In this issue

Features

8 Packaging – ExxonMobil Signature Polymers partnered with Chengdu Boshikeru to improve metallised PE film for food packaging; while OxBarrier has launched a licensing programme for compostable single-serve capsules

10 Recycling Machinery at K2025 – K2025 will feature joint efforts in recycling machinery, with Erema and Lindner and NGR and Leistritz presenting systems to raise efficiency and recovery rates, while Starlinger and CMG bring forward low-carbon technologies

12 Machinery at K2025 – With extrusion processors facing pressure to reduce costs, machinery maker Gneuss offers advanced melt filtration and extrusion equipment for cost savings and competitiveness

14 Extrusion/PET/rPET Machinery at K2025 – At K2025, machinery leaders including Reifenhäuser, SML, MEAF, KraussMaffei, Kreyenborg, and Cypet will unveil innovations ranging from high-output extrusion and stretch film lines to next-generation PET/rPet systems, including co-processing, foodgrade recycling, and large-scale blow moulding solutions

17 Materials at K2025 – Material suppliers such as Asahi Kasei, Polyplastics, Palsgaard, BASF, Dow, OQ, Ineos Styrolution, ExxonMobil, Domo Chemicals, Sabic, LyondellBasell, Kraiburg TPE and Tosla cover a host of topics from bio-based/biodegradable, packaging, recycling/sustainability to flame retardancy

IMA – Conductive Plastics: New cost-effective, chemical-free conductive plastics are emerging for wearables, phones, implants, and 3D-printed electronics

IMA – Electrical/Electronics: At K2025, material suppliers like BASF, Mocom, Syensqo, Envalior and Wacker will feature grades for powertrains, EV connectors, e-mobility, busbars and recycled alternatives

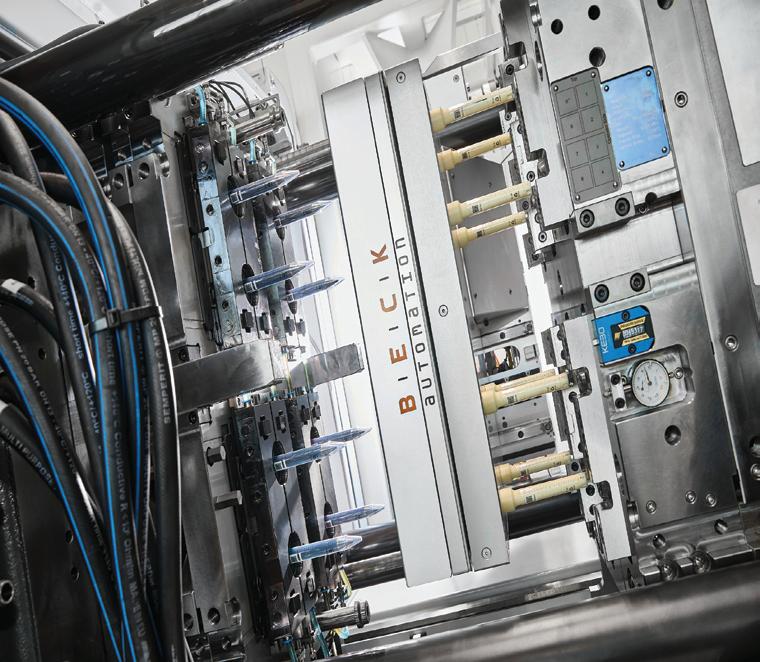

IMA – Machinery at K2025: A line-up from Netstal, Arburg on IML; medical applications from Sumitomo Demag, Wittmann, while Engel will show foammelt technology; Wittmann Battenfeld will display a new model and Husky will unveil a next generation packaging moulding system. Robots/controls/ auxiliaries exhibits include Sepro, Maag, Hasco, Oerlikon HRSflow and Moog

Tyre Industry: The tyre industry is steering toward circular use of rubber, reducing its carbon footprint with sustainable materials in tyres

K2025, to be held from 8-15 October in Düsseldorf, Germany, defines the agenda for sustainable progress in the plastics sector, highlighting circular economy, digitalisation, and social responsibility

Publisher/Editor-in-Chief

Arthur Schavemaker

Tel: +31 547 275005

Email: arthur@kenter.nl

Associate Publisher/Executive Editor

Tej Fernandez

Tel: +6017 884 9102

Email: tej@plasticsandrubberasia.com

European Correspondent

Jeanet Draaijer

E-mail: jeanet@kenter.nl

Asian Correspondent

Angelica Buan

Email: gel@plasticsandrubberasia.com

Circulation

Stephanie Yuen

Email: stephanie@taramedia.com.my

layout/design

Prestige Trading

Email: prestige9a@gmail.com

Permits

ISSN 1360-1245

is published 4 (four) times a year in English by Kenter & Co Publishers’ Representatives BV.

Whilst every effort is made to ensure that the information contained in this publication is correct, the publisher makes no warranty, expressed or implied, as to the nature or accuracy of such material to the extent permitted by applicable law.

© 2025 Kenter & Co Publishers’ Representatives BV No part of this publication may be reproduced, stored or used in any form, or by any means, without specific prior permission from the publisher.

PRA is a digital publication that is circulated free to trade readers in the plastics and rubber industry. Please view this link to subscribe/renew your free subscription: http://plasticsandrubberasia.com/register.html

www.plasticsandrubberasia.com www.rubberjournalasia.com www.injectionmouldingasia.com www.eog-asia.com

Singapore to launch plastic passport for tracking recycling

With governments seeking ways to make plastic recycling work at scale, Singapore is taking the bull by its horns in collaboration with SMX , which has pioneered "physical to digital" supply chain solutions, and governmental R&D agency ASTAR , by building what it says is “the world's first country-backed plastic passport program”.

This partnership combines SMX's chemical molecular marking technology, patented reader and blockchain-based traceability platform with ASTAR's digital, chemical spectroscopic detection and profiling research capabilities, for a system that permanently marks plastics at the molecular level, creating a tamperresistant digital identity that follows materials from manufacturing through recycling.

Policymakers set bold targets, global brands commit billions, and environmental advocates press for accountability, but the system has failed with recycling frameworks designed too narrowly, focusing on plastics like PET and rPET food-grade packaging while leaving out industrial polymers, automotive resins, textiles, and electronics. The result is a loop that could never fully close.

Hence, Singapore intends to do that with SMX's technology. The country generates about 957,000 tonnes/year of plastic waste, with 94% of waste being incinerated, and only 6% recycled.

Phase I will cover more than 5,000 tonnes of postconsumer rigid and flexible plastics. Semi-industrial deployment begins in Q1 2026, followed by a full commercial showcase in Q2 2027, deliberately timed to align with Singapore's tightening extended producer responsibility (EPR) mandateS, giving brands and producers a ready-made compliance pathway.

Once fully scaled, the system will support tagging and tracing capacity of more than 5,000 tonnes/year of plastics, and will be supported by a coalition of global and regional brands, retailers, resin producers, converters, and recyclers.

But it does not stop with tracking as every kg of SMXverified recycled plastic can also be paired with a Plastic Cycle Token, or PCT.

This instrument is backed one-to-one by the molecular marker and its verified audit trail, transforming recycled output into a transparent and tradeable asset. Unlike traditional carbon credits, which have struggled with opacity and credibility, the PCT is built to be measurable, auditable, and economically useful. It allows recyclers to monetise verified output, brands to hedge compliance risks, and investors to treat recycling as a new class of commodity.

FMCG companies, electronics suppliers, and automotive manufacturers across Asia are writing minimum post-consumer resin thresholds into procurement scorecards. Verified PCR already commands a 5% to 15% premium over virgin polymer in regulated sectors, and that premium is expected to widen as EPR schemes spread across Asia. With compliance costs rising and reputational risks looming, companies no longer see traceability as optional.

Meanwhile, the system may stretch beyond Singapore and by embedding chemical molecular "barcodes" in every pellet and logging each hand-off on blockchain, the partners aim to lift regional recycling rates by more than 30% and halve landfill or ash-fill volumes by 2030.

When replicated across ASEAN, the same architecture unlocks an addressable market of S$4.2 billion a year in certified recycled material and platform fees, thereby turning waste into a bankable commodity.

Singapore, with SMX and ASTAR, is building what it calls the world’s first country-backed plastic passport programme, using SMX’s “physical to digital” supply chain solutions

P h ilip pi ne s c o un ter s wa s te p l astic : pi n k f lami n go to t h e rescue !

Akin to other Asian countries, Philippines is plotting waste solutions through policies and consumer awareness campaigns. Meanwhile, social enterprises, like the ironically named The Plastic Flamingo ( The PLAF), are rolling up their sleeves, literally, to counter the waste issue and repurpose it sust ainably for use in the construction industr y The PLAF, which has a pink flamingo as its logo, was named to evoke an image of fun and add colour to an other wise “dirt y” image associated with recycling .

The country’s National Solid Waste Management Commission (NSWMC) has reported that Philippines generates around 40,00 0 tonnes/day of waste, equivalent to an average of 0.40 kg/person/day across both urban and rural areas.

As such, companies like The PLAF collect and upcycle plastic waste into construction materials such as boards, fencing and decking that can be used to build schools, housing, and shelters.

François Lesage, the founder/CEO of The PLAF, was inspired to set up the company while he was on a cycling tour from France to Cambodia. “My wife and I were confronted with how mass consumerism and the production of plastic has led to enormous plastic waste pollution,” he said. The rest as they say is history.

On why the French couple selected Philippines as the base, Lesage said, “Southeast Asia is among the top contributors to marine plastic pollution, and Philippines, in particular, has been the largest contributor globally for a consecutive number of years ”

However, Lesage’s vision extends beyond the country and he adds the company is in the “initial stages of creating a similar recycling facility in Cambodia”

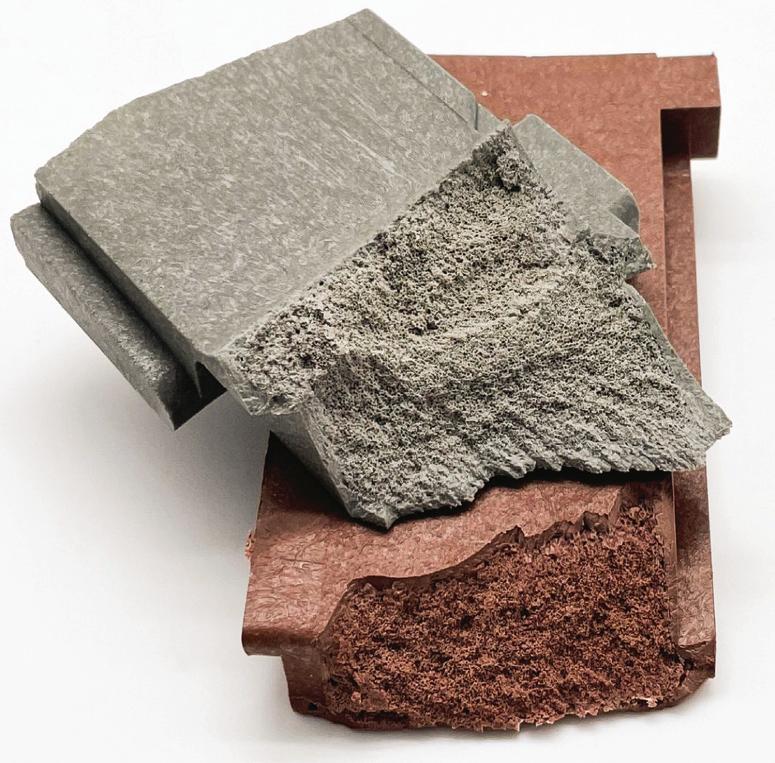

Multitude of plastics for recycling into building boards

The Manila-based company, which is part of the Ellen MacArthur Foundation community and the Alliance to End Plastic Waste (AEPW), is able to recycle PS, PVC and HDPE waste at its facility in Muntinlupa.

The waste is sourced from a network of more than 30 0 collection points that include households, schools, hospitals, local government units (LGUs) and offices, according to Lesage, adding that the company has already managed hundreds of tonnes of plastic waste from collection sites

“We accept diversions of plastic waste free of cost and recycle them into our eco-products. With a view to expanding our products, we are also constantly exploring ways to diversify our recycling capabilities,” he explained.

The company’s eco-boards are made of 10 0% recycled plastic waste, as well as difficult-to-recycle single use packaging such as sachets.

“We use a patented formula for mixing the different types of plastic waste that ensures consistently hard and sturdy eco-boards. The boards are low maintenance and long lasting (even outdoors). They are also weatherproof, splinter and termite-free, which means no maintenance over a short period of time ”

He adds that the entire process is undertaken in the country, creating jobs for Filipinos. “Our warehouse workers and waste collectors come from low-income families, providing them with livelihoods where they can upskill and seek more opportunities,” he reiterated.

The company’s eco-boards are made of 100% recycled plastic waste, as well as difficult-to-recycle single use packaging such as sachets

The company is also able to design and create various made-to-order furniture pieces, partitions and other items from the eco-boards that come in a fixed shape of 115 x 115 cm panels.

“One example is the school chairs that were made from eco-boards, thereby addressing the country’s shortage of school chairs.”

The company also provides rHDPE granules, made 100% from recycled home and personal care HDPE bottles/packaging, which are sorted, crushed and shredded into flakes. “We pack the pellets in 25 kg sacks on pallets. Each pallet contains 50 sacks for a total weight of 1,250 kg,” he added.

Ensuring waste is recycled; pursuing environmental goals

Apart from recycling waste, Lesage says the firm has partnered with organisations for clean-up activities to encourage the engagement of their employees and communities to pursue the recycling goal in the country.

“It is an effective way to involve individuals in the recycling chain as well as expose them to the severity of

Cast

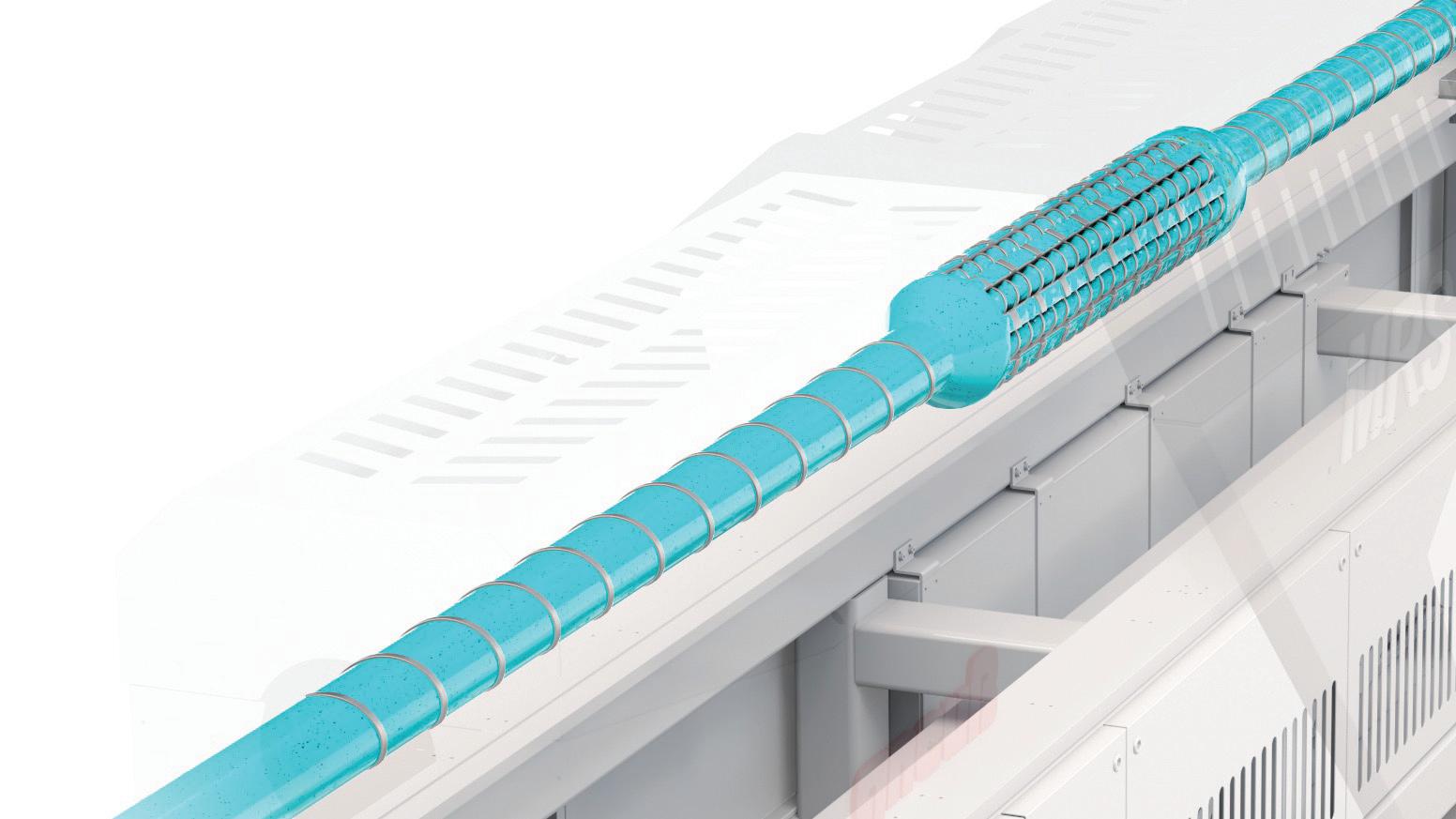

The monoaxial stretching process forms the technical basis for mono-material packaging solutions of tomorrow

Key Features

• Wide application range and

•

• Safe and easy-to-service design

the plastic waste problem. As of August 2025, from the time we started in 2018, we have managed to divert more than 1.2 million kg of plastic waste from the ocean!”

Meanwhile, he adds that the country is taking significant steps towards mitigating plastic waste as evidenced by the EPR law enacted in 2022, which is the first amendment to the Ecological Solid Waste Management Act.

Through this law, plastic manufacturers, brand owners, importers, and other producers categorised as FMCGs are required to recover, recycle, and manage their plastic waste, in line with the aim for plastic-neutrality in ten years.

The PLAF also provides EPR and CSR services working with key partners such as AEPW, logistics provider CMA CGM, US packaging firm Charter Next Generation (CNG) and consumer healthcare firm Haleon.

“No doubt there is a lot of interest coming from the community to undertake recycling but it is vital to overcome the hesitation from the market when it comes to accepting recycled products, since countering plastic waste will not end with collection and recycling only,” adds Lesage, concluding with an observation that market acceptance is slowly taking off in the country based on the number of enquiries the company is receiving.

Theboards are durable, low-maintenance, weatherproof, and resistant to splinters and termites, according to Lesage

Breaking the waste cycle with circular responsibility

Emerging solutions to plastic waste deliver a clear message: industries, communities, and individuals must share responsibility in a circular system, adds Angelica Buan, in this interview conducted with PCX, which offers solutions to help companies meet their sustainability goals and recently launched its recycled plastics platform.

Waste crisis rising

Among the dissenting voices on rising plastic waste, the United Nations Environment Programme ( UNEP ) has expressed concern over the worsening state of the environment. It reports that more than 20 million tonnes/ year leak into waterways and aquatic ecosystems. With plastic consumption continuing and 430 million tonnes/ year produced, the volume of plastic waste is projected to triple by 2060.

To prevent this, UNEP cites proven solutions: reducing plastic use, using non-plastic alternatives, redesigning products for reuse, repair, and recycling; and improving waste management systems.

According to UNEP, over 20 million tonnes of plastic enter waterways each year. With 430 million tonnes produced annually, waste is expected to triple by 2060

ASEAN Plus Three: a plastic waste hotspot

Over in the ASEAN region, which comprises Thailand, Indonesia, Malaysia, Singapore, Philippines, Vietnam, Cambodia, Laos, Myanmar and Brunei, plastics use surged nearly nine times, from 17 million tonnes in 1990 to 152 million tonnes in 2022.

This was largely made up of single-use packaging, according to the Organisation for Economic Co-operation and Development ( OECD ) report, Regional Plastics Outlook for Southeast and East Asia , published in July 2025.

Meanwhile, when combined with Japan, China, and Korea, under the grouping collectively known as ASEAN Plus Three (APT), the region constituted nearly a third of global plastics use. Annual per capita consumption ranges from 32 kg in lower-middle income ASEAN states to over 100 kg in Japan, Korea, and most high-income and upper middle-income ASEAN members.

"PCX plans to scale cleanup credit programmes and recycled plastic supply chains, expand partnerships with local recyclers, and add more high-impact projects to our network," said Sebastian DiGrande, CEO of PCX Markets

Most APT countries have national action plans on plastic pollution and cooperate regionally, which may account for their recycling rates being pegged at 12%, already above the global average of 10%. Still, nearly a third of plastic waste is mismanaged, particularly in ASEAN’s low-middle income countries and rural China, where open burning and dumping persist.

PCX Markets: closing the loop with circular plastics

Amid growing pressure on manufacturers and brands to reduce their carbon footprint, Singapore-headquartered PCX Markets , the “plastic responsibility platform” of the Manila-based non-profit organisation PCX , provides upstream and downstream solutions to help companies meet their sustainability goals, and move along initiatives aimed at reducing plastic waste.

PRA interviewed PCX Markets’ CEO Sebastian Di Grande to learn how the company serves as a linchpin in the plastic recycling and sustainability chain, helping brands access responsible plastic solutions.

PRA: How is PCX addressing the global and Asian plastic waste situation?

Di Grande: PCX Markets work with brands to meet and exceed regulatory requirements through a portfolio of solutions, including plastic clean-up credits, verified recycled resin and upstream reduction consulting.

Since 2019, we have built one of the world’s most trusted networks of waste recovery and recycling partners, generating real impact for communities, ecosystems, and supply chains.

Verified plastic credits can help close the funding gap, connecting brands that want to fund downstream cleanup with project partners that need additional funding.

Currently, only 9% of plastic waste is recycled, 19% incinerated, and 72% landfilled, dumped, openly burned or ends up in the environment. As per UN estimates, we need to invest US$1.64 trillion to beat plastic pollution by 2040.

The ASEAN region is at the epicentre. According to the World Bank, half of the top ten countries contributing to plastic leakage to rivers and seas are located in Southeast Asia.

Emerging markets, however, received only 6% of plastic circularity investments between 2018 and 2023, according to The Circulate Initiative. A recent World Bank report estimates there is a gap of US$28-US$40/tonne for plastic waste collection and US$24-US$40/tonne across plastic recycling value chains in the Philippines, Indonesia, Thailand and Vietnam.

We launched PCX Circular Plastic, which offers the option to bundle plastic credits with verified recycled resin produced by the same project partners.

PRA: What is the purpose of PCX launching the recycled plastics product?

Di Grande: PCX Circular Plastic is a pioneering solution that gives brands the opportunity to fund audited clean-up of plastic pollution and source a steady supply of recycled resin from verified recycling partners.

Companies that choose PCX Circular Plastic can be assured the PCR content they’re buying comes from recycling projects that have been audited according to rigorous, third-party standards that include environmental, social, labour and workplace safeguards.

Our goal with PCX Circular Plastic is to accelerate the transition to a truly circular economy for plastics. By offering high-quality, verified PCR resin, we help brands replace virgin plastic with material that has already been used and recovered, reducing demand for new fossilfuel-based plastics and keeping valuable resources in circulation.

By choosing PCX Circular Plastic, businesses become part of a global ecosystem accelerating the transition to a circular economy. When businesses invest in this solution, they’re not just meeting their recycled content targets, but also closing the funding gap for waste management solutions in markets that need it the most, and creating jobs in communities hardest hit by the plastic pollution crisis.

PRA: What types of recycled plastics are offered, and where are they sourced from?

Di Grande: PCX offers brands access to rPET, HDPE, LDPE, PP and PE in the form of flakes, pellets and powders, sourced from verified PCX recycling partners with a total annual capacity of 70 million kg per 70,000 tonnes.

Right now, we offer circular plastic from eight projects in the Philippines, India, Indonesia and Thailand, with more in the pipeline. These projects, and their facilities, meet strict quality, environmental, and social standards, and much of the material originates from countries with high rates of plastic leakage, where the impact of recycling is greatest.

PCX offers rPET, HDPE, LDPE, PP, and PE from verified partners with a 70,000-tonne annual capacity

PRA: How can companies purchasing PCX Circular Plastic rest assured that the PCR content has been audited?

Di Grande: Let me explain how it works. PCX manages a plastic credit marketplace, where brands that want to fund clean-up can buy credits issued by projects, many of whom are SME recyclers that want to raise additional financing. One credit funds the clean-up of 1 tonne of plastic waste. Projects that wish to issue credits as an additional finance stream first go through a registration process with one of the select standards we accept at PCX Markets. This includes a rigorous verification process conducted by a third-party auditor to ensure the project meets the environmental and social safeguards set out by that particular standard.

The impact they deliver is then audited by an independent verification and validation body (VVB), which reviews documents across the full chain of custody, including collection certification, weigh in/weigh out receipts from truck scales, certificate of processing/recycling, and environmental compliance certificates.

PCX's Indonesian project partner also supplies circular plastic

Once the impact is verified the relevant standards body issues a plastic credit certificate with a unique serial number; the credit is sold to the purchaser and listed on PCX Markets’ public registry.

Most of the credits listed on our marketplace have been issued through the Plastic Pollution Reduction Standard (PPRS), which is managed by our sister organisation, PCX Solutions. We also sell credits issued by The Plastic Waste Reduction Standard (PWRS), which is administered by Verra, and The Ocean Bound Plastic (OBP) Standard, which is administered by Zero Plastic Oceans.

Those standards ensure the projects are operating responsibly and provide an audit for the recovery and recycling of 100% post-consumer plastic waste. For specific supply chain traceability of the physical PCR a customer may receive, many of our projects also employ feedstock-specific traceability, such as the Global Recycled Standard (GRS) and OBP standards.

PRA: How can brand owners be encouraged to use recycled plastics, given that some virgin plastics are competitively priced and certain recycled plastics are in short supply?

Di Grande: Switching to recycled plastic is about more than price – it is about meeting regulatory requirements, achieving sustainability targets, and building brand trust. Governments around the world are setting minimum recycled content mandates, and consumers are rewarding companies that take real action on plastic waste. In short, recycled plastic is not just an input cost – it is an investment in brand resilience, compliance, and environmental impact.

PRA: Since its launch in 2019, PCX has enabled the cleanup of over 140 million kg of plastic waste worldwide. In which regions have this been carried out, and what are the future plans for cleaning up plastic pollution, especially in Asia?

Di Grande: We have supported plastic waste recovery projects in the Philippines, Indonesia, Thailand, India, Kenya, Ghana, and beyond, regions where investment in waste management can have the greatest impact in preventing plastic from leaking into rivers and oceans. Asia remains a critical focus because of its high population density, rapid economic growth, and infrastructure gaps.

Our future plans include scaling both our cleanup credit programmes and our recycled plastic supply chains, expanding partnerships with local recyclers, and bringing more high-impact projects into our network.

PRA: How have local communities, authorities, or stakeholders in these Asian countries responded to these plastic waste recovery projects?

Di Grande: First, and generally speaking, in all of the markets where we have project partners, we witness tremendous excitement and hope for the prospects of credits bringing much needed “consistent” financing to help them de-risk

the investments and scaling of much needed infrastructure, and also see it as a way to deliver economic benefits to the communities doing the work.

So generally, very positive response, though also associated anxiousness about whether and when the market will move beyond “nascent” and deliver these effects at scale.

In 2022, Philippines passed an Extended Producer Responsibility (EPR) Act requiring corporations with assets excluding real estate over US$1.7 million to recover and divert 20% of the plastic the waste generated, upcycling or waste-to-energy recovery by the end of 2023; that number rose to 40% in 2024, then increases by 10% every year until at least 80% is recovered or diverted, annually, by 2028. That 80% goal is just four years away.

The country took a pragmatic approach, and crafted accessible laws that make this achievable. Obliged Enterprises, or OEs, have a menu of upstream and downstream options to choose from, spanning reduction, use of recycled content and adoption of reusable packaging to purchasing audited, verified plastic credits to fund the clean-up of plastic waste to offset the plastic they can’t immediately eliminate. The EPR law refers to these as offsets.

So again, a market-based mechanism like credits, which facilitates the recovery of plastic waste and encourages the private sector to make investments into waste infrastructure, is critical in emerging markets that lack collection and recycling infrastructure.

PRA: What key indicators or metrics do you use to evaluate whether the projects met your objectives?

Di Grande: These indicators are tracked by crediting standards during the conformity and impact assessment process. Projects that wish to issue credits as an additional finance stream first go through a registration process with one of the select standards we accept at PCX Markets. This includes a rigorous verification process conducted by a third-party auditor to ensure the project meets the environmental and social safeguards set out by that particular standard.

As mentioned, most of the credits listed on our marketplace have been accredited through the PPRS.

I would also just add that "financial returns” is not the primary KPI for our operation, other than seeking to ensure that as much of the funding as possible is going to the communities who do the work. Our Northstar KPI is impact in the form of tonnes of plastic waste diverted from nature.

According to PCX, project partners in Asia, including Thailand, operate facilities that meet strict quality, environmental, and social standards

PRA: Could you provide any recent updates or developments in terms of project partners?

Di Grande: Another way to speak to this is the metrics associated with specific project partners. As an example, one of the clean-up projects we support is Royal Rainbow, a PET recycling facility in Bulacan, Philippines.

Royal Rainbow buys used PET bottles from local junk shops and waste pickers, then recycles them into plastic flakes. These flakes are then sold to manufacturers to be used in new products, helping give plastic a second life

In the Philippines, where waste infrastructure is still developing, the informal sector plays a huge role in collecting and sorting plastic. Thanks to the income from plastic credits, Royal Rainbow can now pay better prices for plastic bottles, encouraging more waste pickers and junk shops to join in. It is a win-win: more income for communities, and more plastic kept out of nature.

Since the country’s EPR law came into effect in 2023, Royal Rainbow has seen a spike in demand for credits. That has helped them scale up, expanding from their original sites in Northern and Southern Luzon to the Visayas and Mindanao. In the first half of 2025 alone, they collected over 16% more PET than they did during the same period in 2024.

That is the kind of long term, sustainable impact, metrics and long-term impact we get most excited about.

Circular plastics from Thai project partners

Plastic recovery project in Indonesia

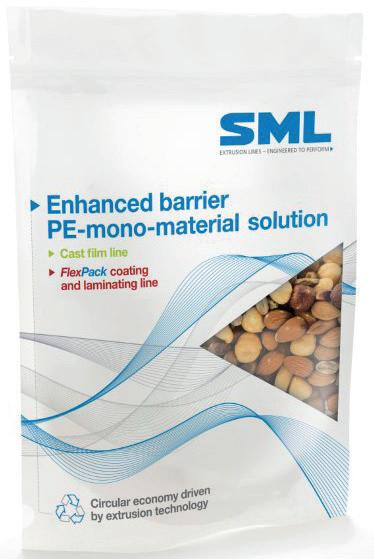

Chengdu Boshikeru’s metallised PE film for food packaging

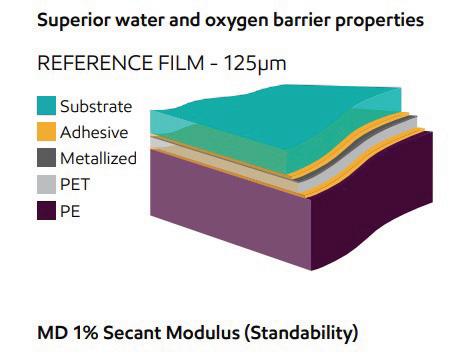

Most vacuum metallised packaging on the market generally has three-ply composite structures, consisting of oriented PET or PP substrate layer, metallised PET barrier layer and coextruded PE sealant layer (BOPET or BOPP//m-PET//PE). However, PET is incompatible with PE or PP.

When implementing PE metallisation plating, the industry often faces challenges such as poor metallisation adhesion and bonding strength, poor appearance, high friction coefficient and weak barrier performance.

Thus, to address long-standing challenges in metallised flexible packaging, ExxonMobil Signature Polymers partnered with flexible packaging maker Chengdu Boshikerui New Materials Co ( BSKR ), Chengdu Fulinda New Materials Co (FLD), and Qinglan New Materials Co.

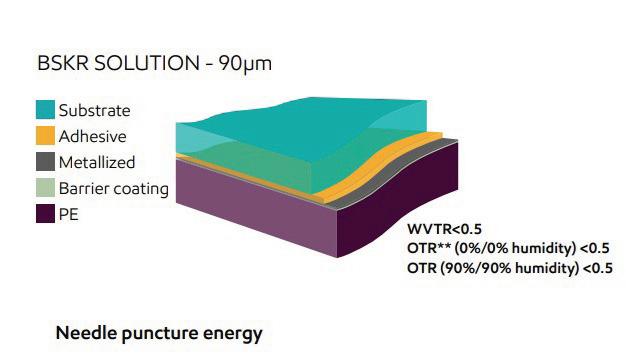

To overcome these limitations, ExxonMobil and its downstream partner FLD, a functionalised film producer that is experienced in metallised technology, BSKR developed a two-ply lamination film that delivers excellent sealing performance, enhanced needle puncture with comparable stiffness to the incumbent three-ply laminate, while still retaining the barrier performance despite the simplified structure.

In the coextruded PE sealant layer it applied:

• Exceed Tough+ m 0814 and Exceed Flow+ m 0516 high performance PE to deliver mechanical strength and toughness, ensuring package integrity and high needle puncture resistance.

• Exxtra Seal m 2012 enhanced performance PE to provide low-temperature sealability, critical for sealing performance.

• Exceed Stiff+ m 0926 to add structural stiffness, allowing downgauging without compromising processing efficiency or mechanical performance.

BSKR utilised its pre-treatment methods to treat the PE sealant film. FLD and Qinglan, a laminator specialising in film coating solutions, co-developed a novel barrier coating technology.

The pre-treated PE film was first coated with a barrier layer, and then went through a metallisation process with excellent uniformity and high adhesion strength, despite the PE film’s higher elongation nature.

Chengdu Boshikerui New Materials addressed longstanding challenges in metallised flexible packaging for food

Subsequently, the vacuum metallised polyethylene film (VMPE) was laminated with BOPP, resulting in a 90μm twoply BOPP//VMPE lamination structure.

Final metallised PE film outcome with better results

The result is a vacuum metallised PE (VMPE) film laminated with BOPP, forming a BOPP//VMPE lamination structure. The solution can be applied to a wide range of food packaging requiring superior barrier properties. With the removal of PET content in the lamination, this new film has a 100% polyolefins (PO) structure.

The resultant film has a simplified structure with thinner gauge while maintaining superior barrier performance and packaging integrity.

Compared to the incumbent, this innovative solution provides following key attributes:

• Simplified film structure from three-ply BOPP//VMPET//PE to two-ply BOPP//VMPE laminate;

• Total thickness of film was downgauged from 125 to 90 microns without compromising the convertibility and standability of stand-up pouch;

• Superior barrier performance versus the incumbent three-ply film with oxygen transmission rate (OTR) at less than 0.5 cc/(m2 ·day) and water vapour transmission rate (WVTR) at less than 0.5g/(m2 ·day);

• Enhanced package integrity with excellent needle puncture resistance.

The partners say the cutting-edge VMPE film with simplified structure developed through the value chain collaboration between is a breakthrough in metallisation technology. The BOPP//VMPE solution can be applied to a wide range of food packaging requiring superior barrier properties.

OxBarrier launches licensing programme for patented compostable capsules

Elsewhere, Netherlands-based OxBarrier has officially launched its first technology licensing programme for its patented compostable single-serve capsule technology. It features an integrated oxygen barrier specifically designed for the single-serve coffee capsule industry, thus ensuring long-term freshness and flavour while eliminating the environmental impact of traditional capsules.

The company's single-serve capsule technology patents have been granted in more than 30 countries, including all major European markets, Canada, and Australia, it added.

While the company did not disclose the material composition of its coffee pods, it has a substantial intellectual property portfolio to protect the technology.

Through its licensing programme, OxBarrier is making its technologies available to partners worldwide. This enables coffee brands and manufacturers to accelerate their sustainability commitments while meeting consumer demand for high-performance, compostable single-serve solutions.

The global coffee pods and capsules market was valued at over US$38 billion in 2023 and is forecast to surpass US$58 billion by 2030, according to Grand View Research This expansion carries an environmental cost, with an estimated 576,000 tonnes/year of capsule waste generated and millions ending up in landfills, according to reports from Mongabay and Earth.org.

"Single serve capsules are a symbol of modern convenience, but they've also created a global waste challenge," says Boele Oltmans, OxBarrier's Managing director. "OxBarrier's technology allows brands to offer compostable capsules without sacrificing quality or shelf life. Our goal is to help the industry transition to sustainable single-serve packaging at scale, hence our drive to 'Preserve with Purpose'," he added.

Globally recognized for polymer expertise, ARDL is now fully equipped and validated to perform testing to the BS EN 455-5 Extractable Chemical Residues Standard – For Single Use Medical Gloves.

This critical standard enhances transparency, safety, and compliance in glove manufacturing by addressing chemical residues that can migrate into the skin. For healthcare, dental, and laboratory professionals, these residues can lead to skin sensitivity, long-term health risks, or even career-ending reactions.

GLOVE & PPE TESTING / COMPLIANCE / FDA DETENTION TESTING

Surgical Gloves, Exam Gloves, Isolation Gowns, Condoms & Medical Devices

ASTM D6978

ASTM F739

ASTM F1670

ASTM F1671

ASTM F3267

ASTM D5712

ASTM D6499

ANSI/AAMI PB70

ISO 16604

NEW - BS EN 455-5 (Single Use Medical Gloves)

Scan the code to learn more or visit

ISO 10993-5

EN 16523

ISO 21420

OxBarrier capsule top

Erema to focus on compact machinery/Lindner jv

With compact footprint and high output being decisive key parameters in post consumer recycling, Austrian machinery maker Erema will show the 2021 model without a cascade at K2025.

Notwithstanding that it offers the largest Intarema system to date, with an output of over 4 tonnes/ hour, Intarema 2021 TVEplus has a diameter of 2 m for the preconditioning unit (PCU) and 212 mm for the extruder screw, which for the first time features a single end-to-end extrusion unit. With an output of up to 3.5 tonnes/hour and a footprint of 15.1 x 3 m, this recycling system is over 2 m shorter than the previous cascade design, in which two extruders were connected by a melt pipe. The new design also reduces the melt temperature, lowers energy consumption and minimises maintenance requirements, it adds.

Erema/Lindner worked on a project where rHDPE is produced for reuse as new HDPE milk bottles

Meanwhile, Erema has established a joint venture with Lindner Washtech , which provides sorting, cold and hot washing for effective cleaning and decontamination with its extrusion and filtration technology. Because the processes are wellcoordinated, consistent recyclate quality is produced with optimised energy consumption, it claims.

NGR and Leistritz have joined forces to enable recycling and compounding in a single step with only one melting process

One example is a project at Polymer Matters in Ireland that applied to the European Commission for food-grade approval. In this application, HDPE milk bottles from household recycling schemes are processed into rHDPE and used for the production of new milk bottles.

Meanwhile, since recyclates for food packaging must meet the requirements of the European and American food safety authorities. Erema says it has initiated numerous approval projects. "A key driver of these projects is the new EU Packaging and Packaging Waste Regulation (PPWR), which stipulates a recyclate content of 10% in sensitive packaging and 30% in all packaging from 2030 onwards," explains Clemens Kitzberger, Business Development Manager.

There are two decisive prerequisites needed for food-grade: an input stream consisting of at least 99% food packaging, and technology that is able to clean and decontaminate the input material.

NGR/Leistritz tie-up for new solution combining recycling/compounding

German twin-screw extruder firm Leistritz Extrusionstechnik and Austrian recycling machinery provider Next Generation Recyclingmaschinen ( NGR ) are tying up to combine their respective strengths in recycling and compounding, especially against the back of PPWR rules coming into effect in August 2026.

Together, they are developing a solution that enables recycling and compounding in a single step with only one melting process.

The cooperation focuses on optimisation of mechanical properties through the addition of additives, fillers (e.g. talc, calcium carbonate, glass fibres), and stabilisers; high-performance degassing for removal of volatile contaminants, for example for food-grade applications, and production of highquality regranulates from PO films.

Material preparation is carried out using NGR’s C:GRAN technology, consisting of a cutter-compactor and a single-screw extruder. The material is then further processed in a Leistritz twin-screw extruder.

A joint recycling/compounding system, designed for approximately 300–500 kg/hour, has been installed at the NGR test centre in Austria for customer trials, the firms add.

Starlinger: reprocessing film waste from the food, fibres, foamed plastics

Elsewhere, Austrian machinery supplier Starlinger ’s new recoSTAR dynamic art recycling system is able to process a wide range of used plastics and scores with its increased output. Upgrades include a larger SMARTfeeder, more powerful drive motors with a lower energy, as well as simplified and shortened machine maintenance. The system is targeted at heavily contaminated post-consumer plastic waste that has high moisture content due to storage or after washing.

Bottle-to-bottle recycling is Starlinger's second focus at the trade fair, having received a positive “opinion” from the EFSA (European Food Safety Authority) for the recoSTAR PET recycling process, which is based on the new EU Regulation 2022/1616.

The new regulation significantly simplifies the approval process, as Starlinger can license the process directly to PET recyclers once the official approval has been granted.

The machines are said to consume 25% less energy and have a 15% higher output compared to the previous model. With the newly added extruder size of 265 mm these cover a range from 1,000 to 4,500 kg/ hour.

CMG to launch largest granulator in industry

CMG Granulators will introduce its EV Evolution Series for post-consumer plastics. It will debut the EV 92-220 model, said to be “the largest and most powerful granulator ever introduced in the industry”.

Designed for heavy-duty applications and massive volume streams, the EV 92-220 features a revolutionary cutting chamber architecture and advanced control integration, for enhanced reliability under extreme operational loads. It boasts an output capacity that is said to “exceed any existing machine in the marketplace”, though the company did not state the amount.

Features include energy utilisation by up to 50% compared to conventional granulators, achieved through cutting geometries, rotor design, and intelligent drive systems. Furthermore, features like the simplified/quick access to key mechanical components, self-lubrication systems and predictive diagnostic capabilities, minimise downtime.

It will also present the EV916 and EV616 models, solutions suitable for wet or dry granulation, with capacity from 2,000 to 5,000 kg/hour.

CMG says its EV 92-220 granulation system is the largest in the industry

Starlinger’s recoSTAR system, with new digital and technical features, is able to process a wide range of used plastics

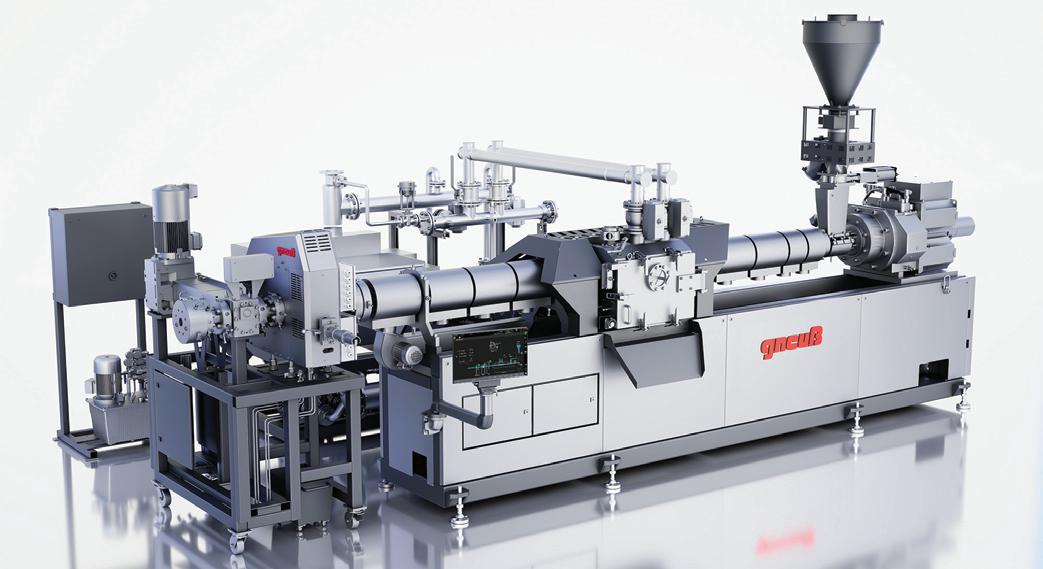

Revolutionising extrusion efficiency with Gneuss

In an era of global uncertainty, extrusion processors face mounting pressure to reduce costs while maintaining quality and output. Machinery maker Gneuss offers advanced melt filtration and extrusion equipment that can be integrated into existing lines to achieve efficiency improvements for cost savings and competitiveness.

Gneuss´ flagship model, RSFgenius, ensures steady melt pressure even when processing recycled material, thanks to its highly-efficient, automatic, integrated self-cleaning system, catering to a wide range of demanding applications. The filter elements can be automatically cleaned in situ up to 400 times and filter elements as fine as 10 micron (1.200 mesh) can be applied.

At Hall 9, Stand A2, Gneuss will display the RS Fgenius 330L, one of the best-selling (and one of the largest) models, with an active filtration area of 2.150 sq cm and filtration fineness of 75 microns for LDPE/LLDPE film recycling.

Retrofitting a fully-automatic RSF genius to an existing extrusion line, whether in a pelletising, sheet, fibre or pipe application, permits the use of more contaminated material and/or the use of finer screens without disrupting the process or reducing production yield. Every retrofit is tailor-made and usually without the need to move any existing equipment.

Three further Gneuss screen changer ranges will be presented: SFXmagnus, SFneos and KSF screen changers. The SFXmagnus is a process-constant screen changer for a wide range of applications; SFneos is a specialised screen changer that offers a high level of process and pressurestability, equivalent to that offered by the RSFgenius.

Lastly, the KSF range of screen changers is processconstant and designed with sensitive polymers in mind. It is mostly used in compounding where its customisable design for fast material and grade changes is a major advantage.

All three Gneuss screen changers are able to operate pressure and time-controlled and process-constant, with screen changes done without disturbing the process.

Patented rotary filtration system

RSFgenius 330

Multiple screw extruder for rPET processing

The MRS extruder is based on conventional single screw technology but is equipped with a multiple screw section for devolatilisation, allowing for efficient and gentle decontamination of the polymer melt.

The MRS extruder permits the processing of r-PET directly into high quality end products such as packaging sheet, strapping tape or filaments without pre-drying by using a simple and rugged vacuum system. All this is achieved by means of its patented processing section, which is a drum containing multiple satellite single screws, driven by a ring gear and pinion transmission.

The satellite screws rotate in the opposite direction to the main screw. This disproportionately increases the surface exchange of the polymer melt. A large opening for venting, exposing the full length of the satellite screws, is under vacuum. This provides unrestricted access to the polymer melt, the surface of which is constantly replaced at a very high rate by the counter-rotation of the satellite screws in the multiple screw section.

MRS extruder is based on conventional single screw technology but is equipped with a multiple screw section for devolatilisation

The surface area and the surface area exchange rate available for devolatilisation are far greater than in other extrusion systems. As the thermal and mechanical stress on the polymer melt is minimised, reclaim has excellent optical and mechanical properties, while in a simple extrusion step, harmful contaminants are thoroughly removed, assuring that the end product is safe for use in food contact applications.

Omni recycling machines for PET recycling

Gneuss’s MRS extrusion technology is known as an alternative for the reprocessing of contaminated materials like PET, PS, PP or PE. In combination with Gneuss’s rotary filtration systems, optimised vacuum technology, an online viscometer VIS and Gneuss measurement technology, customisable recycling lines tailor-made for a specific material can be engineered. As an option, light-weight or fluffy materials can be fed into the extruder via a 3C Rotary Feeder.

Omni recycling lines offer Several Letters of Non-Objection (LNOs) from a North American food safety authority, EFSA conformity and local approvals in Latin America confirm the decontamination efficiency of the technology.

As volatile contamination is removed efficiently in the MRS extruder under vacuum and solid contamination is removed by fine filtration in the rotary filtration system, Omni offers high quality and food compliant recycling in one simple, compact and sustainable extrusion step.

Typical applications for Omni machines include the processing of PET reclaim, such as bottle, sheet regrind or fibre waste, into high quality end products, such as thermoformed sheet (suitable for food contact), staple fibre, POY, FDY, BCF or strapping tapes.

In addition, a wide range of materials such as PS, PP, PE, or PLA can be recycled. The Omni series can also be used in the decontamination of post-consumer waste to produce direct food contact products such as HDPE bottle caps or milk bottles, coffee caps and for odour reduction and degassing of PA, SAN or other polymers.

Omni machine for post-consumer PET reclaim

At the K show, Gneuss will present the core of an Omni recycling machine: a MRS 110 extruder.

After the show, the complete line, including a water ring vacuum system and the fully automatic RSFgenius 90 melt filtration system, will be delivered to Cotnyl, an Argentinian manufacturer specialising in thermoformed plastic packaging.

Omni recycling machine with RSFgenius 90 and vacuum system to be shown at K show will be delivered to Argentinian packaging producer Cotnyl for food-grade rPET and PP sheet production

Designed to process 600 kg/hour of undried and uncrystallised PET or 400 kg/hour of PP, the system will produce high-quality thermoforming sheet for food packaging applications. The technology has already been approved for food contact by Argentina’s food safety authority Senasa. In addition to its compact design, as it requires little space and can be easily integrated into existing premises, Omni scores highly in terms of flexibility.

Machinery

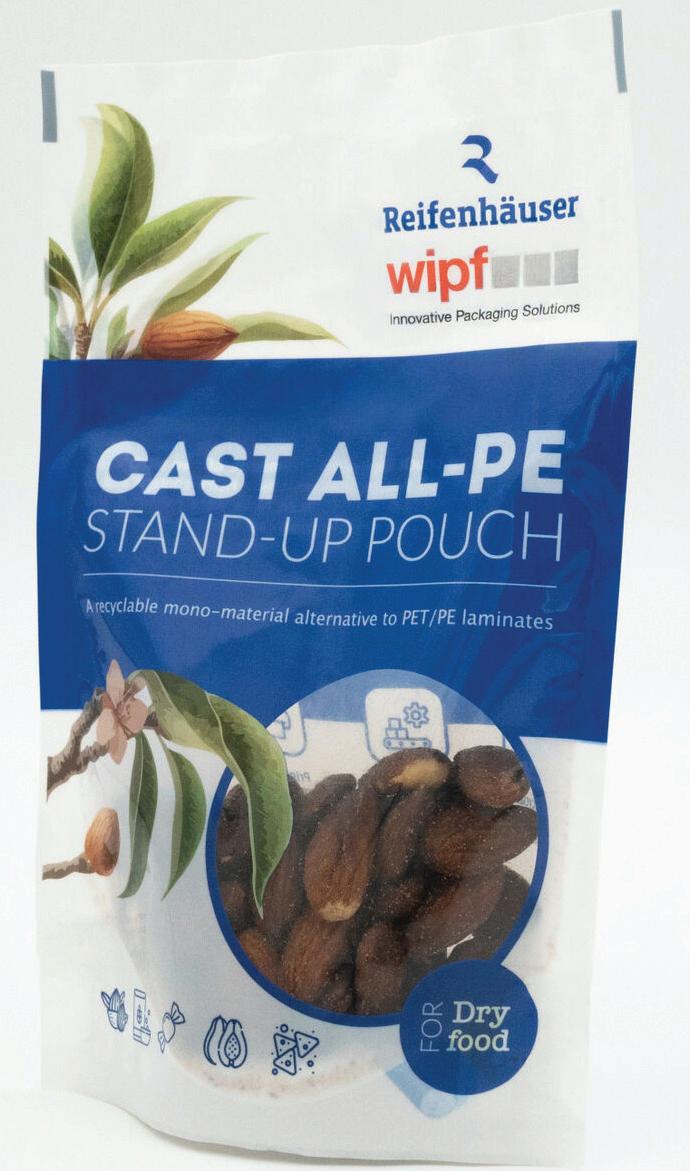

Reifenhäuser proposes machinery with higher outputs

Extrusion machinery maker Reifenhäuser will show how film manufacturers can be less dependent on skilled workers and increase profitability by demonstrating automated extrusion, smart data, and innovative training.

Since circular economy and CO2 reduction will be key topics at K, Reifenhäuser will also be presenting how recyclable products and products made from recyclate can be manufactured profitably. Thus, highlights include the latest MDO technology for recyclable mono-material packaging by film stretching. The firm has succeeded in producing the world's first process-stable 18 micron MDO PE film with further downgauging potential, through its patented MDO unit, Ultra Stretch, which is positioned directly in the haul-off of the blown film line and stretches the film from the first heat.

Other highlights are the Centro Freeze 2 secondary cooling system boasting 25% more output in a compact design and Aqua Cool that doubles output without extra operating costs.

The German firm is also presenting further developments of its patented PAM system (precise, autonomous, mechatronic) for flat film lines, with a second generation to be presented for the first time at K.

Meanwhile, to further expand its commitment to digitalisation, it will bundle its digital and learning solutions under the Reifenhäuser Next brand. The new business unit will focus on the integration of Industrial AI and will launch at the K three product categories: Next. AI, Next.Learning, and Next. Data.

Next.Data will ensure customers have access to all the data generated by the machine and make this actionable.

Next.Learning will facilitate on-boarding and help keep a company’s expertise within the system, once experienced workers leave the workplace, while Next.AI will bring inexperienced and unskilled workers up to speed on machine operations quickly.

According to Reifenhäuser, PP or PE monofilm becomes stiffer through the stretching process, so that PET film can be replaced in the packaging, making it fully recyclable.

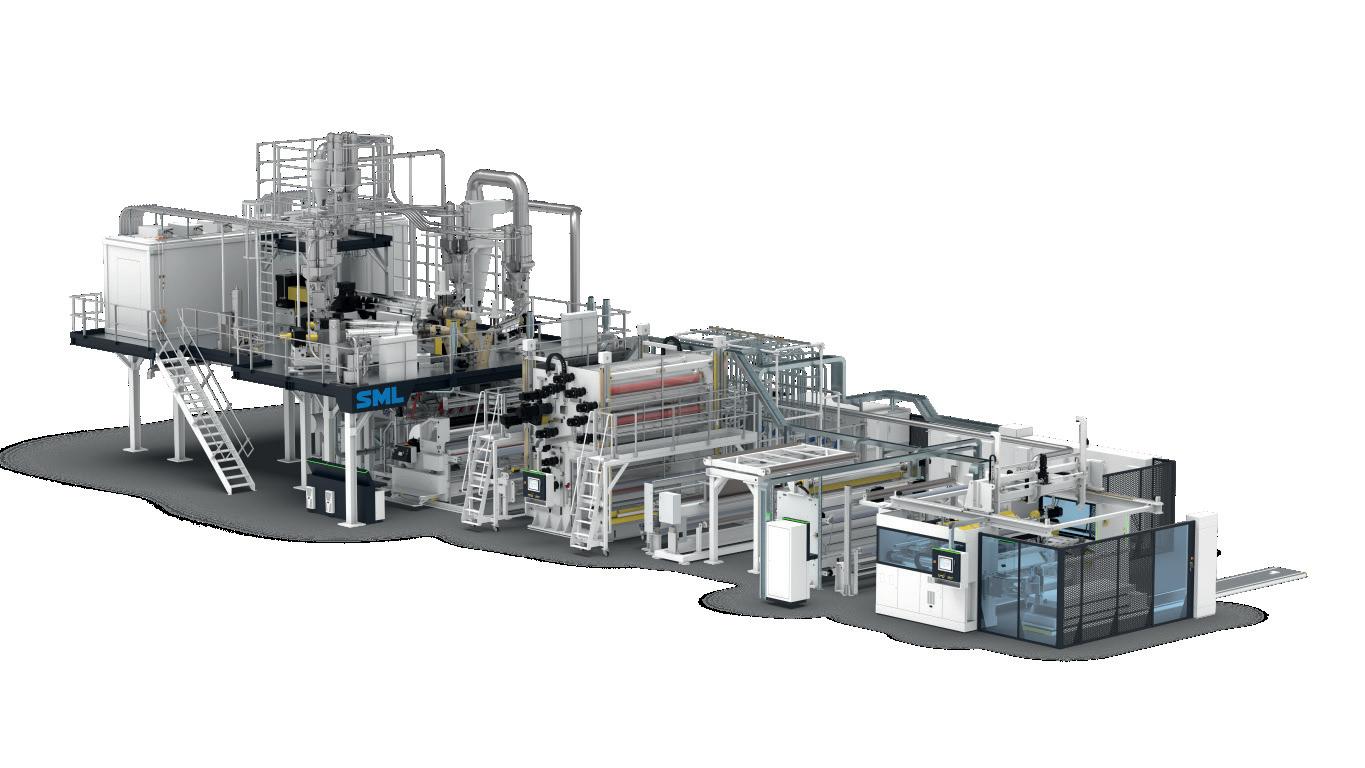

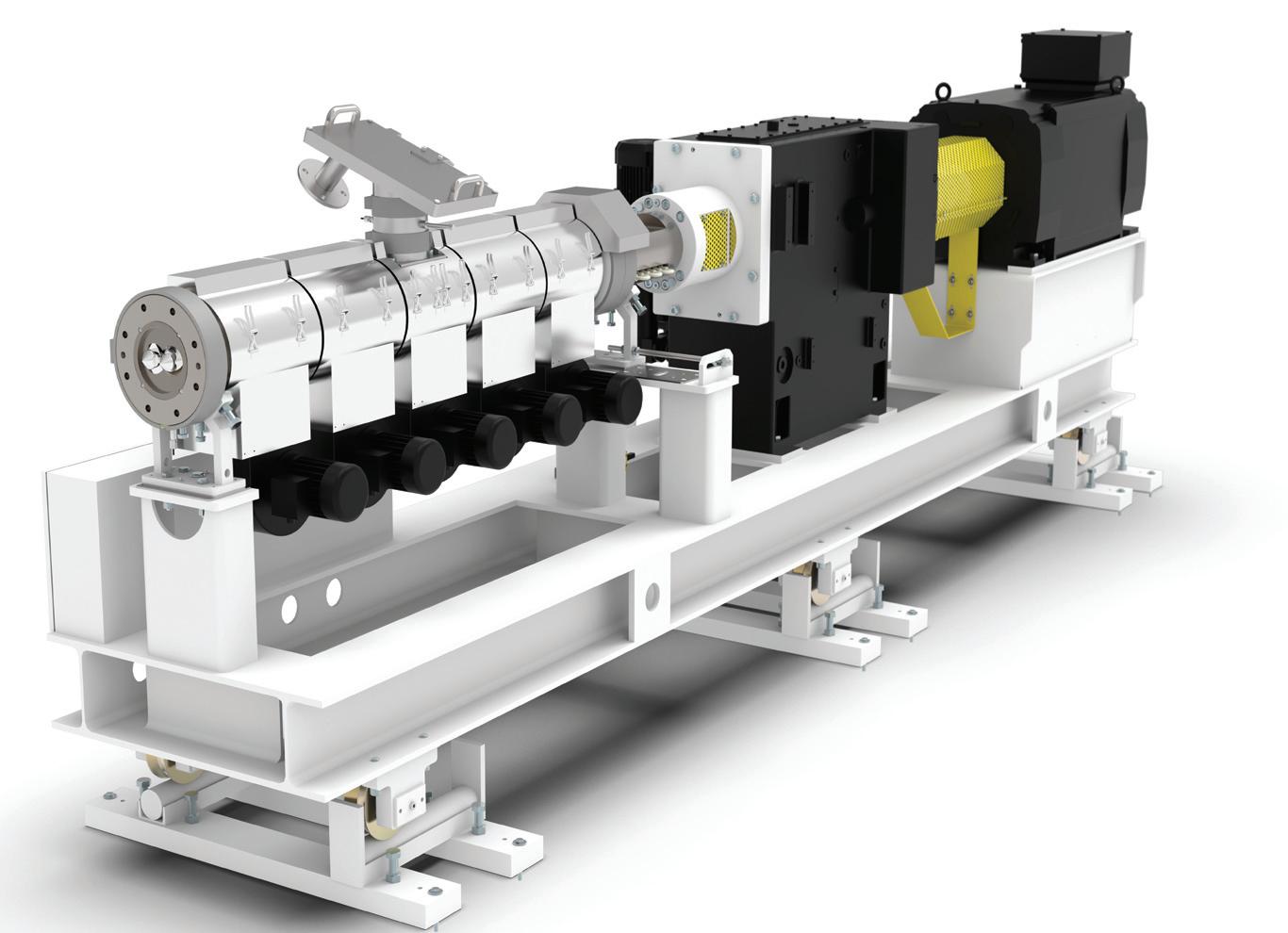

SML unveils TSE twin-screw extruder; Vertex multifilament spinning system and SmartCast stretch film line

Austrian firm SML is expanding its extruder portfolio with the introduction of a co-rotating twin-screw extruder (TSE), its answer to increasing demand for high-output capacities for polyolefins and polyesters. Compared to a large single-screw extruder with the same output capacity, the TSE has a shorter processing unit and, thus, a smaller footprint. Therefore, less heating power is required to maintain the barrel temperatures. Because of starve feeding the extruder drive operates at high torque over the entire output range, where it exhibits the maximum efficiency.

Additionally, the melt temperature can be controlled by adjusting the degree of filling. Extensive tests of the new TSE on a CPP line in SML’s technology centre have shown that the specific energy input (SEI) is 10-15% lower compared to a single-screw extruder. In terms of film quality, the gel count detected by a web inspection system could be reduced by up to 20% for a standard CPP film.

In combination with SML’s vacuum unit, the firm says it can offer a complete in-house extrusion solution for processing PET or PLA without pre-drying. Furthermore, the TSE enables high amounts of regrind or flakes to be processed as well as in-line compounding.

Meanwhile, in the field of spinning systems, SML is presenting its Vertex line to manufacture partially oriented yarn (POY) or fully drawn (FDY) yarn at low titres in higher volumes. Key characteristics are the optimisation for PET, the ability to manufacture a wide range of different yarn types, qualities and colours, as well as the line’s expandability. Beside PET, Vertex lines process PP and PA, too.

A clear strength of the Vertex series lies in the titre range between 50 to 1,200 den at an maximum output capacity of up to 270 kg/hour.

As well, two separate spinning heads enable the simultaneous manufacturing of two different products. Spinning positions can be adjusted flexibly. The Vertex line can be equipped with one or two extruders of different types and performance parameters, exactly tailored to the requirements of each individual customer. Thanks to its modular design, the line can be easily extended to increase capacity, scaling from 24 ends up to 32, 48, or even 64 ends as needed.

Another highlight at the SML stand will be the SmartCast stretch film line (6-up) that features a variety of equipment options for 2-inch hand rolls to high-quality machine rolls, 60 kg-jumbo rolls, and films with folded edges, among others.

Next to an overall face-lift, the new 3 m line concept boasts an ultra-compact footprint with newly arranged, parallel-oriented extruders. This arrangement places all motors, dosing units, and filters next to each other, facilitating faster and easier access for maintenance

and service. Pre-assembled extruder modules further streamline the installation process. In addition, all small electrical components are now housed in an E-container, which eliminates connection boxes in the hot areas of the extruder.

The SmartCast is equipped with the largest chill roll, with a diameter of 1,800 mm and the latest chrome-plated Smart 3.0 surface. The surface finish significantly reduces cleaning efforts for paraffin and other deposits that occur during production. The extended contact area at the chill roll allows for gentle cooling, which results in the highest elongation combined with superior tear propagation. Despite its size, it still offers the fastest cooling for SuperStiff products.

With the new SmartCast design, SML has further developed its coreless winding technology not only to improve production economy but also to save resources and improve sustainability. It improves the winding quality on the inside of the stretch film roll at optimised production speeds. Post-production shrinkage is reduced. But most importantly, quick switches between coreless winding and winding on rigid cores are achieved at the touch of a button. This unique key feature reduces waste

to zero during changeover and maximises production efficiency.

SML’s latest TSE twin-screw extruder, paired with a vacuum unit, is a complete in-house extrusion solution for processing PET or PLA without pre-drying

Catering to sustainability: MEAF, KraussMaffei, Kiefel, Herbold, Kreyenborg

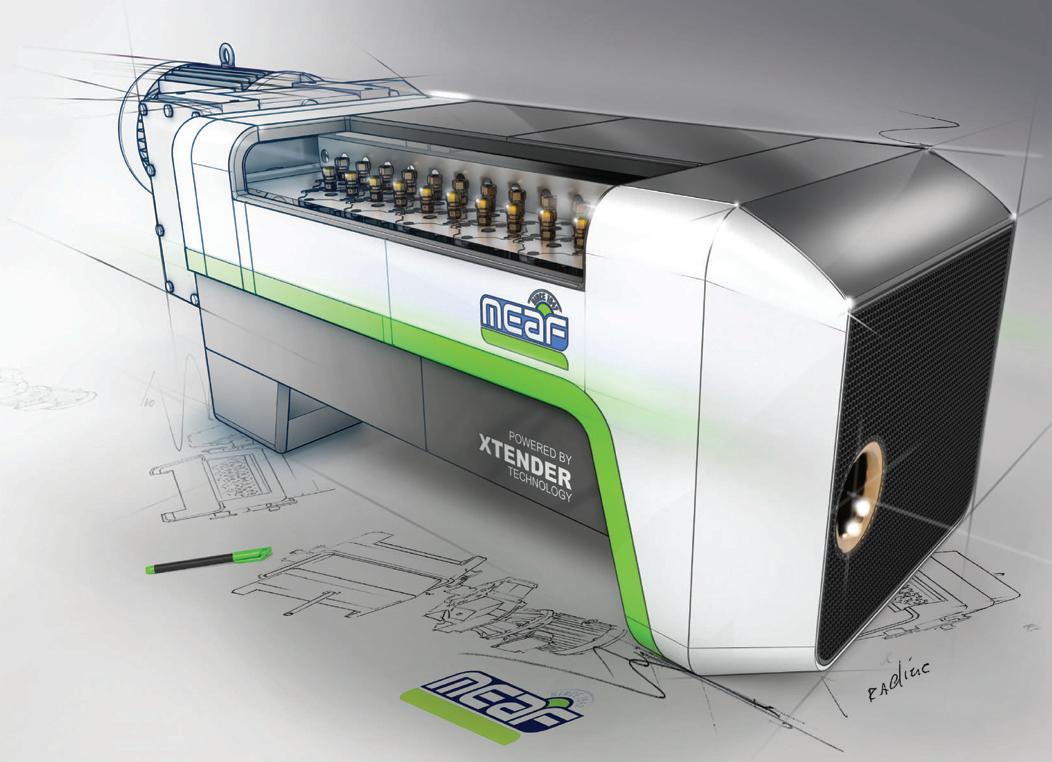

Dutch machinery firm MEAF Machines will launch its new Xtender polymer melt co-processing technology. Developed in collaboration with an Italian partner, it increases the intrinsic viscosity (IV) value of rPET using a patented process and can be (retro)fitted on both single-screw and twin screw extruders.

MEAF will launch its new Xtender technology, a polymer melt co-processing technology with mixing and degassing properties

Located directly downstream of the extruder, the melt is transported axially through a disc processor consisting of several wedge-shaped discs, where

contaminants and unwanted gases are extracted from the polymer by means of a vacuum. The temperature of the melt is regulated by heating elements and a core cooling element, while the setup includes two inline viscometers to detect and control the IV, as well as an adjustable feed for additives to accelerate the condensation reaction.

Kiefel’s latest thermoformer will showcase patent-pending film guide and ProSpacing system for higher outputs

Germany’s Kiefel is presenting its latest Speedformer KTR 6.2 Speed tilting machine, which will be shown producing rPET cups, tested in advance in collaboration with film partner Coexpan . Features include the patentpending SpeedGuard film guide and ProSpacing system, which ensures higher output even when handling varying product geometries.

K2025: Extrusion Machin

KraussMaffei’s twin-screw system based on the BluePower series for outputs of up to 12 tonnes/hour

Meanwhile, KraussMaffei Extrusion will present a twin-screw system based on the BluePower series for outputs of up to 12 tonnes/hour. Compared to conventional twin-screw systems, energy consumption can be reduced by up to 20%. The systems are compatible with standard SSP units and produce foodgrade rPET.

for deodorising regrind before or after the extrusion process (IR-Fresh system), which can be retrofitted on extrusion lines.

Kreyenborg’s IR-Clean, with FDA/EFSA approval, and IRD plus drying solution for decontamination of rPET

Herbold’s new mechanical dryer T 150-300

Auxiliary equipment maker Herbold Meckesheim , a brand of Coperion will present solutions for mechanical processing, including the new high-capacity mechanical dryer T150-300, with output of up to 2.5 tonnes/hour of film or 10 tonnes/hour of PET or rigid flakes, and the latest SMS granulator model.

Elsewhere, German firm Kreyenborg will be demonstrating both a continuous system and a batch version of the infrared rotary drum (IRD). It has developed the IRClean system in addition to the IRD’s classic crystallisation and drying. The rPET flakes are heated from the inside to the outside in just a few minutes, with decontamination performance of the IR Clean achieving a cleaning efficiency of over 95%.

It thus, meets both the EU/EFSA and the US-FDA criteria, with the treated material approved for food packaging. Kreyenborg has also developed a process

Blow moulding machinery for PET bottles: ASB; Cypet Japan’s Nissei ASB will introduce what it says is the world’s first 1.5-step machine capable of moulding double blow heat-set returnable and refillable PET bottles directly from resin. Combining the strengths of one and two-step moulding, ASB’s technology increases material crystallinity and reduces stress, enhancing thermal stability and resistance to environmental stress cracking. The bottle, weighs 90 g, 7.5% lighter than the industry standard, and uses up to 30% rPET, thus, meeting global standards with a 4.2 gas volume rating, making it suitable for carbonated soft drink brands and capable of more than 25 return and refill cycles.

In terms of single-stage Injection Stretch Blow Molding (ISBM) systems, Cypet Technologies says it will display of what it says will be the world’s largest blow-moulded 1,000 l PET bottles, made for an Indian company on its K185 ISBM machine. The Cyprusbased firm will also present its Pro Series, capable of producing bottles from 20ml to 50 l with an output up to 15.000 bottles/hour.

ASB’s

K2025: Machinery for P e T/rP e T

1.5-step double blow heat-set machine

Bio-based/biodegradable

Japan’s Asahi Kasei will display PA and SEBS compounds utilising a bio-based and biodegradable cellulose nanofibre (CNF), made from cotton linter. CNF-reinforced SEBS features softness, has low warpage and shrinkage, and good hydrolysis resistance, making it suitable for jigs & tooling or prosthetics & orthotics devices. As well, Asahi Kasei has developed PFAS-free low-friction Leona PA and will introduce a new grade, said to feature same lowfriction properties as fluororesins, making it suitable for sliding applications in automotive, robot parts, OA parts, and sporting goods.

Asahi Kasei’s SEBS material is suitable for skin and foam layers, moulded in one step by utilising a core back injection moulding process, with chemical bonding between all layers eliminating the need for additional adhesive layers

Engineering plastics major Polyplastics Group will unveil its latest advances in Durafide polyphenylene sulphide (PPS) and the development of bio-based p-hydroxybenzoic acid (PHBA), a key monomer for liquid crystal polymer (LCP). It is also focusing on PBT-to-PBT solvent-based recycling, which can segregate glass-reinforced PC/PBT into its GF, PC, and PBT constituents, thus allowing recyclability of waste PBT-based compounds. Another development of POM-toPOM chemical recycling facilitates 100% re-generation to engineering plastics and is currently in demo phase with a targeted launch in 2028.

Danish specialty materials manufacturer Palsgaard will highlight its Einar 987, a vegetable oil-based anti-fouling additive designed as a drop-in replacement for ethoxylated amines for PP/PE polymerisation processes. The product is food-contact approved, effective at low dosage levels (100–300 ppm), and delivers the same reactor efficiency and product quality while eliminating toxic legacies. It offers resin makers an alternative solution that aligns with anticipated changes in chemical safety requirements.

Palsgaard has a sustainable anti-fouling additive for PP/PE polymerisation

Fraunhofer’s new PBS types can be processed stably using standard blow moulding and injection moulding machinery

Fraunhofer IAP has produced 20 new types of polybutylene succinate (PBS) and scaled from the lab stage to a 100-kg scale, with 3 tonnes of PBS already produced. Melt stability of the materials has been improved with temperature stability of over 200°C. Together with industry partners Sauer GmbH and Gramß GmbH it produced a sports water bottle and cap, using blow/injection moulding. It adds that PBS can be processed under real conditions efficiently and with mechanical properties.

Germany’s BASF at K2022 introduced its LowPCF and ZeroPCF portfolios, to reduce the Product Carbon Footprint (PCF) by a minimum of 30%, through the use of renewable electricity, low-emission steam and renewable raw materials, in a mass balance approach. A current example is Vaude ’s bike bag using Ultramid PA6 ZeroPCF, said to be the first in the industry to achieve a CO2 footprint of net zero. Building on this, BASF has now launched an improved reduced PCF product range, rPCF, for its engineering plastics and TPUs.

Vaude’s bike backpack is based on BASF's ZeroPCF, a sustainable polyamide

US materials firm Dow will showcase D-Pak cartons produced in collaboration with Elopak and Orkla Home and Personal Care ( OHPC ), which offer a mix of rPE and biocircular (renewable) polymers. In the consumer sector, Dow will be showcasing its collaboration with Guerlain, utilising Surlyn Ren Ionomers for La Petite Robe Noir perfume caps, while in the wire and cables sector, it will highlight its Revoloop recycled resins (using PCR material) for cable jackets.

Elopak, its longterm customer Orkla, and Dow have rolled out a new line of D-Pak cartons, made from a mix of rPE and renewable polymers

Packaging

OQ , Oman’s energy group, has introduced 17 new polymer grades over the past year including six PP impact copolymers for rigid packaging such as thinwall packaging, housewares and durables, offering flow and stiffness-impact balance; four PP random copolymers with enhanced transparency and organoleptic performance for housewares, closures, and food containers. Furthermore, it also introduced PE graded, including a rotomoulding grade (Luban LL-8446.21), developed for water storage and road safety applications delivering impact, durability and UV resistance.

OQ has launched new grades for rigid packaging applications; housewares, closures, and food containers and a rotomoulding grade for water storage and road safety applications

With stricter EU rules under the Packaging and Packaging Waste Regulation (PPWR), Ineos Styrolution, on the other hand, has launched its latest circular packaging breakthrough: sour cream cups made with 30% rPS, in collaboration with development partner Aldi and Unternehmensgruppe Theo Müller, scaling sustainable food packaging for mass-market use. It has also commercialised its 100% bio-attributed Styrolution PS ECO 158K BC100, with food trays using this bio-based PS made available on the shelves of the Japanese market through collaboration with a well-known retail franchise.

Ineos

ExxonMobil will have a range of solutions on display, many of which were created in collaboration with machine manufacturers, converters, and brand owners

US materials firm ExxonMobil will highlight solutions, many of which were created in collaboration with machine manufacturers, converters, and brand owners. These include mono-material PE solutions designed for recyclability and/or downgauging opportunities, such as MDO cereal pouches from Colines , freezer pouches from W&H , silo bags from Armando Alvarez , pet food bags from Bandera , and vacuum skin cheese packaging from Alpine. Other solutions incorporating PCR content include cast stretch film from Erema , block bottom valve bags from Selene , compression packaging from Optima, high tenacity stretch film from W&H, stretch hood films from Reifenhauser, and silage covers from RaniPlast. it will also bring product samples and film rolls to the show, including its monomaterial PE solutions designed for recyclability, solutions incorporating PCR content, and the Exxtend technology for advanced recycling.

TotalEnergies/SML have produced films for barrier stand-up pouches and deep-freeze bags

Recycling/Sustainability

Asahi Kasei’s recycling technology enables the recovery of continuous carbon fibres from carbon-fibre-reinforced plastic (CFRP) pressure vessels used in automobiles. Utilising electrolysed sulphuric acid, the process completely decomposes the resin matrix while preserving the carbon fibres' original strength and continuous structure. At K, it will show over 200 m of recycled continuous carbon fibre.

has commercialised a 100% bio-attributed Styrolution PS for food trays in Japan

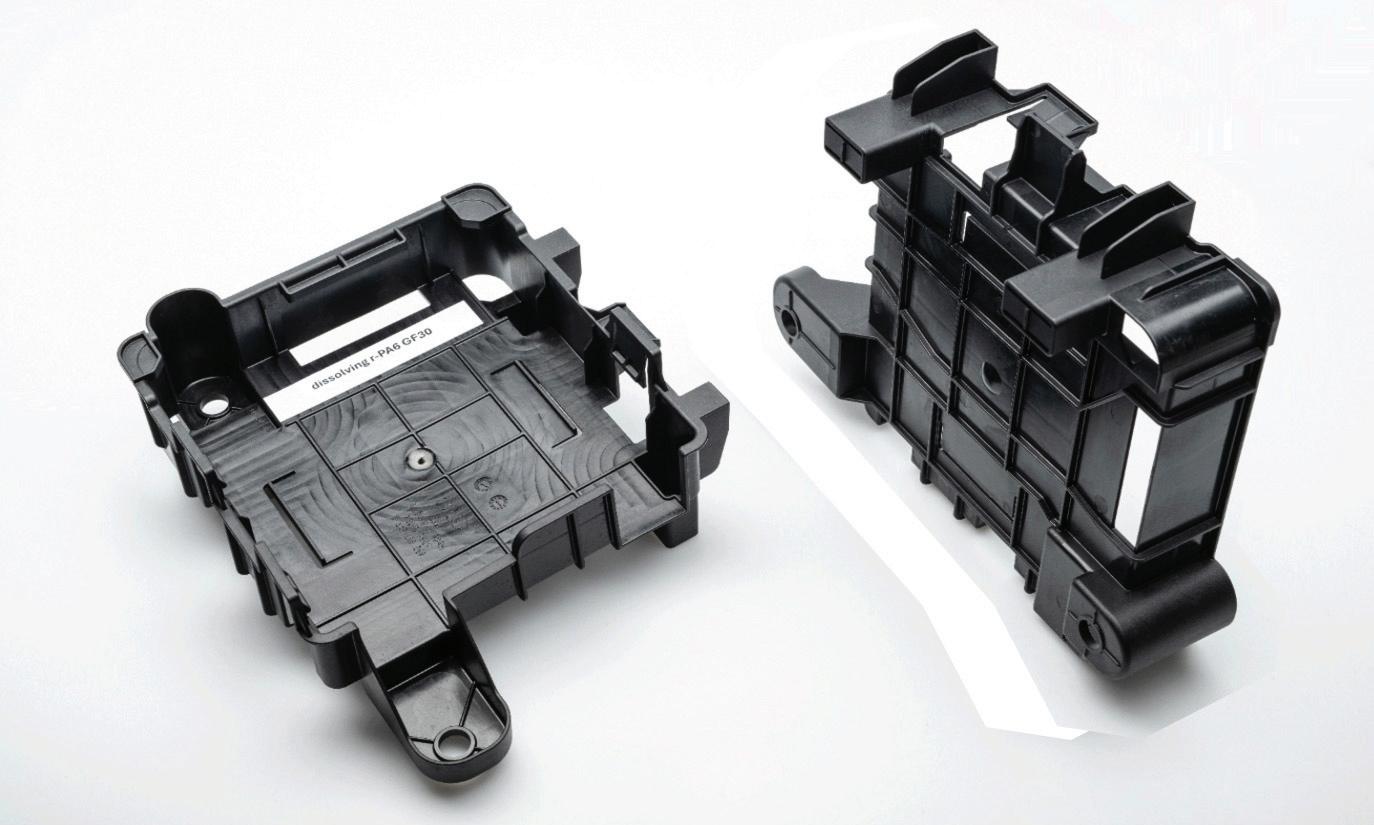

PA supplier Domo Chemicals ’s pilot project, with Audi AG and Fraunhofer Institute , will show PA6/PA66-based parts moulded using 30% PCR materials from end-of-life vehicles, meeting OEM requirements. It will also present ISCC Plus certified-Domamid MBB, a mass-balanced, bioattributed PA6 with up to 69% bio-attributed content.

Domo Chemicals’s pilot project, with Audi and Fraunhofer Institute, will show PA6/PA66-based automotive part moulded using 30% PCR materials

Meanwhile, BASF, in collaboration with machine firms Krauss Maffei, Rampf and Liebherr, is developing a chemical recycling process to return PU to the same material cycle. In the depolymerisation process, recycled polyols are produced, which can be used to manufacture new PU rigid foams as insulation material in refrigerators.

German compatriot materials firm Covestro is also developing chemical recycling of PU mattress foam, under the Evocycle CQ brand. This pilot contributes to a broader “Circular Foam” collaboration involving 22 partners, with the goal of recycling 1 million tonnes of PU foam and saving 2.9 million tonnes of CO2/year by 2040.

Elsewhere, to counter challenges of plastic waste in hospitals, Saudi Arabia’s Sabic says it has worked with two hospitals in Belgium and Netherlands, by demonstrating the feasibility of recycling used medical plastic back into the medical materials stream. Converted to pyrolysis oil

K2025: Materials

in an advanced recycling process, it delivered circular feedstock for Sabic’s production of Trucircle polymers in medical-grade quality with the same performance, purity and physiological safety as virgin-based medical-grade polymers, it adds.

Another company involved in recycling is chemical firm LyondellBasell . Its proprietary MoReTec (molecular recycling technology) advanced recycling technology, being built at its Cologne hub in Germany by 2026, will enable it to convert post-consumer plastic waste into feedstock for the production of new polymers. The pyrolysis oil and pyrolysis gas from the process can be used as a feedstock for new plastic materials under the CirculenRevive brand for use in a range of applications, including medical and food packaging.

Flame-retardant materials

Germany’s KRAIBURG TPE will focus on two new FC/CM3/ AD1 series compounds that comply with both the European Regulation (EU) No. 10/2011 and the US FDA. These were specifically developed for TPE applications with contact to fatty foods or cosmetics. In addition to their processability in multi-component injection moulding, the compounds offer properties such as a pleasant feel and robustness.

Another product highlight will be compounds from the FR3 series, or the third generation TPEs with improved flame retardancy, meeting all requirements of the European standard for railroad applications DIN EN 45545-2 R22 HL3 and R23 HL3. These materials have properties that make them ideal for fire protection applications, including PP adhesion and processing in standard injection moulding and extrusion processes.

Meanwhile, Spain’s Tolsa will highlight its range of Adins flame-retardant additives, which have emerged as a halogen-free and antimony trioxide (ATO) free replacement for a range of matrices including PVC, PA, PP, PE and rubber. Adins products not only replace ATO but also improve flame retardant properties across multiple axes, including smoke suppression, anti-dripping, and heat release reduction. This fire enhancement enables customers to not just substitute but upgrade the fire performance of their material in a sustainable way, adds Tosla.

Covestro and Recticel have shown that a flexible foam sample can be produced from fully recycled polyol and TDI from used mattresses

Kraiburg’s new FC/CM3/AD1 range has been specially developed for contact with fatty foods and cosmetics

Injection Moulding Asia

Making conductive plastics effectively and chemical-free

It’s mouldable, biocompatible and glitters like gold.

Plastic that can conduct an electric charge is a material that can be used for everything from sensors that can monitor our health to self-cooling clothing or electronic adhesive plasters that can be applied to the skin and send data directly to a mobile phone.

Researchers at Chalmers University of Technology in Sweden recently presented a ground-breaking ‘recipe’ that makes it easier to manufacture this kind of soughtafter electrically conductive plastic in larger quantities – without the use of harmful chemicals, and in a much more cost-effective way.

“Once higher production volumes are achieved, it is possible to work with the material in a completely different way. Larger quantities are needed to enable the development of a range of applications, for example in biotechnology, energy storage, and wearable electronics,” says Christian Müller, Professor at the Department of Chemistry and Chemical Engineering at Chalmers and co-author of a study recently published in Science Advances.

In the lab in the Chemistry building at Chalmers, doctoral student Joost Kimpel is able to easily mould the gold-coloured material with his gloved fingers.

Currently, the market price for just 100 g of this type of conductive plastic would be around US$100,000 – about ten times as much as actual gold. But for the human body, it is in fact the absence of metals that makes this material so valuable.

The basic ingredients for the conductive plastic originate from aromatic compounds thienothiophene and bithiophene, which are the building blocks of many organic semiconductors. These substances are mixed in the benign solvent N-butyl-2pyrrolidone in the presence of a palladium catalyst (Photo from Chalmers University)

“While some metals can corrode in humid environments, conductive plastic is an organic material that our bodies are comfortable with. The material is compatible with the body’s own tissue, while also being a semiconductor. There’s also an environmental advantage in that you don’t need to use the rare earth elements required for today’s electronics,” says Kimpel, first author of the new study.

Electronic adhesive plasters with connectivity

There is great interest in conductive plastics or conjugated polymers, the scientific term for them, and the applications are many, not least in biotechnology.

According to the researchers, these applications could include sensors that monitor medical conditions, provide information about fitness and health, or adjust the delivery of drugs for diseases that are difficult to treat.

With this kind of technology, the body can be connected to other wearable electronics, and even to our mobile phones.

Conductive plastics can also be used for various kinds of implants or be 3D-printed to create electronic adhesive plasters that can detect an infection, for example. It is for this reason that research into conductive plastics is being carried out in many parts of the world.

Unexpected lab results behind the latest advances

The key to the new manufacturing method was discovered quite serendipitously during a routine experiment in the lab. When a chemical reaction was happening too fast and the resulting plastic was reaching its final state too quickly, the idea came up of reducing the heat in the process.

This was what led to the discovery that the material can be produced at room temperature in significantly fewer steps, with lower energy consumption, and without toxic chemicals.

“The ingredients in our ‘recipe’ are benign and can be used safely in an industrial setting, unlike the highly toxic substances that must be used to produce many conjugated polymers today. Avoiding toxic chemicals in the production process means a safer work environment for staff, gives the consumer peace of mind, and facilitates recycling. In addition, the costs can be radically reduced, as toxic substances require advanced handling, especially in terms of protective procedures, storage and the disposal of residues,” says Kimpel.

Great

interest in the new method

Even though the study was published very recently, the researchers have already noted a great deal of interest, not least from the many researchers at other universities who have contacted them. Now they hope that this new production method will facilitate making conductive plastics more widely available.

Injection Moulding Asia

Electrically conductive plastic, which is known as a conjugated polymer, can be used for everything from energy conversion and storage to wearable electronics and biotechnology

(Photo from Chalmers University)

“An important discovery made in this study is that the production method makes the conductive plastic much better at conducting an electric charge, which also means

BASF, Mocom offer recycled alternatives

that the electronics that use this kind of material can be made more powerful,” says Müller.

The next step in this research will be to continue working on a method that makes it possible to produce even larger volumes – continuously and with exactly the same results every time.

Conductive plastics as organic electronics

One important ingredient for plastics that can conduct electricity are conjugated polymers, a type of semiconductor with properties that make it possible to produce a new type of technology known as organic electronics. The latter can be used in many different applications such as energy conversion and storage, wearable electronics, electronic textiles, and biotechnology attached to or close to the body.

Unlike inorganic materials such as metals, conjugated polymers can be made flexible and soft. They can be applied to surfaces and used to manufacture solar cells, and are compatible with liquids such as sweat and blood, which is important for bioelectronic applications.

Research to make conjugated polymers stable and improve their conductive properties has been conducted for decades.

Injection Moulding Asia

German materials firm BASF will showcase a Siemens circuit breaker using plastic components made from biomethane derived from recycled biowaste; biomass-balanced (BMB) Ecoflex polybutylene adipate terephthalate (PBAT), used in the compounding of biopolymers. Both materials offer the same quality and performance as conventional plastics and the material changeover in the Sirius 3RV2 circuit breaker production will reduce the emission of carbon dioxide equivalents by around 270 tonnes/year.

Siemens and BASF have announced the first electrical safety product to include components made from biomass-balanced plastic

Mocom has launched bio-based materials compounds for light guides/ bezels in vehicles

With the mass balance approach, various alternative raw materials, such as biomethane, bio-naphtha or pyrolysis oil, can be integrated into the value chain. The bio-naphtha and biomethane used by BASF are certified as sustainable according to established systems such as ISCC Plus and REDcert.

Meanwhile Germany’s Mocom Compounds will present biopolymer-based materials for lighting applications. With the new grades Alcom LD BIO HTC and LG BIO HTC compounds were specifically developed for light guides, bezels or decorative interior elements in vehicles.

Injection Moulding Asia

The materials also meet the requirements for outdoor applications and offer resistance to chemicals and media compared to standard polycarbonate. They are free of Bisphenol A, demonstrate birefringence levels comparable to PMMA and support design flexibility with light diffusion and transmission properties.

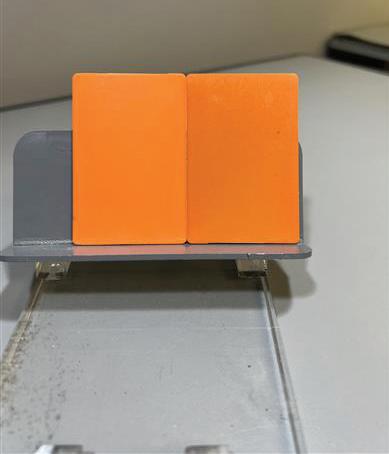

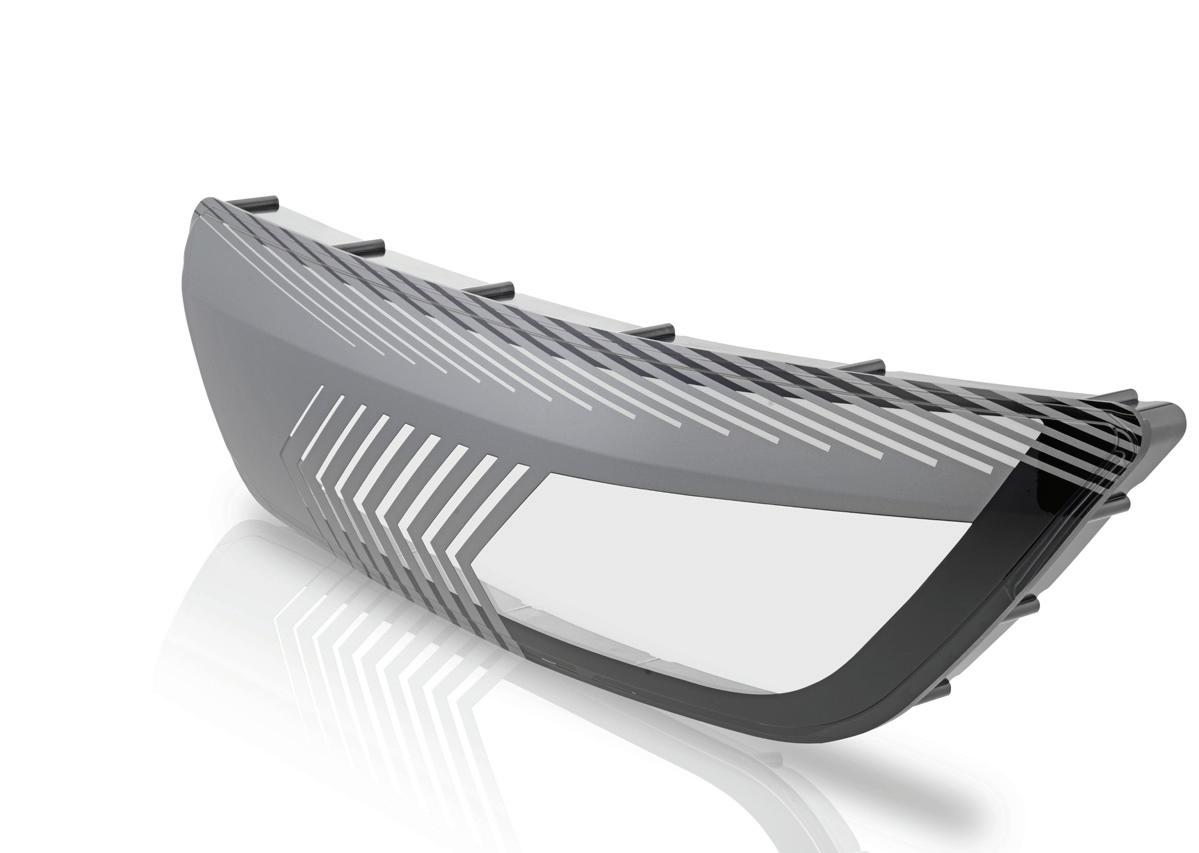

Debuts: Syensqo takes to orange PPA for EV parts; Envalior’s mobility/powertrain grades

Speciality chemicals firm Syensqo that will showcase for the first time at K2025, following its spin-off from Solvay in 2023, will launch Amodel flame-retardant polypthalamide (PPA) HFFR-4133 Orange (OR), which is distinguished by its vibrant orange colour. Targeted at critical electric vehicle (EV) components, such as connectors and busbars, it offers immediate visual identification of live high-voltage components.

Syensqo’s Amodel HFFR-4133 OR as moulded on the left, and after 1,000 hours at 125°C on the right under D65 light source

Syensqo adds its Amodel PPA not only meets but exceeds these safety expectations by retaining its bright colour even under prolonged heat exposure, ensuring compliance with industry standards such as ISO 6469-3, IEC 60664, and relevant UL specifications. It is also hot water mouldable and boasts a V0 rating, making it a choice for high voltage automotive applications. Meanwhile, engineering materials firm Envalior , which will also make its debut at K2025, will focus on a new Pocan PBT grade designed to meet the requirements of future highvoltage connectors in mobility as well as next-generation E&E components, supporting the upcoming transition of AI data centres to 800V HVDC power supplies.

Avient Corporation has additional grades in its portfolio of recycled-content PC/PC blends, with 35% to 98% PCR content, developed for the E&E industry in Europe, Middle East, Africa and Asia. Edgetek REACH and RoHS-compliant solutions add on to 20% to 70% recycled content in previously launched grades, for device enclosures, sockets, and other aesthetic or structural E&E components intended to withstand harsh environments