Contemporary Hot Water Heating

Built-in redundancy was important for this retrofit project in Lethbridge, Alta.

INSIDE

n Choosing the wrong heat pump

n Calculating heat loss, part 2

n Life expectancy of your business

n Ammonia vs. CO2

DOMESTIC HOT WATER HEATING ISSUE

n Hot Seat

Unpredictable 2026

Ithinkit’ssafetosaythatweareoff to abit of an off start in 2026. For the first time in my life, it felt like we were one incident away from global chaos. And I suspect we aren’t exactly out of the woods yet. In fact, for some reason, this editor suspects that we have a little under three years left before there feels like some level of normalcy has returned to the rationale of the world.

I feel like we had to, at the very least, address the craziness that has been 2026 before we shift into some of the more positive outlooks. So, let’s make that shift, as I am sure almost everyone is alreadysickandtiredofthewhiplashwehaveall felt in the past month.

Onto more positive news! We have some big trade shows coming up in the first quarter of the year. We have already had a busy AHR Expo downinLasVegas.LookoutinourMarch/April issue for some of the highlights from that show.

But the big Canadian return of the CMPX Expo in Toronto will be the big news. Anticipated to be bigger than the previous show, the three-

day show will highlight where the HVAC/R and plumbing industry is moving in the future. From what I anticipate seeing, there will be more discussions surrounding the shift towards A2Ls and products that support this shift of product, and I suspect more heat pumps, whether that may be for space heating or for water heating as well.

Another shift that I anticipate seeing at CMPX will be more conversations surrounding artificial intelligence and monitoring within the mechanical room. We are entering into an era which feels almost like we are a part of an old science fiction movie. Hopefully, it’s one with a happy ending. Otherwise, we are at the very least headed towards a very interesting year.

Publisher Mark Vreugdenhil Cell: (416) 996-1031 mark@plumbingandhvac.ca

Editor

Leah Den Hartogh Cell: (289) 830-1217 leah@plumbingandhvac.ca

National Account Manager Brandon Collins brandon@plumbingandhvac.ca

Assistant Editor

Francesco Lo Presti Cell: (647) 531-5697 francesco@plumbingandhvac.ca

Contributing Writers

Glenn Mellors, Greg Scrivener, Michael Ridler, Ron Coleman

Design and Production

Samantha Jackson production@plumbingandhvac.ca

All articles and photos by Plumbing & HVAC staff unless noted.

2025 Canada National Model Codes released

TheCanadianBoardforHarmonizedConstruction Codes (CBHCC) and the National Research Council Canada (NRC) have released the 2025 CanadaNationalModelCodes.

TheNationalModelCodesincludetheNational Building Code of Canada, the National Energy Code of Canada for Buildings, the National Fire Code of Canada, and the National Farm Building Code of Canada. For the 2025 edition of the codes, changesweremadetoeachrespectivecode.

Changes made to the 2025 National Plumbing Codeinclude:

•Introduction of requirements for condensate drainage systems to prevent leaks, odours and mould.

•Clarification of the requirements for roof drainage systems, while providing additional design options.

• Introduction of requirements to protect potable

water from chemical contamination.

•Removal of dilution as an option for treating corrosive or acid waste, while retaining neutralization, to better protect plumbing infrastructure and the environment.

Some changes made to the 2025 National Building Code of Canada include:

•Expansion of the accessibility objective to apply to all types of dwelling units, with flexibility for jurisdictions to adjust how the requirements are applied to suit local needs.

•Increase in the permitted exposure of mass timber elements and the maximum physical height for encapsulated mass timber construction, under certain conditions.

•Expansion of the environmental objective to address greenhouse gas emissions

•Expansion of the objective of protecting adjacent buildings or facilities from fire to apply to

large farm buildings, along with the introduction of related technical requirements.

Changes made to the 2025 National Fire Code include:

•Expansion of the objective of protecting adjacent buildings or facilities from fire to apply to large farm buildings.

• Removal of the application limits placed on the reference to CSA B139 Series:24, “Installation Code for Oil Burning Equipment,” so the standard can be referenced for all tank sizes within its scope.

•Clarification of the maximum quantities of dangerous goods that are permitted for use in laboratories, including the addition of limits for compressed gases.

•Introduction of additional measures to reduce the risk of fire spread in encapsulated mass timber

Continued on page "9"

Important updates were made to Canada’s building codes and released in December 2025.

buildings during construction, while permitting increased exposure of mass timber elements in certain conditions.

Some changes made to the 2025 National Energy Code of Canada for Buildings include:

• Expansion of the environmental objective to address greenhouse gas emissions.

• Introduction of a harmonized framework that aims to reduce the operational greenhouse gas emissions of buildings, offering provinces and territories a harmonized pathway to reduce emissions over time by choosing the performance level that best suits their needs.

• Introduction of energy efficiency requirements for the alteration of existing buildings, offering building officials a harmonized framework to enforce code requirements in retrofits.

• Inclusion of projected climatic data, which anticipates climate trends over the next 50 years, so buildings are better prepared for future climate conditions in Canada.

Technical changes approved by the CBHCC and the NRC for all the national codes were also released. The 2025 Canada National Model Codes can be downloaded electronically on the Canadian Board for Harmonized Construction Codes’ website.

Continued from page "7" Continued on page "10"

Investment in building construction falls slightly in October

The total value of investment in building construction fell 0.5 per cent to $22.3 billion in October. Statistics Canada reports that the residential sector recorded losses, while the non-residential sector recorded a slight increase.

Specifically, investment in residential building construction fell 0.8 per cent ($125.8 million) to $15.5 billion in October. Losses were seen in the single-family component, down 2.5 per cent. The losses in this component were led by Ontario (down $131.8 million) and Alberta (down $48.9 million). In total, eight provinces and one territory contributed to this decline.

However, the multi-unit component recorded a slight increase, up 0.6 per cent. The increase was driven by Quebec (up $154.2 million) and the Northwest Territories (up $10.2 million).

In the non-residential sector, the value of investment in building construction grew slightly by 0.2 per cent ($15.5 million) to $6.8 billion in October. Investment in the commercial and institutional components each edged up 0.3 per cent. Specifically, the

Continued from page "9"

commercial component grew from $10.0 million to $3.4 billion, while the institutional component grew from $6.8 million to $2.1 billion.

In the commercial component, British Columbia recorded the largest growth, up $9.1 million. In the institutional component, gains were seen in British Columbia (up $8.9 million) and Alberta (up $8.5 million).

However, investment in the industrial component dropped 0.1 per cent ($1.3 million) to $1.3 billion in October. The decline in October was led by Alberta (down $5.6 million), Ontario (down $5.3 million) and British Columbia (down $2.4 million).

Canada aims to train 2,000 more skilled workers

Canada is investing in training 2,000 skilled trades workers to help develop infrastructure and build more homes. Through the building and construction trades department, a $9 million investment was made to train sheet metal workers.

Specifically, the project will see the development, delivery, and evaluation of training for unionized and non-unionized sheet metal apprentices and journeypersons. This training project will equip metal sheet workers to better navigate the transition to a low-carbon economy.

“To build major infrastructure and create rewarding careers for Canadians, the Government of Canada is investing in skilled trades training. We are building Canada strong, and we are doing it here at home,” said John Zerucelli, secretary of state, labour.

Funding for this project was provided by the Union Training and Innovation Program’s (UTIP) sustainable jobs stream under the government’s Canadian Apprenticeship Strategy. The sustainable jobs stream is expected to support approximately 29,000 workers in the Red Seal trades over five years.

Apprenticeship registrations on the rise

It was a good year for Canadian apprenticeship registrations in 2024. Statistics Canada reports that there were 101,541 new registrations in 2024. This marks a 5.9 per cent increase from 2023 and a record high since the series began in 2008.

In addition, there were also more certified apprentices with 46,971 gaining certification. This remains unchanged from 2023; however, certifications remained below pre-pandemic levels.

Across Canada, all the provinces, except for Quebec (down 8.4 per cent), exceeded their new registration levels from before the pandemic. However, despite the high number of new registrations, six provinces and two territories experienced year-over-year declines in 2024. Nova Scotia led the decline, down 7.4 per cent, followed by Quebec, down 4.3 per cent.

With regard to specific trades, there were gains in new registrations for electricians, plumbers, pipefitters and steamfitters, and interior finishers in Alberta and British Columbia, along with growth in automotive service workers and electricians in Ontario.

Specifically, there were 4,572 new plumbers, pipefitters, and steamfitters apprentices and 1,545 new refrigeration and air conditioning mechanic apprentices. Overall, there was a 24.2 per cent increase in new construction apprenticeship registrations.

Additionally, the certification rate—the percentage of apprentices completing their programs within the expected duration—rose by 1.1 percentage points to 19.9 per cent in 2024

Continued on page "11"

Continued from page "10"

Space/water heating main culprit in rising building energy usage

A new report states that global energy efficiency progress will improve by 1.8 per cent in 2025, up one per cent compared to 2024. The Energy Efficiency 2025 report, conducted by the International Energy Agency (IEA), is an annual analysisofglobalenergydevelopments.

Thereportshowsthatseveralkeyregionsare showing signs of stronger progress than their average since 2019. For example, energy intensity progress in 2025 is estimated to be over three per cent in China and over four per cent in India, well abovetheiraveragessince2019.

In the United States and the European Union (EU), on the other hand, progress in 2025 is set to fall to under one per cent afterseveralyearsof strongerperformancefollowingtheenergycrisis.

However, the report states that the world remains offtracktoachieveitsCOP28ambition for a four per cent annual improvement by 2030. Specifically,globalenergyefficiencyprogresshas fallen to an average of 1.3 per cent per year since 2019. Thisisjustoverhalfitslonger-termaverage of around two per cent per year over the period from2010to2019.

Thereporthighlightedfourkeytrendsholding back faster progress: accelerated energy demand growth in the industrial sector, lagging progress in technology policy, rising electricity demand, and increasedaccesstoairconditioners.

Going into more detail on the last trend, the report shows that higher living standards have enabled more people to afford much-needed cooling technologies, such as air conditioners, especiallyinemergingeconomies.Thereportadds that energy for space cooling has seen the fastest growth of any end-use in buildings since 2000, growingoverfourpercentperyear.

While on paper this is a good trend, the report shows that the increased demand has been met

with inefficient equipment, further straining energy systems at a time of rapid growth. The report adds that, “If every air conditioner bought since 2019 had been the most efficient available, the world could have avoided electricity demand growth equivalent to the demand growth from data centres over the same period.”

In addition, the report states that around 30 per cent of global energy demand is attributable to buildings, with this sector contributing around 30 per cent of global growth demand since 2019.

Going further, the residential sector accounts for 70 per cent of total energy demand in buildings, while commercial and public buildings make up the remaining 30 per cent. In most homes, the main culprits in energy use are space and water heating, which together account for 70 per cent of global energy use.

■ Removable, replaceable grid keeps drain looking new

■ Grid prevents clogs

■ Simple to snake–remove grid and snake from above

■ Heavy-duty brass or PVC ■ One-piece tube, one-person installation

Case Study: A-1 Truck & Car Wash

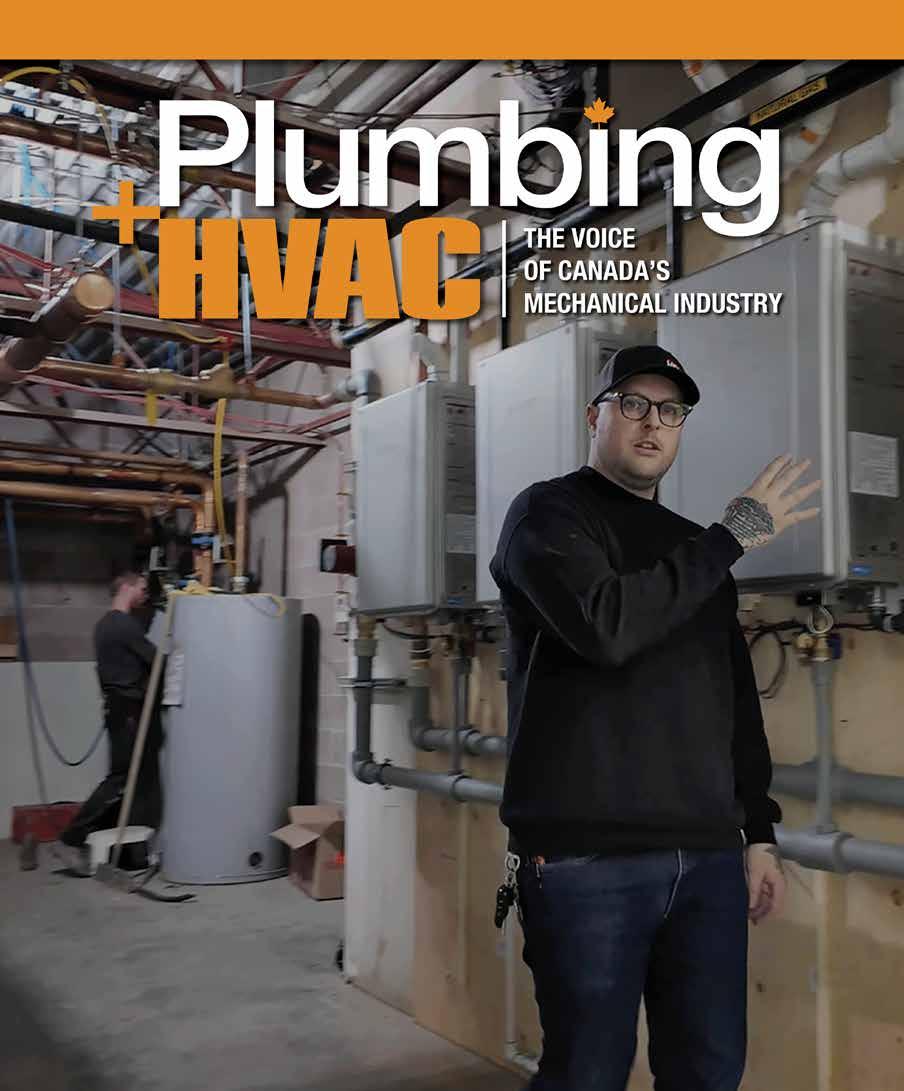

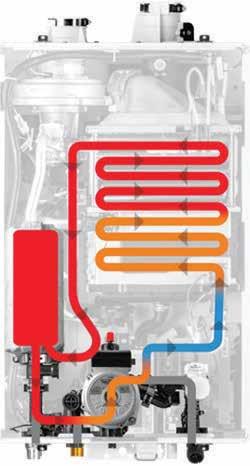

Instead of opting for a simple boiler swap, this project adopted a unique and innovative approach.

By Leah Den Hartogh

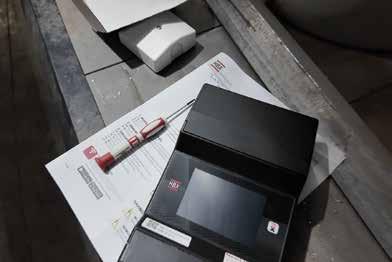

This installation for the five tankless water heaters took only three days to complete and was significantly shorter than the typical seven to twelve days anticipated for a traditional boiler setup.

Youcannotunderestimatetheimportanceofastrongteam.Ittakesmorethanoneperson to ensure that the end result meets the expectations of all those involved. We’ve all heard a version of a saying emphasizing the importance of teammates. A jobsite is no different. A team of industry experts came together on one particular jobsite in Lethbridge, Alta, aiming to solve the issue of an ageing hot water system on its last legs. The team of experts, comprising Simpson Plumbing, Barclay Sales, and Bartle & Gibson, helped ensurethattheprojectransmoothlyandthecustomerwassatisfied.

AtA-1Truck&CarWash,theyhadreliedonaconventionalhotwatersystempoweredby twolarge,two-stageboilers,eachdeliveringtwomillionBTUs.Thislead-legconfiguration meant that one boiler was operating to meet the demand, with the second only activating when needed. TherewereconcernsfromtheownersofA-1regardinga failure— ifthe primaryboilerfailed,thenonlyoneunitremainedtoshoulderthefulldemand,leavingthe facilityvulnerabletoserviceinterruptions.

“We had a long-term, good customer that operates a large commercial car wash, and they were running into issues with their existing boilers,” shared Justin Fisher, owner of SimpsonPlumbing.“Withtherequiredupdates,ColinLaRose(projectmanageratSimpson Plumbing)wenttoworkondealingwiththecustomerandonalternatesolutions.”

Thesolution?FiveNCC199CDVNoritzcommercialcondensingtanklesswaterheaters paired with a Noritz commercial controller. Elements of the older infrastructure were incorporatedtoallowfortheexistingboilertomaintainoperation.

“Going with the tankless option gave us the opportunity to leave the customer up and running the entire time,” shares Fisher. “Therewasmaybeonehourshutdownthatwas required to transfer some water line, and then they were up and running. Therewasno interruption to business doing it the way we did, whereas, if we had gone with a more intrusive method, like adding a new high-efficiencyboiler,or somethinglikethat,there couldhavebeenalotmoresubjecttointerruptiontothebusiness.”

Thismeansthatwhentheboilerdoesfinallycallit quits,moretanklessunitscanbe installed.AseparateHBXcontroller,theCPU-0600,wasinstalledtointegrateandmanage theoldboiler,triggeringittosupplementthetanklessinstallationwheneverneededtomeet theload.

“TheHBXisastagingcontrollerthatenablesthetanklessunitstoactastheprimaryheat source,maximizingbothefficiencyandreliability,”saysJoshuaFerguson,outsidetechnical sales representative for Barclay Sales. “If, for any reason, the tankless system can’t keep up, suchaswhenall10baysareoperatingatonce,theHBXwillactivatetheoriginalboilerasa backuptoboostoutputtemporarily”

Built-in redundancy

Lethbridge sits at a population of around 113,671, according to the province’s website, making it Alberta’s fourth highest population in the province. Due to its geographical location close to the United States border, it sees a high number of commercial trucks throughitscity,meaningthatA-1seesquiteabitofcustomertraffic.

Thiswasa largereasonbehindthesystem’sstageapproach.“Wecangiveyouthisfirst phase of a retrofitofyourentiremechanicalsystemwithouthavingtoblowhundredsof 1,000s of dollars on the budget right away,” explains Ferguson. “Theycandoitpiece-bypiece.Ifyouhavetodomaintenanceononeoftheunits,we’llputinfiveofthesecommercial tankless units to get our million BTUs, as opposed to one single, one-million-BTU boiler.

Continued on page “15”

n Hot Water Heating

Continued from page “13”

We can have that redundancy, whereas the volume of needs is increased for how many bays are being used.”

The old boiler continues providing two million BTUs, meaning the entire system has the availability for three million BTUs. “It’s also really nice to get the chance to be part of a project where we’re bringing in kind of the new way of doing things because there have been a lot of changes,” shares Fisher. “In a situation, probably five years ago, we would have just ordered that same boiler, popped the old one out, put the new one in, and away you go. With a project like this, there’ll be lots more to come, where we’re having to integrate new technology into these systems.”

Hurdles along the way

One of the biggest challenges for this project was simply finding the room to fit each of the components into the upgraded system. “Since it was an older building, filled with two existing boilers and old infrastructure, it always adds complexity to the job,” shares Fisher. “How do we get this to fit in? Where can we locate it? How can we do it so that when we need to add in the future, it’s going to work out? Just prepping the area for the installation is always a bit of a challenge.” To add to the complexities, the mechanical room was located on the second floor.

About six months after the system was already up and operating, there were some issues with the units. A sandblasting company was located across the street, which was causing trouble for the tankless units as they were taking in contaminated air. This meant that Simpson Plumbing had to come up with a different approach for the air intake. “We kind of deduced it was an environmental outside condition of what we had seen. The sandblasting wasn’t even there when we first built the product itself,” shares Ferguson. “The

An HBX controller was installed to integrate and manage the legacy boiler as a secondary heat source, triggering it to supplement the tankless installation whenever needed to meet the load.

The success of this project inspired Simpson Plumbing to utilize this approach in other projects.

“It’s also really nice to get the chance to be part of a project where we’re bringing in kind of the new way of doing things because there have been a lot of changes.”

other environmental condition was the car wash. The road leading into the car wash was completely jackhammered and taken up and rebuilt. A lot more dust contaminants were pushed through the air.”

This meant that attention needed to be paid to the incoming air. “It’s similar to what you would look like if you’re not changing your furnace filter for a year-and-a-half,” explains Ferguson.

Next steps

A-1 Truck and Car Wash plans on a second phase of retrofits, which would see another five additional Noritz tankless water heaters installed, alongside two Noritz Hybrid Hot series units to replace the backup legacy boiler. The Hybrid Hot series utilizes standard tank water heaters in combination with tankless units.

The success of this project inspired Simpson Plumbing to utilize this approach in other projects. “That’s a high-five in our direction,” shared Ferguson.

Included on the project was one of Simpson Plumbing’s current apprentices. The hope is to have the next generation of tradespeople working with new products and installation approaches, so that they are comfortable with the high-efficiency new technology. “We’re also trying to incorporate them into these installs so that they are learning how things will be going ahead… just to ensure that we’re at least producing educated people going forward,” shares Fisher. “We are starting to see a huge crossover between the old-style plumbing and the newer stuff. There’s a lot more technology, a lot more literature and stuff involved in some of these new installations.”

n DHW Products

Storage water heater

HTP, a part of Ariston Group, Providence, Rhode Island, introduces the SuperStor Ultra EVO to customers. The SuperStor Ultra EVO is an indirect-fired water heater designed for integration into a wide range of residential and commercial applications. The water heater features a stainless-steel tank for corrosion resistance; premium stainless fittings, marine-grade AISI 316L stainless steel at the drain valve, inlet/outlet nipples, and T&P valve for reliability. Multi-port flexibility is available on the 30-, 45-, and 60-gallon models.

HTP u www.htproducts.com

Water heater connectors

Air-to-water with DHW

NTI, Saint John, New Brunswick, announces its new Verta Series of air-towater heat pumps, which are designed for single-family homes and apartments with limited space. Featuring R-32 refrigerant, the Verta Series deliver high water temperature even in low ambient conditions. It provides an alternate solution for hydronic heating and cooling, as well as domestic hot water (DHW), a first for the Canadian manufacturer.

NTI u www.ntiboilers.com

Indirect water heaters

QuickFitting, East Providence, Rhode Island, expands its flamefree product portfolio with its new flexible stainless steel water heater connectors: the SurePress and push-to-connect. Designed for installations in tight spaces, the new connectors eliminate the need for glue or flames while also accommodating misaligned supply lines. The SurePress features a patented design with indication windows visible from any angle, while the push-to-connect feature allows quick installation onto copper, PEX, or CPVC supply lines. QuickFitting u www.quickfitting.com

Aerco water heater

Aerco, Blauvelt, New York, debuts its latest high-efficiency gas-fired fire-tube water heaters to market. The Innovation 1600 and 2000 water heaters feature a tankless design with a turndown ratio of up to 20:1, an outlet water temperature range of 50 F to 190 F, and up to 99 per cent thermal efficiency. Aerco’s Innovation also features an integrated Edge Controller for enhanced hot water management, dedicated hot water re-circulation, and AERtrim technology for oxygen levels.

Aerco u www.aerco.com

IBC Boiler, Burnaby, B.C, releases its DTI InterStor indirect water heaters. The water heaters are constructed of stainless steel, with a pickled and passivated tank, and also feature two inches of polystyrene foam insulation. Top domestic water connections are available on the DTI 40, 55, and 65. Side domestic water connections are available on the DTI 30, 80, 119, 80-Max, and 119-Max. The DTI InterStor water heaters can be paired with any IBC condensing boiler for a complete, high-efficiency home heating and DHW solution.

IBC Boiler u www.ibcboiler.ca

Residential water heater

Bradford White, Halton, Hills, Ont., unveils its upright electric residential water heater to customers. The water heaters feature Vitraglas tank lining with Microban and a Hydrojet total performance system, providing corrosion protection and increasing the first-hour rating for hot water. The water heater also features fully automatic controls, direct heat transfer with immersed elements, factory-installed heat traps, and more. The upright electric is available in 120V, 208V, 240V, 277V, and 480V voltages. Single-phase or three-phase operation is available at 120V and 277V.

Bradford White u www.bradfordwhite.com

Expanding the Toolkit, PART 2

Testing empirical heat loss with real data.

By Erik Janssen

In the last edition of the magazine, we explored why heat loss calculations are critical for heat pump retrofits— highlightingemergingempiricalheat loss calculation methods that use utility billing data as a simple option for contractors.

Thelogicisstraightforward:energyuserisesandfallswitha home’sheat loss,sobillingdatacanbeusedtoinferheatloss.Thisfollow-uparticlereviews ongoing research validating these methods, practitioner insights, and early casestudyresultsfromrealhomes.

A national validation effort for empirical heat loss methods is already underway. Jérémie Leger, project lead with Natural Resources Canada’s (NRCan) local energy efficiency partnerships (LEEP) team, explains, “Leveraging real-world data for heat loss and heat gain calculations presents a significant opportunity to improve the sizing and selection of heat pumps in Canada’s retrofit market. We have recognized its potential and are now conducting a large-scale research study on Canadian homes to assess the accuracy of these methods. The objective is to provide insights to the CSA F280 standards committee and, if methods are proven reliable and accurate,

incorporatetheseemergingapproachesintothenextversionsofthestandard”

Theresearchwilltaketime,butcontractorsandenergyadvisorsarealready usingempiricalmethodsinthefield,andtheirexperienceoffersearlyinsights.

Insights from the field

Michelle Hjort, managing partner at Energy Neighbour, has worked on more than 300 retrofitsintheGreaterTorontoArea(GTA).Sheusesboth EnerGuide audit design heat loss (DHL) values and empirical estimates from utility bills. Hjort findsheatlossestimatesfromempiricalmethodsto be consistently lower and relies on them for heat pump sizing, while using EnerGuide DHL values for backup system sizing, “… a significantbarrierto heat pump uptake is lack of confidenceincorrectsizing.Theempiricalheat loadsizingmethodsareagamechangerforcontractorsandHVACcoachesto quicklyandeasilydetermineheatloadbasedonreal-worlddata”

SarahGrant,founderofGoldfinchEnergy,hasauditedover1,500homes,

Continued on page “21”

Continued from page “19”

withmorethan1,000heatpumpinstalls.HermaintoolisVoltaSNAP,which producesaCSAF280-compliantDHLcalculationfromEnerGuideauditdata. Whererelevant,sheaddsempiricalcalculationsfromutilitybills.“Sometimes the empirical and F280 data align while other times they are grossly different with the empirical methods coming in lower. It seems that most oftenthe differencesoccurwithhomesthataren’twellinsulated”

Grantnotesthatuneventemperaturedistributioninolderhomesmaybea contributingfactortothediscrepancy.Bothexpertsseeempiricalmethodsas simplerforcontractorsbutstressunderstandingtheirlimitations.

Overall, a key insight from the fieldisthatempiricalmethodsproduce lowerheatlossestimates.Thisbearsoutinearlyobservationsfromcasestudies.

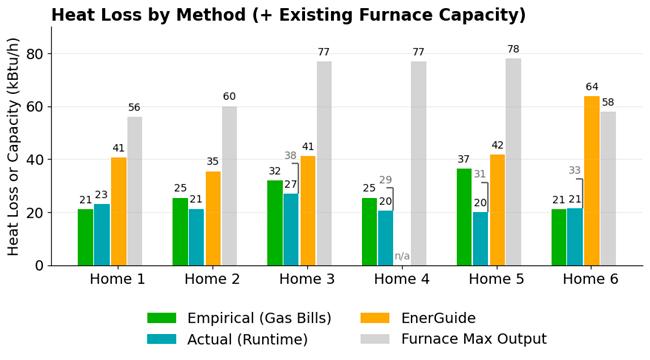

Case studies overview

Supported by The Atmospheric Fund (TAF), the Toronto and Region Conservation Authority (TRCA) Sustainable Technologies Evaluation Program (STEP) tested its free empirical heat loss tool, ThermalPoint, in six GTA homes using data from a previous heat pump study, which is titled ReplacementofAir-ConditionerswithColdClimate Air-SourceHeatPumps.Data included pre- and post-retrofit utility bills, EcoBee thermostat runtime data,EnerGuideaudits,andequipmentspecs.

Homesweretypicallymedium-sized,1960sto2000sconstruction,detached or semi-detached, with cold-climate heat pumps (two to three tons) backed up by existing furnaces.Two homes had small wood stoves (Homes 5 and 6); othershadnoadditionalheatsources.Indoorsetpointsrangedfrom19Cto23 C.DetailsonhomesandequipmentareinFigure2.

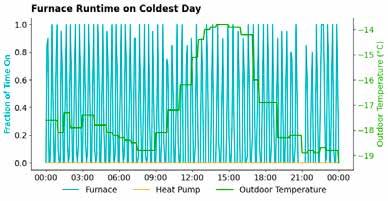

Figure 2: Example furnace runtime data is shown for Home 2.This data was used to estimate the actual heat loss of the home.

Four values were compared for each home, including empirical heat loss, which was estimated by ThermalPoint using pre-retrofit gas bills, actual heat loss calculated from furnace runtime data, EnerGuide audit DHL, and furnace maximum capacity.

Furnace runtime was treated as the closest approximation to the actual real-world heat loss and an independent benchmark to compare against. The runtime analysis went as follows. Taking Home 2 as an example (data in Figure 2), a single-stage Lennox G41UF-36B-070 furnace (60 kBtu/h output) ran 34 per cent of the time to maintain the indoor temperature near 23 C on a

day with an average outdoor temperature of -17 C. The furnace provided the equivalent of 20 kBtu/h (34 per cent times 60 kBtu/h), and this was assumed to be equal to the heat loss. The heat pump was off during this time. Results were adjusted to the design temperature assumed in the EnerGuide audit (-18.3 C). For two-stage furnaces, a range was calculated since the operating stage wasn’t logged. The calculation was repeated for both low- and high-stage outputs, although low-stage was likely closer to reality because the furnaces were typically oversized.

The results

Results are shown in Figure 3. The empirical heat loss prediction based on the

Continued on page “23”

Figure 1: The ThermalPoint empirical heat loss tool was applied in several homes that installed heat pumps.

MARCH 25–27, 2026

Metro Toronto Convention Centre

South Building

STEP INTO THE FUTURE OF HVACR & PLUMBING

Get hands-on with the latest equipment, tools & tech

Connect with 500+ suppliers & manufacturers

Stay sharp with live demos, code updates & training

Unlock timesaving & profit-boosting solutions

“Leveraging realworld data for heat loss and heat gain calculations presents a significant opportunity to improve the sizing and selection of heat pumps in Canada’s retrofit market.”

Continued from page

“21”

pre-retrofit gas bills tends to agree with the actual heat loss determined independently from the furnace runtime data. The EnerGuide audit DHL was greater than the actual heat loss to varying degrees, sometimes by a factor of two times. In all cases, furnaces were on the scale of two to three times larger than needed.

The larger heat loss determined from the EnerGuide audits can impact heat pump sizing. For example, considering Home 1, NRCan’s air-source heat pump sizing and selection web app predicts that furnace back-up is required for outdoor temperatures below -3 C, if assuming the EnerGuide heat loss. If assuming the empirical heat loss, it’s -12 C.

The difference is large and makes the heat pump appear less capable than it is in practice. Furthermore, the post-retrofit thermostat data showed that the heat pump could indeed meet the load in the colder temperatures predicted by the empirical heat loss.

Figure 3: Heat loss was calculated using different methods. The error bars on actual runtime for Homes 3 to 6 represent a range of possible values since the operating stage of these two-stage furnaces was not logged.

The sample set is small. The analysis was simple and didn’t exhaustively evaluate every relevant factor. However, it is enough to build some initial confidence in empirical heat loss methods using utility billing data. Thus far, they seem relatively capable of predicting how much heating a home will need in practice. They predict a lower heat loss than EnerGuide audits, but this appears to be closer to reality.

Early data supporting empirical heat loss methods is promising, but these approaches require careful judgment. As discussed in the first part of this article series, different factors must be considered, and for now, that responsibility rests with those doing the sizing.

LEEP’s research project is a key development. Its goal is to standardize the empirical heat loss calculation process and introduce guardrails that clarify when these methods are appropriate. If validation succeeds, empirical methods could become an option for existing homes in the CSA F280 standard. This would be a critical outcome for building confidence and ensuring these methods are applied effectively.

For the industry, the upshot is broader adoption of heat loss calculations, more accurate system sizing, and better heat pump retrofit outcomes.

Erik Janssen is a program manager at the sustainable technologies evaluation program (STEP) of the Toronto and Region Conservation Authority (TRCA). For more than a decade, he has led data monitoring pilot projects evaluating new heat pump technologies installed in homes, large buildings, and in STEP’s Archetype Sustainable House (ASH) Lab.

INSTALL WITH CONFIDENCE POWERED BY CONTINENTAL

As an HVAC professional, you need systems that deliver performance, reliability, and efficiency—without the hassle. Continental’s fully integrated lineup installs easily, delivers lasting comfort, and drives long-term energy savings.

Why Contractors Choose Continental:

Easy to Install and Service

High-Efficiency Heating and Cooling

Built for North American Homes

Unmatched Innovation and Reliability

Upgrade your installs. Elevate your reputation. Choose Continental.

Unintended Consequences: Choosing the Wrong Heat Pump

Incentive programs need to scale quickly and take into consideration solutions the installer can already understand.

By Michael Ridler

Over the past several years, I have spent a great deal of time travelling through colder climate regions as electrification efforts accelerated, which is a polite way of saying I am Canadian and spend a lot of time crossing the country for work, talking and learning about HVAC.

It has been incredibly exciting to see the massive wave of heat pump adoption. This adoption has been driven by climate commitments and policies that created a sense of urgency that left little room for hesitation. In the push for electrification, air-to-air heat pumps became the default solution across much of the country. Within this decision there is an opportunity.

The opportunity is that air-to-air heat pumps were applied as a universal choice, whereas a more nuanced approach might have been better. But like with any technology, you don't know what you don't know! After years of travelling, sitting in meetings, and participating in workshops and contractor roundtables across Canada, a pattern has become impossible to ignore. In some cases, and regions, air-to-water heat pumps might have been the smarter and more resilient choice. The key takeaway is not that one technology is flawed, but that solution selection requires a case-by-case approach. The intent of these observations is to advocate for choosing the right tool for the job. Whether it's air-to-water, air-to-air, or ground-source heat pump technology, the choice should be driven by the use and the application. Retrofitting a hydronic system? Air-to-water. Conventional gas/air conditioner? Air-to-air, or better yet, the grid powerhouse of a ground-source heat pump.

Default solution

What I have learned from my travels is that electrification is complicated. Programs need to scale quickly. Installers need solutions they already understand. Incentives need clear and simple categories. Air-to-air heat pumps, which are seen as the natural fit for homes with forced-air ducted systems, checked every one of those boxes.

The primary goal was adoption, and with that can sometimes come with unintended consequences. This was nobody’s fault. You don’t know what you don’t know, and in fast moving markets, technology can outpace policy. If a solution looked too different from a traditional furnace replacement, it could be quietly and unintentionally sidelined. Ground-source heat pumps are unjustly seen as too expensive and hydronic systems were not top of mind, even though in some areas they still represent a significant share of the housing stock.

That mindset shaped the market. Training dollars flowed toward ducted solutions. Marketing reinforced the idea that electrification meant air-based systems. In the process, a critical question was rarely asked. What actually works best in these buildings?

Winter cold snaps are where system design really shows its value. This was especially clear during a town hall meeting I attended on the East Coast in the middle of winter. The building itself was beautiful, a well-maintained historical building with beautiful cast iron radiators throughout. It should have been the perfect example of thermal comfort and resilient heating. Instead, the room was cold. Two air-to-air heat pumps had been retrofitted into the space, working hard but struggling to deliver comfort in a building designed for hydronics.

Isn’t it ironic

As the discussion turned to grid peaks and winter reliability, the irony was hard to miss. That same building, with its existing hydronic distribution and thermal mass, could have been turned into a thermal battery using an air-to-water heat pump. Heat could have been stored and released gradually, maintaining comfort while helping ride out peak demand.

Incentives in Canada have heavily skewed towards air-to-air heat pumps.

Homes and buildings equipped with air-to-water heat pumps connected to hydronic distribution can behave differently during extreme weather. Rather than reacting minute by minute to outdoor temperature swings, these systems store heat and release it steadily. These buildings function as thermal batteries. Occupants experience fewer temperature swings and more stable comfort. Installers see systems operating exactly as intended.

The takeaway from these observations is not that one technology is superior to another. Because that wouldn't be true. The difference is not the heat pump alone. It is the system design and picking the right heat pump for the job.

Heat pumps are an essential part of the electrification solution. But as we build more houses, and plan for the future, there will be challenges. The opportunity lies in diversifying the types of heat pumps deployed to ensure a more stable grid and, critically, to deliver predictability and comfort to the consumer.

If a home has a gas boiler, we don't need to retrofit to an air-to-air to electrify. You also don't need to use an electric boiler. There are options.

In effect, an air-to-water heat pump can act as a quiet grid asset. When you replace a boiler with an air-to-water heat pump, the results are predictable. The homeowner has the same system they always had, the same level of comfort and a predictable outcome for them. They don’t need to adapt their lifestyle at all.

Continued on page “29”

n Hydronics

Continued from page “27”

Missed opportunity

In several of the regions I visited, a surprisingly high percentage of existing homes were still heated by ageing boilers. These homes already rely on hydronic distribution, radiators, or in-floor systems that were designed to deliver steady, comfortable heat in cold climates.

Instead of upgrading those homes with air-to-water heat pumps and transforming them into thermal batteries that could support both comfort and grid flexibility, many were retrofitted with either electric boilers or air-to-air systems shoehorned into buildings that were never designed for ducted heating systems. The result was not a failure of the technology, but a mismatch between the system and the infrastructure already in place.

I've been in buildings where the hydronic emitters still existed, pipes capped and boilers removed. Comfort complaints followed. Homeowners described uneven temperatures and drafts that had not existed before. In trying to electrify, we unintentionally compromised the very comfort these systems were meant to improve.

I will remind everyone that this is not a knock against a type of heat pump. Every heat pump technology has an important role to play. The issue arises when we effectively pick a single winner, rather than supporting a range of solutions that allow buildings to be treated as energy assets. When technology advances faster than policy frameworks, we risk locking in outcomes that fall short of what is possible.

A different approach

If these electrification efforts were starting today, the playbook could look different. Technology selection could be based on building type and heating type rather than technology familiarity alone.

Air-to-air heat pumps would still have a significant role, but air-to-water systems would be prioritized where hydronic distribution exists. This emphasis

When retrofitting a hydronic system, the most correct solution for which a heat pump is best suited is likely an air-to-water.

on leveraging existing hydronic infrastructure and thermal storage is the crucial differentiator for long-term resiliency. Incentive programs would reward system performance, not just equipment type. Thermal storage would be recognized as infrastructure, not an accessory.

Canadians didn’t make these choices out of ignorance or bad intent — we made them under pressure; speed mattered, simplicity mattered, but now, real world data, and contractor experience are telling a clearer story. The next phase of electrification won’t be defined by how fast heat pumps can be installed. It will be defined by how well they serve homeowners, trades, and the energy system as a whole. Choosing the familiar solution is easy. Choosing the right one takes a bit more thought.

Michael Ridler, is the owner/general manager at Eden Energy Equipment. He started out working for a Ont-based HVAC company and now focuses on providing field support and technical training to contractors, engineers, and builders on heat pumps, boilers, and all things hydronics. He can be reached at edenenergymike@gmail.com

In the push for electrification, air-to-air heat pumps became the default solution across much of the country.

n Hydronics Products

Expanded condensing boiler offering

U.S. Boiler Company, Lancaster, Pennsylvania, expands its line of Citadel condensing boilers and volume water heaters. The Citadel is now available in seven capacities, ranging from 399 to 1,500 MBH, all with a 10:1 turndown ratio. It is available in natural gas and propane configurations. In addition, they can be stacked two high without the need for accessory racking systems, as it requires zero side and top clearance.

U.S. Boiler Company u www.usboiler.net

New line of condensing gas boilers

Conforto, Cowansville, Que, announces the introduction of its new line of residential and commercial high efficiency condensing gas boilers. It has an efficiency rating of greater than 95 per cent, up to a 10:1 turndown ratio (for its residential boilers), direct venting up to 150 ft, and a built-in cascade control for up to 16 boilers.

Conforto u www.confortohvac.com

Heat pump hybrid system

Weil-McLain Canada, Burlington, Ont., announces the Canadian launch of its Eco Hybrid dual-fuel hydronic system, a solution that pairs an air-to-water heat pump with a high-efficiency boiler. Ideal for new custom homes, renovations, and retrofits, the Eco Hybrid integrates the new Eco HP air-to-water heat pump with a boiler, switching between the two based on outdoor conditions. The Eco HP outdoor unit delivers up to 55,000 BTU/h and a maximum water outlet temperature of 65 C. The system uses R-32 refrigerant and has a COP of up to 5.37.

Weil-McLain Canada u www.weil-mclain.ca

AMMONIA VS. CO2

The decision on which refrigerant depends greatly on the type of application but there are some generalizations that can help narrow down which one is best suited.

By Greg Scrivener

Two new ammonia reciprocating compressors replaced compressors that had operated for 40 years.

"I think that there are some really great applications for CO2 and we are starting to see a lot of success with it as a refrigerant in industrial settings... Ammonia, however, remains the powerhouse of large industrial refrigeration systems; at least for now.”

Over the years, there has been an increased usage of CO2 as a refrigerant. In Canada, the more traditional CO2 refrigeration market has been grocery stores. It’s difficult to get accurate data, but there has been a fairly high adoption rate of CO2 amongst grocers. The more interesting, more rapid changes, are happening on the opposite end of the refrigeration spectrum — small commercial units and large industrial systems.

In industrial applications, like food processing, CO2 is taking market share that used to belong to halocarbons, particularly in locations where the toxicity component of ammonia is undesirable. It is also taking market share from ammonia systems because of the perceived lower ongoing safety and operations costs. This is really apparent in jurisdictions that have operator requirements which increase the operation costs for ammonia disproportionately. Operators are expensive and difficult to find; in some jurisdictions, this is quite literally the only design requirement we hear from clients — “Do what you think is best, but NO operators.”

Incidentally, I presented on this topic at the Canadian Society for Chemical Engineering (CSChE) conference in Montreal last May and spoke at length about what I believe is a serious and unfortunate disconnect between regulation and actual safety in the current and proposed operator requirements throughout Canada. If that presentation ever gets turned into a paper, I will certainly share a summary of it here.

In any case, I get asked a lot about how to make the decision which refrigerant to use in many of these applications. Of course, it always depends, but here are a few generalizations, in my opinion. And they are just that, my opinions only. The one caveat I will mention now is that in all these cases, I’m assuming the CO2 system is “industrial,” which I will explain more further on.

Standard cold storages

In short, for standard cold storages, ammonia and CO2 are both good options. Generally speaking, the refrigeration loads for small and medium sized cold storages fall within a range that works well with both a multi-compressor CO2 rack and a small ammonia system.

Loads in most cold storages don’t change quickly, and they vary season to season requiring operation in low loads. The larger the cold storage, the more I would tend to go with ammonia. CO2 rack systems have some advantages in low load operation, and they tend to be good in a lot of medium/smaller applications. From an energy perspective, the most recent detailed energy study I was involved with showed that in a climate like Edmonton, Alta., there is effectively no difference in annual electricity consumption between the two refrigerants in a cold storage environment. There is however, a higher electrical demand for CO2 because of it’s higher energy use in the summer.

Ice

rinks

Ammonia has an advantage with ice rinks, but CO2 is good, too. Ice rinks are often affected by two additional design considerations in Canada. There are energy code regulations introducing requirements to perform heat recovery in several jurisdictions, and arenas have a “closeness” to the public that most industrial facilities don’t.

Here, my opinion is that ammonia has an advantage that stems from the simplicity of its operation. With proper maintenance, a system using one or two reciprocating compressor systems with a plate and frame heat exchanger can be made almost bulletproof from a function standpoint. If it is designed and commissioned properly, and then well maintained, the system will last almost forever. CO2, on the other hand, requires more complex controls and, even though they have dramatically improved, the compressors are more susceptible to failure.

On the other hand, there are advantages to doing heat recovery with CO2, on top of the lower toxicity. CO2 can also gain some significant efficiencies if you are doing a direct CO2 floor. A method/installation that I personally think is really interesting.

Process cooling

Ammonia is generally best, but CO2 has some great applications for process cooling. Process cooling is the most complicated to discuss. I think there are generally two factors that influence whether ammonia or CO2 is the better choice — size and variability. Size is self-explanatory: the bigger the system, the more likely ammonia is the better solution. This is primarily a function of the size of compressors and components that are easily available.

Variability, in this context, is a measure of how fast loads on the system change. The example I often use is a French fry tunnel freezer. If you’ve ever seen one of these in a large fry plant, you know that they can be huge; hundreds of tons of refrigeration at -30 C or colder, hundreds or even thousands of horsepower.

These tunnels push the limit of evaporator coil heat transfer and almost always use pumped liquid refrigerant to maximize heat transfer efficiency. The product going through a tunnel is part of a process that includes many continuous steps in production. If any one of those steps has a problem, the product can stop moving instantly. When that happens, the refrigeration system goes from working extremely hard to needing almost no refrigeration in seconds. This causes wild swings in control valves, liquid surges in vessels, and rapid unloading of compressors.

It’s been my experience that ammonia systems, with their inherent simplicity and thermodynamic properties that are more conducive to better liquid/vapour separation, function more reliably in these applications. Spiral

Continued on page “35”

RELIABILITY MEETS EFFICIENCY

00e Series High-Efficiency Circulators

At Taco, we believe in making water work—for you, your clients, and the environment. That’s why we’re excited to share the benefits of our High-Efficiency Circulators. When it comes to optimizing performance and saving energy, our circulators are designed to do more with less.

n Refrigeration

Continued from page “33”

freezers are similar, but since they are smaller and have longer dwell times, they don’t seem to be as affected. I’ve been involved with several CO2 spiral freezers that work really well.

Ammonia is also particularly efficient at the temperatures used for chilled process glycol, and a similar size and variability consideration can be applied to these types of systems. Large dairy and brewing applications are almost always better served by ammonia.

On the other hand, ready-to-eat (RTE) facilities that have a lot of room separation and separate temperature, cleaning, sanitation, pressurization, and load requirements in all of the spaces are more often better served by CO2. These facilities can be really large, but they require a lot of smaller evaporators. Here, direct expansion (DX) CO2 can be employed really effectively to avoid the risk associated with so many evaporators in a production area. CO2 still requires leak detection and alarms, but it doesn’t contaminate the food if it leaks.

Industrial CO2

There is a very important distinction that needs to be made between a CO2 grocery store rack and a “proper” industrial CO2 rack. This comparison is often overlooked when it comes to the financial first cost comparisons. A grocery store rack system is often piped primarily in copper and copper alloys; it uses smaller oil separators, heat exchangers, and vessels. These systems are not designed for a 30 to 40-year life expectancy. A more industrial system, on the other hand, uses larger compressors, stainless steel piping, and often has much more conservatively sized flash tanks, and superheat heat exchangers to help prevent the damage from liquid floodback.

There are obviously many other things to consider, but in general, I think that there are some really great applications for CO2, and we are starting to see a lot of success with it as a refrigerant in industrial settings. I am excited to continue trying to implement it wherever we get the chance. Ammonia, however, remains the powerhouse of large industrial refrigeration systems, at least for now.

Greg Scrivener is the lead refrigeration engineer and a partner at Laporte Consultants, Calgary, and works throughout Canada and the U.S. He is a professional engineer and journeyperson refrigeration mechanic. He can be reached at GScrivener@laporteconsultants.com

A copper to stainless weld on a CO2 system.

A CO2 evaporator installed in a ready-to-eat area.

FIND TRAINING COURSES AND VIDEOS!

Search by keyword, category, or geolocation.

Taco Tuesday Commercial: Deep Dive into Taco Custom Skid Packages – 1 PDH

TACO | FEBRUARY 24

Taco Tuesday Commercial:

Data Center Systems – 1 PDH

TACO | MARCH 3

HRAI: Residential Heat Loss/Heat Gain Calculations

HRAI | FEBRUARY 24 TO 27

HRAI:

Residential Ventilation using CSA-F326-M91 (R2019)

HRAI | MARCH 3 TO 5

n Tools & Instruments

Mini pump offerings

TheMalcoGroup,Annandale,Minnesota,introducesfournew mini pumps from Aspen Pumps — the Mini White and Silent+ Gen5 Series, now available for distributor orders, with end-user availability coming soon. Aspen Pumps’ Mini White is designed for below-unit ductless mini-split installations, delivering up to fivegallonsofflow,a33ft.head,andhandlingsystemsofupto7.5 tons or 90,000 BTU/h. It’s ideal for visible installs and residential andlightcommercialapplicationswhereeasyaccessandmaintenance are necessary. TheSilent+Gen5seriesisavailableinthree models:theSilent+MiniAqua,theSilent+MiniOrange,andthe Silent+MiniWhiteGen5.Thispumpisoptimizedforin-unitand remoteinstallations,includingductedsystems,flooring-standing units,chassisunits,andtrunkingapplications.

The Malco Group u www.malcogroup.com

Clear toilet blockages

General Pipe Cleaners, McKees Rocks, Pennsylvania, announces its new Teletube closet auger, designed to clear stoppages just beyond the bowl without the need to pull the toilet. The Teletube carries three extra feet of Flexicore cable telescoped inside the guide tube that can be accessed by pushing the button for extra cable length when needed. Flexicore is comprised of two layers of tempered spring steel coiled tightly over a core of 49-strand wire rope.

General Pipe Cleaners u www.drainbrain.com

Refrigerant recovery machine

Milwaukee Tool, Mississauga, Ont., introduces its M18 brushless refrigerant recovery machine, ideal for residential and light commercial HVAC service. Powered by the M18 Redlithium Forge HD12.0 battery, it transfers up to 10 lbs of refrigerant per charge, eliminating the need for outlets, extension cords, or external power on the job. The machine is A2L compatible and features a daylight-readable LCD screen, adjustable pressure shutoff, and a balanced carry handle for transport. It is available now.

Milwaukee Tool u www.milwaukeetool.com

LIFE EXPECTANCY OF YOUR BUSINESS

How are we maximizing our value based on our life expectancy?

By Ron Coleman

All good things come to an end. There is a natural progression from conception to end for almost everything found on Earth. Sometimes it is simply the final chapter for something as its value decreases. There is a myriad of examples found in history books, think single-use cameras, skinny jeans, or floppy disks.

This begs the question, “How are we maximizing our value based on our life expectancy?” We tend to spend most of our time dealing with the nuisances of the day-to-day, and, as a result, we don’t have the time, energy, or inclination to look at the life expectancy of ourselves, families, businesses, or the elements that make up our businesses. The old adage, “Never do today what you can put off until tomorrow,” catches us all. In some way or another, we all suffer from what I refer to as the FTI disease — the failure

to implement disease. We often have lots of very good intentions, but along the way comes an inability to see things through. This is where things get thrown into that bottom drawer to collect dust. We know what the road to hell is paved with.

This is when you should be asking yourself, “What life expectancy issues should you be considering now to maximize your value to yourself and others?”

Eyes on the business

Looking to your business, should your main focus be on your exit strategy? How to improve profitability? Or how to extricate yourself from the day-today operations?

What about your personal life? How comprehensive is your estate planning? Are you getting enough family time? What are you doing to stay healthy, fit, and happy?

We don’t get realistic about enough of the elements that make up our life expectancy because life gets in the way. These are two of my favourite John Lennon quotes: “Life is what happens while you are busy making other plans,” and “Reality leaves a lot to the imagination.”

Many of the things in our lives that we want to change are simple, but they’re not easy. Try giving up smoking. Sounds simple, but it’s never easy.

In my previous article, I focused on labour productivity. The process is simple, but implementation isn’t easy. The simple part is just knowing that you need to identify the hours billed to the clients compared to the hours paid to your technicians.

Then of course, when it’s time to start implementing the process, that’s when you find the implementation isn’t always easy. That is true regarding many other business strategies. Try eliminating processes that add no value to your business.

Exit strategies

I've written extensively about exit strategies in this magazine over many years and I'm still rather stunned to find so many people coming to me with no realistic exit strategy.

If you look at the surveys done by various organizations in Canada, you'll find that you're not alone in this area. I asked ChatGPT.

Fewer than 10 per cent of small and medium-sized enterprise (SME) owners in Canada have a formal or solid exit strategy in place, despite a large majority planning to leave their businesses within the next decade.

Key statistics from recent reports by the Canadian Federation of Independent Business (CFIB) and the Business Development Bank of Canada (BDC) highlight this significant planning gap.

I empathize with the fact that this is a very difficult part of business to deal with, but my sympathy is lacking when the information is known without any action. Your life expectancy in your business might not be very long but it's not going to get any longer. The businesses that I find most difficult to sell are those that are in a downward spiral and or have a very weak exit strategy for owners and maintenance of senior management.

If I said to you that you must exit your business in 90 days, that you are going to fire yourself, how would your daily activities change? It would be simple enough to make a list of what you should be doing — become a teacher and teach others to do what you do because you won’t be doing it forever. That’s the simple part. Implementation is not so easy, particularly if you don’t have good, detailed, documented procedures.

"

Commitments you make to others are far more likely to get done on time and on budget.

Here are some of the questions that you should be looking at:

☐When do I want to exit my business and how is that going to happen?

☐ What would happen to my business if I got disabled tomorrow?

☐Am I streamlining the business procedures to become more automated?

☐ Am I selling the latest technology and guidance to my customers?

☐ Which processes in my business are adding no value and how do I eliminate them?

☐ Should my business be making more profits? If your normalized profit is under 10 per cent then the answer is definitely, yes.

☐How would my family fare if I were to stop generating income tomorrow?

☐ Am I healthy, fit, and happy?

☐ Are my loved ones and employees happy, fit, and happy?

Score each of these points on a scale of A, B, C. Start working on theApointsnow

Remember that “Life is what happens while you are busy making otherplans”

To avoid FTI disease, share this article with someone who you respect, who will help you develop your accountability process. Get them to do likewise and hold each other accountable. Commitments you make to others are far more likely to get done on time and on budget.

The Heating, Refrigeration, and Air Conditioning Institute of Canada(HRAI)supportssomegreatpeermentoringprograms.

Iunderstandandrespect,frompersonalexperience,thedifference betweensimpleandeasy.Don’tletthedailygrindgetyoudown.Make this your New Year's resolution and make 2026 the year you enhance thevalueofyourlifeexpectancy

Ronald Coleman is a Vancouver-based accountant, management con sultant, author and educator specializing in the construction industry. He can be reached by e-mail at ronald@ ronaldcoleman.ca.

Built with AquaPLEX engineered duplex stainless steel in a highly specialized process, PVI water heaters offer unbeatable reliability and extended product life at lower operating costs.

Introducing the Durawatt Mini

Compact Electric Water Heater

Use as a:

• Standalone water heater

• Sidearm unit for system backup

• Booster heater

• Building recirculation heater

n People & Places

The

People

Rheem Canada has started the new year with a new hire. Chris Rock has been appointed its new director of sales and marketing. Effective Jan. 30, Rock will oversee all aspects of Rheem Canada’s sales and marketing strategy, as well as driving the expansion of Rheem’s air-to-water business model.

Heat-Line formalizes its next-generation leadership succession plan, with various new appointments: Matthew Roberts as president, Brent Heise as vice president of sales and technology, and Laura Roberts as vice president of quality management. Co-founders Lorne Heise and Robin Heise will continue in strategic roles as vice president of product development and innovation and vice president of finance, respectively. These appointments mark the transition to the next generation of the founding family, as Brent and Laura are the co-founders’ children, and Matthew is their son-in-law.

John Burch is the new president of Dart Controls. Bringing executive leadership experience in industrial manufacturing and business growth, Burch will lead Dart Control’s strategic direction and facilitate initiatives that improve product offerings, operational efficiency, and customer value.

Armstrong Fluid Technology names Chintan Kharche as its new global director of offering management. In this role, Kharache will help shape the future of five product lines and lead innovation across the entire product lifecycle, driving market research, competitive analysis, and product planning and launches.

Brad Monaghan joins Stone Mountain Technologies (SMTI) as its North American sales director. In this newly created role, Monaghan will manage SMTI’s network of manufacturers’ representatives. Monaghan has been with SMTI since 2022 and has over 25 years of HVAC and water heating experience.

Nidec announces two organizational structure changes. Tim Schamel has been promoted to president of Nidec commercial and industrial. Schamel first joined the company in 2016 and served as president of Nidec/ U.S. Motors and as president and general manager of HVAC/R and appliance motors. In addition, Tim Albers has been named chief technology officer at Nidec commercial and industrial. With over 15 years of engineering and industry experience, Albers previously served as senior director of product management.

Greg Tatro joins Mojave Energy Systems as the new vice president of sales. Tatro has more than 25 years of experience in sales-growth roles in the HVAC industry. In his new role, Tatro will lead Mojave’s global sales initiatives, driving revenue growth, strengthening customer relationships, and expanding the company’s market presence.

Wolseley Canada adds Tasha Medeiros to its team as strategic account manager. Medeiros brings 15 years of sales experience, previously working at A.O. Smith Enterprises in various sales roles.

Chris Rock Brad Monaghan

Brent Heise

John Burch

Greg Tatro

Tasha Medeiros

Matthew Roberts Laura Roberts

Tim Schamel Tim Albers

n People & Places Companies

The

Triangle Tube announces it has completely halted operations in North America as of Nov. 3. This information comes after a product recall in February regarding the company’s Prestige Solo and Prestige Excellence. According to the recall, the boilers can release carbon monoxide due to delayed ignition or component damage, posing a risk of serious injury or death. Improper combustion settings can increase this hazard. Triangle Tube received two reports of death, one in 2015 and one in 2016, following a repair due to carbon monoxide poisoning, and 25 reports of carbon monoxide leaks associated with the recalled boilers.

Fujitsu General enters 2026 with a new name. Effective Jan. 1, the company’s trade name will be referred to as General Inc. This name change applies to all domestic and overseas consolidated subsidiaries of General Inc.

NTI Boilers is undergoing a rebrand and will now be legally known as Ariston Canada. The Ariston Group announces that this change is strictly a legal matter, and the NTI brand will remain unchanged.

Milwaukee Tool has opened a new service hub in Georgina, Ont. The new 54,000 sq. ft. facility will allow Milwaukee Tool to centralize service operations, improve turnaround times, and strengthen nationwide customer support. The facility is expected to be fully operational by the fourth quarter of 2026.

Kerr Controls and LG are starting the new year off with a new relationship. Effective Jan. 1, Kerr Controls is an authorized LG distributor in Atlantic Canada.

Taco Inc. Canada announces JF Taylor Enterprises as its new authorized manufacturer’s representative in Atlantic Canada. Effective Jan. 1, JF Taylor Enterprises will represent Taco’s wholesale (residential) and commercial product lines throughout the region.

Calefactio announces that starting in 2026, Air Solutions will expand its coverage of Calefactio’s product line. Previously, Air Solutions was responsible for the East Toronto market. Now, it will expand its coverage across the entire Greater Toronto Area (GTA).

Carrier announces an agreement to sell its Riello business to Ariston Group. Founded in 1922 and based in Italy, Riello is a manufacturer of heating and cooling systems and technologies, including boilers and burners, for residential and commercial applications. In 2020, Riello was acquired by Carrier Global’s then-parent company, United Technologies Corp.

Classic Fire + Life Safety opens its first branch in Atlantic Canada. Located in Amherst, Nova Scotia, the new branch will open in February and will serve as an operational hub for the Atlantic region.

Mits Airconditioning Inc. is entering into a strategic distribution with Exinda for its eco-energy solutions products. Headquartered in Boston, Massachusetts, Exinda is a manufacturer of heat pumps and ventilation systems. They specialize in air-to-water heat pumps, pool heat pumps, and ERVs.

After nearly a century, the Canadian Institute of Plumbing and Heating (CIPH) is undergoing a rebrand, including an updated logo, website, and brand messaging. With this rebrand, the association is reiterating its message of collaboration and advancing the plumbing and heating sector.

HVAC/R PRODUCT TESTING & CERTIFICATION

Ensure your HVAC/R appliances, equipment, and components are certified to meet the latest regulatory requirements utilizing low global warming refrigerants. Intertek’s experts are here to help you through the process and outline certification requirements for flammable refrigerants.

+1 800 WORLDLAB (967 5352) icenter@intertek.com Intertek.com/HVACR FOR MORE INFORMATION

Canada’s biggest mechanical trade show returns

This March will see the return of Canada’s largest mechanical trade show to Toronto. Held at the Metro Toronto Convention from March 25 to 27, the Canadian Mechanical and Plumbing Exposition, or commonly known as CMPX, brings together the entire HVAC industry for three days of networking, discussion, and innovation.

Running biannually since 1972, CMPX is jointly produced by the Heating, Refrigeration, and Air Conditioning Institute of Canada (HRAI) and the Canadian Institute of Plumbing and Heating (CIPH). The 2024 CMPX Show had a record-breaking 13,400 guests,.a54percentincreaseoverthe 2022 show, which was during the COVID-19 pandemic.

Down to business

Attendees of the show will have access to over 500brands,allshowcasingthelatestequipment, products, technologies, and services across each HVAC category These categories include: heating, cooling, refrigeration, ventilation, plumbing, piping, pumps, indoor air quality, water quality, building automation, controls, sustainability/energy efficiency, software, tools and instruments, smart technology, and more.

KeepaneyeoutfortheNewProductShowcase display,whichwilltakeplaceineachparticipating exhibitor’s booth. Thefulllistofnewproducts canbefoundontheCMPXShow’swebsite.

In addition to the products on display, the CMPX Show will offer educational sessions for attendees via its Learning Forum. The Learning Forum will feature a lineup of free educational programs on the latest trends, applications, and regulations in the industry. These sessions will include strategic panels, tech talks, hands-on workshops, business sessions and Mitsubishi Electric education.

There will also be continuing education credits (CECs) available to attendees, covering HVAC/R, plumbing, building codes, energy efficiency, and industry best practices. Attendees can earn 1 CEC for 1 hour of instructional time or a half CEC for 30 minutes of instructional time. To earn CECs, attendees must be present for at least 80 per cent of each session.

The Learning Forum will also feature the Social Hub and Podcast Theatre. This is a chance for attendees to sit, grab a drink, and listen to a live podcast from some of the best in the industry. The full agenda for the free sessions, CECs, and podcasts is yet to be announced.

As always, the show will host its HVAC/R Skills Competition, featuring the next generation of contractors and technicians showcasing their talents. The competition runs the entire show and will see participants battle to be named champion in their respective categories. Competition details and schedule information are yet to be announced.

Suited and booted

Forguestswhoareinthecityearly,CIPH’s“Gala inSupportofHabitatforHumanity”willtake placeonMarch24attheMetroToronto ConventionCentre.CIPH and Habitat for Humanity have been in partnership since 1994. Through its participation, CIPH has raised over $17 million in product and cashandhas sponsored15homebuilds.

The theme for this year’s gala is “Proudly Canadian,” and it will celebrate the spirit, creativity, and generosity that define Canada. This gala will feature a bar reception, a three-course dinner, and a silent auction in support of Habitat for Humanity Canada. Peter Katz, a Canadian Juno-nominated singersongwriter,willhosttheevening.

March 24:

CIPH Habitat for Humanity Gala: Metro Toronto Convention Centre, Toronto, Ont. For more information, please visit www.ciph.com.

March 24 – 25:

CWQA Conference & AGM: The Rec Room, & Room 714A – South Building, Metro Toronto Convention Centre, Toronto Ont. For more information, please visit www.cwqa.ca.

March 25 – 27:

CMPX 2026:

Metro Toronto Convention Centre, South Building, Toronto, Ont. For more information, please visit www. cmpxshow.com.

March 25 – 27:

Emerging Leaders Conference: Novotel Toronto Centre, 45 The Esplanade, Toronto, Ont. For more information, please visit www.mcac.ca.

Temper Water. Not Expectations. Temper Water. Not Expectations.

Unmatched Versatility. Effortless Efficiency. Experience the Next Generation of Digital Mixing. CONSISTENT TEMPS IN