any design. any material. any technology. Lockers Manufacturing

Batesville, Mississippi has always embraced and followed opportunity. In the 19th century, when rail lines connected Memphis, TN to Grenada, MS, the town of Panola moved toward the newly established tracks and took on the name of Batesville a ter an influential local reverend. That same railroad now runs through downtown Batesville.1 A ter a period of economic downturn surrounding the great recession, downtown Batesville is now experiencing another market transition with can maker Crown closing up shop in March 2024, forcing people to travel to Oxford to find work. A key part of that revitalization in downtown Batesville was the introduction and planned expansion of Lockers Manufacturing.

Beginning in 2014, Lockers Manufacturing set out to not only produce the highest quality storage systems but to ensure that the community surrounding them improves and expands. In 2021, Lockers Manufacturing expanded their operation and opened a state-of-the-art facility in downtown Batesville. Their attention to quality extends beyond to their employees, customers, and their community. With faith leading the way, the leaders at Lockers Manufacturing utilize their servant-leadership style to change their industry and community for the better.

“When Lockers Manufacturing came in, they said, ‘look, we want to be in the part of town where we can serve the community the best.’ From day one, I'm working with a completely di erent company with a completely di erent mindset.”

-Joe Azar CEO of Panola Partnership

As the company continues to expand, the opportunities continue to expand with them. With over 5,000 completed projects, each customized from inception to installation, Lockers Manufacturing is a leader in their sector and a bulwark of their community.

The current operations of Lockers Manufacturing have a significant impact on the State of Mississippi. The 2023 economic impact of Lockers Manufacturing totals $31.2 million ($22 million direct and $9.2 million indirect and induced). Lockers Manufacturing supports and sustains 97 jobs (55 direct jobs and 42 indirect and induced jobs). The company generates $1.6 million in local ($173,384), state ($417,691), and federal ($974,809) tax revenues.

Lockers Manufacturing is planning to significantly grow its operations in Batesville, MS over the next ten years – increasing their spending to $250 million annually and growing their workforce to employ 250 people. This strategic growth will make an impact locally and throughout Mississippi. The projected economic impact of Lockers Manufacturing in 2033 totals $345.4 million ($250 million direct and $95.4 million indirect and induced). Lockers will support and sustain 664 jobs (250 direct jobs and 414 indirect and induced jobs). Operations will generate $13.5 million in local ($1.7 million), state ($4.1 million), and federal ($7.7 million) tax revenues.

“I am proud to be a partner with Lockers Manufacturing, because they are truly an American story.” Brad Runion

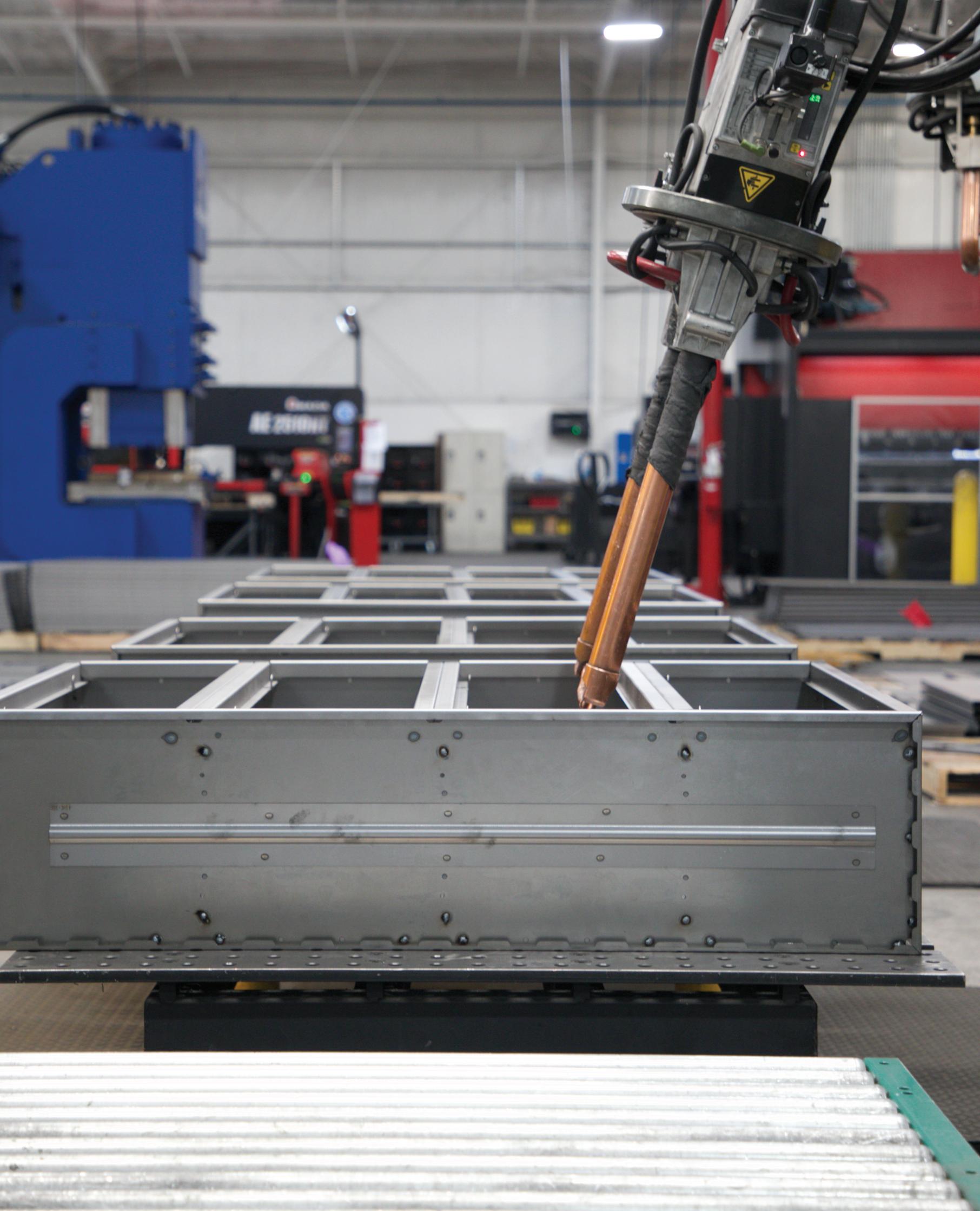

A dedication to quality sets Lockers Manufacturing apart from its competition. They begin with the selection of superior raw materials, notably American steel. Lockers Manufacturing chooses cold rolled steel, a process that involves the cooling of steel as it is formed, giving it added strength and more surface finish options. This process, despite being more expensive, leads to a better product.

According to Brad Runion of Majestic Steel, cold rolling steel leads to a “much better-looking product in the long run.” Many companies would favor their bottom line over product quality, but Lockers Manufacturing believes that quality will continue to lead their company’s success.

““We invest in testing and 3rd party certifiers for our lockers, and we don't cut corners. Our employees feel great pride in their work producing high-quality, custom made lockersand it shows. Our customers come back again and again.”

-Brad Jolly Executive Director Lockers ManufacturingA ter the high-quality, cold rolled steel makes it way to the facility in Batesville, the lockers are made using the latest laser technology and run through a battery of quality control tests. The doors, latches, and hinges are tested, and the thickness--produced at 2-3mm vs. our competitors 1-2mm paint thickness--- is evaluated for consistency. A 1,000-hour salt spray test is administered to ensure that the lockers can withstand the elements and the wear and tear that comes with use. This industry-leading attention to detail and quality sets Lockers Manufacturing above the competition.

Community involvement requires commitment, and o ten that commitment reflects the amount of drive and prioritization that a business’s leadership must go beyond profit. In other words: the quality of community involvement by a business o ten starts from the top. As soon as Lockers Manufacturing arrived in Batesville, the commitment to the surrounding community was evident from the top.

“If Lockers weren’t here, it would be like a puzzle missing a piece. They don’t just sponsor events, they get involved and participate.”

-Joe Azar CEO of the Panola Partnership

From the “Pull for Panola” skeet shooting legislative event to Music on the Square nights and the Art Mart, Lockers Manufacturing not only has a corporate presence but an authentic participation from all levels of employees. This immediate and meaningful integration into the local community has elevated Lockers Manufacturing from a successful business to an integral part of the community.

A key component of this community involvement stems from “Warehouse3,” a non-denominational church that was created and located in one of the Lockers Manufacturing warehouses with 1 Corinthians 15: 1-4 used as a guidepost for the support programs. Led by the same servant-leadership style that guides their successful business, this faith outreach has expanded to include startup churches in Rossville, TN, Dallas, TX, and Denver, CO.

Building from this initiative, Warehouse3 has expanded to include faith-based youth basketball programs. Beginning in 2018, the Warehouse3 middle school basketball teams have competed to become better players and better people. Keith Dunham and Drew Schofield, two of Lockers Manufacturing’s own, work together to provide guidance on and o the court to young men of the community.

"We produce the single best product because we treat our employees like family. We are proud to be a part of Batesville's resurgence and be a part of Mississippi's manufacturing present and future."

-Keith Dunham CEO, Lockers Manufacturing

Products at Lockers Manufacturing are built with the highest quality steel, supported by the stronger, longer-lasting steel production process. Lockers Manufacturing currently generates $32.2 million in economic impact, with 96 jobs supported and sustained, and is poised for growth and expansion in Mississippi over the next 10 years – resulting in increased economic opportunity for Mississippi.

Manufacturing Current Impact on Mississippi

$31.2M generated in economic impact

97 jobs supported and sustained

55 people employed by Lockers $1.6M in local, state, & federal tax revenue

The current operations of Lockers Manufacturing have a significant impact on the state of Mississippi. The economic analysis presented to the right is based upon the dollars spent by Lockers Manufacturing, their local suppliers, and Mississippi-based employees1 in the state.

Analysis of operations in 2023 shows an overall economic impact of $32.2 million ($22 million direct and $9.2 million indirect and induced), 97 jobs supported and sustained (55 direct jobs and 42 indirect and induced jobs), and $1.6 million in local ($173,384), state ($417,691), and federal ($974,809) tax revenues.

$138.8M generated in economic impact

295 jobs supported and sustained

125 people employed by Lockers

$5.7M in local, state, & federal tax revenue

The operations of Lockers Manufacturing have a significant impact on the state of Mississippi. The economic analysis presented to the right is based upon the dollars spent by Lockers Manufacturing, their local suppliers, and Mississippi-based employees2 in the state.

Analysis of projected operations in 2028 shows an overall economic impact of $138.8 million ($100 million direct and $38.8 million indirect and induced), 295 jobs supported and sustained (125 direct and 170 indirect and induced jobs), and $5.7 million in local ($716,653), state ($1.7 million), and federal ($3.3 million) tax revenues.

$345.4M generated in economic impact

664 jobs supported and sustained

250 people employed by Lockers

$13.5M in local, state, & federal tax revenue

The operations of Lockers Manufacturing have a significant impact on the state of Mississippi. The economic analysis presented to the right is based upon the dollars spent by Lockers Manufacturing, their local suppliers, and Mississippi-based employees3 in the state.

Analysis of projected operations in 2033 shows an overall economic impact of $345.4 million ($250 million direct and $95.4 million indirect and induced), 664 jobs supported and sustained (250 direct and 414 indirect and induced), and $13.5 million in local ($1.8 million), state ($4.1 million), and federal ($7.7 million) tax revenues.

Making high-quality products in the United States is priority. In a favorable business environment, the expansion of Lockers Manufacturing will increase the economic, employment, and tax revenue impact. This economic activity will occur in the backdrop of a resurgent and modernizing American South and will again benefit from the logistical ties to Memphis.

While the growth of Lockers Manufacturing will certainly benefit the economy of Batesville, Panola County, and Mississippi overall, the company will also have a profound impact on the community. The revitalization of downtown Batesville, led by the opportunities provided by businesses like Lockers, will take the area back to its thriving, middle-class-supporting days.

Direct Employment

Dollar Year

Government Revenue/ State and Local Tax Impact

All direct expenditures made by a corporation due to its expenditures. These include operating expenditures, capital expenditures, and pay and benefits expenditures.

Total number of employees, both full-time and part-time, at the corporation based on total jobs, not FTEs.

Presented in 2023 dollars.

Government revenue or tax revenue that is collected by governmental units at the state and local levels in addition to those paid directly by a corporation. This impact includes taxes paid directly by the corporation itself, employees of the corporation, and vendors who sell products to the corporation and at the household level.

Indirect Economic Impact

Indirect Employment

Induced Economic Impact

The indirect impact includes the impact of local industries buying goods and services from other local industries. The cycle of spending works its way backward through the supply chain until all money is spent outside of the local economy, either through imports or by payments to value added (multiplier e ect).

Additional jobs created because of a corporation’s economic impact. Local companies or vendors that provide goods and services to a corporation increase their number of employees as purchasing increases, thus creating an employment multiplier.

The response by an economy to an initial change (direct e ect) that occurs through re-spending of income received by a component of value added. IMPLAN’s default multiplier recognizes that labor income (employee compensation and proprietor income components of value added) is not lost to the regional economy. This money is recirculated through household spending patterns causing further local economic activity (multiplier e ect).

Induced Employment

Multiplier E ect

Study Years

Total Economic Output/ Economic Impact

Additional jobs created because of household spending by employees of a corporation and the employees of vendors. This is another wave of the employment multiplier.

The multiplier e ect is the additional economic impact created because of the corporation’s direct economic impact. Local companies that provide goods and services to a corporation increase their purchasing by creating a multiplier (indirect/supply-chain impacts). Household spending generated by employees of the corporation and the corporation’s suppliers create a third wave of multiplier impact (induced/household-spending impacts).

2023, 2028, 2033

Includes spending on operations, capital expenditures, labor income expenditures, and value added to the economy because of expenditures made by a corporation. It is the combined impact of direct, indirect, and induced impacts.

Data used to complete the economic analysis was provided by Lockers Manufacturing. Data supplied included projected operating expenditures, capital spending, pay and bene ts, and total employees. Primary and secondary data was used to complete the input-output models in IMPLAN. The study approach and economic-impact ndings are a conservative estimate of impact and are based on actual nancial information. The study is a snapshot of the current and projected economic impact.

The most common and widely accepted methodology for measuring the economic impacts of economic sectors is input-output (I-O) analysis. At its core, an I-O analysis is a table that records the ow of resources to and from companies/corporations and individuals within a region at a given time. For a speci ed region, such as a state of the nation, the input-output table accounts for all dollar ows among di erent sectors of the economy in a given period. With this information, a model can then follow how a dollar added into one sector is spent and re-spent in other sectors of the economy, generating outgoing ripples of subsequent economic activity. This chain of economic activity generated by one event is called the “economic multiplier” e ect.

The primary tool used in the performance of this study is the I-O model and dataset developed and maintained by IMPLAN Group LLC (formerly Minnesota IMPLAN Group Inc.). IMPLAN is a widely accepted and used software model rst developed by the U.S. Forest Service in 1972. Data used in the baseline IMPLAN model and data set come largely from federal-government databases. The input-output tables themselves come from the Bureau of Economic Analysis. Much of the annual data on labor, wages, nal demand, and other market data comes from the Bureau of Labor Statistics, the U.S. Census Bureau, and other government sources.

Government agencies, companies, and researchers use IMPLAN to estimate the economic activities associated with spending in a particular industry or on a particular project. The IMPLAN model extends conventional I-O modeling to include the economic relationships among government, industry, and household sectors, allowing IMPLAN to model transfer payments such as taxes. Producers of goods and services must secure labor, raw materials, and other services to produce their product.

The resources transferred to the owners of that labor, or those raw materials and services are then spent to secure additional goods and services or inputs to the products they sell. For example, a corporation may start a manufacturing plant that produces tractors with a value of $1 million. However, to produce that product, they may be required to spend $500,000 in wages and bene ts, $200,000 to suppliers of tractor parts, $100,000 for electricity, $50,000 for transportation of goods and raw materials to and from the plant, and $50,000 in various professional services associated with operating a business (e.g., attorneys and accountants). The suppliers will, in turn, spend those resources on labor and raw materials necessary to produce tractors. Workers and the owners of the company will buy goods and services from other rms in the area (e.g., restaurants and gas stations) and pay taxes. The suppliers, employees, and owners of this second tier will, in turn, spend those resources on other goods and services whether within the study region or elsewhere. The cycle continues until all the money leaves the region.

The model uses national production functions for over 546 industries to determine how an industry spends its operating receipts to produce its commodities. Sectors utilized in this study include 371: Showcase partition, shelving, and locker manufacturing. These production functions are derived from U.S. Census Bureau data. IMPLAN couples the national production functions with a variety of county-level economic data to determine the impacts at a state and congressional-district level. IMPLAN collects data from a variety of economic data sources to generate average output, employment, and productivity for each industry in each county. IMPLAN combines this data to generate a series of economic multipliers for the study area. The multiplier measures the amount of total economic activity generated by a speci c industry’s spending an additional dollar in the study area. Based on these multipliers, IMPLAN generates a series of tables to show the economic event’s direct, indirect, and induced impacts to gross receipts, or output, within each of the model’s more than 546 industries.

The model calculates three types of e ects: direct, indirect, and induced.

There are three important points about the use of IMPLAN (or any other input-output model):

It is a xed-price model. The model assumes that changes in consumption are not limited by capacity and do not a ect prices. This assumption does not cause a problem for the analysis presented here because we are taking a snapshot of Mississippi in a speci c year.

As in many studies using this type of model, the direct impacts are not calculated by the model; they re ect actual and projected spending levels and patterns created by Lockers Manufacturing and their proposed projects. Changing the level of direct spending allows us to calculate the magnitude of the indirect and induced e ects associated with the initial level of spending.

Because the model continues to calculate additional spending until all the money leaves the region (i.e., “leakage”), the larger and more economically diverse the region, the longer it will take for spending to leave the region and the larger the impact is likely to be. For example, employees of Lockers Manufacturing may spend some amount of their income on buying a car. Since there are no car manufacturers in Mississippi, this spending will leave the region and the multiplier e ect will stop. At the national level, some portion of that same spending by that same individual may go to a national auto producer. That spending would lead to more spending at the national level than would be captured by a more regional or statewide model.