brookland Sand & Aggregates in Cornwall, south-west England.

For many modern operations, purchasing new equipment is often seen as reaching a pinnacle in their business’ development, obtaining the most modern, fuel-ef cient kit with a full manufacturer’s warranty and decent residual values when it comes to trading it in within a few years. For others, running a mixed eet of new and quality used machines offers a better balance for their operations and business.

Across the UK, there are very few privately owned quarrying operations that produce approximately one million tonnes of aggregates annually. One such company is Cornwall’s Brookland Sand & Aggregates (Brookland), who operate just north of St Austell, supplying the entire south-west peninsula with high-quality materials.

Where the company differs from similar out ts is that the material it produces comes from what is deemed waste material taken

from the adjacent China Clay pits, which dominate the landscape.

Marshall Cleave, the third generation of the family, is stepping into his father, Barry’s, footsteps to run the company.

“We take the material that the clay producers don’t use,” Marshall said.

“This can range from the nest of sand up to large rock armour-sized pieces, which means we have to be able to deal with a wide variety of material at any given time.”

Processing the sand and aggregates at the Cornwall-based operation requires a large and comprehensive eet of Kleemann and McCloskey International crushing and screening equipment, along with a state-ofthe-art CDE wash plant.

With this equipment, over 75 different grades of materials are regularly produced from the waste, with just a tiny fraction of unusable grit being rejected.

While the majority of the crushing and screening equipment has been purchased new, Brookland relies on a eet of used Liebherr excavators, wheeled loaders and a solitary dozer to handle over one million tonnes of material per year.

“Dad purchased the rst Liebherr wheeled loader back in the early nineties,” Marshall said. “At the time, we were running a variety of brands, but the new arrival quickly impressed us with its class-leading low fuel consumption.

“This is a very important factor to us as we are very keen to lower our environmental impact wherever we can.”

Purchased through Liebherr Great Britain’s used equipment department, it was the well-respected John Diggens who set the ball rolling for Brookland to build a eet currently standing at 24 machines, 16 of which are wheeled loaders.

The majority of Brookland’s work is centred around the main clay producing areas, with the material tipped at their central processing area where a pair of L 566 XPower and a single L 576 XPower loaders are stationed. These three machines handle incoming and processed material, loading the company’s small eet of articulated dump trucks (ADTs), which haul the product to the stocking area.

“It would be nice if we could have suf cient area around the processing plant to store and load our materials,” Marshall said. “Sadly, we are limited on space, but with so many operations on the go around the huge site, a centralised stockyard keeps the large volume of outgoing tippers away from the day-to-day quarrying operations.”

There are several other satellite processing points scattered around the quarry, where L 580 XPower and L 586 XPower loaders are in operation, handling both raw and processed materials. Concreting sand is one of the most popular products processed at the quarry, with Brookland supplying many of the batching plants across Cornwall and Devon with consistently high-quality material.

Recent months have seen the company supply a large volume of aggregates to the road improvements just a stone’s throw from the quarry gates on the A30.

“We have worked hard to make sure the aggregates we produce are consistent and of high quality,” Marshall said.

“The investment we have made in setting up the plants has paid off with our ability to sell around a million tonnes on a regular basis.” Around 60 per cent of Brookland’s nal grade product is collected by customers, with the remaining 40 per cent delivered by subcontractor trucks.

Away from the main operations, the company is removing one of the Clay Pit’s former tip sites. With an estimated 20 million tonnes of material in the pile, steady progress has begun to lower the imposing mountain of material at Goonbarrow, with Mick Howell operating a ‘new’ R 945 excavator.

Sitting on a pile of material feeding a Kleemann MOBICAT MC 120 Z PRO jaw crusher, Howell loads the mixed material into the large hopper of the crusher slowly and steadily to ensure no pieces of rock big enough to bridge the jaws are hiding in the material.

Producing a sand and 100mm down aggregate at around 60–80 tonnes per hour may seem slow for a crusher of this size, but with a small volume of clay still within the material, the slower speed ensures the feeder deck and jaws do not get clogged up.

“She’s a fair tool and far more powerful than my last R 946,” Howell said. “She has a fair turn of speed on her, too, and I have much more room in the new cab, which is far more comfortable, too.”

Howell is joined on this project by L 586 XPower operator Kev Mitchell, another longstanding Brookland employee. Mitchell’s role is managing the processed material, either ferrying it away into its relevant stockpile or loading trucks to deliver to the site.

“I really like the loader. It’s extremely powerful and very quick across the ground, which is handy when you have such a large site to cover,” Mitchell said.

“One of the most surprising things for me is the lack of fuel it uses. When I swapped from an equivalent-sized machine to the L 586 XPower, we noticed a huge drop in fuel consumption equating to around 100 litres per day doing the same sort of work.”

Marshall employs a team of skilled tters to maintain all of his equipment unlike many operations around the UK.

“We are pretty isolated from the rest of the UK here and have learnt to be self-reliant when it comes to maintenance,” Marshall said.

“Our team of tters is very experienced in handling almost any issues that arise with the Liebherrs. However, on those odd occasions where a laptop is needed, the team at Weston-super-Mare is always on hand to help. We get our parts delivered in exactly the same way a home-based tter would, making it easier for our team to keep on top of maintenance work.

Keeping in regular contact with John Diggens at Biggleswade, Marshall is always noti ed when ex-Liebherr Rental machines are up for renewal.

“We don’t have a strict replacement policy here and run machines until there is a suitable replacement coming from John,” he said. “Whilst most of our loaders are XPower models, we still have a 2008-year L 566 2 Plus 2 in the yard which is used as a back-up machine should a front-line loader need attention.”

To run this volume of new machinery would put a strain on any company’s nances. Taking the used option has allowed Marshall and his experienced team, led by quarry manager Bob Trise, to bene t from the exceptional fuel savings offered by the XPower loaders at just a fraction of the cost.

“We know the machines are coming from John, having been thoroughly inspected and looking good,” Marshall said.

“The ex-rental machines are always well speci ed and are available with reasonably low hours in some cases. Our relationship with John and Sarah Allen at Biggleswade is excellent; they are always making sure we are happy with the machines.

“The operators like them, they are as reliable as any other make, and we are saving in excess of £100,000 in fuel costs by running Liebherr machines.” AB

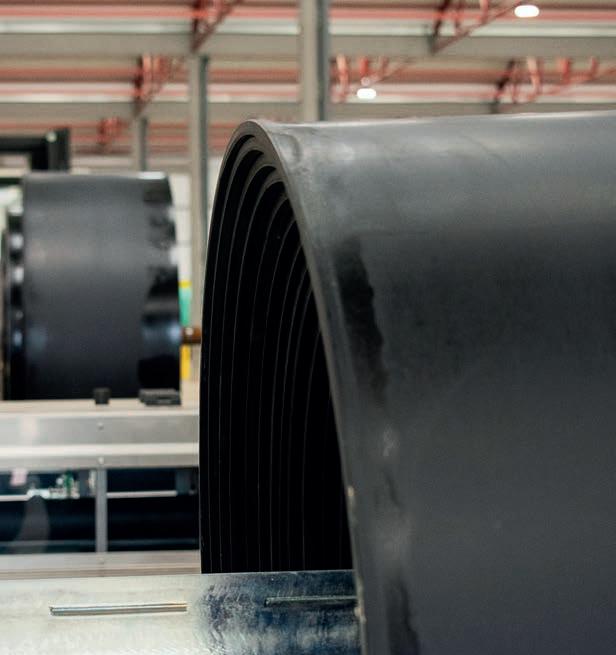

Global conveyor belt supplier Smiley Monroe Group has opened a new hub in the English Midlands in response to customer demand for faster lead times. Aggregates Business visited the new facility in Ilkeston, Derbyshire, and spoke to chief executive o cer Chris Monroe about the new hub and the ambitious company’s growth plans.

These are exciting times at Smiley Monroe Group. Chief executive of cer Chris Monroe is speaking with Aggregates Business Europe at the site of ce of the new conveyor belt hub in central England, a hub offering full conveyor belt rolls and cut lengths of belt with expedited delivery options available for customers in England, Scotland and Wales, including next-day delivery and same-day collection.

“The idea for the hub is one we’ve had for a while. The tipping point was the last two editions of Hillhead [the biennial quarrying machinery exhibition in Derbyshire, England], when we had customers asking us why we don’t have stock here on the ground,” he said.

“Those customers were typically service companies, and they weren’t giving us as much business as they could. Some of them couldn’t live with the lead time of two to three days across the Irish Sea.

“It became clear we needed to have a new [GB] stock and distribution model to better support the dozens of service companies we have across England, Scotland and Wales, who don’t have the space to keep huge amounts of stock.

“We chose a central England location for the hub after looking at the heat map of our [England, Scotland and Wales] service customer base and growing areas of demand, such as London and the south-east, which is particularly linked to recycling sector growth and waste handling. Those service companies are going to be very, very busy going forward.”

Smiley Monroe business development manager Jeremy Cross joined Monroe as he spoke to Aggregates Business Europe about the company’s journey.

“Our service company customers, including CSM Services and Rugeley Vulcanising Services in England, and Ace Vulcanising and Lining Solutions in Scotland, have long wanted to do more business with us, but were holding back because we didn’t have this conveyor belt hub. They are very loyal to us and, for the hub to work, we have to offer next-day delivery to job sites or, at the very least, the day after that,” Cross said.

With a wide array of at and chevron options available, the Northern Ireland-based manufacturer claims to hold the largest stock of conveyor belting across the UK and Ireland. Its range of premium conveyor belts and linked solutions includes Endless,

Chevron, Customised Cleated, ToughFlex, Fabric Breaker, Cut Length and EP Multiply conveyor belts, along with ZIP CLIP replacement conveyor belts.

The company also supplies highquality Cut Rubber and Plastic Parts, PU conveyor belt cleaners, and conveyor impact bars and skirting.

“Because we are working with all the leading [crushing, screening and conveyor] OEMs [original equipment manufacturers], we have such a variety of stock in Lisburn. We have already moved a lot of that material over here,” Monroe said.

“We can also quickly replenish stock in this hub. We are hiring three new staff for the hub and have relocated a team leader from our Lisburn head of ce. However, we’re conscious of keeping the hub lean and cost-effective for our customers.

“Over the years, we’ve invested a lot in our ERP [enterprise resource planning] system and have a stock management tool within that. We also have a very slick Epicor automated order acknowledgement system.”

Recognised by Lloyds Banking Group investment partner LDC, in partnership with The Times newspaper, as one of the top 50

most ambitious business leaders for 2024, Monroe said that the new English Midlands conveyor belt hub is part of Smiley Monroe’s future-focused plan to grow its UK business ve-fold, from £2 million to £10 million a year, by the end of 2028.

“It is a target we’ve carefully projected out. It’s a stretch, but we’ve seen the path to reach it,” Monroe said.

“The new conveyor belt hub is a millionpound-plus investment, supported by ongoing annual investment.”

Cross said the new hub will help Smiley Monroe serve many sectors including quarrying and aggregates.

“It’s hard to say, as all our service customers service many sectors, including quarrying. Our new hub stock range includes ToughFlex, which we introduced as a [heavy-duty] upgrade conveyor belt for the OEM market. It has proven successful in GB among our resellers, who visit operating sites and see that some end

customers require a conveyor belt offering a longer lifespan,” he said.

Smiley Monroe has a strong record in terms of sustainability and progressive working practices. In 2020, the team behind Northern Ireland’s only 100 per cent green energy supplier for businesses, 3T Power, partnered with Smiley Monroe to ‘green’ the company’s local electricity supply. This clean energy transition encompassed the rm’s 55,000-square-foot manufacturing facilities and administrative of ces, resulting in Smiley Monroe’s full Northern Ireland operation being powered purely by renewable energy generated by Northern Ireland-based wind turbines.

The expected annual CO2 reduction is around 270,000kg, equal to the weight of over

55 African elephants, in carbon offset. The Smiley Monroe-3T Power partnership is also guaranteeing long-term savings through a low-cost and secure energy tariff. In 2023, the company implemented a four-day work week across its two Northern Ireland production facilities, following a successful trial.

Since the move to a four-day work week, more and more Northern Ireland companies are adopting this approach, with successful examples demonstrated within Smiley Monroe’s customer base. Monroe said that the new conveyor belt hub will further enhance the company’s sustainability offering.

“We haven’t done the hard numbers on it, but logically speaking, the amount of logistics it will reduce by not having to send things across

the Irish Sea while consolidating a lot of required stock in one place makes it the right thing to do, both sustainability wise and commercially,” he said.

Founded in Northern Ireland in 1979, Smiley Monroe has grown from a local service company into a global conveyor belt partner, with manufacturing and distribution facilities in the UK, the US and India, supplying some of the largest equipment manufacturers across the construction, recycling, and environmental sectors.

ZIP CLIP replacement belts are hugely popular in the US market. Monroe said the company saw a bright future for the product in other markets like the UK.

“I see the potential for it. The plan is to work with our distribution service partners. As they become busier, they will only have a limited capacity unless they can scale up their companies. We have observed in our Northern Ireland services offering that it is becoming increasingly dif cult to recruit for that business area,” he said.

“I envisage having positive conversations with our GB distribution service partners to see if they can have some ZIP CLIPS in their own stock or offer their end customers bespoke, fast-delivery ZIP CLIPS to order.”

In 2026, Smiley Monroe will be exhibiting at major quarrying and construction equipment industry shows, including Hillhead (UK), steinexpo (Germany), CONEXPO/CON-AGG (US), and bauma CONEXPO India.

“We’ve had our busiest ever six months marketing-wise in America, doing a conveyor belt of different shows, including AGG-1 [St Louis, Missouri]. We are looking to supply more of our product range to US distributor companies. At CONEXPO/CON-AGG, we will mainly focus on [US] dealers and growing our ZIP CLIP business, which is currently around 60 per cent of our business there,” Smiley Monroe head of marketing Aimee McCracken said.

“ZIP CLIP is changing the conveyor belting industry. There just wasn’t a product like it on the market before,” Monroe said. “In America, the rst ZIP CLIP went out in 2020. We are only scratching the surface with it there. We are currently doing $2 million to $3 million in ZIP CLIP sales, but we can grow that by ve to six times. We’ve onboarded 30 to 40 dealers [in the US] in the last two years.

“We’re already doing business in 48 of America’s 50 States,” adds McCracken. “We’re also starting to supply (ZIP CLIP) to Central and Latin America.”

Monroe said the company had set ambitious long-term goals.

“The longer-term plan is for Smiley Monroe to triple its growth to £100 million [revenue] by the end of 2028. In the next 12 months, we’re committing over £1 million to belt-cutting technology. It will see the installation of new machinery in our production facilities in Northern Ireland, America and India,” he said.

“We are doubling our footprint in Hosur, India, and growing its sales team. We’ve won several signi cant contracts in India, which will kick in in the fourth quarter of this year.

We’re also expecting 50 to 60 per cent growth in India next year. There are also signi cant opportunities to supply our ZIP CLIP replacement conveyor belts to the rest of Asia, Africa and Australia from India.

“In Europe, we’ve won over the last 18 months in excess of £5 million of new contracts. That has been really helpful to offset a bit of a slowdown in the construction sector.

“All that new business is going to be massive for us. The shows coming up, like Hillhead and steinexpo, together with nurturing the £20 million to £30 million pipeline of leads we have, give us plenty to be getting on with out of our Northern Ireland-based business.”

Increased machinery automation and the growing use of arti cial intelligence (AI) in equipment engineering, manufacturing, and day-to-day on-site operations are notable features of the modern aggregates industry.

“We’ve set up an AI council to look at how best to use AI in all departments,” McCracken said. “Naturally, some departments have adopted the use of AI faster than others. We’re using it in marketing for different things, with some caution.

“When it comes to factory production, in the future, you’ll want automation and AI to be used as much as possible, reducing the amount of required process steps and increasing ef ciency.”

Monroe said the company had started investing in an AI, including an AI consultant, to understand how the technology could support its operations.

“AI can also help progress our conveyor belt [research and development], getting the belts smarter in terms of nding out where they are working, how they’re performing and their condition,” Monroe said. “Developing the software linked to this will be huge. Combining this and our ZIP CLIP solution will take our business to another level.”

Aggregates Business is a go-to source for up-to-date news and views on the European, Asian, African, Middle Eastern and American aggregates and building materials sectors. Our wide-ranging features line-up includes in-depth articles on the latest crushing and screening, loading and hauling machines. Subscribe today:

subscriptions@primeglobalpublishing.com

Holcim Italy’s Paolo Zambianchi talks to Aggregates Business about the critical importance of aggregate supply and why he is advocating the use of technology to optimise primary and secondary production.

Holcim Italy technical director of aggregates and ready-mix Paolo Zambianchi believes the current global geopolitical landscape has awakened politicians and policymakers to the critical importance of essential raw materials, including aggregates, and the need to secure their supply for the health of their nations.

“I have seen over the last 20 years a political regression regarding the critical importance of raw materials, at a national and European level,” Zambianchi said.

“After dramatic events, including the Russia–Ukraine war, perspectives are changing. The European community now understands the crucial role of raw materials as strategic resources. Without raw materials, there is nothing.”

An Italian national, Zambianchi has been in his current role since 2011 and is responsible for production, maintenance, safety, and investment at Holcim Italy’s four aggregate quarries and 22 ready-mix plants. The former produce a combined 1.3 million tonnes of aggregate and sand annually, while the latter generate up to 1.5 million cubic metres of ready-mix per year.

“Holcim concentrates its operations in northern Italy. I am also in charge of these sites’ environmental side and their relationships with the authorities,” he said.

Another key element of Milan-based Zambianchi’s work is securing operating permits and licenses for Holcim’s aggregate and ready-mix sites. This increasingly complex and challenging aspect of production has long been a focus of the European sector.

“Permitting and licensing for our business is crucial. Without approvals, we won't produce any more aggregate and ready-mix cement, and we won’t have the civilisations we have now,” Zambianchi said.

“Every region and every state in Europe has to be able to guarantee the quantities and supply timing of raw materials for more than 50 years, but we are getting permits and licenses for only two to ve years. It’s such a short time.”

Zambianchi said ensuring work site safety is his most signi cant constant challenge.

“Holcim wants to achieve a fundamental target of zero Injuries. It’s a tough target we face every day,” he said. “This is not just for Holcim employees; we work with many third parties.

“While Holcim is already a sustainable company, we want to reduce our CO2 footprint further and also do more to improve our circularity. We have tough targets to reach by 2030, so our transformation must be achieved in a short time.”

1. Example of a Ma-estro digitalised quarry plant optimisation solution. Ma-estro was among the key partners involved in the Holcim Italy Pioltello DigiEcoQuarry pilot.

2. Paolo Zambianchi believes big geopolitical changes have brought home to politicians and policymakers the critical importance of essential raw materials, including aggregates.

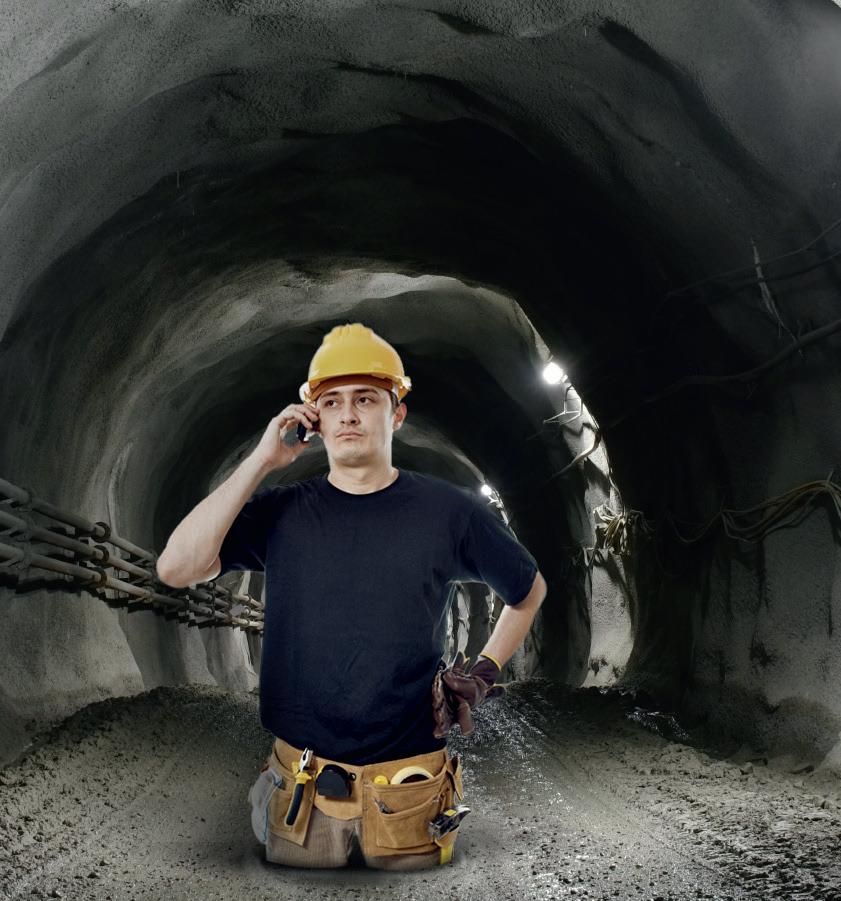

A keen advocate of the role of technology in modern aggregate production, Zambianchi led Holcim Italy’s involvement in the fouryear, EU-funded DigiEcoQuarry project, the brainchild of Asociación Nacional de Empresarios Fabricantes de Áridos (ANEFA), one of Spain’s oldest and most reputable associations for the national extractive industries and construction products.

DigiEcoQuarry saw ve pilot quarry sites (in Italy, Germany, France, Spain and Portugal) with different characteristics adopt Innovative Quarrying Systems (IQS), comprising sensors, processes, tools, and methods for data capture, processing and sharing, to provide integrated digitalised, automatic, and real-time process control for aggregate quarries.

Completed last year, the results of and conclusions from the DigiEcoQuarry project were shared by Zambianchi and other pilot leaders via in-person presentations to an independent international advisory board and other stakeholders at Aggregates Europe’s headquarters in Brussels in June.

Each pilot site reported signi cant improvements in health, safety and security, as well as in ef ciency, selectivity, and pro tability, while reducing environmental impact and increasing social acceptance.

With DigiEcoQuarry technology now rmly embedded in each pilot site, the project offers best practice examples for aggregates processing sites in Europe and the wider world.

“Holcim’s Pioltello San Bovio sand and gravel quarry, a 400,000-tonnes-a-year operation near Milan, was one of the pilot sites,” Zambianchi said. “It was exciting to be part of the DigiEcoQuarry project and to be working with so many great people. We focused on some key performance indicators related to the environmental and ef ciency aspects of production. Regarding the former, we explored ways to increase the amount of recycled water used in material production, thereby reducing the amount of freshwater required.

“We designed a system with around 80 to 90 machine sensors to add to the site’s

existing automation and help the quarry team focus on how they were processing materials through crushing, screening and washing. We also focused on safety, installing new sensors on some of the site’s heavy mobile machinery and utilising arti cial intelligence [AI] for stockpile measurement.

“We built a cloud platform where all the data was collected and analysed. It was a very interesting experience. Across the 25 or so partners involved, we had representatives from IT, software and arti cial intelligence companies.”

Firms working with Zambianchi and his Pioltello San Bovio project quarry team included Ma-estro, the Italian quarry

“I designed the CavoExpoTech brand and patented the name under ANEPLA. We’ve run it for 10 years and it’s the reference event for quarrying in Italy.”

and plant optimisation specialists; Arco, a leading Spanish industrial weighing solutions business; Sigma Cognition, a Spanish end-to-end, data-centric AI and machine learning solutions business; and Mintek, South Africa’s national mineral research organisation and one of the world’s leading technology companies specialising in mineral processing, extractive metallurgy, and related elds.

“The overall systems we and the other pilot sites chose had to be cheap and easy to install and manage, as this was linked to quarrying rather than mining,” Zambianchi said. “Over the four years of the project, Pioltello achieved around 10 per cent more productivity and ef ciency, cut production costs, and reduced freshwater use by two per cent. With ANEFA, the DigiEcoQuarry project leader, we are studying some other technology that we can test at Pioltello and the other pilot sites.”

Zambianchi is also excited about the circular economy opportunities offered by Holcim Italy’s rst construction and demolition (CDM) waste recycling hub at Gorla Quarry in Varese, around 60km northwest of Milan.

“This is a very important new development in our decarbonisation journey,” he said. “The EU target for recycling CDM [construction and demolition] waste is 75 per cent by 2030, and in Italy, we are already at 85 per cent. It’s a big success story.”

Zambianchi told Aggregates Business about his insights into the current state of the Italian aggregates market.

“The situation is dif cult for many reasons, including high energy costs and the fallout from what is happening internationally. More positively, the European Union is investing in large-scale infrastructure projects, such as new high-speed train lines and highways, which are bene cial for companies like Holcim,” he said.

“As a country, Italy is also investing in infrastructure, particularly in the north of the country.

“We have the [Milan Cortina] Olympics in February 2026, and Holcim is giving a lot of aggregate, cement and ready-mix to construction works, including our ECOPlanet green cement.

“The market is very interested in how our sustainable products relate to environmental product declarations [EPDs]. Enhancing

sustainability in building works is a key strategy for us. Holcim Italy is focused on supplying ECOPlanet and other sustainable products to bigger infrastructure projects, as the regulations are clear around the amount of recycled and low-carbon materials that need to be used by contractors.”

Zambianchi is the vice chairman of Aggregates Europe’s environment committee and continues to serve on the board of ANEPLA, having previously served as the association’s president from 2014–20. Under Zambianchi’s leadership, ANEPLA became a prominent association member of Aggregates Europe and launched CavaExpoTech, an annual meeting place for producers of mining goods and services and quarry entrepreneurs.

Each event, held at different ANEPLA member sites throughout Italy, is traditionally divided into classroom-based professional development on current industry trends, followed by static and dynamic demonstrations of quarrying machinery and linked technology. In addition to each live event, a series of CavoExpoTech webinars is staged throughout the year.

In his six years as president, Zambianchi also signi cantly increased ANEPLA’s membership, bringing in aggregate industry service companies, and strengthened the association’s working relationship

with Con ndustria, the main association representing manufacturing and service companies in Italy.

“I designed the CavoExpoTech brand and patented the name under ANEPLA. We’ve run it for 10 years and it’s the reference event for quarrying in Italy,” Zambianchi said.

“We do one or two CavaExpoTechs per year. If we host two events, based on member demand, one will be held in the north and the other in the south of Italy. We invite industry stakeholders and local politicians, and always have one quarry site day for families, with children participating in all kinds of fun activities.

“At a CavaExpoTech event last year, Caterpillar and CGT, its Italian dealer, attended with Cat Command [remote control machine solutions]. Some important politicians heard about this and were eager to try it, so they took turns operating the excavator remotely. It was very nice to see.”

A geology graduate who also holds a master’s degree in business administration with a focus on the oil, gas and raw materials industries, Zambianchi spent three years working in the Italian oil and gas sector before entering the aggregates industry with Holcim Italy in 2001.

“I think we need to do more with schools and universities as industry companies

and, in ANEPLA’s case, as associations, otherwise we will lose the next generation’s interest and quarrying and mining industry competencies,” Zambianchi said.

“This is why Holcim Italy has started an academy near our headquarters in Milan that teaches local schoolchildren industry knowledge and skills.”

After an extensive career, Zambianchi is clear that there is still plenty wants to achieve in the Italian and wider European aggregates industries.

“Like in a rugby match, it is impossible to win without the support of your team and playing for each other. My team at Holcim Italy aggregates and readymix is crucial,” he said.

“You come to Milan, and in the last 20 years it has undergone signi cant changes, with skyscrapers, subways and buildings made from green, sustainable building materials supplied by Holcim.

“It’s a big transformation, and it makes me very proud. I am also proud of being the rst Holcim Italy manager to receive authorisation for a CDM waste recycling hub [at Gorla Quarry]. I want this hub and Holcim Italy in general to be the reference point when it comes to recycled materials to enable sustainable construction, not just in Italy but the whole of Europe.” AB

SunEnviro is expanding its waste processing capabilities to produce premium aggregate products and sand at its site in Thetford, England, following a £3 million investment in a state-of-the-art McLanahan waste recycling plant. Aggregates Business visited the site for a close-up look and to hear about the long-term expectations for the set-up.

When Aggregates Business toured the SunEnviro open day, the company’s managing director Mat Stewart said his three business brands, SunSkips, SunDemolition and SunAggregates, generate no waste that is directly sent to land ll.

SunEnviro’s new up-to-70-tonnes-perhour (tph) waste recycling plant in Thetford, Norfolk, one of several SunEnviro operates in eastern England, will process up to 100,000 tonnes of waste annually into premium aggregate products and sand in compliance with (BSE 9321) British Standards.

While SunEnviro’s signi cant seven- gure investment in the comprehensive McLanahan set-up has already started to prove its worth since becoming fully operational in May, the rm’s notable increase in its waste processing is likely to also prove highly shrewd.

Introduced in 1996 to encourage more sustainable waste management practices, the Land ll Tax applies to taxable disposals at land ll sites and, more recently, unauthorised sites. In April 2025, HM Treasury, the UK Government’s economic and nance ministry, and HM Revenue & Customs, the UK’s tax, payments and customs authority, launched a consultation on Land ll Tax reform, proposing the removal of the lower rate of Land ll Tax (£4.03 per tonne for inert materials such as rocks and soil) by 2030. In its place, an escalator will be applied to the lower rate until it reaches the standard rate level (currently £126.15 per tonne), with the qualifying nes regime and quarries and dredging exemptions being removed from April 2027. The new Land ll Tax rules will be coupled with increased penalties for illegal disposals.

Stakeholders, including the Mineral Products Association (MPA) and British Aggregates Association (BAA), have expressed concerns about the economic impact of the Land ll Tax reform proposal. Consultation closed in July, with a wide range of industries, including quarrying, construction and recycling, awaiting the UK Government’s next steps.

Stewart, who has nearly 30 years of experience working in environmental services, with SunEnviro, which started as SunSkips in Stowmarket in May 2020, now covering sites in Thetford, Cambridge, Haverhill, Ipswich, Dereham and Hoddesdon, told Aggregates Business this could present an opportunity for his company.

“If all goes to plan, we thought we’d start seeing a return on our investment in three to four years, but if the Government do what they say they are going to do [on Land ll Tax

reform], it will be a lot quicker, potentially 12 months,” he said.

“We are saving £600,000 to £700,000 a year by not having to put 30,000 to 40,000 tonnes of waste and nes into land ll, and that’s at the lower [Land ll Tax] rate. If the standard tax rate applies, I don’t know how many businesses like ours will be able to put a skip out and be competitive.

“We are also fortunate in being able to control what we bring here in our own vehicles. We can keep material coming in, but our guys have got to sell the recycled aggregate and sand product that goes back out, so we adjust the daily volumes we are processing.”

SunEnviro’s bespoke waste recycling plant features a McLanahan UltraSCRUB, UltraSAND and HRT10 Thickener, which work together to ensure high throughput, minimal water usage, and full site circularity, culminating in the nal step of the process: a McLanahan Filter Press.

The McLanahan set-up at Thetford, which washes and recovers materials from construction and demolition sites, excavation waste and trommel nes, is part of SunEnviro’s nationwide effort to turn waste into valuable recycled aggregates under its SunAggregates brand.

Comprised entirely of McLanahan equipment and plants, the Thetford solution has been designed to minimise water intake and ensure the process retains as much material and water on site as possible.

The site’s tight two-acre footprint has necessitated a considerable planning process for McLanahan. The system forms an ‘L’ shape along two sides, maximising room for feed material and clean, sorted end products.

Stewart said a lot of research went into the decision to opt for a McLanahan waste recycling plant at SunEnviro Thetford.

“I looked at eight suppliers and then a friend of mine at Global Machinery Solutions introduced McLanahan to me,” he said.

“I whittled it down to three suppliers and then worked with McLanahan to optimise what we wanted here, looking at the site we had available. It was good to work with people who wanted to provide us with a solution: a, to t on the site; and b, to wash what we wanted to wash.

“McLanahan was the easiest to work with and had the breadth and depth of knowledge that others didn’t, or didn’t want to share. I also think they really wanted to work with us. The whole [recycling plant investment] deal took around 10 months.”

SunEnviro manages more than 120,000 tonnes of waste across the east of England, with an inventory of 4000 skip containers and a eet of 65 fuel-ef cient vehicles. The company only processes waste collected from its SunSkips and SunDemolition sites.

“The plant feed is half crushed rubble and half trommel nes, which is turned into 0–4mm sand, and 4–10, 10–20 and 20-plusmillimetre aggregate,” Stewart said.

“I like to say that what we do is spinning plates. All of our [SunSkips and SunDemolition] sites are full of nes and

With support from McLanahan, SunEnviro is turning waste into valuable recycled aggregates under its SunAggregates brand.

rubble, which is great feedstock for here. This Thetford site sits in the middle [of SunEnviro’s site network], and I can bring nes in from, say, Norwich and take washed sand or 0–10mm aggregate back to sell out of bags at that site.

“We sell to local construction companies, housing developers, highway contractors, and civils and utilities companies.”

SunEnviro and McLanahan partnered for an open day at SunEnviro’s Thetford site in September. The two companies welcomed around 80 industry professionals representing a variety of construction and civil engineering companies, as well as council highways authorities, to experience SunEnviro Thetford’s innovative McLanahan recycling system.

This open day offered those looking to improve or add a recycling process to their plant, as well as those who are struggling with the upcoming costs associated with the end of qualifying for trommel nes in the UK, signi cant insight into best practices for building a circular system.

“We are really excited about what’s happening in Europe. We made a substantial investment in the market over the past veplus years and have over 100 employees in the UK and [mainland] Europe,” McLanahan chief executive of cer Sean McLanahan said.

“We are continuing to expand, and part of that is in construction and demolition [C&D] waste recycling, which is extremely important to us.

“The two areas in which our company continues to grow around the world are

in C&D recycling and water management, utilising our thickeners and lter presses.”

Stewart said his company was proud to showcase its latest solutions with McLanahan.

“I think it’s great to work with McLanahan and help them get into a market that is desperate for professional businesses to sell them a product that works,” he said.

“I think [the open day] has been good for people to see how we t and operate this kind of plant on an industrial estate site. Everyone automatically thinks it would be based in a quarry.

“If you look at the Norfolk Local Plan, all inert recycling is being directed towards industrial sites rather than extending the life of quarries. We are very proud of what we have here. We want to replicate it at some of our existing sites and potentially at some new ones that we buy in the future.”

McLanahan business line director David Hunter said the process shows what could happen when suppliers and producers collaborate together,

“This installation has been a real collaboration, a lot of sitting down together, talking through the process and adjusting,” he said. “This is the rst time we’d put a plant like this in, and we were saying, ‘Guys, we will make this work’.

“Changes in legislation are increasing interest in what we can offer. There are a lot of operators who aren’t geared up yet for what might be coming. SunEnviro has got ahead of the game, and it’s great to be part of that.”

Stewart said he wants the Thetford McLanahan plant to feature an eddy current separator (ECS). This machine uses highspeed rotating magnets to induce eddy currents in non-ferrous metals, such as aluminium and copper, creating a repulsive magnetic eld that pushes them out of the waste stream. The process is used in recycling facilities to recover valuable metals from materials such as plastics and wood,

increasing recycling rates and reducing land ll waste.

“I don’t think many McLanahan customers had asked for this, but they found us a supplier we could work with and included it in their package. We didn’t want to have to nd our own supplier and add bits into the plant,” Stewart said.

“We were also clear that we wanted to meet the WRAP quality protocol (a document that sets ‘end-of-waste’ criteria for the production of a speci c recovered product, such as aggregates, compost or glass cullet). This plant does.

“We like the fact that McLanahan is a 190-year-old family business, with a similar philosophy to SunEnviro. Just looking at the quality of the equipment and the fact that they were keen to handle any problem were also big selling points for us.”

“We don’t look at changes in legislation as a pain in the neck; we look at them as opportunities.” AB

As the only national quarrying publication and the official journal of the Institute of Quarrying Australia, you’ll always be up to date with the latest developments in industry news, technology and events with Quarry Magazine. It’s quick and easy to subscribe to our monthly print issues, our annual Suppliers Directory and our weekly eNewsletter. Don’t miss out!

PMG Services has reinforced its commitment to sustainability by making its second purchase of a CDE waste recycling plant. Aggregates Business took a close-up look during a CDE openhouse event at the company’s new headquarters.

Clare McGuinness is excited about the future of PMG Services (PMG). And the managing director of the family-owned-and-operated business has every right to be given PMG’s impressive new headquarters in Severn Beach, 10 miles north-west of Bristol.

At its heart of the HQ is a new 25-tonnesper-hour (tph) CDE waste recycling plant solution, part of PMG’s ‘zero-to-land ll’ movement, which is setting the rm up for a new era of success.

“We’re on a journey to process even more waste across the south-west of England. Our vision is to keep growing the waste processing capability at PMG and be able to divert more valuable material from land ll,” Clare said.

“We’re a family-run business with over 35 years of experience, and in that time there has been a lot of change and investment.”

For over a decade, PMG operated a 10tph CDE waste recycling plant set-up at its former site in Albert Road, behind Bristol Temple Meads train station. Clare said this enabled a better understanding of CDE’s new waste recycling plant technology.

“We’d outgrown our previous city centre site and needed to move to a new one. During the early stages of this investment, we ensured that the design and layout were tailored speci cally to our operation, such as making the plant quite compact and allowing as much automation as possible. An example of this is the automated liquid feed into the plant, which was previously a manual process,” she said.

“As we were doubling the size of the operation, we also wanted to consider wider yard operations and traf c ow around the site. To gain a better understanding, we visited a few reference sites across the UK.

“It can be dif cult to process the gully waste and road sweeping waste we’re working with, so with the new design we were able to prioritise access to ensure that the operation and maintenance of the plant is easier, and so that we can continue to optimise the solution going forward.”

A signi cant amount of PMG’s waste material is recovered by the company’s vehicles, with a growing amount brought in from third parties, such as councils and other road sweeper and tanker companies.

“We service a lot of housebuilders, groundworks contractors and councils,” Clare said.

“We may collect waste from a construction site customer, and the same customer is then taking it back as PMG recycled sand for use in a building project. It’s a fantastic circular economy.

“We have a 62-strong vehicle eet and cover Gloucester down to Taunton and into south Wales with our road sweepers. We also have a depot in Swindon, which enables us to extend our service to Oxfordshire.

“Here at Severn Beach, we are open from 6:00am to 5:30pm, Monday through Friday. We can also open on Saturday and Sunday by appointment, and when we have night shifts booked we can be open for tipping then as well.”

Designed for what Clare is a decade-long growth plan for PMG, the new CDE waste recycling plant comprises an R1500, one of CDE’s R-Series primary scalping screens, an AggMax scrubbing and classi cation system, an EvoWash sand washing system, and an AquaCycle high-rate thickener and static screen.

When the tanker or road sweeper arrives on-site, it allows the water to drain out of the body into the pit, removing any solids or lightweight organics using a bespoke PMG-designed system. The remaining liquid contents are then pumped automatically into the AggMax.

Once the truck has released the liquid, it will then discharge all solid waste, such as road sweepings. This waste is then loaded into the R1500, where oversized material will begin to be processed. Anything under 80mm will continue to the AggMax, which is eventually passed to the EvoWash.

All material that remains in the liquid and can’t be extracted through solid separation is sent to water treatment. Any sludge is then sent to a centrifuge, where the silt is separated to ensure process ef ciency.

The water gets returned to the system for further processing through the AquaCycle, which recycles up to 90 per cent of the process water for immediate re-use in the system.

The solution enables PMG to produce two products: a 5–25mm aggregate and a 0–5mm sand product for use in Bristol’s construction market.

“We’ve built in the ability to add a third deck in the screener so that we can have the option of producing another stone size,” Clare said.

PMG’s recycled aggregates and washed sand are mainly used in earthworks, but also meet the speci cations for highway works, pipe bedding and cable laying.

With strict regulations on waste products that can be sent to land ll, there is a pressing need to turn gully waste and road sweeping waste into an opportunity.

Under European land ll regulations, liquid waste consisting of road sweepings with a water or liquid content of 10 per cent or more can no longer be sent to land ll. In turn, this presents a challenge for disposing of this waste.

According to the Mineral Products Association (MPA), the UK’s market share of recycled aggregates is three times higher than the European average, highlighting the increased importance of repurposing waste.

Clare said PMG’s operation not only supports sustainability objectives but also generates new revenue streams to bene t the local economy.

“This was an investment that we had been thinking of for several years, and we are delighted to see the plant in action,” she said. “We’re proud to be recovering this material to transform it into high-value materials for the local industry. We’ve also been taking on people over the past year to prepare for this next business step.

After a year living and working in Australia, Clare joined the family business in 2020, during the COVID-19 pandemic.

“I studied civil engineering at university and had worked on the other side of this business as a contractor working on major projects such as Crossrail and Thames Tideway. I understand the pains inherent in construction sites and the need to offer a seamless service to customers,” she said

“It’s been great. The CDE people visiting us are extremely knowledgeable. If they are making a minor change to the plant, they also ensure the whole plant is running as well as it can. They are very proactive and

really helpful.”

Joining Clare and the CDE team to welcome customers and dealers at the open house event in June were her father, PMG founder and director Pat McGuinness, and her brother, PMG technical lead Paul McGuinness. Clare’s mother, Bernie, who, along with Pat, is originally from Ireland, played a key role in building PMG’s nance function and continues to support the business today.

“We’ve had a very good relationship with CDE throughout the last 10 years or so,” Pat said. “About two years ago, we wanted to invest and move to a bigger site, as our site by Bristol Temple Meads station was only 0.6 acres.

CDE’s AquaFlo 450 is part of the turnkey CDE waste recycling plant solution for PMG.

“This new site spans 6.5 acres, and we already have four acres of planning approval for the waste recycling plant, of ce premises, storage facilities, lorry parking, and other amenities. We have more room to tip off and can accept more material deliveries on site at any one time. We’ve got good customers and they’ve all come with us to this new facility.”

Paul said CDE has been a great support to the family business during this process.

“We learnt a lot from the rst CDE plant and worked closely with them on designing the new one,” he said. “Their engineers have been with us these rst few months of operation, ne-tuning the plant. You always get a few teething issues, but it’s been running well. We’re happy.”

CDE key accounts manager Fergal Campbell said the company is proud to be associated with a forward-thinking organisation like PMG.

“PMG’s commitment to recovering and repurposing material is second-to-none. Over the years, we’ve seen the team’s ambition grow and how sustainability is truly at the heart of every decision they make,” he said

“This type of material is challenging and costly to dispose of, but PMG identi ed the opportunity in this space over a decade ago, and since then they’ve continued to push boundaries and invest in the right technology to divert even more material from land ll.

“With depletion of virgin materials across the world, there’s a greater need more than ever to turn today’s waste into tomorrow’s resource, and we will continue to champion the vital service that PMG is providing.” AB