192021 November 2025

INDIA’S LEADING EXHIBITION ON TECHNICAL TEXTILES, NONWOVENS & COMPOSITES

• Explore 150+ brands from India & 10+ countries

• Discover solutions for 12+ sectors: from medical to mobility

• Network with industry leaders & decision-makers

CONFERENCE

Pre-register now for a hassle free entrance

Editorial

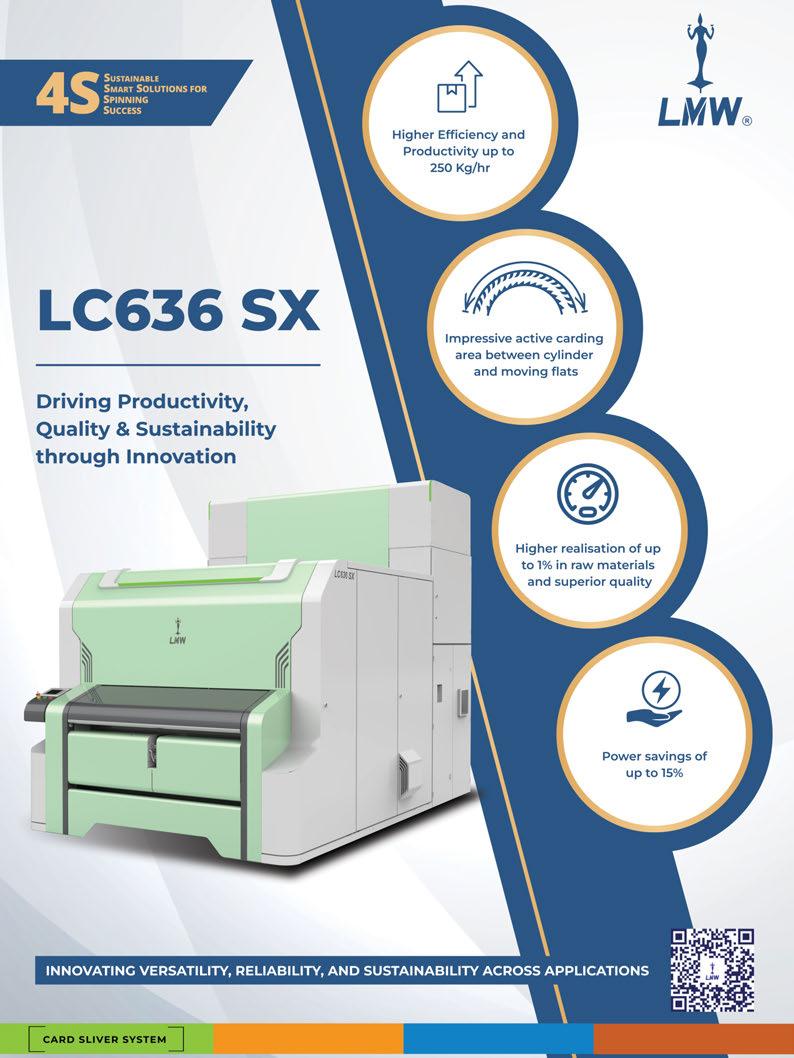

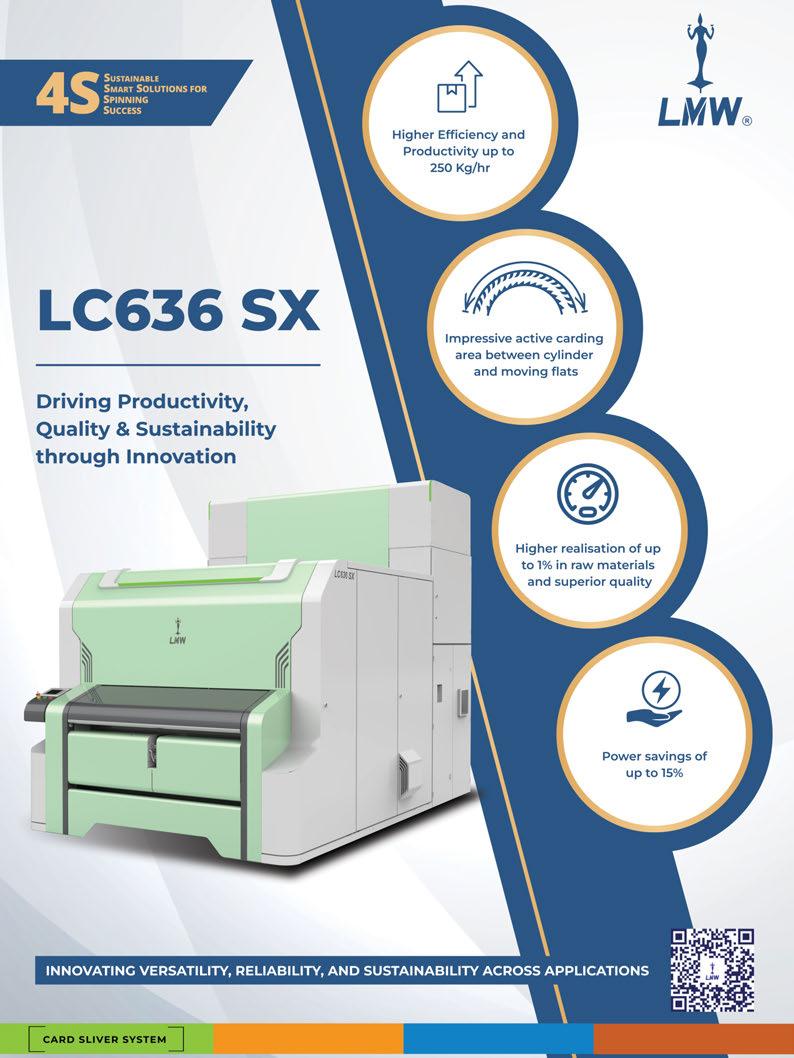

ErbeysJourneytoExcellenceinYarnProductionwithLMW

WeavingtheFuture

Mr. Sanjeev Bahl, Founder & CEO

ReengineeringtheFutureofTextileManufacturing:HowSAITEXisLeading withSustainability,Digitalization,andVerticalIntegration

Pullingapartpatternsandfabricfingerprinting

BrücknerTextileTechnologiesopensnewsubsidiaryinCoimbatore,India

BMSvisioncelebrates50yearsofinnovationinManufacturingExecutionSystems

Autocoro11–Leadinginnovationforspinningrecycledfibres

SurgingCottonImports:India'sGlobalFibreQuestMarksaHistoricHigh

SustainabilityinFocus:SwissTechnologiesReshapeTextileEfficiency

07798189485

From 28 to 31 October 2025, the world's textile leaderswillconvergeattheSingaporeExpofora landmark edition of ITMA Asia + CITME—where technology meets vision,andinnovationfuelstransformation.

Withover770exhibitorsfrom33countriesacross a sprawling 70,000 m², the event has already expanded by 30% due to unprecedented global demand. This isn't just a trade show—it's a bold statement of momentum, resilience, and futurereadiness.

ThechoiceofSingaporeisstrategicandsymbolic. With its visa ease, unmatched connectivity, and world-class infrastructure, the Lion City becomes the gateway to the booming markets of South and SoutheastAsia and the Middle East. Exhibitors hail this as Asia's most important textile event, tailored for meaningful regional engagementandstrategicgrowth.

Butwhattrulyelevatesthiseditionisitsalignment with sustainability and smart automation—the twin engines of tomorrow's textile industry. From AI-powered dyeing to energy-efficient knitting, thisplatformbringsfuture-forwardtechnologiesto life. The Sustainability Forum, supported by the European Commission, highlights the industry's collective pledge toward circularity and climate responsibility.

AsglobalvaluechainsshiftandESGprioritiesrise, ITMAAsia+CITME2025standstall—notjustas a showcase, but as a beacon of reinvention.With livedemos,researchinsights,andinnovationhubs, itiswhereideasbecomeaction,andambitionmeets execution.

This is more than an event. It's where the textile industryfindsitsnewrhythm—sustainable,smart, andunstoppable.

FromleftMr.BeytullahYıldız,ChairmanoftheBoardofDirectors,AtlasDenim TekstilSan.Tic.AŞ,Mr.JaidevJayavarthanavelu,Director,LMWGlobalFZE,Mr. ErdoğanTürkmen,Vice-ChairmanoftheBoardofDirectors,AtlasDenimTekstil

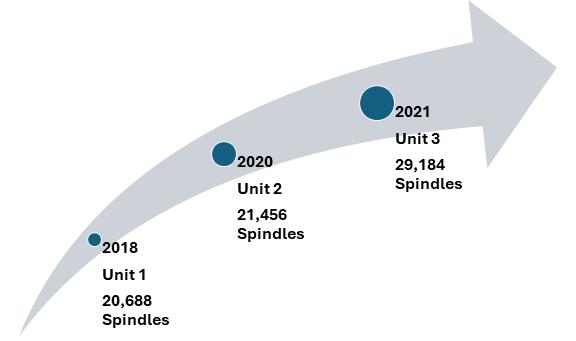

Establishedin2018,ErbeyDokumaİplikSanayi veTicaretA.Ş.,headquarteredinSarıçam,Adana, Turkey,quicklyroseasaprominentplayerinthe textile industry. With three modern units and a spindle capacity of 71,328, Erbey İplik has consistentlyexpandeditsproductioncapabilities, achieving a total yarn production capacity of 62 tons/day for ring yarn and 28 tons/day for openendyarn.

Erbey İplik specializes in processing counts rangingfromNe6toNe36,producingavarietyof high-quality yarns, including Cotton Carded, Slub, Core, Dual Core, and Combed Compact Hosiery yarn. While coarse counts cater to inhouse weaving requirements, their combed compact yarn primarily serves the domestic market.

Mr. Beytullah Yıldız, says, “LMW's machines are with the latest technology andensuresfasterreturnon investment. It'saonestopsolution,offeringtheentire rangeofspinningmachinery”.

Erbey İplik's journey began as part of Atlas Denim'sinitiativetointegratebackwardintoyarn production.Initiallybuyingyarnfrommarketfor its denim fabric operations, the company took a strategicleaptoproduceitsownyarn.

In 2017, Erbey Dokuma Iplik, evaluated various options for setting up the denim manufacturing unitandfinalizedLMWmachinery,basedonthe deliverablesonoffer.Thefirstplantwassetupin theyear2018with20,688Spindles.

Erbeyplannedforanexpansionprojectintheyear 2020andbasedonthesuccessfulperformanceof LMWmachinesintheirUnit1,ErbeyIplik,Unit2 projectwasfinalizedwith21,456spindles.

Following the success in both Unit 1 & Unit 2, ErbeyplannedforaCombedApplicationProject intheyear2021.Thefirstchoiceofmachineryfor

the customer was LMW. Having seen the performanceintermsofproductivity,quality,user friendliness & maintenance friendliness, Erbey Iplik – Unit 3 was established with 29,184 spindlesproducing100%combedcompactyarn.

Partnering with LMW proved instrumental in Erbey İplik's success. LMW's advanced machinery with Automation solutions like Lap Transporation System (LTS), Roving Transportation System (RTS), Spinconnect provided flexibility to handle a wide range of counts and special yarns, ensuring consistent productivityandfasterreturnsoninvestment.

Mr.AhmetÇağrıDALKIR-GeneralManager,AtlasDenimSan.VeTic.A.S.says,“We haveaverystrongassociationwithLMWforthepast7years.Wearehighlysatisfied withthepre-salesactivities,quickandpromptsupportfromthelocalteamonpost-sales aswell.WewishtocontinuewithLMWforallourfutureendeavours”.

Mr.TunçBurakErdoğan-FactoryManager,ERBEYDOKUMAİPLİKSAN.TİC.A.Ş

The technical team says, “With LMW machines, we achieve the targeted productionquiteconsistentlywiththerequiredquality.Themachinesareflexible torunawiderangeofcountsandspecialyarn.Weareverymuchsatisfiedwiththe quickaftersalessupportofthelocalteam”.

ThecompleteLMWSpinninglineupinstalledatErbey,

ThetechnicalteamatErbeyİplik'salongwithLMWTeam

Erbey İplik's strong association with LMW over thepastsevenyearshasbeenacornerstoneforthe success.Theirfacilityservesasareferencepoint for LMWinTurkey, hosting numerous customer visits and demonstrating the excellence achievablewithLMWtechnology.

The synergy between Erbey İplik's strategic vision and LMW's advanced Automation solutions has positioned the company as a leader in textile innovation. With commitment to productivity, quality, and customer satisfaction, Erbey İplik continues to set benchmarks in the yarnmanufacturingindustry.

Scanheretovisitourwebsite

WeavingtheFuture:HowSAITEXisRedefiningResiliencewith Localized,SustainableDenimManufacturing”

In an era where global supply chains face increasing scrutiny and disruption, SAITEX emerges as a powerful example of how strategic localization and sustainable innovation can future-proofapparelmanufacturing.Operatingat the intersection of environmental responsibility andeconomicforesight,SAITEXisoneofthefew manufacturersinVietnamthatrunsitsownonsite Denim Mill, creating a fully integrated and traceablevaluechain.

With operations spanning Vietnam and the UnitedStates,thecompanyisuniquelyequipped to meet the rising demand for in-country value creation. Its vertical model—from spinning and weavingtocuttingandsewing—notonlyreduces dependence on imported raw materials but also enhances supply chain agility and transparency. Impressively, 90% of SAITEX's cotton is

sourced from the U.S., ensuring material traceability while strengthening local-global synergies.

At a time when many exporters face margin pressures due to shifting trade policies and compliance demands, SAITEX stands apart by investing in infrastructure that is built for the long game. Under the visionary leadership of CEO Sanjeev Bahl, SAITEX has become a trustedpartnertoleadingsustainablebrandssuch as Everlane, Madewell, Ralph Lauren, and others.

SAITEX's story is not just about manufacturing—it's about shaping the future of fashion with purpose, resilience, and an unwaveringcommitmenttosustainability.

ReengineeringtheFutureofTextileManufacturing:How SAITEXisLeadingwithSustainability,Digitalization,and VerticalIntegration”

Mr.SanjeevBahl,Founder&CEO

1. Key Technologies Used Across SAITEX Operations

Ÿ Vertical integration: At its Vietnam site, SAITEX Mill integrates spinning, weaving, dyeing, finishing, and garmenting under one roof—atruecircularsetup .

™

Ÿ Smart Indigo dyeing: Employs electrochemical, hydrosulphite-free indigo dyeing,cuttingCO₂by90%,energyuseby70%, andwaterconsumptionby30% .

Ÿ Laserdistressing&ozonewash:3Dlaser and ozone-enabled washes in both Vietnam and L.A. replace manual, chemical-heavy processes —e.g.,distressingin90 svs.20–30 minmanually

Ÿ Closed-loop water systems: Recycle ~98% of factory water via reverse osmosis and multi-stagefiltration.

Ÿ Automation & “SPEED TO MARKET” smart factory tech: IoT sensors, real-time data

tracking, semi-auto sewing, robotic arms for spraying, 3D Mactec curing ovens, and datadrivenproductionschedulingviaSAIDigitaland Speed-to-Marketplatform.

2.ExpansionPlansinVietnam&USA

Vietnam:

Ÿ SAITEX is ramping up the mill's closedloop system to achieve full carbon neutrality by 2030

USA(LosAngeles):

Ÿ ThemicrofactoryinL.A.openedin2021, featuring “smart factory” capabilities like realtime QC, AI-driven scheduling, semi-auto sewing, robotic spraying, laser washes, ozone, and98%waterrecyclinginplace .

Ÿ SAITEXhaspubliclyexploredopeninga NewYork facility but remains focused currently onoptimizingLAandVietnamoperationsbefore scalingfurther.

Ÿ Robotics: Used for automated spraying andlaserdistressingingarmenting

Ÿ AI & data systems: Real-time data analytics and AI power “smart factory”

operations—optimizing production, energy use, qualitycontrol,andspeedtomarket

Ÿ 3D Mactec ovens and automated sewing: Support precision finishing and efficient semiautostitching.

Ÿ Digitalplatforms:TheSAIDigitalsuite and“Speed-to-Market”enablebatch-on-demand, quick-turnproductionwithdigitaltraceabilityand resourceoptimization

4.PrincipalMachinery&TechnologyPartners

VietnamMill:

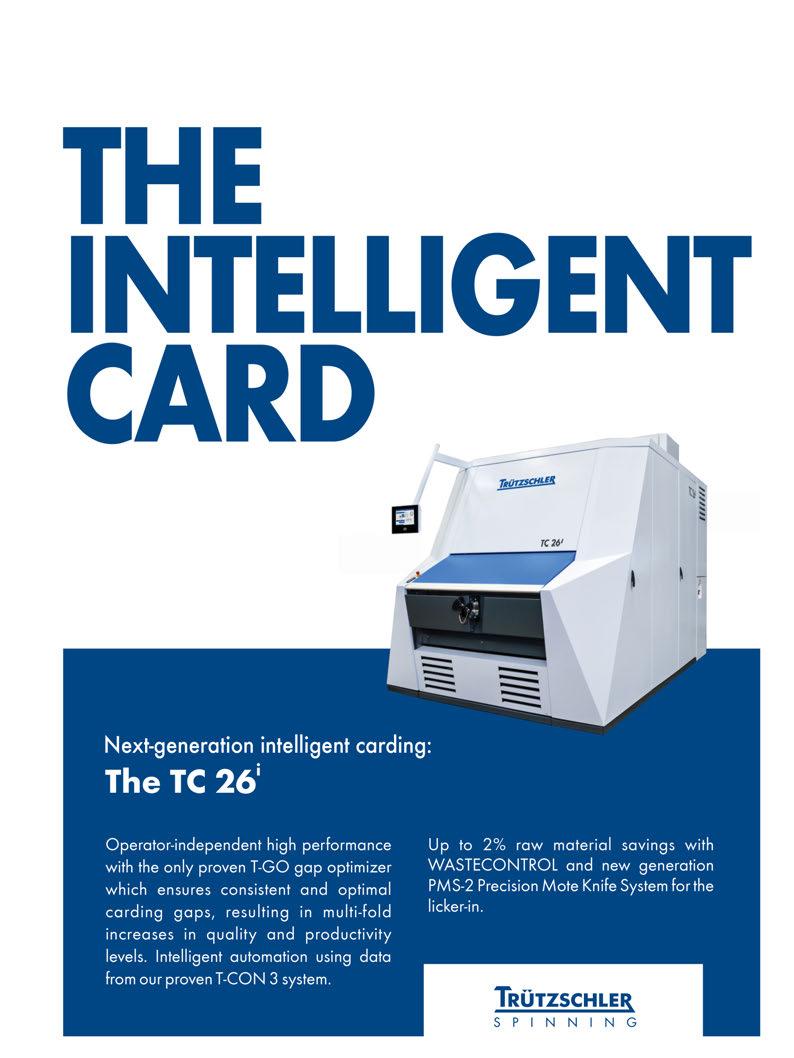

• Spinning: Truetzschler (Germany) for blow-room,carding,drawing . ™

• Dyeing: Smart Indigo system by Sedo; ropedyeingviaKarlMayer .

• Weaving:Picanolrapierlooms(Belgium); GrozBeckertknotting/drawingtools .

Vietnam&USAGarmenting(cut&sew):

• Semi-automaticsewingmachinery.

• 3Dlasersystemsforfinishing.

• Mactec ovens and IoT/robotics systems forsprayinganddistressing .

• Finishing: Equipment from Osthoff (singeing), Goller (pad-steam), Benninger (padbatch dye), Pentek tumblers, Monforts stentering/sanforizing .

We reduce our own indigo with the SmartTMIndigo System to produce hydrosulfite-free indigo dye baths that only use indigo pigment, caustic soda, water and electricity. That system utilizes an electrochemical dye bath preparation that emits 90% less CO2, consumes 70% less energy and 30% less water where the only waste productisoxygen.

Besidesthatweareusingropedyeingtechnology TM from Karl Mayer that produces with just eight dyeing units deep, pure shades with a dye applicationofupto5.5%oftheyarnweight.

Thankstotheshortwetzone,upto25%lessbath volume is required compared to conventional counterparts.

Overall, the machine uses less energy, less water and fewer chemicals. Water consumption can be reduced by roughly 30%. Our main target is to produce sustainable, unique and laser friendly indigo shades. Especially the laser-friendliness plays a major role in the concept of our circular integration as it allows our garment factory to create wash effects with less water and less chemicals used and ultimately will lead us to create vintage effects without any water or chemicalsused.

Inourdyeingfacilitiesweusenofreshwaterbut recycled water in cooperation with the industrial park which is possible through the reverse osmosis and ultrafiltration technology that we haveinvestedinto.

All the fibers which we use are only sustainably produced and use sustainablyprocessablefibers

Ÿ OrganicCotton(GOTScertified)

Ÿ RegenerativeCotton

Ÿ LycraEcomadeandLycra162R(Lycra)

Ÿ T400Ecomade(Lycra)

Ÿ RoicaV550(AsahiKasei)

Ÿ LubrizolX4J-zol(Lubrizol)

Ÿ RefibraTrueCo2Zero(Lenzing)

Ÿ RecycledCotton(Purfi)

Ÿ RecycledPolyester-GreenGold(Reliance)

Ÿ Hemp(PandaBiotech,Canvaloop,Marmara)

5. Sustainable Wastewater Treatment & Energy Optimization

Ÿ Zero discharge system: 98% recycled + 2% evaporated; no wastewater released into the environment .

Ÿ Multi-stage filtration & RO: Water is cleanedtodrinkablestandards .

Ÿ Sludge-to-bricks initiative: Facility sludge is repurposed into building bricks for socialhousing .

Ÿ Energy efficiency:Solarpower:3–4 MW of panels in Vietnam, covering ~25%+ of power needs; saves ~5.3 M kWh/year and cuts CO₂ emissions~80% .

Ÿ Heat recapture & air drying: Reduces dependenceonelectricdryers .

Ÿ Smart pumps/IoT: Plant digitalization supports energy-efficient wastewater/power systems(Industry 4.0) .

SAITEXstandsattheforefrontofsustainable, digitallyadvancedtextilemanufacturing:

Ÿ Technologies: Vertical integration, Smart ™ Indigo,IoT,robotics,lasers,closed-loopwater.

Ÿ Expansion: Scaling in Vietnam toward carbon neutrality and optimizing a smart microfactoryinL.A.,withafutureexplorationof NewYork.

Ÿ Partners: Leading European machinery (Truetzschler, Karl Mayer, Picanol, etc.) plus proprietarydigitalsystems.

Ÿ Sustainability: Zero discharge ethos, sludgereuse,large-scalesolar,heatrecapture,and data-drivenoptimization.

A leading position in the areas of testing, instrumentationandmachinecontrolhasbeen established by members of the British Textile MachineryAssociation(BTMA)andanumber of new developments in these fields will be showcasedatthisyear'sITMAAsia+CITME exhibition, which takes place in Singapore fromOctober28-31.

“Many of our members are currently developing newtechnologies,eitherin-houseorincreasingly through joint projects, and there will be much to reveal by the time of ITMAAsia in Singapore,” saysBTMACEOJasonKent.“Someofthemost recentdevelopmentsarereallygoingbeyondwhat haspreviouslybeenpossible.”

Thetactilitychallenge

A case in point is the new Sentire fabric handle tester which has just been launched by Roaches International.

Oneofthebiggestchallengesfacedbydesigners and manufacturers, the company explains, is in describing and sharing information about fabric aesthetics before manufacturing, or without the costly and time-consuming process of transportingphysicalsamples.

Theelusiveconceptof'fabrichandle'–thetactile sensation experienced when touching and manipulatingfabric–isacriticalaspectoftextile evaluation,buttodateit'sbeenverysubjective.

“Notwopeoplewilldescribehowafabricfeelsin thesamewayandthelackofacommonlanguage to describe fabric tactility poses communication challengesacrossthecomplexglobalfashionand textile supply chain,” says Roaches International MD Sean O'Neill. “How do you objectively measure qualities like softness, smoothness, drape,andstiffness?”

TheansweriswiththenewSentire

RoachesworkedwithspecialistsattheUniversity of Leeds to develop the new finished fabric evaluation system which defines the tactile propertiesoffabricsviaahapticspatialsystem–similar,forexample,tothewaycolourchartsare digitallydefinedforcolourpalettes,orTogvalues ratewarmth.

FabricsamplesareplacedintotheSentiretoruna series of tests which generate quantitative fabric tactile property data akin to a fingerprint for the fabric,whichcanthenbecomparedagainstother samplesandcommunicateddigitallytopartnersin differentlocations.

“This technology has the potential to impact the supply chain in a similar way to the spectrophotometer for the communication of colour,” says O'Neill. “We have had a fantastic initialresponsetotheSentireanditspossibilities are huge. Not only can it be used to compare textile tactility globally, but we are also seeing interest from online retailers who want to accurately display the way a particular fabric drapesonthebody.”

The precise detection of defects during the production of fabrics has meanwhile recently beensignificantlyadvancedwiththeintroduction of the latest WebSpector automated fabric inspectionsystembySheltonVision.

Building on its market leading vision system for plain, single colour textiles, Shelton's patentpending image processing techniques now recognise and adapt to complex patterns such as camouflage and even on fabrics with significant distortionanddeformation.

Fabrics are not rigid and can be sheared or stretched while also being subject to local distortion, but the WebSpector system now successfully deals with such anomalies in real timetoprovideareliableinspectionprocessatthe samelevelsasplainfabric.

The unique and advanced software techniques ensure a totally clean image, allowing the full detection of faults on fabrics running at high speeds. WebSpector systems have already been supplied to manufacturers of performance wear and high-end fashion, automotive interiors, denim, outdoor upholstery, sunscreen, mattress ticking, window dressings and even carbon fibre composites.

The latest Webspector was introduced at ITMA 2023 in Milan to great acclaim and will be demonstrated for the first time in Asia at the Singaporeexhibition.

Abrasionandpillingtesting

Martindale testing needs little introduction to textile manufacturers, being well established as the industry standard for abrasion and pilling testing since its initial development and introductionbyJamesHealbackinthe1940s.

For 2025, however, James Heal's development team have taken a fresh look at this classic instrument and the result is the new Martindale Motion.

This redesigned nine-station Martindale instrument with individual lifting heads now offers the flexibility to run each station independently for carrying out different textile testssimultaneously.

Multiple textiles can be tested at the same time throughtoconclusionwithoutintervention.Once setup,theMartindaleMotioncanbeleftrunning with the sample holders automatically lifting at the required evaluation points, freeing up the

operator'stimetodootherworkwithouttheneed to return until the abrasion or pilling test is fully completed,includingovernight.

Each sample is kept in-tact at the end point for evaluation and checking, reducing queries on grading and the potential need for re-testing. Further refinements include a new hinged access to change the self-aligning drive pins, allowing quickandsafeswitchingbetweentests.

DesignedandmanufacturedintheUK,theJames Heal Martindale range has seen numerous updates, models and innovations over the years, such as touchscreen and user-friendly software, best-in-class safety features combined with the signature near silent running of this staple lab instrument. Added to this have been the introduction of the DurAbrasion multi-function testing machine, later followed by the marketleadingevolution,theAquAbrasionwetabrasion testerlaunchedin2019.

The Martindale Motion, however, is now taking productivityandefficiencytoahigherlevelthan everbefore.

Pushingtheboundaries

“These BTMA companies continue to push the boundariesofwhat'spossibleintheareaoftextile testing,”saysJasonKentinconclusion.“Theyare eachmakingsolidcontributionstothequalityand performance properties of today's textile products, and just as importantly, enabling manufacturers to prove their claims. We look forward to meeting customers old and new in Singapore.”

Founded in 1940, the British Textile Machinery Association actively promotes British textile machinerymanufacturersandtheirproductstothe world.Thenon-profitorganisationactsasabridge betweenitsmembersandtheincreasinglydiverse industrieswithinthetextilemanufacturingsector.

From Left to Right Mr R Murali ,Commercial Head, BRUCKNER Textile India Pvt Ltd, Mr Alexander Mandel Sales Director ,BRUCKNER Textile Technologies GmbH & co.kg, Mr Thomas Wiget ,Director ,BRUCKNER Textile India Pvt Ltd, A.Venkatesh Babu,Area Sales Manager , BRUCKNER Textile India Pvt Ltd and Mr Vinodkumar .V, AreaSalesManager, BRUCKNERTextileIndiaPvtLtd

WiththeestablishmentofBrücknerTextileIndia Pvt.Ltd.,theBrücknerGroup,basedinLeonberg, Germany, marks another important milestone in itslongandsuccessfulcompanyhistory.Thenew subsidiaryinCoimbatore,India,bringsBrückner significantlyclosertoitsIndiancustomers–both geo-graphically and strategically. “Having a presence on the ground enables us to respond morequickly,precisely,andflexiblytotheneeds of the Indian market,” says the management. “Brückner stands for German technology and precision – in India, we combine this with local speedandagility.”

The new subsidiary offers the full range of Brückner'sproductsandservices:newmachines, modifications, spare parts, technical consulting, machine upgrades, and after-sales service. All machines are still manufactured in Tittmoning,

Bavaria, Germany, while sales, installation and service are handled by the newly formed local teaminIndia.

TheleadershipofBrücknerTextileIndiaPvt.Ltd. reflects deep industry experience and regional expertise: Mr. Thomas Wiget, who brings over 31 years of professional experience in India, has beenappointedasDirectorofthesubsidiary.Mr. A.VenkateshBabuisresponsibleforsalesacross India, with a particular focus on the Eastern and Southern regions, while Mr. Vinod Kumar V. manages sales in the Northern andWestern parts of the country. Together, this experienced team ensures close customer proximity, professional consultation and reliable support throughout India. With the foundation of Brückner Textile India Pvt. Ltd., the family-run company underlinesitslong-termcommitmenttotheIndian marketandcontinuestostrengthenitsglobalsales andservicenetwork.

Halfacenturyofempoweringproductivityinthetextilesandplasticsindustry.

BMSvision, a global leader in Manufacturing Execution Systems (MES) for the textiles and plastics manufacturing industries, proudly celebratesits50thanniversarysincethelaunchof its very first MES system, Sycotex. This milestone celebrates five decades of expertise, innovation,reliabilityandoperationalexcellence.

Sinceitsdebutin1975aspartoftheBarcoGroup, BMSvisionhasevolvedintoatrustedpartnerfor the discrete manufacturing industry worldwide, streamlining production, improving efficiency, reducing waste, and making smarter, data-driven decisions based on real-time information. From pioneering digital manufacturing in textiles to delivering advanced MES solutions tailored to today's industrial needs, BMSvision continues to leadthewayinsmartmanufacturing.

"Reaching this 50-year milestone is more than a celebration of our past – it's a testament to the partnerships we've built, the industries we've helped transform, and the people who've shaped our journey," says Jan Bogaert, CEO of BMSvision. "As part of the Vandewiele Group, we remain committed to driving operational

efficiency and empowering productivity for decadestocome.”

CharlesBeauduin,PresidentVandewieleGroup, adds to this: "Vandewiele has been focussing on technical innovation for years. Continuing to invest in product development and digital transformationisthekeytothefuture.BMSvision plays a crucial role within the group to achieve thesetechnologicalambitions.”

Today,BMSvision'sMESsolutionsaredeployed in factories across the globe, offering real-time data insights and seamless integration from shop floor to top floor. With a focus on textiles, packaging and plastics, BMSvision continues to combine in-depth industry domain knowledge and state-of-the-art technology expertise with a relentlessfocusoncustomersuccess.

AsBMSvisionmarksthissignificantanniversary, thecompanylooksaheadwithaclearmission:to continue innovating, integrating, and delivering solutions that manufacturers can rely on, today andtomorrow.

Saurer's Autocoro 11 is redefining rotor spinning with its revolutionary technology for spinning even the shortest recycled fibres. With increased global focus on circular manufacturing and stricter environmental regulations,thedemandforrecyclingintextile production is increasing. Saurer anticipated thistrendandhasdevelopedmultiplefeatures displayedintheAutocoro11RecyclingXtreme version, making it the leading technology for circular spinning mills. Read how Polat İplik Tekstil in Türkiye is utilising Autocoro 11 for their sustainable high-speed spinning with lowestenergyconsumption.

InitsRecyclingXtreme(rX)edition,theAutocoro 11 fully automated rotor spinning machine processeseventheshortestmechanicallyrecycled fibres with exceptional raw material efficiency, unlocking new levels of circularity in yarn production.Italsosetsnewbenchmarksinenergy efficiency, productivity and operational autonomy. Since its launch in 2023, mills worldwide have recognised its transformative potential.

Recycled fibres are obtained from pre-or postconsumer waste. Pre-consumer waste, often cutoffs from garment production, consists of fibres thatareveryuniformintypeandcolour,butvary in length due to tearing during the opening process.Inpost-consumerwaste,mostlyobtained from worn-out garments, the spinnability of the fibres is less predictable and requires a high degreeofflexibilityandfine-tuningofthesettings

bythespinningmill.

Saurer's engineers have developed the smart featuresthatallowAutocoro11toprocessahigh contentofshortestfibresfrombothpre-andpostconsumerwastematerial.Recyclingthefibresina morecircularwaysavesnaturalresourcesforthe future of our planet (Fig. 1). It is also a costeffective alternative to virgin fibres, enabling millstoreducetheircosts.

New garment made from yarns with recycled fibres.

Highest flexibility and quality with Autocoro 11

The Autocoro 11 is a fully automated rotorspinning machine. Precise adjustments for differentfibresareeasilydonethankstothesingle drive technology. By fine-tuning the yarn twist, speed of the opening rollers and rotor size, it is possibletoachievearecycledyarnqualitywhich almost matches that of yarns made from virgin cotton. The wide range of adjustment options

open new ways for spinning mills to achieve greater profitability and flexibility in yarn production.

Mr Fahri Polat, owner of Polat İplik Tekstil, is profiting from the benefits of Recycling Xtreme technologies: “For 40 years, we have been focussing on yarns made from recycled raw materials, where quality is paramount. With the Autocoro 11 and the Recycling Xtreme equipment, we now have a much higher raw materialutilisationandcanguaranteeoutstanding yarn quality. We now produce better and at the same time more economically - a benefit for us andtheenvironment”.

Quality paired with machine efficiency in recycling

Recycled cotton yarns have a narrower count rangethanthosemadeofvirgincotton.Whilenot all blends can be spun into both coarse and fine yarns alike with the necessary properties for furtherprocessingsteps,theuseofcarrierfibresis essentialtoachievesufficientyarnstrength.

The finer the yarns are, the more carrier fibres with a homogeneous length, i.e. polyester fibres, areneededtohavetherequiredminimumnumber of 110 well-bonded fibres in the yarn crosssection and thus ensure adequate yarn strength and sufficient spinning stability. Increasing recycled content without adapting spinning settings,oftenleadstoanincreaseinyarnbreaks. Fortunately,theAutocoro11cancompensatesuch

increaseofyarnsbreakswiththeSynchropiecing 60technology(Fig.2),alwayskeepingthehighest levelofeconomicefficiency.

Higherproductivityandlessmaintenancewith RecyclingXtreme

The new yarn guides with their self-cleaning mechanism in combination with continuous blow-off (Fig. 3) increase productivity while significantly reducing maintenance costs. In a Turkish spinning mill, the manual cleaning intervalswereextendedfrom3daysto6weeksanimpressivefourteen-foldincrease!Atthesame time,productivitywhenspinningNe10weaving yarn was significantly increased. Thanks to the new yarn guides, disruptions to yarn guide movementscausedbydepositsarenowathingof thepast.Thedaysofpackageswithunevenflanks are also a thing of the past - real progress that raisesefficiencyandqualityinthespinningmillto anewlevel.

Fig.3

The new rX yarn guides with pneumatic selfcleaningmechanismonAutocoro11.

Intervalcleaningforfirst-classyarnquality

Recycled fibres tend to accumulate in the rotor grooves.Suchcontaminationcanimpairtheyarn qualityandincreaseyarnbreaks.TheAutocoro11 has an innovative solution to this problem: the new patented interval cleaning of the rotors implemented in the Doffing Cleaning Unit (Fig. 4).

Fig.4

Interval cleaning for rotors in the Doffing CleaningUnitofAutocoro11.

State-of-the-art linear motor technology ensures that the cleaning process is now digitally controlled and perfectly synchronised. The combination of pneumatic and mechanical cleaning at regular intervals ensures effective removal of deposits. The recently integrated movementmodeofthecleaningscraperoptimises cleaningevenfurther.Aprecisepositioningofthe scraper in the rotor groove ensures that deposits cannotstickinthefirstplace.

All these advanced technology features enable excellent spinning stability and high, constant yarn quality. Yarn breaks are significantly reduced, and the processing of recycled fibres is mademucheasieronAutocoro11withRecycling Xtreme.

Focusonrawmaterialefficiency

Inthepast,theaimwastoeliminateshortfibresto achieve maximum yarn quality. Today, the focus is on minimising the loss of valuable raw materials to achieve a more circular economy in textiles.

Saurer–forsavingfibresfrombaletoyarn

Fromthebaleopenertocardsanddrawframesup to the spinning machine- in the production of cardedrotoryarn,upto9%ofcottonandrecycled fibres are discarded as waste during the production process. To reduce the ecological footprint, it is essential to reduce the share of waste. The new Autocoro 11 in the Recycling Xtreme edition offers innovative solutions for processing a wide range of recycled fibre types andblendseconomicallyandwithlowlosses.

Innovative three-chamber system separates cleanfibres

In the new Autocoro 11, fibres of good quality, which are sorted out during the piecing process fromthespinningbox,arecollectedseparatelyin an innovative three-chamber system (Fig. 5). These process-related rejected fibres can simply befedbackintothespinningprocess.Thissaves on raw material costs while contributing to sustainableproduction.

Thethree-chambersystemisanimportantfeature for Fahri Polat, owner of Polat İplik Tekstil in Türkiye: “The three-chamber system is simply great!Itensuresthatallvaluablefibresremainin theproductioncycle-nofibreislost.Forus,thisis perfect recycling and genuine, loss-free spinning”.

Fig.5

Three-chamber system for better raw material utilisation.

Newstandardsincleanliness

Equippedwithdirt-repellentaluminiumcaps,the SE21spinboxsetsnewstandardsincleanliness. The caps prevent fibre fly from accumulating in the housing of the opening rollers. In addition, newfibrebeardsupportsinvariouslengths,which can be clipped in without tools, ensure that the

shortfibreseparationisregulatedasrequired(Fig. 6). Long clips minimise the amount of waste, whileshortclipsincreaseit.Unusablewastefibres areefficientlyremovedinthedirtchannel.

Fig.6

FibrebeardsupportsindifferentlengthsforSE21 spinbox.

Recycling Xtreme extraction technology increasesproductivity

AnewpatentedsuctionsystemintheAutocoro11 section frame ensures removing a large share of thewastequicklyandeffectively(Fig.7).Thisis particularly important for long machines and helpstokeepthelowerpartofthespinboxclean, thusincreasingproductivity.

Fig.7

ThenewdirtextractionsystemintheAutocoro11.

Recycling Xtreme + Synchropiecing 60 - a guaranteeforhigheroutput

Spinning recycled fibres presents challenges: a high number of yarn breaks and clearer cuts are not uncommon, especially at high rotor speeds. Over 1000 yarn breaks per 1000 rotor hours are the norm for many recycled yarns. This is not a challenge for theAutocoro 11 Recycling Xtreme edition combined with Synchropiecing 60 as it can perform up to 60 piecings simultaneously to achieve high efficiency even in difficult environments. This is particularly true in combination with long machines, coarse yarns, short package running times and frequent interventionsbytheCorolabyarnclearer.

Customers worldwide appreciate the quick startup of the machines. Fahri Polat, owner of Polat

İplik Tekstil, is no exception: “Thanks to Synchropiecing, we can innovate with smarter mixing strategies and increase the share of sustainablefibres-abenefitforourresourcesand profitability.Fromthemomentthemachinestarts, theadvantagesareclear–withinminutes,all816 spinningpositionsarerunningatfullspeed”.

Autocoro 11: Synergy of efficiency, economy andsustainability!

With its pioneering and energy-saving technologies, the Autocoro 11 impressively demonstrates how spinning mills can produce economically, efficiently and more sustainably withthehelpoftheAutocoro11.TheAutocoro11 offers tailor-made solutions for every spinning millandeverytypeofyarnandfibre.Moreabout theenergysavingfeaturesofAutocoro11

In a defining shift for India's textile economy, cotton imports have reached record highs in the2024–25season,asrevealedintheLokSabha by Union Minister of State for Agriculture & Farmers'Welfare,ShriRamnathThakur.Imports from Brazil have grown nearly 10 times, while UScottonimportshavemorethandoubled—a reflection of India's commitment to quality and innovation, particularly in the extra-long staple (ELS)segment.

Ÿ KeyHighlights(2024–25seasonuptoMay 31)

BR

Ÿ BrazilianCotton

From 67,805 bales (₹152 Cr) → 6,54,819 bales (₹1,620Cr) Nearly10xgrowth

US Ÿ USCotton

From 2,68,728 bales (₹1,361 Cr) → 5,25,523 bales(₹1,802Cr) Doubledinvolumeandvalue

AU Ÿ AustralianCotton From3.58lakhbales→5.13lakhbales

Significantjump

Ÿ TotalImports:

27lakhbalesimportedbyMay-endvs15.19lakh balesin2023–24 Arecord-settingpace

Ÿ Risingdemandforhigh-qualityELScotton forpremiumyarn&garments

Ÿ StrengtheningIndia'spositioninglobaltextile valuechains

Ÿ StrategicpartnershipswithBrazil,USA,and Australia to ensure raw material quality and stability

Ÿ Reflects India's pursuit of textile excellence, innovation,andglobalintegration

IN India’sCottonIndustry:AGlobalOutlook

From self-reliance to strategic imports, India is rewriting its cotton narrative. This is more than just raw material sourcing — it is a movement towards world-class textile production, sustainablegrowth,andgloballeadership.

ITMAASIA+CITME,Singapore2025

28to31October2025

SingaporeExpo,HALLH6,STANDA202

Reducing the carbon footprint is becoming more important: Swiss company showcases new technologies for lowering water and energyconsumption

The textile industry is one of the biggest consumers of water globally, requiring approximately 93 billion cubic meters annually. This is equivalent to around 4% of thetotalfreshwaterconsumedworldwide.The industry is facing increasing criticism as a result and is coming under pressure. Sustainabilityisthereforenolongerjustabout image,butisakeycompetitivefactorfortextile manufacturers. Companies across the entire textile chain with a sole focus on conventional processeswillhavetoaddresssalesissuesover the medium term and will be faced with ever greaterregulatorypressure.Atthetradefairin

Singapore, the Swiss company TextilcolorAG is showcasing how textile treatment is still fit

for the future. Technologies such as EcoDye and EcoFix enable the company to reduce water consumption by up to 71 %. These processes also allow the amount of fossil-fuel energy used to be reduced by up to half of the previous level across the entire production process. The results achieved speak for themselves.Theyallowasignificantreduction in the carbon footprint and provide an advantage in terms of innovation for an industrycurrentlyinthemidstofanecological transformation.

ITMAAsia+CITME2025isregardedasoneof the leading trade fairs in textile and clothing manufactureintheAsianregion.“Wehavealways stoodforinnovative,sustainableandhigh-quality solutions in textile chemistry,” explains Detlef Fischer,CEOofTextilcolorAG.“Forus,thetrade fair in Singapore is the right platform for effectivelyshowcasingourtechnologiesaspartof

a future-focussed industry”. The slogan for this year's trade fair is 'ECO Performance TechnologiesfromSwitzerland'.Sustainabilityis firmly established within the corporate philosophy–thecompanyhasalwaysdeveloped technologies which lower resource consumption andwhichcontinuetoreducethecarbonfootprint of textile production. One particular focus is on using raw materials from renewable sources.An example of this is the use of plant-based oils in order to conserve fossil resources as much as possible.Inmanypartsoftheworld,freshwateris in increasingly short supply; companies are having to be ever more focussed on using this element in a sustainable way. The company has also led the market here in the development of water-savingtechnologies.

Future developments are increasingly focused on sustainable and resource-saving technologies

Under the EcoDye label, a process has been developed which is specifically tailored to the requirements of PES dyeing processes. TextilcolorAGwasthefirstcompanyintheworld to successfully launch this product onto the market. The optimisation and enhancement of EcoDye has continued ever since in order to guarantee a sustainable and efficient dyeing technology and to facilitate its ongoing development.Itreduceswaterconsumptionbyup to71%,andatleast34%lessenergyisusedinthe polyester dyeing (PES) process. These resource savings mean it is regarded as one of the most efficient and environmentally-friendly dyeing systems in synthetic textile dyeing, with the smallest carbon footprint. With the EcoDye

process,specificworkstepscanberemoved(e.g. prewash),ashorterheatingratemeansthedyeing process can be accelerated and subsequent treatment processes can be reduced. Use of this methodmeansthat,forthecustomer,theduration oftheprocessissignificantlyshorter.Onespecific advantageforusersisthattheEcoDyeprocesscan be used with pre-existing recipes. All EcoDye ® components are bluesign-approved. When combinedwithothertechnologiesfromtheSwiss company – such as EcoFix and EcoThren, two rapiddyeingprocessesforreactiveandvatdyeing –thereductionintherinsebathsrequiredenables atime-savingofupto40%.Productionoutputcan alsobesignificantlyincreased,markedreductions in manufacturing costs can then be achieved and product quality can be improved. For safeguarding the entire process and for ensuring optimal dyeing results, Textilcolor has the appropriateproductsinitsrangesuchaslevelling and dispersing agents. Other speciality products preventingtheagglomerationofoligomersorfor reductive after-clearing complete the product range. These products ensure the stability and reliability of the entire dyeing process on an ongoing basis. At the trade fair, Textilcolor AG willalsohaveotherproventechnologiesavailable such as EcoPhob, a PFC-free hydrophobicity solution. EcoPhob EXT is also an environmentally friendly product with an excellenthydrophobiceffect.Itissuitableforuse generallywithalltypesoffibreand,forexample, hasexcellentwashingresistance.Theproductalso consists of the maximum possible proportion of renewable raw materials. It can also be used for manufacturing textiles which meet the requirementsforclass1productsundertheÖkoTexstandard.

Wide-ranging offer covering the entire textile processchain

Textilcolor AG is not only known for manufacturing all products in accordance with strictecologicalandsustainabilitystandards.The continual development of new products and solutions is indicative of the company's leading roleinthemarket.Thesearefrequentlytailoredto thewiderangeofprocessingrequirements–often in close collaborationwith customers.The broad

productrangehasnowbecomeafurtherfeatureof thecompany.Incontrasttoothersuppliers,which generally only offer products for individual processes, Textilcolor covers the entire textile processchain.Thebroadproductrangecoversall steps from pre-treatment, printing and dyeing, finishingandcoating,topigmentationandoptical brighteners.ThisalsounderlinesTextilcolorAG's commitment, as a solution provider, to environmentally-friendly, efficient and futureorientedtextileproduction.

Left to right Shailendra Pandey, CMO – Fashion Yarn Business and Satyaki Gosh- CEO, Fashion YarnBusiness-GrasimIndustriesLimited

Grasim Industries' Cellulosic Fashion Yarn business has launched Raysileco, a transformative offering under the trusted Raysil brand, featuring sustainable ViscoseFilamentYarn(VFY)thatisfullytraceableto its origin. Produced from wood pulp, responsibly sourced from certified, sustainably managed forests, Raysileco upholds strong environmental credentials andensurescompletesupplychaintransparency.

The brand was unveiled at the 7th edition of Yarn Expo in Surat, hosted by The Southern Gujarat ChamberofCommerceandIndustry.

Speakingatthelaunch,Mr.SatyakiGhosh,CEOof Cellulosic FashionYarn business, said: “Raysileco embodies the spirit of innovation with robust sustainability credentials and advanced traceability technologies. This launch reflects our drive to evolve withdynamicmarketneedsanddeliveringvaluewhere performance, responsibility, and trust converge.” He furtheradded: “This product not only reinforces our commitment to sustainability and end-to-end traceability but also empowers our value chain partners with confidence to verify and trust every filamenttheyuse.”

Raysileco marks a significant advancement in yarn manufacturing by embedding both molecular-level and technology-enabled traceability directly into the yarn.Thisinnovationoffersend-to-endvisibilityinto the product's journey, empowering value chain partners with confidence, transparency, and seamless verification from yarn production to retail. A key differentiator of Raysileco is its integration of both physicalanddigitaltraceabilitytechnologies,ensuring transparency at every stage. By addressing the growing demand for transparency in the fashion industry, Raysileco enables brands and partners to authenticateproductsandverifyresponsiblesourcing acrosstheentiresupplychain.

Manufactured at Grasim's strategically located plants at Kalyan (Maharashtra) and Veraval (Gujarat), Raysileco reflects the company's continued investment in smart, scalable, and technology-driven manufacturingcapabilities.

Mr. Ghosh explained “The traceability mechanism employs both physical markers and digital technologies. Our partnership with TextileGenesis™ enables secure, blockchain-based traceability for sustainable Viscose Filament Yarn. Using unique digitaltokenscalledFibercoins™,wetracktheyarn's journey from source to store, creating a tamper-proof, real-timedigitalrecordforbrandstomonitor.”

As global regulations become more stringent and sustainability goals grow increasingly ambitious, leading fashion brands worldwide are turning to traceability tools to ensure transparency and accountability. At Raysileco, sustainability is embedded into every stage of the product lifecycle, from sourcing natural-origin raw materials to implementing environmentally responsible production practices and ultimately offering a sustainableyarnthatsafelyreturnstonatureattheend ofitslife.

Raysilremainstheonlyplayergloballyofferingthree distinct technologies in Viscose Filament Yarn: Pot SpunYarn (PSY), Continuous SpunYarn (CSY), and SpoolSpunYarn(SSY).WiththelaunchofRaysileco, Grasim'sCellulosicFashionYarnbusinessissettinga new benchmark in transparency and responsible manufacturingintheglobalfashionlandscape.