n Cold climate retrofits

n To Buffer Tank or Not, Pt. 2

n The Blue Pages

n Heat Pumps Technical Training Day Supplement

n Cold climate retrofits

n To Buffer Tank or Not, Pt. 2

n The Blue Pages

n Heat Pumps Technical Training Day Supplement

When temperatures plunge, performance matters most. The LG Residential Cold Climate Heat Pump delivers reliable heating down to -35°C, redefining comfort in extreme Canadian winters.

• 100% heating capacit y at -25°C, reliable operation at 70% capacity down to -35°C

• Sof t Air mode & Dual Vane design for faster comfort

• Freeze-and-defrost cycle reduces dust and bacteria

• Built-in occupancy sensor for smar ter operation

• Wireless control with LG ThinQ app

ENERGY STAR® Cold Climate Certified — engineered for efficient year-round comfort.

Winner of the 2025 Ontario Home Builders' Association Innovation Award and the 2025 AHR Innovation Award – Sustainable Solution.

Viega press technology delivers consistent, secure connections with every press, ensuring reliable performance on the jobsite. With more than 2,500 approved applications, Viega ProPress ® and MegaPress ® systems can save you up to 90% on installation time compared to traditional methods.

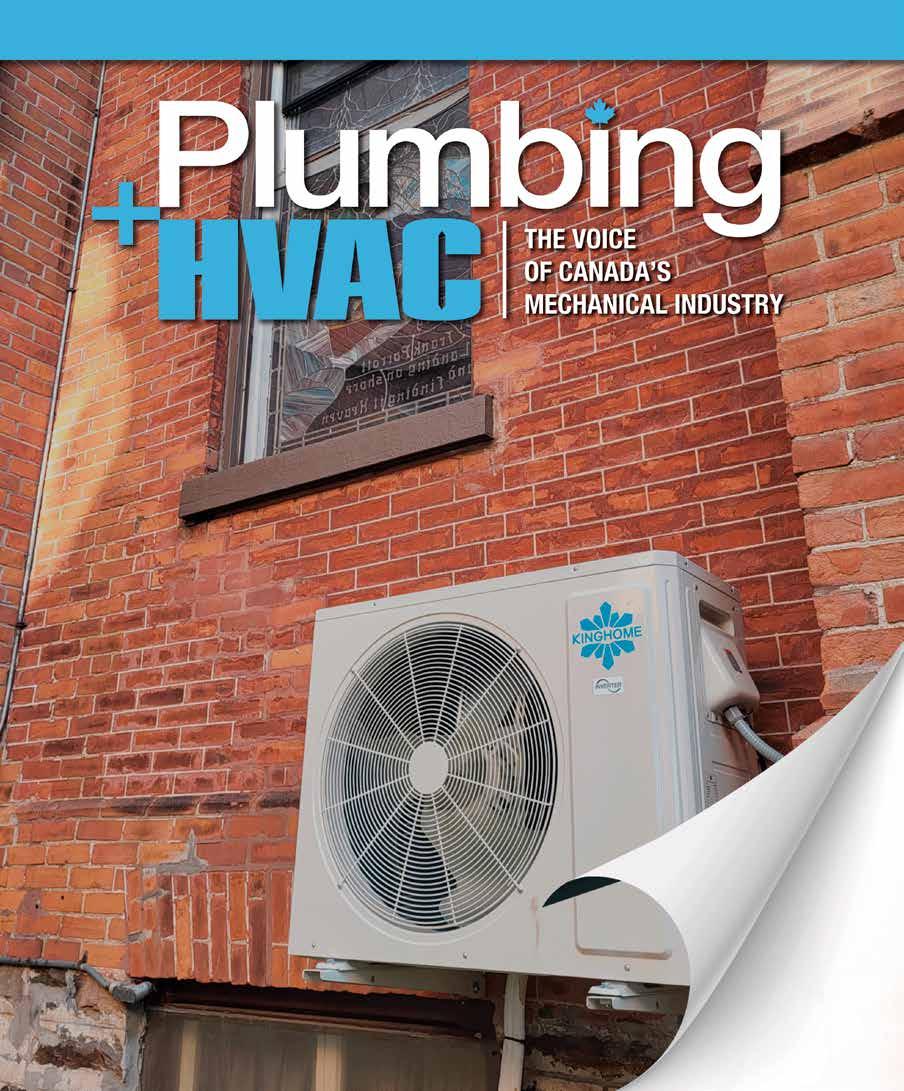

It almost feels ridiculous to say that there was a time in my role when the term “heat pumps” wasn’t included in the magazine even once. As we all know, the technology itself isn’t new, with Canadian installations tracked all the way back to the 70s. But it wasn’t until a few years ago that we were able to say heat pumps in Canada were mainstream. It has dominated and penetrated the heating and cooling sector at an incredibly fast rate.

To the point where homeowners, who many times cannot even tell you the proper type of system they own or have in their home, are now at the very least aware of the technology. It’s been a fun experience sharing a beer with family and friends on a weekend and discussing their heat pump, whether or not they are happy with it, and the amount of money they received back from some type of government incentive.

Recently, I was able to put on my work boots and

safety glasses to play the role of an apprentice for the day and install a mini-split unit. The experience wasn’t like anything before. No matter the number of articles that I write about heat pumps, there is something to be said about getting the tools in your hands and installing the unit yourself.

But as much fun as I had during that day, I cannot say that I’d be able to do it all on my own. The other day, while I was on my morning walk with my dog, there was a particularly puzzling installation of a heat pump on one of my neighbour’s properties. Any time that I see a heat pump, they are installed in a way that makes them parallel to the home. This installation had the heat pump perpendicular to the house, which was just so strange to me. So, I want to task anyone reading this column to let me know why this was the case. If we get some good responses, I will highlight them in our next issue.

Why do you think this heat pump was installed this way?

Plumbing & HVAC magazine is pleased to announce the appointment of Brandon Collins as national accounts manager. Brandon holds a bachelor of engineering in mechanical engineering, with a specialization in the automotive industry, from the University of Sunderland in London, England, and a master of business administration, with a specialization in business analytics, from Cardiff Metropolitan University, Cardiff, Wales. He joined the team at Marked Business Media in Oshawa, Ont. on Oct. 6. Please welcome Brandon to the industry! He can be reached at brandon@plumbingandhvac.ca

October 2025 Volume 34, Number 11 ISSN 1919-0395

Publisher Mark Vreugdenhil Cell: (416) 996-1031 mark@plumbingandhvac.ca

Editor Leah Den Hartogh Cell: (289) 830-1217 leah@plumbingandhvac.ca

National Account Manager Brandon Collins brandon@plumbingandhvac.ca

Assistant Editor

Francesco Lo Presti Cell: (647) 531-5697 francesco@plumbingandhvac.ca

Contributing Writers

Glenn Mellors, Greg Scrivener, Michael Ridler, Ron Coleman

Design and Production Samantha Jackson production@plumbingandhvac.ca

articles and photos by Plumbing & HVAC staff unless noted.

Heat pumps are a key to Canada’s electrification goals, and they provide year-round comfort for homes. However, customers sometimes are afraid to agree to switch from a technology they know to something unfamiliar. The Building Decarbonization Alliance, in partnership with the Heating, Refrigeration, and Air Conditioning Institute of Canada, and Plumbing & HVAC magazine have created a third-party sales tool to help educate homeowners on heat pumps and why they are the perfect solution for their home.

We know that there is some confusion in the industry regarding heat pumps; there are even more misconceptions when we get to the homeowner level. We are trying to play our part to help contractors sell more heat pumps. As such, we’re teamed up with industry leaders to help dispel some of these concerns and make it through some tough conversations with homeowners in one piece!

Mark Vreugdenhil Publisher, Marked Business Media

The four-page flyer can be downloaded from the Plumbing & HVAC website at www. plumbingandhvac.ca/heatpumpsalestool or on our homepage pop-up. This pamphlet helps you

bridge the knowledge gap and make the case for heat pumps with confidence.

It can help you:

▶ Build trust by answering customer questions up front

▶Reinforce your expertise with the “What to Ask Your Contractor” checklist

▶Boost customer confidence in heat pump performance – even in Canadian winters!

Standard and customizable print ready versions are available, allowing you to add your company’s logo. You can also contact us to order printed copies at cost. Use it as part of your sales conversations, leave it behind after quotes, or share it with customers who are still considering their options.

Contractors who lead with education – not just pricing – win more business and overcome customer hesitation. Download it today and sell more heat pumps!

By Leah Den Hartogh

Thisyear’sHeating,Refrigeration,andAirConditioningInstituteofCanada (HRAI)annualgeneralmeetinghadadashofthehomecomingspirit.It startedwiththehighlightofsomefamousNovaScotians,includingthe birthplaceofMountHanley,thefirstmantosailaroundtheworldsinglehandedly,SarahMcLachlan,afamoussinger-songwriter,andHRAI’sown SandyMacLeod,presidentandCEO.

Overthetwo-dayconference,whichranSept.21-22attheWestinNova ScotianinHalifax,NovaScotia,therewasalotoffocusontheCanadian economy,withhighlightsregardingtheTrumpadministration.Inaddition, therewasaparticularfocusonCanada’sleaders,includingMarkCarney, primeministerofCanada,andPierrePollievre,leaderoftheConservative PartyofCanada.

Inoneofthecoolestvenues,thefirstnight’scocktailandnetworking receptionwaslocatedattheViaRailTrainStation,whichwasattachedtothe WestinNovaScotian.

Duringthecocktailevent,aromantictalewastoldaboutanoldEnglish princewhowasshippedofftoNovaScotiaaspunishmentforfallinginlove withsomeonenotapprovedbytheKing.Asanylovestorygoes,thiswoman travelsinsecretacrosstheAtlanticOceantobewithhim.Heproceedsto

(From left to right) Kent Steeves, chief technical design officer at Greenfoot Energy, Dale Comeau, general manager of Comeau Comfort Systems, Joe Fiander, coowner of Conroy HVAC, Nathan Horton, president and CEO of 1Clickheat.com, and Jamie Hutt-Semple, vice president of sales and operations at Kerr Control Ltd, assemble to make up part of the closing panel on Canada’s evolving marketplace.

build her a music studio and a trail that spells out her name that connects to her home. You could tell what a touching and moving story it was, as you could see tears in Jim Thomas’, president of Refrigerant Services Inc., eyes as he was retelling it. By the end of his speech, the audience could feel his love for Nova Scotia, especially when he told the crowd, “If you don’t enjoy your time in Halifax, that’s your fault.”

The second day of the event featured more sessions and educational seminars. There were two specific sessions that many people spoken to gushed over. This included the email writing bootcamp by Scott “Coach” Colby, national best-selling author, newspaper opinion editor, and creator of Coach Colby Writing Academy, and Tareq Hadhab, founder and CEO of Peace by Chocolate.

To wrap up the two-day event, everyone gathered in the ballroom, dressed in their best, to participate in HRAI’s awards dinner. The entertainment to wrap up the event was Shaun Majumder, a Canadian comedian and actor.

It was announced that the 2027 AGM will be held in Winnipeg, Manitoba, alongside another Heat Pump Symposium.

Continued on page “11”

NEW NAZ Air-to-air heat pump

inverter-driven heating and cooling systems

Navien introduces its full line of HVAC products, featuring new NAZ Heat Pumps, NAS Air Handlers, NAM Cased Coils, and other forced-air components. Deliver a whole-home AHRI matched Navien comfort system when pairing with the NPF Hydro-furnace, including a powerful dual-fuel system with gas-powered NPF and the NAZ Heat Pump.

To learn more about Navien HVAC comfort, visit us at navieninc.com

Continued from page “8”

“Heat pump mania has been running rampant in the Maritimes for many years now,” shared Jamie Hutt-Semple, vice president of sales and operations at Kerr Control Ltd, during the Atlantic Heat Pump Symposium in Halifax, Ont. “A lot of knowledge can be found in this area regarding heat pumps.”

On Sept. 23, the popular event in Toronto, Ont., shipped off and headed to Eastern Canada. It landed at the Westin Nova Scotian with a sold-out attendance record. To kick off the shenanigans, there were three main areas of focus as part of the opening remarks by Hutt-Semple. Firstly, it was that incentives matter – something that hasn’t always been extremely popular amongst the contractor community. The second was labour challenges all over the country, and lastly, the T word: tariffs. He stressed the degree to which this will likely affect all businesses.

The rest of the day was filled with educational opportunities in the form of keynote speakers, panel discussions, and breakout sessions. To break up the day, a buffet-style lunch was served

Continued on page “13”

Born and raised in Nova Scotia, this year’s HRAI AGM was a bit special for Sandy MacLeod, president and CEO of HRAI.

At A. O. Smith we put innovation first. And that means going beyond energy efficiency to offer industry-unique technologies and features that streamline installation, extend versatility, and provide the performance that residential and commercial customers need.

Maximize flexibility, simplify installation, and boost energy efficiency with Bluetooth-enabled zoning solutions.

At Taco, we know that making water work means providing peace of mind at every turn. That’s why we’ve designed the Next Generation Zone Valve Controls and Enhanced Switching Relay systems to deliver unmatched reliability and ease of use. Whether you’re installing or troubleshooting, our innovative features—like Bluetooth connectivity, enhanced diagnostics, and customizable settings—ensure the highest levels of performance and comfort.

Let Taco be the partner you can trust for reliable, customized zoning solutions.

CONFIDENT AUTHENTIC INNOVATIVE EFFICIENT SUPPORTIVE NT RELIABLE ECONOMICAL

Continued from page “11”

whilethetradeshowfloorwasopen.Thisallottedoneofmanyopportunities attendeeshadtomeetandgreetwithexhibitorsandcheckoutsomeofthe latestproductshittingtheCanadianmarket.

ThefirstpaneldiscussionofthedaysawNathanHorton,presidentand CEOof1Clickheat.com,AbhilashKantamneni,directorofgovernment relationsatHRAI,MichaelRidler,ownerandgeneralmanagerofEden EnergyEquipment,andDarrenScott,nationalaccountmanagerofhome buildersatSiemens,haveaconversationaboutthestateoftechnologyin Canada.

Whenthingsshiftedtothetopicoftheworkforceshortageandnew technology,Ridlerarguedthat“newtechnologywon’tmakeitmoredifficult forpeopletogetintothisindustry”Hewentontosaythat“thisshortage isn’taboutthelackofresources,talentorpeoplewantingtodothework. Rather,it’saboutgettingthemintotheirreal-lifeexperiences”

Theideaofnewtechnologycouldn’tbetterbeembodiedthanitis byHorton’scompany,whichisanHVACcompanythatfocuseson electrificationandaidingCanadiansinswitchingawayfromfossilfuels, accordingtoitswebsite.

Hiscompanyisallonlineandusesartificialintelligence(AI)tohelpgrow hisbusiness,hesharedduringthepanel.“Thesurprisewasthatthemore AI wasintroducedintothebusiness,themorepeopleneededtobehiredto

helpwiththegrowthoftheefficiencies”

Theeventwrappedupwithanotherpaneldiscussion,thistimeabout the evolvingmarket.ThispanelfeaturedDaleComeau,generalmanager of ComeauComfortSystems,Horton,Hutt-Semple,JoeFiander,co-owner of ConroyHVAC,KentSteeves,chieftechnicaldesignofficeratGreenfoot Energy,andDrewTozer,partneratFoundryHeatPumps.

Whenaskedabouthowbesttomanagehomeownerexpectations,the firstsuggestionwastofindasolutionthatmakesthemcomfortableand happy “You’reanexpertineverythingthattheyarenot,”statesHutt-Semple. Andmakesurenottounderestimatetheimportanceofwordofmouth;“If theneighboursarehappy,thenI’llgothere”mentality

Forthesamequestion,Hortonrespondedwithastressoroverthesales pitchprocess.OrasHortonstates,“Itisduringthediscoveryphasethat itisdeterminedwhattheirmotivationwillbe.”Hegoesontosharesome positivemotivations,includingenvironmentallyconscientiousnessor maybe justpurecuriosity.‘There’salwayscostsavingsandenvironmental benefits,” statesHorton.“Ifyouhavetherightconversationswiththe customer,you willfindtherightmotivationforthecustomer.”

TheeventendedwiththeexpectedannouncementforthenextHeat PumpSymposium,whichissettoruninVancouveronMay20,2026.More detailsareexpectedtobeannouncedclosertotheevent.

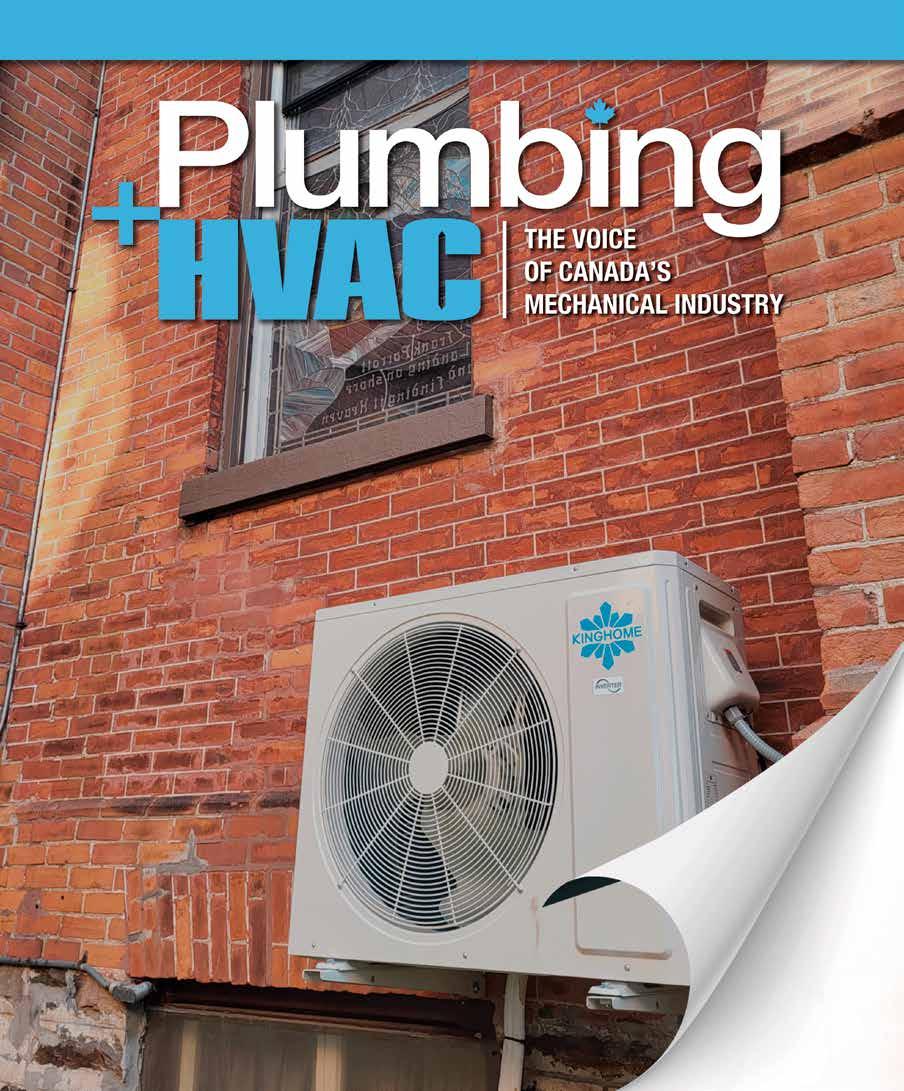

Skilled trades workers are set to play a pivotal role in Canada’s decarbonization goals. A new report, titled Building Tomorrow, conducted by the Conference Board of Canada (CBoC) and the Future Skills Centre – Centre des Compétences futures (FSC-CCF), highlights how policies described in Canada’s 2030 Emissions Reduction Plan(ERP),whichwasreleasedinMarch2022,will transformthedemandforskilledtradeworkers.

Canada’s 2030 ERP outlines a strategy to cut greenhouse gas (GHG) emissions by 40 per cent from 2005 levels by 2030, and then to achieve net zero emissions by 2050. The set plan for Canada’s ERP spells some troubling news for residential construction. In recent years, there has been a high demand for residential construction jobs, however, due to changes to the ERP, this demand is expected to reduce. This includes home building and renovating managers, carpenters, painters and decorators,andconstructionhelpers.

“These trades are also expected to see a decline in their employment propensity under the ERP, meaning workers in these roles will make up a smaller share of the overall economy than they would without the implementation of additional climate policies,” according to the report. This can beseeninFigure1.

decline slightly over the next few years until 2030, largely due to a weakening economy dampening near-term construction and infrastructure activity.”

Some good news for plumbers; it is estimated that in 2024, a total of 54,460 plumbers were in demand, and this is only going to climb over time, with a total of 67,340 needed in 2030, and 85,190 in 2040.

Heating, refrigerating, and air conditioning mechanics also see an increase, but not quite as much as plumbers. In 2024, it was estimated that 26,930 were in demand, with an increase to 34,260 in 2030, and 43,150 in 2040.

Lastly, for residential and commercial installers and services, the demand will constrict a bit from 2024 to 2030 (36,310 down to 34,620, respectively), before rebounding by 2040 to 36,690.

Going a step further, the report shows that roles such as water well drillers and power system electricians are projected to see the largest increases in demand under the ERP, with demand rising by approximately 13 per cent and eight per cent, respectively, by 2040, as shown in Figure 2.

Additional skilled trades roles, such as welders, pipefitters, sprinkler system installers, and transport truck drivers, will also see an increase in demand, as these roles support the development of renewable energy infrastructure and logistics for a clean economy.

As stated in the report, “While demand for most trades is forecast to grow over the long term, we project that demand for some occupations will

The report also outlines how heavy equipment workers are expected to see the most growth in demand under the ERP.

Fits 24 inch basins

External control panel and alarm

Odourless dry pit

Easy access to major components

Fail-proof triple air pressure switches

Tradespeople view their mental health as less than good, according to a study by the Canada Building Trades Union. The new report, titled Mental Health and Substance Use, surveyed over 1,000 of its members, including plumbers, pipefitters, and electricalworkers.

“Findings show tradespeople face unique mental health and substance use issues linked to high stress, jobsite hazards, and financial strain,” according to the report. “Research revealed that the level of mental health distress among tradespeople ishigh,butnearlyin-linewithallCanadianworkers from other sectors. Though the overall results are nearly the same for mental health distress related to work for tradespeople in comparison to other professionals, our research shows that the specific psychological and environmental hazards, and workplace pressures that lead to mental health distressarequitedifferent”

Nearly half of those polled rated their mental healthasfair(29percent)orpoor(17percent). Surprisingly, only one-third have sought some type of help, while 25 per cent use substances daily or weekly to cope. Yet, 84 per cent still believe that their union offers the necessary mental health support for the job. Non-surprisingly, 72 per cent opposedrandomdrugtesting.

Many tradespeople reported having experienced serious pain, which may vary from other sectors and may also contribute to substance abuse,accordingtothereport.

Recurring concerns highlighted by members, over the past 12 months, included stress (58 per cent), anxiety (47 per cent), burnout (38 per cent), depression (34 per cent) and insomnia (29 per cent).

The report also showed that 42 per cent of tradespeople who reported their mental health is less than good are using drugs or alcohol daily or weekly to manage their mental health. More than 27 per cent of respondents stated they use alcohol or drugs daily, and 17 per cent reported using drugs and alcohol weekly to manage their mental health. Additionally, 28 per cent stated they have experiencedsomeformofaddiction.

Suffering an injury or experiencing pain was another primary concern, as 36 per cent of tradespeople report they’ve suffered a job injury/ strain severe enough to require a program of pain management or a prescription. Among respondents who have this experience of pain, the rates of alcohol and drug use to manage pain at least monthly are 2.5 times higher than among those who have never suffered a job injury or strain requiring pain management or prescription.

However, the report highlights that tradespeople who stated they have good mental health in comparison to those who have poor mental health have sharply different assessments of how work affects them.

For example, 62 per cent of workers who report their mental health is less than good say their mental health is extremely or significantly affected by their job. Compared to those who say their mental health is good or better, 25 per cent report the same intensity of impact from their job.

Additionally, 41 per cent of tradespeople whose mental health is good or better say their job has no effect or only a slight impact on their mental health. Compared to 11 per cent of workers with less than good mental health, who feel the same.

When it comes to alcohol and drug use, 18 per cent of workers who reported good or better mental health indicated that they use alcohol daily or weekly to manage mental health.

The report also highlighted how most tradespeople feel a strong sense of community and support within their unions compared to other sectors (but those with mental health concerns feel divided on this), value their work and have a high level of autonomy.

Additionally, among workers with good or better mental health, 89 percent say their coworkers are always or most of the time supportive. Compared to those with less than good mental health, only 61 per cent report feeling they have supportive coworkers.

24 inch basins External control panel and alarm Odourless dry pit

access to major components

EfficiencyCanada iscallingformorefundingfor Canada’s GreenerHomesLoanProgram,astheprogramis runningoutofmoney

Firstestablishedin2021,theloanprogramprovides interest-freeloansforenergy-efficienthomeupgradeslikeheat pumps,insulation,windows,andsolarpanels.In2024,the federalgovernmentallocatedanadditional$600milliontothe program.

“Asofearly2025,only$444millionincapitalremains, withtheprogramcommittingapproximately$90million permonth.Atthisrate,fundingcouldbeexhaustedby thefall,” reportsEfficiencyCanada initslettertoGregor Robertson,ministerofhousingandinfrastructure.

EfficiencyCanadaisadvocatingforimmediateactionin budget2025.Specifically,EfficiencyCanadaisrequestingan immediaterecapitalizationtocontinuetheprogram,afouryearextensionwith$4.3billioninloancapital,thetransition oftheprogramintoapermanent,statutoryframework,and consultationonprogramdesignimprovementstoexpand participation,achievedeeperretrofits,andfosterbetterpublicprivatecooperation.

Canada’s Greener Homes Loan Program is running out of money after operating for four years

Plasticwasteintheconstructionindustryisundermanaged,undertracked, and overlooked, according to a new study conducted by Light House. The Construction Plastics Initiative (CPI) Benchmarking Study analyzes plastic wastediversionacross253LEED-certifiedconstructionprojectsinCanada completedbetween2009and2019.

Thestudy’sfindingsshowedthattheintensityofplasticwastediversion isinfluencedbybuildingtype,withtheaverageplasticwastediversion intensityrangingfrom1.1to2.7kg/m².Notably,institutionalandresidential buildingsproducedsignificantlymoreplasticwastepersquaremetrethan educationalbuildings.Thestudyalsoreportsthatcurrentreportingsystems rarelyseparateplasticsbymaterialtype,makingthebenchmarkingprocess challenging.

“Whilesingle-useplasticshavelongbeeninthespotlightbyindustryand policymakers,constructionplastics,afarmoresignificantsourceofplastic

B.C. introduced a pilot program in December 2024, which would collect, separate, measure, and process plastics to study the use and types of these plastics found on commercial construction sites.

waste,haveremainedlargelyignored.Withglobalnegotiationsforaplastics treatyrecentlystalled,nationalandindustry-levelactionhasneverbeenmore urgent.Canada’sFederalPlasticsRegistrywillexpandin2026toinclude constructionplastics,requiringcompaniesthatsupplyorusebuilding materialstoreporthowmuchplastictheyproduce,recycle,anddisposeof,” statesLightHouse,viaitspressrelease.

Thestudyhighlightedthattheyearinwhichprojectsarecompletedisa factorinwastediversionintensity.Specifically,therewasaspikeindiversionin 2015. CPI’sstudyalsorevealedregionaldifferences,withsupplychains, infrastructure,andpolicyframeworksinfluencingplasticwasteoutcomes.

With these discoveries, the report suggested recommendations on how to reduce plastic waste generation and improve how plastic waste can be tracked. These recommendations include implementing standardized tracking for specific materials, facilitating on-site source separation, encouraging research and pilot projects, adopting supportive policies, engaging with suppliers, and promoting smarter procurement practices. The study also highlighted opportunities for increased waste diversion, as approximately 80 per cent of construction plastics are clean packaging and readily divertible.

Sixty-three per cent of British Columbians want more choices in how they heat their homes, and are opposed to the province’s natural gas heating bans. A total of 801 B.C. residents were polled via the Energy Futures Institute’s latest study, which showed that residents want to have the choice of using natural gas and/or electricity for heating their homes and workplaces, instead of just electricity.

Only 24 per cent supported the province’s municipal bans on natural gas heating, while 13 per cent remained undecided. Specifically, the support for having heating choices was higher in the Southern Interior/North, around 69 per cent, and was highest among the 35 to 54 year old demographic, around 68 per cent.

In addition to the support of having more home heating choices, 62 per cent of B.C. residents say they support the development of additional liquid natural gas (LNG) export facilities in the province. However, 19 per cent of residents are against more LNG export facilities, and 19 per cent were undecided. Keeping with LNG exports, 52 per cent of residents supported the introduction of B.C. exports of LNG in provincial emission reduction targets because these exports may displace the use of higher-emission diesel and coal in power plants in other countries. Additionally, residents polled were in support of delaying the timeline of emission reduction targets to help meet B.C.’s electricity demand in the next few decades. Specifically, 54 per cent of residents were in support, while 31 per cent opposed the delay, and 15 per cent

B.C. residents are interested in expanding options for how they can heat and cool their homes, including natural gas.

were undecided.

For context with the polling results, BC Hydro’s debt increased by $8.75 billion in the last five years, with the utility depending a lot on electricity imports. According to

their 2024/25 annual report, “BC Hydro spent $861 million to buy 8,356 GWh from outside B.C., which is about 1.6 times the output of the new Site C dam in a normal water year,” states the Energy Futures Institute in its press release.

stars have aligned. Discover 100% capacity and 100% performance down to -30°C.

The new Orion XLTH+…a star performer in extreme weather.

Like the Orion Constellation brightening the winter night sky, the Fujitsu AIRSTAGE Orion XLTH+ Series stands out as a brilliant star for heating performance...even in the harshest climates. While others fade in extreme cold, Orion shines brighter, delivering more than 100% capacity even at -30°C.

• Beyond 100% Performance at -30°C – No derating, just powerful, consistent heating.

• No Lockout Temperature – Unlike other systems, Orion keeps running in relentless cold.

• ProCore™ Corrosion-Resistant Technology – Built to endure and perform.

• Advanced Defrost Cycle – Reduces downtime, maximizing comfort and efficiency.

• Flexible Installation – Designed for seamless integration into a variety of applications.

Orion XLTH+...the stellar performer in low-temperature heating.

Manitobaembarksonanewcarbonemissionreductioninitiative.The provincehasreceived$30millioninfundingaspartofthenewlylaunched CanadaGreenerHomesAffordabilityProgram(CGHAP).

TheCGHAPisaninitiativethatwillhelplow-tomedian-income householdsreducetheirenergybillsandgreenhousegasemissionsthrough no-costhomeretrofits.Throughtheprogram,homeownerscanundertake retrofitssuchasinsulation,airsealing,heatpumps,solarpanels,and replacementofwindowsanddoors.

“ToomanyCanadiansarestrugglingwiththehighcostofheatingand coolingtheirhomes.TheCanadaGreenerHomesAffordabilityProgramis aboutmakinglifemoreaffordablewhiletacklingclimatechange.Byhelping Canadiansretrofittheirhomesatnocost,we’reloweringenergybills, cuttingemissionsandimprovingcomfort—especiallyforthosewhoneed itmost,”saidTimHodgson,ministerofenergyandnaturalresources.

Across Canada, over 96 per cent of direct building emissions come from

spaceandwaterheating.ThroughprogramsliketheCGHAP,homeowners canreplacetheirfossilfuelheatingsystemswithlow-carbonoptions,suchas electricheatpumps.

Todate,over260,000newheatpumpshavebeeninstallednationallywith federal support since 2020, including provincial/territorial support from codeliverypartners,accordingtoStatisticsCanada.

TheCGHAPwillbedeliveredinpartnershipwithprovincesand territoriestoensuretheprogrammeetsthedistinctneedsofcommunities acrossCanadaandisavailabletotenants.ThroughtheCGHAP,participants willnothavetopayoutofpocketfortheirhomeupgrades.

Todate,ManitobaisthefirstprovincetoparticipateintheCGHAP; however,thefederalgovernmentstatesthattheprogramisexpectedtobe availableinadditionalprovincesandterritorieswithinthefollowingyear.

TheCGHAPisconsideredacomplementaryprogramtotheOiltoHeat PumpAffordability(OHPA),whichisavailabletoManitobahomeowners.

Why buffer tanks might be hurting your heat pump system.

By Michael Ridler

Buffer tanks are great tools that offer value, including reduced short cycling.

Last month’s issue, we discussed why you need a buffer tank and the importance of a buffer tank as part of the hydronic design. In addition, we highlighted why we need to design systems for people and the applications and not just based entirely off what we read somewhere on the internet. Not all systems need a buffer tank. At the end of the day, you could have the exact same equipment installed and, depending on the home and the application, you may or may not have a buffer tank.

Buffer tanks are an important part of your design in hydronic heating and cooling systems, but with better modulating condensing boilers and new airto-water technology, there are cases where we may not need a buffer tank. Buffer tanks traditionally added water volume to prevent short cycling in fixed-output boilers and early heat pumps. But things have changed. With the rise of inverter-driven, variable-speed heat pumps, the logic behind buffer tanks, at times, needs a rethink. The fact you have an inverter drive on your heat pump doesn’t mean you don’t need a buffer tank. It comes down to good engineering and understanding your application. It may start with the heat pump and the boiler, but it isn’t the end of the discussion.

Depending on the flow rates in your system and the size of your buffer tank, you can end up in a situation where you have significant mixing happening in your buffer tank, so it ends up not being stratified. Instead, it becomes a mixed tank, which can lead to problems. This constant mixing leads to temperature blending. The result? The water sent to the heating system is cooler than what the heat pump is actually producing.

Let’s say your heat pump is set to deliver 45 C (113 F) water. Due to mixing, depending on the buffer tank design and size, the system may only reach 42 C (107 F). To compensate, the heat pump may work harder to produce hotter water. This increases the temperature lift and reduces its coefficient of performance (COP). As we talked about in the previous article, there is lots of research that suggests every 1 C of added lift reduces efficiency by two to three per cent. Over a season, this blending can create a six to 15 per cent efficiency drop, which shows up in the cost of operation to heat and cool the home.

So, instead of solving a problem, the buffer tank may introduce a permanent thermodynamic penalty. You need to make sure you pick the right buffer tank for your situation and size it accordingly. Understand the goal of what you are trying to achieve when using it.

When in cooling mode, a hydronic heat pump supplies chilled water typically around 8 C or 46 F. Fan coil units use this cold water to cool and dehumidify the air. But a buffer tank may in fact blend the cold water with the warm return water, raising its temperature.

This can be a big deal. Dehumidification only works when coil surface temperatures fall below the indoor air’s dew point. If your chilled water temperature rises above that dew point, moisture stays in the air. You get sensible cooling but limited or no latent cooling. The result is a cold and clammy indoor climate, poor air quality, and a higher risk of mould growth.

The reality is we need to better understand sensible and latent cooling loads. The buffer tank isn’t the real problem here; it’s a combination of a buffer tank and the fact that sensible and latent cooling loads are getting out of alignment. We need to apply proper humidity controls or face unintended consequences. If your air-to-water system will be used for cooling in a humid environment, put thought into your buffer tank sizing. They can impact latent cooling

Sometimes the buffer tank isn’t the real problem. Here, it’s a combination of a buffer tank and the fact that sensible and latent cooling loads are out of alignment.

performance by raising chilled water temperatures. Comfort, air quality, and moisture control depend on hitting low coil temps. Blending makes this difficult. Pick the right buffer tank if you are using one and pipe it properly.

Some argue that buffer tanks help defrost cycles by storing thermal energy. That’s true in principle, but the tank, as we discussed, already can reduce the average water temperature. Defrost performance depends on temperature, not just volume. Lukewarm water from a blended buffer tank may extend defrost times and increase compressor energy use.

In comparison, a system without a buffer tank, but with high-temperature thermal mass, can perform quicker, more efficient defrosts. So, if you have a radiant floor heating system zoned to the hilt, you definitely need some buffer but not necessarily a giant buffer. If you have a higher volume system with cast radiators, you may not need a buffer. How does your air-to-water heat pump manage defrost? What will a buffer tank do for you, and will it work against you when it comes to defrost? Think outside the box, but start reading the manual for the equipment.

Continued on page “27”

Powered by electricity and CO2 (non-toxic R744 refrigerant), Aegis delivers reliable hot water up to 170°F at temperatures as low as -4°F.

No need for supplemental heat

Operates in all types of climates; indoor and outdoor

Fully integrated system offered with heat pump, heat exchanger module, tanks, and digital mixing valve - all from a single source

Available in air, water, and a unique hybrid air source with cool recovery

Energy-Saving, Year-Round Hot Water.

817.335.9531 | order@lyncbywatts lyncbywatts.com/aegis

Continued from page “25”

Inverter-driven heat pumps are built to respond to real-time demand. They read temperatures and flow rates to adjust compressor speed for maximum efficiency, and some buffer tanks create hydraulic separation. It decouples the heat pump from the system load which can be good or bad depending on the scenario.

Sometimes with a buffer tank on the heat pump, depending on how we pipe it, it can blindfold the control algorithm. Instead of modulating smoothly, the system could swing between on and off, like older fixed-speed units. The advanced benefits of inverter technology are lost. In the same token, if you have a system without a buffer tank and an inverter drive and your loads are too small, you will end up needing some thermal buffer to make sure the heat pump (or boiler for that matter) isn’t banging on and off repeatedly shortcycling the system and damaging the equipment.

A buffer tank is a tool. Just like with any other tool in your utility pouch, whether that may be a screwdriver or a crowbar, the tool changes with the job and sometimes a screwdriver is my crowbar.

For fixed-output systems, buffer tanks are great tools that offer value,

including reduced short cycling. But with modern inverter-driven heat pumps, it’s a solution that can sometimes create new problems. We could reduce heating efficiency, impact dehumidification, slow defrost, and impact performance.

Smart system design means simplifying where we can. That starts with understanding the type of buffer tank, your application, and what you are trying to achieve. Are you in a high humidity zone? Do you have a means to control the sensible and latent cooling loads? How much mass is in your system? What is your minimum drive speed on the inverter and how does that relate to the system design? More importantly, don’t just look at design day. What happens when your system is at its lowest turn down and your loads are 20 per cent of design? The answer on a buffer tank changes, depending on many variables, and it is important we understand them.

Michael Ridler, is the owner and general manager at Eden Energy Equipment. He started out working for a Ont-based HVAC company and now focuses on providing field support and technical training to contractors, engineers, and builders on heat pumps, boilers, and all things hydronics. He can be reached at michael@edenenergy.com.

A successful heat pump retrofit requires careful planning and plenty of technical knowledge.

By Glenn Mellors

As energy efficiency, environmental responsibility, and long-term savings become top priorities for homeowners, retrofitting traditional gas furnaces with modern heat pumps has become increasingly popular. This hybrid setup — combining the comfort and reliability of a gas furnace with the energy efficiency of a heat pump — can offer the best of both worlds when executed properly.

However, a successful retrofit requires careful planning, technical knowledge, and an understanding of both systems. There are also common pitfalls that can undermine performance and cost-effectiveness. Whether you are a homeowner or an HVAC contractor, following these dos and don’ts can help ensure a seamless and efficient transition.

The hybrid system

Before jumping into the list, it is important to understand what a gas furnace and heat pump hybrid system is. A gas furnace is a traditional

A common misconception with heat pumps is that it can be swapped in place of an A/C and paired with the furnace without issue.

forced-air heating system using natural gas to generate heat. Whereas a heat pump is an all-electric system that transfers heat from the outside air (or ground) to heat your home. It can also work in reverse to cool your home in the summer.

In a dual-fuel system, the heat pump operates during mild to moderately cold weather, and the gas furnace takes over in extreme cold, providing reliable heating during peak winter conditions.

Even before the retrofit job begins, it’s important to evaluate the condition and capacity of the existing gas furnace, ductwork, and electrical. Inspecting the existing equipment and infrastructure is essential to provide the right solution for your customers. Is the furnace in good shape and capable of operating as a

Continued on page “31”

Continued on page “31”

backup? Are the ducts sealed, insulated, and properly sized for a heat pump? Can your electrical panel support a high-efficiency heat pump? As an HVAC technician, we need to perform a full system audit, which is essential.

The right components

Not all heat pumps are created equally. You will want to select one that suits your climate and goals. In colder regions, look for cold-climate air-source heat pumps (ccASHP) that remain efficient at sub-zero temperatures.

Consider variable-speed or inverter-driven units for greater efficiency and comfort.

If space permits, ducted systems integrate well with existing furnace ductwork, but ductless mini-splits can work in zones if full retrofitting is not feasible.

One of the most critical components of a hybrid system is how it is controlled.

Install a dual-fuel-compatible thermostat that can switch between the heat pump and gas furnace automatically based on outdoor temperature. Smart thermostats can also optimize energy costs, using the most efficient heat source depending on fuel prices and conditions.

The balance point is the outdoor temperature at which the heat pump becomes less efficient, and the gas furnace should take over. We as technicians should calculate the balance point based on local climate and your home’s heat loss rate. Set this point carefully in your control system to maximize energy savings without sacrificing comfort.

Proper sizing is one of the most important steps in the retrofit. Oversized systems can lead to short cycles, leading to inefficiency and poor humidity control. Undersized systems will not adequately heat or cool your space. Load calculations, such as Manual J, should be used to determine the appropriate capacity.

Heat pumps require more electricity than a typical A/C unit. The electrical panel may need upgrades to support the added load. Plan for this ahead of time to avoid delays and surprise costs.

Many provinces offer rebates, tax credits, and incentives for installing energy-efficient heat pumps, especially in retrofit applications. Check with your local utility, energy authority, or federal programs like Canada’s Greener Homes Grant or the Inflation Reduction Act in the U.S. These programs can reduce upfront costs significantly.

The don’ts

Firstly, don’t assume it’s a plug-and-play installation. A common misconception is that a heat pump can be swapped in place of an A/C and paired with the furnace without issue. Heat pumps require different control logic, defrost cycles, and auxiliary heat coordination. Always ensure compatibility with the existing furnace and thermostat controls.

Many older homes have ductwork designed solely for a hightemperature gas furnace. Heat pumps deliver lower air temperatures and may require higher air flow. Leaky or undersized ducts can

Consider installing a backup generator or battery system, especially if you are in a region prone to blackouts.

drastically reduce system efficiency. Have the ductwork pressure tested and, if needed, reconfigured or sealed.

Another important rule to remember is when the switch-over temperature is set too low, it may cause the heat pump to run inefficiently in very cold weather. In extreme cold, a heat pump can lose capacity and become a costly way to heat a home. A conservative balance point (e.g., 0 C to -5 C in Canada) ensures reliable performance and lower operating costs.

Both the furnace and heat pump require annual maintenance to perform optimally. Heat pumps need coil cleaning, refrigerant checks, and airflow diagnostics. The furnace still needs filter replacements, burner inspections, and safety checks. Regular service ensures longevity and prevents performance degradation.

In an electric-heavy system, power outages can leave your home without heat. Consider installing a backup generator or battery system, especially if you are in a region prone to blackouts. Gas furnaces can still run during outages (if they have a pilot light and don’t rely entirely on electronics), but the heat pump

Continued on page “32”

Continued from page “31”

will be offline.

While a retrofit can save money, there are upfront costs and variable operating costs.

Compare electricity and natural gas rates in your area. Factor in seasonal performance (HSPF and SEER2 ratings) and expected maintenance costs. A heat pump may be cheaper to run in spring/fall, while gas may still be more economical in peak winter.

HVAC systems should never be sized using rules of thumb (e.g., “one ton per 500 sq. ft.”).

Heat loss and gain vary dramatically based on insulation, window quality, air leaks, and local climate. Only trust Manual J, S, and D calculations for sizing and ductwork.

Retrofitting a gas furnace with a heat pump can be a smart investment in energy efficiency, comfort, and sustainability, if done correctly. The key to success lies in balancing the strengths of both systems. Use the heat pump when it is efficient and economical, and rely on the gas furnace when it is

Proper sizing is one of the most important steps in the retrofit.

more effective in extreme cold.

By following these dos and don’ts, you can avoid the common pitfalls that lead to poor performance, excessive costs, or dissatisfied homeowners. Whether you are a contractor recommending upgrades or a homeowner planning for the future, a thoughtful, customized approach will always yield better results than one-size-fits-all solutions.

Glenn Mellors was born into a plumbing family and started in the industry in 1973. He entered the HVAC side of the business in the 80s, working in wholesale, and then joined Lennox in 1992. In 2008 he joined the ClimateCare Co-operative Corporation, an Ontario contractor group, where he is director of training and implementation. Glenn can be reached at gmellors@ climatecare.com.

It is encouraged for clean flares to be made with a properly torqued tool; if the flare is uneven or not properly torqued, it can become damaged and create a leak.

n Installing heat pumps

n Ductless systems

n Heat pump products

n The future of heat pumps

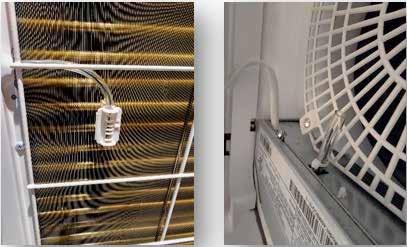

This photo was taken live during the Heat Pump Technical Training Day presentation at LG’s Air Conditioning Institute.

The most important best practice for any heat pump installation is to revert back to the manufacturer’s manual.

By Francesco Lo Presti

View the full presentation on “Heat Pump Installation and Troubleshooting Tips” here:

The goal of any installation is for things to go smoothly. The old adage is “do it right the first time, and you’ll save yourself in the long run.” There are a few tips and tricks that are available for contractors to help ensure a painless heat pump installation. First and foremost, it’s always recommended to follow each manufacturer’s manual for how to install their product.

From there, your first step is always going to be mounting the equipment. When it comes to the installation of a mini-split system, the first recommendation is to mount the outside unit on a stand/ rack that is at least 18-inches off the ground. The reason for this is so the unit can be free and clear of things such as snow or other debris, which is extremely helpful when the unit goes into defrost mode, as the

Continued on page “37”

Backed by industry leading technology, The HPX™ Air-to-Water Heat Pump is the perfect solution to year round comfort. Pair it with the SKy-35 control to optimize your comfort, operating costs and energy consumption.

Continued from page “35”

condensate has a place to drain.

It’s important that the holes at the bottom of the pan don’t get clogged up, which can make the condensate refreeze and damage the outdoor coil, potentially ruining the entire system.

Depending on your geographical area, the outdoor unit may need to be raised higher than the advised 18-inches. For instance, if you are in Northern Ontario, there will likely be a lot more snow; it’s encouraged to mount the unit around 12-inches higher than the anticipated snow level. The worst-case scenario is having the unit standing or lying directly on the ground/snow.

It will be said over and over again that the best practice for installing any type of heat pump will be to refer back to the manufacturer’s manual. This is important when you are trying to determine the correct clearances around the unit for airflow and service. For reference, a common occurrence on the light commercial side is seeing multiple units on the same roof. With this example, it’s important to keep them fan to fan, never fan to coil, and ensure there is enough space around the units to allow for proper airflow.

If the units are too close together and are in that fan-to-coil setup, you run the risk of having hot air from one unit being sucked into the neighbouring unit. During the winter season, this will change to cold air, and again, there is the potential for defrosting issues, product failure, and reduced performance.

Indoor unit recommendations

Now let’s turn our attention to the indoor unit. Again, the manufacturer’s manual is your best friend, as clearances will vary depending on the manufacturer. However, there are also some common practices when it comes to this installation.

Figure 1: It’s always best practice to resort to the manufacturer’s manual, but even when doing so, you should always have the “more than” concept in mind.

As you can see in Figure 1, the manual suggests a clearance of greater than four inches on the right-hand side. However, we know that there is a circuit board there facing outwards. So, it’s ideal to leave more space on the righthand side of the unit, which will make it easier to service in the future. Again, the clearances will differ depending on the product, but the common practice in this scenario is to keep the “more than” concept in mind, as well as service access, airflow, noise, and the path for electrical, refrigerant piping, and condensate lines.

Continued on page “39”

"Some of the biggest changes coming within the A2L products are the electrical wiring. Some recommended tips for this change are to always use stranded conductors and fork/ring terminals, terminate and torque the wiring connections correctly, have continuous runs of wiring — no splices, wire nuts, or junction boxes — and pay attention to polarity and labelling."

Continued from page “37”

With the adoption of R-32, there have been changes, specifically in the piping connection from the outdoor to the branch distribution unit. The old connection was a flare fitting, whereas the new connections are braze fittings. This change has also been made with the Y-branch fittings.

In the event that you are using two branch distribution units, you will need a Y-branch fitting, which is brazed with Nitrogen, and it needs to be vertically straight or horizontally level, as shown in Figure 2.

Figure 2: With the adoption of R-32 changes have been made to the branch distribution units of LG’s Multi-F max product, specifically in the piping connection from the outdoor to the branch distribution unit.

Any deviation or angle will alter the distribution of refrigerant and also impact the oil return, defrost, and overall performance of the system. The Y-branches also need to be supported within 12 inches of the centre on all three lines to keep them nice and level.

General piping practices

Turning our attention to general piping best practices, it is always encouraged for clean flares to be made using quality flaring tools, as well as having the flares properly torqued. If the flare is uneven or not properly torqued, the flare can become damaged and create a potential leak.

Another general rule is not to use any Nylog or thread sealant-type products, as these can contaminate the system. The system should only have refrigerant and oil. It is also recommended never to install liquid line driers or solenoid valves, as the system is meant to be free-flowing.

Going back to the brazing of Y-branches, it is always recommended to use Nitrogen. The reason for this is that there are strainers and small orifices in these systems that can get clogged up with carbon if Nitrogen is not used when brazing.

When it comes to confirming the pipe and connection sizes, always refer to the manufacturer’s guidance. Now, within the manual, what we are paying attention to is the minimum and maximum pipe lengths.

Generally, the maximum pipe length is more than adequate. However, there have been cases where not maintaining the minimum pipe length has caused some concern. Specifically, the concern is that the refrigerant will not have sufficient time to boil off properly and will return to the compressor as a liquid, potentially damaging the compressor.

It is also recommended to keep the piping out of the snow and to use the

proper outdoor-rated insulation or conduit to protect the piping from the elements.

Now, in some rare combinations, there may be a difference between the refrigerant connection size (indoor and outdoor) compared to what the installed piping should be, as shown in Figure 3.

Figure 3: In some rare combinations, there may be a difference between the refrigerant connection size (indoor and outdoor) and what the installed piping should be.

Some of the biggest changes coming within the A2L products are the electrical wiring. Some recommended tips for this change are to always use stranded conductors and fork/ring terminals, terminate and torque the wiring connections correctly, have continuous runs of wiring — no splices, wire nuts, or junction boxes — and pay attention to polarity and labelling.

With single-split units in the past, it was standard to have four wires run from the outdoor to the indoor unit: L1, L2, a signal/communication wire, and a ground wire. All these wires would need to be at least 14-gauge stranded wire. However, going forward, it is noted that the multi-compatible units are transitioning to an RS-45 communication, which means the wiring requirements will change (except for the single-split model, even with A2L, which will maintain the previous wiring).

The new equipment will utilize RS-45 communication, which is a highfrequency, low-voltage DC signal that fluctuates very quickly. The change for this will be with the running of the 14-gauge stranded copper wire from the outdoor to the indoor unit. You will now need to have a separate 18/2 stranded and shielded copper wire to go from IDU A/B on the outdoor unit to IDU A/B on the indoor unit. It’s important to maintain at least two inches of separation between the high voltage and low voltage communication lines.

Also, the RS-45 type communication is sensitive to electrical interference. This means that if it runs in the same conduit or parallel to a high voltage wire over long distances, the magnetic field can interrupt the signal and cause communication issues.

TECA and BCIT have partnered to launch a new microcredential program designed to meet the growing demand for skilled residential heat pump professionals.

• Industry-recognized certification through TECA

• Hands-on learning in BCIT’s post-secondary environment

• Accessible tuition – affordable rates with additional grant opportunities for eligible participants

• Upskilling support – provincial funding streams available to help workers advance their careers

This program combines TECA’s industry expertise with BCIT’s proven training approach, giving professionals the skills and certification needed to succeed in Canada's growing clean energy sector.

For the inverter technology to function, sensors are needed within the system.

It is important to remember the proper steps for installing mini-split systems and to always refer to the manufacturer for guidance.

By Francesco Lo Presti

View the full presentation on “Heat Pumps and Ductless System Essentials” here:

Heat pumps are becoming increasingly more popular for space heating and cooling Canada’s buildings and homes. With multiple countries committing to reducing their carbon footprint, this technology is a crucial step in providing comfort while lowering carbon emissions.

Now, we often hear about this technology, but there may still be people who are not entirely familiar with how heat pumps operate and the benefits

they can provide to customers.

As a quick jumping-off point, heat pumps are a device that transfers sensible heat from one location to another, rather than generating heat. Heat pumps also come in various forms, including air-sourced, geothermal, water-sourced, and VRF.

Air-sourced heat pumps tend to fall somewhere in the category of ductless, ducted, or some combination of both. A ductless system consists of three components: the indoor unit (in various forms), the controller, and the outdoor unit.

One sample configuration of a ductless system could see a single unit,

Continued on page “43”

-30°C

HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

Heat pump combination AHRI Certified for installation with ANY 3rd party furnace.

OFFICIAL DISTRIBUTOR IN CANADA

COLD CLIMATE

DC INVERTER HEAT PUMP

Two-stage, two-cylinder compression and hot gas injection for unparalleled heating efficiency.

Eligible to financial incentives in certain provinces, contact us for more detail.

TO FULLY SUPPORT OUR DEALER NETWORK

*GREE Canada is not responsible for warranty on units sold outside GREE Canada’s sales channel.

For more detail, contact our team at proservice@gree.ca.

Continued from page “41”

with an outdoor unit paired with an indoor unit, and connected via a refrigerant line set. Depending on the outdoor unit, more than one indoor unit can be connected.

In a heat pump’s first mode, or rather cooling mode, rejected heat from inside the house is set to the outdoors via an outdoor coil. Moisture is also removed from the interior and drains by gravity or a condensate pump. During the heating mode, the circuit reverses, absorbing heat from the outdoors and reflecting it through the inside coil to the interior of the house.

The size of a heat pump can vary, with the largest available in Canada coming in around 60,000 btu/hr, and this depends on whether the heat pump is a ducted or ductless system.

Now that we’ve gone through a synopsis of what we mean by a heat pump, the natural next question becomes which type of heat pump is best for your customer.

To answer that, there are some criteria you should consider. The first is the customer’s budget and whether there are any government rebates available.

The geographic location or region for the installation will play a factor in which type of system would result in the highest level of comfort for the customer. This can affect things such as the coefficient of performance (COP), whether a hybrid system is the best decision, or whether it will be a ductless or ducted system.

There is a surplus of resources available to find a detailed rundown on the installation practice of multi-split systems. Check out our Contractor’s Guide to Heat Pumps on our website for a detailed guide.

A ductless system means exactly what you’d think it would. There is no ductwork needed, save for a small puncture through the wall to allow for the refrigerant to flow. And as most people know in the industry, a ductless system often consists of a mini-split.

Ductless systems utilize inverter compressor technology, which allows both the indoor and outdoor units to continuously adjust heating and cooling capacities to best match a room’s current condition.

It’s important to note that ductless heat pumps are not meant to be the primary source of heat in extreme cold temperatures. This system should always have an alternative source of heat in the event of failure.

Inverter technology, for heat pumps, uses variable-speed systems to

"Things such as what region the heat pump will be installed in, whether it will be ducted or ductless, whether it should be a single unit or multi-unit, what the COP of the heat pump is, and what the heating seasonal performance factor, is are other things that need to be considered in the heat pump selection process."

As an HVAC professional, you need systems that deliver performance, reliability, and efficiency—without the hassle. Continental’s fully integrated lineup installs easily, delivers lasting comfort, and drives long-term energy savings.

Why Contractors Choose Continental:

Easy to Install and Service

High-Efficiency Heating and Cooling

Built for North American Homes

Unmatched Innovation and Reliability

Upgrade your installs. Elevate your reputation. Choose Continental.

FEB 2 -4 2026

Continued from page “43”

provide efficient cooling and heating. The variable-speed technology enables the system to adjust its power output according to the targeted area’s needs, maintaining a consistent temperature while using less energy than traditional furnaces or air conditioners. Essentially, inverter technology allows the HVAC system to adjust the amount of heating or cooling it constantly provides.

For the inverter technology to function, sensors are needed within the system. Most major manufacturers of heat pumps utilize five sensors: return air, refrigerant pipe, outdoor air, heat exchanger, and discharge sensors. These sensors serve as the communication devices for the control board of the outdoor unit, which in turn receives this information to operate the unit as efficiently and economically as possible, depending on the demand and setpoint.

When it comes to installing these units, it’s important to know the brand of heat pump you are installing, its limitations, and also the clearances. This is why it is recommended always to follow the manufacturer’s instal-

Continued on page “49”

For over 70 years, KANE International has been at the forefront of HVAC/R innovation, providing professionals like you with the tools they need to succeed. Now, upgrading to the unparalleled performance and reliability of KANE is easier than ever with our industry-leading trade-in program.

WE’RE RIGHT THERE WITH YOU — EVERY PART, EVERY PROJECT.

We’re the teammate who’s got your back when the pressure’s on (literally). From boilers to ball valves, we make sure you get what you need, when you need it.

Check out our Fall Rebates in the flyer — just scan and save!

LET’S GET TO WORK.

Continued from page “47”

lation instructions.

However, there are some general rules of thumb that you should follow when installing these units. The first is the exit location for the condensate and line set tubing, as shown in Figure 1, with the high wall hang unit.

In this example, there are four possible angles you can use: left-hand side, right-hand side, left rear, and right rear. Also, with this example, it’s important to drill a hole (refer to the manufacturer’s manual) to allow the drain line, refrigerant line, and interconnecting wiring to pass through. A helpful trick for this is to not drill the hole straight through the wall. You should give yourself about a half-inch angle downwards. The reason behind this is that, if you are using a condensate to flow out/ into a hard pipe wall, this will help maintain a positive slope down or away from the unit. This ensures that the condensate will be taken away from the indoor head unit.

Keeping with the condensate, you must ensure that the drain hose is as vertical as possible to ensure swift water drainage when connecting to the included drain spout in cold climates. Most manufacturers have a heater in the base pan, which helps prevent the condensate from icing up.

As shown in Figure 2, seen on page 43, at the bottom of most units, the unit is designed to allow condensate to flow through the port. It is angled, not flat, and is designed to allow the condensate to flow away from the unit, preventing buildup. To see the full presentation, follow the QR code.

Figure 1: When installing a ductless heat pump unit, you need to ensure that there is plenty of space and angle for the exit hole for condensate and line set tubing.

From coast to coast, Canadian homes demand heating and cooling solutions built for year-round comfort. The LG Builder Series Heat Pumps deliver reliable performance at a price that fits today’s market—without compromising on quality or innovation. Whether for retrofits or new builds across Canada, the LG Builder Series Heat Pumps provide an affordable, reliable solution for builders and simplify installation for contractors. Available in capacities of 9,000, 12,000, 18,000, and 24,000 Btu/h.

| VENTILATION | DOMESTIC HOT WATER

THE MITSUBISHI ELECTRIC ADVANTAGE

u Quality And Reliability You Can Trust

u Efficient Products Designed For The Canadian Climate

u Over 35 Years Of Successful Installation

u Strong Canadian Customer Support Team

u Local Supply of Products

R-32 minisplit system

Johnson ControlsHitachi Air Conditioning, Irving, Texas, announces its new portfolio of environmentally sustainable residential ductless heat pumps utilizing R-32. The airHome mini-splits are available in cold-climate models, reduce energy use and carbon emissions, and improve indoor air quality. These heat pumps feature a GWP rating of 675 and have a highly efficient heating seasonal performance factor (HSPF2) of up to 11.5 and can operate at 100 per cent capacity as low as -4 F depending on the model. The airHome mini-splits are also Energy Star certified and are available in two systems: 600 and 800.

Johnson Controls-Hitachi Air Conditioning u www.hitachiair.com

Copeland, St. Louis, Missouri, launches two compressor platforms, enabling electrification across a range of commercial and residential heating applications. Copeland’s YAW and YAV variable-speed compressor platforms help heat pump manufacturers overcome heating capacity challenges in cold climate applications down to -25 F, supporting the acceleration of sustainable heat pump adoption.

Copeland u www.copeland.com

Carrier, Charlotte, North Carolina, introduces its new AquaSnap 30RQM modular air-sourced reversible heat pump. The 30RQM can generate up to 140 F hot water and operate at ambient temperatures below 0 F. It is designed to use R-454B, also known as Puron Advance. The modular design offers greater flexibility for individual building needs, allowing up to 16 units to be linked for a total cooling capacity of 320 tons or 4,222 MBH of heating capacity.

Carrier u www.carrier.com

Ariston USA, Providence, Rhode Island, introduces its Nuos side-connect and Nuos multi-fit hybrid heat pump water heaters. Units are available in 40-, 50-, 65-, and 80-gallon models. It includes a 10-year limited warranty on the tank and parts. The Nuos range is equipped with five operating modes and includes i-Memory. This algorithm learns the homeowner’s hot water usage patterns over the previous four weeks and provides hot water when needed.

Artison USA u www.artison.com

Allied Air Enterprises, West Columbia, South Carolina, introduces an addition to its MagicPak all-inone M-Series: the MGE9. This series features patented and patent-pending products, including the new FreezeShield system, and delivers 95 per cent AFUE. Ideal for multifamily and elderly care developments, the MagicPark M-Series MGE9 gas heating/electric cooling unit and through-the-wall application eliminates bulky outdoor equipment. It features a constant torque ECM blow motor and two-stage heating.

Allied Air Enterprises u www.alliedair.com

LG Electronics, North York, Ont., launches its S1 prestige ductless mini-split heat pump for customers. Engineered for extreme cold, the mini-split heat pump features LGRed core technology that provides 100 per cent heating capacity down to -25 C and reliable operation down to -35 C. These heat pumps also feature dual vane technology for adjusting airflow, a built-in occupancy sensor that automatically adapts operation, and soft air for gentle cooling. LG u www.lg.com

n Heat Pump Technical Training Day

The biggest hurdle affecting the adoption of heat pumps in Canada is training, training, and training.

By Francesco Lo Presti

View the full presentation on “The Canadian Heat Pump Landscape” here:

During our Heat Pump Technical Training Day event on Sept. 10, the day wrappedupwithapaneldiscussionon“TheCanadianHeatPumpLandscape.”

In this panel discussion, our editor, Leah Den Hartogh, sat down with Kevin DupuisofKingHomeCanada,PerryChaooftheHeating,Refrigeration,andAir ConditioningInstituteofCanada(HRAI),ToddBackusofTECA,BoDeAngelo of Stone Mountain Technologies, and Tom Breen from Metalworks, to discuss thefutureofheatpumps,andthegood,badanduglysidesoftheindustry.

Herearesomehighlightsofthediscussion.

Question One: What are the main factors contributing to the slow adoption of heat pumps?

Breen:I’lljumpinonthisfirst.Ithinkitcomesdowntothreethings—training, training,training.We’refindingarealslowtranslationofinformationfromthe manufacturer/engineering level to the homeowner level. This process involves working with distributors and contractors, which is currently being done at a slowpace.

Dupuis: Iagreewiththis100percent.Iwouldalsoarguethatthegovernment subsidiesthathavebeenputinplacearehurtingtheadoptionaswell.Specifically, theyarepromotingtheinstallationofincorrectequipmentinthewronghouses. Alotofpeoplearejustgoingforthe“maxvalue,”whichmeanstheyarelooking forthesmallestnumberontheirreceipt.So,manypeoplearesimplyproviding whattheclientwants,butperhapsnotwhattheclientneeds.

Backus:Ithinktheadoptionisalsoregional.Forme,I’moutinB.C.,andwhat I’venoticedisthatthereareadvantagesforheatpumpadoptionhere.Ourclimate

is very mild, where the bulk of the population resides, and there were some early adopters of heat pumps on Vancouver Island, as there was limited access to gas. We have also had a very successful rebate program that has gone on, but there are a lot of challenges on the training and regulatory side of things.

Breen: It would be really helpful if everyone were moving at the same speed. Unfortunately, that’s not the case.

Backus: Also, one of the interesting changes that’s gone on in the B.C. building code, as of 2024, is that there is a requirement for cooling in at least one room. I think this will clearly drive heat pump adoption up because it is challenging to cool just one room; it’s possible, but there are challenges. Additionally, the reality is that most homes have a centrally ducted system, making it more sensible to install a heat pump. There could be dual systems being installed, but again, given our mild climate, we can get away with just a heat pump.

Question Two, asked by DeAngelo: With this new change in the code, do you anticipate this will affect retrofits or new construction, and will this drive energy consumption up in B.C.?

Backus: This will impact just new construction, and I do believe it will increase energy consumption. However, BC Hydro does offer a number of rebates for retrofitting older dwellings. Additionally, one of the latest developments in multi-unit residential buildings is the effort to remove old baseboard heaters and replace them with heat pumps. Many of these are electric, and there are some hydronic ones, but electric is extremely popular here.

From top left to right, bottom left to right: Kevin Dupuis, technical support manager at King Home Canada, Perry Chao, public affairs and stakeholder engagement at HRAI, Tom Breen, business development manager at Metalworks, Todd Backus, mechanical engineer at TECA, Bo DeAngelo, service manager at Stone Mountain Technologies, and Leah Den Hartogh, editor of Plumbing & HVAC magazine sit down and discuss the Canadian heat pump landscape.

Dupuis: Well, coming from Québec, we’ve been on electric heat pumps for a really long time. I know that in newer condos, we are forced to interlock our heat pumps with baseboard heaters. So, there needs to be a separate control on the wall that controls both at the same time. We are implementing a lot more heat pumps in newer residences. As far as retrofits go, getting that gas and oil out is really difficult because the people who know that heat love that heat.

Breen: That’s a good point. A significant part of the challenge for contractors speaking with building owners or homeowners who are not as familiar with the equipment is moving them out of their comfort zone. You know, most of them all they’ve ever known is heating their home with gas, or their home is rural, so all they know is heating with oil. A good step is to show them the technical information at the kitchen table, which is a great way to do so, and rebates always help. However, there is an onus to make the rebates easy to understand, and I don’t believe the government has achieved that.

Chao: To echo what Tom said earlier, education is extremely important for contractors. Obviously, consumers need to be educated because they only know what they know, and it will take a lot of effort from all parties involved (government, utilities, contractors) to encourage them to move out of their comfort zone.

Question Three: So, does the onus fall on the contractor to educate homeowners on heat pumps?

Breen: Ultimately, yes. They are the ones in contact with the customers. Continued on page “55”

Continued from page “53”

"A significant part of the challenge for contractors speaking with building owners or homeowners who are not as familiar with the equipment is moving them out of their comfort zone. You know, most of them all they’ve ever known is heating their home with gas, or their home is rural, so all they know is heating with oil."

DeAngelo: I was going to echo what Tom said because he alluded to it before, and Perry went out and stated it. The consumer does need to be educated, and it really comes down to the contractor. This also requires a different set of training skills and a different set of application skills for the contractor. One of the significant obstacles we see throughout North America is that consumers are confused between return on investment and payback. If they spend $20,000 on a system, they want to know when they will get that back, and they’re not. So, contractors need to be really comfortable in explaining this and explaining where that return on investment is coming from. Unfortunately, there is a significant difference between the two, and many contractors dislike getting into that conversation.

Audience Comment: You are also forgetting the major costs quoted and the misrepresentation by contractors.

DeAngelo: I can start. On a parallel, and probably Tom and Perry can speak to this, there is more work than you have contractors to do. So it is very easy for contractors, distributors, and manufacturers to sell boxes of equipment rather than sell value or the result. This is a challenge I’m not sure how we overcome, but the better contractors are able to separate themselves in that setting and sell the value of what they are doing.

It’s very easy for contractors to just say, “Yup, sure, we can give you a new heat pump, etc.” But we need to move away from that approach.

Dupuis: Coming from a more manufacturer’s background and also being the guy who has installed it, what happens is sales guys don’t get the training they need as well. You come in as a manufacturer and you say, “I have a unit and we can do x, y, z, within these limitations.” But all the salespeople heard was, “You can do that.” So, the salespeople go out and start selling what they are told, but they forget about the limitations. Again, this brings us back to the original topic of training.

Chao: Just to put it out there, HRAI does spend a lot of time talking to the government about the design of rebate programs, and this conversation has touched on two key points: ensuring technicians have the confidence and certification and also that the consumers have many different voices to hear from when they are making their decisions.

Get ahead of the season with the Ion™ System built for dependable comfort when it matters most.

Increasing pressure on municipal stormwater infrastructure, driven by urban expansion and dense land development, presents a great opportunity for rainwater harvesting systems.

n Rainwater harvesting

n Water treatment products

n Reverse osmosis applications

Rainwaterharvestingpresentsacompelling opportunitytoaddresstheincreasingdemandfor alternativewatersources.

By Wayne Lamers & Usha Mathur

Increasingpressureonmunicipalstormwaterinfrastructure,drivenbyurbanexpansion,denselanddevelopment, andshiftingprecipitationpatterns,haspromptedmanyCanadianmunicipalitiestoshiftpartofthestormwater managementresponsibilitytodevelopersandbuilders.Asaresult,buildingbylawsincreasinglymandatethecapture andreuseofrainwatertoreducetheburdenonpublicsystemswhilepromotingsustainablewaterusepractices.

However,reusingrainwaterisnotasstraightforwardasitmayinitiallyseem.Variousregulationsandstandards mayapplyandrequiredifferenttypesofwatertreatmenttosafelyreusethewater,dependingontheapplication.The keystandardsincludeCSAB128.1-06/B128.2-06,CSAB805,aswellasmanyreferencesinbuildingcodesand municipalbylaws.

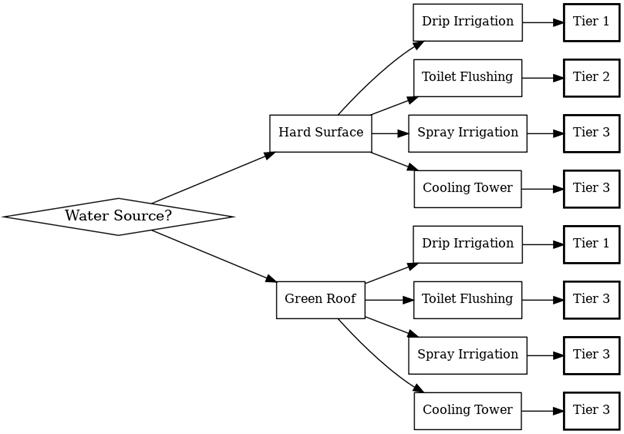

Theenduseoftherainwaterwilldrivedecision-makingrelatedtowatertreatment.Thedifferencebetweendrip andsprayirrigationdrivesdifferentneedsforoverallwaterquality,asthepotentialexposuretohumanschanges dependingontheuse.Similarly,thesourceoftherainwater,beitfromhardsurfaceroofs,orthroughagreenroof,will drivedifferenttypesoftreatmenttrainspriortoit’sultimateuse.

Atypicalrainwaterharvestingsysteminvolvesvariouskeycomponents,consistingofacatchmentarea,a conveyancesystem,pre-filterdevices,astoragetank,adistributionsystem,andanoverflowsystem.

Thecatchmentareaisthesurfaceonwhichprecipitationfallsdirectly,usuallyarooftop(hardsurface)orother low-permeabilitysurfaces(greenroof)canalsobeincluded.Collectedrainwaterthenmovesthroughaconveyance system,usuallygutters,downspouts,andpipes.Pre-filteringisanessentialprocessinwhichscreens,leafeaters,and first-flushdivertersremovegrossdebris,e.g.,leaves,twigs,andbirdmanure,fromenteringstoragetanks.

Astoragetank,usuallycalledacistern,isusedforstoringcollectedrainwaterforfutureuse.Tankscanbemade ofdifferentmaterials,suchasplastic,concrete,andmetal,eachofferingdifferentadvantagesandconsiderationsin termsofcost,longevity,andsuitabilityinvariousapplications.Adistributionsystem,usuallyconsistingofpumpsand pipes,distributestreatedrainwatertoitspointofuse,usuallyanindoorinstallationoranirrigationsystemrequiring pressurization.

"Properly

implemented, rainwater harvesting can serve as a sustainable, resilient component of modern water management strategies — a necessary step toward preserving freshwater resources for future generations.."

Tier 1

These are moderaterisk applications, such as toilet or urinal flushing, where the contact with humans is indirect.

The various tiers demand different levels of water treatment. Tier 1 are low-risk applications, such as drip irrigation, where contact with humans is unlikely. In this case, basic filtration is all that is required, but depending on preferences, the filters can either be a basic cartridge filtration system or a more refined backwashing filtration system.