Hybrid Frames System

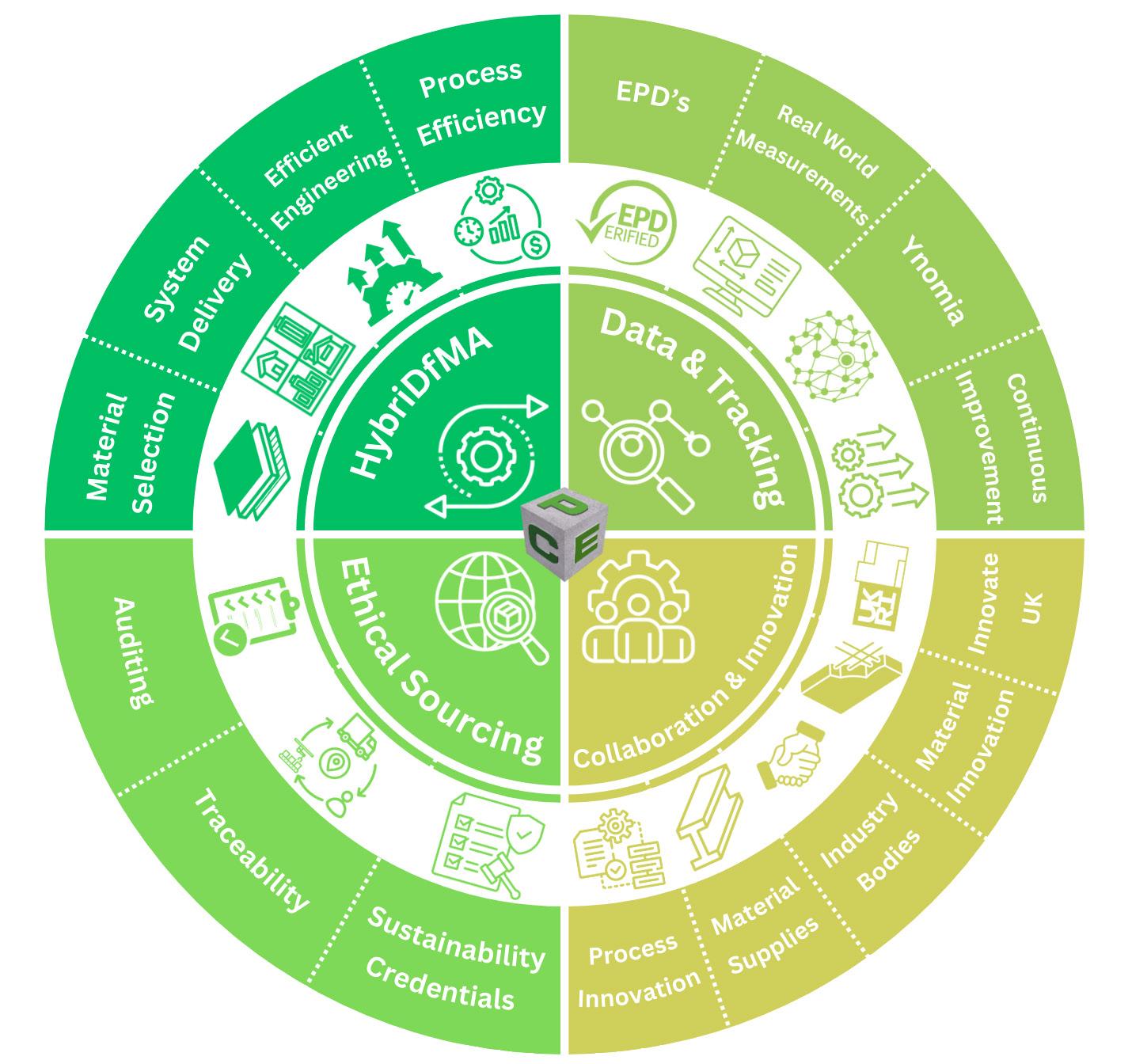

National innovative superstructure and façade builder working with a HybriDfMA 2D Kit-of-Parts approach. Performance Compliance Engagement Value

Overview

Hybrid

Hybrid Kit-of-Parts

Repeatability

Smart Connectivity

Supply Chain

Follow-on Trades

Healthcare

Science/Research

Education/Civic

Data Centre/Industrial

Commercial

Integration - Partitions

Integration - External Spaces

Golden Jubilee Hospital

Capella Laboratory

University of Warwick IBRB

Kingston University Townhouse

CEF’s Data & IT Centre

The Lexicon

Assembly Building C

Tottenham Court Road

Fulton & Fifth Podium

Digital Construction

RIBA Overlay Alignment

Site Logistics

Cranes & Lifting

Hybrid Frames System

Portfolio

Hybrid Frames System Overview

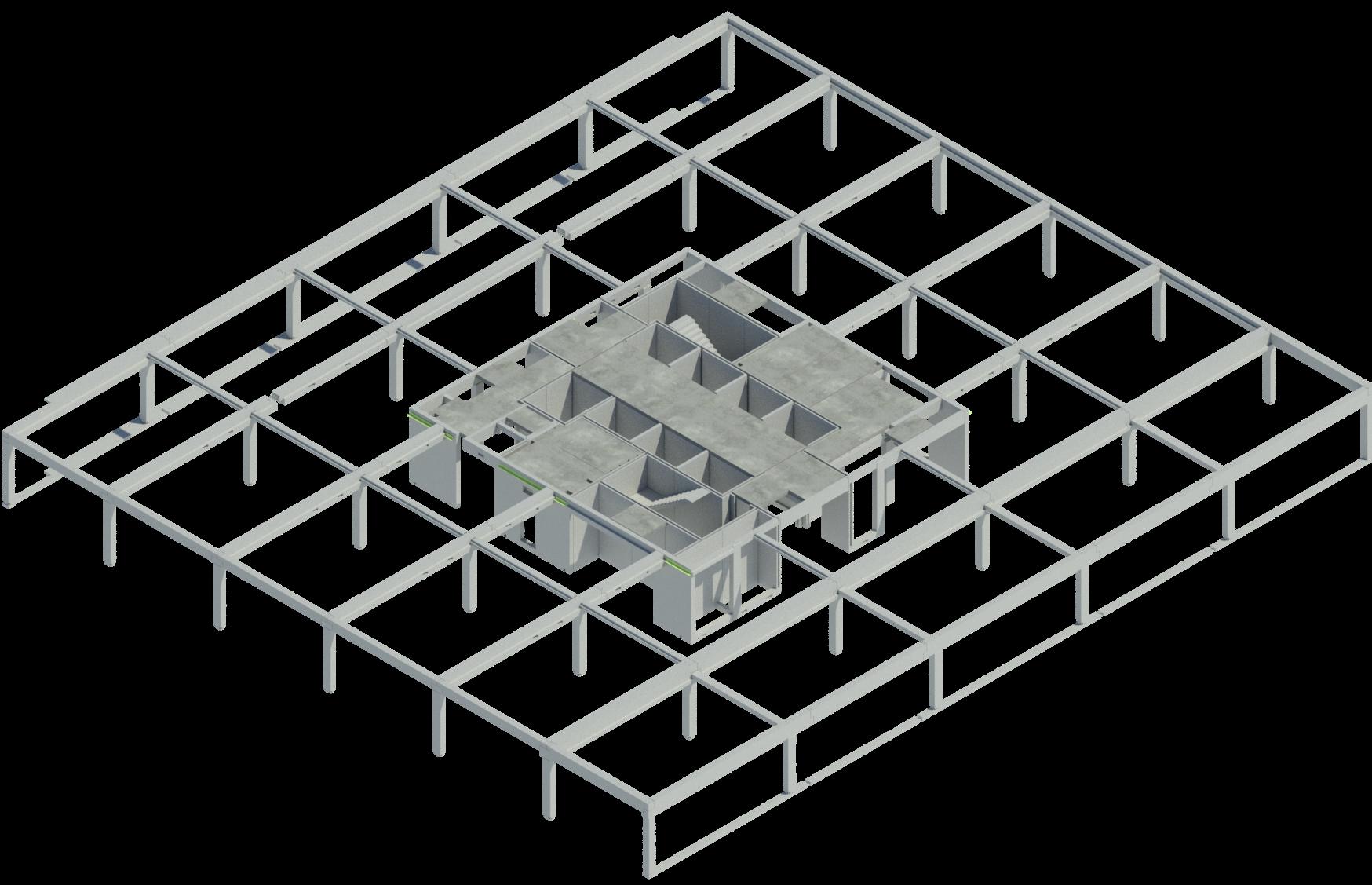

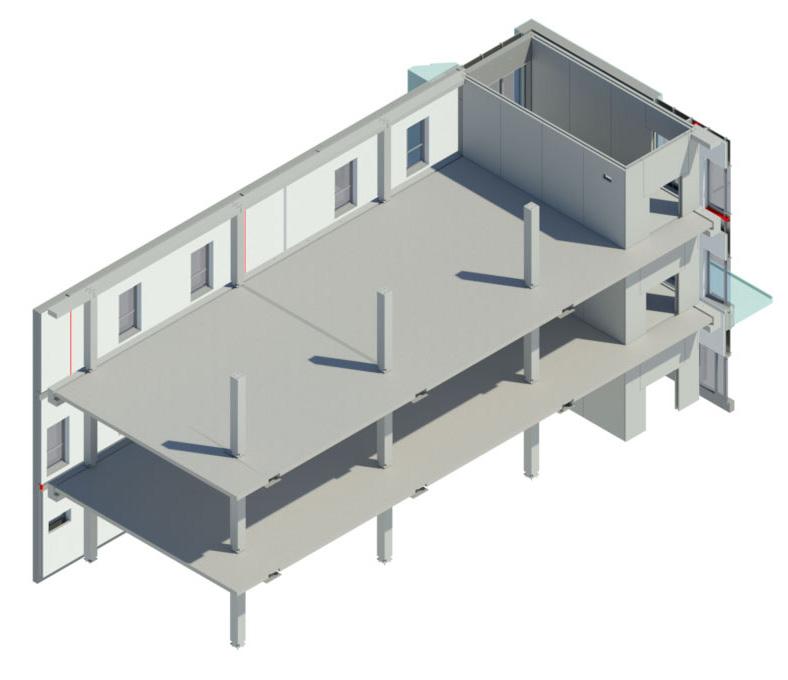

PCE’s HybriDfMA Frame System leverage’s Modern Methods of Construction to deliver fully integrated structural frame solutions.

Designed for Manufacture and Assembly, it incorporates structural frames, cores, walls, façades, windows, balconies, and MEP, optimising value from design to delivery.

Our Kit of Parts approach ensures high-quality, offsitemanufactured components with consistent connection details and adaptable configurations. This guarantees reliability, efficiency, and sustainability while providing cost, programme, and quality certainty

Tottenham Court Road hybrid frame in London

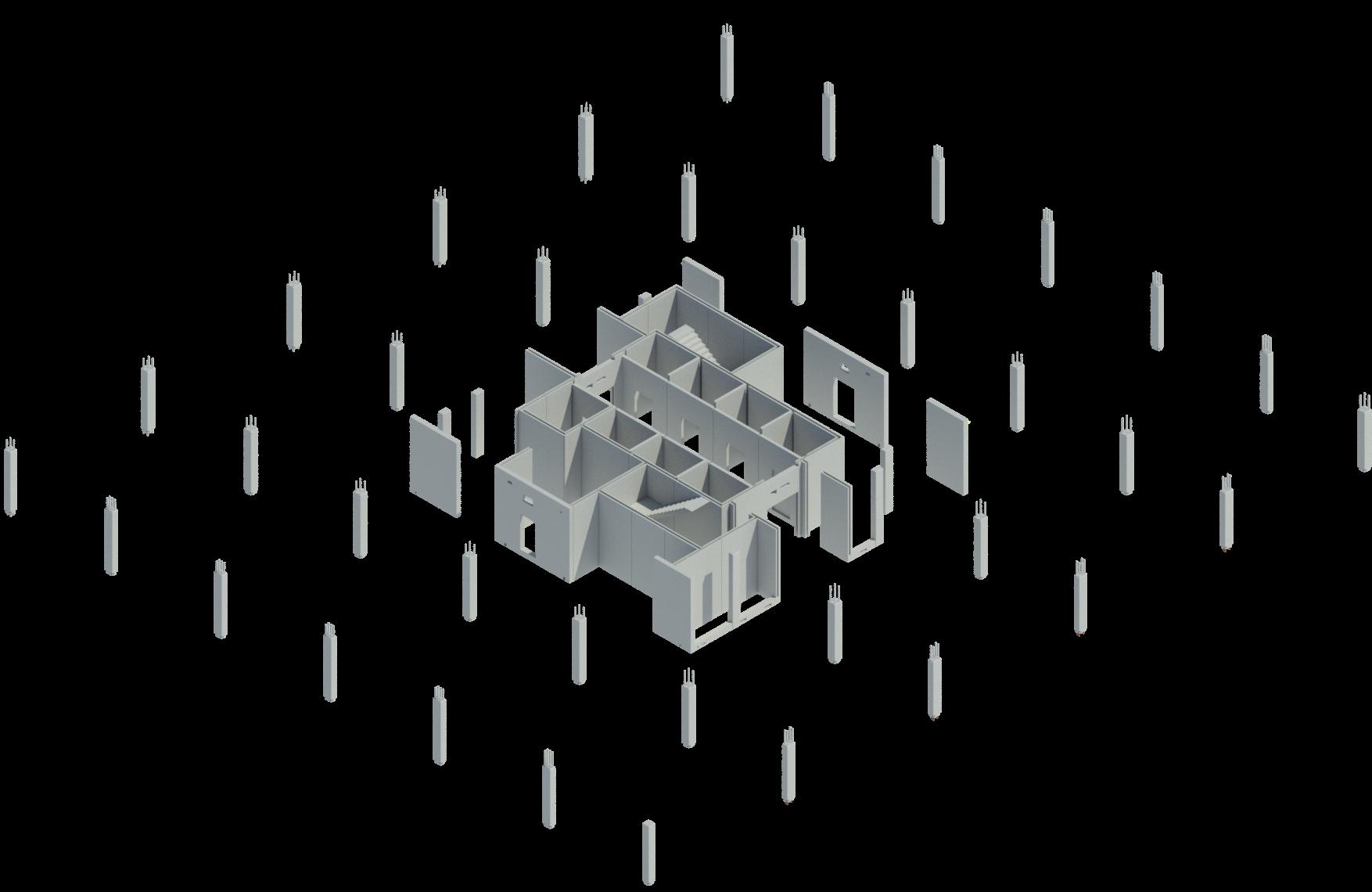

Hybrid Frames assembly visual

Hybrid Frames System Hybrid Approach

Our systemised design and build approach optimises safety, quality, speed, and value from

From RIBA Stage 2, we tailor solutions to each project’s materiality, grid layouts, M&E, façades, partitions, and core requirements,

Buildings are de-constructed into elemental components, complete with required integrations, creating a Kit of Parts. standardised installation techniques. A delivery strategy is established early, with fully costed elemental breakdowns

System libraries provide critical data to optimise design, manufacture, and assembly - accelerating delivery, reducing risk,

Cutting-edge digital systems are employed to not only track and trace project delivery, but capture key lessons learned

from early design to handover, including follow-on trades and fit-out.

requirements, taking a DfMA mindset from concept to completion.

Parts. Once manufactured, components are delivered just-in-time where they are assembled on-site using ensuring cost and programme certainty from the outset.

risk, and ensuring quality across the entire structural solution.

learned which feed into a culture of continuous improvement and added value gains.

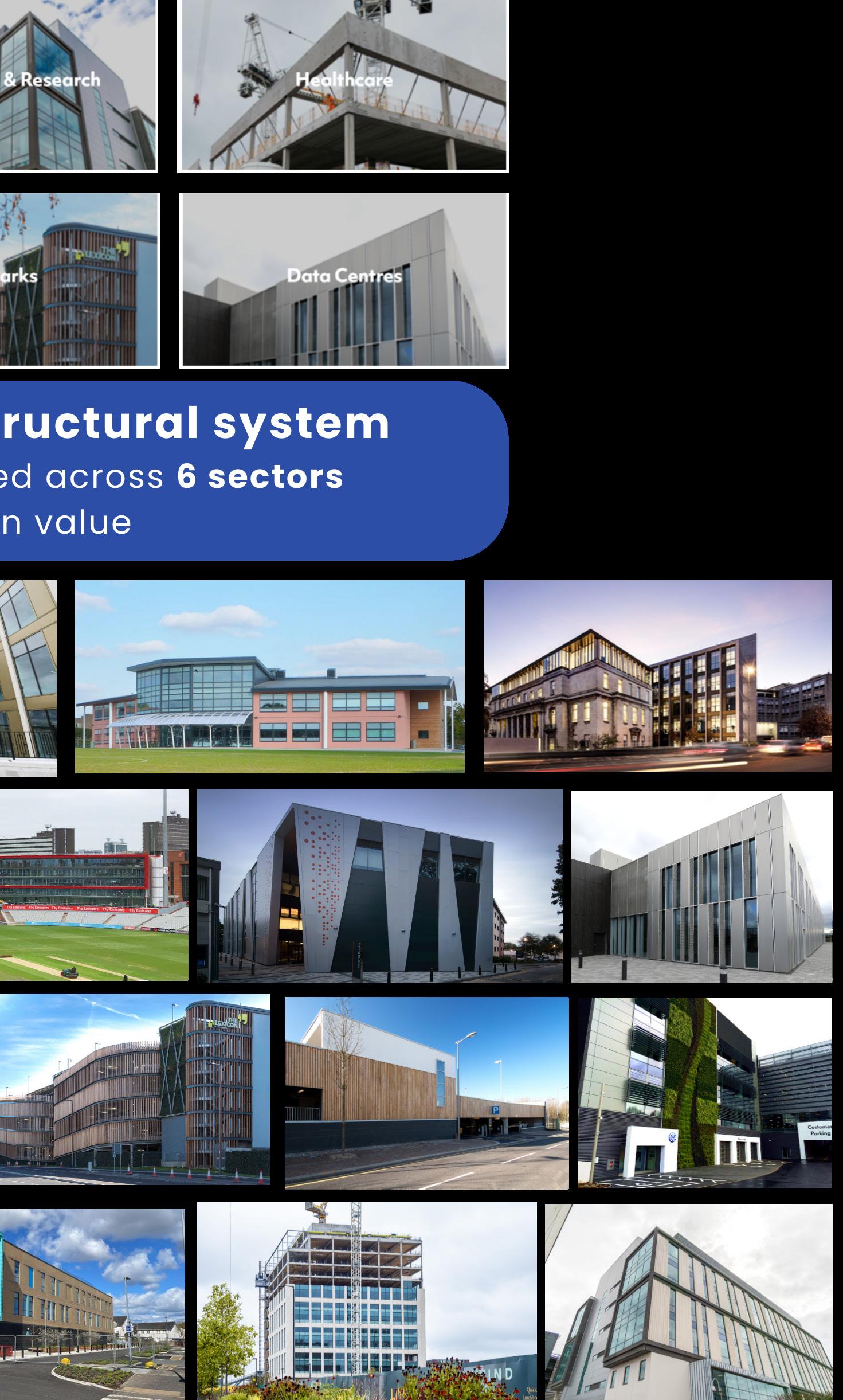

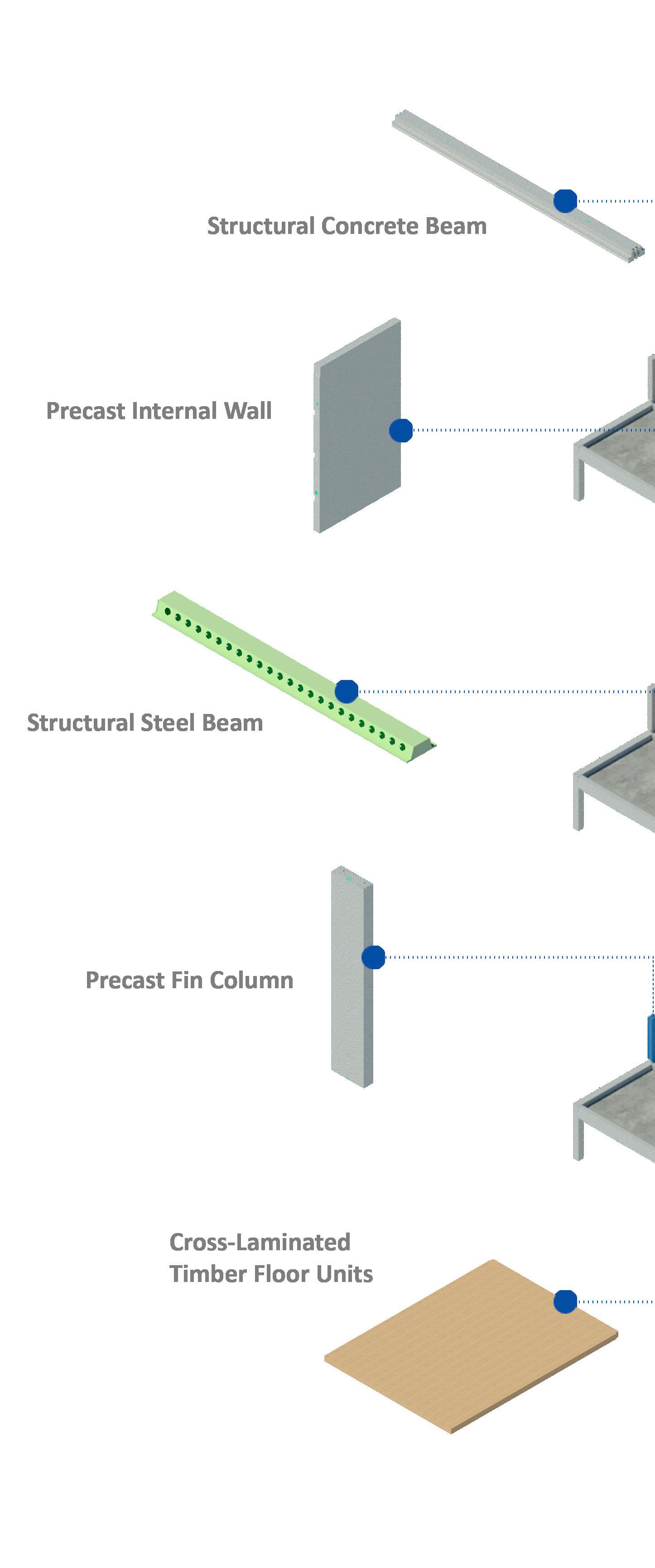

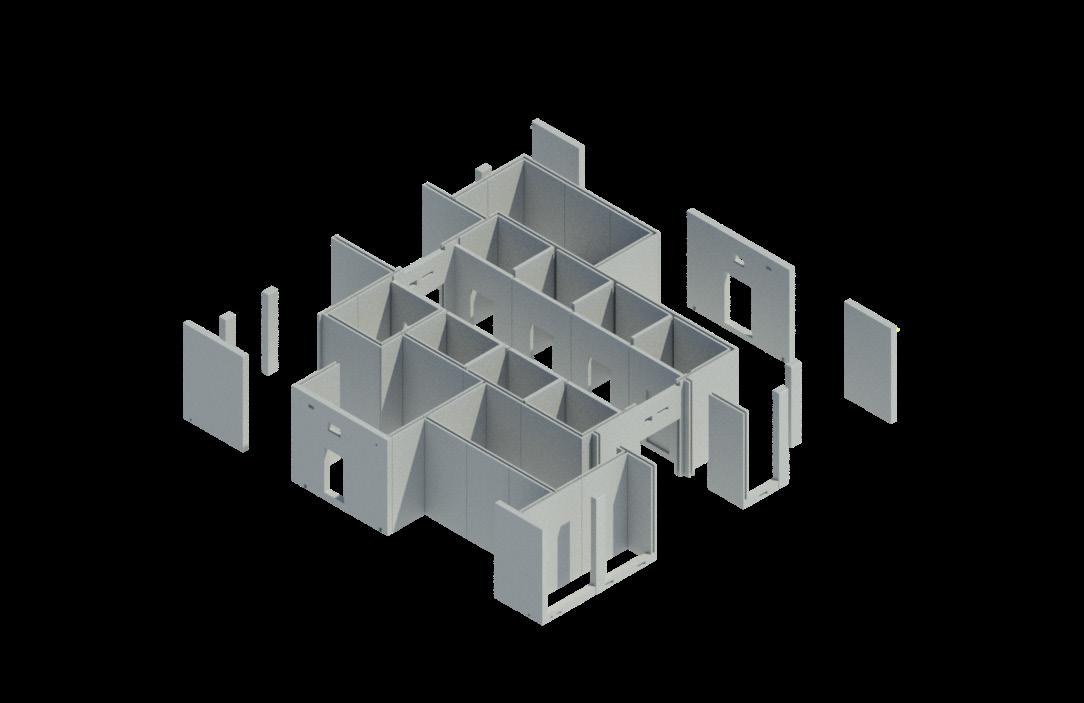

Hybrid Frames System Hybrid Kit-of-Parts

At the heart of PCE’s Hybrid Frame solution is flexibility without compromise.

Our Kit-of-Parts approach ensures consistency, repeatability, and hybrid flexibility. HybriDfMA system builds use repeatable components, standardised methodologies, and smart connectivity - delivering faster, more precise, and predictable design, manufacture, and installation without compromising quality.

Our portfolio of optimised structural components - spanning precast concrete, structural steel, and mass-engineered timber - gives clients the freedom to configure the right mix of components and materials for their project. Whether the priority is architectural expression, structural performance, sustainability, cost, or combination, our system allows tailored solutions without the risks of delay, uncertainty, or added design cost.

Standardised connections and interfaces provide reliability, while configurable component shapes, sizes and materials enable seamless integration of façades, windows, and M&E. This hybrid Kit-of-Parts approach empowers architects and developers to realise their vision while maintaining full assurance of programme certainty, buildability, and safety.

From a purely precast solution to a true hybrid blend of concrete, steel, and timber, PCE’s continuous improvement philosophy means every component is tested, refined, and ready to deliver - enabling clients to achieve their architectural ambitions with absolute confidence.

Stage 1 - Core

Stage

Stage 4 - Beams

Stage 3 - Stairs

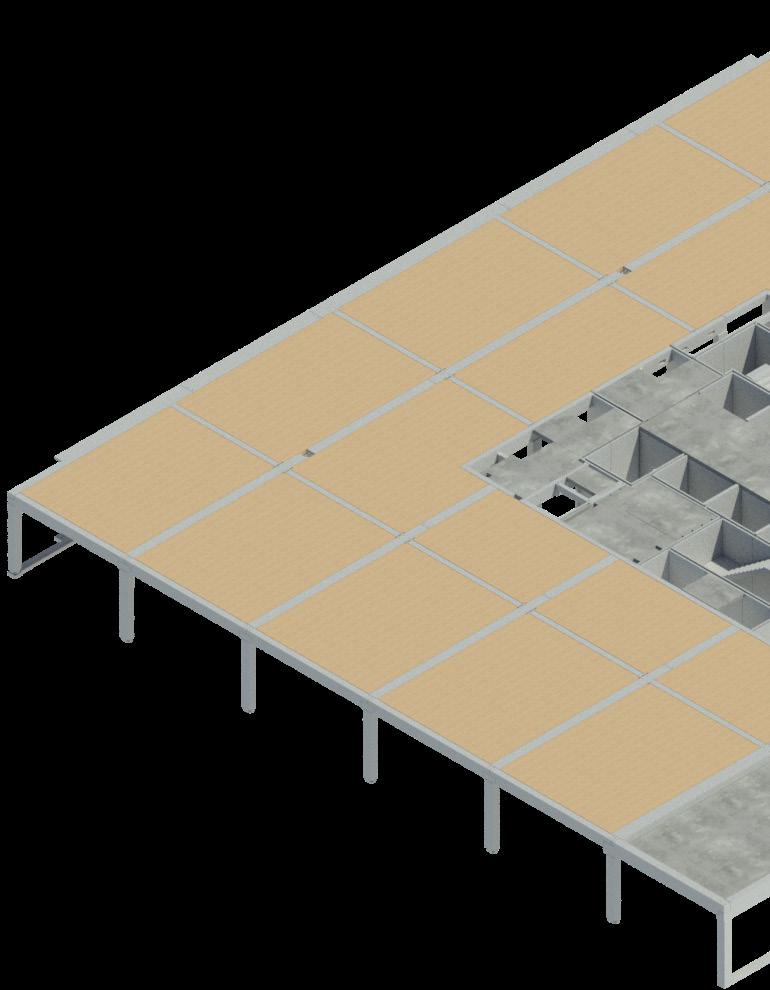

Repeatability is a key aspect of PCE’s structural systems - the ability to deliver efficiency, assurance, and buildability through a systemised Kit-of-Parts, repeatable in design and assembly.

By designing floor plates and structural systems around optimised, repeatable components, construction becomes faster, safer, and more predictable. Each element is configured to fit seamlessly, enabling projects to benefit from standardised methodologies that minimise risk and maximise productivity.

This repeatable process not only accelerates design, manufacture, and assembly but also drives continuous improvement. As projects progress, floor plate assembly becomes increasingly efficient, with every cycle building on the last - ensuring consistent gains in speed, quality, and performance.

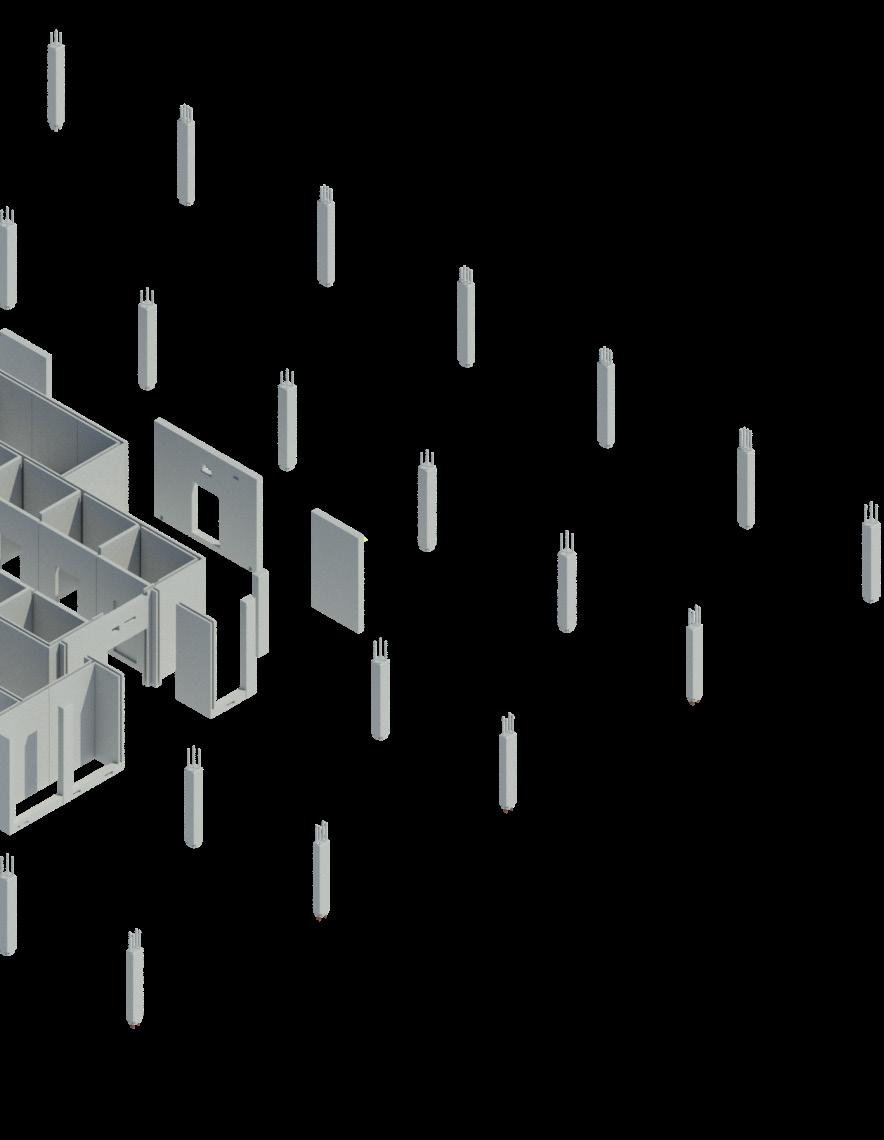

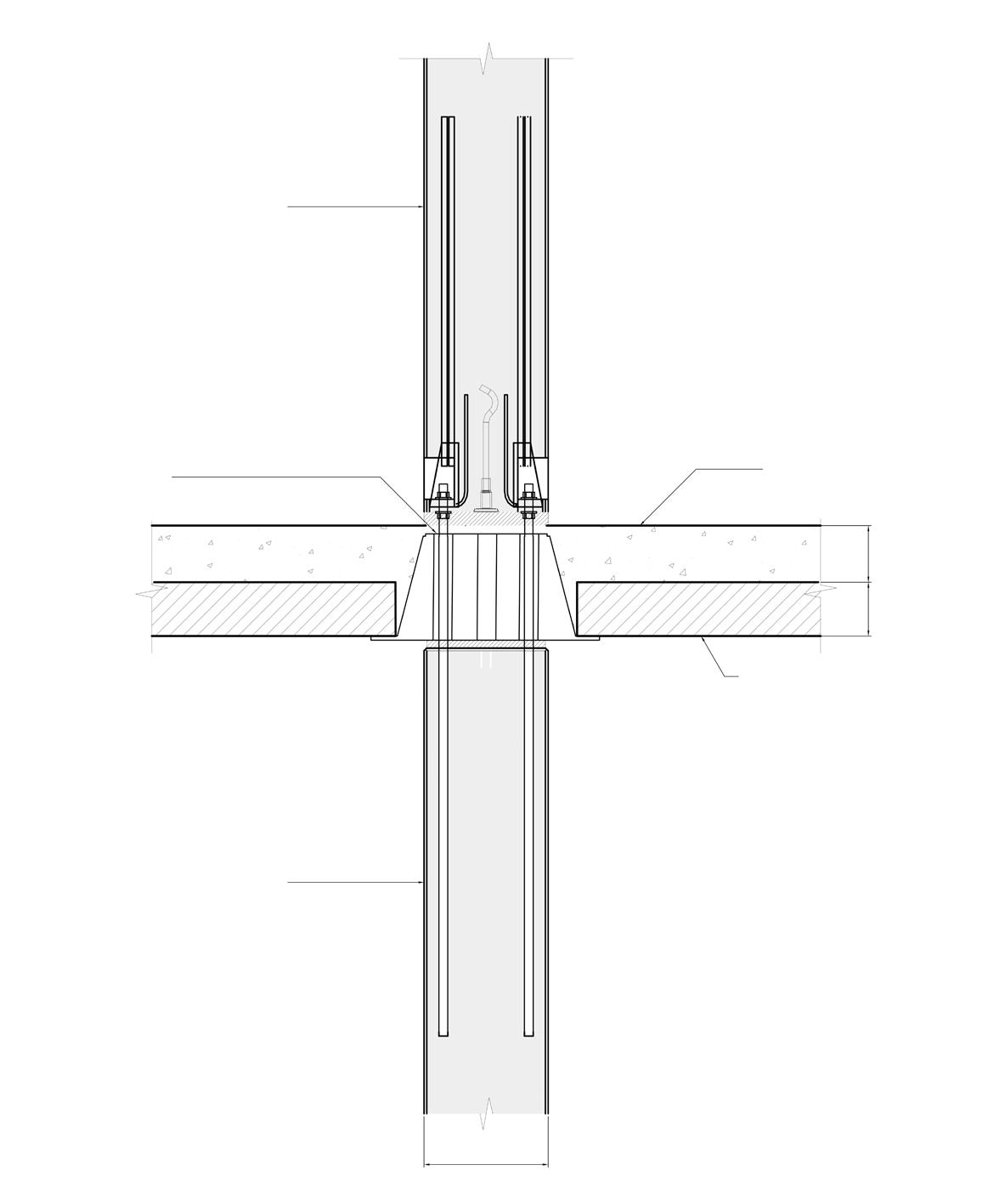

Hybrid Frames System Smart Connectivity

Key to the quality and efficiency of the system is the way that the components predictably interface with each other.

Landing to Stair Units

Twin Wall to Twin Wall

Concrete Column to Edge Beam

Fabrication and specification information for each component is created by our design specialists, ensuring complete control of how structural components are manufactured and integrated within the system. Interchangeability of components is then achieved through common connection principles, providing flexible design and material selection, without design delays and ambiguity.

Concrete Beam to Concrete Beam

Twin Wall to Solid Floor

Concrete Column to Precast Beam

Solid Floor Unit to Concrete Beam

Hybrid Frames System Supply Chain

Supply Chain Flexibility

The integration of our offsite supply chain is critical to project delivery. Our flexible business model enables us to collaborate with a broad network of partners—often spanning the UK, Southern Ireland, and mainland Europe—working concurrently across multiple sites and factories. This extensive reach presents logistical challenges, managed through a focus on seamless coordination between offsite production and on-site assembly.

We don’t own our own factory by design. This strategic choice removes fixed overheads and gives us the freedom to select the most appropriate offsite specialists for each project, leveraging capabilities such as automation, robotics, and aerospace-grade innovation. It also allows us to invest more in digital systems that enhance visibility, coordination, and quality assurance across our supply chain.

Supply Chain Coordination

Our dedicated team of supply chain expeditors work directly within partner factories to:

• Brief manufacturing teams on project-specific requirements

• Coordinate planning, programming, and mould setup

• Manage trials, samples, and first-off QA inspections

• Ensure clarity and accuracy of issued information

• Validate free-issue and integrated components for readiness

• Audit quality systems, including a minimum 10% QA/QC check of components

• Implement and support digital QA/QC reporting and progress tracking

• Coordinate logistics, load planning, and tracking

• Document and close out NCRs and observations

• Capture lessons learned and share best practice across all stakeholders

This integrated approach ensures our supply chain delivers to programme, meets specification, and supports just-in-time delivery - providing clients with assurance of quality, compliance, and efficiency.

Hybrid Frames System Follow-on Trades

Concurrent Construction

- The operational benefits of the DfMA approach

If a structural facade is incorporated in a project, the structure is wind and weathertight as it is installed. This allows earlier access for follow-on-trades (yellow zone), reducing overall programme

Scaffold-less construction with no external access required

No back propping or temporary works to levels below construction

Safe access & egress for all operatives via stair cores

Floor levels can be loaded out with bathrooms, utility cupboards, modular M&E, plasterboard and partition materials

Level under construction

2 clear floors between current construction level and levels accessible to follow-on-trades

Temporary

Weathering layer

Hybrid Frames System Healthcare

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade Logistics

Up to 15

LL - 3kPa + SIDL 1.1 - + Partitions - 1.5kPa

60-120mins

Rf=1 to Theatres and treatment Spaces, Rf=2 elsewhere

Suspended ceilings and floor finishes on screeds

Cores internally potentially exposed. Columns potentially exposed

XC1

Heavily serviced including medical gasses - typically underneath the slab. Mechanical heating and cooling

E

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Golden Jubilee Hospital

SPINE BEAM

PCC Column

PCC Column

Deltabeam

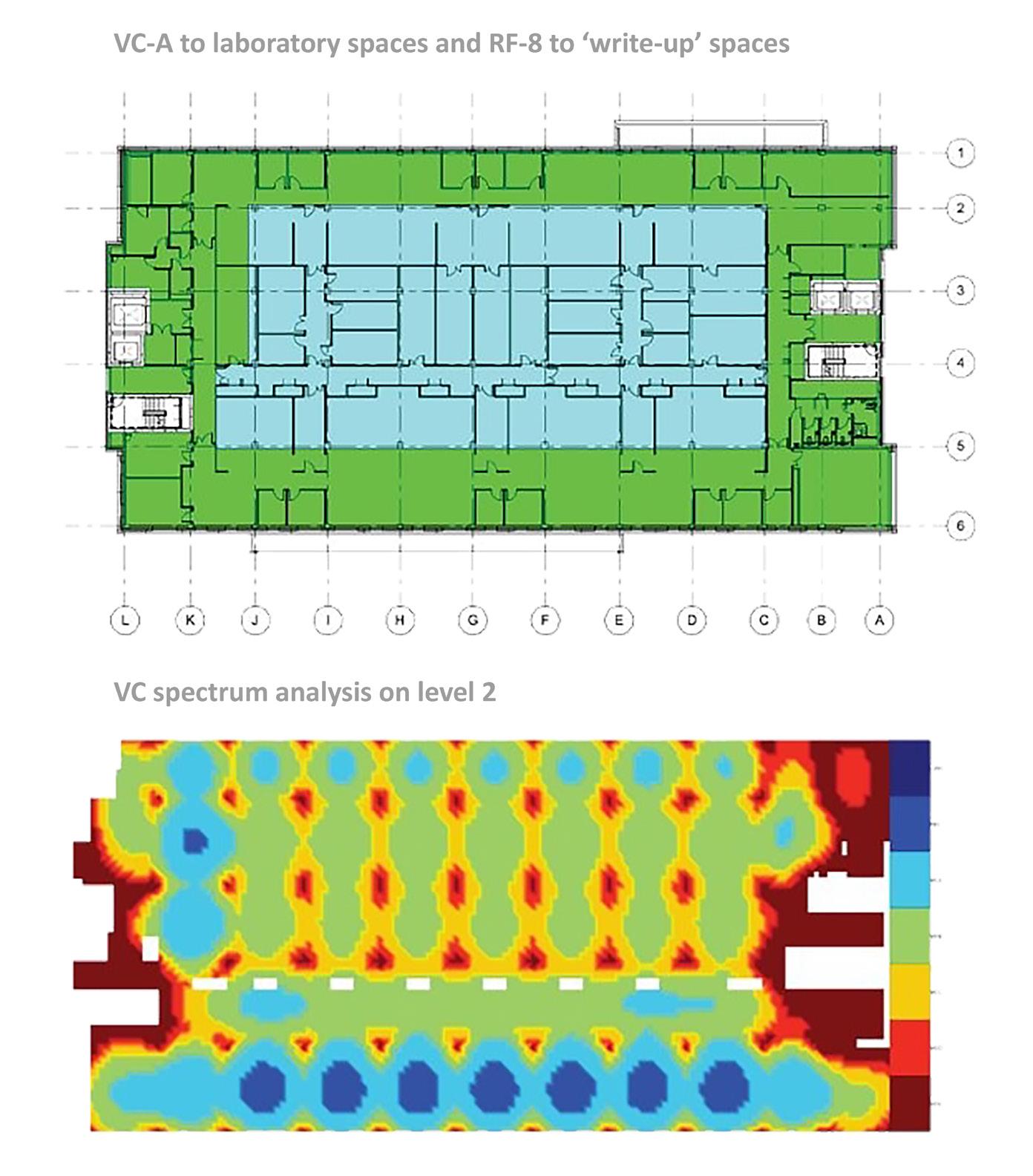

Hybrid Frames System Science/Research

Sector Parameters:

Capella Laboratory Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade

Logistics

7.8/8.4 * 7.8/8.4 4.5-5.0m

Up to 15

LL - 4kPa + SIDL 1.1 - + Partitions - 1.5kPa

60-120mins

Typically VC-A or VC-B to sensitive spaces

Suspended ceilings and floor finishes on screeds

Cores internally potentially exposed. Columns exposed XC1

Heavily serviced including medical gasses - typically underneath the slab. Mechanical heating and cooling E

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Structural Topping

Pre-Stressed Slab

Hybrid Frames System Education/Civic

Sir William Henry Bragg Building

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade

Logistics

6.0m/10.0m * 7.0-8.0m

3.5m-4.5m

Up to 15

LL - 3.5kPa + SIDL - 2.0kPa

60-120mins (Typically 60-90 mins)

RF=4.0-8.0

Soffits potentially exposed. Raised access floor above slabs or screed finishes with exposed services

Cores internally potentially exposed. Columns exposed XC1

Exposed services and Thermal Mass commonly used so exposed concrete surfaces. Natural ventilation through façade F1

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Hybrid Frames System Data Centre/Industrial

CEF’s Data and IT centre

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade

Logistics

Up to 15

LL - upto 15kPa 120mins

RF=1

Suspended Ceilings and floor finises on screeds

Cores internally potentially exposed. Columns exposed

XC1

Heavily serviced in terms of power. Mechanically ventilated (cooling primarily)

F1

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Hollowcore

Deltabeam

Structural Topping

Hybrid Frames System Car Parks

Staffordshire multi-storey car park

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade Logistics

7.5/7.8m * 16.0m

3.0m floor to floor

Up to 15

LL - 2.5kPa

60-120mins (Cores usually 120mins)

N/A

Exposed soffits with deck finishes applied directly to pcc slabs. Top deck will have waterproofing layer

Cores internally potentially exposed. Columns exposed

XC3/4 - XD3 - XF1/XF3

Surface mounted - light touch (lighting and fire detection only). Naturally ventilated

N/A

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Structural Topping

Pre-Stressed Slab

SPINE BEAM

PCC Column

PCC Column

Deltabeam

Hybrid Frames System Commercial

Assembly Building C

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade

Logistics

7.5-15.0m * 7.0-8.5m 3.8m - 5.5m

Up to 15

LL - 4.0kPa + SIDL - 1.5kPa

60-120mins

Rf=4.0-8.0 typically

Soffits potentially exposed. Raised access floor above slabs or screed finishes with exposed services

Cores internally & externally exposed. Columns exposed XC1

Exposed services and Thermal Mass commonly used so exposed concrete surfaces. Combination of Mechanical and natural ventilation through façade

E

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

CLT Slab

PC

Hybrid Frames System Podium/Infrastructure

Sector Parameters:

Grid

Height

No. of storeys

Loading

Fire

Vibration

Finishes - Floor

Finishes - Walls/Columns

Durability

M&E Strategy

Classification

Embodied Carbon

Façade

Logistics

9.0m * 9.0m

upto 6.0m

Up to 15

upto 25kPa

60-120mins

N/A

Fully exposed

Fully exposed

XC3/4 - XD3 - XF1/XF3

Surface mounted - light touch (lighting and fire detection only). Naturally ventilated

N/A

Target 170kgCO2e/m2

Structurally integrated or non-structural facade modules

Constrained sites, sensitive environments & often interconnected with existing buildings which may need to remain in operation

Fulton & Fifth Podium

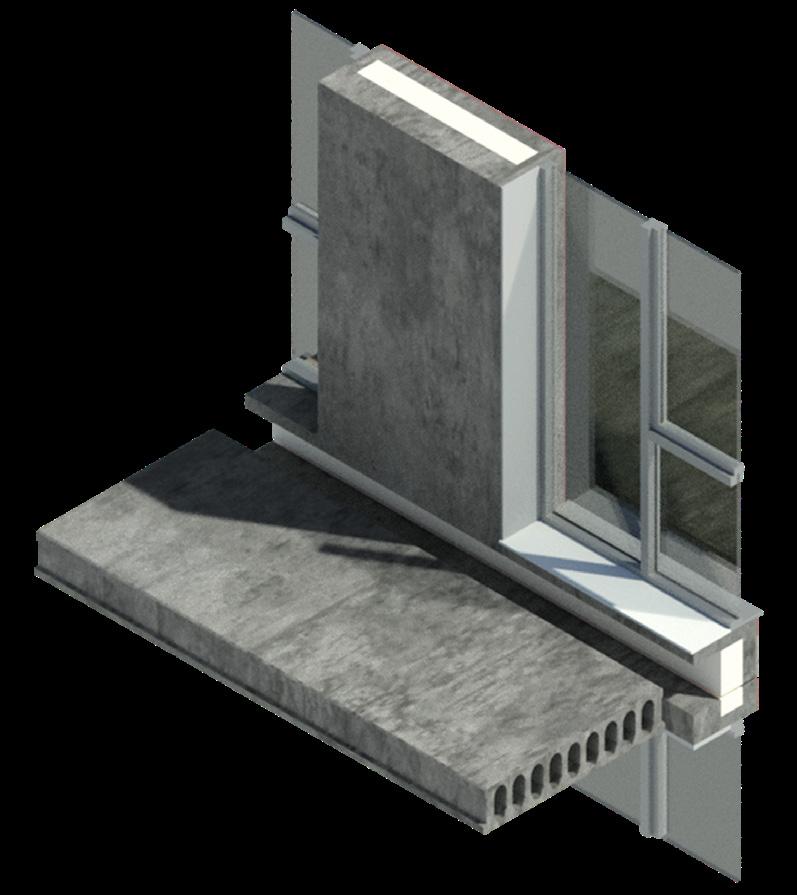

Hybrid Frames Structure Integration

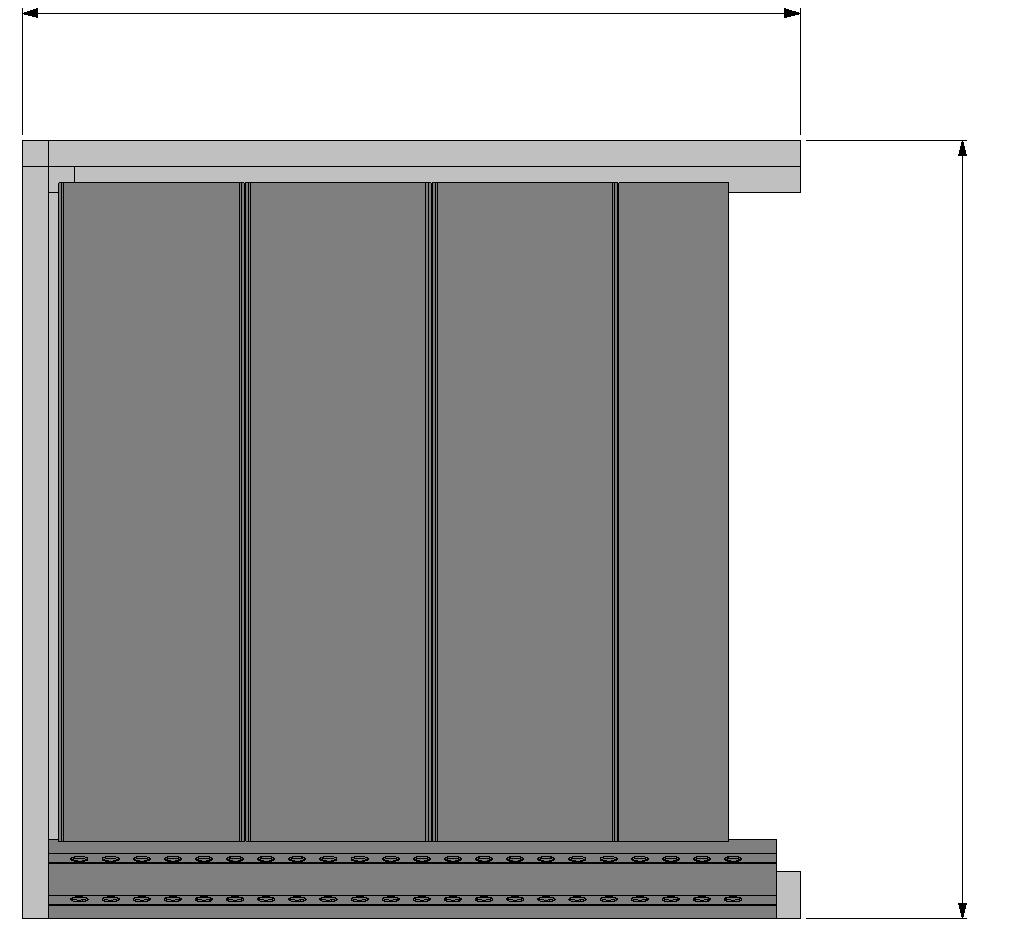

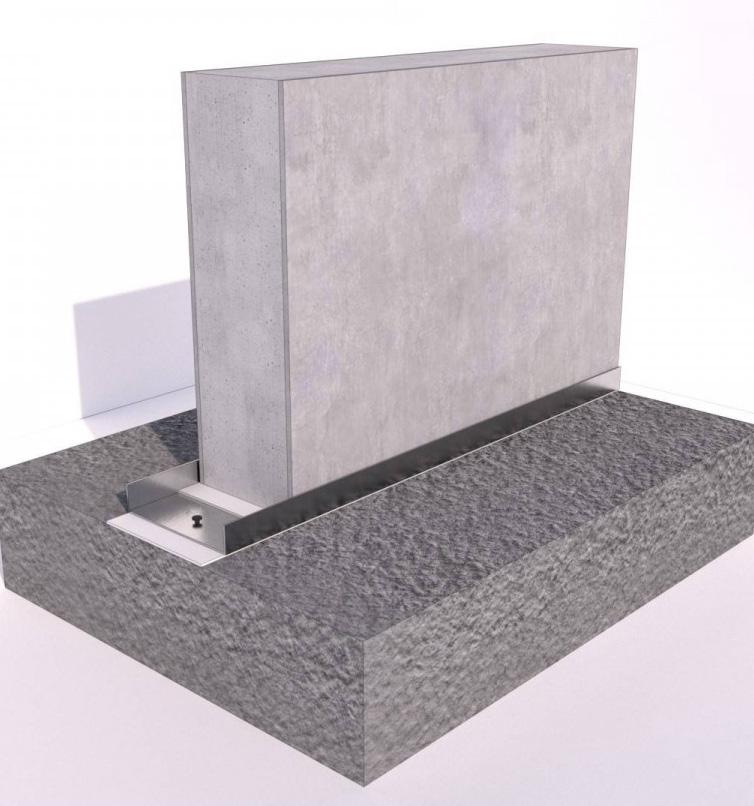

Structural & Non-Structural Façade Panels

Structural façade panel connection detail

Structural Façade Panels

Hybrid Frame solutions offer a highly efficient construction approach by integrating the façade with the structural system. Key benefits include:

• Façade and frame built simultaneously

• Early weather-tight envelope

• Removes structure/envelope from critical path

• M&E and fit-out can occur just two levels below active construction level

• Removes scaffolding and minimises waste

• Cuts programme duration by up to 50%

Structural façade panel connection detail

Façade panel being lifted on-site at Golden Jubilee Hospital

Non-structural façade panel connection detail

Non-structural façade panel connection detail

Non-structural Façade Panels

Most Hybrid Frame structures are designed with a nonstructural façade as they offer additional benefits, in addition to weatherproofing:

• Increased design flexibility

• Improved energy efficiency through natural light penetration

• Lightweight construction reduces overall building load

• Enhanced thermal insulation

• Strong aesthetic appeal

• Easier maintenance

• More cost-effective than traditional load-bearing walls

Assembly Building C façade lifting into place

Architectural façade at Tottenham Court Road in London

Hybrid Frames System Integration

Façade Finishes

Brick Veneer

Brick veneer panels deliver the warmth and character of traditional brickwork while benefiting from the precision, speed, and consistency of offsite manufacturing. They combine classic aesthetics with modern performance and efficiency.

Reckli façade finishes bring architectural freedom by enabling intricate textures, patterns, and designs to be cast directly into precast concrete. This achieves a high-quality aesthetic while maintaining durability and cost efficiency

Reckli Formed

Reconstructed Stone

Reconstructed stone façades replicate the look and texture of natural stone at a fraction of the cost and weight. Durable, versatile, and consistent in finish, they provide a premium architectural appearance without the limitations of quarried stone.

Metalwork

Metal façade elements bring a modern, refined aesthetic with options for a wide variety of colours, textures, and profiles. Lightweight, durable, and highly adaptable, metalwork provides both visual contrast and longterm performance.

Hybrid Frames System Integration

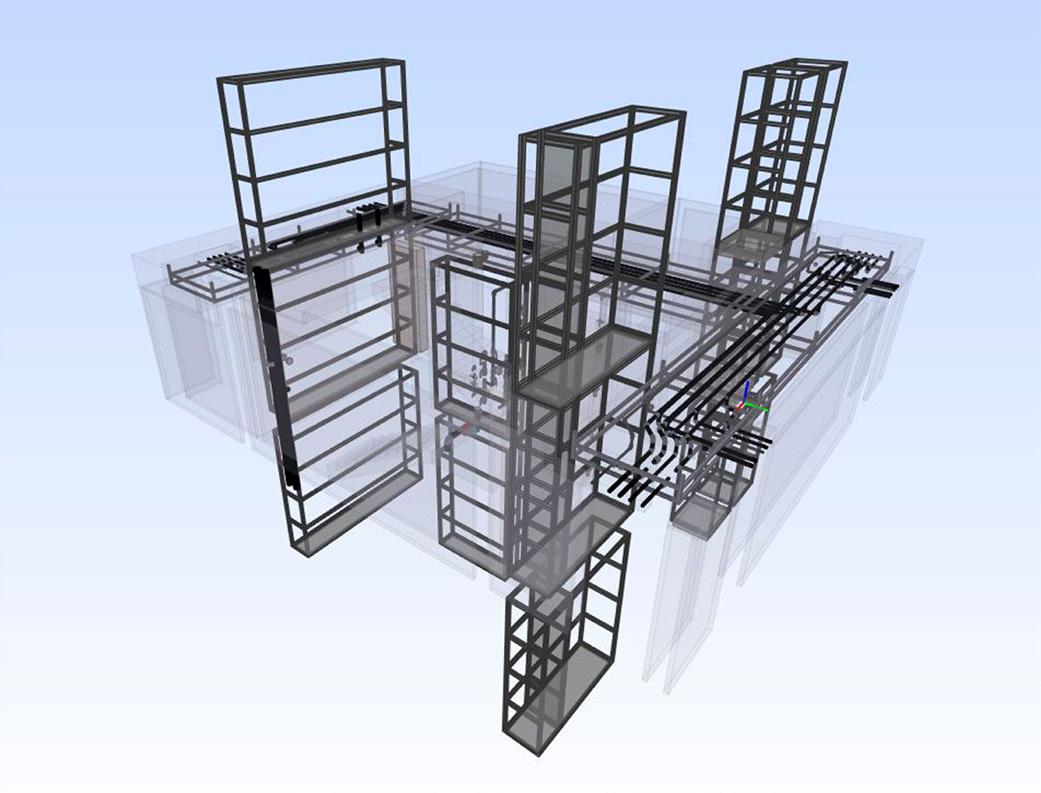

M&E

Bathroom pods and other amenities can be integrated within the Hybrid Frames System as there is no backpropping required to the floor plate. This means the floor plate is completely open giving the flexibility to pre-load the construction deck with modular M&E components prior to the next floor plate being assembled.

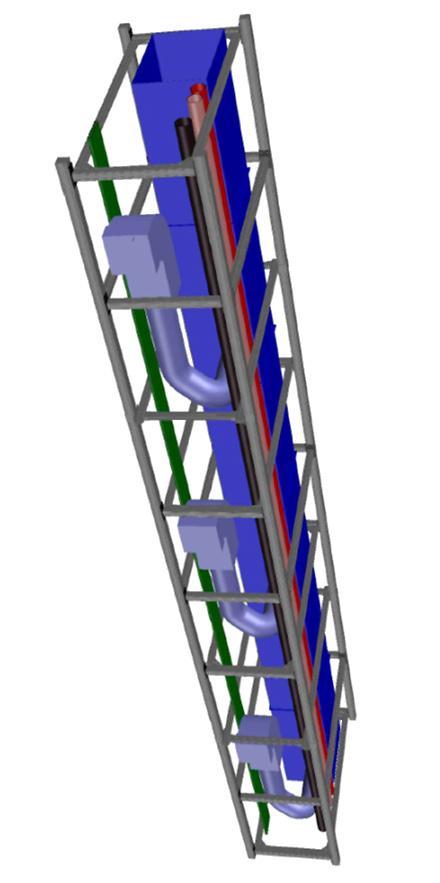

Model showing the M&E components

Cast in channels in the columns at Kingston

M&E in the ceiling space at the Brent Cross project

This approach to integrated services dramatically improves predictability of quality and streamlines on-site delivery with primary distribution routes already being set-out. This approach also allows internal finishes such as direct decoration or floor finishes to be applied directly to the concrete structure, further reducing the extent of ‘followon’ works and reducing both risk and time.

Cast-in M&E within the ceiling space at Assembly Building C

Exposed pipework at Assembly Building C

TABS heating system being installed at Kingston

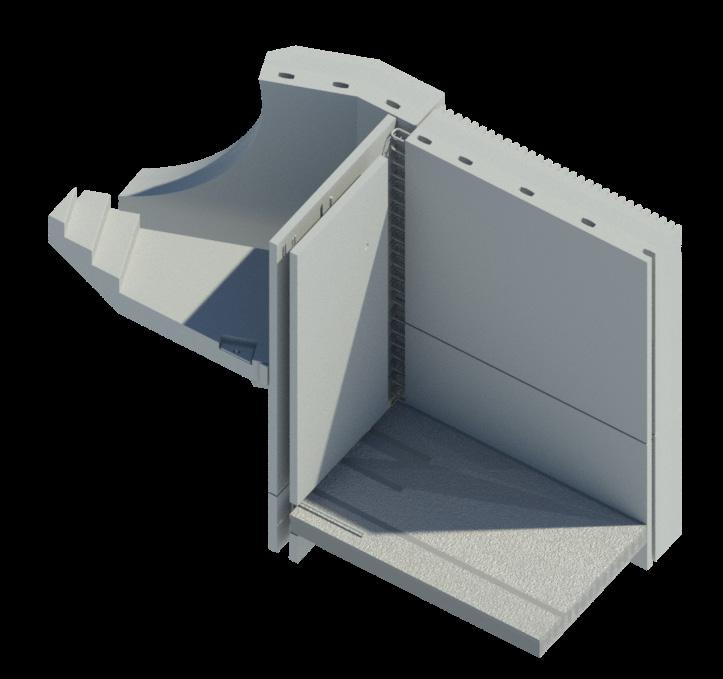

Hybrid Frames System Integration

Risers

In addition, the main risers and services distribution openings are extremely accurate both in terms of geometry and verticality so preassembled volumetric M&E riser modules can be easily slotted into the structure as assembly works progress.

Localised services distribution such as electrical containment or hot water distribution can be integrated within the structural components resulting in the ‘first fix’ M&E already being in place when the ‘fit-out’ works commence.

Riser cages built and ready to install

A M&E rider module being installed on-site

A large riser being lifted into place on-site

A module being secured by operatives on-site Model showing the placement of riser modules

A riser being lifted by the crane

BIM model of M&E riser

Hybrid Frames System Integration

Partitions

The Hybrid Frames System enables efficient integration of lightweight partitions, streamlining follow-on trades. With no back propping and open floor plates, pre-cut and packaged components can be preloaded as the structure rises - delivering a ready-toinstall Kit-of-Parts for each unit. Alternatively, fully modular partitions can be assembled alongside the superstructure.

Early engagement and planning ensure tight tolerances, enabling components to fit precisely and perform as designed. This accuracy streamlines both structural installation and internal interfaces - such as partition walls - simplifying fit-out and accelerating overall construction.

Partition walls being assembled on-site

Model showing structure of partition wall

Inside structure of partition wall on-site

Specwall partition system 3D model

System

Specwalls assembled at Assembly Building C

PCE’s Hybrid Frame structural system is designed to integrate seamlessly with Specwall - a safe, efficient, and sustainable A1 fire-rated walling solution.

Manufactured offsite, Specwall is a modular wall system that installs rapidly and is ready to decorate without plastering, accelerating the internal fit-out process. Its proven performance covers:

• Thermal insulation

• Airborne sound insulation

• Reaction to fire resistance

• Robustness

Key benefits:

• Up to 55% reduction in labour requirements

• Structural and insulating properties deliver significant programme time savings

• Water-resistant, enabling installation ahead of full water-tightness

• An all-in-one product that minimises waste - fully recyclable at end of life

• Reduced costs through faster programmes, less waste, and increased durability

By combining Specwall with PCE’s Hybrid Frame, clients gain a streamlined, high-performance structural and walling solution that saves time, cuts waste, and enhances sustainability - all while meeting UK, EU, and international standards across a wide range of building types.

Specwall

Hybrid Frames System Integration External Spaces

Different balcony configurations are easily integrated with the Hybrid Frames System through smart connectivity back to the structure.

Cantilever steel or concrete balconies are fixed back to the structure through proprietary thermal break systems, cast within the structural façade panel or the structural slab.

Structural steel balconies can be pre-fixed to the façade panel prior to assembly, or fitted to the structure once the modular façade panels are in place.

Concrete balconies can be pre-manufactured offsite, integral with the internal structural slab, or propped and cast into the structural slab on site. In either scenario the balcony can be a ‘finished unit’ with the balustrade, soffit and deck finishes already in place.

Model detail of balcony intersection

Shared rooftop garden area added to the top of Assembly Building C

Inset balconies are formed within the structural slab using embedded thermal breaks to create a recessed thermal line. This can be achieved offsite with pre-manufactured slabs or onsite with in-situ concrete as part of a composite system. External spaces at roof level can also be incorporated where the design allows, across all Hybrid Frame System structures.

Balconies added to Assembly Building C

Rooftop garden at London project

Outside colonnade spaces at Kingston

Hybrid Frames System Healthcare Case Study

Golden Jubilee Hospital - 16,500m2

1,200 components

15-week assembly

22 operatives

350 fewer deliveries

Flexible structural grid

Converted from insitu to DfMA

5 orthopaedic theatres

50,000 less site operative hours

Golden Jubilee Hospital completed exterior

Golden Jubilee Hospital completed building frame

Vibration Floorplates

To meet the stringent vibration limits required for sensitive operating theatre equipment, the suspended floors had to achieve a vibration response factor of ≤1.0. PCE worked closely with vibration experts and carried out testing using specialist equipment to validate performance. Leveraging extensive experience in healthcare and biosciences, PCE ensured its HybriDfMA Frame system met the technical demands

The final floor plate design included reinforced precast concrete edge beams and internal composite concrete/steel Deltabeams, supporting 200mm solid prestressed concrete units compositely topped with 200mm of in-situ reinforced concrete.

Golden Jubilee Hospital

Façade being lifted into place

Frame structure at Golden Jubilee Hospital

Golden Jubilee Hospital’s Full Scale

Hybrid Frames System Science/Research Case Study

Capella Laboratory - 17,000m2

4,150 components

17 months concept to complete

16 operatives

3,500t concrete reduction

VC-8 vibration levels achieved

100,000 operative hours saved

4,000sqm facade installed in 4 weeks by 8 operatives and no scaffolding

Capella Laboratory completed exterior

Capella Laboratory frame construction

To ensure the exceptionally low design vibration criteria was met, PCE employed University of Exeter‘s Head of Engineering, Professor Paul Reynolds, a leading world specialist in the field of structural vibration for specialist advice and full-scale test procedures.

The final PCE composite floor plate solution also reduced the self-weight from 11.25kN/m² for an in situ concrete solution to only 9.0kN/m², resulting in a project saving of over 3,500 tonnes of insitu reinforced concrete.

Non-structural façade panels being rotated on-site

Concrete core boxes being lifted into the basement

Vibration Floorplates

Hybrid Frames System Education/Civic Case Study

University of Warwick IBRB - 7,000m2

1,400 components

24-week assembly

18 operatives

150 fewer devilries

23,000 accident-free hours

850t concrete reduction

98.3% national Quality Audit score

University of Warwick completed interior

University of Warwick completed exterior

High-quality exposed concrete finishes—key architectural features in the café, auditorium, and core areas—were achieved using formliners placed into bespoke moulds within a controlled factory environment. Close coordination with the timber structure was maintained through detailed design and strict tolerance control in offsite production.

All concrete elements were locally manufactured within 70 miles of the site. As part of the structural solution, PCE incorporated some of the most heavily loaded composite steel beams ever produced— measuring 16 metres long and weighing 18 tonnes each, setting a new benchmark in structural steel delivery.

Structural steel being beams assembled on-site Interior walls being propped on-site

Architectural Interior Walls

Warwick University’s architectural interior walls

Hybrid Frames System Education/Civic Case Study

Kingston University Townhouse - 10,000m2

2,150+ components

40-week assembly period

RIBA award winner

6 stories

10,000m2 exposed concrete

BREEAM Excellent rating

TABS - Thermally Active

Building System

Kingston Townhouse auditorium

The University’s bespoke façade design

The ribbed soffit provided the opportunity to take advantage of the TABS (Thermal Activated Building) system which utilises the thermal mass of the concrete structure to cool/condition the air within the building. Ambient water is fed through the embedded pipework to control the concrete surface temperature. This means that warm air rising within the building is then cooled to maintain a comfortable internal air temperature without the need for significant HVAC (Heating Ventilation Air Conditioning) installations.

TABS will assist Kingston University with achieving its aim of a BREEAM ‘Excellent’ accreditation by reducing overall energy consumption. It is also highly versatile and can be adapted according to conventional and renewable energy sources, whilst also taking into consideration site dynamics.

Concrete component intersection between floors Kingston Townhouse during construction

TABS System

Bespoke interior concrete staircase

Hybrid Frames System Data Centre Case Study

CEF’s Data & IT Centre - 2,100m2

CEF’s Data and IT Centre completed exterior

400 components

9-week assembly period

RIBA award winner

TABS - Thermally Active

Building System

Precast concrete frame constructed

Completed interior frame of CEF’s Data and IT Centre

PCE delivered an innovative hybrid solution that met structural requirements, while integrating a Thermally Active Building System (TABS) by embedding heating and cooling pipework directly into precast GT floor units.

Originally used in long-span car park structures, GT units offered flat soffits, eliminated structural toppings, and reduced floor thickness, driving programme savings. For the CEF project, PCE adapted the design to incorporate Velta’s embedded pipework, delivering both structural efficiency and in-slab climate control.

Structural steel being lifted on-site

Internal staircase inside concrete frame structure

TABS System

Hybrid Frames System Car Park Case Study

The Lexicon - 24,000m2

3,400 components

40-week assembly period

4,550t concrete reduction

24,000m2 of long-span flooring (up to 18m long per unit)

Five story structure

1,300 parking spaces

The Lexicon car park in use after completion

The Lexicon multi-story car park completed exterior

Factory engineered GT Flooring units were manufactured with consistent non-slip brush finish wearing surfaces to keep the high-quality finishes obtained over time.

The hybrid offsite manufactured structural frame was designed using latest BIM technologies and enabled a 40-week on site programme. Construction was quicker than a fully on-site build approach, resulting in less on-site personnel and plant resources that would otherwise be required.

Suspended car park decks fall in two directions enabled by stepped bearings in wall and beam corbels.

Bespoke concrete components used for the ramp Completed car park frame interior

The frame structure under construction

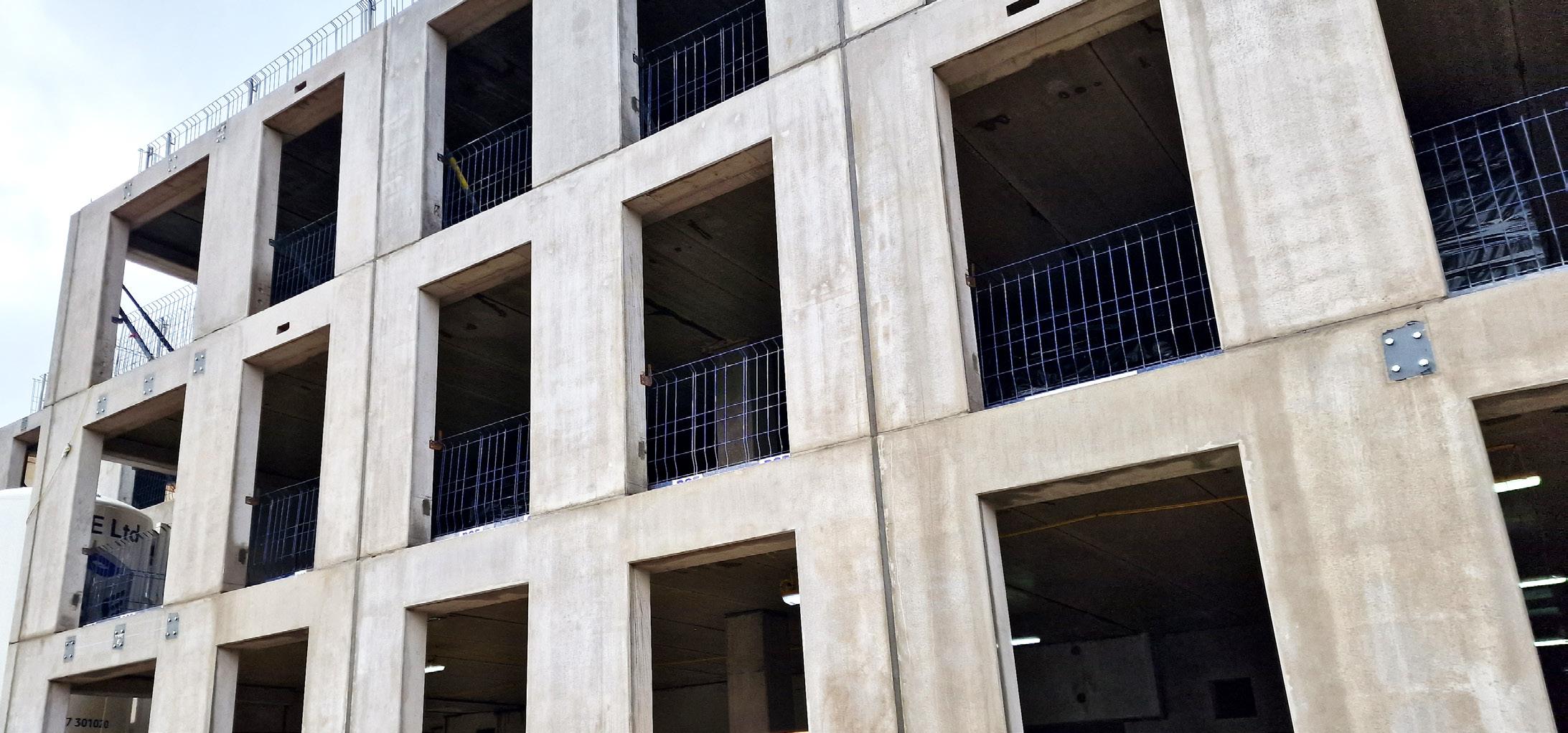

Hybrid Frames System Commercial Case Study

Assembly Building C - 8,600m2

Assembly Building C completed frame interior

2,460 components

32-week assembly

12 operatives

14 stories

75% exposed concrete

13 days per level installed

26% reduced embodied carbon

Pre-glazed modular façade panels being lifted into place

Assembly Building C completed structure with balconies connected

The project adopts Modern Methods of Construction (MMC) from the outset, maximising the use of offsite precast concrete to streamline production, enhance quality, and maintain control. A stand-out feature is the exposed architectural sandwich panels, which form part of the northern core and are complemented by twin and solid precast walls—all deliberately left unpainted to highlight their raw, architectural aesthetics.

To deliver this vision, 44 architectural sandwich panels weighing up to 17 tonnes with Reckli pattern and offsite integrated windows, were installed directly from the delivery wagon.

Architectural façade panels being lifted on-site Steel and concrete frame connection

Architectural Façade Panels

Hybrid Frames System Commercial Case Study

Tottenham Court Road - 8,000m2

2,100+ components

26-week assembly

25 operatives

286 product deliveries

6 days per level installed

292t concrete reduction

90% recycled steel used for structural beams

Tottenham Court Road hybrid frame structure

Interior of the hybrid frame structure with steel and concrete components

Sustainable Solutions

Use of Ground Granulated BlastFurnace Slag (GBBS) resulted in a reduced-cement mix that saved 25,000 kilograms of CO2. The project saw further carbon-saving initiatives, such as the use of basalt fibre reinforcement (BFR) for the reinforcement of the nonstructural concrete floor topping. Use of BFR instead of steel mesh saved over 30,000 kilograms of CO2. Additionally, prefabricated structural steel beams encased with reinforced concrete with 90% recycled steel saved the project an impressive 237,000 kilograms of CO2. These sustainable practices align with the project’s sustainablydriven design, helping to achieve a BREEAM Outstanding Design rating and a 5-Star Design for Performance NABERS rating, demonstrating adherence to the highest environmental standards.

Hollowcore and steel beam connection

Screed being applied over the completed floor

Hybrid Frames System Podium Case Study

Fulton & Fifth Podium

17,000+ components

23-month assembly

13 operatives per crew (x4)

85 stories in total

500t delivered and installed daily

10 days per level installed

239kg CO2e/m²

6-month programme reduction

Fulton & Fifth Podium frame structure

Podium structure constructed under the hyTower® solution

Fulton and Fifth is a mixed-use development comprising 846 residential units across five towers (15–24 storeys), set above a 2–3 storey podium housing retail, leisure, and light industrial spaces.

Due to misaligned column grids between the towers and podium, large precast concrete transfer beams—up to 1.6m deep—were required at podium level. In one location, where loads were exceptionally high, a hybrid concrete solution was used: a 24m-long transfer beam measuring 2.0m wide by 2.2m deep.

This beam was formed using three offsitemanufactured reinforced concrete ‘U’ sections (150mm thick walls and base), completed in situ with concrete and reinforcement, weighing over 250 tonnes.

The podium also included 9.5m tall precast columns and hollowcore flooring (200–400mm deep). Over 1,200m³ of in situ concrete and other precast elements helped achieve a robustness class of 2B.

Fulton

Structure being assembled on-site

Podium concrete frame connection

Fulton & Fifth Podium connecting to the residential structure

Hybrid Frames System Digital Construction

Golden Thread Compliance

PCE’s digital systems are designed to help achieve compliance with Golden Thread requirements by creating a single, accurate, and continually updated record of the building throughout its lifecycle.

Working in Revit, every structural component is fully modelled and embedded with metadata covering geometry, performance, fire safety, and maintenance requirements. This coordinated digital model provides the foundation for design interrogation, sign-off, and regulatory approval, ensuring that safety is prioritised from the earliest stages.

As the project develops, the model evolves into a digital twin that tracks each component from design to installation. Using Ynomia’s advanced technology, unique digital IDs link elements to their design records, QA inspections, and manufacturing data, creating a complete audit trail. Manufacturing progress and quality checks are captured in real time, while on site, elements are digitally inspected and signed off before assembly. Once installed, each component retains a permanent digital passport containing all safety, quality, and compliance information.

Component being scanned and checked in by the online system.

The result is a model that reflects the building exactly as constructed, not just as designed.

All safety-critical data is securely stored, instantly accessible, and easy to share with contractors, regulators, and building safety managers.

By integrating BIM, digital QA, and lifecycle tracking into a single platform, PCE delivers the transparency, accountability, and traceability required by the Building Safety Act. This ensures a fully compliant Golden Thread of information, giving clients and stakeholders confidence in the safety, quality, and long-term reliability of every project.

Hybrid Frames System RIBA Overlay Alignment

The RIBA Plan of Work provides a solid framework for delivering DfMA projects. As an offsite specialist, PCE aligns its proven delivery methods with these established stages—ensuring efficient, structured, and coordinated progress from concept to completion.

Early involvement from Stage 2 allows us to fully embed offsite principles, driving certainty, quality, and programme success to maximise added value.

Early engagement of a specialist contractor leads to:

• Stronger design coordination

• Reduced risk and rework

• Better cost and programme control

• Performance specification validation

• Greater safety and quality on site

• Clarity and coordination of key interfaces

• Integrated temporary works and lifting designs

• Clear design ownership and responsibility

Hybrid Frames System Site Logistics

With extensive logistical expertise and the latest in digital technology, we plan, manage, and deliver tailored solutions that bring a European supply chain to site just-in-time—no matter the site constraints.

By coordinating casting, delivery, installation, and crane schedules, we minimise disruption, reduce on-site storage, and maximise speed, efficiency, and predictability. This enables reliable construction, even in the most spacerestricted environments.

Structural steel beams being delivered at Assembly Building C in Bristol city centre

CLT floor unit being lifted into place on Brent Cross Plot 1

Accelerated Delivery

Every component and activity is precisely planned down to the minute during construction. From assembly sequencing and site access to temporary works and specifications, all decisions are embedded into the construction programme. Our BIM models, containing key assembly data, are used daily to coordinate tasks across our teams and the wider project.

Digital Bluetooth tags track each component in real time—from factory dispatch to on-site installation and final sign-off—providing a live, fully auditable timeline. This seamless process links directly to a Digital Twin, integrating QA/ QC records and offering complete transparency across the build.

Tottenham Court Road project in London with limited site space

Assembly Building C was constructed in just 32 weeks

Hybrid Frames System Cranes & Lifting

A critical factor in the successful delivery of any Offsite solution is the crane strategy and how ‘hook time’ can be maximised for productive activities and how components can be safely and efficiently offloaded from the delivery vehicle and assembled. Our critical path will always run through the crane activities so for every project, a detailed study is undertaken focussing on crane types, positions, coordination, assembly, dismantling and safe operation. To supplement this approach, we are also able to offer our own fleet of heavy lift crawler cranes.

Cranes positioned on-site at Brent Cross Plot 14

Site logistics drawing for Golden Jubilee Hospital

Programming

Every component and activity is meticulously planned to the minute during the construction phase with the sequence of assembly, the on-site methodology for accessing and undertaking the works, the temporary design requirements and the specification are all part of the decision-making process when developing the construction programme. BIM models contain key assembly data and are used to communicate and coordinate the days activities within our own assembly teams and the wider project resources.

Cranes positioned inside the building at TCR

Crane positioned to lift components into tight spaces at Golden Jubilee Hospital

One of PCE’s crawler cranes

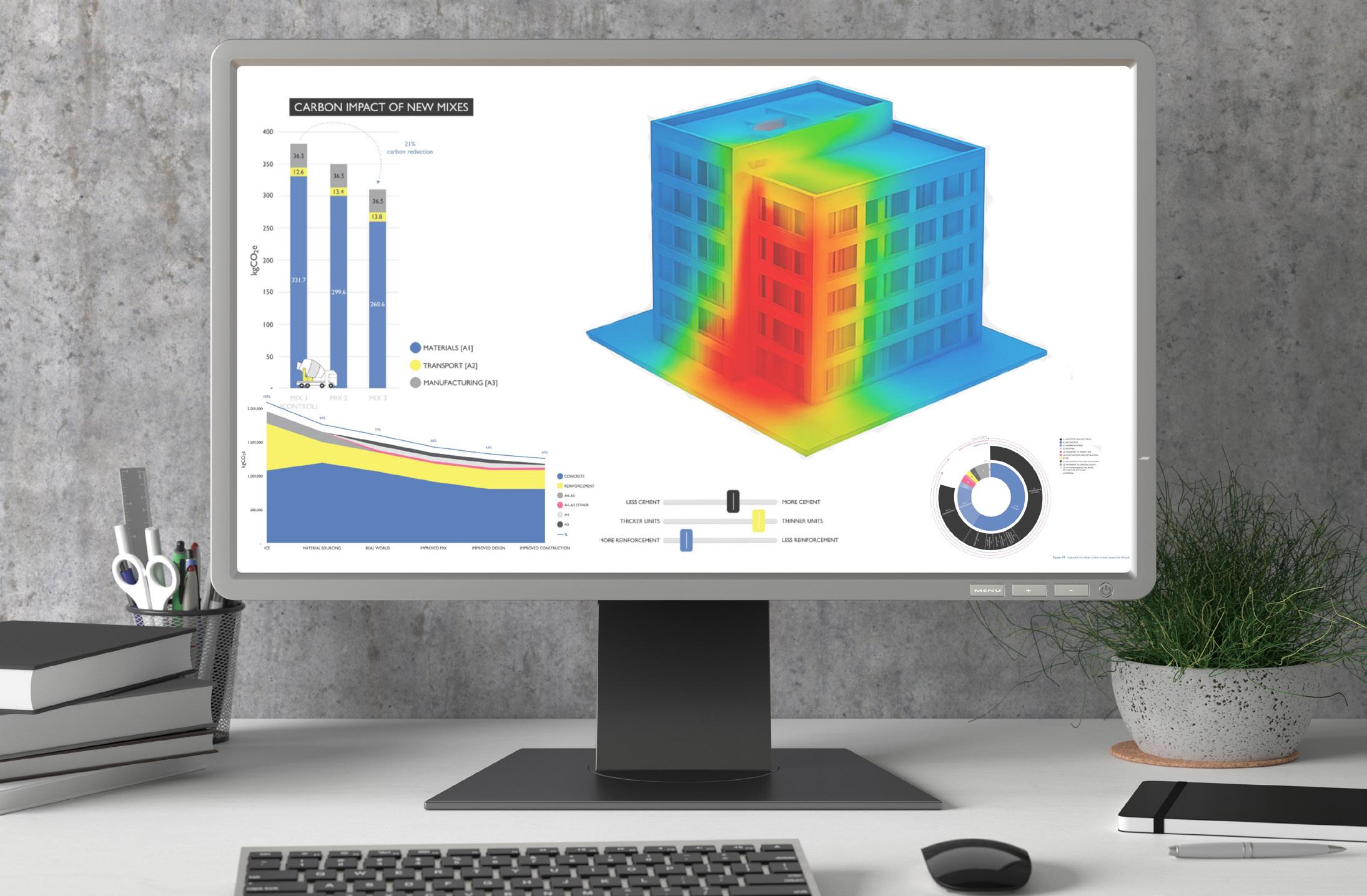

Hybrid Frames System Embodied Carbon

Our material expertise and offsite innovation enable significant embodied carbon reduction.

Carbon heat mapping, carbon calculators, and material flexibility coincide with a proactive and collaborative approach to finding meaningful carbon-reducing measures across stages A1-A5, helping clients achieve their sustainability targets.

PCE’s sustainability strategy has four fundamental pillars:

• Systematic delivery alongside material and structural optimisation ensure the carbon footprint of our solutions is minimised.

• Utilisation of ‘real-world’ data ensures we understand our actual carbon footprint and allows us to target meaningful and tangible improvements, with a culture of continuous improvement.

• We aim to lead industry best practice by embracing emerging technologies and taking a collaborative, holistic approach to innovation across the value chain.

• Responsible sourcing, supplier culture, and corporate ethics are central to our sustainability strategy. We work only with vetted partners who meet our standards for quality, safety, and value—and who share our commitment to continuous environmental improvement.

Examples of carbon reduction:

• Decarbonising Precast Concrete Study - https:// akerlof.co.uk/clients/ groundbreaking-rd-to-cutcarbon-in-concrete/

• Development of the innovative reinforcement solutions with Metlasehttps://www.unipart.com/ construction-technologies/

• Trailing of MEVO, IBA, and other innovative cements and cement replacements - https://materialevolution. com/

Embodied carbon heatmap on a frame structural solution

A frame building utilising solar energy to decrease carbon footprint

Hybrid Frames System Compliance

Predictability in outcomes is only possible when compliance is assured at every stage.

PCE’s Hybrid Frame system is built around proven processes, rigorous standards, and digital transparency - giving clients total confidence that their project will meet all regulatory, safety, and performance requirements.

Built for Assurance

• Seamlessly aligned with the Building Safety Act and Golden Thread principles through PCE’s digital twin technology and secure single source of truth, capturing every detail of quality assurance.

• Clear, traceable records support smooth passage through Building Safety Act Gateways, reducing risk and uncertainty.

Certified to the Highest Standards

• LETI-compliant design principles that help deliver sustainable, future-ready structures.

• Fully supportive of NHBC compliance, ensuring approval processes are efficient and predictable.

• Independently accredited to ISO 9001, 14001, and 45001, reinforcing our commitment to quality, environmental responsibility, and safety.

Proven Performance in Specialist Sectors

• Extensive track record in life sciences, healthcare, and medical projects where vibration control is critical.

• Collaboration with vibration specialists and use of advanced testing, analytics, and software ensure predictable, validated outcomes

• Proven capability in meeting stringent vibration performance criteria, such as VC-A compliance, HTM-08 standards, and R=1 outcomes.

Vibration testing equiptment on a concrete unit

Vibration testing and analysis for a healthcare project using Hybrid Frame

Hybrid Frames System Awards

PCE has received over 40 awards from some of the construction industry’s most prestigious award bodies, with multiple accolades recognising projects delivered through our Hybrid Frame system.

This continued recognition reflects not only the innovation and added value benefits that our design and build approach brings, but also the consistent success achieved across a wide range of projects.

Behind every award is the hard work, dedication, and passion of our people and supply chain partners. Their commitment to collaboration, quality, and pushing boundaries ensures that we deliver the very best results, every time. Our industry recognition is a testament to this collective effort, reinforcing PCE’s position as a leader in hybrid construction solutions.

PCE won Best Use of Concrete Technology at the Offsite Awards 2023 for Assembly Building C

won and were highly commended at the Offsite Awards 2024

PCE