Welcome to our first issue of PERIscope 2022. As the Customer Services Director, I’m delighted to open this issue as it showcases the very best of our specialist services, from smart engineering to advanced digital tools to extraordinary fabrication work.

One of my responsibilities since starting in this role was to take the feedback from our customer survey and implement changes to solve some of these challenges. I’m pleased to share some of our successes with you.

Excellent customer service is at the heart of our business, so it was only right that we expanded the customer services team. I’m pleased to say that this function has developed significantly despite the challenging environment created by the COVID-19 pandemic. All our customer-facing functions are office-based to create a seamless journey for our customers, from order to delivery to post-purchase support.

One of our best results from the action we took is a 50% reduction in the off-hire processing time, which involves resolving discrepancies swiftly with our customers.

It was also important to our customers that we were available during their working hours. To accommodate this, we extended our opening hours, starting earlier to provide support at the earliest opportunity in the day.

In addition to right timing, having the right people in place was equally important. We employed project specialists to support complex projects, ensuring the right stock is in the right place at the required time. These new roles complement our existing site demonstrator and project delivery engineer roles, ensuring projects can take off and be delivered smoothly.

Over the last year, we introduced three key initiatives – Ready to Rent, Damage Waiver and PERI Priority have been a success since roll out. Ready to Rent ensures our returned products are fit for purpose on the next project, meaning our customers receive only the highest quality and nothing less.

Continuingwiththethemeofquality,weintroduced our Damage Waiver initiative to give you peace of mind during the off-hire process when returning rental equipment. This initiative enables customers to pay a small percentage to cover them for scrap and repair charges throughout their rental period.

We’re living in a world where people want products andservicesondemand,andthisisbecomingmore apparent in the construction industry. PERI Priority is our fast-track delivery service for customers who need products urgently. With this service in place, we’ve halved delivery times by transporting goods to project sites within 24 hours.

Allofthesechangeshavebeeninspiredbyfeedback from you, our customer. With your feedback, we can continue to tailor our business around your needs and make long-term improvements that make a difference.

No matter how big or small your project, the impact of quality service cannot be underestimated. We aim to offer more than just a quality product. From pre-planning with digital insights to engineering the optimal solution on site, we partner with you every step of the way. I hope you enjoy reading how our customers have benefitted from some of these services in this issue.

Stuart Robinson Customer Services DirectorEditor PERI Ltd.

Formwork

Scaffolding Engineering

Market Harborough Road

Clifton upon Dunsmore Rugby CV23 0AN

United Kingdom

Responsible PERI UK

Editor-in-chief

Jinal Kansara

Editing and graphics

Dekany Design

Photos

Simon Turner

Darren Powell

Neil Terry Design & Print

Copyright

The photos used in this brochure feature certain situations at particular moments on various construction sites.

Additional images, e.g. regarding safety and anchor details, cannot always be considered as conclusive or final. These are subject to the risk assessment carried out by the contractor.

© PERI GmbH

7

Read Director at Assemble Scaffolding, Shaun Somerton‘s thoughts on the PERI UP Easy system

8 Shaft formwork for Thames Tideway‘s largest site yet Thames Tideway Tunnel, London

10 Constructing a Digital Environment with the Digital Engineering team at PERI UK

Faster connections and built-in safety means you can build 4x faster than tube and fitting. Why not experience the benefits of PERI UP Easy on your next project?

To find out more about PERI UP Easy Scaffolding, scan or click the QR code or visit: link.peri.ltd.uk/PERI-UP-Easy

We interviewed Shaun Somerton, Director at Assemble Scaffolding, to learn more about his experience with our lightweight façade scaffolding system, PERI UP Easy. Shaun worked in collaboration with scaffolding contractor, Legion Scaffolding, on this recladding project in central London.

Q: Can you tell us about the project and why you chose PERI UP Easy?

We are working on The Link building, City Road which is one of the many recladding projects in London undergoing work to reduce its fire risks. The reason why we used PERI scaffolding, both Easy and Flex, is because of the reduced fire risks of a metal system.

With traditional scaffolding you typically have wooden boards that can be combustible, which increases the fire risk. That’s why we opted for the metal decks, metal toeboards and metal system.

Q: How did the scaffold accommodate the geometry of this building?

We found that the splayed corner components worked perfectly when we were adapting and modifying the scaffolding around corners. It’s a unique feature of the scaffolding, I’ve not seen it anywhere else. It certainly allows for a nice flush finish that is pleasing to the eye. The cover plates go over the splays to create a neat and safe platform, but also leaves the adaptions on the internal sections.

Q: What other challenges did you face on site?

Another complication we found on site was the gas flumes. With this system, we were able to avoid clashes with ledgers that were directly in line with the gas flumes. We were able to miss

a bay and completely leave it out, continuing with the progress across the rest of the building and then installing it later once the gas men were informed. It was a huge benefit that allowed us to carry on – without the ability to do that we would have had to stop our work.

Q: How did you find working with the system?

We found PERI UP very easy to use. It’s light, the built-in safety factors like the handrail and advanced guardrail makes it really easy to install. The locking decks prevents any uplift.

The system is also advantageous in adverse weather conditions we often experience in the UK. With a lot of the traditional scaffolding systems, the boards have the potential to fly up and become a trip hazard or a risk of falling over with additional tubes. With the PERI UP system, everything is locked down and it’s safe and accessible.

Q: Were there any time-savings as a result of the system on this project?

Normally, we’re averaging 10 to 13 sq m a day in scaffold terms to install independent scaffolding with tube and fitting. With the PERI UP Easy system, we were averaging between 30 to 35 sq m a day, and on some occasions even 40 sq m, which is completely different in comparison to tube and fitting. The prelims are saved for our client. The quicker we can erect a system, the less time spent on site, which reduces the cost of welfare facilities.

Q: How did you find working with the scaffolding team at PERI?

We found working with PERI very easy. Mark’s knowledge of the industry is second to none. With him involved it’s been quite simple and easy.

Q: Any final words?

I’d definitely recommend visiting PERI’s exhibition hall in Brentwood to understand how the system works and use it prior to going onto site. It’s all down to the base out and knowing the size of the components. It’s also key to take time during the planning process which will guarantee big savings. You’re going to save half of your programme if you have the right planning.

Thames Tideway Tunnel, London

Thames Tideway Tunnel is one of the UK’s biggest infrastructure projects, involving over 20 construction sites.

We’ve supported the construction of multiple shafts on this project, one of the more challenging ones due to its size situated at the Kirtling Street site. Precise designs and smart engineering provided by our skilled team helped shorten the construction time and reduce costs.

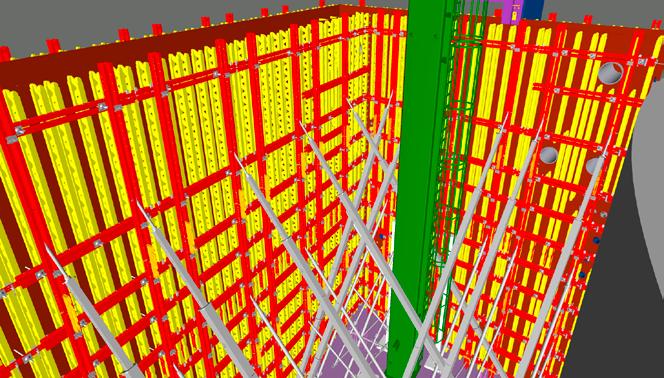

With a diameter of 30m, this shaft is the largest across the entire Tideway project. Our engineering team worked collaboratively with the Ferrovial Laing O’Rourke JV (FLOJV) site team to deliver a temporary works system for two tunnel portals that were 7.3m wide and 6.5m deep in addition to 1m thick secondary lining for the shaft walls.

The customer required the tunnel portals to be cast in tandem with the tunnel drum – the 15m height of these portals making the formwork design more challenging. To ensure timely and simultaneous delivery of these structures, our engineers proposed an innovative solution comprising standard rentable components from our VARIOKIT range, minimising costs and maximising reusability.

Our formwork solution split the concreting process into two halves to accommodate the height of the portal. For the lower half, the tunnel drum was integrated with a moving frame used in conjunction with SB brace frames. The top half comprised SB brace frames integrated with PERI UP heavy-duty shoring. To support and keep the SB brace frames securely in position, anchors were cast into the concrete structure at a 45-degree angle.

For the secondary lining, our client required an efficient temporary works system that would reduce cycle times. Our engineers evolved the solution delivered at the Blackfriars site to accommodate the larger diameter of this shaft. This comprised a hybrid RCS (rail-guided climbing) and SCS (single-sided climbing) climbing system, which enabled faster cycles as all platforms climbed simultaneously with the support of RCS MAX hydraulics. Hydraulic operations accelerated the lift, as the entire climbing arrangement could be jumped in just 1-2 hours, compared to crane operation which took considerably longer.

SCS climbing was used to support the concrete load from the single-sided pours. RCS MAX lifted the entire ring consisting of 41 formwork platforms to the next level in 3.2m lifts with the push of two buttons. In addition to faster cycling, RCS MAX provided builtin leading-edge protection, an important safety provision as formwork units climbed seamlessly without needing to be repositioned at each level.

Safe access to the shaft walls was efficiently integrated into the climbing formwork design by extending the platform at level +1. The platform accommodated a 4-person man rider, which was used to transport workers to and from various levels inside the 50m-deep shaft.

The entire solution was fabricated offsite in our depot, contributing to time savings, reduced labour and minimised safety risks on site.

The drum formwork was integrated with heavy-duty trusses comprising RCS rail frames and heavy-duty rollers to facilitate movement. The efficient solution was designed to serve multiple purposes, such as enabling safe installation into the casting position, height adjustment and preventing uplift during concreting. It also facilitated the safe removal of the formwork unit out of the shaft.

Minimising cost and wastage were important considerations of the design. The flexibility of VARIOKIT components and cost-effective design ensured that the same solution could be reused for the second tunnel entrance.

Our Digital Engineering team share how PERI is keeping up with changes in digital technology and utilising its benefits to support customer projects.

Digital technology has transformed how we design, plan and supply our formwork and scaffolding solutions at PERI, driving efficiencies from start to finish.

We are seeing more customers request and incorporate these services as construction demands more accuracy and faster build times.

At PERI, we have the capacity to provide integrated digital solutions, including 3D,4D and 5D services. We use 3D modelling to create animations and visualisations, demonstrating the process throughout all stages of the build. Applying digital technology to construction enhances early engagement and planning, improves productivity and safety, and reduces costs for our customers.

3D drawings are becoming a normal requirement on projects as more contractors adopt Building Information Modelling (BIM) processes. Using our 3D models, we can demonstrate sequencing, resource management, assembly, system integration and removal, and this too from multiple viewpoints to provide the required level of detail.

By adding data to our 3D models, we can give your team more insight into the design and more scope to manage the model. We can embed data such as pour IDs, asset tags and equipment statistics which enable additional BIM processes and procedures.

One of the biggest advantages of creating a digital twin of our designs is that we can coordinate and clash detect our designs against structural models and site environments in advance.

Through our clash detection process, we are able to identify and redesign our solutions to accommodate integral structural components such as rebar and embedded steelwork, removing and illuminating issues before reaching site.

Our declashing model on Hinkley Point C enabled both teams to detect whether the rebar and cast-in

embedded steel work would come into contact with formwork elements such as ties or props.

In the same way, we can ensure various construction elements work in harmony with the 3D PERI design model. By overlaying our model with that of the project’s, we can check model coordinates and alignment, positioning, and facilitate operations such as lifting and striking of PERI systems.

Coordination is vital on complex projects that consist of multiple design elements, site limitations and other constraints. Lack of coordination is a risk to your construction programme as delays and construction issues can occur as a result.

Coordination also provides a more streamlined construction process for all stakeholders as there is transparency from the start.

Similarly, virtual tours help you to understand the environment in which PERI systems are being erected and struck. We use virtual reality software to combine a series of panoramic renders from a 3D model to create a virtual tour of the project model. This service enables you to investigate our temporary works designs in an interactive way, bringing your project to life ahead of the build.

We can add further insights within the tour, by embedding data such as images, videos and other supporting information. All of this data can be accessed via a single QR code or web link, which is then ready to view on your smartphone, tablet or laptop.

Animations can demonstrate assembly, operations and sequencing of our design solutions, making it a useful resource for those on site or project managers responsible for risk assessments and method statements (RAMS), and timely delivery.

The animations we produce are guided by your requirements and the elements you want to focus on. Created specifically for your project, our team can alter or configure the content to meet changes in requirements throughout different phases of construction.

South Quay Plaza 4 is the second phase of the South Quay Plaza residential development in London’s financial district, Canary Wharf. Once complete, the newest tower will stand 56-storeys high and comprise 400 residential units.

Following the successful delivery of the first phase in 2018, we were appointed to design temporary works solutions for the complex shape of the core and all the slab work for this tower. Where possible, the solution had to incorporate the customer’s PERI equipment used in the first phase.

Construction started at the peak of the COVID-19 pandemic in the UK — a time when the industry was already experiencing labour and material shortages due to BREXIT.

These unforeseen issues in addition to the complexity of the project meant that site support was crucial. Our demonstrators made regular visits to site, supporting operatives with system installation in line with social distancing guidelines.

The core was split into two climbing zones to achieve the customer’s desired pouring sequence and 6-day cycle time. This enabled installation of rebar and fixings on one half of the core to take place while concrete was poured on the other half.

Hydraulic climbing reduced crane operation, enabling it to be used primarily for transporting reinforcement cages to the working levels. Our fully enclosed climbing solution was made up of 3.3m-high MAXIMO formwork shutters combined with ACS-G to construct the external core walls and ACS-P for the internal walls. Four ACS-P systems were used inside the core, two of which comprised built-in hatches to facilitate pours and the installation of precast stairs. Two smaller ACS-P systems climbed inside the shafts, with suspended

“The South Quay Plaza 4 superstructure features a complex and challenging core geometry. With the experience of both teams, we collaborated on design, planning and installation. We used a combined ACS jumpform solution within a tight footprint on site where pre-fabrication and just in time deliveries were key. We utilised PERI’s digital 3D model for planning and briefing. The

result was great, as it allowed us to capture the detail and lifecycle of the system from erection to operation to the dismantling stage. The team at PERI were proactive in meeting our needs with engineered safety at the forefront of their solutions, including built-in access hatches and access stairways from top to bottom.”

PERI UP 75 stair towers providing emergency access to the levels below. RCS bridge platforms were also used to accommodate smaller areas and provide access to the core.

Another complex aspect of this project was the change in wall thickness throughout the core. Our designers had to adapt the formwork arrangement to achieve 450mm-thick walls up to level 18, reducing to 250mm from level 53 upwards.

The project’s small footprint, proximity to the DLR (Docklands Light Railway), and adjacent South Quay Plaza tower

meant that just-in-time deliveries were crucial to controlling storage capacity on site. All external platforms were prefabricated in sequence by our team in Rugby to limit the amount of equipment on site at once and to simplify installation. In total, we prefabricated over 80 elements ready for final assembly on site.

We also provided digital services to support our customer with complex areas of the build. 3D models of the structure were produced to visualise the climbing sequence, enable clash detection, and identify spatial limitations ahead of construction.

Transport PERI UP scaffolding components to the working level in minutes

The Alimak STS 300 scaffold transportation system has been developed to work seamlessly with PERI UP scaffolding systems, providing a smarter way of transporting components and material from the ground up to any level. Through automated transportation, the hoist system reduces manual operations and labour throughout the installation and removal process. Productivity is boosted with the system, as two scaffolders can erect an average of 300 sq m a day.

It’s the fastest way to get PERI UP scaffolding components up a building, making it ideal for structures requiring multiple lifts.

The simplest way to achieve continuity of reinforcement between pours

We’ve partnered with DY.CO to offer you an efficient and safer alternative to protruding rebars and couplers when pouring connecting concrete elements. The continuity strip contains enclosed rebars which can be extended out when required, creating a safer working environment and minimising the risk of water ingress.

*CARES approved

To enquire about these products, get in touch at info@peri.ltd.uk

Form footings and foundations with minimum effort

With no additional support required for heights below 500mm, this permanent formwork solution helps you to construct large foundations and beams at lower costs. Get the perfect level and edge every time as there’s no need to strip the formwork.

Invest in high-quality. For infrastructure that is built to last.

To find out more about our infrastructure solutions, scan or click the QR code or visit: link.peri.ltd.uk/infrastructure