In this issue

7 Building Industry – ExxonMobil, with its Vistamaxx performance polymers, collaborated with recycling machinery provider Erema, foaming supplier Moxietec and machine maker Engel to produce lightweight locking blocks for the construction sector

8 Packaging – ExxonMobil collaborated with machine maker Hosokawa Alpine on a recyclable, mono-material HFFS pouch for cheese packaging; and with Windmöller & Hölscher (W&H) for a 40% thinner non-laminated MDO PE freezer pouch

10 Chemicals Sector – The speciality chemicals industry is bracing itself to gallop ahead into 2026, with joint ventures and expansion plans in Asia, says Angelica Buan in this article

12 Recycling – Germany’s Fraunhofer institute is undertaking a research project involving the recycling of PP/PET waste into geotextiles fibres

publisher/editor-in-chief

Arthur Schavemaker

Tel: +31 547 275005

Email: arthur@kenter.nl

Associate publisher/executive editor

Tej Fernandez

Tel: +6017 884 9102

Email: tej@plasticsandrubberasia.com

european correspondent

Jeanet Draaijer

E-mail: jeanet@kenter.nl

Asian correspondent

Angelica Buan

Email: gel@plasticsandrubberasia.com

circulation

Stephanie Yuen

Email: stephanie@taramedia.com.my

layout/design

Prestige Trading

Email: prestige9a@gmail.com permits

ISSN 1360-1245

Medical Sector: Materials suppliers are offering sustainable propositions to support the needs of the medical industry; while TPE and LDPE solutions afford possibilities and a new mould concept accelerates the production of medical devices

Medical: researchers in canada have discovered the ability of liquid crystal elastomers to form flexible artificial muscles

Tyres: Innovative rubber tyres are entering the era of space missions as a catalyst to advancing science and mobility technology on Earth and beyond

is published 4 (four) times a year in English by Kenter & co Publishers’ representatives BV.

Whilst every effort is made to ensure that the information contained in this publication is correct, the publisher makes no warranty, expressed or implied, as to the nature or accuracy of such material to the extent permitted by applicable law.

© 2025 Kenter & co Publishers’ representatives BV No part of this publication may be reproduced, stored or used in any form, or by any means, without specific prior permission from the publisher.

PrA is a digital publication that is circulated free to trade readers in the plastics and rubber industry. Please view this link to subscribe/renew your free subscription: http://plasticsandrubberasia.com/register.html

www.plasticsandrubberasia.com www.rubberjournalasia.com www.injectionmouldingasia.com www.eog-asia.com

COP30: funding approved; future without fossil fuels remains unseen

At the global level, a long history of fossil fuel use is believed to have caused a build-up of heattrapping gases, driving up the planet’s average temperature. According to the World Meteorological Organisation ( WMO ), each degree of warming above the 1.5°C limit is expected to increase extreme daily rainfall by 7%.

Echoing the same sentiment, the United Nations Environment Programme ( UNEP ) Emissions Gap Report warns that even if countries meet their climate pledges, global temperatures could still rise 2.3°C to 2.5°C by the end of the century. This is slightly better than last year’s forecast but still enough to trigger more droughts, typhoons and other extreme weather.

As the world reviews progress under the Paris Agreement, a legally binding international treaty on climate change enforced in 2016, questions remain about whether global efforts are enough.

Serving as a critical global forum for countries to review the Paris Agreement and accelerate climate commitments, the 30th session of the United Nations Climate Change Conference ( UNFCCC ) Conference of the Parties ( COP30 ) took place recently in Belém, Brazil.

The conference initiated momentous objectives,

including implementing the outcomes of the COP28 Global Stocktake, which had shown that the world is off track to meet the 1.5°C warming limit. COP30 also strengthened the UNFCCC Action Agenda, mobilising voluntary climate action from civil society, businesses, and investors through a new five-year plan aligned with Paris goals.

Climate finance was another priority, focusing on scaling up support for developing countries from the initial US$300 billion toward the US$1.3 trillion annual target by 2035, guided by the Baku to Belém Roadmap. Nations presented updated Nationally Determined Contributions (NDCs) to assess gaps between current plans and Paris Agreement targets.

Other highlights at the COP30 included forest protection, particularly in the Amazon, supported by Brazil’s US$125 billion Tropical Forest Forever Facility. In addition, the conference addressed gender equality and human rights, strengthening the Gender Action Plan and launching the first official Justice and Human Rights Days. Finally, COP30 tackled super pollutants through the Super Pollutant Country Action Accelerator, providing initial funding to seven countries to reduce emissions of these highly warming pollutant.

No consensus secured for fossil fuels; funding approved

After days of grueling discussions and intense negotiations, COP30 concluded with a commitment to mobilise at least US$1.3 trillion per year by 2035 for climate action, alongside a plan to triple funding for adaptation.

The conference also introduced two major initiatives: the Global Implementation Accelerator and the Belém Mission to 1.5°C, designed to help countries deliver on their national climate plans. For the first time, COP30 recognised the importance of combating climate disinformation, pledging to promote accurate and reliable information.

The recent UNFCCC COP30 served as a key global forum where member states reviewed the Paris Agreement and worked to advance climate commitments (Photo by Raimundo Pacco/COP30).

However, the forum stopped short of directly addressing the energy transition, leaving many nations and civil society groups disappointed. Expectations had been high for a formal plan to phase out fossil fuels, with over 80 countries supporting Brazil’s proposal.

While a draft text had included it, the final outcome instead referenced only the “UAE Consensus” from COP28, which called for “transitioning away from fossil fuels.”

Experts warned that fossil fuel use must drop to zero by 2040 to 2045 to avoid global temperatures rising by up to 2.5°C – a scenario that could destroy coral reefs, collapse the Amazon rainforest, and speed-up the melting of Greenland’s ice sheet.

To address these challenges, COP30 established two roadmaps: one to halt and reverse deforestation, and another to guide a just, orderly, and equitable transition

away from fossil fuels, providing the necessary resources in a planned and fair manner.

Meanwhile, environmental organisation Greenpeace warned that so-called “false solutions,” such as carbon offsets, carbon capture and storage (CCS), and similar solutions are little more than a ploy that enables polluters to put off actual reductions and sidestep transformative climate action. These measures cannot replace urgent emission cuts, yet they appear to be the dominant approach at the forum.

Greenpeace asserted that to stay within 1.5°C, the world must drastically cut fossil fuel use, end deforestation, safeguard ecosystems, and uphold the rights and solutions of Indigenous and local communities.

In short, major polluters have long profited from environmental harm, and it is time for them to take responsibility and pay their fair share, it said.

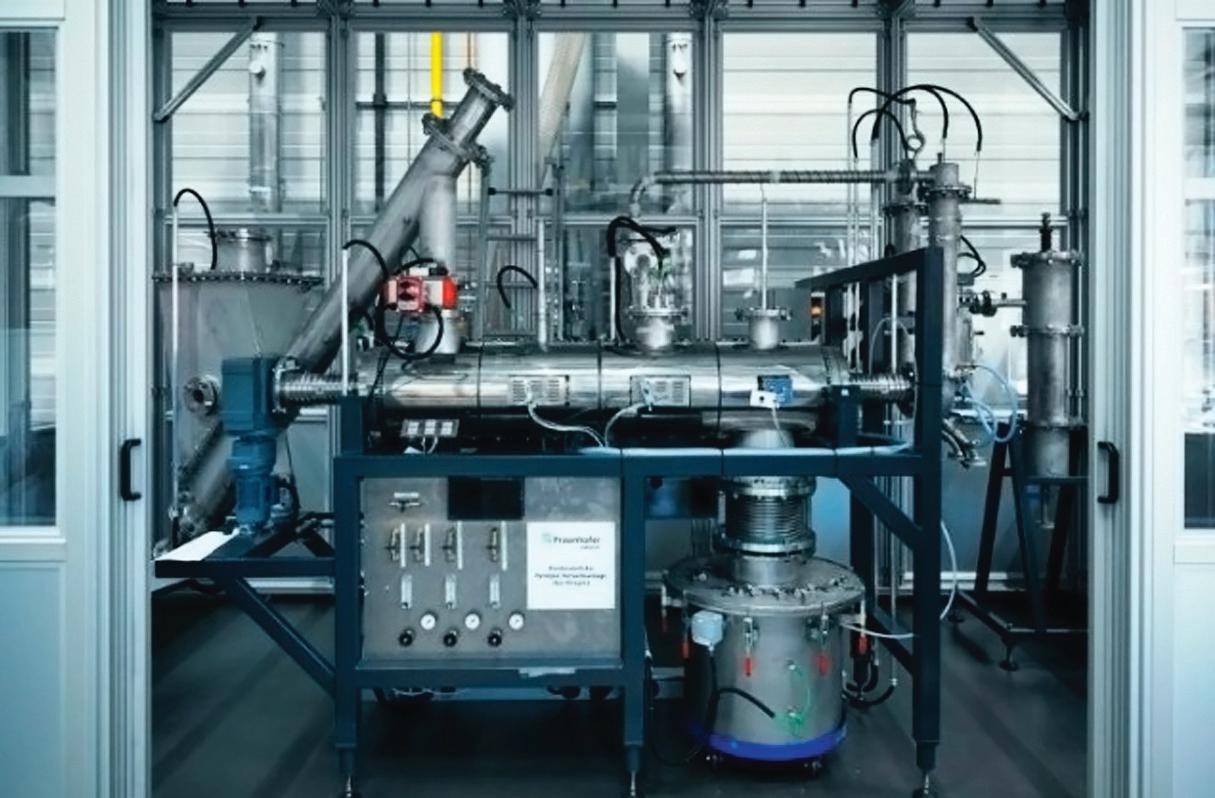

Research project to address PET-based textile waste in Europe

AEuropean research initiative coordinated by Fraunhofer UMSICHT and funded by the EU has been launched to develop integrated solutions for textile waste recycling. Known as Autoloop, it aims to create a system that could process 1.24 million tonnes/ year of textile waste by 2050, whilst potentially creating over 130,000 green jobs across the EU, as well as reducing municipal waste management costs (currently EUR60-110 per tonne) and decreasing the textile industry's reliance on virgin materials.

This project aims to develop, test and integrate automated sorting, tracing, and closed-loop recycling technologies for polyester-based textiles (NRT), addressing the pressing challenge of textile waste management.

Europe's textile and clothing industry employs 1.3 million people and generates around EUR170 billion a year. However, it produces 10.9 million tonnes of postconsumer textile waste each year, with less than 1% currently recycled through closed-loop processes back into new textiles.

The project comprises several key technological innovations for the complete recycling of PET-based textiles, which are being further developed and validated by the project partners:

• AI-Powered Sorting: Zoritex's artificial intelligence system identifies over 15 different fibre types and their blends using hyperspectral near-infrared technology. This automated approach could increase sorting throughput tenfold whilst reducing costs by 50-75%.

• Chemical-Free Recycling: Aalto's Ioncell process uses innovative ionic liquid solvents to extract cellulose fibres from textile blends, achieving over 95% recycling rates without harmful chemicals.

The Autoloop project for PET-based textiles will feature next generation sorting, tracing and closed loop recycling

• Advanced Synthetic Recovery: The ReSyn technology developed by Fraunhofer UMSICHT and SKZ breaks down synthetic fibres into high-purity building blocks for creating new materials, working efficiently even with contaminated textiles.

• Smart Fibre Tracking: TLX's IntegriTEX technology embeds invisible identifiers in fibres, enabling contactless detection and complete supply chain transparency.

• Digital Integration: Texroad's cloud-based Data Hub standardises information management across the entire recycling process, ensuring compliance with emerging regulations like the Digital Product Passport.

The project brings together 14 partners from seven countries, combining research institutions with industrial partners. Key organisations include Zoritex ( UK ), Aalto University ( Finland ), Fraunhofer UMSICHT ( Germany ), TLX ( Germany ), and Texroad ( Netherlands ). Additional partners include ELT ( UK ), Trasborg ( Denmark ), VTT ( Finland ), SKZ ( Germany ), S4L ( UK ), LEEDS ( UK ), Norion ( Denmark ), Temasol ( Switzerland ), and LGI ( France ).

As European regulations on waste management continue to develop and demand for sustainable textiles

Pyrolysis research reactor for chemical recycling of plastic containing textiles at Fraunhofer grows, Autoloop provides a research foundation for advancing circular economy principles within the textile industry.

ARDL is now fully equipped and validated to perform testing to the BS EN 455-5 Extractable Chemical Residues Standard – For Single Use Medical Gloves.

manufacturing by addressing chemical residues that can migrate into the skin. For healthcare, dental, and laboratory professionals, these residues can lead

GLOVE & PPE TESTING / COMPLIANCE / FDA DETENTION TESTING

n Surgical Gloves, Exam Gloves, Isolation Gowns, Condoms & Medical Devices

n ASTM D6978

n ASTM F739

n ASTM F1670

n

n ASTM F1671

n ASTM F3267

n ASTM D5712

n ASTM D6499

n ANSI/AAMI PB70

n ISO 16604

n ISO 10993-5

n EN 16523

n ISO 21420

n NEWLY ACCREDITED! BS EN 455-5 (Single Use Medical Gloves)

Scan the code to learn more or visit

A panoptic plastic waste solution under pressure

Finding a win-win solution to end plastic pollution, one that satisfies every sector, remains elusive. Yet, environmental advocates like UK-based NGO WRAP (Waste & Resources Action Programme) continue to push forward, undeterred by the setbacks, says Angelica Buan in this article.

A treaty in jeopardy

A crumpled plastic wrapper here and a discarded PET bottle there: all these are a slow-burn build-up of plastic waste that has turned into a pollution problem too gargantuan to rein in; unleashing its toll on the world’s ecosystem and slowly choking it.

Plastic pollution is a global problem, according to the United Nations Environment Programme ( UNEP ), which says up to 23 million tonnes of plastic waste enters aquatic ecosystems, polluting lakes, rivers, and seas.

The damage is heavy and far reaching, according to the Global Plastic Action Partnership , which says of the 460 million tonnes/year of plastic produced, only 9% is recycled. Furthermore, without intervention, plastic waste is expected to triple by 2060 and incur an estimated cumulative damage cost of US$281 trillion between 2016 and 2040.

On this ground, the United Nations Environment Assembly ( UNEA ) convened in 2022 (its fifth session) and adopted a resolution that mandated it to form the Intergovernmental Negotiating Committee (INC) to establish an international legally binding instrument on

plastic pollution, including in the marine environment (ILBI).

The Global Plastics Treaty attempts to cover, as comprehensively as possible, a full life-cycle approach, from design and production to disposal and waste management. The treaty, initially slated to be finalised by the end of 2024, missed that deadline.

At INC-5.1, delegates were unable to reach agreement on a new treaty. When the high-stake talks continued for INC-5.2, the process took a downturn, with key disputes still unresolved.

While INC-5.3 is planned, it is expected to focus only on organisational and administrative matters. In the meantime, the resumption of talks on the global treaty is uncertain or may never happen.

Treaty stalemate: are industries turning a blind eye?

The issue of stemming plastic pollution is indeed polarising. It is no surprise that when issues like this are tackled, opposing voices will emerge, and at INC-5.2, they eventually drown out those who proposed a more systemic approach to addressing plastic waste.

At INC-5.1, delegates were unable to reach agreement on a new global treaty that would address plastic pollution. (Photo from IISD/ENB - Kiara Worth)

Oil-exporting countries such as the US, Saudi Arabia, Russia, India, and their industry allies pushed for voluntary measures and a focus on plastic use and waste management rather than production caps or restrictions that could affect their fossil fuel sectors

The so-called “petrostates”: oil-rich and oilexporting countries such as the US, Saudi Arabia, Russia, India, and others, along with allied industry lobbyists allegedly undermined the negotiations, countering for voluntary measures rather than a binding obligation, and prefer focusing on plastic use and waste management instead of capping production or imposing bans or restrictions on hazardous chemicals, among other proposals that would affect their fossil fuel industries.

Among the delegations that expressed disappointment, Graham Forbes who was the Greenpeace head of delegation to the Global Plastics Treaty negotiations and global plastics campaign lead for Greenpeace USA, said, the plastics crisis is accelerating and that the petrochemical industry seems intent on prioritising short-term profits at great cost to the planet.

He stressed that civil society has been calling for a strong, legally binding treaty that reduces plastic production, safeguards human health, secures fair and reliable financing, and stops plastic pollution from extraction to disposal, and he urged world leaders to pay attention, likewise reminding them that the future of both human health and the planet rest on these decisions.

The World Wildlife Fund’s (WWF) global plastics policy lead, Zaynab Sadan, said the choices being made will affect generations ahead, and that the world will eventually look back on this period and remember how these choices were made, urging the need for courage rather than compromise.

WRAP: not letting up on plastics action

Meanwhile, Catherine David, CEO of the Waste and Resources Action Programme ( WRAP ), said the outcome of INC-5.2 was “a missed opportunity,” as well as a setback for those working to reduce plastic pollution. She added that without binding global rules, the world would continue to fall short of the pace and scale of action required.

WRAP, a UK-based environmental NGO, attended the Geneva meeting and co-hosted a side event with the Ellen MacArthur Foundation .

In an interview with PRA ( www. plasticsandrubberasia.com ), WRAP’s David shared that the outcome of the recent INC-5.2 meeting left many observers disappointed, as what was expected to be the final round of negotiations on a treaty ended without an agreement.

Nevertheless, she explained that this setback does not halt the work of the Plastics Pact Network (PPN). The network, which was established before the treaty process began, continues to operate independently of the negotiations.

“PPN was set up before the Plastics Treaty process began and is delivering impact independently of the Global Treaty and its progress is not directly linked with the progress of the treaty. The PPN is comprised of 13 pacts all focused on advancing to a circular economy of plastics and reflecting the priorities and challenges in each market that they operate in. This will continue,” David explained.

Voluntary initiatives to lead the way

According to WRAP, the absence of a treaty shows the continued value of voluntary initiatives that are already producing results, but noted it still supports a global agreement to create consistent expectations across markets and encourage broader investment in circular systems.

“The lack of a global treaty shows that voluntary initiatives that are delivering positive impact NOW, have a crucial role to play in demonstrating to negotiators what can be achieved by leading countries and businesses. Why WRAP and the PPN is keen to see a global treaty is so that it will ‘level the playing field’ and mean many more countries and businesses will need to adopt more circular plastics policies and business practices – helping unlock much needed investment,” the organisation said.

Pertaining to the discussion deadlock in Geneva, WRAP reiterated its support for a treaty that covers the full life cycle of plastics - from production to design, consumption, and end-of-life.

“We do call for an ambitious treaty that covers the full life cycle of plastics as we believe a waste management only focus would not incentivise the reduction in growth of plastics and lead to a growing environmental issue,” according to David.

Funding an important element of treaty

WRAP also says that as regards funding the implementation of the global treaty, this is one element of the negotiations that will need to be resumed when it reconvenes.

The funding types and sources will vary depending on the need, e.g., funding for innovation and exploring new materials and solutions is likely to be a different funding source than funding for infrastructure to sort and recycle more plastics.

It also adds that many countries are introducing/have introduced EPR policies to help fund increased recycling and collection and this is an important component of any future funding requirements.

Meanwhile, within this broader context, WRAP elaborated on how plastics pacts work at the national level.

“In short, a plastic pact is a voluntary agreement, open to any major business who uses, creates, collects, recyclers plastics to work with the value chain to overcome the challenges to transition from a linear to circular plastics economy. “

WRAP further explained that this collaboration often involves agreeing on design guidelines that ensure packaging is recyclable and retains value in the recycling system.

“For example, this may be to define, agree and then implement good design guidance that means businesses design and specify plastic packaging that can be recycled and has a value to the recycling sector. So, in the UK, this has led to a near elimination of PVC rigid packaging and non-NIR detectable black plastic packaging. Other markets may have different priorities depending on their situation and infrastructure,” said WRAP’s David.

Circular economy and a legislation to boost all initiatives

On the matter of recycling technologies, WRAP stated that there is no single prescribed approach, but pacts follow established principles for a circular plastics economy, saying that both mechanical and non-mechanical recycling are included within pact targets so long as the output can be used again in plastics packaging, for example pyrolysis to a fuel oil.

WRAP calls for a treaty that covers the full life cycle of plastics, as it believes a wastemanagement-only focus would not incentivise the reduction in the growth of plastics and would lead to a growing environmental issue.

(Photo from WRAP)

Meanwhile, progress across all pacts is tracked through annual data reporting from member companies that place packaging on the market.

“These annual reports are published and help each pact secretariat, and the members focus resources and efforts on the key challenges. Data gathering is historical, and change takes time, so while progress may be slow in the first few years, experience tells us that pace gathers as businesses embed the targets and policies develop. The IPP annual reports are online, and the 2024/5 report will be published in the coming few months,” David shared.

That said, WRAP pointed out the significance of plastics pacts in addressing plastic pollution.

“It works at a systemic level to reduce the waste arising, ensure that the plastic that is produced is recyclable or reusable and help create a demand for recycled plastics to keep it out of the environment,” said the association.

So, the pacts are contributing to the solution, however, they are only ever part of the solution as they do not cover the majority of plastic placed on the market. This is why a robust and well-enforced legislation is required to complement the many positive initiatives that exist, WRAP concluded.

Plastics pacts work at a systemic level to reduce plastic waste, ensuring that is recyclable or reusable and help create a demand for recycled plastics to keep it out of the environment, according to WRAP

Creating sustainable building materials

With the increasing demand for alternative materials, the plastics industry is experiencing interest in the incorporation of recycled content into products. However, incorporating recycled content into foamed products, particularly in the building and construction sector, can compromise product consistency, mechanical strength, and overall performance.

Without effective solutions to process and reuse these mixed plastic streams, designing for recyclability remains a formidable challenge, adds materials supplier ExxonMobil

To address the challenge, a collaborative effort across the value chain was initiated, involving key industry players including recycling machinery provider Erema, foaming supplier Moxietec LLC, injection moulding machine maker Engel, and ExxonMobil with Vistamaxx performance polymers playing an important role.

Recycling systems provider Erema produced pellets using its filtration and degassing system. The process handled a mixed stream of recyclates comprising 95% PP rigid materials and 5% PE film supplied by Prezero

Foam technology provider Moxietec utilised its technology to produce lightweight locking blocks that can be used in the construction sector without reducing impact strength which other conventional foaming processes often compromise.

The addition of Vistamaxx performance polymers helped to improve the impact resistance and toughness of the foamed components, enabling the incorporation of recycled content without compromising structural integrity.

Meanwhile, machinery maker Engel integrated these elements by incorporating recycled materials and foaming technology into its injection moulding systems to produce thick-walled foamed blocks designed specifically for building and construction applications.

Promising end results

The dart drop impact testing shows that foam parts manufactured using Moxietec’s technology exhibited a 10% improvement in impact strength, measured by total energy at break, compared to conventional solid parts. This enhancement was particularly significant given that traditional foaming processes typically compromise impact performance relative to solid materials.

In addition to mechanical benefits, Moxietec’s technology enabled incorporation of rPP content with a final part weight approximately 30% lower than conventional solid parts. Further performance optimisation was achieved through the incorporation of Vistamaxx performance polymers without sacrificing the weight reduction.

• Vistamaxx 3020 boosted foam impact strength by approximately 10% over Erema foam alone

• Vistamaxx 6102 delivered an even greater enhancement of around 17%, making it the preferred choice for the final formulation

Despite these polymer enhancements, the foam maintained its fine, uniform cellular structure with no compromise in quality or performance, indicating successful integration of the additive materials into the manufacturing process.

These resulting blocks, designed for the building and construction industry, offer design flexibility for single walls, double walls, and corner structures.

According to the companies, the collaboration demonstrates the potential for cross-industry partnerships to solve complex sustainability challenges while maintaining performance standards.

By leveraging complementary expertise across the value chain, the partnership shows how innovative foamed solutions can meet demanding performance requirements while optimising material use.

Polymer additives were used to boost impact strength by 17% in lightweight building blocks designed for construction applications

Packaging

Reducing weight, keeping mechanical performance

Driven by economics and legislation, for example the European Packaging and Packaging Waste Regulation (PPWR) it is becoming desirable to decrease the weight of packaging and produce materials that are designed for recyclability, whilst keeping mechanical performance and optical properties at a high level.

Thus, ExxonMobil Signature Polymers has collaborated with industry experts in developing solutions to this end.

Reimagining cheese packaging with recyclable, mono-material HFFS pouch

Recently, ExxonMobil took the challenge to replace conventional multi-material cheese packaging, typically rigid trays with lid films, with a monomaterial PE pouch that is thinner, designed for recyclability, can provide the same shelf-life as existing cheese packaging and runs efficiently on horizontal form, fill & seal (HFFS) pouch-forming lines.

Machine maker Hosokawa Alpine ’s latest ninelayer barrier blown film line, equipped with inline machine direction orientation (MDO) technology utilizing the vacuum system for ensuring excellent film processability, offers enhanced flexibility for film extrusion. On this single line, ExxonMobil Signature Polymers resins were used to produce both the MDO PE barrier substrate and the PE sealant film.

Thanks to Alpine’s advanced die head geometry and MDO capabilities, an ultra-thin 2 micron

In the cheese packaging collaboration, the mono-material HFFS pouch has a 60% material reduction and is designed for recyclability

barrier layer was achieved using EVAL LT172B - a low ethylene EVOH grade suitable for orientation. This thin layer delivers strong barrier performance, supporting food shelf life.

The MDO PE barrier substrate film was reverse printed and laminated to the PE sealant film. The following high-performance resins were used:

The laminate film was converted into pouches on IMA Ilapak ’s HFFS machine, engineered to handle both conventional polyester substrates and monomaterial packaging solutions supporting nextgeneration packaging solutions.

The key resins used in the pouch were:

MDO PE substrate film:

- Exceed HD 6107 – optimised for MDO processing

- Exceed Stiff+ m 0238.RA and Exceed Flow+ m 0938.RA – enhanced stiffness and tailored mechanical properties

- Exceed Stiff+ m 0820.RL – improved process stability

Sealant film:

- Exxtra Seal POP 2008.RK – low seal initiation temperature and hermetic sealing

- Exceed Stiff+ m 0820.RL – balanced stiffness and toughness

- Exceed m 2018.RA – ideal for lamination

- ExxonMobil HD 6207FL – stiffness modification

- ExxonMobil LD 07523.AC – enhanced processing stability

The resulting mono-material HFFS cheese package provides the following benefits:

• Weight reduction: Over 60% weight savings compared to rigid thermoformed trays.

• Design for recyclability: Comprising > 90% PE, the package can meet design-for-recyclability criteria by keeping the EVOH barrier layer below the 5% threshold.

• Oxygen barrier: MDO technology enhances the efficiency of the ultra-thin EVAL EVOH layer (2 micron). Oxygen transmission rate (OTR): < 0.5 cc/m2 x day — suitable for a typical cheese package.

• Hermetic seal and processing: Reliable performance on a full-scale HFFS packaging line, achieving consistent hermetic sealing and smooth machine conversion.

• Optical properties: Low haze and good product visibility from all sides, enhancing shelf appeal for consumers. Total haze = 6.9% for the MDO PE substrate film.

Windmöller & Hölscher (W&H)/ExxonMobil create a 40% thinner non-laminated MDO PE freezer pouch

Meanwhile, a collaboration between ExxonMobil and German machine maker W&H was initiated to unlock the full potential of MDO PE, boosting stiffness and clarity, while ensuring the film stays tough and robust, even after MDO.

“In this collaboration, we set out to unlock the full potential of MDO PE boosting stiffness and clarity while ensuring the film stays tough and robust, even after machine-direction orientation,” said Corvin Hurtienne from W&H.

An improvement in robustness will supersede the need for lamination, which is an additional process step that can incur extra costs and lead to increased final packaging weights. Without further lamination, the MDO PE film must exhibit good sealing properties.

This collaboration was an opportunity to find solutions that go beyond traditional solutions for freezer film packaging applications.

Furthermore, the development of a fully monomaterial, well-sealable MDO PE freezer film offers a high-performance solution with superior film properties. This solution allows the production of thin films with superb optical properties, excellent mechanical performance even at demanding conditions such as freezer temperatures and good stiffness/toughness balance.

The significant boost in film performance enables downgauging and eliminates the need for lamination.

The mechanical performance was significantly enhanced, as demonstrated by exceptional pouch

robustness under extreme testing conditions. The film maintained structural integrity during bag drop tests conducted at -30°C from a height of 6 m, confirming its high rupture resistance.

To support high-quality converting, the film was processed on a W&H Novoflex II press, achieving top quality and high-speed printing with inline slitting to ensure clean edges and optimal web control for seamless downstream processing. This makes the solution ideal for demanding frozen food packaging applications.

ExxonMobil Signature Polymers resins in the design provide:

• Exceed Tough+ m 0516 and Exceed Tough+ m 0518 offer high dart drop impact and needle puncture resistance, as well as a significant boost in MDO PE film performance and robustness

• Exxtra Seal POP 2008 offers sealability of MDO PE

• Vistamaxx 6102 offers improved blocking of collapsed bubble structures

The benefits of the resulting packaging include:

• High dart drop impact resistance properties

• Very good needle puncture resistance

• High stiffness

• Excellent optical performance

• Drop resistance proven at low temperatures and extreme heights

• Opportunity for downgauging

• No lamination process involved

• Fully convertible (sealable and printable) MDO PE film

Thus, it can be seen that value partnerships are able to deliver enhanced mechanical properties and enable significant downgauging potential thereby improving operational efficiency across the value chain.

W&H collaborated with ExxonMobil to create a non-laminated MDO PE freezer pouch

Specialty chemicals: staying on course for growth

As the going gets tough in the global market, the chemical industry is bracing itself with a plan to gallop ahead into 2026, with joint ventures and expansion plans in Asia, says Angelica Buan in this article.

Galloping into the year of the horse with optimism No pun intended, but legend has it that 2026, the Year of the Fire Horse, is expected to bring a more stable economic climate and a general return of confidence after years of imbalances and volatile trends. One sector that could use a strong break from the flat and sluggish growth of recent years is the chemicals industry.

The global chemicals industry has been stuck in a prolonged down-cycle, weighed down further by geopolitical realignments and other headwinds that have slowed any momentum toward growth.

Consultant Deloitte’s 2026 industry outlook projects a grim year ahead as the sector deals with sluggish demand, excess capacity and rising uncertainty.

The Year of the Fire Horse in 2026 could be a make-or-break moment for the industry, which has been mired in a prolonged down-cycle, overcapacity, and market uncertainties

According to the report, weaker economic conditions, continued geopolitical and trade tensions in Europe and the Middle East and supply chain disruptions have dashed hopes for stronger growth in 2025. A regulatory environment that has become increasingly fragmented across regions has also set a bleak precedent for next year’s prospects.

Deloitte reported that net profit margins, which averaged 5.8% between 2000 and 2020, fell sharply in 2023 and stayed low through the first half of 2025. Companies responded with bolder moves such as cost cuts, restructurings, closures and divestments. This trend is expected to continue into 2026 as companies focus on earnings and adjust portfolios more strategically.

Positioning in an innovation-driven market

On the other hand, the specialty chemicals market remains robust. According to Precedence Research, the global specialty chemicals market is poised to grow from US$940.7 billion in 2025 to over US$1.3 trillion by 2034, at a CAGR of 3.94%. Asia-Pacific remains the largest market, driven by industrialisation and urbanisation in India and China.

Innovation is driving market resiliency, and companies are relying on new technologies and collaboration with start-ups for solutions that cut costs and improve production efficiency, rather than depending solely on in-house development.

As well, digital investment, and science-based policies are keeping speciality chemical manufacturers on an even keel, according to the 2026 contract manufacturing outlook by the Society of Chemical Manufacturers & Affiliates (SOCMA), the only US-based trade association for the speciality and fine chemicals industry.

The report, in which nearly 70% of survey responses came from small and mid-sized companies with annual revenues of US$100 million or less, found that companies are investing in automation, digital systems, and health, safety, and environmental improvements, with the majority of respondents boosting reliability and expanding digital infrastructure.

Charging forward: companies expanding to China

In the Asia-Pacific region, China and India dominate the market, with expected annual growth rates of 7.4% and 6.8%, respectively, from 2022 to 2030. By 2030, the two countries alone will account for two-thirds of the region’s total market value, according to a Krungsri Research report on speciality chemicals published in August 2024.

China is aiming for self-sufficiency in the chemicals sector by shifting from being import-dependent to becoming an exporter, and ultimately a leading global supplier. For specialty chemical majors that stand to benefit from China’s competitiveness goals, capacity expansions, consolidation and joint ventures are in the playbook to reorganise business lines, gain scale, and access new technologies and markets.

Nouryon has completed a capacity expansion for metal alkyls production, which will ultimately double its ability to produce triethylaluminum for the production of PE/PP for packaging, automotive components, and consumer goods

One such company taking on the China market is speciality chemicals firm Nouryon that has completed a capacity expansion for metal alkyls production, which will ultimately double its ability to produce triethylaluminum, a co-catalyst essential in manufacturing PE/PP for packaging, automotive components, and consumer goods.

In 2026, the company will open an organic peroxides innovation centre in Tianjin, China, to provide specialist polymer application capabilities.

Moreover, in 2027, Nouryon will also begin producing modified methylaluminoxane (MMAO) in China, a key component in catalysts for polyolefin elastomers used in solar panels, another rapidly growing segment in the country.

Nouryon’s Jiaxing site, which houses an R&D laboratory established in 2024, focuses on improving process efficiency and developing new production methods for metal alkyls, supporting polyolefin innovation and regulatory compliance in China.

Nouryon operates metal alkyl production sites in La Porte, Texas; Rotterdam, the Netherlands; and Jiaxing, China. Application centres are located in Deventer and Jiaxing, with transfilling and blending stations in China, Paulínia, Brazil, and Mahad, India.

Germany-based chemicals supplier BASF is responding to structural overcapacities in the global chemical fibre market by consolidating its Asian

polytetrahydrofuran (PolyTHF) operations into its Caojing site in China and discontinuing production at its Ulsan site in South Korea. The closure is targeted for completion in 2026.

After the closure, BASF, which generated sales of EUR65.3 billion in 2024, will continue supplying customers with PolyTHF, leveraging its regional production bases in Caojing, Ludwigshafen (Germany), and Geismar (US). Together, these sites have a total capacity of 250,000 tonnes/year. PolyTHF is an essential starting material for elastic spandex and elastane fibers used in textiles such as swimsuits, sportswear, and underwear.

Along the same vein, Swiss chemical firm Clariant has forged a joint venture with China’s Shaanxi Fuhua Chemical for a new facility producing halogen-free flame retardants in Leshan, Sichuan Province, China.

The CHF100 million expanded capacity at Clariant's Daya Bay facility, along with the new Nylostab S-EED production line in Cangzhou, which opened in early November, is expected to further strengthen Clariant’s position in the country and serve industries such as building and construction, automotive, and electrical/ electronics.

The company adds it is directly responding to the tightening technical and regulatory environment in these sectors on traditional flame retardant technologies.

Gaining ground in Asia

To stay in the saddle in one of the world’s largest markets, Southeast Asia is a winning move. According to BIS Research , the region’s specialty chemicals market is growing rapidly, driven by rising demand across textiles, construction, automotive, and electronics. It was valued at nearly US$46.9 billion in 2024 and is projected to surpass US$84 billion by 2034, growing at a CAGR of 6.04%.

Chemi C als s e C tor

BASF is consolidating its Asian PolyTHF operations at its Caojing site in China and will halt production at its Ulsan site in South Korea by 2026

Clariant partnered with Fuhua Chemical for a new facility producing halogen-free flame retardants in China

sets out a framework for joint studies and initiatives to drive product innovation and reinforce value chains

Building on this momentum, Singaporean chemical supplier Aster and US speciality chemicals firm Lubrizol have tied up to explore collaboration opportunities. The partnership brings together Aster’s fully integrated refinery and petrochemical operations on Jurong Island with Lubrizol’s capabilities in lubricants. The MoU sets out a framework for joint studies and initiatives to drive product innovation and reinforce value chains.

Similarly, German chemical manufacturer Brenntag and US-based silicones materials company Momentive Performance Materials have signed an

reCyCling

agreement covering the Philippines market, building on their existing distribution partnerships in Indonesia and Vietnam.

Brenntag’s product portfolio features silicone and specialty solutions that enhance performance across a wide range of industries, including building and construction, as well as niche sectors such as speciality fluids, silanes, and additives.

With this extension, Brenntag’s Material Science CASE division will provide customers in the Philippines access to Momentive’s portfolio of advanced silicone and specialty solutions, including CoatOSil additives for coatings and Silquest silanes.

Santosh Satam, Director of Material Science, CASE Asia Pacific at Brenntag Specialties, said the collaboration can help customers in the Philippines improve their products and accelerate growth.

Moreover, RMS Sandhu, Regional Segment Leader, CAS & PE at Momentive (Thailand) added that the partnership enables the introduction of products designed to improve performance and durability in coatings, adhesives, and sealants applications.

Not surprisingly, in the wake of a continuously challenging market climate, more developments like these are unfolding across the industry and if companies play their cards right they will definitely be winning the race.

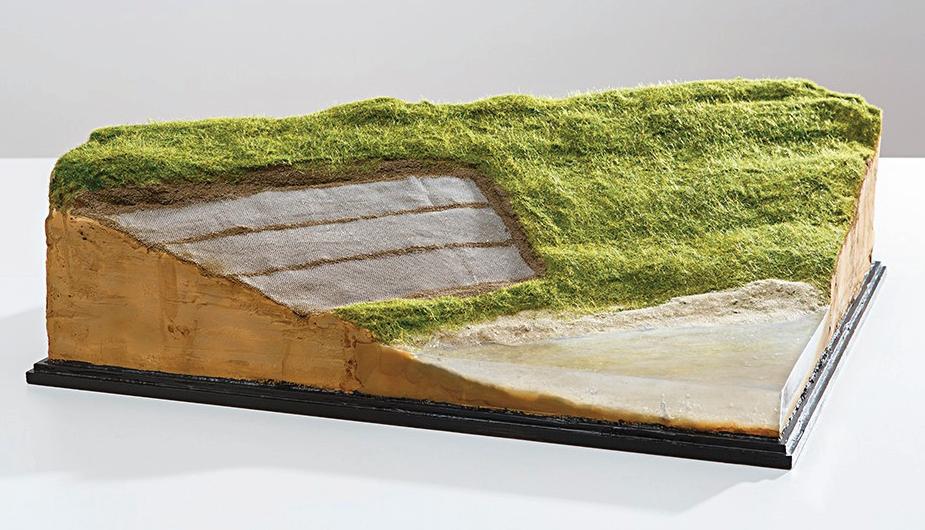

Fraunhofer repurposes waste into fibres for roofing

Among the dissenting voices on rising plastic waste, the United Nations Environment Programme (UNEP) has reported that more than 20 million tonnes leak into waterways and aquatic ecosystems every year. With plastic consumption continuing unabated and 430 million tonnes produced and used annually, the volume of plastic waste is projected to triple by 2060.

UNEP has cited proven solutions: reducing plastic use, using non-plastic alternatives, redesigning products for reuse, repair, and recycling; and improving waste management systems.

However, recycling has remained low globally, pegged at only 9%, with much of the waste and a significant volume still ending up in landfills or in nature.

Thus, as part of the Fraunhofer Cluster of Excellence Circular Plastics Economy (CCPE), the Fraunhofer institutes IAP, IML, UMSICHT, IVV, ICT, IME, and IOSB, under the project management of the LBF, are nearing

completion of a joint research project that has set two priorities:

1. Is it possible to recycle and add different waste streams to produce high-quality recyclates that can be used to produce fibres and films that can be further processed into competitive nonwovens and films for roofing membranes?

2. Can fibres be produced from bio-based polymers that can not only be spun into nonwoven fabrics, but whose degradation in the environment can be adjusted and at the same time pose no risk to the environment?

Making recycled plastics economically viable

In the case of mass-produced plastics such as PE and PET, the proportion of recycled plastics in products available on the market still has room for improvement compared to the quantities of new materials put into circulation.

Lubrizol and Aster's MoU

Chemi C als s e C tor

The proportion of bio-based polymers is even lower in comparison and limited to a few applications. Regulatory changes in particular, but also increasing customer demand, are driving a growing need for more sustainable solutions.

Plastic recyclates can become more widespread if compounders and end users have access to higherquality recyclates.

Despite the many fractions offered by the various collection systems, the possibilities for reuse are limited because contaminants and foreign materials make sorting, purification, and processing into recyclates difficult for recyclers.

As a result, recycled materials cannot compete with virgin materials due to quality or economic factors. Plastics developed from renewable raw materials are often not yet available in large quantities and are limited in their application due to their mechanical properties or their degradation properties in end-of-life scenarios.

Recycling process chain for PP/PET for nonwovens and geotextiles

In the Fraunhofer project, which is nearing completion, the entire process chain for PP and PET was developed, from sorting previously low-quality material streams through the recycling process (solvolysis (glycolysis) and solvent-based recycling), the application-optimised improvement of recyclate quality through the selection of customised additive packages by Fraunhofer LBF, and shaping.

As application scenarios, fibres for nonwoven production (PET and PP) and films (PP) for the manufacture of roof underlayments were specifically developed.

With regard to the use of biopolymers, the project focused on polylactide (PLA) and polybutylene succinate (PBS) for the production of biodegradable geotextiles, which are subject to a defined degradation period at the end of their defined service life.

The German institute is proposing new approaches to making geosynthetics and roofing membranes more sustainable through the use of plastic recyclates and biopolymers as raw materials for fibres

The development work for both the recycled plastics and the biopolymers was supported from the outset by life cycle analyses (LCA). In addition to controlled degradation in soil, tests were also carried out in aquatic environments to verify the ecotoxicological safety of the new developments.

Fraunhofer LBF contributed its expertise and many years of experience in aging and weathering tests and in the development of additive concepts to the project.

The subsequent applications will have to meet special requirements in terms of stability and, in the case of biopolymers, controlled degradation of the materials at the end of their service life, with the additives department ensuring that these requirements are met.

Fraunhofer says it was able to demonstrate that the degradation behaviour of bioplastics can be adjusted by adding a customised additive system. In addition, the additives were found to have no negative effects on ecotoxicological properties.

Furthermore, it was shown that high-quality processed waste streams can be made suitable for the intended applications through re-additivisation.

Fraunhofer says that after five years of successful collaboration, it is successfully transferring its experience with recyclates and biopolymers to market-relevant applications in construction and landscaping

Injection Moulding Asia

Healthy propositions for medical devices

With the increasing demand for sustainable, compliant, and future-proof materials, materials suppliers are offering propositions built to support the needs of the medical industry; while TPE and LDPE solutions afford possibilities and a new mould concept accelerates the production of medical devices.

Sustainability: bioplastic pipette for healthcare; recyclable medical packaging

Combining sustainability with pharmaceutical-grade quality and marketability, German manufacturer of dosing aids and primary pharmaceutical packaging elm-plastic has brought to market the first commercially available bioplastic pipette for use in pharmaceuticals and healthcare.

Partners in the development were materials manufacturer Biovox, using its MedEco bioplastic, and the German subsidiary of plastics distributor Ultrapolymers, which is a part of Ravago, provided initial consulting services for material selection and processing up to the start of series production.

MedEco polymers are either 100% based on polylactic acid (PLA) or 95% based on bio-based PE and are approved for use in the medical sector. Compared to existing pipettes made of PE/PP, this step enables a 113% reduction in the CO2 footprint (cradle to gate).

Biovox, which has been developing bioplastics since 2021, adds its MedEco bio-compounds are intended for use in medical and laboratory technology. They are available with a wide range of properties, are compliant with ISO 10993, and can be sterilised using EO/radiation and SCC.

Biovox also adds that MedEco PLA is particularly wellsuited to producing dimensionally stable injection-moulded

and plastics distributor Ultrapolymers

parts with a non-slip surface. Thanks to its high rigidity and strength, applications with low wall thickness can be realised, reducing material consumption. Additionally, its processability at low temperatures enables significant energy savings compared to fossil-based plastics.

In another take on sustainability, Portugal-based copolyester provider Selenis has introduced a recycle-ready medical-grade polyester film engineered for medical packaging.

Selenis’s resin reportedly delivers exceptional clarity and meets the performance requirements of medical device OEMs

Selcare CE 500, which joins the range of Selcare medical grade, is a low glycol modified polymer resin. The company also adds that by offering this at a price point between standard APET and PETG healthcare grades, its Selcare is a costcompetitive solution.

Further benefits of the resin are its clarity, a neutral colour, and a high-gloss finish, ensuring visual performance and product visibility. Furthermore, it comes with regulatory declarations, including ISO10993, and is free of intentionally added BPA, aligning with the industry’s safety expectations

The Selcare model also ensures security of supply through manufacturing at multiple sites and full technical support and advice across development and production stages, the company says. Customers can also expect dedicated assistance for MDR (Medical Device Regulation) compliance, along with complete formulation disclosure and notification of change protocols, giving them confidence and control.

Medical-grade TPEs make their mark

Mobility impairment can affect both social well-being and mental health. With the aid of assistive technologies like wheelchairs, individuals can regain movement autonomy, rebuild confidence, reconnect with their communities, and reclaim their quality of life.

Recent developments in materials science have led to the use of lightweight yet high-strength compounds in wheelchair design for improved operability.

German TPE manufacturer KRAIBURG TPE offers medical-grade Thermolast H TPE that features compression set characteristics to allow device elements to maintain their shape and resist pressure, even during prolonged use. The soft-touch, smooth surface of the TPE compounds ensures that wheelchair parts like handles and grips do not cause discomfort or injury, while allowing better control when operating the device, it adds.

Said to be the first bioplastic pipette for pharmaceutical and healthcare applications, the product was jointly developed by Elmplastic, materials manufacturer Biovox

CHINAPLAS 2026: Driven by technology, thriving future powered by green solutions

CHINAPLAS 2026 will take place at National Exhibition and Convention Centre (NECC) in Hongqiao, Shanghai, China, from 21-24 April 2026. As one of the global leading plastics and rubber exhibitions, this edition is expected to span over 390,000 sq m across 16 exhibition halls, and bring together more than 4,600 exhibitors from around the world to showcase breakthroughs in new materials, intelligent innovations and green transformations. The trade fair aims to strengthen the industries’ upgrade towards high-end, intelligent, and green development, as well as the transition from “Made in China” to “Innovated in China”.

Amidst the accelerated revolution in technology, energy and industries worldwide, the new quality productive forces, particularly in innovation and green low-carbon, have become crucial drivers of high-quality development. CHINAPLAS 2026 precisely captures these industry trends by gathering top global exhibitors to present cutting-edge products and solutions, thereby constructing an ecosystem of industrial innovation.

With rapid growth in downstream sectors including new energy vehicles, low-altitude economy, aerospace, rail transportation, humanoid robotics, wind power and photovoltaics, CHINAPLAS 2026 will focus on “driving application upgrades with material innovation” and feature the renewal of advanced frontier materials. Diversified modified plastics and special thermoplastic elastomers enhance the strength and electrical conductivity of plastics and rubber products, making them suitable for new energy vehicles’ batteries and aerospace seals; high-performance engineering plastics offer resistance to both high and lowtemperatures, as well as corrosion for high-end equipment; light and durable thermoplastic composites materials have become critical supporting materials for the low-altitude economy and humanoid robot industries.

Artificial intelligence and automation technologies are restructuring the manufacturing logic of the plastics and rubber industries, accelerating their transition into the “smart manufacturing era”.

At CHINAPLAS 2026, comprehensive intelligent manufacturing solutions reshaping the entire production chain will be showcased - from automated injection moulding, extrusion and blow moulding production lines, to industrial IoT-driven digital management systems, intelligent inspection and quality control platforms. These advancements enable enterprises to improve production efficiency and optimise labour costs, further driving the manufacturing industry’s leap from automation to intelligence.

In reaching the national carbon peaking and neutrality “Dual Carbon” goals in China, green and low-carbon solutions have become the crucial factors for high-quality

growth. They have also laid the pivotal path for sustainable development of plastics and rubber industries.

CHINAPLAS 2026 will introduce numerous innovative environmental and carbon reduction technologies and solutions, providing clear directions for enterprises to achieve green transformation. Efficacious boost with carbon reduction: additives produced with carbon capture technology can reduce carbon emissions during the plastic production process.

As for recycling: technologies in recycling oil and repurposing volatile organic compounds convert waste into valuable resources, fostering achievement of circular economy. Materials advancement will focus on enhancing the functionality of recycled plastics and bioplastics, the adoption of bio-based/ bio-degradable/ eco-compatible coupling and toughening agents into productions empower enterprises to expand their business into the green product markets, and achieve operational transformation to streamline their compliance with environmental standards.

As well, the organiser is actively engaging in international events to establish partnerships with overseas associations and buyers in the industry, strategically inviting top global buyers from sectors including automotive, electronics & electric, packaging, etc. By leveraging CPS+ eMarketplace, which is CHINAPLAS’s O2O strategy partner, the trade fair offers seamless “online and offline” journey - buyers can access exhibitor information and schedule on-site meetings year-round via the platform

Pre-registration for CHINAPLAS 2026 has begun! Click HERE to pre-register for an admission ticket at USD7.5. Visitors will receive an eConfirmation letter (Hong Kong/ Taiwan/Macau region of China and overseas visitors) upon completion of pre-registration.

For more information or enquiries, please visit www.ChinaplasOnline.com or contact Chinaplas.pr@adsale.com.hk

Injection Moulding Asia

KRAIBURG

TPE’s medicalgrade TPE offers softtouch comfort, strong adhesion and colour customisation

The TPE compound also features excellent adhesion to PP and PE, two of the most commonly used plastics in medical device housing and structural parts. This property enables efficient multi-component injection moulding, simplifying production of composite parts such as buttons, grips, and structural seals while maintaining strong mechanical bonding and design flexibility.

With easy colourability, the material is ideal for colour coding wheelchair functions such as brake and adjustment buttons and power switches. This wheelchair material application enhances accessibility and improves accuracy in identifying and using the correct controls.

Other benefits are that it allows for sterilisation via autoclave (121°C) and ethylene oxide (EtO) processes, an essential advantage for use in sterile environments such as hospitals and clinics. Moreover, these sterile material compounds are free from toxic substances, silicone, latex, PVC, phthalates, and animal-derived ingredients. They comply with medical standard ISO 10993-5 and food-contact regulations, including US FDA CFR 21, Regulation (EU) No. 10/2011, and China GB 4806.7-2023.

LDPE for healthcare applications made in UAE

To cater to the Middle East, Asia and African healthcare markets, and to strengthen UAE’s position as a hub for medical manufacturing, polymers maker Borouge has launched what it says is the first made-in-UAE low-density polyethylene (LDPE) for healthcare applications.

Manufactured at Borouge’s Ruwais facility, Bormed LE6607PH marks a significant milestone in strengthening regional medical supply chains and enabling localised production of critical sterile pharmaceutical packaging.

Borouge, which is owned by Austria’s Borealis and Abu Dhabi’s ADNOC, is leveraging Borealis’ established Bormed

By producing its LDPE for healthcare applications in UAE, Borouge says it is adding value to the supply chain

technology for the healthcare sector with its additive-free LDPE engineered for use in pharmaceutical and medical packaging, including blowfill-seal bottles, ampoules, and other pharmaceutical packaging.

The grade is optimised for purity, compliance, and stability, minimising the level of extractables, leachables in final products and ensuring compatibility with aseptic processing standards. It meets the stringent specifications of both the EU and US Pharmacopoeia.

The launch builds on the introduction of Bormed RG868MO, Borouge’s first UAE-made healthcare product, earlier this year, and now extends the company’s healthcare portfolio even further.

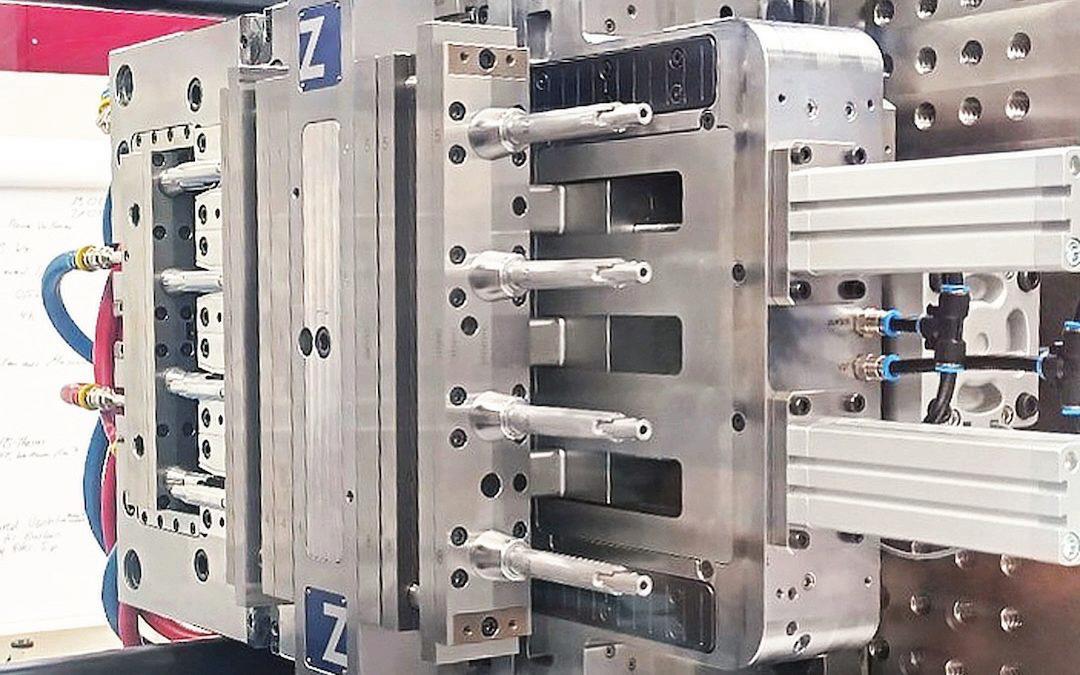

Mould concept for output of medical device housings German mould maker Zahoransky has introduced a mould concept that is said to significantly accelerate the large-scale production of housings for pen and autoinjectors, in an energy and space-efficient production.

Known as Z.Sonic turn it, the solution enables cycle times to be reduced by up to 30% and increase output by around a third, and reduces manufacturing costs per part by 20% for this application, according to Zahoransky.

It also says ROI calculations also show that the investment can be amortised after nine months, compared to conventional moulds.

The system was developed in response to growing demand for injectors, primarily because of the rapidly growing market for GLP-1 drugs to treat Type 2 diabetes and chronic weight management.

It was presented to the public for the first time at K2025 at injection moulding machinery maker Netstal’s booth as part of a production line with the Elion Med machine and hot halves with servo-electric needle valve control from Ewikon

A feature is the indexing technology that shifts part of the residual cooling away from the mould and makes part removal cycle-neutral. While the mould remains closed, an integrated rotary unit takes over the positioning for removal. At the same time, the next shot is already starting.

In the four-cavity mould for autoinjector housings shown at the trade fair, a cycle time of around twelve seconds was achieved. The compact design also reduces the mass of the mould by around 1,000 kg compared to conventional solutions.

This shortens heating times, reduces the energy required, and simplifies the design, as complex relative movements are no longer necessary.

Z.Sonic turn mould concept from Zahoransky accelerates the large-scale production of housings for insulin pens and autoinjectors

Injection Moulding Asia

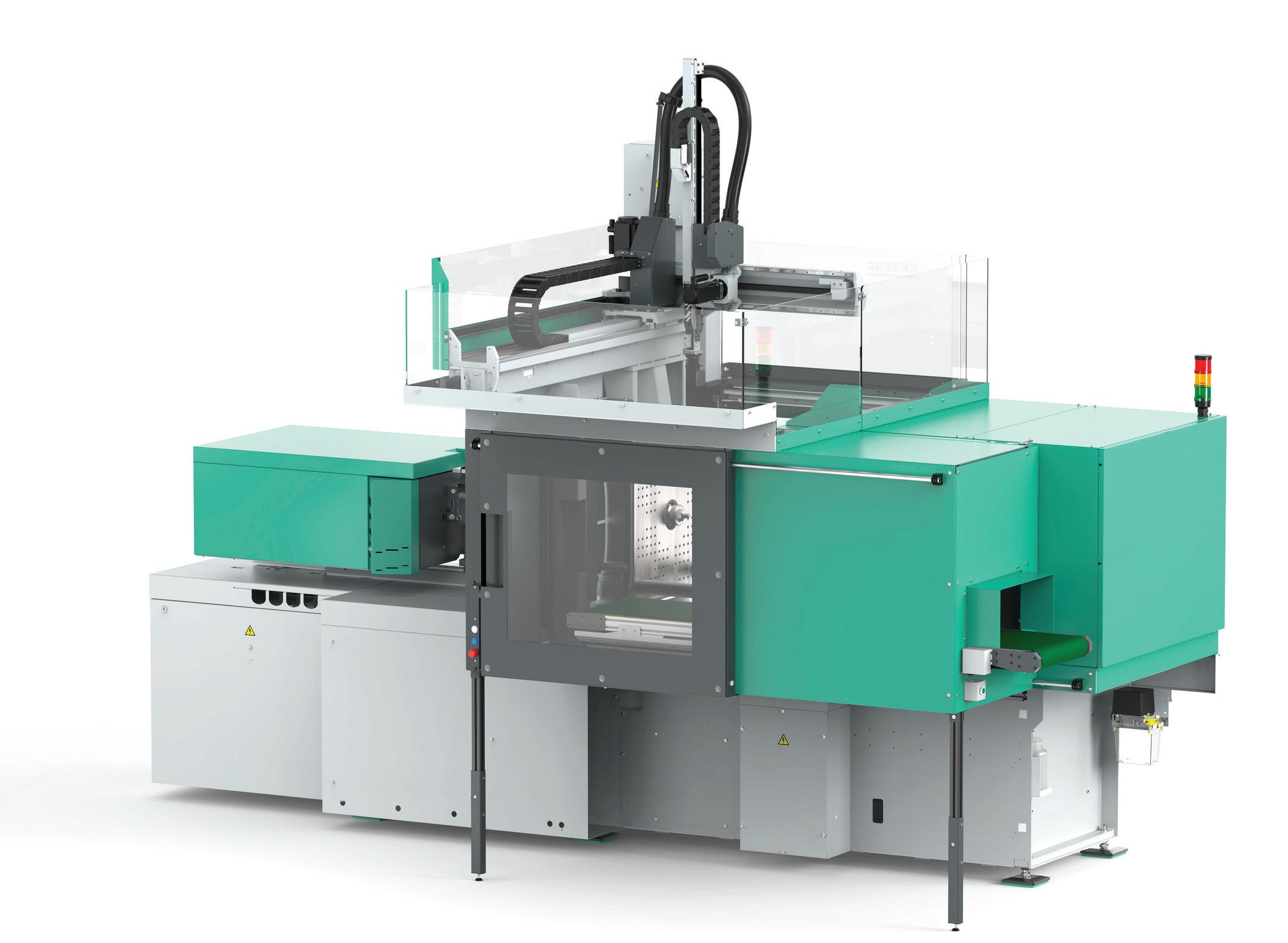

Setting the Trend: German machinery at cost effective pricing To compete with machinery from Asia, German machinery maker Arburg launched redeveloped electric machines for standard applications to its portfolio, Allrounder Trend, a lower-cost machine aimed at high-volume, standardised applications, competing with Asian manufacturers, at the K2025.

The machines are touted as quick to set up, particularly easy to operate and maintain and produce injection moulded parts extremely reliably and energy-efficiently.

The three machines shown at K2025 were producing electronic connectors, demonstrating automated LSR production and processing recyclates.

“We have completely redeveloped the Allrounder Trend - from the all-electric drive train, energy-efficient clamping and high-performance injection unit to the dynamic electric ejector and the new Gestica lite control variant,” summarised Guido Frohnhaus, Managing Director Technology & Engineering.

He furthered, “The machine technology is very easy to master, even without specialist personnel, and enables quick and easy entry into injection moulding of standard components.”

The machine’s slim design ensures a compact footprint and space-optimised production, resulting in increased output per/sq m. The new electric Trend machines will be available worldwide from spring 2026, with Arburg adding that with this new launch it is expanding to completely new markets where high-quality moulded parts have to be produced efficiently and precisely under intense cost pressure.

The Allrounder Trend is relevant for all industries, such as technical injection moulding and electronics. However, they are not high-speed machines and are not suitable for all special processes. The performance has been specifically optimised for standard applications. At market launch, there are four sizes in the clamping force range from 500 to 2,000 kN and with electric injection units in sizes 100 to 800. The injection speed is between 200 and 500 mm/second.

Engel furthers Clearmelt process with new tech centre

The finishing of plastic surfaces through polyurethane (PU) flooding is gaining rapid momentum in the plastics industry, especially in the automotive sector. To provide its customers with optimal support in implementing complex PU projects, Austrian machinery maker Engel has established its new clearmelt-Competence-Centre at its facility in St. Valentin, Austria.

With the finishing of plastic surfaces through PU flooding gaining rapid momentum in the automotive sector, Engel is providing optimal support in implementing complex PU projects at its new Clearmelt process tech centre

Engel says its clearmelt process delivers excellent surface quality with high scratch resistance and visual depth that cannot be achieved with pure thermoplastics. It also significantly shortens the process chain, increasing efficiency, simplifying part logistics and reducing costs.

At the centre, Engel says it not only handles the specification of the injection moulding machine and matching peripherals but also takes care of all communication and coordination with system partners.

Based on the customer’s 3D part data, the team carries out a detailed analysis to define the optimal overall process layout. They evaluate the ideal configuration for trials and the future production cell. Practical trials are then conducted, culminating in the final sampling of the series part.

To support a wide range of customer applications, the centre provides Duo two-platen injection moulding machines with clamping forces ranging from 7,000 to 55,000 kN for trials and sampling. In addition, further testing opportunities are available through cooperation partners such as toolmakers and raw material suppliers.

Arburg has launched

the Allrounder Trend machine to offer competitively priced electric machinery to the market

Flexible artificial muscles from liquid crystal elastomers

In Canada, an international team led by researchers at the University of Waterloo and other UK unversities has developed new material that can be used as flexible “artificial muscles” to replace rigid motors and pumps in robots and allow them to move more naturally and fluidly.

Soft robots differ from hard robots in that they are pliable and flexible, making them safe for interaction with people, but the materials currently used for components enabling their movement aren’t strong enough to be effective.

Rubber-like materials

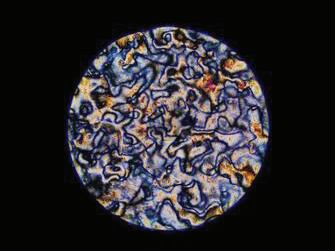

The Waterloo-led research group found a way to dramatically strengthen smart, rubber-like materials by mixing liquid crystals (LCs), which are commonly found in displays for electronics and sensors, into promising building blocks for soft robots known as liquid crystal elastomers (LCEs).

“What we call artificial muscles are essential for unlocking the true potential of soft robots,” said Dr. Hamed Shahsavan, a professor of chemical engineering at Waterloo, who led the research group. “They allow robots to move flexibly, safely, and with precision. This is especially important for applications like micro-medical robots.”

The LCEs provide output work of almost 24 J/kg, about three times more than the average work provided by the muscles of mammals, he added.

X-ray analysis showed that LCs disperse inside LCEs and form small pockets, like chocolate chips in cookie dough. While still in liquid form, the LC pockets surprisingly behave like solids, holding their shape and making the LCEs around them feel stiffer when pulled or stretched.

Significant role in soft robotics

The researchers expect LCEs with these improved mechanical properties to play a significant role in the emerging field of soft robotics by enabling extremely wide ranges of motion and powerful movements for everything from delivering drugs inside the human body to working alongside humans in manufacturing plants.

“Materials with such capabilities are highly desired in robotics as they can replace old-school, bulky, heavy actuators and electromotors with light, soft, artificial muscles without sacrificing performance,” Shahsavan said. “This is the simplest yet most robust strategy to stiffen LCEs and still maintain their programmable nature.”

The international research group also included: Dr. Tizazu Mekonnen, a chemical engineering professor at Waterloo, Sahad Vasanji and Matthew Scarfo, engineering graduate students at Waterloo, Dr. M.O. Saed of the University of Cambridge , and Dr. Antal Jakli of Kent State University .

Researchers are now focused on using the new materials as 3D-printing inks to create artificial muscles.

LCEs are rubbers that undergo massive shape change, in a reversible and programmable manner, when they are heated. Researchers discovered that mixing small amounts of LCs with LCEs made them much stiffer and up to nine times stronger.

“To put this in perspective, fibres from the new LCEs can, when heated, lift loads up to 2,000 times their own weight,” said Shahsavan, who is also director of the Smart Materials for Advanced Robotic Technologies (SMART) Lab at Waterloo.

A look through a microscope at a liquid crystal used to make rubberlike materials stiffer and stronger for artificial muscles in soft robots. (University of Waterloo)

Matthew Scarfo (left), a Waterloo engineering graduate student, and Dr. Hamed Shahsavan, professor of chemical engineering, both worked on the research that developed the flexible “artificial muscles” material that could replace rigid components in robots. (University of Waterloo)

Rubber Journal Asia

Space’s the limit for rubber tyres

Innovative rubber tyres are entering the era of space missions: as a catalyst to advancing science and mobility technology on Earth and beyond, says Angelica Buan in this article.

Rubber tyre’s cosmic journey

Space exploration is making history with landmark events, while the use of rubber in tyres contributes to humankind’s broader knowledge of the infinite expanse of space.

Rubber tyre innovation has become a catalyst to advancing science and mobility technology on Earth and beyond

As recounted in the National Aeronautics and Space Administration (NASA) Glenn Research Centre’s Reinventing the Wheel article, the transporter of the Apollo 14 mission in 1971 was as one of the earliest applications of rubber tyres in space exploration.

Manufactured by US tyre maker Goodyear Tire & Rubber Company the tyres featured nitrogen-filled inner tubes and were designed to facilitate pulling the cart through soft lunar soil and over rocks.

Partnership for lunar mobility

In 2022, Goodyear announced a partnership with aerospace firm Lockheed Martin to commercialise lunar mobility. The vehicles, which operate either autonomously or with astronauts, are part of NASA’s Artemis programme.

Goodyear and Lockheed Martin partnered to commercialise lunar mobility, delivering the first vehicle in time for NASA’s crewed lunar landing in 2025, which included the first woman and first person of colour to walk on the Moon

Goodyear has adapted its advanced airless tyre technology, currently used for micro-mobility and autonomous vehicles, to handle the moon’s extreme conditions, where temperatures range from -250°F at night to more than 250°F during the day.

Testing was carried out using lunar soil simulants and the collaboration delivered the first vehicle for NASA’s 2025 mission.

Tyres to the Moon and back Tyres for spacecraft are engineered to handle extreme conditions, from high-speed landings to sharp temperature changes. Built with specialised rubber compounds and reinforced structures, they provide durability, stability, and performance for vehicles returning from space or operating on other planetary surfaces.

Among the recent developments, Japanese lunar exploration company ispace and tyre maker Bridgestone Corporation have tied up to develop tyres for small and medium-sized lunar rovers. Bridgestone has been developing lunar tyres using its AirFree technology to meet the stringent lunar durability and traversability requirements.

Bridgestone develops tyres using its AirFree technology to support ispace’s goal of expanding human activity in space and providing sustainable, low-cost transportation services on the Moon

NASA’s Glenn Research Centre has developed next-generation tyres using shape memory alloys that flex with terrain instead of staying rigid. They conform to rocks without puncturing, providing a smoother ride and acting like built-in shock absorbers to protect rover systems

Rubber Journal Asia

Under the agreement, both companies will work to enhance the performance of ispace’s small and medium-sized lunar rover prototypes. Bridgestone’s tyres, designed to flex and absorb shocks, will be tested on Earth before deployment on the moon. The collaboration will evaluate the feasibility of these technologies and potential business opportunities, with practical application targeted around 2029.

Bridgestone added that it started its R&D on lunar rover tyres in 2019, unveiling lightweight concept models in April 2025. Its thin metal spoke design allows flexible deformation, shock absorption, and reliable traversal over lunar terrain, including rocks.

Technology for lunar tyre development

On a similar quest, French tyremaker Michelin, as part of the Moon Reusable Autonomous Crewed Exploration Rover (RACER) team, has been awarded the phase 1 feasibility study for the Artemis project, which involves designing a lunar vehicle capable of operating in extreme conditions on the moon for ten years.

For NASA’s Artemis LTV1 study, Michelin will use its airless technology and advanced materials to design lunar wheels that withstand extreme temperatures, radiation, and loose soil, ensuring maximum traction and durability

The team, led by Intuitive Machines, a US space exploration company, secured US$30 million to conduct an assessment, ushering the company’s entry into human spaceflight operations under NASA’s US$4.6 billion LTV services project.

A key partner in the project, Michelin will leverage its expertise in airless technology and advanced materials to design lunar wheels capable of withstanding extreme temperatures, solar and cosmic radiation, and loose lunar soil, ensuring maximum traction and durability. The company conveyed that the technical innovations developed for the moon could also advance terrestrial mobility applications.

The team also includes AVL, Boeing, and Northrop Grumman, contributing expertise in drivetrain, vehicle systems, and mission planning.

New horizons in Mars mobility

From Galileo Galilei’s first telescopic observation of Mars, to the early flyby attempts of the 1960s, and the several missions that followed from major space agencies, Mars wayfaring has advanced significantly. Spacecraft and rovers are now built to withstand the planet’s freezing temperatures, intense solar radiation, corrosive salts and noxious dusts.

Vehicle tyres are engineered differently for space exploration. Using rubber for rover wheels and tracks has proven extremely difficult due to the planet’s harsh daily temperature changes of 50–100°C and an atmosphere 150 times thinner than Earth’s.

Thus, the Netherlands’ University of Twente ’s RED 4 Mars project is a game changer. The project, supported by the Marie Skłodowska-Curie Actions programme, aims to create rubber capable of withstanding these extreme temperatures.

Current rovers use thin-walled aluminium wheels, which are light but cannot absorb energy like rubber, limiting speed and cargo capacity.

The RED 4 Mars project seeks to develop rubber that can endure conditions on Mars and support exploration of the planet’s surface, while improving transport safety and comfort. The designed rubber could also be used in suits, shoes, cable covers, inflatable structures, and sealing gaskets.

The compound blend combines silicone rubber, which is highly elastic at temperatures as low as -125°C, with butadiene rubber, which provides mechanical strength and wear resistance. To unify the two normally immiscible elastomers, carbon black filler particles were added, along with liquid butadiene rubber as a processing aid to prevent contamination in the vacuum of Mars. A specialised sulfur-based vulcanisation system ensured proper curing and elasticity under stress.

Mechanical testing of the prototype tyres showed they retain viscoelastic properties across the widest possible temperature range. Simulations suggest the tyres could maintain their mechanical integrity for up to 80,000 years, even under high radiation exposure on Mars.

Innovative tyres for red-hot planet

Meanwhile, continued advances in tyre design are helping ensure successful expeditions on the so-called “red” planet. One example is a next-generation tyre developed by NASA using shape memory alloys (SMA).

These shape-shifting materials offer exceptional durability, flexing with the terrain instead of remaining rigid like current wheels. They can conform to rocks without puncturing and provide a smoother ride, acting almost like built-in shock absorbers that reduce the risk of damage to rover systems.

The Cleveland-based facility began collaborating with the US tyre industry years ago to create a better non-pneumatic, or airless, lunar tyre. This resulted in the Spring Tyre, built from a network of steel springs that adapted to terrain much like a traditional rubber tyre.

Engineers have since replaced conventional steel with SMA springs to improve performance in rugged terrain and extreme cold. This approach appeals to mission planners because of its lighter weight, improved traction, and durability.

Current work at NASA’s lab focuses on refining SMA processing, optimising designs, and conducting environmental testing on the new tyre.

Dr Santo Padula, lead SMA materials and design engineer at the research centre, intoned that developing a Mars-grade material capable of reversible deformation in harsh conditions without losing performance remains a key milestone.

Testing shows the tyre’s grip meets or exceeds traction requirements, allowing rover drivers to navigate varied terrain.

These advanced tyres also support a four-tyre rover design instead of the traditional six, offering more flexibility for future robotic or human missions.

Meanwhile, engineers are further advancing SMA technologies for use on Mars and on Earth, including in the military, aviation, and passenger segments, where passenger tyres have already been tested and may eventually replace conventional air-filled tyres, eliminating punctures, reducing under-inflation risks, and improving fuel efficiency and safety.

2 – 5 DECEMBER

Labelexpo Asia

Venue: SNIEC, Shanghai, China

Tel: +86 (21) 6157 3832

Email: jenny.wang.cn@informa.com Website: www.labelexpo-asia.com

3 – 6 DECEMBER

Plast Eurasia Istanbul

Venue: Istanbul, Turkey

Tel: +90 (212) 867 11 00 Fax: +90 (212) 886 67 48

Email: info@plasteurasia.com Website: www.plasteurasia.com

9 – 11 DECEMBER

CIBRUSH

Venue: SNIEC, Shanghai, China

Tel: + 86 10 5867 7299 Fax: +86 10 5867 7126

Email: cibrush.ouyang@hjtexpo.com Website: www.cibrush.com

9 – 11 DECEMBER

9th Oman Plast