Editorial

TM

PerstorpLaunchesNeptem RangeofEmulsifiers–AnInvaluableSolutioninWaterborne AlkydTechnology

Syensqopresentsitslatesthigh-performingandsustainablecoatingsolutionsatECS2025

ClariantClimateCampaignwinnerGNFCcuts44,000tons/month

TM

LucasMeyerCosmeticsbyClariantintroducesGlowCytocin tocapturethescienceof"LoveGlow"

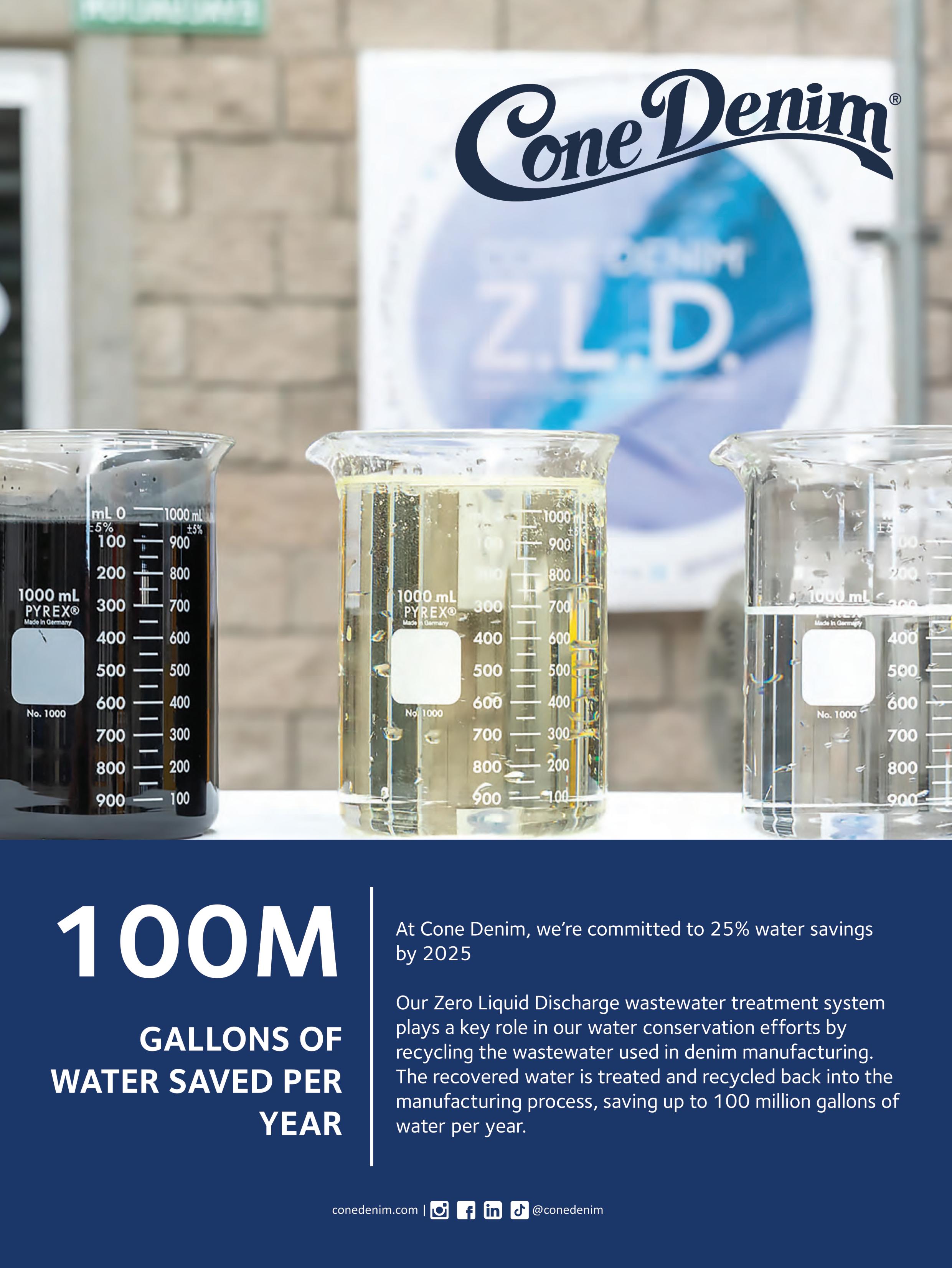

ArchromaandGradiantpartnertoadvancewatercircularitywithinnovativeZLDtechnology inThailand

®

ArchromalaunchesAVITERA RASPBERRYSEtoextendtheGENERATIONNEXT platformforeconomicalsustainabilityindarkshades

Clariant'snovelsolutionsforenhancingcrophealthandbiologicalformulationsatCAC 2025

BeaulieuFibresInternationalatIDEA25:showcasingfibresthatbuildfutures-highin performanceandsustainability

MimakiUnveilsTx330SeriesforTextiles

NewNipaguardTMSCEVita:Clariant'slatestfullynaturallyderivedpreservationblend forcosmetics

AdvancedCHEMSORB-RFilterIntroduced True

Editorial:

editor-in-chief

Prakashkinny

contributor

ThomasChang

circulation

PamelaJones administration

JoePereira

accounts

RameshJain

photography

TonyFernandes

RetailPrice:Rs.150.00

InsideIndia

Annualsubscription:Rs.600.00

OutsideIndia

AnnualSubscription:US$30.00

editorial office

DYESCHEMICALSANDCOLOURTECHNOLOGY

House No. 157, Satpala, Bhandra Lee

Post: Agashi, Tal: Vasai

Dist: Palghar (401 301) State: Maharashtra, INDIA

Mobile: +91-7798189485/09892723562

Email:info@timesinternational.in prakashkinny@yahoo.com

www.timesinternational.in

JAPAN

KatsuhiroIshii

MediaRepresentative ACEMEDIASERVICEINC. 12-6,4-chome,Nishiiko,Adachi-ku, Tokyo121-0824Japan

Tel:81-3-5691-3335Fax:81-3-5691-3336 amskatsu@dream.com

TAIWAN,R.O.C

Kenlychang

BUILDWELLINTERNATIONALENT.,CO.,LTD. HeadOffice:No.120,Huludun2ndSt., FongyuanCity, TaichungCounty42086,Taiwan,R.O.C

Tel:886-4-25123015Fax:886-4-25122372

E-mailaddress:buildwel@ms23.hinet.net

India,Pakistan,Bangladesh,Srilanka,Vietnam,Indonesia,Thailand, China,HongKong,USA,Germany,Spain,Italy,U.K.&France

The 24th edition of the China International Dye Industry, Pigments andTextile Chemicals Exhibition willbeheldfromApril16–18,2025,attheShanghai World Expo Exhibition & Convention Center

Spanning 60,000 sq. m, this UFI-approved event standsastheworld'slargestspecializedexhibitionin thedye-chemindustry.

Located in the heart of the Yangtze River Delta Economic Zone, the exhibition continues to attract globalattentionasapremierplatformforshowcasing dyes,pigments,andtextilechemicals.Itremainsopen exclusively to trade and professional visitors, providing direct access to innovations, business collaborations, and the latest developments in textile processing.

Complementing the exhibition is a robust technical program,featuringconferencesorganizedbynational industry associations and technical seminars hosted by key exhibitors. These sessions will highlight advancements in sustainable chemistry, eco-friendly dyeingsolutions,andnewformulations.

With strong international participation, the event draws manufacturers, chemical suppliers, R&D experts, and industry leaders from across the textile valuechain.Itsstrategiclocationandfocusedcontent make it a must-attend for professionals seeking growthandinsightintheglobaldye-chemmarket.

Perstorp,arenownedglobalinnovatorinspecialty chemicals and a wholly owned subsidiary of PETRONASChemicalsGroupBerhad(PCG),has ™ unveiled its Neptem range of emulsifiers designed for waterborne alkyd systems. This launch marks a significant advancement in the development of sustainable, high-performance coatings by addressing key technical and environmentalchallengesinthecoatingsindustry.

™ The Neptem portfolio is specially formulated to enhance the stability, compatibility, and performance of waterborne alkyds. These novel emulsifiers enable the development of low-VOC (volatile organic compound) formulations without compromising on durability, gloss, or ™ drying time. This positions Neptem as a key enabler in transitioning from solvent-borne to more sustainable waterborne solutions, aligning with increasingly stringent environmental regulations and growing market demand for greeneralternatives.

By supporting the production of low-emission, ™ water-based alkyd paints, Neptem contributes directlytoreducingtheenvironmentalfootprintof the coatings industry. Its formulation helps manufacturers meet sustainability targets while maintainingcompetitiveproductquality.

ThislaunchunderscoresPerstorp'scommitmentto innovative, sustainable chemistry and PCG's strategic vision of expanding specialty chemical ™ offerings.TheNeptem rangenotonlystrengthens Perstorp's leadership in emulsifier technologies but also enhances the group's portfolio tailored to eco-friendly applications in architectural and industrialcoatings.

™

Perstorp'sNeptem emulsifiersaresettoreshape the landscape of waterborne alkyd technology, offering manufacturers a cutting-edge tool to develop advanced, low-VOC coatings. This innovation exemplifies the synergy between technological excellence and sustainability in the modernchemicalssector

Syensqopresentsitslatesthigh-performingandsustainable coating

AtECS2025,Syensqo presentitselfasapreferred formulation partner of the paints and coatings industry, with an advanced portfolio of highperformance and sustainable additives for enhanced durability, safety and decarbonization.

(Photo:Syensqo,Pr046)

The company's newest solutions help coating formulators meet more demanding requirements while enabling safer and more eco-conscious formulations.

Syensqo, formerly part of Solvay Group, will showcase new additives, specialty monomers and green solvents at this year's European CoatingsShow(ECS)inNuremberg,Germany. The company's latest innovations are designed to enable step-change improvements in the durability and sustainability profile of paint andcoatingformulations.

“The paint and coatings industry is striving for safer and more eco-friendly formulations with

comparableorsuperiorperformancetoincumbent solutions,” says Corinne Duffy, Market Director, Coatings, EMEA at Syensqo. “As an innovative companydedicatedtoanticipatingtheneedsofthe coatingsmarket,weareproudtojointheindustry atthispivotalevent,sharingourlatestinnovations withourtrustedpartners.”

Syensqo's exhibit at ECS 2025 builds on three pillars to meet the industry's sustainability needs: solutions for safety improvements, decarbonizationanddurabilityenhancement.

ThefirstpillarofSyensqo'sECSplatformfeatures food-contact-approved, label-free, low-dioxane and fluorosurfactant-free solutions for architecturalandindustrialpaints.Akeyhighlight ® in this category is Rhodoline HBR, a new substrate wetting agent for waterborne coatings and paints. This fluorosurfactant-free specialty additive shows exceptional early hot block

resistance (HBR), which refers to a coating's ability to resist sticking or softening under high temperaturesorpressure.Italsoprovidesdirtpickupandstainresistance.

Aiming to drive business growth through decarbonization, Syensqo is presenting lowcarbon-footprint solutions and partially biobased products.

® The Rhodiasolv range of green solvents is designedtodeliversustainableperformanceacross a wide array of applications, from industrial processes to consumer products. Made from ® circularraw materials,Rhodiasolv solvents offer lowerrisk,highperformance,andcompliancewith localandinternationalenvironmentalregulations, ensuringasaferandmoresustainablefutureforall.

Additionally, Syensqo's new wetting and

® dispersing agent,Rhodoline 6100, enhances pigment paste formulations, which are concentrated mixtures of pigments that add color

® topaints,coatingsorinks.Rhodoline 6100offers strong tinting power, excellent color consistency and long-lasting stability. It helps paints spread easilyforasmooth,evenfinish.Theproductislow in volatile organic compounds (VOCs), free of alkylphenol ethoxylates (APEs) and is made with 33% biobased materials. Versatile and unique, ®Rhodoline 6100 works well with both solventborne alkyds and water-based systems, offering compatibility with a wide range of pigments and binders.

Inanefforttoimprovecoatingsdurabilitywithout sacrificingperformance,Syensqoisfeaturing:

Ÿ . Specifically designed for ™Addibond 106 waterborne coating formulations, this adhesion promoter additive helps metal coatings maintain their adhesive properties once dried and when exposed to moisture or water (i.e., dry and wet ™ adhesion). Addibond 106 effectively protects metal surfaces from rust and corrosion in C1 and C2environments.

® Ÿ Sipomer MAC.Thisnext-generationspecialty monomer has been engineered to improve adhesion and provide excellent corrosion protection in direct-to-metal (DTM) coating formulations, which refers to coatings applied to metallic surfaces without a primer, meeting the requirements for medium-risk (C3) and high-risk (C4)corrosionenvironments.

In addition to these innovative products, Syensqo showcase its architectural and industrial binder solutions,furtherdemonstratingitscomprehensive offerforthepaintandcoatingsindustry

™Addibond is a trademark of Syensqo. ® ® ® Rhodiasolv , Rhodoline and Sipomer are registeredtrademarksofSyensqo.

ClimateCampaignwinnerGNFCcuts44,000 tons/monthCOeemissionswithEnviCatNOremovalcatalyst 2 2

GujaratNarmadaValleyFertilizers&ChemicalsLimited(GNFC) facilityinGujarat,India,whereClariant'sEnviCat N2O-Scatalysttechnologyishelpingreducegreenhousegas emissionsby44,000tonsCO2epermonth.©Clariant

Ÿ Gujarat Narmada Valley Fertilizers & Chemicals Limited (GNFC) implemented Clariant's EnviCat NO-S catalyst for nitrous 2 oxide(NO)abatement. 2

Ÿ ThecatalystinstallationatGNFC'snitric acidplantinGujaratdemonstratesexceptional performance, reducing N O emissions by 2 44,000tonspermonthofCo2e.

Ÿ EnviCatNO-S,awell-established,drop-in 2 solutioncapableofremovingmorethan95%of NO from the off-gas of nitric acid plants 2 proveshighlyefficient.

-Clariant, a sustainability-focused specialty

chemical company, today announced remarkableresultsfromitsClimateCampaign for nitrous oxide abatement at Gujarat Narmada Valley Fertilizers & Chemicals Limited's (GNFC) facility in Gujarat, India. The installation of Clariant's EnviCat NO-S2 catalyst has shown outstanding performance since October 2024, with monitoring data demonstrating significant reduction in NO2 emissionsequivalentto44,000t/monthCo .2eq

Xaver Karsunke, Head of Specialty Catalysts at Clariant, commented, "Our partnership with GNFC,apioneeringforceinIndia'sfertilizerand chemical industry, marks a significant milestone in industrial decarbonization efforts. The

exceptional performance of EnviCat NO-S at 2 GNFC'sfacilitydemonstrateshowoursustainable catalyst solutions can help industry leaders achievesubstantialgreenhousegasreductions.”

Mr. M. I. Shamsi, Executive Director, Gujarat NarmadaValleyFertilizers&ChemicalsLimited, stated, "As a company committed to environmental stewardship since our establishment in 1976, this collaboration with Clariant aligns perfectly with our sustainability goals. The impressive performance of the NO2 abatement system not only showcases our dedication to reducing environmental impact but alsostrengthensourpositionasanindustryleader insustainablechemicalmanufacturing.”

The implementation at GNFC's facility has demonstrated strong and consistent performance inCO reduction.Basedontheinitialfourmonths 2e ofoperation,theprojectedannualCO reduction 2e isexpectedtoreachapprox.520,000metrictons, with further improvements anticipated following a planned catalyst addition during the next maintenanceshutdown.

PrakashBabu,CEOofSüd-ChemieIndiaPvtLtd (SCIL), added, "We are delighted to see such encouraging results at GNFC's facility The successfulimplementationofEnviCatNO-Sand 2 its remarkable performance in reducing COe2 emissions reinforces our commitment to providing high-quality products, services, and

innovativesolutionsthatsupportIndia'sfertilizer and chemical manufacturers in achieving their sustainability goals. This project exemplifies the significant impact our technologies can have in industrialdecarbonization.”

While nitric acid is essential for manufacturing fertilizers, its production process emits NO,2 which is almost 300 times more harmful to the climatethanCO TheEnviCatNOcatalystseries 2 2 effectively removes NO and other nitrogen 2 oxides,designedasadrop-insolutionthatcanbe easilyinstalledwithoutdisruptingmanufacturing processes. With over 50 successful installations globallyand20yearsofmarketpresence,EnviCat NOcontinuestodemonstrateitseffectivenessin 2 industrialapplications.

Clariant initiated the Climate Campaign to offer producersaneconomicalwaytoreduceemissions and inspire them to transition towards climate neutrality FromNovember2021toMarch2022, winnerswereselectedtoreceiveacomplimentary load of the EnviCat NO-S catalyst. All selected 2 companies had no existing NO abatement 2 systems in place, representing a significant opportunity for reducing greenhouse gas emissionsinthenitricacidproductionsector

Learn more about Clariant's EnviCat N2O-S catalyst fornitrousoxideabatement.

™EnviCat ISATRADEMARKOFCLARIANT.

™

LucasMeyerCosmeticsbyClariantintroducesGlowCytocin,tocapturethescienceof "LoveGlow"Caption.(picture:AI-generated)©Clariant

Ÿ First-of-its-kind active cosmetic ingredient directly activates the oxytocin receptor, mimicking thedermatologicaleffectsofbeinginlove.

Ÿ Clinically proven to enhance skin luminosity, comfort,andyouthfulappearance.

Ÿ SourcedfromDutchHyacinthbulbsgrownusing thebiodiversitypositive'flowerstrip'method.

Lucas Meyer Cosmetics by Clariant is excited to announce the global launch of GlowCytocin, the first skin care ingredient that harnesses the benefits associated with the feeling of being in love. This breakthroughingredientactivatesoxytocinreceptorsto delivermultiplescientificallyprovenskinbenefits.

"GlowCytocin is a significant step forward in neurocosmeticsandskincare,offeringbothimmediate and long-term benefits for skin appearance and emotional well-being," says Isabelle Lacasse, Head of Global Marketing, Product Line Management and Formulation at Lucas Meyer Cosmetics by Clariant. "This innovation aligns with the growing consumer demand for multi-functional skincare products that deliverbothvisibleresultsandpositiveemotions.”

GlowCytocin (INCI: Glycerin and Water and Hyacinthus Orientalis (Hyacinth) Extract) is derived from the bulbs of white Hyacinth, a plant that symbolizes pure love, aligning its origin with its purpose.

Able to activate the oxytocin receptors in the skin

GlowCytocinbiomimicsmanyofthebeneficialeffects of oxytocin, known as the love molecule. In vitro and organ-on-a-chipstudieshaveshownthatGlowCytocin increases the proliferation of fibroblasts and sensory neurons, promoting skin rejuvenation and heightening skin receptivity to pleasant tactile sensations. Further, this ingredient decreases nociceptive nerve sensitivity foracomfortingeffect.

In a placebo-controlled clinical study of 60 male and femalemixed-ethnicityvolunteers(betweentheagesof 18and65),twicedailyapplicationof1%GlowCytocin for 28 days visibly and significantly enhanced the participants' skin appearance. Skin luminosity and healthy glow both increased, evaluated by clinical gradingandself-evaluationtoreleasethe"LoveGlow".

Inaddition,thenumberofwrinklesdecreased,andskin elasticityimprovedforarejuvenatedskinlookandfeel.

In the same clinical study, receptiveness to pleasant sensations of touch was measured by electroencephalogram(EEG)uponfeathertouchonthe forearm.30minutesafterasingleproductapplication, this showed a significant increase in frontal cortex activity, an area associated with positive mood states andhigherhappinesslevels.Thiswasfurtherconfirmed withasignificantincreaseinself-reportedskincomfort and pleasantness. While enhancing receptiveness to pleasant sensations, GlowCytocin simultaneously significantly decreased capsaicin-induced skin discomfort.

GlowCytocinisChinacompliant,COSMOSapproved, vegan,andhasanaturaloriginindexof99.6%.

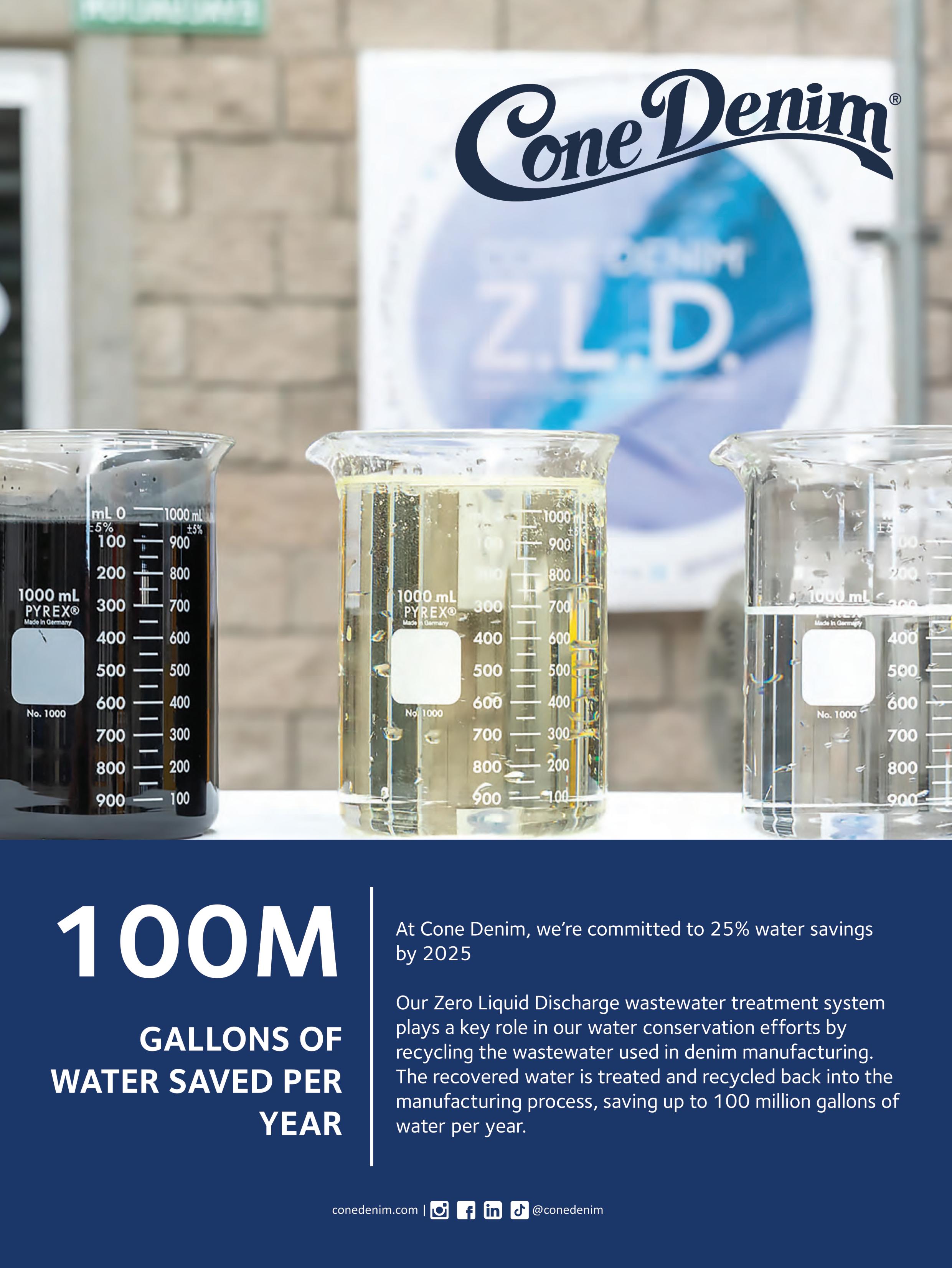

ZeroLiquidDischarge(ZLD)SolutionMinimizesImpactonWaterResources, ConvertingWastewaterintoCleanWaterandUsableMinerals

Archroma, a global leader in specialty chemicals, has successfully implemented a state-of-the-art Zero Liquid Discharge (ZLD) technology at its Mahachai plant in Thailand. The ZLD solution was designed and built by Gradiant, a global leader in advanced water and wastewater treatment. This milestone project marks a major leap forward in water circularity, enabling the recovery of 90-95% of wastewater for reuse and the extraction of valuablemineralsforindustrialapplications.

Archroma,agloballeaderinsustainablespecialty chemicals, partnered with Gradiant to deploy a high-efficiency, membrane- and oxidation-based ZLD solution, reinforcing its commitment to responsible water management in the textile industry. Located in a water-stressed region near Bangkok, the Mahachai plant now serves as a model for sustainable textile dye production, significantly reducing reliance on local water supplies while improving environmental resilience.

As part of its broader sustainability endeavor, Archromaaddressescriticalchallengeswithinthe apparel and textile industry, particularly water consumption.“Webelieveinreducingwaterusein production and home laundering. We innovate to remove toxins and contaminants from our products, making wastewater treatment easier for ourplantsandcustomers,”saidDhirendraGautam, VP Global Marketing and Strategy, Archroma. “Ourgoalistorequireourplantstohaveeffective waterconservationfacilitieswithspecialfocuson water stressed areas, contributing to water conservation and helping to combat acute water scarcityworldwide.”

Since2019,ArchromahasevaluatedvariousZLD solutions to address growing water challenges in Thailand. Gradiant's Counterflow Reverse Osmosis (CFRO) was selected as the preferred technology for its ability to treat diverse wastewater compositions with superior efficiency and minimal energy consumption. The modular system seamlessly integrates with the plant's existing wastewater treatment infrastructure, maximizing desalination capacity and water recoverywhilereducingtheplant'senvironmental footprint.

In addition to CFRO, Gradiant's Free Radical Oxidation(FRO)technologyhasbeendeployedto remove color and organics from the RO concentrate, ensuring safe discharge and meeting stringent environmental regulations. The system also enables the recovery of concentrated brine, which Archroma repurposes within the dyeing process or supplies to industry partners for applications such as resin regeneration and chlorine production, further promoting a circular economyinwaterandresourcemanagement.

“Water-intensive industries are under increasing pressure to adopt responsible solutions, and this partnership with Archroma demonstrates how advanced water treatment can drive sustainability without compromising operational efficiency,” said Prakash Govindan, COO of Gradiant. “Our ZLD solution at Mahachai leverages innovative membrane and oxidation technologies to maximize water recovery, reduce environmental impact, and create valuable resource streams. We are proud to support Archroma's commitment to sustainablemanufacturingandwaterstewardship.

Thailand faces mounting water stress due to climate change, extreme droughts, and aging infrastructure, making sustainable water management an urgent priority By implementing Gradiant's ZLD solution, Archroma significantly reduces its dependence on freshwater sources, ensuring long-term operational resilience in a resource-constrainedenvironment.

This multi-million-dollar investment underscores Archroma's dedication to water conservation and itsbroadermissiontotransformthetextileindustry throughsustainableinnovation.BeyondThailand,

ArchromacontinuestoexpanditsZLDinitiatives globally, including its Sustainable Effluent Treatment (SET) plant in Jamshoro, Pakistan, which has been providing irrigation water to surroundingcommunities.

By partnering with Gradiant,Archroma reaffirms itscommitmenttoemployinginnovativesolutions thatdriveeconomic,environmental,andindustrial sustainabilityonaglobalscale.

©2025Archroma

®

toextendthe

Archroma, a global leader in specialty chemicals towards sustainable solutions, has taken sustainable and cost-effective cellulosic dyeing to the next level with ® theintroductionofAVITERA RASPBERRYSE.

® Extending the AVITERA SE GEN NEXT platform color of deep shades, the IP-protected brilliant trichromatic red empowers mills to achieve rich, dark and extra-dark shades while meeting the stringent fastness and sustainability requirements of leading brands and retailers. The newest element also offers significantly lower processingcosts,withfocusonreducingtherecipe cost together with reliable right-first-time ® performance as well, “AVITERA SE revolutionized the dyeing of cellulosic fibers and blends when it was introduced 15 years ago –setting a new benchmark with state-of-the-art application and fastness performance and advanced sustainability,” Dhirendra Gautam, VP Marketing,Archromasaid.

“Our goal was always to offer a full range of ® attractive colors without limits. With AVITERA SERASPBERRYSEasournewtrichromaticred, wearenowenablingfashionandtextilecompanies toproducedifferentiatedendarticlesinconsistent and long-lasting dark and extra-dark shades with the same cost-competitiveness as in pale and mediumshades.Thisisanothermajorstepforward on our PLANET CONSCIOUS+ journey to economicandenvironmentalsustainabilityforour industry,”hecontinued.

Substantial Savings on Challenging Dark Shades

Dyeing darker shades – such as black, navy and especially red – has traditionally been more

challenging and costly than dyeing lighter colors. Achieving a deep, uniform color requires higher dyeconcentrationsandmorewaterandenergy,and often also demands additional steps or re-dyeing. Dark shades, particularly red, also tend to fade more quickly than light colors, especially when exposedtosunlightandrepeatedhomelaundering.

With high-speed low-temperature wash-off, high processreliabilityandexcellentreproducibilityon ® dark and ultra-dark shades, the AVITERA SE GENERATION NEXT dyestuffs allow mills to achieve water and energy savings of up to 50% comparedtobestavailabletechnology,andtoslash CO emissionsandeffluentdischargebyupto50% 2 aswell.Theycanalsoincreasemilloutputbyupto 25%ormore.

Excellent Fastness for Vibrant Colors, Wash AfterWash

® The AVITERA SE GENERATION NEXT dyes offer excellent fastness properties, retaining their vibrant colors through repeated home laundering, even when exposed to chlorine and oxidative bleach. They also demonstrate good resistance to lightandperspiration.Thisperformancemeetsthe stringent color fastness standards of leading industrystandardsandmakesthemsuitableforthe ® ® High IQ Lasting Color and High IQ Lasting ColorEcocolorretentionprograms.

® Crucially, all of the AVITERA SE dyes are free from arylamines, including pCA*, and comply ® withbluesign andZDHCLevel3.

Maximum Resource Savings, Highest PerformanceLevels

Under the PLANET CONSCIOUS+ framework, ®AVITERA RASPBERRY SE qualifies for the

IMPACT+ category on the SUPER SYSTEMS+ matrix. This indicates that it delivers maximum durability and resource savings with the cleanest chemistryandhighestperformance.

WideColorRangewithTopColorConsistency

®AVITERA SE RASPBERRY SE sits alongside ® threeotherdeepcolorsintheAVITERA SErange, providingopportunitytoexpandtothedarkshade arena with both environmental and economical sustainability:

® Ÿ AVITERA BLACK PEARL SE: A strong, greenish-castblackdyethatcanbeusedtocorrect metamerism.

® Ÿ AVITERA BLUE HORIZON SE: A trichromatic,greenish-castblueelementwithhigh resistance to nitrogen oxides (NOx) in the atmosphere.

® Ÿ AVITERA NIGHTSTORM SE:Astrong navyshadewithagreenishcast,recommendedfor dyeingthedeepestnavyandcombinationshades.

®AVITERA SE set a new benchmark for sustainability in the textile industry when it launched in 2010. The range's color palette has been significantly expanded over the years, while performance has improved, and greater cost savings have been made possible through recipe optimization and added environmental benefits. Generation Next, the fourth generation of the revolutionary dye solution, adds dark and extra darkshadesfornext-leveleconomicsustainability

*Non-detectableonthegarment

®TrademarksofArchromaregisteredinmany countries.

©2025Archroma

Clariant'snovelsolutionsforenhancingcrophealthand ™ biologicalformulationsatCAC2025:Synergen Soiland SynergenGuard100

Ÿ Clariant's next-generation solutions for biologicals contribute to a more sustainable agriculture

Ÿ Synergen Soil improves waterinfiltration, leading to optimal growing conditions to supportcrophealth

Ÿ Synergen Guard 100 is an advanced performanceboosterandrainfastnessagentfor biologicals

AsleadersinagrochemicalsandAgriTechmeet in Shanghai at the 2025 China International Agrochemical and Crop Protection Exhibition (CAC), Clariant has unveiled its nextgeneration solutions for biologicals and innovative approaches to sustaining plant healthbyoptimizingsoilwatermanagement.

With a growing global population and the challenges that climate change is posing to agriculture and food security, biologicals have emerged as a more sustainable alternative to conventional pesticides to enhance yields while usingfewerresources.

Clariant's Synergen Soil is an advanced soil adjuvant that optimizes water-use efficiency connected with sustainable agricultural practices. It improves water movement both vertically and laterally within the soil ensuring a consistent distribution of moisture. This leads to optimal growing conditions, supporting healthy roots and maximizingplants'potentialforrobustgrowth.

AlsoinfocusatCAC2025istheSynergenGuard range, including Synergen Guard 100, a

performance booster and rainfastness agent for biologicals.Thisinnovativenano-emulsion-based tank-mix adjuvant contains renewable wax and is produced by a unique proprietary highly efficient emulsificationtechnology.Itisbiocompatiblewith a broad range of microorganisms, giving a powerful boost in coverage, efficacy, and rain protectiontothebiocontrolagent.

“Asaleaderinglobalcropsolutions,atClariantwe are excited to be showcasing our next-generation biological formulations at CAC 2025. Our stateof-the-art research facilities and expertise in microbiology put us at the forefront in the developmentandoptimizationofcustom-designed formulations that enhance bio-efficacy,” said Toshiaki Shinohara, Clariant's Head of Crop SolutionsAPAC.

AdditionallyatCAC2025,discoverClariant'snew ™ ™ Dispersogen TP 100 T and the Sapogenat T range.

Dispersogen TP 100 T is a high-performance anionic dispersing agent for application in suspension concentrate (SC). As a universal SC dispersing agent, it can be used alone in conventional SC formulations with high costeffectiveness, under a recommended dosage of 3~5%.

Designed for high load SC formulations with traditional actives like Carbendazim, Chlorothalonil, Methyl-thiophanate,Atrazine and Diflufenican,DispersogenTP100Tcanbeusedto solvecommonSCproblemssuchaspoorwetting, rapid growth of particle size, viscosity build-up, bad flowability, and even pseudoplastic and creamingissues.

The Sapogenat T range has been designed as a replacement for nonylphenol ethoxolates (NPE), restrictedsinceMarch2023.Itfunctionsasanonionicemulsifierbasedontri-sec-butylphenolwith variousethoxylationdegrees.Consideredthebestperforming NPE alternative, it offers excellent emulsification power, making it a good wetter capable of increasing pesticide efficacy in foliar application.

Join us on our journey towards sustainable agricultureandGreaterChemistrybetweenPeople and the Planet. Learn more about Clariant's innovative agricultural solutions to help solve today'schallenges.

VisitClariant'sCACeventpageaheadoftheshow tofindmoreinformationontheproducts.

™ARETRADEMARKSOFCLARIANT.

BeaulieuFibresInternationalatIDEA25:showcasingfibresthatbuildfutures-highin performanceandsustainability.(Photo:©BeaulieuInternationalGroup)

Ÿ Discover Beaulieu's self-reinforced PPfibres forfullyrecyclableautomotivecomposites

Ÿ LaunchingabicomponentfibrerangeinNorth Americaforthermo-bondedfiltrationmedia

Ÿ Introducing premium outdoor PP fibres for needlepunched crop covers, improving the protection of agricultural crops against adverse weatherconditions

Ÿ Designed for recycling, Ultrabond fibres significantly reduce waste generation and end-oflifeenvironmentalimpact

Ÿ Strengthening its position in the hygiene market with latest advancements in specialty bicomponentfibres

As thousands of industry leaders look towards IDEA25 in Miami Beach in April, Beaulieu Fibres International is exhibiting its nextgeneration sustainable fibre solutions for high performancenonwovensinvariousindustries.

“IDEA25 is at the intersection of nonwoven materials and sustainability, with a focus on

innovation and research to address environmental challenges and new opportunities. With our SustainableFibresProgram,weofferlowcarbon, recyclable and circular solutions where performance and sustainability go hand in hand, bringing value in co-design and TCO performance,” said Maria Teresa Tomaselli, GeneralManager,BeaulieuFibresInternational.

Self-reinforced PP fibres for fully recyclable automotivecomposites

Beaulieu will be showcasing its comprehensive range of polypropylene (PP) bonding fibres designedforthermoplasticlightweightcomposites andautomotiveinteriorfabrics.Thesefibresassist carmanufacturersandOEMsinmeetingstringent performance, cost-efficiency, and sustainability standards.

Beaulieu'sPPfibresareengineeredtoenhancethe mechanical, thermal, and functional properties of compositeswhilereducingvehicleweight.

Fibres for high performance liquid and air filtration

Beaulieu Fibres International has set new performancestandardsforthefast-growingairand liquidfiltrationindustryrollingoutitsfullrangeof MONOandBICOfine-mediumcountfibres,asan outcome of its investment into R&D efforts to promotestaplefibresinthefieldofhighefficiency filtration.

InadditiontoitsexistingportfolioofPPfibresfor liquid filtration, compliant with FDA and European food contact regulations, Beaulieu is launching a new bicomponent fibre range in PET/PE, PP/PE for high loft filtration media and fine count mono PP fibres for tribo-electric chargedairfiltermedia.

The fine count mono fibres are customized according to the line specifics of the nonwoven producerandguaranteeupto20%higherfiltration efficiencies for nonwovens in combination with state-of-the-art acrylic counter fibre compared to standardPPfibresusedinthisapplication.Typical applications are air handling units in larger buildingsandresidentialfurnaces.

Premium outdoor PP fibres for resilient, weather-resistantcropprotectionsolutions

Engineered for superior mechanical strength and resistance to environmental stress factors, these fibres enhance durability in needle-punched fabrics, ensuring long-lasting protection in the field. Their advanced UV stabilization prevents degradation from prolonged sun exposure, extending the lifespan of crop covers, while their hydrophobic properties repel water, reducing moisture-related damage and maintaining breathability.

Ultrabond,designforrecycling

Discover UltraBond innovative bonding staple

fibres that replace the need for chemical binders. They open a path to create 100% polypropylene (PP) needlepunched fabrics which meet the same performance requirements as traditional constructions, while reducing end-of-life environmentalimpact.

The 100% polyolefin-based needlepunched fabrics are fully recyclable, reducing waste generation and creating high value PP recycled products as new materials. Furthermore, the sustainablefabricsareproducedwithanimproved Total Cost of Ownership and with a significant ecologicalfootprintreduction.

Beaulieu strengthening its position in the hygienemarket

With a full portfolio already serving the hygiene sector, Beaulieu is focusing on next-generation speciality bicomponent solutions designed to enhancesoftness,processability,andsustainability inabsorbenthygieneproducts.

Hypersoft fibres are specifically engineered for topsheet applications in direct contact with the skin: 25% improvement in softness compared to standard reference fibres while maintaining optimalprocessabilityhasbeenachieved.

Meralux is a bicomponent trilobal fibre that improvesnonwovenmaterialsbyprovidingbetter opacity,comfort,andabsorption.Italsopromotes sustainability by saving raw materials and reducingcarbonemissionsbyupto60%.

AtIDEA25,April29-May1inMiamiBeach,visit Beaulieu Fibres International at booth 521 to explore its next-generation fibre solutions with a focus on innovation and co-design for performanceandsustainability.

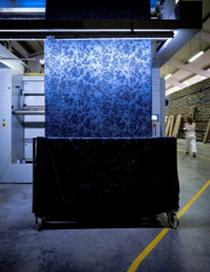

Mimaki launches Tx330-1800 and Tx330-1800B for on-demand, sustainable and high quality textileapplications

• Mimaki launches the Tx330-1800 and Tx3301800Bforthetextileandapparelmarkets

• Builtforoptimalaccessibilityandsustainability, the Tx330 Series offers high quality printing for on-demandandvariedprintruns.

Mimaki Europe, a leading provider of industrial inkjet printers, cutting plotters, and 3D printers, unveils two new direct-to-textile printers, the Tx330-1800andTx330-1800B.TheTx330Series offersextensivetextileprintingcapabilities,ableto print on a variety of materials with minimal wastewater. In contrast to conventional textile printing processes that require pre- and postprocessing equipment, the Tx330 Series streamlinesproductionintoamorespace-efficient solution—ideal for users with limited space. FESPAinBerlin(6th-9thMay2025)willmarkthe EMEAdebutoftheTx3301800andtheunveiling offurtherdetailsconcerningbothprinters.

TheTx330Seriesdrivesthetransformationofthe textile industry towards waterless, high-quality solutions, as well as for apparel manufacturers, wholookforaprinterwhichoffersbothqualityand sustainability.Theprintersareequippedwithdual ink set capability to seamlessly switch between textile pigment inks and dye sublimation inks, further diversifying application possibilities. Unlike conventional dye inks, these solutions simplify the process with a straightforward

printing and heat fixation procedure. This eliminates the need for extensive facilities for water supply, drainage and wastewater treatment, as well as the dyeing expertise needed to operate, makingdigitaltextileprintingmoreaccessible.

The Tx330-1800 allows for seamless printing on both fabric and paper in one machine, ideal when producing textile signage and interior fabrics.

Meanwhile,theTx330-1800Busesaspace-saving beltconveyortostablyprintonstretchy,thick,and thin fabrics commonly used for apparel, ideal for the production of short-run and varied apparel in small spaces, such as offices, schools, and retail stores.

Arjen Evertse, General Manager Sales EMEA at Mimaki Europe, comments,“Looking at today’s textile market, we anticipate that the demand for textile products produced on-demand and locally will continue to grow. So, with that in mind,wereleasedtwoproductswhichareeasy-touse, versatile and sustainable, for those printers looking to incorporatetextileprintingcapabilities within a small space, without compromising on capabilitiesandquality.

“Theinkversatilityaspectoftheseprinterstackles theimportantconcernofindustrialwaterpollution, of which traditional textile dyeing alone contributes around 20% to. Utilising textile pigmentanddyesublimationprocesses,Mimaki’s latest printing solutions remove the need for the large amounts of water typically required in postprocessing, creating a much more resource efficient process with almost no water used at

all—while also significantly reducing energy consumption.”

The Tx330-1800 Series utilises Mimaki’s “330 Engine”,providingthesamesharpdetails,smooth colouring and accurate colour printing as other entries in the 330 Series due to smooth gradation expressionandhigh-densityprintingcapabilities.

To accompany the Tx330 series, Mimaki is also introducing a textile RIP software, the TxLink5. This latest version of the TxLink software is designed to further improve the workflow in

environmentswithmultipleprinters,whichallows for users to manage their printing processes more efficiently.

The Tx330-1800 and Tx330-1800B will both be availableforthetextileandapparelmarketinJune 2025.

For more information about Mimaki’s innovative productsandsolutions,visit https://www.mimakieurope.com/

TheTx330-1800hybridmodelprovidesseamlessprintingonbothfabricandpaper

TheTx330-1800Bisanidealspace-savingsolution,withaddedstabilityforprintingoncomplexfabrics

ClariantcolleaguesfromthepreservationlabsattheClariantInnovationCenterinFrankfurt, Germanyevaluatingproductperformance.©Clariant

Ÿ Nipaguard SCE Vita delivers comprehensive antimicrobial protection for personal care formulations

Ÿ Designedforformulationswithoutcontroversial preservatives

Ÿ Witha100%RenewableCarbonIndex,itoffersa more natural alternative to synthetic-based preservativesforeffectivebeautyprotection

As the personal care industry prepares for incosmeticsGlobal,theworld'spremierlaunchpadfor new ingredient innovations, Clariant unveils Nipaguard SCE Vita, its naturally derived preservation solution for formulations without controversialpreservatives.

In today's conscious beauty landscape, consumers are increasingly aware of the ingredients in their personal careproductsandtheirimpactonbothhumanhealthand the environment. This is driving demand for the cosmetics industry to do "more with less", delivering high-performanceproductswhileminimizingtheuseof controversialingredients.

NipaguardSCEVitaoffersapowerful,modernsolution that enhances product protection while aligning with consumer expectations for safety and sustainability. Based on 100% renewable Sorbitan Caprylate, it is synergistically combined with naturally derived, rather thanfossilbased,benzoicacid.

This new blend represents an innovative modern preservation system to create next-generation formulations that strike the perfect balance between efficacy, safety, and environmental responsibility. It is

idealforcustomerslookingtodevelop100%Renewable CarbonIndex(RCI)formulations.

Besides offering broad-spectrum protection to a broad rangeofapplicationsandformatsNipaguardSCEVitais easy to use, safe and effective at low concentrations. Extensivetestingshowsthatthenewformulameetsthe highest standard on the market, giving formulators complete confidence in its effectiveness to deliver the sameperformanceastraditionalpreservatives.

“At Clariant we are proud to be a market leader in solutions for the preservation of cosmetics. Nipaguard SCE Vita contains no controversial preservatives and marks a significant step in our broader commitment to address the needs of health- and sustainabilityconscious consumers and brands at the same time as creating value for customers with renewable-carbon, high-performance products,” said Karolina Scierski, Clariant'sPortfolioManagerforPreservation.

As the environmental, health, and social impacts of purchasing decisions come to the forefront, customers increasingly seek products that align with their own commitments to sustainable practices Clariant's innovationsinthepersonalcareandcosmeticsindustries reflect these values, addressing both market demands andsustainabilitygoals.

Find Clariant at in-cosmetics global inAmsterdam, the world's leading global event for personal care ingredients,8-10AprilatBooth1D30.

™Nipaguard ISATRADEMARKOFCLARIANT.

GE TECHNOLOGY INC. (Getek), an ODM supplier to top semiconductor and cleanroom facilities, introduces the CHEMSORB-R Series. This innovative chemical filter is designed to effectively eliminate Airborne Molecular Contaminants(AMC)andcontrolVolatileOrganic Compound (VOC) contamination, significantly advancingESGcompliance.

With full in-house production, Getek customizes chemisorptive media using the TAFS Engineered Approach to match each site's needs, ensuring precise alignment with each client's specific contaminant-removal needs.The CHEMSORB-R filterefficientlytargetsACIDs,BASEs,Molecular Gases, IPA, Acetone, O₃, RC, Boron, and phosphorusgases.Itsprecisemediadesignensures peakfiltrationperformanceandlowpressuredrop, optimizing energy efficiency, and reducing maintenancefrequency.

TheCHEMSORB-RSeriesfeaturesamodulartray system designed for MAUs. Its tool-free maintenance capability allows teams to easily replace media trays independently, reducing downtime and waste. The standard frame dimensions (24 inch W x 24 inch H x 18 inch D) accommodatemultipletraysforimprovedairflow. Tray dimensions and frame materials (SUS, Galvanized Iron,ABS Plastic) can be customized tospecificsiterequirements,providingrobustanticorrosionpropertiesandoptimizedspecificallyfor critical HVAC systems in semiconductor and cleanroomapplications.Thetraydesigneliminates theneedforfiltercottonlinings,preventingmedia leakagethroughitspreciselyengineeredstructure. It also allows for easy on-site replacement and refilling of the media mix, further simplifying maintenance and extending product life

Getek's CHEMSORB-R Series supports

sustainability on several fronts. The low pressure drop of the filters significantly reduces energy consumption without compromising airflow performance. The customized media mix extends filterlife,reducingmaintenance.Additionally,the modulartrayandframedesignssupportindividual replacement and refilling, allowing reactivation and reuse multiple times. Robust, anti-corrosion framesenhancereusability,significantlyreducing wasteandfurtheraligningwithgreenprocurement practicesandsustainabilitystandards.

TheTAFSEngineeredApproachcombineson-site analysis,diagnostics,andcustommanufacturingto match each facility's contamination profile, beginning with comprehensive on-site analysis and molecular-level diagnostics, followed by custom design and performance optimization. Unlike conventional filtration systems, TAFS solutions are engineered and manufactured entirelyin-housetopreciselymatcheachfacility's contamination profile, ensuring enhanced energy efficiency,prolongedfilterlife,andalignmentwith ESGobjectives.

The CHEMSORB-R Series complies with key international standards, including ISO 9001, ISO 14001, ISO 45001, ISO 14064-1, ISO 14067,

RoHS, REACH, and ANSI/ASHRAE Standard

145.1. This ensures reliability, safety, and regulatoryalignmentforcleanroomandhigh-tech manufacturing environments. This compliance guaranteesreliability,safety,androbustregulatory alignment for critical manufacturing and cleanroomenvironments.

To learn more about the CHEMSORB-R Series, please contact the Getek sales team at sales@getek.com.tw or visit the product page at https://www.ge-tek.com/amc-solutions

GE Technology Inc. (Getek) focuses on engineering air filtration solutions designed to address Airborne Molecular Contamination (AMC). With comprehensive in-house control from raw materials to finished products Getek develops filtration systems aligned with ESG standards, optimizing energy efficiency and sustainability. The TAFS EngineeredApproach ensures low pressure drop, reducing energy consumption and environmental impact while improving filter reusability Getek's filtrationsolutionsservediversesectors,including semiconductors, pharmaceuticals, electric vehicle battery production, electronics assembly, and commercial HVAC, meeting regulatory compliancetailoredtocustomerrequirements.For moreinformation,visithttp://www.ge-tek.com/

Authoredby:SatishPanchani,CEO&Co-founderofTrueColors

TrueColorsisrevolutionisingtheDigitalTextilePrinting sector through a combination of innovation, tech, and sustainable-orientedpractices.

The Indian textile industry is going through rapid changes, driven by three forces – digitalisation, sustainability, and personalisation. True Colors Limited of Surat has been the leaderindigitaltextileprintingsince2013,andisleadingthis change.Thefirmhasemergedastheflagbearerofinnovation indigitaltextileprintingandisservingclientsfromallover theworld.

WhenTrueColorslaunched,themissionwastodevelopthe first sublimation textile printer in India. The firm faced multiple issues in developing tech-oriented sustainable solutions. However, the management persevered and successfullytackledallchallenges.Today,TrueColorsowns alargeproductionfacilitylocatedinSurat,backedbyateam ofover650trainedprofessionals.Thefirmoffersacomplete ecosystem of end-to-end digital textile printing solutions. It goes beyond just selling printers, which include high-speed digital printers, inks, sublimation papers, textiles, and even providingessentialtechnicalassistance.

MarketMomentum:DigitalPrintingontheRise

India'sdigitaltextileprintingmarketwasworthabout$467 millionin2024andisprojectedtobevaluedat$1.13billion by 2030. Global expansion will reach $20 billion by 2034 from a $6 billion market cap of 2024. These strong growth projectionssignalthegrowthpotentialofthesegmentinthe comingyears.Besides,thesestatisticsconfirmthattheworld is fast-moving towards digital and sustainable textile manufacturing.

WhyisDigitalTextilePrintingGrowing

a)Flexibilityandcustomisation:Digitalprintingallowsfor fastersamplingandshort-runproduction.Itallowsflexibility indesignstomeetthedemandsofcontemporaryconsumers. Inaddition,TrueColorshasthecapabilitytoproduceinboth small-batchunitsandlarge-scalelots.Ithasacapacityofover 50,000meters/day,whichisphenomenalfromtheproduction viewpoint.

b) Fast and Efficient: Advanced digital printers produce output quickly and accurately with an automated process. Besidesreducingturnaroundtimes,thisautomationreduces production costs as well. Faster time-to-market provides organisations with agility and responsiveness, which is imperativeforcompanycompetitioninthemarketplace.

c) Eco-Friendly Production: Digital printing uses drastically less water and energy than traditional printing methods. Digital also produces disproportionately less waste,permittingfirmstosaveevenmoreandincreaseprofit margins. True Colors utilises processes that minimise ecologicalfootprintsandprovidethehighestqualityprinting outcomes. This eco-friendly process is essential not just to expressintent,buttoprotecttheenvironmentforgenerations.

d) Aligning with Sustainability Trends: As the Indian fashion industry aims to grow significantly while also reducingemissions,digitaltextileprintingisapotentialkey technology in working towards both goals.The adoption of sustainability is also necessary to meet compliance and counterthenarrativeagainstthemanufacturingsectorbeing calledthemostpollutingsegmentamongindustries.

TrueColors'CompetitiveAdvantage

True Colors distinguishes itself with more than 1200 installationsinIndiaandawell-establishedteamofengineers and professionals who handle everything machines, inks, papers, and fabrics, as well as continuing support. True Colors provides complete solutions that include up-to-date technology,alongwithenvironmentallyfriendlyproduction systems, thereby ensuring reliability and sustainability for theircustomers.

MovingBeyondFabrics:ChangingtheValueofTextiles

Digital textile printing is changing the industry holistically. From allowing precise and location-specific services to fast and flexible supply chains, the possibility of sustainable production at scale sets True Colors apart. True Colors products allow businesses to innovate and compete in domestic and international marketplaces. Its services are used across the spectrum of artists, SMEs, exporters, and large-scale firms, making the firm a leading name in the digitaltextileprintingindustry

True Colors invites textile manufacturers, exporters, designers, and startups to take advantage of this digital printing to catalyse their growth. From innovation to manufacturing flexibility, True Colors' in-house and complete solutions are there to assist in the growth and sustainability of this ever-changing market.True Colors is dedicated to growing the innovation, quality, and environmental sustainability of the current market position of India as a leader in global digital textile printing. Summarily,therevolutionintheDigitalTextile Printinghasheralded,andit'stimetomakethemostofit.

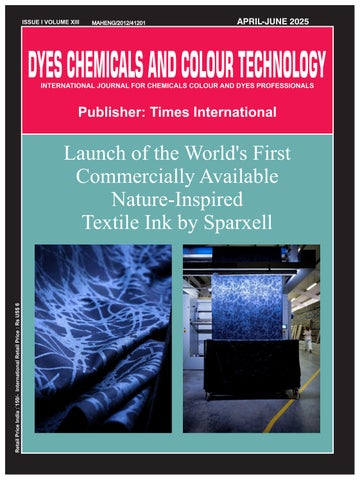

Inalandmarkdevelopmentforsustainablefashion and textile innovation, Cambridge-based colour platform technology company Sparxell has officially launched the world's first commercially available nature-inspired, plantbased textile ink. Developed in partnership with Positive Materials, this breakthrough innovation marks a pivotal step in replacing environmentally harmful dyeing processes with bio-inspired, biodegradablealternatives.

Sparxell's textile ink is formulated from structurally coloured, plant-based pigments that mimicthewaycolourisformedinnature—such as in Morpho butterfly wings—through light manipulation rather than chemical dyes. This approachremovestheneedfor:

· Toxicdyes

· Syntheticplastics

· Minedmetalsandminerals

· Petroleum-basedmaterials

As a result, the ink offers superior colour vibrancy and durability while significantly reducingenergyconsumption,waterusage,and chemical pollution associated with traditional

textiledyeing.

CommercialAvailabilityandApplications

· Product:Sparxell'ssignaturebluetextile ink

· Formats: Available in both matte and shimmerfinishes

· Availability:Commercialkilogramorders availablefromendofJune2025

· Processing Partner: Positive Materials willhandleproductionanddistribution

· Initial Products: An all-over printed cottonjerseyusingSparxell'sinkwillbeavailable fromSeptember2025inEuropeanmarkets

This rollout represents the first of multiple colours planned for release throughout 2025, enabledbySparxell'sscalable,virtuallyunlimited bio-inspiredcolourplatform.

Sparxell's solution is positioned to democratise access to sustainable colour technology by enabling standard ordering for commercial use, rather than relying on custom development. The partnershipwithPositiveMaterialsensures:

Ÿ Seamless integration into existing textile productioninfrastructure

Ÿ Scalable,production-readytechnology

Ÿ Maintenance of strict sustainability standards

This approach meets rising demand for environmentallyresponsibleoptionsinanindustry that uses over 10,000 different chemicals, emits 1.5 million tonnes of toxic dyes annually, and contributesupto2%ofglobalGHGemissions

Dr Benjamin Droguet, Founder and CEO of Sparxell:

“Thistextileinklaunchtransformshowbrandscan accessourbreakthroughtechnology...Ourvisionis to make bio-inspired colour technology the new standard across fashion, proving that high performanceandworkinginharmonywithnature areperfectlyaligned.”

Elsa Parente, Co-CEO and CTO of Positive Materials:

“Fashion designers and procurement teams can now order the most sustainable colourant options aseasilyasconventionalones...Ourcollaboration

with Sparxell represents exactly the kind of innovationthetextileindustryneeds.”

Sparxell's textile ink launch follows recent strategicwinsincluding:

Ÿ A€1.9 million grant from the European InnovationCouncil

Ÿ Selection for LVMH's La Maison des Startupsacceleratorprogramme

These recognitions underscore the commercial potentialandglobalrelevanceoftheirbio-inspired innovation.

ThelaunchofSparxell'snature-inspiredtextileink is a transformational moment for the textile industry—offering a scalable, high-performance solution that aligns sustainability with design innovation. By eliminating toxic materials and enabling easy commercial access, Sparxell and Positive Materials are pioneering a new era of environmentallyconsciouscolourationinfashion.

Learnmore:https://sparxell.com/