The Fitzrovia - 247 Tottenham Court Road

Hybrid Frames System

The Fitzrovia is a Grade A mixed-use building in the prominent city centre location of Tottenham Court Road for property developer M&G Real Estate, working with Co-RE. The Architect is PDP London, with consulting engineers AKT II. The Hybrid Frames structure provides 5,570sqm of office space on the upper floors, mixed retail space on the ground and lower floors and eight premium residential units.

PCE Ltd was pleased to have been appointed by Kier Construction to design, manufacture, and construct the Hybrid Frames building, embracing a ‘kit-of-parts’ philosophy using offsite manufactured structural steel and precast concrete components, together with insitu reinforced concrete.

By utilising PCE’s innovative Hybrid Frames System, this MMC (Modern Methods of Construction) build delivered a much faster programme compared with traditional construction methods, excelling in speed, quality, safety and value.

292,000 Reduction In Embodied Carbon

27 Weeks

Constructing

25 Site Operatives

2,300+ Off-site Manufactured Components

0 Back Propping

6 Days Per Level Installed

286 Just In Time Deliveries 100% Structure Exposed

6 Storey Building 0 Additional Fire Protection Required 86,000 sq.ft Office Space 0 External Scaffolding

PCE PROJECT VALUE

CLIENT

MAIN CONTRACTOR

ARCHITECT

CONSULTING ENGINEERS

COST CONSULTANT

M&E ENGINEERS

Avison Young Project Management Ltd Kier Mechanical & Electrical

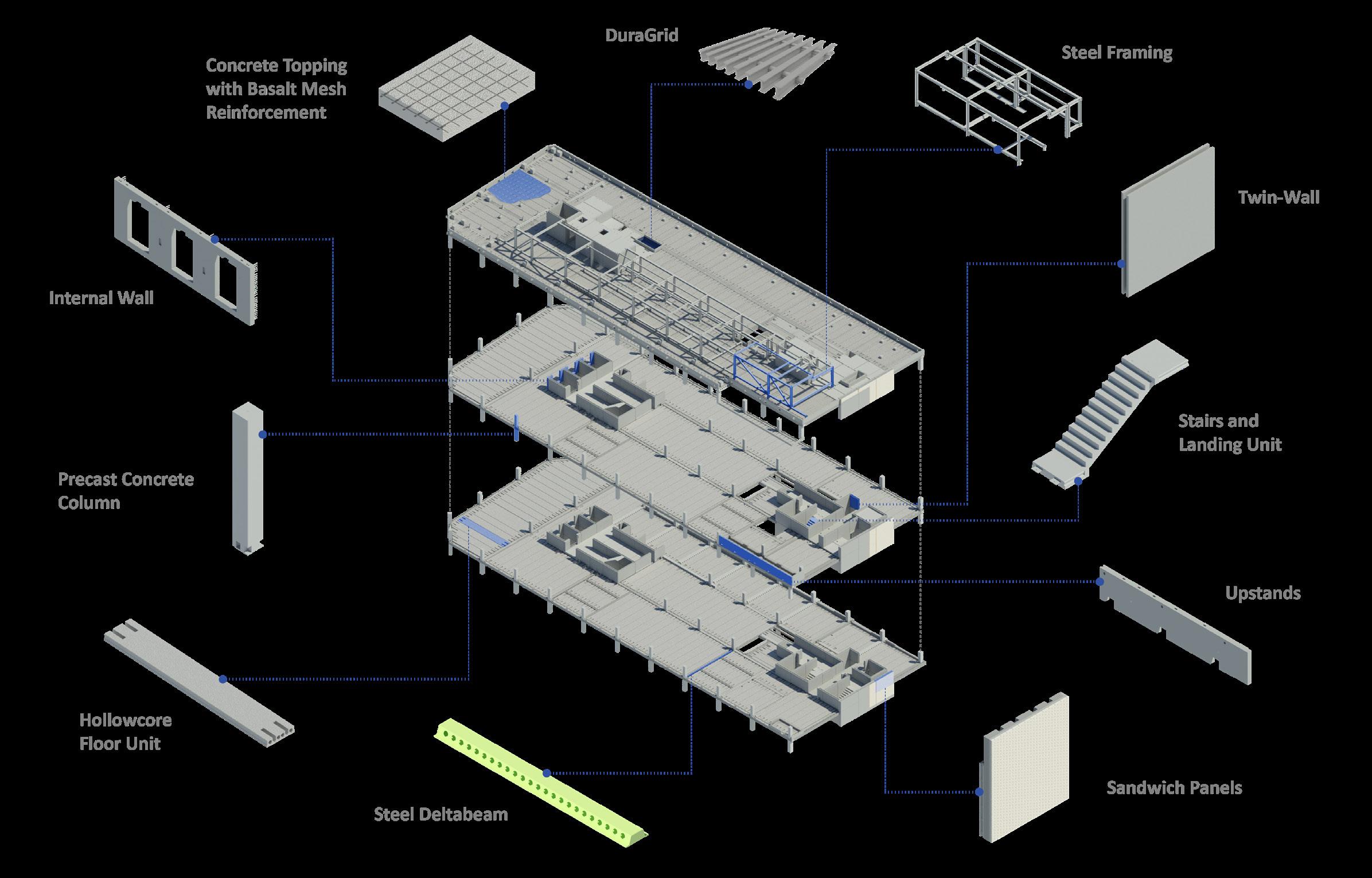

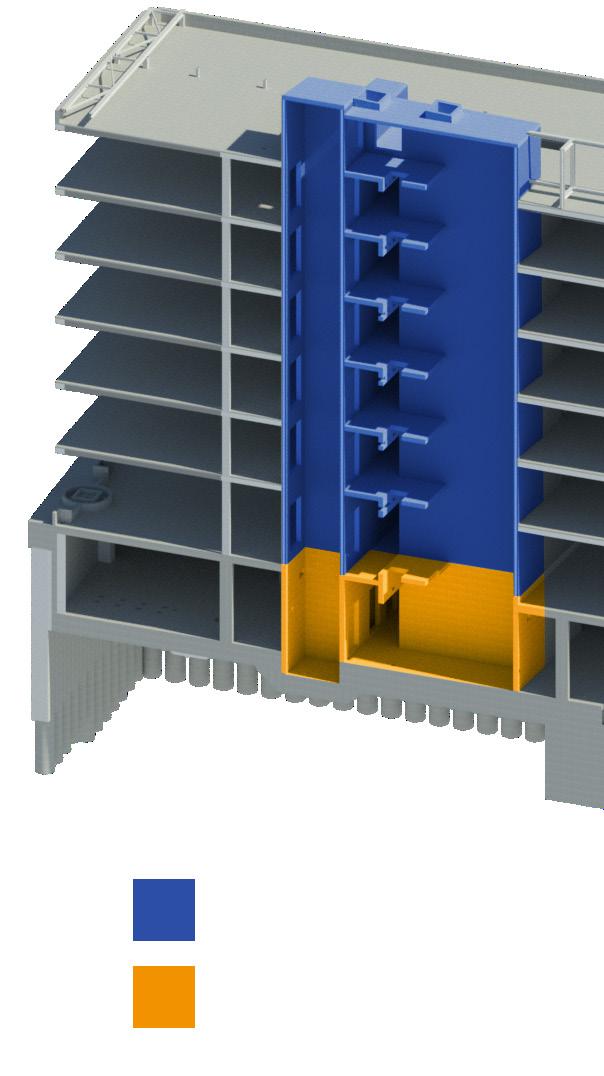

At the heart of the solution is PCE’s HybriDfMA Frame - a highly engineered, systemised structural frame built from pre-designed, offsite-manufactured components. These form a coordinated ‘Kit of Parts’ assembled rapidly and reliably using PCE’s proven smart connectivity and standardised installation methodology. The result: faster construction, consistent quality, and predictable cost and programme outcomes.

Despite its systemised nature, HybriDfMA Frame is fully configurable - supporting a range of materials and enabling seamless integration with bespoke architectural and structural designs to meet project-specific and sustainability targets. This enables truly hybrid structures, such as The Fitzrovia W1, delivered through Modern Methods of Construction.

• 50% reduction in construction programme

• 90% reduction in waste

• 80% reduction in site deliveries

• 80% reduction in on-site personnel

• Improved productivity

• Fully configurable HybriDfMA Frame integrates seamlessly with existing designs

• Optimised component geometry improves carbon efficiency

• Long-span solutions enable flexible, efficient grid layouts

• Façade and M&E systems integrated with minimal coordination required

• Safer working environment with no back-propping and improved access at height

• Early access for follow-on trades streamlines the critical path and boosts productivity

• Offsite manufacture delivers predictable tolerances and industry-leading quality

• Fire-resistant with excellent thermal and acoustic performance

• Flat soffits simplify M&E coordination and partition construction

• High-quality exposed concrete finishes enhance aesthetics

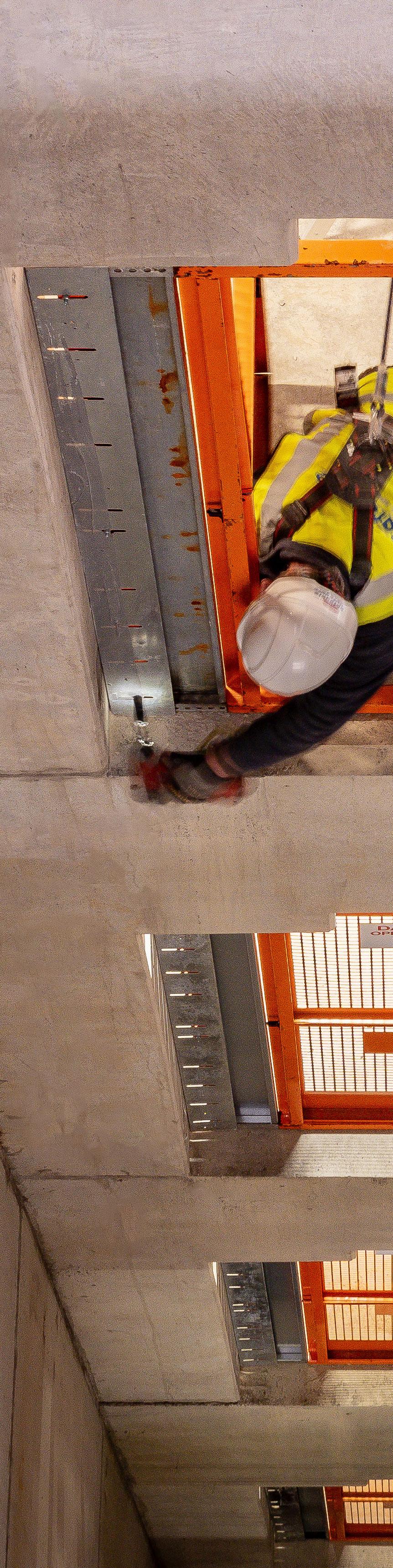

• Designed-in safety, including integrated riser-safe systems

The project, designed as a PCE Hybrid Frame, combined a number of offsite manufactured precast columns, stairs and GRP riser covers. In addition, there were in excess of 1,000 engineering initiatives were implemented by using basalt fibre reinforcement

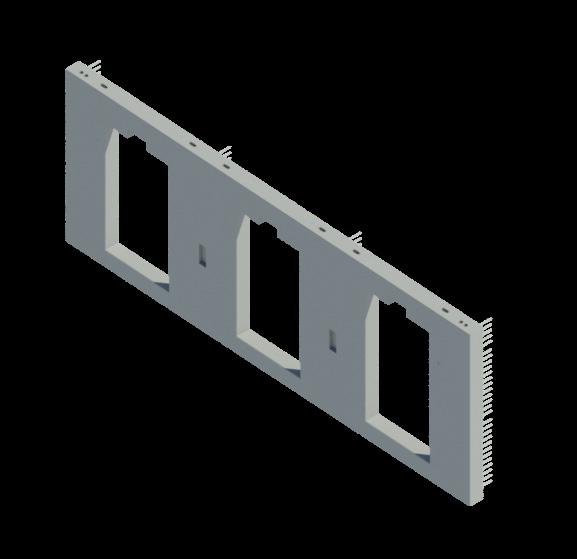

Precast solid walls were cast flat on variable steel tilt tables, ensuring a high-quality finish. Tilt tables were used to minimize unnecessary handling reinforcement that would otherwise have been required to turn the unit vertically into its delivery orientation.

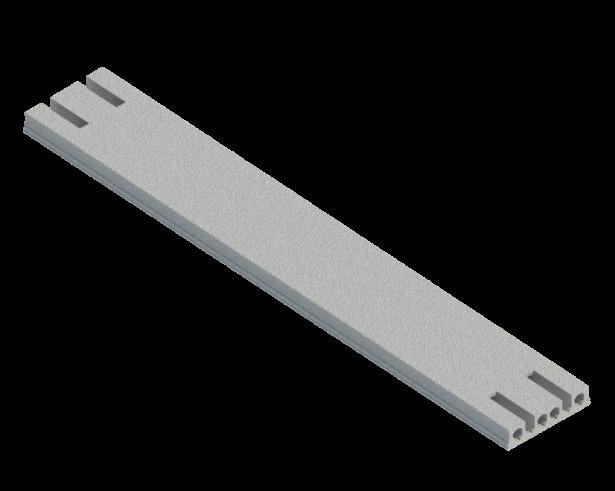

250mm deep pre-stressed concrete hollowcore units, designed to work compositely with the 100mm deep reinforced structural topping.

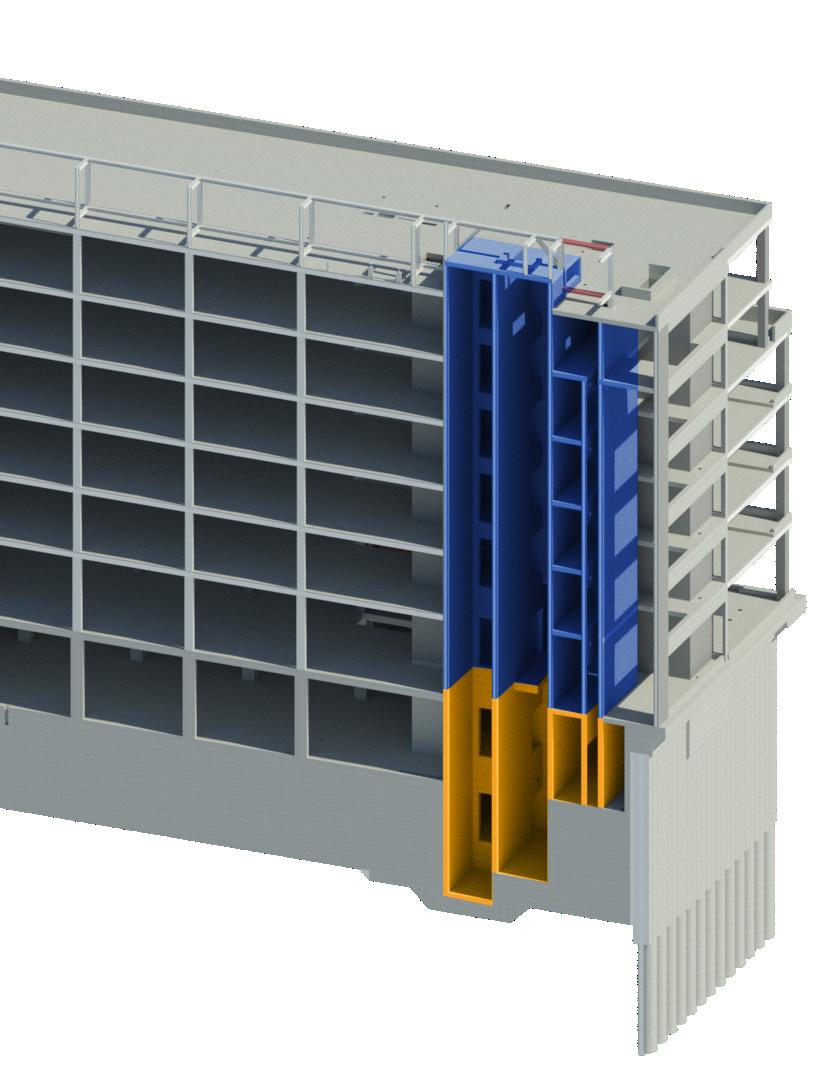

Twin-wall cores provide stair and lift shafts as well as frame stability.

Stair flights were pre-fitted with handrails before lifting for a quicker install.

manufactured components including precast concrete, twin and solid walls, steel Deltabeams, 1,000 hollowcore slabs and over 5,000m2 of concrete insitu flooring. Carbon reducing value reinforcement in the structural insitu concrete floor topping, replacing the steel mesh.

Deltabeams were used compositely with reinforced structural concrete to support the floor structure without any down stands. These new steel Deltabeams were made using 90% recycled steel.

Offsite constructed external preglazed panels with a tiled finish form the non-structural façade. Grey and brick faced panels form the structural party wall against the adjacent plot.

Precast concrete columns for the length and breadth of the structure at each level providing stability of the building.

Structural steelwork was used for framing the plantroom on the roof of the building. Duragrid riser solutions were added throughout the floor levels to safely cover voids in the structure.

PCE’s flexible, multi-partner supply chain model reduces reliance on any single manufacturer, de-risking projects and ensuring resilience against fluctuations in industry capacity. Each manufacturer is selected based on their proven expertise, infrastructure, and product specialisms - ensuring components are produced by the partners best placed to deliver them efficiently and to the highest standards.

This approach balances demand across the supply chain, supporting consistent output and near-limitless scalability. Just-in-time deliveries, coordinated through PCE’s digital systems, streamline logistics and drive programme certaintybringing assured quality, cost control, and schedule confidence to every project.

2,300+ Off-site Manufactured Components

3 Countries Across the Supply Chain

15 Component Types

6 Supply Chain Specialists

6 Factories Used

High-level quality control and a well-defined manufacturing strategy were critical to ensure the success of assembly and construction delivery. Without these measures in place, the overall process could be compromised.

With nearly 50 years of MMC and offsite expertise, PCE has established and refined its own manufacturing specifications that complement its system build approach. With strong collaborative relationships across its supply chain, these methodologies assist production factories to comply with PCE’s high standards.

To strengthen its manufacturing capability, PCE embeds in-house precast coordinators across its supply chain. Working closely with supply partners, they ensure consistent, uncompromising quality.

The Fitzrovia project exemplifies this approach. It features a refined hybrid structure that showcases high-performance materials as part of the architectural expression. With no additional cladding or concealment, the exposed reinforced precast concrete and structural steel form an integral part of the building’s aesthetic. This seamless fusion of structure and design demonstrates how PCE’s systemised offsite solutions align perfectly with architectural intent - where engineering precision enhances, rather than competes with, the architectural vision.

PCE’s approach to quality at the Fitzrovia W1 project was underpinned by a rigorous, integrated process - ensuring control, accuracy, and full traceability from design through to final handover.

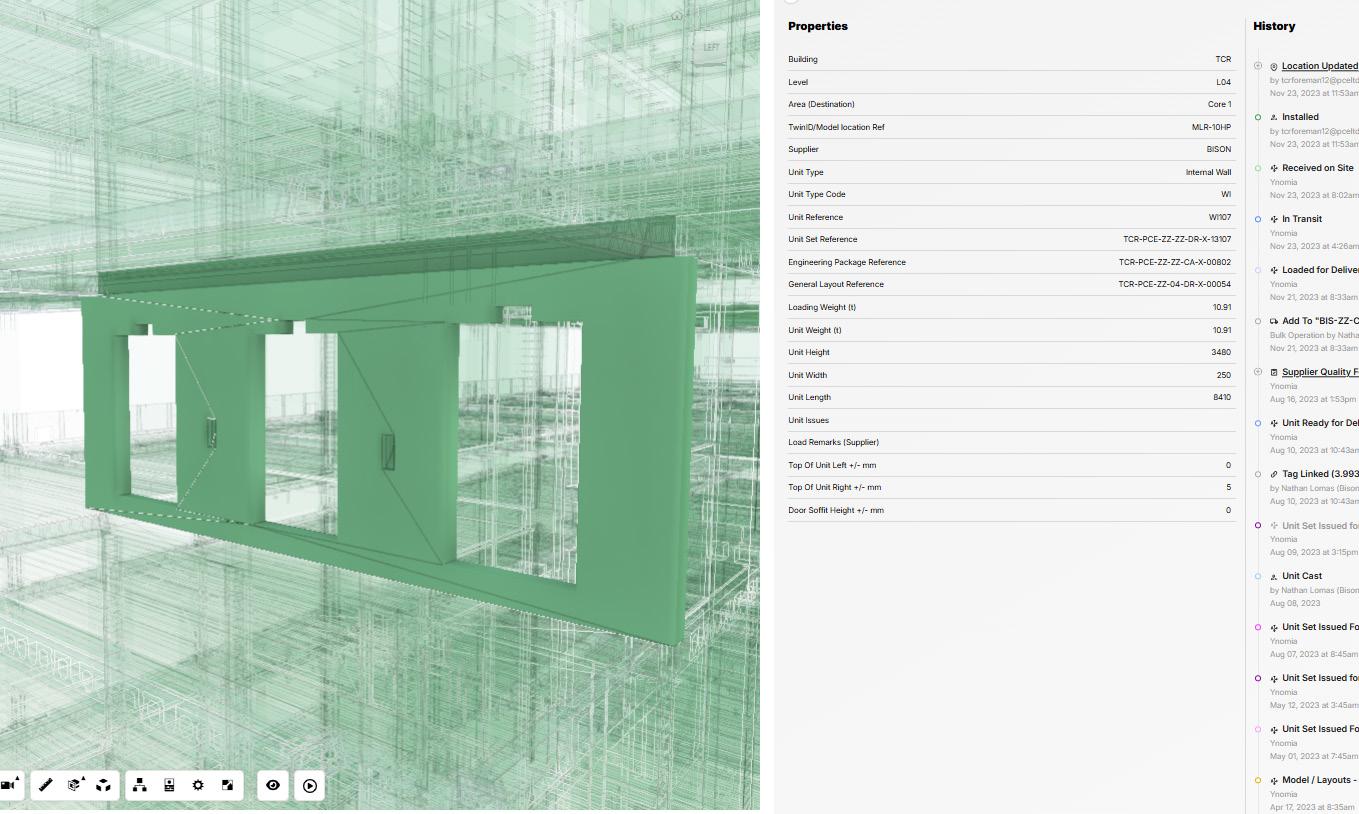

At the heart of this system was a fully coordinated 3D digital twin, linking every component to live quality data across design, manufacture, and assembly. This created a transparent, accessible, and audit-able record of compliance that all stakeholders could view in real time.

• A componentised 3D model, including structural and M&E coordination, enabled full clash detection and design validation.

• Fabrication data was extracted directly from the model to ensure manufacturing precision and consistency with architectural intent.

• Each component underwent rigorous pre- and postpour inspections, with photographic records and full dimensional checks logged into the digital twin.

• Quality standards were set via ‘first-off’ samples and maintained through in-factory QC controllers and robotic processes.

• 10% of all components were randomly subjected to full secondary inspections by PCE’s factory expeditors.

• On-site inspections began at delivery, with all units visually checked and any damage tracked digitally.

• Setting out was controlled by PCE engineers using offset grid lines for precise placement, with ‘as-built’ tolerances logged for each component.

• Every critical activity - such as reinforcement or grouting - required hold-point inspections and signoff by multiple parties.

• Site benchmarks, sample approvals, and “what good looks like” documentation ensured consistency of finish and workmanship.

• A dedicated Handover Manager oversaw final inspections, finishing, and client liaison - closing the loop on a robust, transparent quality process.

Thorough using our Ynomia Platform, we are able to create a ‘linked’ Digital Twin representation of our BIM Model. This digital twin becomes the repository for all data associated with each individual component within the building. Unique location identifiers within the Digital Twin allow us to tag a component with relevant data throughout the life-cycle of the component.

• All QA/QC data was captured in the Novade and Ynomia platforms and linked to the digital twin.

• Components could not progress without verified compliance, and any defects were tracked, assigned, and resolved through a clear visual interface.

• Supplier visits, H&S audits, and inspection reports were all integrated into the same quality environment.

• Comprehensive QA/QC

• Single Source of Truth

• Defect/Observation Management

• Interactive

• Life-cycle Traceability

• Golden Thread

• 14-Stage Real-time Tracking

• Suppler, Unit, Level Filtering

• Linked Ancillary Actions

• Time-Travel Functionality

• Provides True ‘As Built’ Record

• Stakeholder Access

• Centralised Compliance

Assembling on the exceptionally busy Tottenham Court Road demanded meticulous planning and expert execution. PCE’s systemised approach was critical in overcoming the challenges of this highly constrained central London site. With just 100mm between the new structure and neighbouring properties, and pedestrian pathways remaining open throughout, every element had to be delivered and installed with pinpoint accuracy.

Morwell Street, adjacent to the site, remained operational during construction, requiring all logistics and cranage activity to be carefully choreographed to avoid disruption. PCE’s in-house design and planning teams optimised every component and sequence, reducing the need for site personnel and minimising noise, dust, and vibration. The offsite-manufactured elements enabled swift, safe installation with minimal local impact - allowing work to take place just inches from neighbouring buildings without compromise to safety or quality.

This project stands as a testament to PCE’s ability to deliver complex inner-city construction with complete control, precision, and respect for the surrounding community.

Demonstrating the flexibility of its systemised HybriDfMA approach, PCE successfully integrated its precast superstructure with the insitu-constructed three-storey basement. This required careful coordination and alignment of two construction methodologies, with differing tolerances.

A key technical achievement was the seamless connection between the precast stair cores and those cast insitu within the basement. By bridging the gap between insitu and offsite construction with exacting precision, PCE ensured structural continuity and programme efficiency - highlighting the adaptability of its hybrid delivery model.

A key enabler of the build’s efficiency was the building footprint, designed into the flexibility around the structure’s perimeter, required, crane bases were seamlessly and maintaining structural integrity.

With the Hybrid Frame system’s repeatable methodology, and smart connectivity, PCE’s level rapidly and accurately - using just and design-led flexibility set the foundation

was the early strategic positioning of cranes within the build solution. This approach maximised lifting perimeter, despite tight site boundaries. Once no longer infilled - leaving no trace within the finished frame

repeatable components, standardised installation PCE’s multidisciplinary team was able to install each just 16 operatives. Early planning, logistical precision, foundation for a safe, efficient, and assured build.

At The Fitzrovia W1 project, safety has been embedded from the very beginning. PCE’s design-led approach ensures that risk is designed out and safe systems of work are designed in - supporting consistent, assured, and efficient assembly on site.

• Early development of an assembly methodology plan, including risk assessments and work sequences.

• Safety built in: handrails and edge protection pre-fitted offsite to minimise manual handling.

• Standardised install methods, with protection systems modelled in BIM, enabled safe, accurate assembly.

• Edge protection fixed to components where possible; Viper Line fall restraint used when not.

• Temporary works removed after each level, allowing safe, rapid access for followon trades.

Clear, task-focused drawings ensured operatives understood the sequence, risks, and mitigation measures. Every aspect - from lifting and handling to temporary works - was fully integrated into the design, placing safety at the heart of the build.

To complement its systemised HybriDfMA solution, PCE used Ynomia - an advanced asset tracking and insight platform - to bring together a diverse European supply chain with pinpoint precision. Seamlessly integrating with supplier systems, Ynomia provides real-time visibility of each component from early design through manufacture to site assembly.

Components are Bluetooth-tagged and automatically tracked via electronic gateways as they leave factories and arrive on site. This live data feeds into a colour-coded 3D digital twin, enabling the project team to monitor progress and plan with absolute clarity. Crucially, it supported a highly efficient, just-in-time delivery strategy - essential given the logistical constraints of the busy Tottenham Court Road location.

The system enabled a ‘touch it once’ philosophy: with meticulous planning, components were installed directly from the delivery wagon into their final position. This eliminated the need for temporary storage or re-handling, saving time, space, and labour.

The Fitzrovia W1 project reached structural completion in just 27 weeks with a peak site team of only 25 PCE operatives - a testament to the control, efficiency, and repeatability of PCE’s Hybrid Frame build system.

The Hybrid Frame system ensured every component arrived to site manufactured to exacting standards. This precision enabled exposed structural elements - such as concrete soffits, beams, and columns - to meet both aesthetic and structural requirements, eliminating the need for additional finishes like plasterboard. The result: a clean, architectural finish that reduces material use, programme time, and embodied carbon.

By designing-in quality from the outset and integrating safety, logistics, and buildability into every stage, PCE maintained consistent control throughout delivery - despite the challenges of a constrained central London site.

At Fitzrovia W1, PCE applied design and material expertise to cut carbon at every stage:

• Low-carbon concrete using GGBS saved 25,000 kg of CO₂.

• Basalt Fibre Reinforcement (BFR) in floor toppings replaced steel mesh, saving 30,000 kg of CO₂.

• Prefabricated steel beams with 90% recycled content saved 237,000 kg of CO₂.

By designing out finishes like plasterboard and suspended ceilings, and leaving exposed concrete soffits and columns, PCE reduced materials, programme time, and embodied carbon.

Further savings were achieved through smart design and build choices:

• Finishes designed out – exposed soffits and columns removed the need for plasterboard and ceilings, reducing materials and carbon.

• Exposed thermal mass supports passive heating/cooling, cutting operational energy demand.

• Lightweight Hybrid Frame slab reduced material use and structural load.

• Electric cranes and pumps lowered site emissions and noise.

Together, these measures contributed to BREEAM Outstanding and 5-Star NABERS Design for Performance ratings—demonstrating how sustainability, speed, and quality were delivered together.

PCE’s delivery team for the project have continued to demonstrate the value of PCE’s HybriDfMA system build approach. Achieving such standards in a short period of time is no mean feat, especially considering the project site was in one of the busiest London locations.

The project’s Senior Project Manager, noted:

“Big thanks to the team for their constant hard work across the project. Someone once said, a successful construction project is a symphony of skilled workers, precise planning, and unyielding perseverance. Structural delivery of the Fitzrovia is a great example of how this mindset pays off!”

Being an EOT business means PCE are equally owned by its employee partners. As business owners, our people take ownership for PCE’s continued success and enjoy the rewards that come with it; the more successful our business, the more reward we collectively enjoy.

We recognise that for PCE to be successful, we need our people to be at their best, which is why we have established a culture built around development and succession planning, investing into our workforce and providing challenging, inspiring and rewarding careers for our people to realise their potential.

Our people are given the tools and support to develop their careers, increase their knowledge, skills and experiences to help drive our EOT forward, and ultimately, enjoy the rewards we share for our collective success. It’s this culture that has been installed, that enables us to deliver great projects.