Resource Circularity

Reimagining Cities as Regenerative Ecosystems

Preface

Executive Summary

Introduction

Policy Frameworks

Market Analysis

Ecological and Environmental Impact

Technical Analysis and Guidelines

Design Implementation and Human Experience

Conclusions and Recommendations

Appendices

Appendix A: Publication List

Appendix B: Sources

Appendix C: Supplementary Data

Acknowledgments

Funding for this project has been provided by Agriculture and Agri-Food Canada through the Agricultural Clean Technology (ACT) Program

Matching funding for this project was provided by Perkins&Will and the BC Centre for Agritech Innovation (BCCAI).

The research team would also like to thank the following organizations for their valuable partnership and support. Their contributions were integral to the success of this project.

Agritecture

Bubbly Dynamics (The Plant)

City of Vancouver

Framlab

kono Deisgns

Quanto Tech Ltd

Simon Fraser University

The Growcer Inc.

University of British Columbia

University of Oregon

University of the Fraser Valley

Contributers

Perkins&Will Team

Mohamed Imam, Senior Research Lead

Yehia Madkour, Director of Innovation

Cheney Chen, Senior Research Lead

Amy Brander, Regenerative Design Advisor

Tyrone Marshall, Senior Research Lead

Nicole Pfeifer, Sustainable Design Advisor

Juan Rovalo, Director of Ecology

Tatiana Kaida, Designer III

Sam Ibrahim, Urban Designer II

Janna Fahmy, Designer I

Brainard Amay, Marketing Coordinator

Perkins&Will Review

Leigh Christy, Director of Research, Principal

Kimberly Seigel, Research Manager

Kathy Wardle, Regional Director of Regenerative Design, Principal

Jesce Walz, Senior Research Lead

Enlai Hooi, Head of Innovation

Myer Harrell, Senior Regenerative Design Advisor

Phaedra Svec, Director of Regenerative Design

Workshops Team

Aaron Knorr, Senior Architect

Aik Ablimit, Senior Architect

Alex Buss, Senior Architect

Cillian Collins, Senior Architect

Eli Wolpin, Senior Architect

Fargol Moshiri, Technical Coordinator

Jason Leblanc, Director of Urban Design

Johanna Becker, Architect III

Kevin Casey, Architect III

Laurence Rumble, Senior Project Manager

Manuela Londono Suarez, Senior Regenerative Design Advisor

Marco Mandelli, Project Architect

Negin Shakibi, Senior Urban Designer

Shiva Honarvar, Sustainable Design Advisor II

Stephanie Matkaluk, Project Architect

Academic, Industry & Policy Advisors

University of the Fraser Valley (UFV)

Alesandros Glaros, Vertical Agriculture Research Lead

Charmaine White, Assistant, Food and Agriculture Institute

Stefania Pizzirani, Associate Director, Food and Agriculture Institute

University of British Columbia (UBC)

Bridgette Kelly, Architecture Dual-Degree Student

Daniel Roehr, Professor and Chair, Landscape Architecture

Kevin Wong, Architecture Dual-Degree Student

Robert Ferguson, Architecture Dual-Degree Student

Simon Fraser University (SFU)

Zohreh Hassanpour Kahnamouei, Designer at Computational Design Lab

Halil Erhan, Professor, Director of Computational Design Lab

University of Oregon (UoO)

Aidan Teppema, Graduate Research Fellow

Gwynne Mhuireach, Assistant Professor

University of Guelph

Ajwal Dsouza, Ph.D. Candidate, Controlled Environment Systems

BC Centre for Agriculture Innovation (BCCAI)

Laila Benkrima. Ph.D., Agronomist Consultant

Micheal Bolu, Project Manager

Alycia Van der Gracht, Founder, Quanto tech

Chadd Bauman, Co-Founder Circular Harvest

Corey Ellis, Co-Founder & CEO, The Growcer Inc.

David Ceaser, Lead Agronomist, Agritecture

Emily Van Halem, Social Planner City of Vancouver

Erin Nichols, Senior Project Manager City of Vancouver

Henry Lau, Social Planner City of Vancouver

Jason Wegman, gökotta studio + lab

Kristina Zalite, Landscape Architect, Zale Design

Kyle Born, Co-Founder Circular Harvest

Laura Marie Neubert, Founder of UpFront

Peter Van der Gracht, Quanto tech

Sayon Chandrakanthan, Founder of Advanced Autoponics

List of Figures

Figure

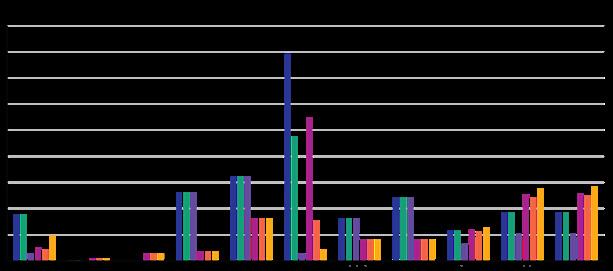

Figure 3: Food systems contribution to global anthropogenic GHG emissions. Source EDGAR-FOOD,

Figure 4: Food waste comparison across North America, MENA, and Latin America. Adapted from World Resource

Figure

Figure 7: Farming systems examined in this report. Adapted from Dorr, Goldstein, Horvath, Aubry, & Gabrielle, 2021 and Benis, Gashgari, Alsaati, & Reinhart, 2018.

Figure 8: Soil-based green roof types and requirements. Adapted from Gundula Proksch,

Figure 9: Urban agriculture taxonomy. Adapted from Dorr, Goldstein, Horvath, Aubry, & Gabrielle, 2021 and Benis, Gashgari, Alsaati, & Reinhart,

Figure 34: Pasona Group Headquarters, Tokyo, Japan. Interior farming activities. Image courtesy of Kono Design..

Figure 35: Gotham Greens, Davis, CA. Image by Jim Heaphy (Creative Commons).. .........................................................................87

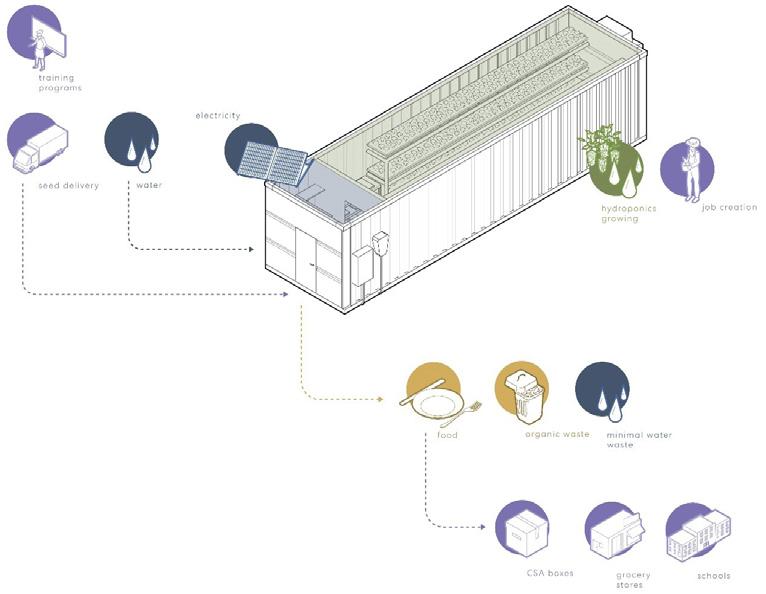

Figure 36: Systems diagram of The Growcer Inc. modular farm..

Figure 37: The Growcer Inc.

Figure 38: The Growcer Inc. modular containar farm interior hydropnic system..

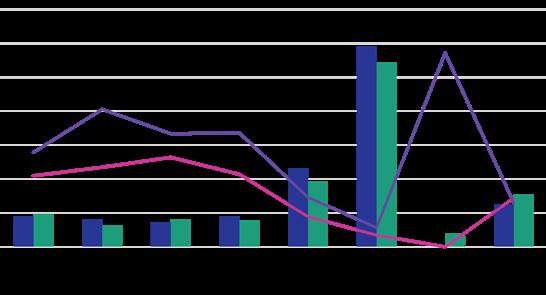

Figure 39: Comparative performance of vertical farms vs. greenhouses for lettuce and tomatoes across key operational categories in Vancouver, BC.. .......................................................................................................................................................................

Figure 40: Comparison of net profit and payback periods (in CAD) for vertical farms vs. greenhouses across selected cities..

Figure 41: Operational cost comparison (in CAD) for vertical farms and greenhouses by crop and city.. ......................................

Figure 42: The carbon cycle. Adapted from Proksch, 2017..

Figure 43: Perkins&Will, Skeena Terrace, Vancouver, BC. Rooftop urban farming integrated into the BC Housing project.. ........

Figure 44: Perkins&Will, systems diagram of Skeena Terrace, Vancouver, BC..

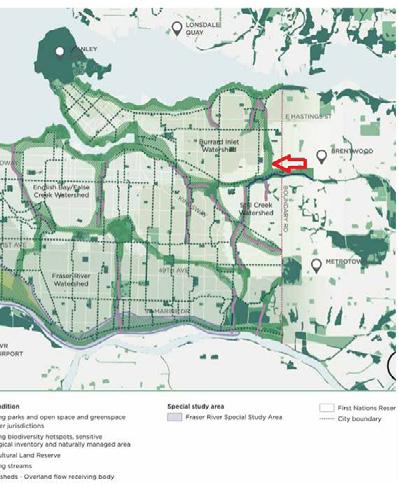

Figure 45: Vancouver Plan, 2022, future ecological corridors with Skeena Terrace highlighted.. ....................................................

Figure 46: Tree retention plan for Skeena

:

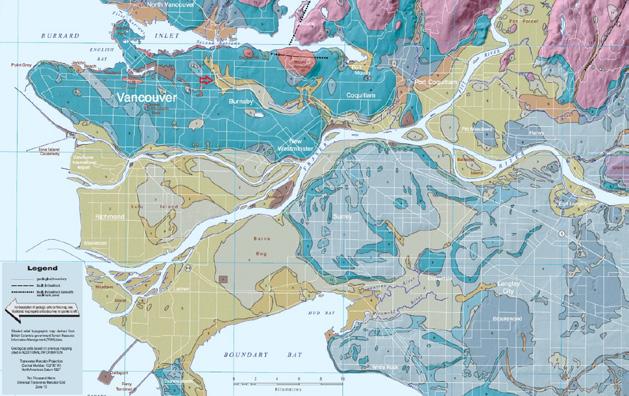

Figure 48: GeoMap section showing Vancouver, BC. Skeena Terrace indicated by red circle. Source Turner & Clague,

Figure 49: Food miles and sourcing for British Columbia. Tomato and lettuce imports from the USA. Source Canada Food Flows,

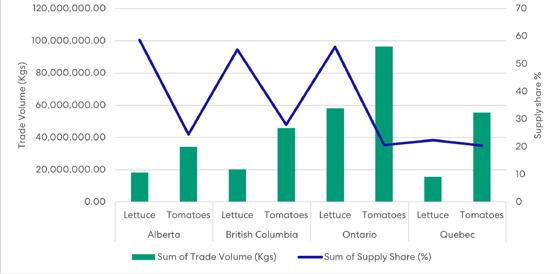

Figure 50: Total trade volume (kg) and supply share of lettuce and tomatoes. Source from Canada Food Flows, 2024..

Figure 51: Perkins&Will, Skeena Terrace, Vancouver, BC.

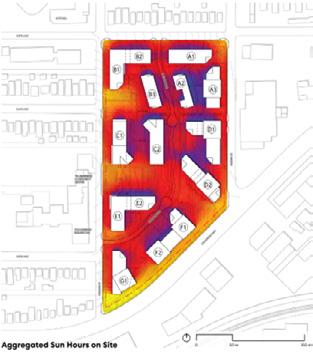

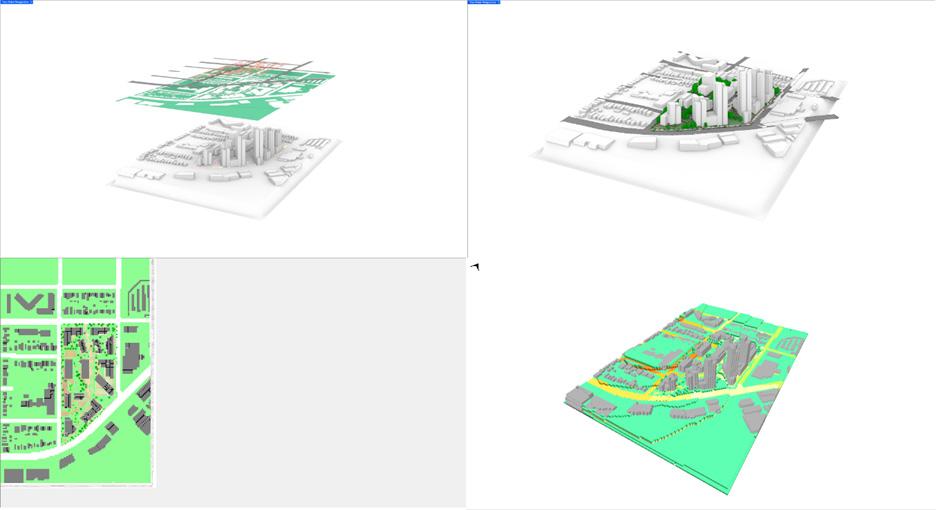

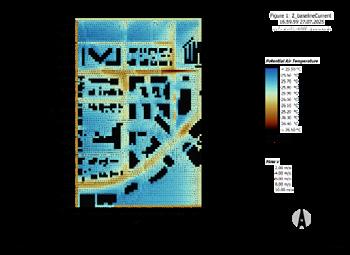

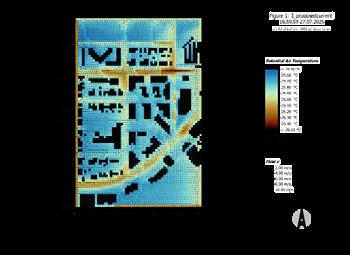

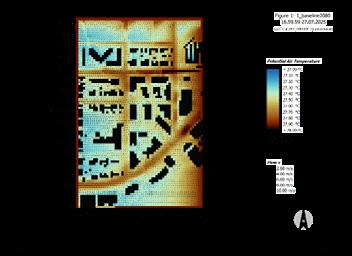

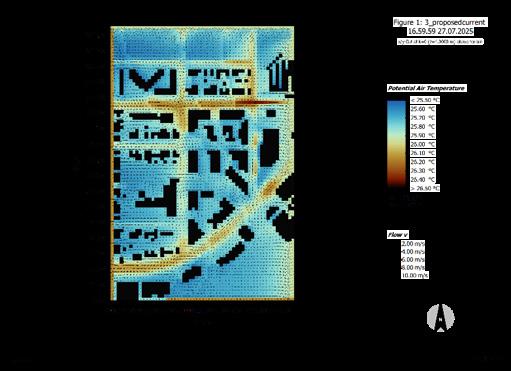

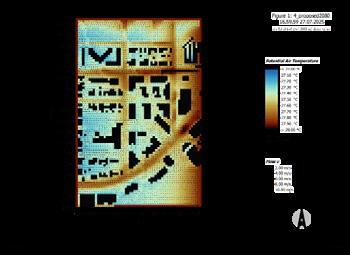

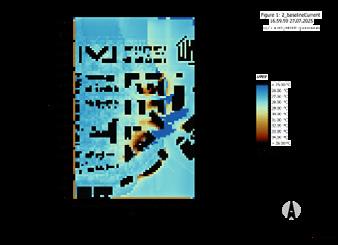

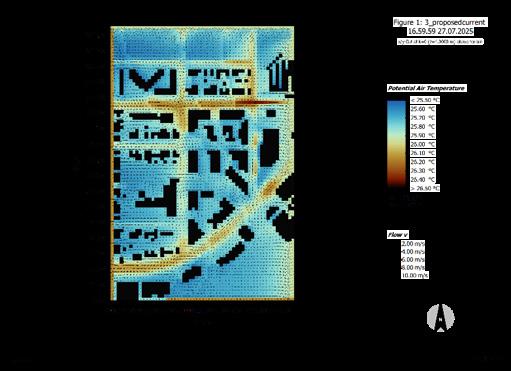

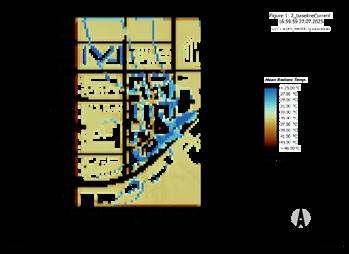

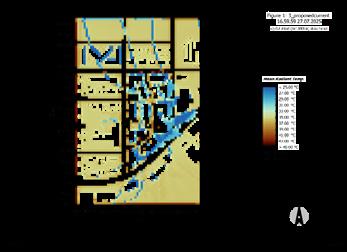

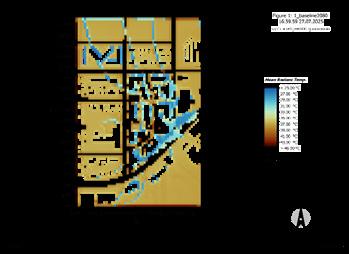

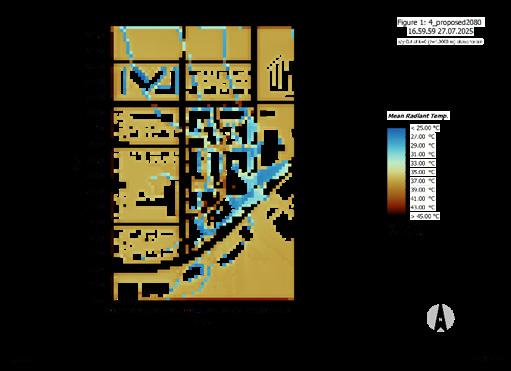

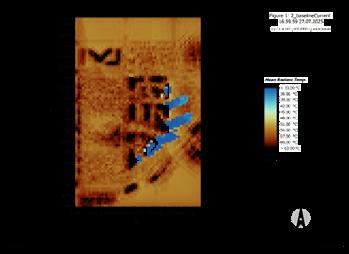

: Temperature

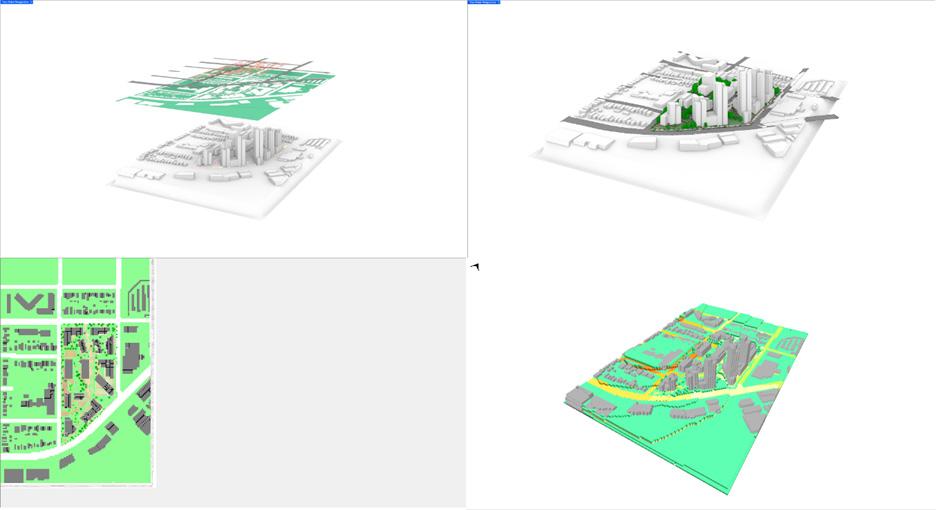

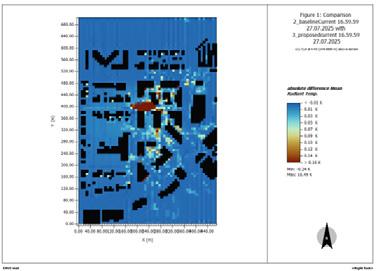

: Cross-comparison of

Figure 64: Perkins&Will, Skeena Terrace, Vancouver, BC. Urban farming integrated into the BC Housing project..

Figure 66: Perkins&Will, 800 Granville proposal, Vancouver, BC. Sky gardens across the building core..

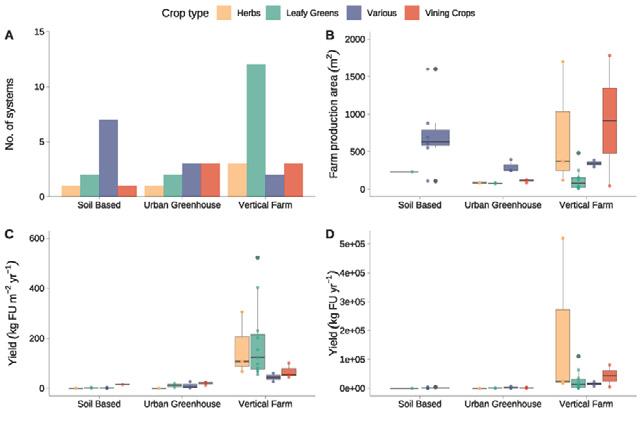

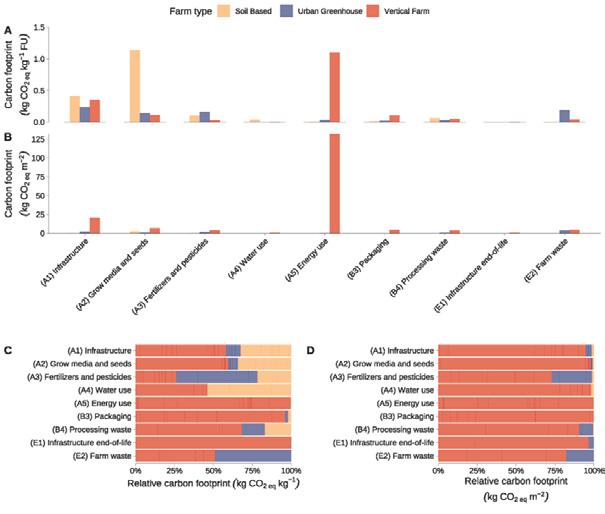

Figure 67: LCA studies dataset farm operations reviewed, yield, grow area, and production volumes..

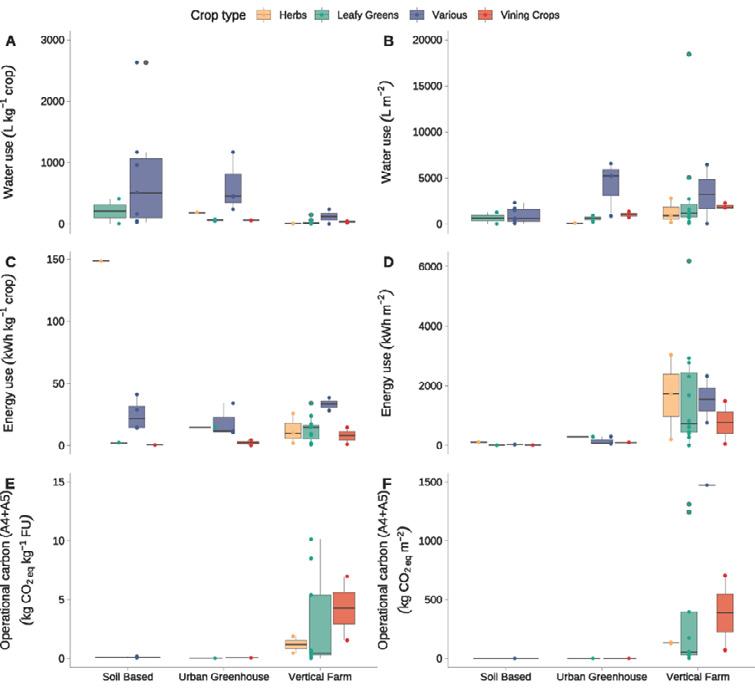

Figure 68: Energy, water use, and operational carbon values per square meter and kg crop.. 163

Figure 69: EUIa and EUIb energy use breakdown across common infrastructure types. . .................................................................

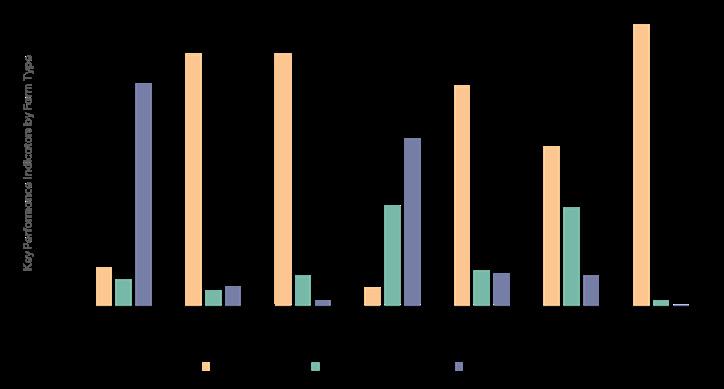

Figure 70: Relative performance indicators by farm type as a percentage of total category values..

Figure 71: Carbon emission equivalents by life cycle phase across different farm types...................................................................

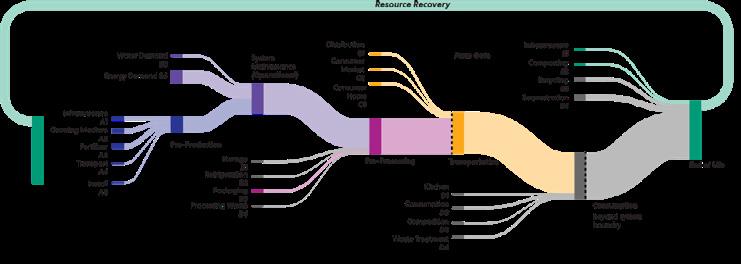

Figure 72: BIA system boundary and Sankey diagram illustrating relative carbon flows. Grey zones are excluded due to data limitations; post-farmgate transport is not quantified, consistent with the BIA LCA framework in Table 32..

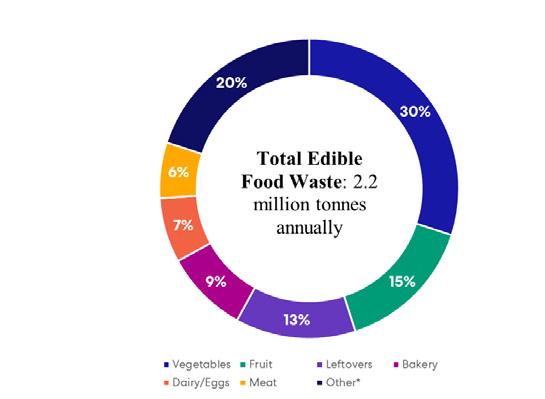

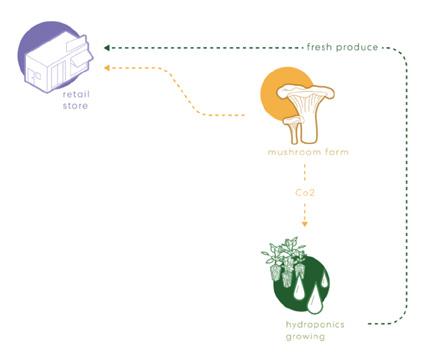

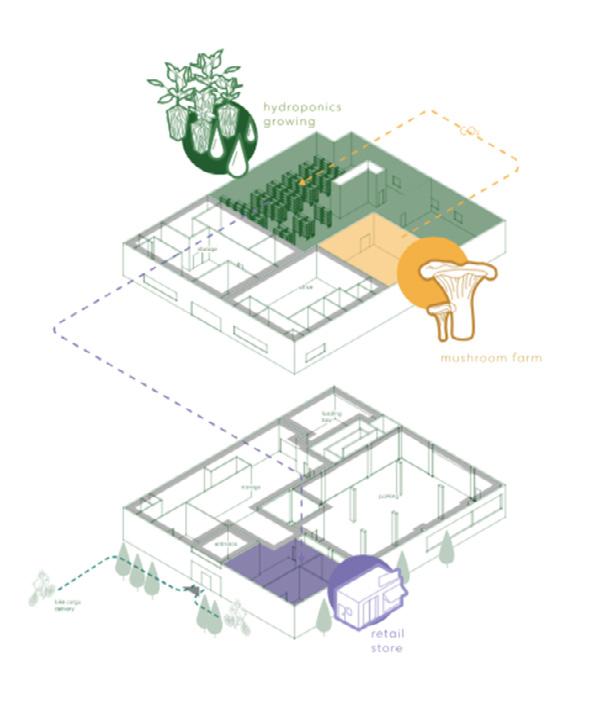

Figure 73: Hypothetical systems diagram of a circular waste-to-resource ecosystem.. 169

Figure 74: Perkins&Will, Daphne Cockwell Health Sciences Complex, Toronto Metropolitan University, Toronto, ON.. 173

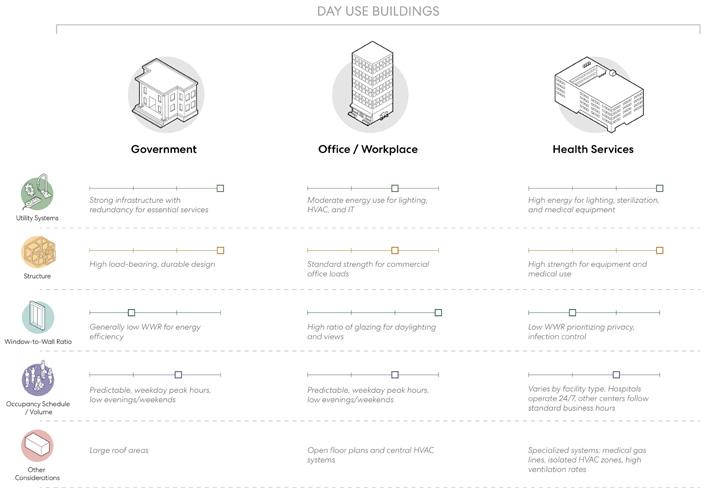

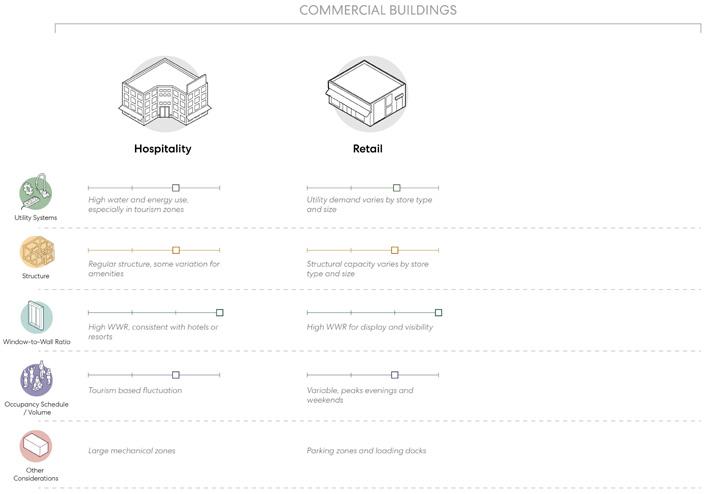

Figure 75: Typology breakdown (government, office/workplace, health services, hospitality, and retail), and associated waste stream potential..

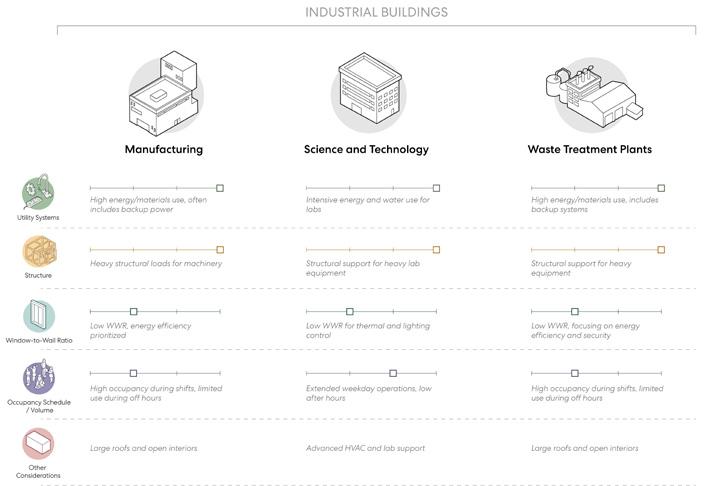

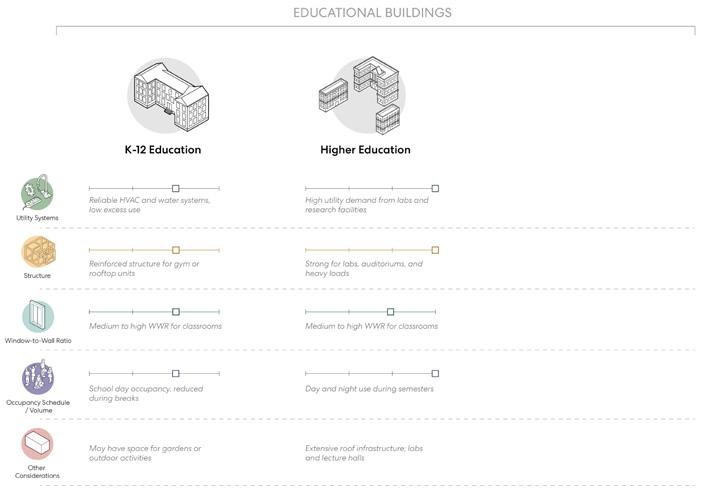

Figure 76: Typology breakdown (manufacturing, science and technology, waste treatment plants, educational) and associated waste stream potential.. ..........................................................................................................................................................

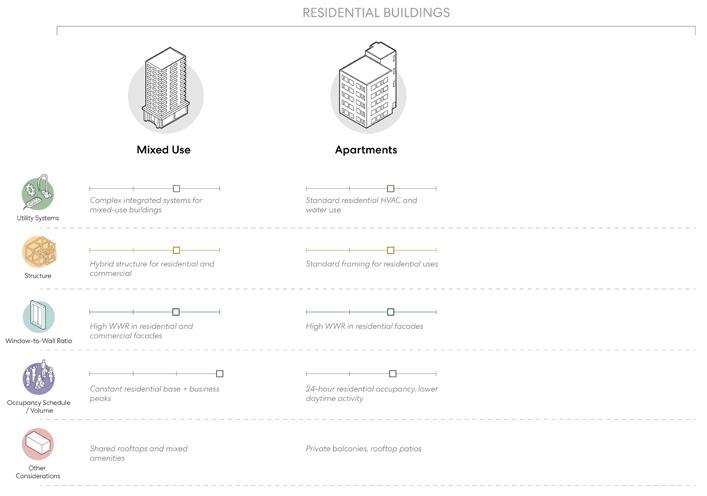

Figure 77: Typology breakdown (mixed use, apartments, and event spaces) and associated waste stream potential..

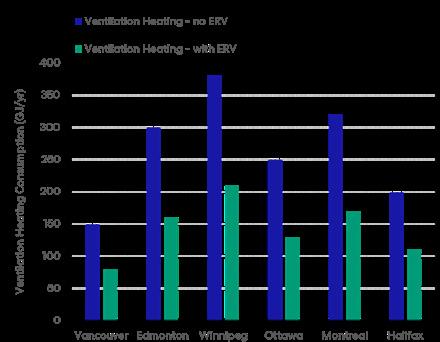

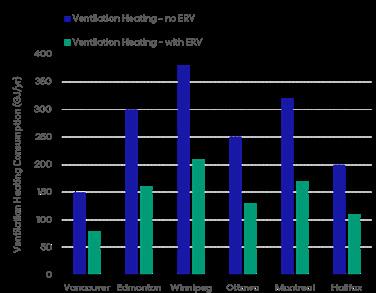

Figure 78: Comparison of HVAC energy use (GJ/year) with and without ERV across Canadian cities. Illustrates waste heat recovery potential. Source from Natural Resources Canada, 2024..

Figure 79: Perkins&Will,

:

Figure 83: Location of Quanto

:

Figure 85: Quanto Tech system diagram illustrating the symbiosis between the vertical farm and the mushroom chambers..

Figure 87:

Figure 92: Perkins&Will, Hudson’s Bay Company, Vancouver, BC. Proposed design featuring three integrated food assets responding

Figure 98: Pasona Group Headquarters, Tokyo, Japan. Interior farming activities. Image courtesy of Kono Design..

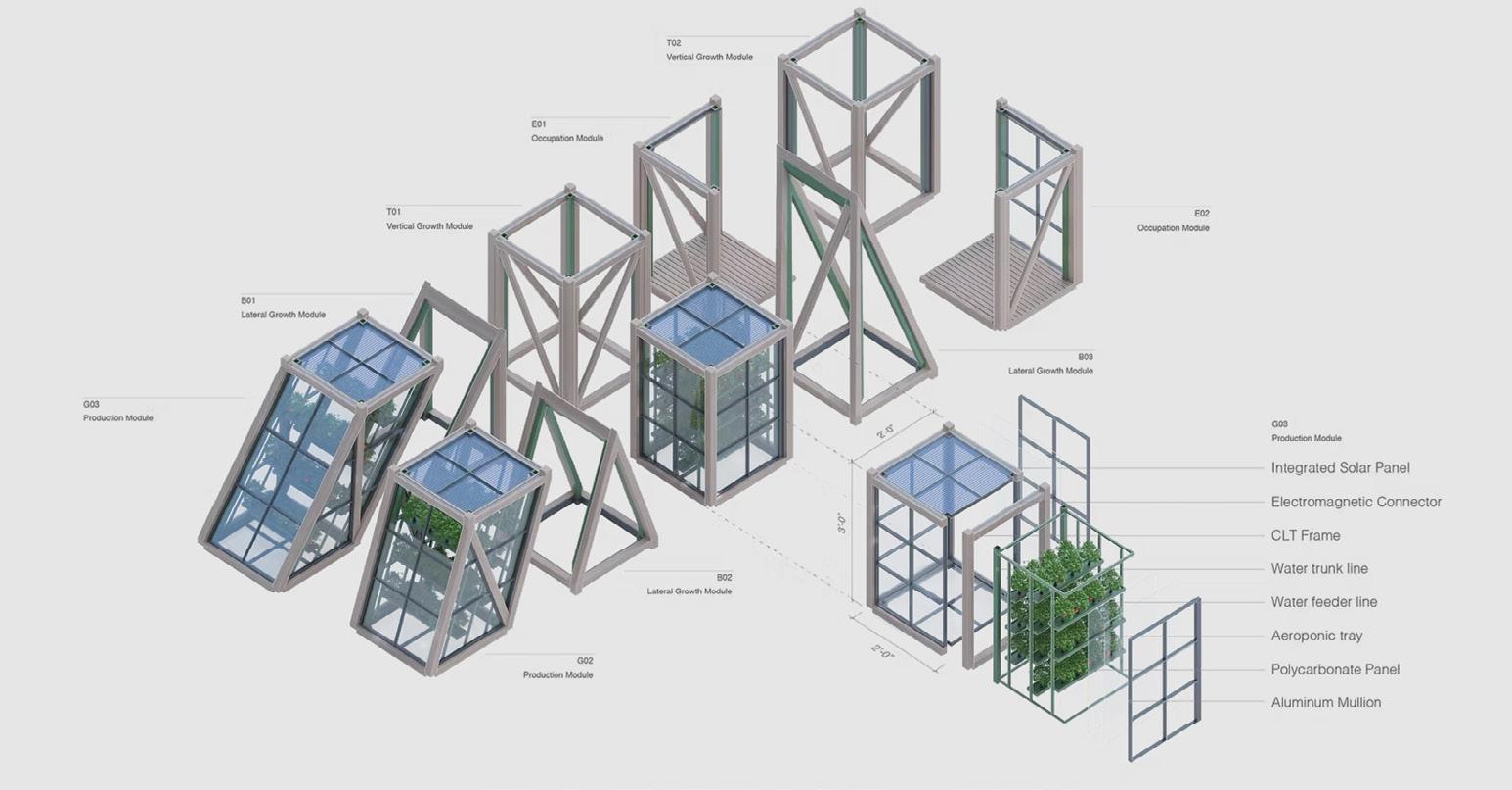

Figure 99: Location of Framlab’s conceptual Glasir design, Brooklyn,

Figure 100: Glasir modular farm system components..

Figure 101: Glasir modular farm system diagram..

Figure 102: Expanded Glasir modular farm system layout..

Figure 103: Conceptual illustration of Glasir modular farm design.. ...................................................................................................

Figure 104: Location of Pasona Group Headquarters, Tokyo, Japan. Design by Kono Design..

Figure 105: Pasona Group Headquarters, Tokyo, Japan. Urban farm system components.. ..........................................................

Figure 106: Pasona Group Headquarters, Tokyo, Japan. Interior farm partitions. Image courtesy of Kono Design..

Figure 107: Pasona Group Headquarters, Tokyo, Japan. Exterior vertical farm façade. Image courtesy of Kono Design.. .......

Figure 108: Pasona Group Headquarters, Tokyo, Japan. Urban farm systems diagram..

Figure 109: Pasona Group Headquarters, Tokyo, Japan. Urban farm systems diagram.. ...............................................................

Figure 110: Pasona Group Headquarters, Tokyo, Japan. Urban agriculture systems diagram..

Figure 111: Pasona Group Headquarters, Tokyo, Japan. Interior farming activities. Image courtesy of Kono Design.. ...............

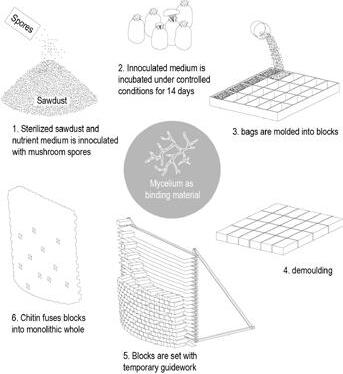

Figure 112: Mycelium production process by Joseph Dahmen, Associate Professor, SALA, University of British Columbia..

Figure 113: Perkins&Will, Daphne Cockwell Health Sciences Complex, Toronto Metropolitan University, Toronto, ON.. .............

Figure 114: Perkins&Will, Daphne Cockwell Health Sciences Complex, Toronto Metropolitan University, Toronto, ON..

Figure 115: Perkins&Will, Daphne Cockwell Health Sciences Complex, Toronto Metropolitan University, Toronto, ON..

Figure 116: Perkins&Will, VanDusen Botanical Garden Visitor Centre, Vancouver Board of Parks and Recreation, Vancouver, BC..

Figure 117: Perkins&Will, Albion Library, Toronto Public Library, Toronto, ON.. ...................................................................................

Table

Table 37: Indoor water consumption baseline (per person per day). Adapted from U.S. Green Building Council, 2025.

Table 38: Estimated wastewater volumes and their nutrient content, compiled from Statistics Canada (2024), EPA (2009), and Usman et al. (2024).

Table 39: Technologies reviewed and their associated assessment criteria.

Table 40: Case study analysis and compiled dataset of BIA projects. This dataset supports the analysis presented in Chapter V, Pillar 1 Data-Driven Insights.

Table 41: Life Cycle Assessment (LCA) data set compiled per square meter. This dataset supports the analysis presented in Chapter V, Pillar 2 Metric Pairing-Bridging Two Industries. ..............................................................................

Table 42: Life Cycle Assessment (LCA) data set compiled per kg crop. This dataset supports the analysis presented in Chapter V, Pillar 2 Metric Pairing-Bridging Two Industries.

Table 43: Compiled data from market studies reviewed in this research. This dataset supports the analysis presented in Chapter III, Economic Feasibility BIA Performance Across 8 Cities.

181

191

194

272

276

278

280

Glossary

Aerated Static Piles (ASP): Composting method using forced air through perforated pipes, eliminating the need for mechanical turning. Suitable for medium-scale operations with moderate process control.

Aerobic Digesters: Systems that use oxygen to break down organic waste into stabilized solids. Common in institutional or municipal settings; odor is low, but no energy is recovered.

Aeroponics: A soil-less farming technique where plant roots are suspended in air and misted with a nutrientrich solution.

Algal Photobioreactors (PBR): Enclosed systems that grow microalgae to treat wastewater and capture CO₂ through photosynthesis.

Anaerobic Digesters: Oxygen-free systems that convert organic waste into biogas and nutrient-rich digestate. Scalable and often used for renewable energy generation.

Aquaponics: A combined system of fish farming and hydroponics where fish waste provides nutrients for plant growth, and plants purify the water.

Bio-Based Catatonic Flocculant: Natural, positively charged agents (e.g., from starches or oils) that coagulate suspended materials in wastewater.

Biochar: A carbon-rich soil amendment produced from organic material via pyrolysis, improving soil fertility and water retention.

Biochar Production: Thermal conversion of biomass into biochar using pyrolysis or gasification. Often co-produces heat or gas for energy.

Biodiversity Corridors: Connected habitats that allow wildlife movement and promote species diversity.

Black Soldier Fly (BSF) Composting: A composting method using larvae to convert food waste into protein and fertilizer. Effective for high-fat or meat-based inputs.

Carbon Sequestration: Capturing and storing atmospheric carbon dioxide in plants, soil, or biomass to mitigate climate change.

Closed-Loop Irrigation System: A water-saving system that captures, filters, and recycles irrigation water.

Composting Toilets: Dry sanitation systems that convert human waste into compost via aerobic decomposition, separating urine and feces to reduce odor.

Controlled Environment Agriculture (CEA): High-tech farming in fully enclosed systems where light, temperature, humidity, and nutrients are precisely controlled.

Cover Cropping: Planting crops like clover or legumes to improve soil health, prevent erosion, and add nutrients during off-seasons.

Energy Demand: The amount of energy (electricity, gas, oil) required for crop production.

Eutrophication: Excessive algae growth in water bodies caused by nutrient runoff, leading to oxygen depletion and ecosystem damage.

Food Miles: The distance food travels from production to consumption, influencing its environmental footprint.

Greenhouse Gas (GHG) Emissions: Gases like carbon dioxide and methane that trap heat in the atmosphere and contribute to global warming.

Growing Medium: The material used to support plant roots, such as soil, coir, perlite, or rockwool. Varies by production system.

Harvest Process: The method of collecting mature crops. In urban agriculture, this is typically manual due to limited mechanization at scale.

Hydroponics: A method of growing plants in nutrient-rich water without soil. Common in vertical and indoor farms.

Intercropping: Growing two or more crops together to increase biodiversity and optimize space and resource use.

Last-Mile Distribution: The final leg of food delivery, from distribution hub to consumer, often affecting cost and emissions.

Membrane Bioreactors (MBR): Advanced systems combining biological treatment with membrane filtration to produce high-quality reusable wastewater.

Monocropping: Growing the same crop repeatedly on the same land, often leading to reduced soil fertility and pest resilience.

Mycorrhizal Fungi: Fungi that form symbiotic relationships with plant roots, improving nutrient uptake and soil structure.

Nutrient Leaching: Loss of nutrients from soil due to excessive watering or rainfall, often leading to water contamination.

Organic Matter: Decomposed plant and animal material in soil that improves structure, fertility, and microbial health.

Planetary Boundaries: A scientific framework identifying nine critical Earth system processes (such as climate change, biodiversity loss, and freshwater use) within which humanity can safely operate. Crossing these boundaries increases the risk of large-scale environmental instability.

Rooftop Greenhouse (RG): A greenhouse installed on a building roof to grow food under controlled conditions.

Soil-Based UA Systems (SB): Traditional growing systems using soil, often found in community gardens or open lots.

Soil Compaction: Compression of soil that limits aeration and root growth, typically caused by heavy machinery or overuse.

Soil Degradation: Decline in soil health due to erosion, nutrient loss, or pollution.

Soil Erosion: Displacement of topsoil by wind or water, reducing soil productivity and ecosystem function.

Stormwater Runoff: Rainwater that flows over impervious surfaces, carrying pollutants into natural water bodies.

Synthetic Fertilizers: Manufactured chemical nutrients used to promote plant growth. Can cause water pollution and soil degradation if overused.

Three-Dimensional Planting: Layered planting systems, such as trellises or vertical towers, to maximize yield in limited spaces.

Urban Agriculture (UA): Food production within urban environments, including community gardens, green roofs, and indoor farms.

Urban Heat Island Effect (UHI): Higher temperatures in urban areas caused by built surfaces absorbing and retaining heat.

Urine Source Separation (USS): The practice of diverting urine at the source to recover nutrients for reuse in fertilizers.

Vermicomposting: Composting organic waste using worms, producing nutrient-rich castings.

Vertical Farm (VF): A multi-level farming system using stacked surfaces, often indoors, with hydroponic or aeroponic methods.

Waste: By-products of farming operations, including plant waste and packaging, either composted, reused, or sent to landfill.

Waste Heat Recovery Technologies: Systems that capture heat from used water or exhaust to pre-warm incoming water, improving energy efficiency.

Water Demand: Total irrigation needs, including water from rain or potable sources.

Windrow Composting: Composting in long, turned piles; effective but requires space and regular management.

Abbreviation

BIA Building Integrated Agriculture

CAGR Compound Annual Growth Rate

CAPEX Capital Expenditures

CEA Controlled Environment Agriculture

CUA Commercial Urban Agriculture

EUI Energy Use Intensity

FAO Food and Agriculture Organization of the United Nations

GHGI Greenhouse Gas Intensity

H Herbs (focused on basil)

HVAC Heating-Ventilation and Air Conditioning

LCA Life Cycle Assessment

LED Light Emitting Diode

LG Leafy Greens (focused on Lettuce)

LUE Light Use Efficiency

NFT Nutrient Film Technique

OPEX Operational Expenditure

R&D Research and Development

TEDI Thermal Energy Demand Intensity

UA Urban Agriculture

USDA United States Department of Agriculture

VC Vining Crops (focused on Tomatoes)

WUI Water Use Intensity

Executive Summary

This

study examines the feasibility of Building-Integrated

Agriculture (BIA)

systems and their agency in facilitating regenerative cities through a crosssector analysis, interviews with BIA system providers, review of local and national policies, and evaluation of case studies and their associated performance data.

Our Approach

The findings reveal that while BIA systems offer compelling environmental and urban resilience benefits, their economic and regulatory frameworks remain underdeveloped. A shift from conceptual support to structural integration—across land-use planning, infrastructure policy, and investment mechanisms—is essential for scaling in urban centres.

Over the past decade, interest in BIA has intensified as cities seek local strategies for climate adaptation, food security, and circular economy development. BIA positions the built environment as a productive asset—integrating food systems, waste recovery, water reuse, and renewable energy into underutilized urban surfaces. However, despite growing pilot projects and policy ambitions, BIA is not mainstream, hindered by fragmented regulations, opaque performance metrics, and market immaturity.

Unlike conventional urban agriculture (UA), which is often soil-based and decentralized, BIA systems are defined by their architectural integration, higher yields per area, and frequent reliance on controlled-environment technologies. These systems typically involve high capital expenditures and annual operational expenditures driven largely by energy and maintenance costs. Food production is concentrated in high-turnover crops such as leafy greens and herbs, reflecting their short cycles, high harvest index, and compatibility with modular cultivation systems.

Energy and Environmental Performance

Although vertical and rooftop farms can reach high production rates, their resource intensity and dependency on energy raise environmental performance questions. For instance, lighting and HVAC loads account for 40–70% of total energy consumption in indoor BIA systems, leading to higher energy intensities relative to open-field agriculture, particularly in regions with carbon-intensive grids.

While new energy-efficient technologies (e.g., dynamic LED lighting, climate control algorithms, heat recovery systems) offer performance gains, the report shows that access to clean, affordable, and reliable energy remains a critical limiting factor. Most BIA operators interviewed identified energy costs as their highest operational risk, with some projects reporting over 50% of OpEx dedicated to electricity. In this context, climate resilience is linked to energy resilience, systems that can integrate renewables and reduce thermal vulnerability are better positioned to withstand both climatic and economic shocks.

Market Viability and Business Models

On the market side, BIA remains a marginal contributor to food supply and a high-cost producer relative to conventional agriculture. While direct-to-consumer sales, institutional contracts, and education programs offer supplementary revenue streams, few operators achieve breakeven solely through produce sales. This has led to a proliferation of hybrid models combining food production with research, tourism, and education.

Despite increasing public interest, consumer willingness to pay premium prices for BIA products remains uncertain. In the absence of verified data on nutritional benefits, carbon savings, or certification labels, BIA products struggle to differentiate in the retail market. This has further delayed investor confidence in regions where real estate and energy costs are high.

Several notable BIA ventures have exited the market in recent years, pointing to over-optimistic projections, underestimated OpEx, and insufficient attention to market demand. As in other capital-intensive sectors, failure to align technical ambition with operational realities can have grave consequences.

Barriers to Scaling BIA

One of the important findings of the report is the lack of standardized metrics for performance evaluation, which has hampered peer learning, investment benchmarking, and public-sector integration. Many of the environmental claims made by BIA proponents—ranging from Greenhouse Gas (GHG) reductions to stormwater mitigation—are difficult to verify due to inconsistencies in data reporting and lifecycle boundary definitions. This opacity also limits the ability of municipalities to integrate BIA into climate plans, food strategies, or infrastructure policy. Without clearer performance benchmarks and climate-aligned incentives, BIA’s potential to deliver climate resilience—through cooling, water retention, and food localization—remains largely untapped.

To address this, the report introduces a carbon-centric evaluation framework that harmonizes data across sectors and enables comparative assessment of BIA systems using four core metrics: Energy Use Intensity (EUI), Water Use Intensity (WUI), Greenhouse Gas Intensity (GHGI), and food yield. Applied across 48 BIA case studies, this framework reveals significant variability based on system type, climate, and building context. It also identifies a range of “lowcarbon leverage points,” such as waste-heat recovery, renewable integration, and passive environmental controls, that can improve system performance over time.

BIA’s Role in Climate Resilience

In parallel, BIA offers tangible pathways to strengthen climate resilience in cities. As extreme weather events intensify and supply chains grow more fragile, BIA systems provide local redundancy—through food production, water retention, and thermal regulation—embedded within the built environment. Whether through rooftop water capture, renewable energy integration, or urban heat mitigation, BIA enhances a city’s capacity to adapt and respond to climate shocks. Its multifunctionality positions it as both infrastructure and strategy for resilience planning.

Regulatory Landscape

From a regulatory standpoint, the report finds that BIA remains poorly integrated into most planning and permitting systems. While leading jurisdictions—including Vancouver, New York, Paris, and Montréal—have introduced zoning reforms, rooftop exemptions, and pilot incentives, most urban policies treat BIA as a niche or temporary intervention. Without clear legal status or integration into utility, infrastructure, or food systems policy, BIA projects face high costs and uncertain approval pathways. The lack of access to public subsidies or tax incentives—available to conventional agriculture or renewable energy—further disadvantages the sector.

“This report highlights that circular cities are an urgent necessity. By rethinking urban infrastructures— with agriculture at its core—as a regenerative, productive ecosystem, we move toward a new paradigm for sustainable cities—one where buildings are not just shelters but living systems that feed, sustain, and regenerate.”

Mohamed Imam, Ph.D. | Perkins&Will Senior Research Lead

Design Integration and Human Experience

The report also underscores the role of modular design and human-centered integration in scaling BIA. Standardized yet adaptable systems support adoption across building types—such as schools and mixed-use developments—and support decentralized deployment. These approaches not only enable flexible integration but also enhance human experience through improved environmental quality and more accessible green spaces.

Moving forward, the report identifies key enablers for scaling BIA:

Policy Frameworks:

Treating BIA as critical infrastructure by embedding it into zoning, building codes, and green development incentives.

Market Analysis:

Developing hybrid funding models that combine grants, private investment, and service contracts, while derisking upfront CAPEX.

Ecological and Environmental Impact:

Positioning BIA as an ecological infrastructure that supports biodiversity, reduces urban heat, and closes resource loops through on-site reuse of energy, water, and organics.

Technical Analysis and Guidelines:

Mandating carbon and resource reporting standards to enable verification, benchmarking, and eligibility for environmental incentives.

Design Implementation and Human Experience:

Standardizing hybrid modular BIA systems to integrate with diverse building types, climates, and programmatic uses—from schools and hospitals to housing and retail.

In conclusion, BIA is a tangible, scalable, and local solution to multiple urban challenges, from food insecurity to waste management and climate resilience. But realizing this potential requires a shift from experimentation to systembuilding. This report serves as a baseline and roadmap for that transition, providing the evidence, tools, and guidance needed to elevate BIA from innovation to infrastructure.

About This Report

The purpose of this report is to guide designers, planners, urban farmers, policymakers, and investors through the key dimensions of BuildingIntegrated Agriculture and resource circularity.

This report assesses the feasibility of implementing BIA projects and maximizing their potential for resource circularity. It lays the groundwork for integrating agriculture in, on, and around a variety of building typologies, and provides practical methods for doing so. The sections that follow examine BIA policy frameworks, market analysis, ecological and environmental impacts, technical systems and design guidelines, and human experience. These dimensions are considered in relation to hybrid BIA models, place-based research needs, and the careful negotiation of trade-offs unique to each project context.

How This Report Was Developed

This report is the outcome of a multi-disciplinary collaboration between architects, designers, engineers, academics, agri-food business leaders, planners, farmers, and engaged community members. The research team conducted in-depth case studies of BIA systems, engaged with stakeholders through interviews and workshops, and analyzed performance data across a wide range of contexts.

The findings are structured across seven parts, progressing from policy and market frameworks to ecological, technical, and design considerations, and culminating in actionable recommendations for scaling BIA as a strategy for regenerative urban ecosystems.

Planting The Seed Introduction

Reimagining Cities as Regenerative Ecosystems

Until the 20th century, cities were intertwined with their surrounding landscape, producing food while consuming local resources. These localized food systems provided resilience, ensuring communities had steady supplies even during natural, political, or social disruption periods (Barthel & Isendahl, 2013).

However, over time, globalized food supply chains replaced local production, improving efficiency to support growing urban populations but creating vulnerabilities to external shocks. The COVID-19 pandemic, for instance, exposed the fragility of these systems, disrupting trade and accelerating food insecurity (Clapp & Moseley, 2020).

As cities expand, rebuilding resilient, decentralized food networks to complement global supply chains is more urgent than ever.

This chapter introduces the critical opportunity to reposition cities as regenerative ecosystems by integrating BuildingIntegrated Agriculture (BIA) into the urban fabric. With rising urban populations, strained food systems, and increasing climate vulnerabilities, there is a growing imperative to embed food production within cities themselves.

This section sets the stage for the report by framing the urgency of transforming how food, waste, water, and energy are managed through architectural innovation. It positions BIA not merely as a technical intervention, but as a strategic response to systemic urban challenges—capable of addressing food insecurity, reducing emissions, and localizing resource loops.

Produce Less Emissions

From 12 Gt CO₂e to 4 Gt CO₂e: A 67% Reduction by 2050

Feed 10 Billion People in 2050

We will need 56% more food to feed nearly 10 Billion people in 2050

+56% more food for 2050

2010

Use Less Land

Stopping agricultural expansion could protect forests twice the size of India

Ensure Affordable Food Access

Food that is Steady and Reliable

Figure 1: The global food challenge by 2050. Adapted from: World Resources Institute, 2018.

The Global Challenge: Feeding 10 Billion Sustainably by 2050

By 2050, 70% of the projected 10 billion world population will live in cities (UN, 2023), placing unprecedented pressure on food, water, and energy systems.

Urban consumption remains linear and resource-intensive, with cities consuming substantial resources with minimal recovery or reuse mechanisms.

Meanwhile, global food demand is projected to rise by 56%, yet agricultural land use has already reached a tipping point. Nearly 50% of the world’s vegetated land— an area twice the size of India—is already dedicated to farming (World Resource Institute, 2018), see figure 1.

Expanding farmland further would accelerate deforestation, biodiversity loss, and climate instability. 1. Land Use

Food production is also a leading driver of climate change, responsible for nearly one-third of global anthropogenic Greenhouse Gas (GHG) emissions (Crippa, et al., 2021), see figure 2. Agriculture alone contributes 12 gigatons (Gt) of CO₂ equivalent annually, which must shrink to 4 Gt by 2050 to meet climate targets (World Resource Institute, 2018) Currently:

nj 70% of agricultural emissions stem from land-use conversion, deforestation, and soil degradation.

nj 30% originate from post-production activities, including refrigeration, long-distance transportation, industrial processing, and waste-heavy distribution (Poore & Nemecek, 2018) (Crippa, et al., 2021), see figure 3.

TRADITIONAL FOOD LIFE

TRADITIONAL FOOD LIFE CYCLE

PRODUCTION

DISTRIBUTION WASTE

Processing

1. Land Use 3. Processing

Farm and Harvest 5.7 Gigatonnes (32%) + 7.2 Gigatonnes (40%)

0.72 Gigatonnes

2. Farm and Harvest 5.7 Gigatonnes (32%) + 7.2 Gigatonnes (40%)

0.72 Gigatonnes

0.9 Gigatonnes (5%)

Transport

0.9 Gigatonnes (5%)

0.72 Gigatonnes + 0.54 Gigatonnes

0.9 Gigatonnes (5%)

Transport

0.9 Gigatonnes (5%)

0.72 Gigatonnes + 0.54 Gigatonnes

Figure 2: GHG emissions across the food production stream (EDGAR-FOOD, 2021).

Figure 3:

WHERE FOOD LOSS AND WASTE OCCURS ALONG THE SUPPLY CHAIN

Middle East, North Africa, Latin America North America, Oceana

Middle East, North Africa, Latin America North America, Oceana

Where Food Loss and Waste Occurs Along The Supply Chain

While global food production faces mounting pressures, access to nutritious, affordable food remains inconsistent. Supply chain disruptions, inflation, and extreme climate events have exacerbated food insecurity, increasing reliance on imported goods and volatile pricing.

In Canada, the National Farmers Union (NFU) has called for stronger food sovereignty policies to support local production, reduce import dependence, and ensure equitable food access. Resilient, decentralized food systems are not just an environmental goal but a social and economic imperative.

nj In North America and Oceania, waste is driven by overproduction, strict retail standards, and consumer habits, with 61% of losses occurring at the consumption stage.

nj In the Middle East, North Africa (MENA), and Latin America, food is lost much earlier in the supply chain due to poor storage and distribution infrastructure (World Resource Institute, 2018), see figure 4.

Tackling food waste requires comprehensive action across all levels of production and consumption, from improving consumer awareness to implementing policies that support food recovery and redistribution.

Furthermore, over 92% of farmed vegetable varieties have disappeared in the last century, eroding biodiversity and increasing reliance on monoculture-driven industrial food systems. Given that cities consume 80% of global food production while generating 1.3 billion tonnes of organic waste annually (FAO, 2019) which contributes to 8-10% of global GHG emissions (IPCC, 2021), they must actively reimagine sustainable food systems.

This disconnect presents an opportunity: What if cities could be redesigned to produce more than they consume?

Imagine if urban buildings could be designed as selfsustaining ecosystems, transforming waste streams into valuable resources. Instead of importing food and exporting waste, cities could close the loop, recovering nutrients, water, and energy to support localized food production.

The challenge is not just to grow more food—but to grow it smarter, integrating food production into the fabric of cities, transforming urban spaces into circular, regenerative food systems, reducing waste, lowering emissions, and increasing food security.

Figure 4: Food waste comparison across North America, MENA, and Latin America. Adapted from: World Resource Institute, 2018.

From Waste to Resource: A Circular Model for Cities

Different Diet

Integrated Food, Water, Waste and Energy

INNOVATIONS NEEDED IN THE WAY WE GROW AND CONSUME FOOD

Restoration of Degraded Farmland and Forests

The Balancing Act: Feeding a Growing Population Sustainably

The balancing act of feeding a growing population while reducing agriculture’s environmental footprint requires a fundamental shift in how cities grow, distribute, and consume food. Experts highlight four key innovations to ensure global food security within planetary boundaries (Porter, et al., 2014):

a. Shifting Diets: Reducing food waste and diversifying protein sources.

b. Restoring Degraded Farmlands and Forests: Protecting biodiversity while improving productivity.

c. Shifting Production Zones into Cities: Urban and periurban farming to reduce land-use pressure.

d. Integrating Food, Water, Waste, and Energy Systems: Designing circular urban metabolisms that minimize emissions and resource waste.

While the first two strategies focus on global agricultural reform, the built environment has an immediate role in the latter two. Cities must move beyond linear consumption models, where food is imported, consumed, and discarded, toward circular food systems that repurpose waste into valuable resources.

This is where Building-Integrated Agriculture (BIA) emerges as a transformative solution, bridging the gap between urban waste streams and food production to create a regenerative ecosystem. Though BIA alone won’t solve all food system challenges, scaling and integrating it into urban design will be crucial for building resilient, localized, and sustainable food networks.

Shift Production Zones to Cities

Figure 5: Innovation pathways for food security. Adapted from: Porter, et al., 2014.

Positioning: Building-Integrated Agriculture as an Urban Asset

The Solution: Circular, Integrated Resource Systems

BIA offers a closed-loop solution by embedding resource recovery and food production within the built environment to address these inefficiencies. Instead of treating waste as an externality, BIA leverages urban waste streams to create circular, integrated resource systems. Key strategies include:

Turning Building Waste into Farm Inputs

nj Capturing CO₂ emissions from HVAC systems to enhance plant growth in controlled-environment agriculture (CEA), reducing emissions while increasing plant productivity

nj Greywater treatment captured from sinks and showers for hydroponics, lowering urban potable water demands.

nj Kitchen food waste can be composted or converted into biofertilizers, creating a nutrient loop that supports soil health and regenerative farming.

Integrating Farms as Urban Infrastructure

nj Rooftop greenhouses and green roofs serve as insulating climate buffers, reducing heating and cooling energy loads while producing fresh food.

nj Vertical farms in underutilized building spaces (e.g., atriums, facades, and underground spaces) enable year-round urban food production.

nj Adaptive reuse projects can incorporate urban farms into existing buildings, transforming them into productive assets.

Enhancing Circular Urban Metabolisms

nj Currently, cities import over 80% of their food, increasing vulnerability to supply chain disruptions.

nj City-wide BIA systems like rooftop greenhouses and vertical farms can meet 35-77% of a city’s vegetable demand (Orsini 2014) (McDougall et al. 2020) (Astee and Nirmal 2010) (Haberman 2014).

nj BIA using waste heat and renewable energy can cut food miles by 90% and lower agricultural sector emissions by 50% relative to traditional farming methods. (Poore & Nemecek, 2018).

nj Localized food systems improve food affordability, ensuring a steady supply of nutritious food, particularly in vulnerable communities.

The Role of Building-Integrated Agriculture (BIA)

BIA is not just about food production. It is a system-based approach to urban resilience, repositioning buildings from static, resource-consuming structures into dynamic, self-sustaining ecosystems. A BIA-integrated city leverages its existing infrastructure to create a regenerative relationship between agriculture, water, energy, and waste.

How buildings and farms work together

Our built environment generates waste streams that align seamlessly with agricultural needs:

nj Waste Heat: Enables year-round crop cultivation, particularly in rooftop greenhouses.

nj CO₂ Emissions: Enhances photosynthesis and crop growth in controlled environments.

nj Greywater: Treated and reused for irrigation, reducing municipal water demands.

nj Organic Waste: Converted through composters or anaerobic digestors into compost or biofertilizers, closing the nutrient loop.

In turn, these farms generate critical outputs that enhance urban ecosystems:

nj Fresh Food: Localized production reduces reliance on global supply chains.

nj Improved Air Quality: Plants sequester carbon, filter pollutants, and produces O2 as a by-product of photosynthesis.

nj Climate Resilience: BIA mitigates urban heat island effects by adding green roofs and facades, improving building energy efficiency (Zhang et al., 2022).

nj Restoring Local Ecosystems: embedding green spaces into urban infrastructure through rooftop and vertical farms restores urban biodiversity for a variety of animals and insects (Lanner, et al., 2019), and improve quality of life.

nj Water Efficiency: BIA contributes to sustainable urban water management through stormwater capture and greywater reuse.

While BIA offers a promising pathway to urban food security, its sustainability remains a topic of debate. Energy and resource intensity are key concerns, with some studies suggesting that BIA may not consistently outperform conventional agriculture in terms of environmental efficiency.

Assessing BIA’s life-cycle impact remains challenging due to limited standardized metrics and inconsistencies in evaluation methods. Studies indicate that GHG emissions and resource use efficiency vary widely depending on system design, location, and integration strategies.

For instance, Goldstein, et al. (2016) found that BIA may not always yield lower emissions than conventional agriculture, particularly when energy-intensive controlled environment systems are used.

Similarly, Kulak, Graves and Chatterton (2013) reported that producing strawberries in rooftop greenhouses in London resulted in a higher carbon footprint than importing greenhouse-grown strawberries from Spain.

In contrast, Goldstein, et al. (2016) found that importing tomatoes from Spain or Italy to Austria produced fewer emissions than growing them locally under energyintensive conditions.

A limitation of these assessments is their narrow system boundaries, which often exclude the building-level benefits of BIA. When integrated properly, BIA systems contribute to insulation, waste heat recovery, and stormwater management, offsetting some operational impacts.

These reciprocal efficiencies are rarely captured in conventional LCA, leading to an incomplete picture of BIA’s sustainability potential. A more holistic evaluation framework is needed to account for both agricultural outputs and building performance synergies to fully assess BIA’s role in creating climate-positive urban food systems.

Figure 6: Synergies between host buildings and integrated farms. Adapted from: Porter, et al., 2014.

BIA Typologies and the Scope of This Report

Unlike conventional urban agriculture, which primarily occupies ground-level spaces, BIA integrates soil-based and farming technologies into rooftops, facades, underutilized interiors, and adjacent building areas.

Studies by Dorr, Goldstein, Horvath, Aubry, and Gabrielle (2021), and by Benis, Gashgari, Alsaati, and Reinhart (2018), categorize BIA typologies into three primary types, each with distinct advantages and trade-offs:

Soil-Based System

Rooftop Greenhouses

Aeroponic System

Plants are grown by suspending their roots, receiving nutrients through misted solution.

• Efficient water use

High O2 exposure improves nutrient uptake

• Precise control over nutrient delivery

System failure risk

High initial cost and technical complexity

Soil Based System

Climate-dependent community gardens and rooftop farms.

nj Efficient biodiversity and urban ecosystem health.

nj Community building

nj Higher exposure to weather variability

nj Lower yields

Hydroponic System

Soil Based System

Climate-dependent community gardens and rooftop farms.

• Enhance biodiversity and urban ecosystem health.

nj Plants are grown in waterbased mineral nutrient solutions.

• Community building

nj Highly climate-controlled

Higher exposure to weather variability

• Lower yields

nj Maximize space and resources

nj Efficent water use (90% less water)

nj Higher energy demand

nj Soil-Based Systems: Climate-dependent community gardens and rooftop farms.

nj Rooftop Greenhouses: Climate-controlled structures utilizing building emissions and waste heat to optimize crop growth.

Hydroponic System

Plants are grown in water-based mineral nutrient solutions.

Highly climate-controlled

• Maximize space & resources

Aeroponic

Plants are grown their roots, receiving through misted

• Efficient water

• High O2 exposure nutrient uptake

nj Hydroponic Vertical Farms: Highly climate-controlled environments that maximize space and resource efficiency through hydroponics, aeroponics, and aquaponics.

Efficient water use (90% less water)

Higher energy demand

Hydroponic Vertical Farms

Hydroponic System

• Plants are grown in water-based mineral nutrient solutions.

Highly climate-controlled

• Maximize space & resources

Efficient water use (90% less water)

Higher energy demand

Aquaponic System

Plants are grown in water-based symbiotic environment with aquatic organisms.

• Dual output (vegetables and fish protein)

Efficient nutrient cycling through fish waste

Low water use, closed loop system

• Complex system management

Limited crop variety (works best with leafy greens)

• Precise control delivery

• System failure

• High initial cost complexity Soil Based

Climate-dependent gardens and rooftop

• Enhance biodiversity ecosystem health.

• Community building

• Higher exposure variability

• Lower yields

Aquaponic System

Aquaponic System

Plants are grown in water-based symbiotic environment with aquatic organisms.

Dual output (vegetables and fish protein)

Plants are grown in water-based symbiotic environment with aquatic organisms.

Efficient nutrient cycling through fish waste

• Low water use, closed loop system

• Complex system management

nj Dual output (vegetables and fish protein)

• Limited crop variety (works best with leafy greens)

nj Closed loop nutrient cycling through fish waste

nj Low water use

nj High initial cost and technical complexity

Aeroponic System

Plants are grown by suspending their roots, receiving nutrients through misted solution.

nj Efficient water use

nj High O2 exposure improves nutrient uptake

nj Precise control over nutrient delivery

nj System failure risk

nj High initial cost and technical complexity

Figure 7: Farming systems examined in this report. Adapted from: Dorr, Goldstein, Horvath, Aubry, & Gabrielle, 2021 and Benis, Gashgari, Alsaati, & Reinhart, 2018.

The most cultivated crops in these systems include:

nj Leafy greens (lettuce, spinach, kale): fast-growing, highyield crops ideal for hydroponic and soil-based systems.

nj Herbs (basil, mint, cilantro): compact plants with high market demand, well-suited for vertical farms.

nj Vining crops (tomatoes, cucumbers, peppers) – thriving in CO₂-enriched environments, these crops benefit from controlled greenhouse and vertical farm conditions.

Each BIA typology presents unique opportunities and constraints:

nj High-yielding vertical farms and rooftop greenhouses prioritize maximum food production per square meter but may place less emphasis on biodiversity conservation, or waste reduction (Newman, et al., 2023).

nj Soil-based rooftop farms enhance biodiversity and urban ecosystem health yet may offer lower yields and higher exposure to weather variability.

Balancing these trade-offs requires strategic planning to align BIA systems with specific urban needs, environmental goals, and food security priorities.

Extensive green roof

- 5” substrate depth

Intensive green roof

- 8” Roof garden

- 24”

Figure 8: Soil-based green roof types and requirements. Adapted from: Gundula Proksch, 2017.

Vertical Farming

Aquaponics

Aeroponics

Hydroponics

Green roof

Greenhouse

Green Wall

Soil/medium-based Farming

Mushroom

Open Air

Green Facade On Grade Greenhouse Productive Greenroof

Container Garden Permaculture

Rooftop Greenhouse Indoor Farm Indoor Farm Indoor Farm

Climate Dependent

Controlled Environment

Soil-Less growing

Soil Based growing

Mushroom Cultivation

Figure 9: Urban agriculture taxonomy. Adapted from: Dorr, Goldstein, Horvath, Aubry, & Gabrielle, 2021 and Benis, Gashgari, Alsaati, & Reinhart, 2018, Gundula Proksch, 2017.

Part II:

Policy Frameworks

Cultivating the Landscape

Positioning: Policy as the Catalyst for Change

BIA is poised to reshape urban food systems, yet its success depends on supportive policies integrating resource circularity into urban planning, building codes, and economic frameworks. Without strategic policy interventions, BIA remains a fragmented innovation a concept with promise but without the regulatory support to scale effectively.

The central question guiding this chapter:

What systemic conditions enable or hinder the integration of resource circularity in BIA, and how can policies drive its adoption at scale?

Despite increasing municipal interest in local food production, most urban policies remain stuck in a linear paradigm. Food, energy, water, and waste are treated as separate systems, limiting opportunities for synergy and resource optimization and preventing buildings from functioning as productive assets contributing to urban food security, waste valorization, and climate adaptation (De Jesus & Aguiar Borges, 2024).

Cities continue to operate with outdated land-use restrictions, misaligned incentives, and permitting barriers, preventing BIA from becoming a mainstream urban development strategy.

A global survey of municipal food policies reveals a stark reality

Fewer than 15% of municipal food policies explicitly reference BIA as a sustainability strategy.

Fewer than 10% provide dedicated funding, zoning provisions, or building codes that facilitate its integration.

“The positive influence of policy on the transformation of the green building sector in Canada has been evident. Municipal green building policies have played an important role in promoting the adoption of best practices, particularly in energy conservation, greenhouse gas mitigation, and resilient design, thereby enhancing the capacity within the local marketplace. Looking ahead, policies that support BIA best practices will facilitate the broader adoption of BIA technologies and the integration of urban developments.”

Kathy Wardle | Perkins&Will Regional Director of Regenerative Design Principal

Without targeted policy reform, cities will continue to discard valuable resources—food waste, greywater, heat, and CO₂—rather than reintegrating them into regenerative urban systems. BIA presents a unique opportunity to embed circularity within cities by leveraging underutilized building resources to support localized food production, but it cannot succeed without institutional backing.

Historically, food system planning has been a national and international policy concern, in recent years, with the increased interest in integrating food production into urban environments, city-regions are emerging as a key scale and planning priority for integrating food production, processing, retailing, distribution, and waste systems, as observed in the rise of local food plans and policies in cities across the world (Blay-Palmer et al., 2021; Issac et al., 2022).

While planning and policy support for local food production and BIA is still emerging (Liu, Korthals Altes, Melot, & Wallet, 2024), leading cities are beginning to adapt urban food strategies to regional governance structures, demonstrating how zoning reform, building code updates, and financial incentives can enable BIA (Speckt, et al., 2019).

This section identifies critical policy gaps and outlines the regulatory frameworks necessary to scale BIA from isolated pilot projects to a city-wide strategy for urban resilience. By examining leading Canadian and global cities at the forefront of local and regional agri-food planning, we assess existing policy supports, regulatory barriers, and opportunities for resource circularity. Through case studies, policy analysis, and strategic recommendations, this chapter explores how cities, businesses, and communities can leverage policy tools to embed urban agriculture into mainstream urban planning, transforming it into a fundamental pillar of sustainable development.

The Disconnect Between Urban Policy and BIA Implementation

Despite growing recognition of sustainability in urban development, policy frameworks governing food production and waste-to-resource strategies remain fragmented. The primary barriers preventing the widespread adoption of BIA include:

Zoning Restrictions

Many municipalities classify BIA as agriculture rather than an integrated building function, leading to land-use conflicts that limit its placement in commercial, residential, and mixeduse properties.

Lack of Financial Incentives

Unlike renewable energy infrastructure, urban farms receive little to no tax credits or subsidies, making BIA less financially competitive than traditional assets.

Building Code Challenges

Existing regulations for structural integrity, fire safety, and water use were designed for conventional buildings, making it challenging to incorporate controlled-environment agriculture, hydroponics, and rooftop farms.

Limited Circular Economy Integration

While many cities focus on waste reduction and resource recovery, food production is often left out, missing the opportunity to link BIA with energy, water, and waste management strategies.

Fragmented Governance

Urban food policy is often managed separately from zoning, sustainability, and infrastructure departments, leading to slow policy development and lack of coordination.

Beyond policy barriers, several key challenges impact the scalability and viability of BIA:

Food Safety Risks

Urban food production is vulnerable to air pollution, heavy metal exposure, and contamination from urban waste inputs. Soil-based UA in uncontrolled environments lacks strict quality checks of conventional food systems (Buscaroli, et al., 2021). Ensuring safe substrates, water sources, and growing conditions is crucial for BIA’s success.

Gentrification and Social Equity

While BIA and UA projects can enhance community amenities and neighbourhood greening, they may also increase property values and contribute to displacement and gentrification (Hawes, et al., 2022). These projects risk prioritizing private developers over local communities without equitable policy frameworks.

Uncertain Impact on Food Security

BIA’s role in urban food security is constrained by land use competition, high energy demands, yield variability and crop limitations (Lal, 2020).

Approach: Analyzing Policy Frameworks

This research examines civic policy frameworks incentivizing UA and BIA, focusing on leading international cities with well-developed local food, urban agriculture, and circular economy policies. The goal is to identify best practices and policy strategies to guide future BIA policy development.

The study evaluates large Canadian municipalities and global UA leaders based on:

nj Local food policies and plans

nj Government reports, news, and press releases

nj Technical reports and academic literature

nj Industry knowledge and interest in future BIA project

Canadian cities were initially screened based on their population size (over 250,000) and the presence of urban agriculture policies (e.g., zoning bylaws and strategic plans). Vancouver, Calgary, Toronto, and Montréal were prioritized due to their comprehensive policy frameworks.

A detailed analysis of Vancouver, BC, highlights its Sustainable Large Developments Policy as a progressive model for BIA integration.

Figure 10: Perkins&Will, Nathan Phillips Square, non-edible green roof, Toronto, ON.

Data Collection and Analysis

This section employs desktop analysis and stakeholder consultations to refine policy recommendations and identify gaps in BIA integration at scale. Policy documents, action plans, and government websites were systematically coded to:

nj Track the number and type of BIA projects initiated under specific policies.

nj Assess government support mechanisms, including funding, incentives, and regulatory frameworks.

nj Conduct a gap analysis to identify policy deficiencies that may hinder BIA integration, particularly in technology adoption and local adaptation needs.

The study applies content analysis to UA, BIA, and circular economy policies to identify common policy goals, incentives, regulatory trends, and funding priorities (Issac, et al., 2022) (Vaismoradi, Turunen, & Bondas, 2013). This method helps to:

nj Analyze how food system policies are framed (e.g., sustainability, economic development, food security).

nj Map policy mechanisms that support or constrain UA/BIA adoption.

nj Correlate funding priorities with specific policy motivations.

Additionally, a case study approach was used to illustrate key policy trends, applying an instrumental case study methodology that considers one case to understand a common issue (Gerring, 2016) (Crowe et al., 2011) to examine BIA projects in practice.

This approach identifies best practices for BIA policy development at the city-region scale, offering insights into effective policy integration strategies for urban food systems.

While resource recovery is rarely a standalone policy, it is increasingly embedded within urban planning and food system policies to enhance food sustainability and shorten supply chains. Circular economy policies generally focus on resource reduction, reuse, and recycling, aiming to establish closed-loop systems that minimize environmental impact while strengthening local food security.

The chapter has three core objectives:

nj Identify the most incentivized forms of BIA, such as vertical farms and rooftop agriculture.

nj Analyze policies supporting or hindering BIA implementation, assessing regulatory frameworks and policy barriers.

nj Develop strategic policy recommendations, drawing insights from international case studies.

The Policy Landscape: Global, National and Municipal Frameworks

Policy frameworks at multiple governance levels shape the transition to resource circularity.

Global directives set overarching sustainability goals, national and regional policies define implementation mechanisms, and municipal regulations determine urban deployment strategies. The alignment of these policies directly influences the feasibility and scalability of BIA within cities.

While initiatives such as the Living Food Challenge, the European Union’s Farm to Fork Strategy, and the UN’s Food and Agriculture Organization FAO’s urban agriculture models highlight the importance of integrating food systems into circular economy goals, implementation at the national and local levels remains fragmented.

Sets overarching sustainability goals and indicators

Global scale

Creates policy implementation mechanisms that align with global goals

National scale

Implements regulations determining urban development strategies

Municipal scale

Regenerative food loops, waste elimination, and nutrient cycling, aligning food systems with nature’s processes.

Circular economy approach to food systems, with goals for food waste reduction, nutrient recovery, and urban farming incentives.

RELEVANCE TO BIA & RESOURCE CIRCULARITY

Advocates for food system integration into urban infrastructure and zero-waste systems but lacks enforceability in municipal policies.

Supports nutrient recovery from organic waste and urban farming incentives but does not mandate integration of BIA into city infrastructure.

Holistic regenerative framework with measurable targets in waste reduction, nutrient cycling, and energy balance.

Legally binding at the EU level includes structured funding for urban food initiatives.

Voluntary, with no legal mandate, making adoption inconsistent and slow.

Focus on urban resilience, food security, and integrating organic waste into agricultural systems.

Encourages organic waste integration into farming but does not explicitly reference BIA as an urban planning requirement.

Provides a strong global framework linking food resilience to waste valorization.

Lacks architectural integration strategies and building-level implementation frameworks.

Circular economy framework emphasizing food waste reduction, regenerative agricultural practices, and biocycling of organic materials.

Promotes food system circularity through waste-toresource principles, supporting nutrient recovery and lowimpact urban farming models.

Provides research-driven strategies linking agriculture, urban design, and waste valorization into a single framework.

Does not mandate BIA policies or formal integration into urban zoning.

Supports major cities in reducing food-related emissions and developing climate-aligned food policies.

Encourages BIA and urban agriculture as a strategy for reducing food miles, food waste, and emissions.

Engages a global network of cities, allowing policy innovation and best practice exchange for integrating BIA.

Conceptual focus; requires adaptation for city-level policies and enforceable regulations.

Primarily policy-driven with limited direct funding or enforcement mechanisms for BIA-specific projects.

National and Regional Approaches

While Canada has established food policy frameworks that promote sustainability, specific provisions for urban farming and BIA remain underdeveloped nationally. Existing policies primarily focus on:

nj Conventional agriculture and rural food security, rather than food production within cities.

nj Community gardening and rooftop farming incentives, but without structured support for integrating BIA into urban infrastructure.

nj Circular economy strategies that prioritize waste diversion, with limited emphasis on waste-to-resource conversion for local-regional food systems.

However, several national and regional initiatives have begun embedding urban agriculture and BIA within policy frameworks. These examples highlight opportunities for Canada to adopt best practices in developing structured approaches for BIA integration.

POLICY/INITIATIVE KEY FOCUS

Canada

Food Policy for Canada (2019) (Agriculture and Agri-Food Canada (AAFC), 2019)

United States USDA Urban Agriculture and Innovation Program (2020) (USDA, 2020)

France Green Roof & Urban Agriculture Law (2016)

Singapore 30 by 30 Food Security Initiative (2020)

Food security, local food systems, sustainability

Urban agriculture incentives, research funding

Mandatory green roofs or solar for commercial buildings

Local food production, agri-tech, vertical farming

RELEVANCE TO BIA & RESOURCE CIRCULARITY

Recognizes urban agriculture as a sustainability strategy but lacks specific funding or mandates for BIA integration into building codes or urban planning.

Lacks architectural integration strategies and building-level implementation frameworks.

Allows urban farming as an alternative to traditional green roofs, directly supporting BIA projects.

Incentivizes controlled-environment urban farming, with government funding for integrating urban farms into mixed-use developments.

Table 2: Comparison of key national policies focused on food systems.

Municipal Approaches

Vancouver has emerged as a leader in urban agriculture policy, implementing initiatives that encourage BIA adoption.

However, these policies remain fragmented, lacking comprehensive zoning, financial incentives, and regulatory support to integrate BIA into urban development fully.

Vancouver’s Food Policy Framework:

Key Strategies and Challenges

The Vancouver Food Strategy, adopted in 2013, is one of Canada’s comprehensive municipal food policies. Unlike previous frameworks, it integrates food production, processing, distribution, access, and waste management into municipal planning (City of Vancouver, 2024).

Key Objectives

nj Expanding food-friendly neighbourhoods by incorporating food systems into urban planning and infrastructure.

nj Empowering community stakeholders to participate in urban agriculture initiatives.

The strategy has driven progress in urban agriculture, food accessibility, and waste reduction. It has been implemented through actionable policies such as:

nj The Rezoning Policy for Sustainable Large Developments (SLD) mandates at least three food assets in large projects.

nj Urban agriculture project grants, supporting community gardens and urban farming.

Impact and Limitations

Since its adoption, the Vancouver Food Strategy has expanded urban food infrastructure. The key achievements can be summarized as:

nj Community garden plots increased by 60%, from 3,260 in 2010 to 5,500 in 2020.

nj Urban farms grew from 1 to 35 over the same period.

nj Farmers’ markets more than doubled, from 4 to 22.

nj The city’s green bin program diverted 216,000 tonnes of organic material (18% of total waste).

nj Total food assets: +71% growth (3,340 to 5,723).

nj Over 22,000 residents engaged through 11 neighbourhood food networks, supported by $169,000 in annual city funding.

Table 3: Assessment of Vancouver’s food policy framework impact (2010–2020).

Despite these successes of a 40% increase (2010-2017), the growth rate dropped to 10% (2013–2017) and 4% (2015–2017) (Vancouver, 2022) This is partly due to:

nj Limited availability of sites for new food assets.

nj Temporary gardens being repurposed for development.

nj Gaps in zoning and financial incentives for larger-scale BIA projects.

Zoning, Incentives, and Economic Policies for Building-Integrated Agriculture

While sustainability policies, food security strategies, and circular economy directives are gaining global traction, BIA implementation remains limited to minor zoning code adjustments or grant-funded pilot projects.

Key barriers include the absence of financial incentives and resource-recovery mandates, particularly for technology-intensive models like vertical farming and rooftop greenhouses. In contrast, renewable energy, water conservation, and waste reduction have received consistent regulatory and financial backing, enabling widespread adoption. This lack of policy integration for BIA results in limited incentives and regulatory misalignment.

Figure 13: Perkins&Will, Daphne Cockwell Health Sciences Complex, Toronto Metropolitan University, Toronto, ON.

Policy Summary

KEY POLICIES AND CITY RESOURCES

Vancouver, BC Vancouver Food Strategy

Vancouver, BC

Sustainable Large Development Policy (SLD)

London, Ontario

UA Strategy & “Making UA Easy”

Ottawa, Ontario

The New Official Plan & Ottawa Food Action Plan

Calgary, Alberta

Calgary EATS & Indoor Farming Business Support Program

Montréal, Quebec Stratégie d’Agriculture Urbaine

Montréal, Quebec Circularity Gap Report

Edmonton, Alberta

Edmonton Fresh & Zoning Bylaw 20001

✓

✓

✓

Establish a just and sustainable food system; increase access to affordable, culturally diverse food.

Foster sustainable site design; promote energy and water efficiency; enhance urban biodiversity; support sustainable food systems.

Increase adoption of vertical and rooftop agriculture; support midstream infrastructure for food processing and distribution.

Develop “15-minute neighbourhoods”; increase local food access via grocery stores, UA, and farmers markets.

✓

Expand local food access and production.

Strengthen self-sufficiency and urban resilience; integrate UA into city planning.

Expand urban food access and circularity initiatives.

Improve food security and local economic development.

Toronto, Ontario GrowTO UA Action Plan & Green Roof Bylaw ✓

Toronto, Ontario

Baselining for a Circular Toronto

Guelph, Ontario

Our Food Future

Mitigate urban heat island effect; integrate UA into rooftop developments.

Focus on food redistribution, waste avoidance, and local food procurement.

Support local economic development; improve food accessibility.

Mandates food assets in large developments; integrates urban food systems into community planning.

Requires integration of food assets in largescale developments; aligns food assets with sustainable infrastructure (rainwater management, zero-waste planning).

Separates container farming from other container-based uses, allowing expansion across multiple land zones; allows 50% of greenhouse area to count towards landscaping requirements; permits UA in all land-use designations.

Defines UA as a ‘food asset’ within 15-minute neighbourhoods; proposes tax incentives for landowners donating land for urban food production.

Provides property tax exemptions for farmed areas in buildings; waives business license fees; connects producers with vacant city land and buildings.

Invests $5 million to establish a circular food economy, develop urban agri-commercialization projects, and support local food markets.

Establishes ‘living labs’ for stakeholder collaboration; enhances food waste measurement and collection; increases UA infrastructure.

Examines regulatory barriers to rooftop agriculture; explores agricultural demonstration zones within urban neighborhoods.

Requires green roofs (not necessarily for agricultural purposes) on buildings exceeding 2,000m²; provides eco-rebates of up to $100/m² for green roofs.

Targets increasing locally sourced food tonnage; fosters circular economy integration.

Develops urban food asset datasets; implements incubator-accelerator services; creates impact funds and social currency models for carbon credits.

10% increase in food assets; UA bylaw adoption; 40% increase in community garden plots; 216,000+ tonnes of organic waste diverted.

Successful integration of BIA in multiple developments; increased developer engagement with food networks; greater awareness and adoption of BIA projects.

Zoning law Z-1, Section 4 amended to classify UA as permitted land use; removal of zoning restrictions for greenhouse and shipping container farms.

UA permitted in all zones; 80% of intensification in 2022 occurred within 15-minute neighbourhoods.

Established Canada’s largest vertical farm (as of 2023) and other high-yield controlled-environment farming operations.

Expansion of urban food production from 120 to 160 hectares (by 2026); increase in UA enterprises from 40 to 55; establishment of 50 school gardens.

Initiated $5 million circular economy strategy for food system integration.

Commercial indoor cultivation permitted for industrial zones; UA (outdoor farms and community gardens) permitted in most zones.

Over 1,000 green roofs constructed; limited operation of BIA farms on green roofs.

88 circular economy initiatives launched; establishment of Toronto’s circular economy consultation framework.

Launched multiple circular food economy initiatives, including food waste diversion programs, climatesmart agriculture platforms, and a B2B food waste exchange platform. Table 4: Overview and coding summary of

KEY POLICIES AND CITY RESOURCES BIA INTEGRATED KEY GOALS

Copehagen, Denmark

Food Strategy & Climate-Resilient Neighbourhood Østerbro

State of California UA Incentive Zone (UAIZ) Act

New York City Green Roof tax Abatement & UA Action Plan

Paris France Parisculteurs & Parisculteurs Toolbox

United Arab Emirates

✓

✓

Promote green infrastructure and biodiversity; support community urban farming.

Expand UA in food-insecure communities.

Increase transparency in food systems; educate the public on sustainable food production.

Expand urban food access through innovative farming.

URBAN PLANNING STRATEGIES RELEVANT TO BIA KEY ACHIEVEMENTS

Mandates green roofs on new developments (since 2010); integrates BIA into climate-resilient district planning.

Allows local governments to grant property tax incentives for UA integration within designated areas.

Requires reporting on urban food systems; establishes a UA-focused municipal office; implements training programs in VF, green roof operations, and UA.

Matches land and building owners with potential UA producers.

Established ØsterGRO rooftop farm in 2014; redeveloped 50,000m² in Østerbro into green infrastructure, including UA spaces.

Widespread adoption of UAIZ legislation across multiple counties and cities.

Supported 380 community gardens; developed 74 controlled-environment agriculture projects citywide.

80+ BIA projects supported through Parisculteurs program.

National Food Security Strategy & Emirates Sustainable Agriculture Label ✓

London, United Kingdom Strategy & Capital Growth Organization

Singapore 30x30 Initiative & Food Story Programme

Increase food selfsufficiency through waterefficient agriculture.

Strengthen communitybased food systems and green infrastructure.

Improve national food self-sufficiency through controlled-environment agriculture.

Table 5: Overview and coding summary of global policies and best practices.

Prioritizes investment in agritech solutions such as hydroponics and vertical farming.

Provides grant funding for urban food projects; develops UA networks.

Directs funding to agritech R&D; integrates UA within national food security planning.

Launched Food Tech Valley, a high-yield research and innovation zone; UAE captured 1.1%

£75 million allocated to 138 projects, including urban farming initiatives.

Allocated $309 million, with an additional $90 million for highyield urban agriculture projects.

Rezoning for Large Developments: City of Vancouver’s Sustainable Large Developments (SLD)

The SLD Policy, adopted by the City of Vancouver (CoV) in 2018 and last updated in 2023, represents a progressive regulatory effort to integrate sustainability and food systems into large-scale urban developments.

By mandating three diverse food asset inclusion and aligning urban food production with stormwater, energy, and waste management strategies, the policy aims to make BIA an integral part of Vancouver’s urban planning framework.

The policy applies to all rezoning applications for developments exceeding 8,000 m² (86,110 ft²) of land area or 45,000 m² (484,375 ft²) of new floor area. It ensures that major urban projects contribute to the city’s climate, biodiversity, and food security goals.

The SLD Policy is structured around six core sustainability priorities, with food assets as a required component: Sustainable Site Design, Food Assets, Water Management, Energy Efficiency, Green Mobility, and Zero Waste Planning.

At the rezoning stage, developers must identify and describe three food assets within their project. For sites over 10 acres, developers must provide a detailed operational and maintenance plan for at least five years to ensure the longterm viability of these food assets.

At the development permit stage, developers must submit detailed designs, confirmed programming partnerships, and long-term operational strategies to ensure food assets are not just symbolic additions but fully functional components of the development.

Figure 14: Perkins&Will, Skeena Terrace, Vancouver, BC. Urban farming at ground level and on rooftops. Rezoning