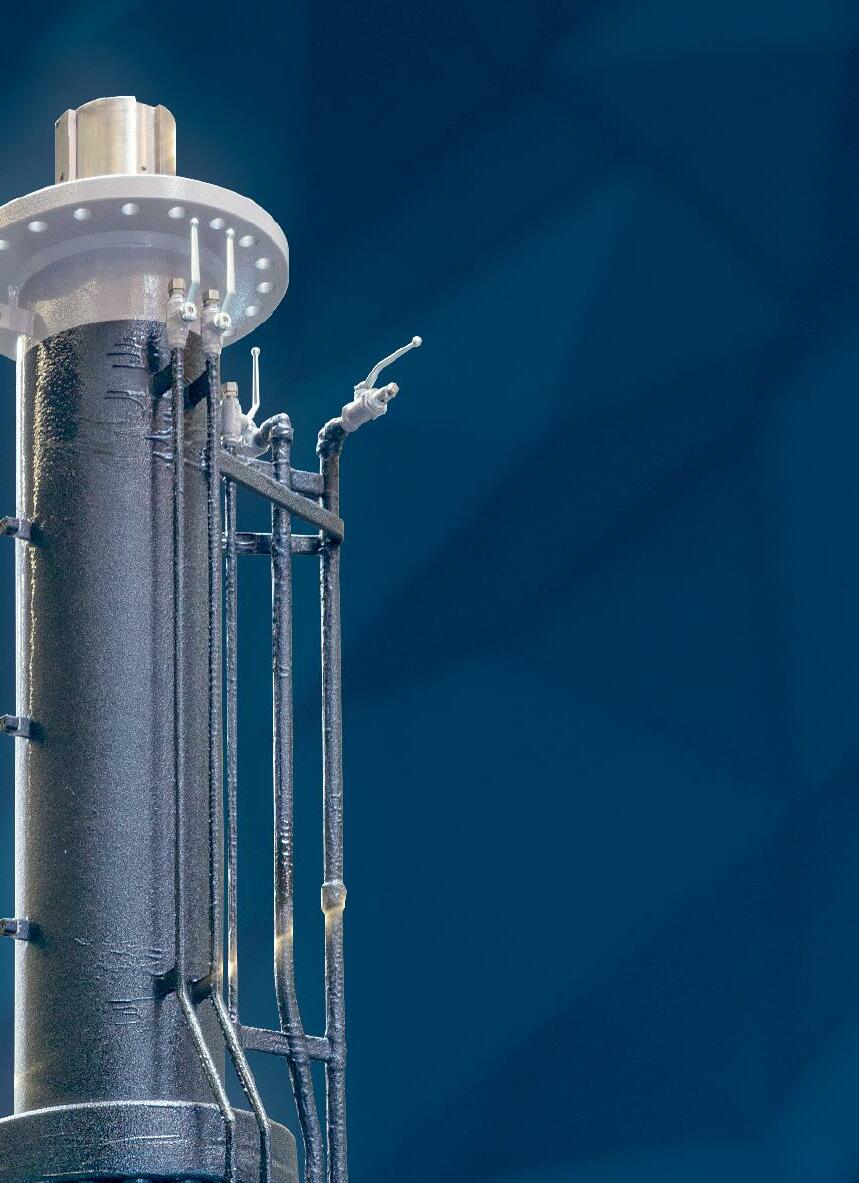

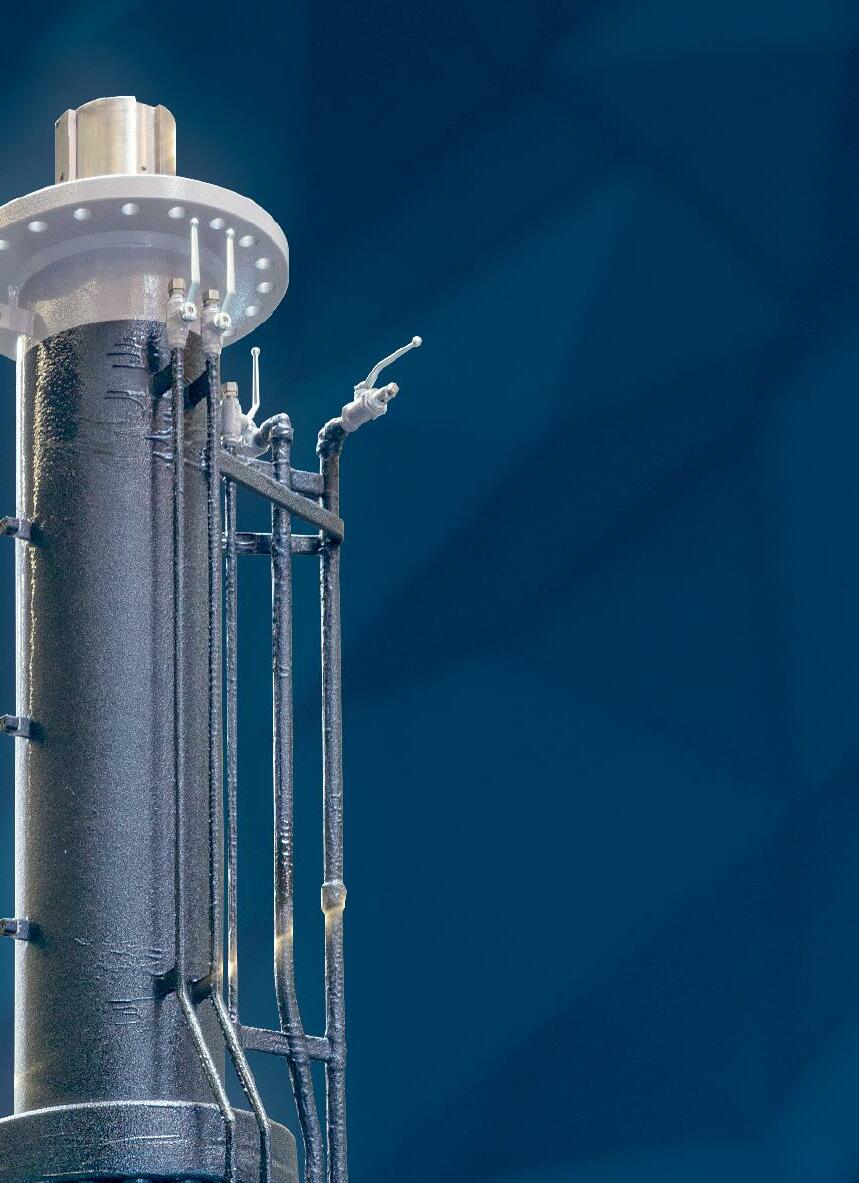

ONSHORE /OFFSHORE OIL & GAS SECURES YOUR INSTALLATIONS IN ANY ENVIRONMENTS INNOVATIVE REPAIR SOLUTIONS FOR YOUR INSTALLATIONS www.3xeng.com HIGH PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT REINFORCEKiT®4D ® Volume 22 Number 12 - December 2022

The leading innovator supplying cutting-edge integrity solutions. Together we can ensure sustainable decision-making. Our combination of advanced inspection systems and expert consultants delivers a comprehensive understanding of asset safety, lifetime, and performance.

Comprehensive Asset Integrity Management

www.rosen-group.com

comment

SENSING

THOUGHT LEADERSHIP:

REPAIR AND REHABILITATION SERVICES

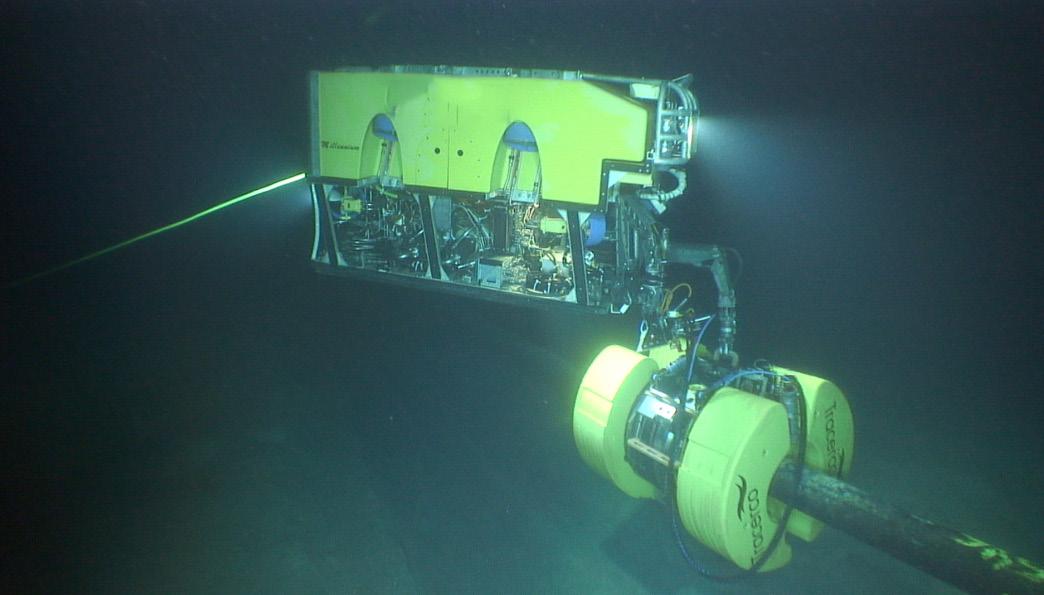

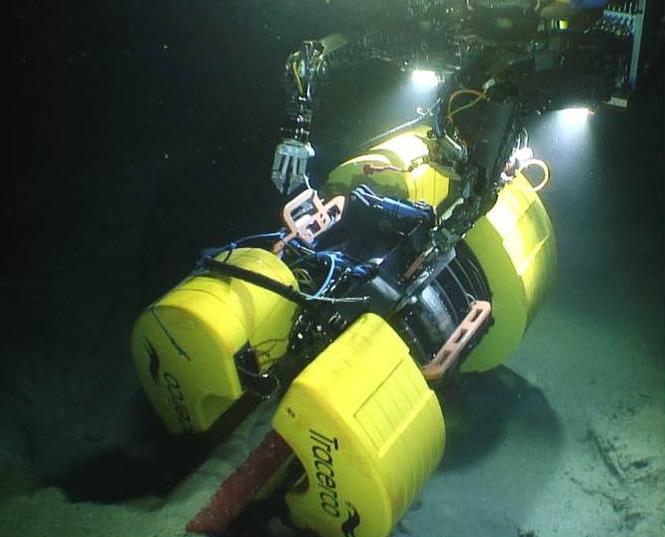

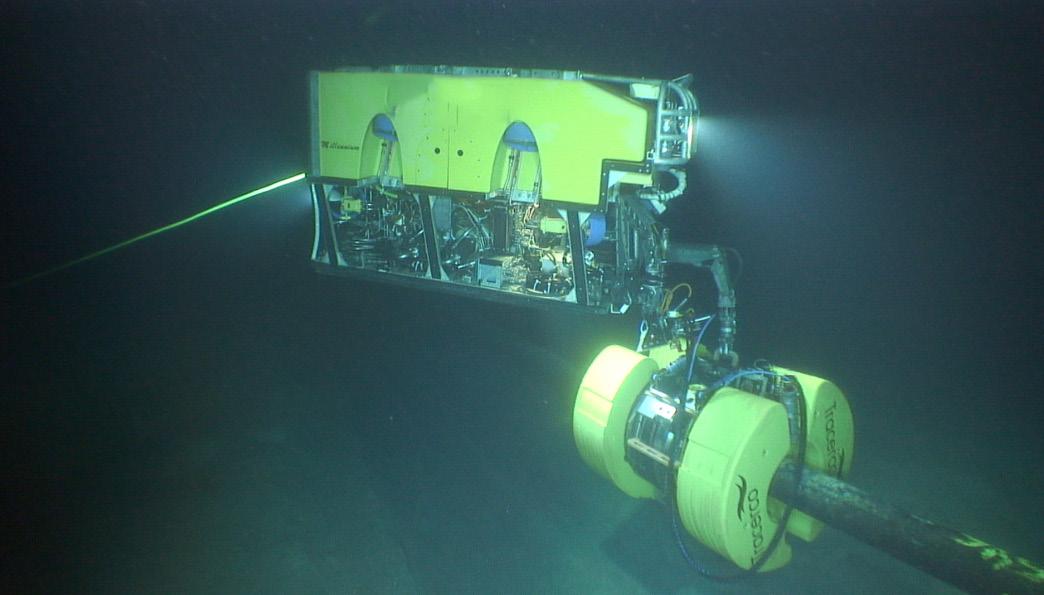

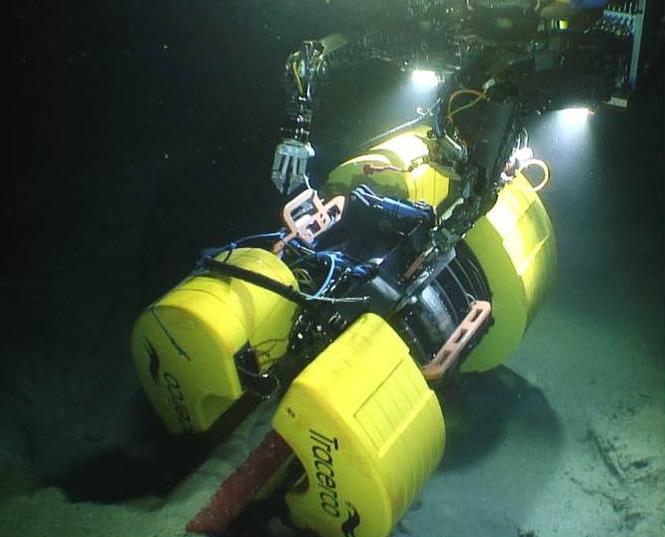

45. Prolonging the life of assets Jim Bramlett, Tracerco, USA.

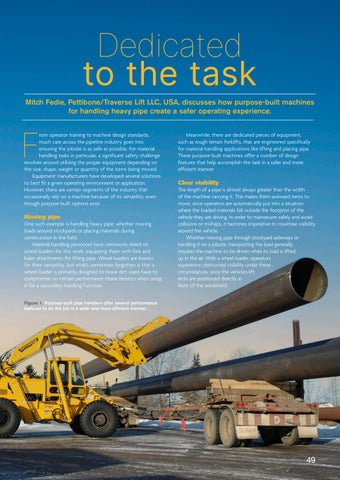

PIPELINE MACHINERY FOCUS 49. Dedicated to the task Mitch Fedie, Pettibone/Traverse Lift LLC, USA.

TUBE AND PIPE 51. Detecting weld defects Cameron Serles, President, Xiris Automation Inc., Canada.

TOOL PERFORMANCE

ISSN 14727390 Member of ABC Audit Bureau of Circulations

Reader

C O NTENTS Copyright© Palladian Publications Ltd 2022. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are

the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements. Printed

the UK.

|

|

|

3X ENGINEERING

pipeline maintenance

ON THIS MONTH'S COVER

enquiries [www.worldpipelines.com]

not necessarily

in

WORLD PIPELINES

VOLUME 22

NUMBER 12

DECEMBER 2022 For over 30 years,

has been one of the leading companies specialising in

using composite technology. We offer our clients a complete integrated service; development, manufacturing, retail, and installation. From our head offices in Monaco, we operate worldwide, in any environment (onshore, offshore or subsea), thanks to our large qualified distribution network of over 60 partners. www.3xeng.com

33 CBP006075 49

03. Editor's

05. Pipeline news With updates from E.ON, DNV and ExxonMobil.

PAGE 08 13

CYBERSECURITY 08. Keep the ball rolling Chris Grove, Director of Cybersecurity Strategy, Nozomi Networks, USA, shares some advice for moving the cybersecurity ball forward, with the goal of being better positioned to accommodate changing regulations.

Chris Grove, Director of Cybersecurity Strategy, Nozomi Networks, USA, shares some advice for moving the cybersecurity ball forward, with the goal of being better positioned to accommodate changing regulations. than it’s ever been before. As demand surges, exasperate, and risks become realities, it’s more security secure, crucial to our survival. critical infrastructure; in some, they are even more security strategy. As governments attempt to tackle the burdening infrastructure operators with redundant or on minimum-level to operate safely and securely. For the bar for minimum physical, design, and operational Series recent update ‘C’, are focused on cybersecurity for the pipelines. Both had the best interests of public safety in mind when they were drafted. At the time of drafting, there were cases of overlap, contention, and industry/government back and forth. As we discover new data, collaborate on issues, and new risks emerge and old risks evolve, the recommended minimum for safe operations is updated, thereby ‘raising the bar’ on what the minimum is, in order to safely operate the regulated asset. There will also be multitude of applicable, interconnecting, and overlapping regulations, standards, and best practices that reside-between the aforementioned rules and directives. In some cases, they may even have of sustaining vast those that will be regulated rarely works out well; collaboration that pipeline operations can bring. As an example, attempting copy and paste type rule setting, challenging and ambitious into the equation, the impact from mistake can be larger than what many are willing to accept. At the time that many of today’s regulations were drafted, the physical world and cyberspace was quite different place. Common risks were low-level cyber criminals, or disorganised one-off saboteurs. But the changing landscape due to the Russian invasion of Ukraine has resulted in turning the internet into a hot warzone, with multiple threat actor groups, ranging from state-sponsored, to hacktivists, to quasi-state cybermilitia viciously and relentlessly attacking critical infrastructure around the world. Their goal to create mass destruction by any means necessary. Another facet is the energy war being waged, with pipelines front and centre. After the Colonial Pipeline incident, it’s clear, nation-state actors will commit the same types of attacks when the time comes. Defending the pipelines against cyberattack is more than just protecting profit, it’s fighting in the trenches in new frontier of war. Government regulators know this, and are working 8 9 OIL & GAS SECURES YOUR INSTALLATIONS IN ANY ENVIRONMENTS INNOVATIVE REPAIR SOLUTIONS FOR YOUR INSTALLATIONS www.3xeng.com HIGH PERFORMANCE COMPOSITE REPAIR SOLUTION FOR PIPE REINFORCEMENT REINFORCEKiT®4D WORLD PIPELINES DECEMBER 2022 ® Volume 22 Number 12 - December 2022 www.worldpipelines.com OFC_WP_December_2022.indd KEYNOTE: ENVIRONMENT 13. Embracing the measurement economy Pauline Morrice, Senior Communications Advisor, UK and Steve Kemp, Senior Director of Customer Success, Project Canary, USA, consider why the measurement economy is changing the methane emissions game. METERING AND MONITORING 20. Machine learning models Dr Yanfeng Liang, TÜV SÜD National Engineering Laboratory. 25. Unmanned: the future of monitoring? Richard Hjelmberg, UMS SKELDAR, Sweden. 28. Flow balancing Tommi

Engineering Analysis

33. No moving forward without it Rolf

Lie,

Williamson, Asia

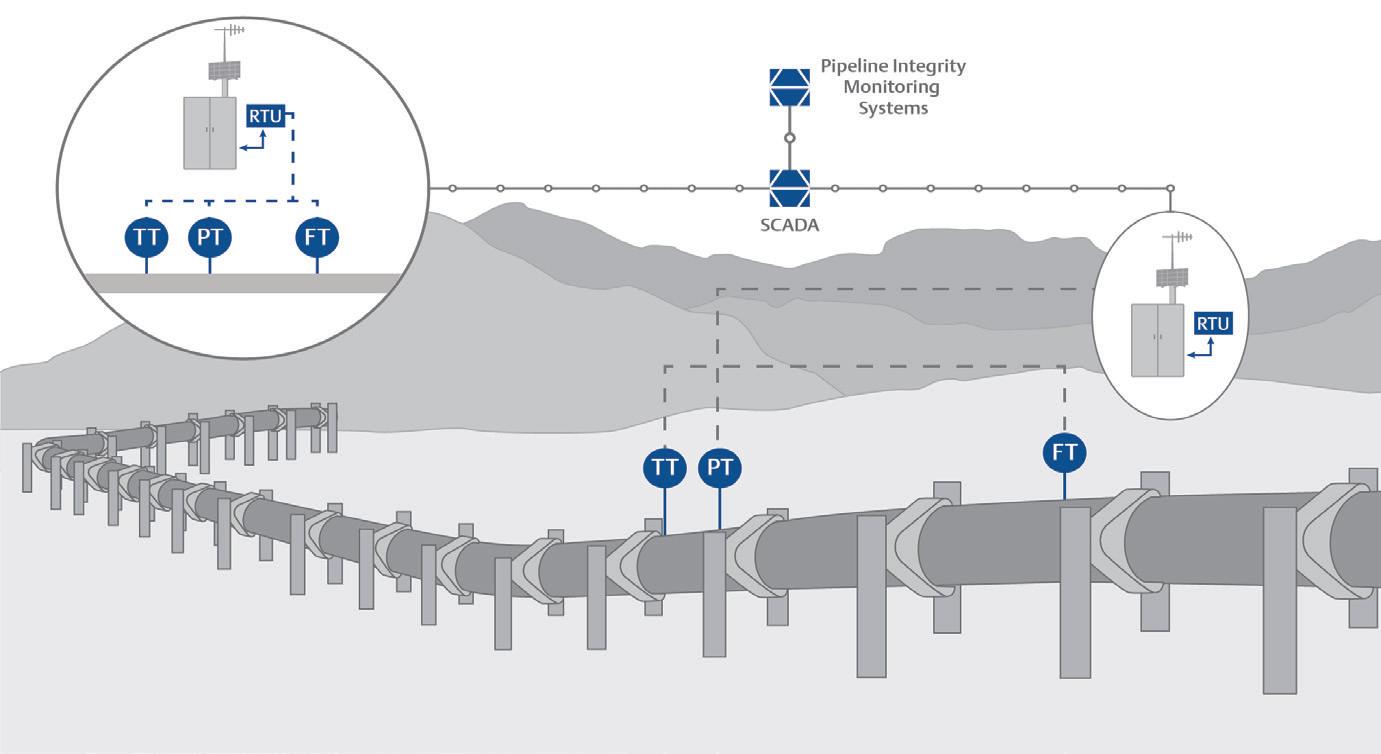

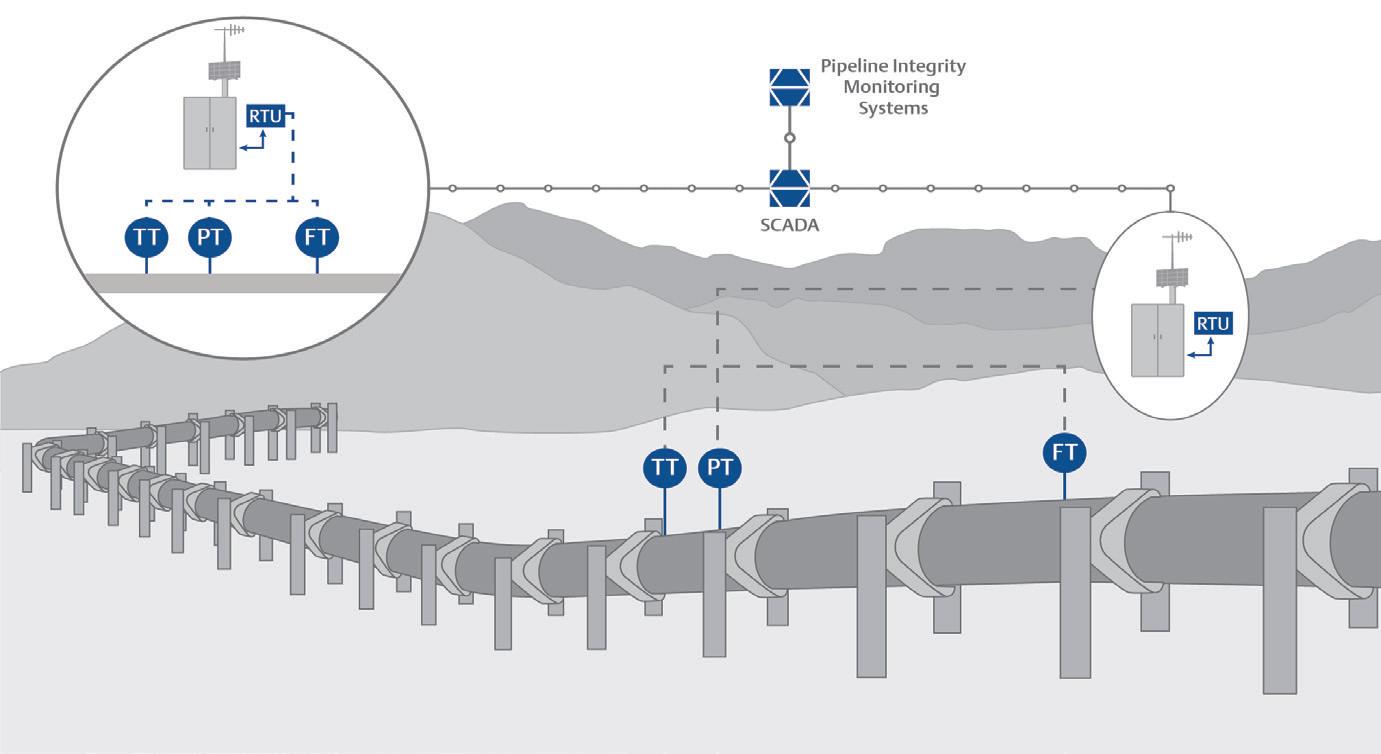

PAGE 38 The energy industry is rapidly embracing the DNP3 protocol for fast and cybersecure pipeline monitoring, suggests Steve Hill, Emerson, USA. afe and efficient transmission of product via energy pipelines has become more important than ever due to the growing need to efficiently manage an evolving product mix that includes newer products, such as biofuels and renewable natural gas (RNG), along with petroleum-based products. Global trends and shifting public opinion have led pipeline operators to focus increasing effort on eliminating transmission delays and leaks, which can only be accomplished through careful monitoring of every mile of a pipeline. However, not every mile of every pipeline will have access to reliable communication backbone capable of delivering real-time data securely. To overcome these obstacles, field operations and operational technology (OT) teams are pursuing new combinations of software, technologies, and communication infrastructure to address the challenges of unreliable networks, while simultaneously improving cybersecurity across the entire pipeline. Distributed network protocol (DNP3) is at the heart of this shift, prompting forward-thinking organisations to include it as part of their future The importance of robust pipeline protocols To ensure safe, effective transmission of product across miles of pipeline, operators and maintenance personnel need constant and clear visibility into what happening in even the most remote locations. To enable this visibility, teams need communication infrastructure that ensures data provided reliably and delivered efficiently, while simultaneously minimising the risk of cyberattacks. One of the most common strategies teams rely upon to ensure data integrity is storing historical data in remote terminal units (RTUs). When everything operates as planned, RTUs gather data from the pipeline and transmit to supervisory control and data acquisition (SCADA) system, in real-time or near-real-time. However, 38 39

REMOTE

38. Communicating across networks Steve Hill, Emerson, USA.

Bergman, Manager of

and Taija Hämäläinen, Director of Butterfly Valves, Valmet, Finland. PIGGING

Gunnar

T.D.

Pacific.

Headline sponsor The forum for the pipeline community, exploring pipeline coatings, hydrogen transportation, new technology and markets Hear from the global supply chain, including: SECURE YOUR DISCOUNTED PLACE TODAY www.ami.ltd/event-pipeline-wp Thierry Kerzerho Integrity Engineer GRT Gaz Denis Melot Expert Non-Metallic Materials and Coatings TotalEnergies Michele Castano Senior Coating Engineer EniProgetti Haralampos Tsaprailis Coatings Specialist Enbridge Employee Services Canada Pipeline Coating 13-15 February 2023 | Vienna, Austria *Discount cannot be used in conjunction with other offers. Only available for new event attendees. Other speaking companies include: Charter Coating Services (2000), Dam Coating, The Sherwin-Williams Company, Norner, Cefracor, AkzoNobel Powder Coatings, Seal For Life, AMI, Axalta, Borealis and more! Also sponsored by: Supported by:

EDITOR’S COMMENT

CONTACT INFORMATION

MANAGING EDITOR

James Little james.little@palladianpublications.com

EDITORIAL ASSISTANT

Sara Simper sara.simper@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Chris Lethbridge chris.lethbridge@palladianpublications.com

SALES EXECUTIVE

Daniel Farr daniel.farr@palladianpublications.com

PRODUCTION MANAGER

Calli Fabian calli.fabian@palladianpublications.com

EVENTS MANAGER

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR Stirling Viljoen stirling.viljoen@palladianpublications.com

DIGITAL CONTENT ASSISTANT Merili Jurivete merili.jurivete@palladianpublications.com

DIGITAL ADMINISTRATOR Leah Jones leah.jones@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey, GU9 7QU, UK

Tel: +44 (0) 1252 718 999 Website: www.worldpipelines.com Email: enquiries@worldpipelines.com

Annual subscription £60 UK including postage/£75 overseas (postage airmail). Special two year discounted rate: £96 UK including postage/£120 overseas (postage airmail). Claims for non receipt of issues must be made within three months of publication of the issue or they will not be honoured without charge.

Applicable only to USA & Canada: World Pipelines (ISSN No: 1472-7390, USPS No: 020-988) is published monthly by Palladian Publications Ltd, GBR and distributed in the USA by Asendia USA, 17B S Middlesex Ave, Monroe NJ 08831. Periodicals postage paid New Brunswick, NJ and additional mailing offices. POSTMASTER: send address changes to World Pipelines, 701C Ashland Ave, Folcroft PA 19032

An editorial team reads each issue of a magazine many times over before it’s published: we check for inaccuracies, typos, breaks in flow and all sorts of things we hope to catch before the printer springs into action. This month, as every month, Editorial Assistant, Sara Simper made some pertinent notes in the margins of the paper proofs, and one note caught my eye: she wrote that a section from the Nozomi Networks article was an interesting point (and a good starting point for a column). So here I am, thinking about the quote, which goes: “Essentially, it’s the realisation that all great things will fail one day, eventually. It is therefore not entirely about the prevention of failures; sometimes we also need to plan on being resilient to failure.”

The context of the quote is designing cybersecurity for pipelines. The article explains that software companies tend to design network security in layers, with the understanding that each layer could eventually be compromised. They resist security breaches by building in the layers, but they make the network resilient to security breaches by making sure the system can withstand one of those layers failing. Read the article (p.8) to learn how Nozomi is leveraging a resiliency-based mindset to tackle pipeline cybersecurity, even in the face of changing regulations and an ever-changing threat reality.

It strikes me that resisting something means pushing back against it with all of your might: planning, strategising, shoring up defences. This is worthy work and a vital part of creating safe, efficient pipeline systems. However, being resilient means that even if the worst happens and a breach occurs, you have options: a plan B and a plan C, a way to re-route and regain control. So, within resilience we find being quick-thinking a good attribute, but also the ability to accept change. Starting on p.13, Kellas Midstream and Project Canary write about the measurement economy and how it is changing the business of methane emissions. The article addresses the problem of pipeline leaks and fugitive emissions, and explains how midstream operators need to look towards leak detection technologies that measure in real-time and utilise analytics. Continuous methane monitoring sensors are able to offer advanced monitoring and insight, to enable rapid interventions should a leak be found. This is resilience.

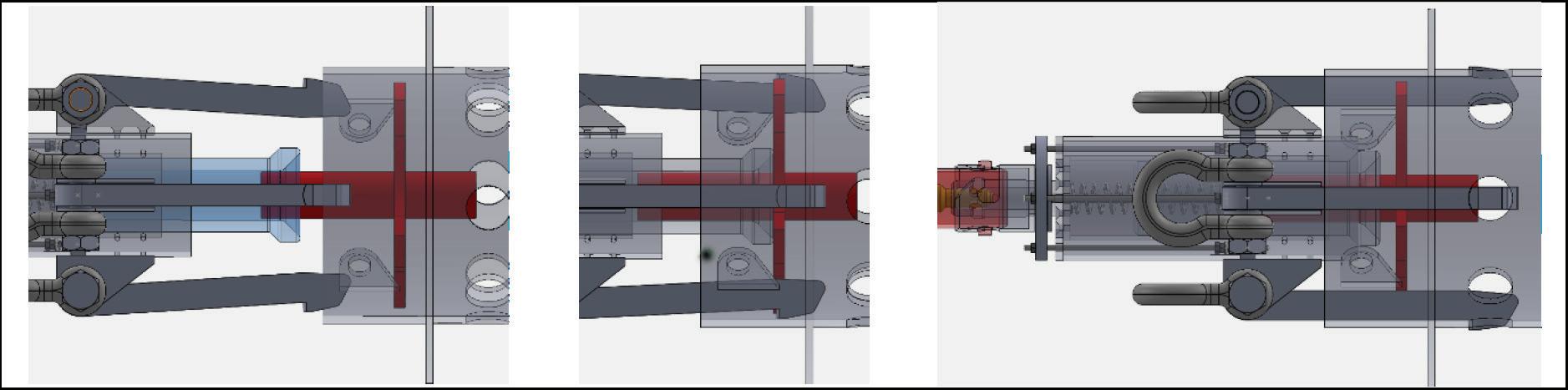

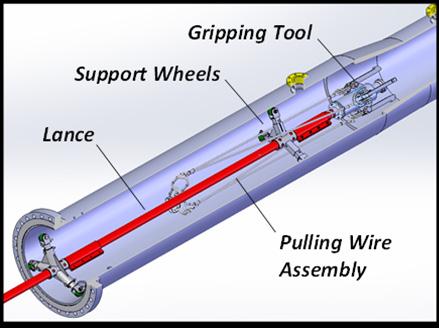

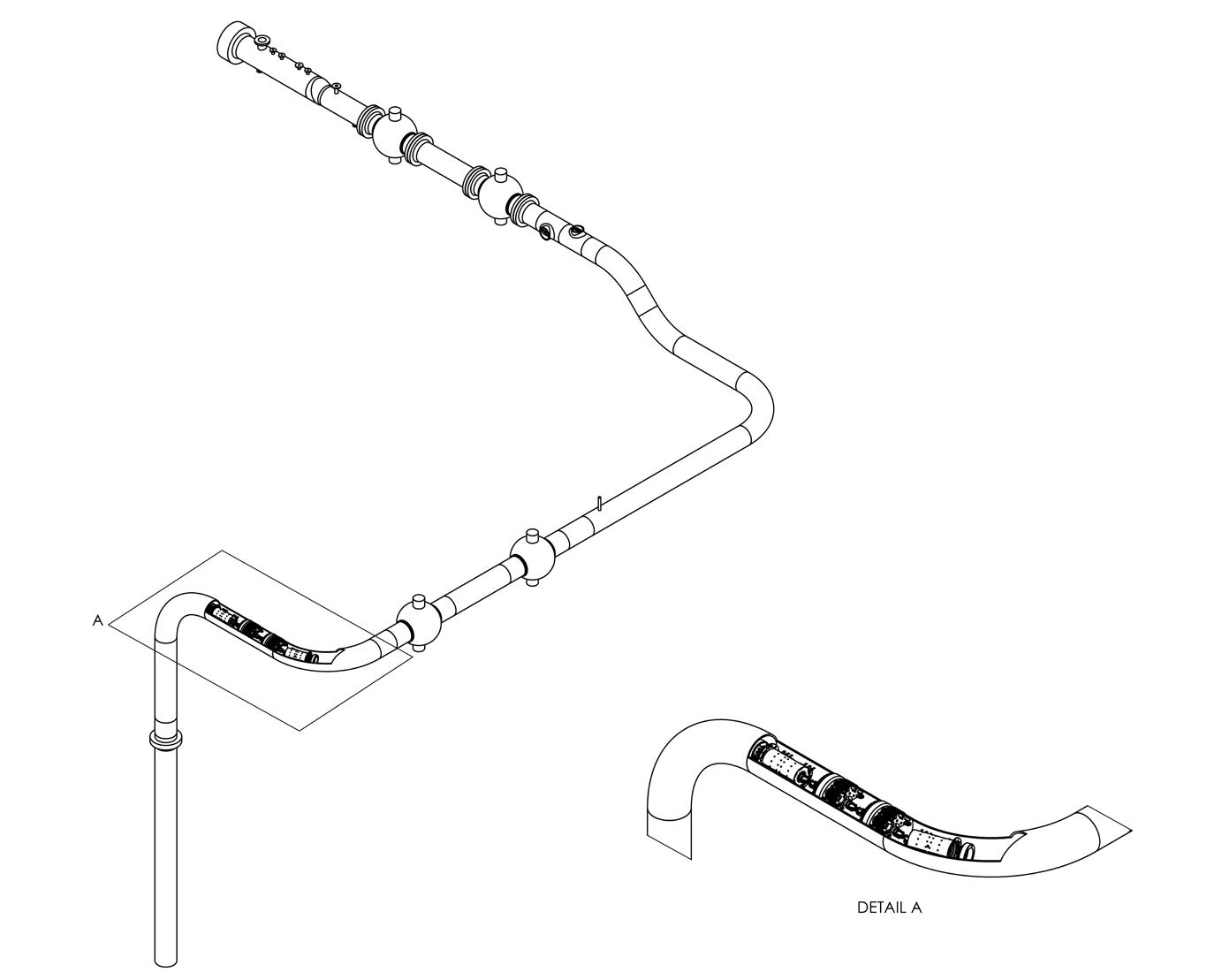

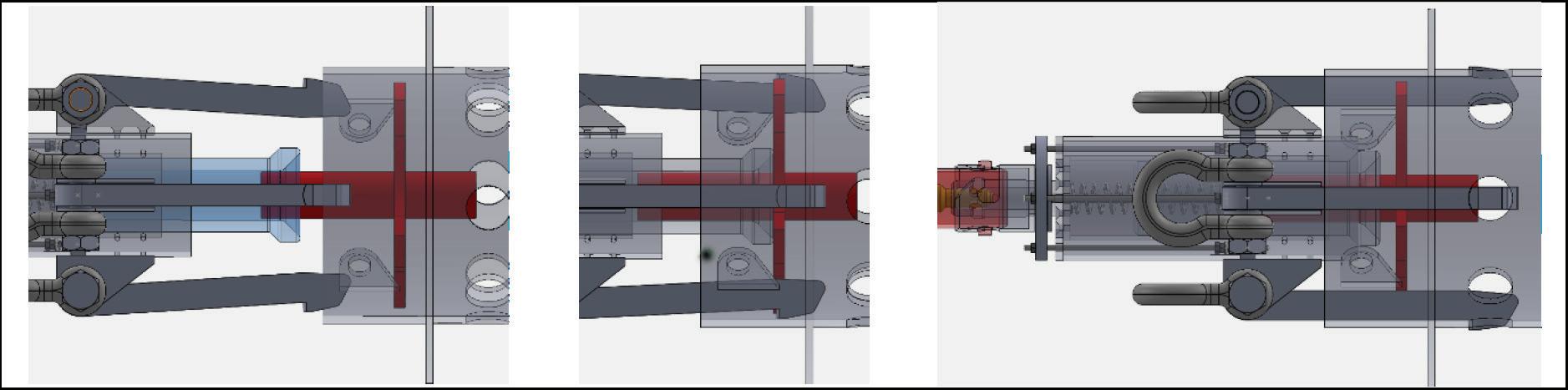

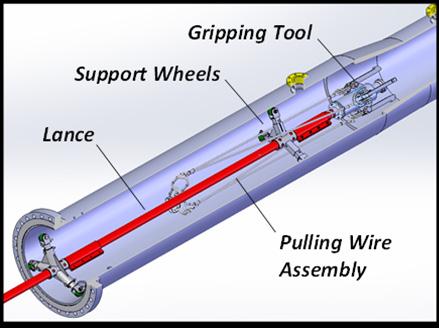

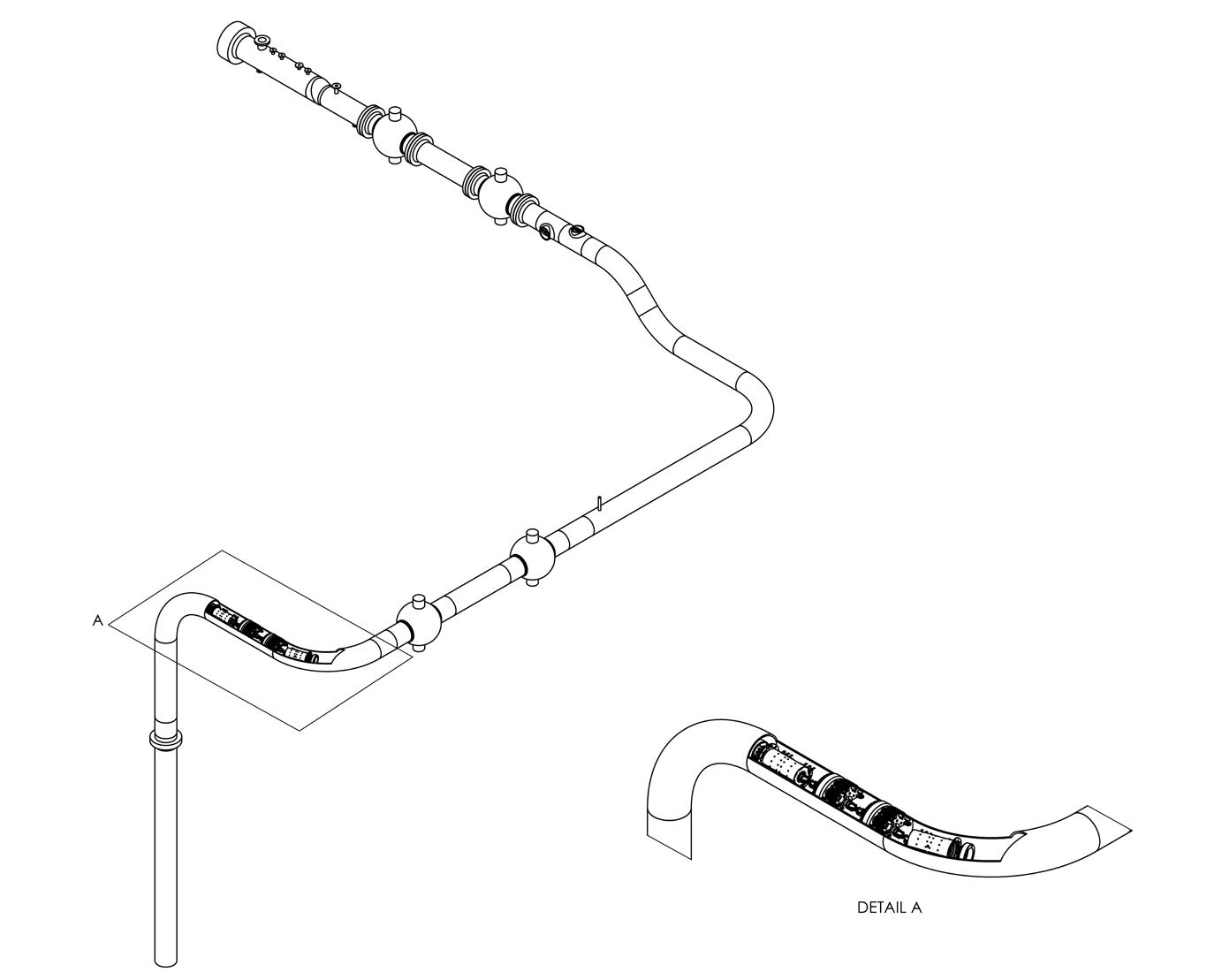

Throughout this issue of World Pipelines, there are many examples of the pursuit of resilience: TUV SUD National Engineering Labroratory describes optimising flowmeter data to make for better decision-making on flowmeter fault detection and diagnosis. Machine learning and data-driven models can be used to react to, as well as prevent, flowmeter failure. Valmet offers insight into improving process performance in demanding control valve applications: flow control can be made more resilient by simulation-driven development, and by building in versality to valve design. UMS Skeldar writes about using unmanned aircraft for preventative maintenance, which brings about resilience in terms of cost cutting (crew, fuel etc.) and also reducing risk. The very existence of pipeline isolation technology (T.D. Williamson, p.33) is resilience in action: TDW outlines a bespoke recovery tool in a case study that showcases technical excellence and flexibility on the job.

See also, Emerson on developing robust pipeline protocols for a changing pipeline product mix (p.38); Tracerco on the operational benefits of extending a pipeline’s life (p.45); and much more.

Sara and I look forward to building resilience with you all in 2023! Questions, comments and feature ideas always welcome at elizabeth.corner@worldpipelines.com

SENIOR EDITOR Elizabeth Corner elizabeth.corner@palladianpublications.com

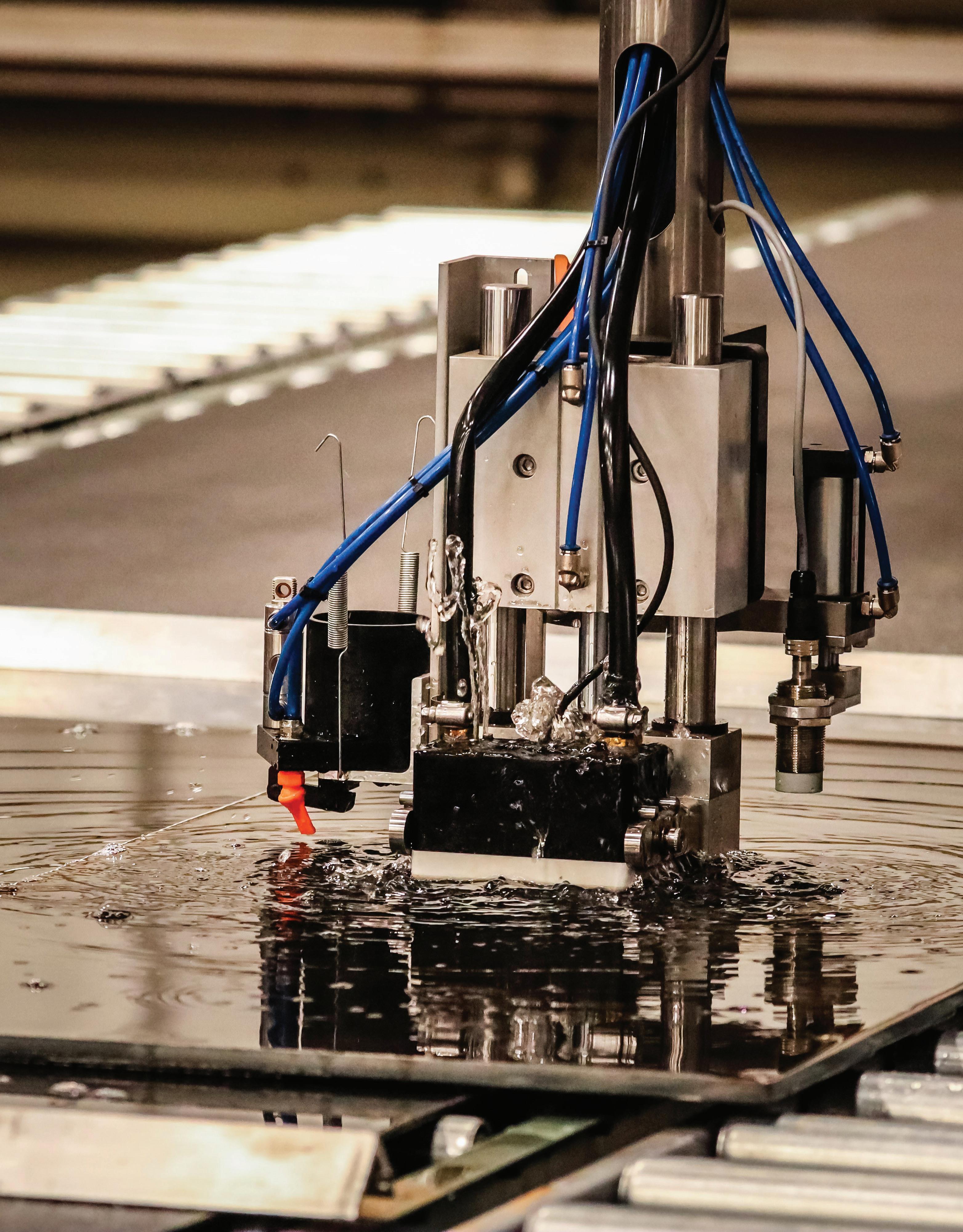

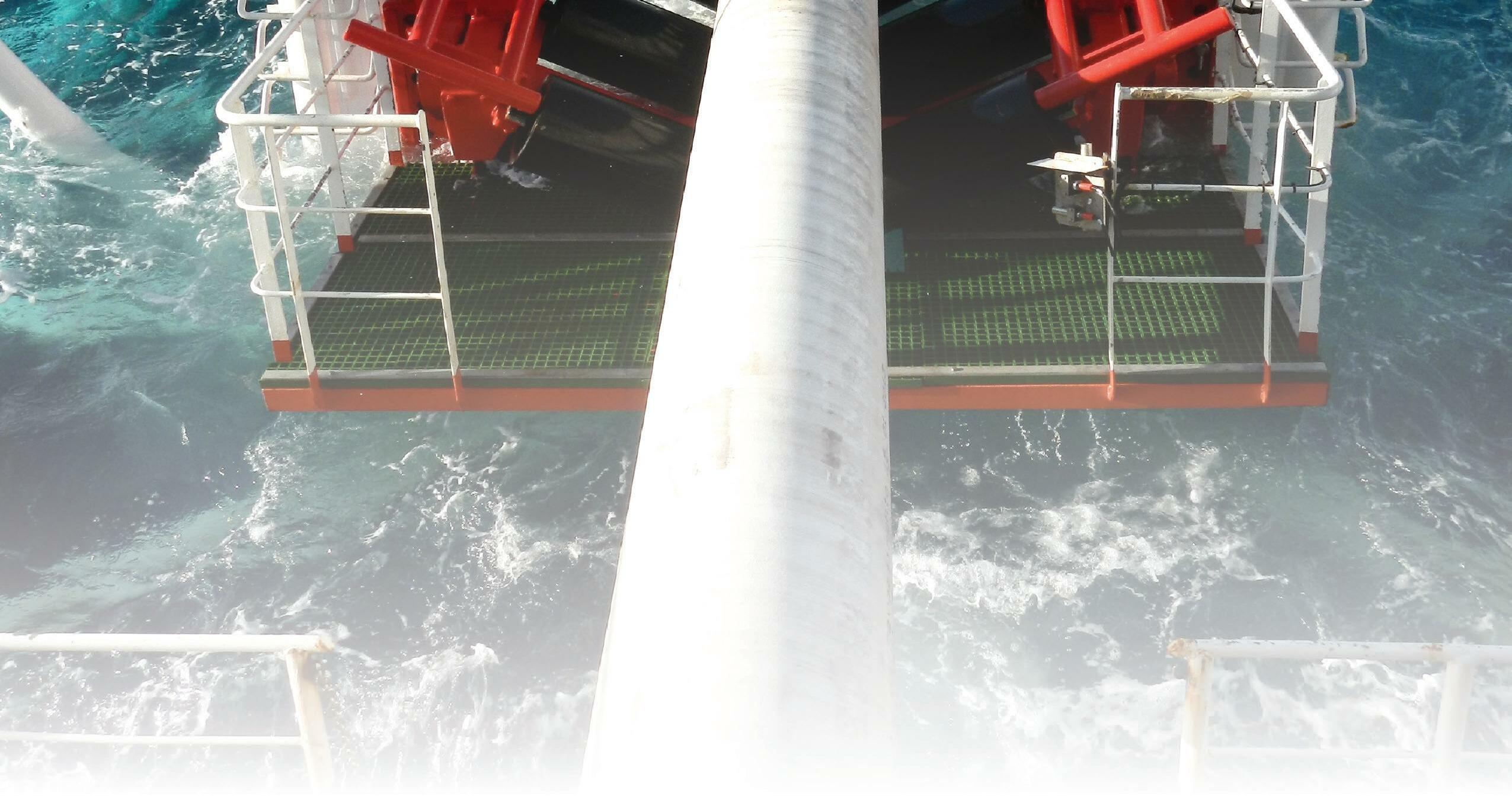

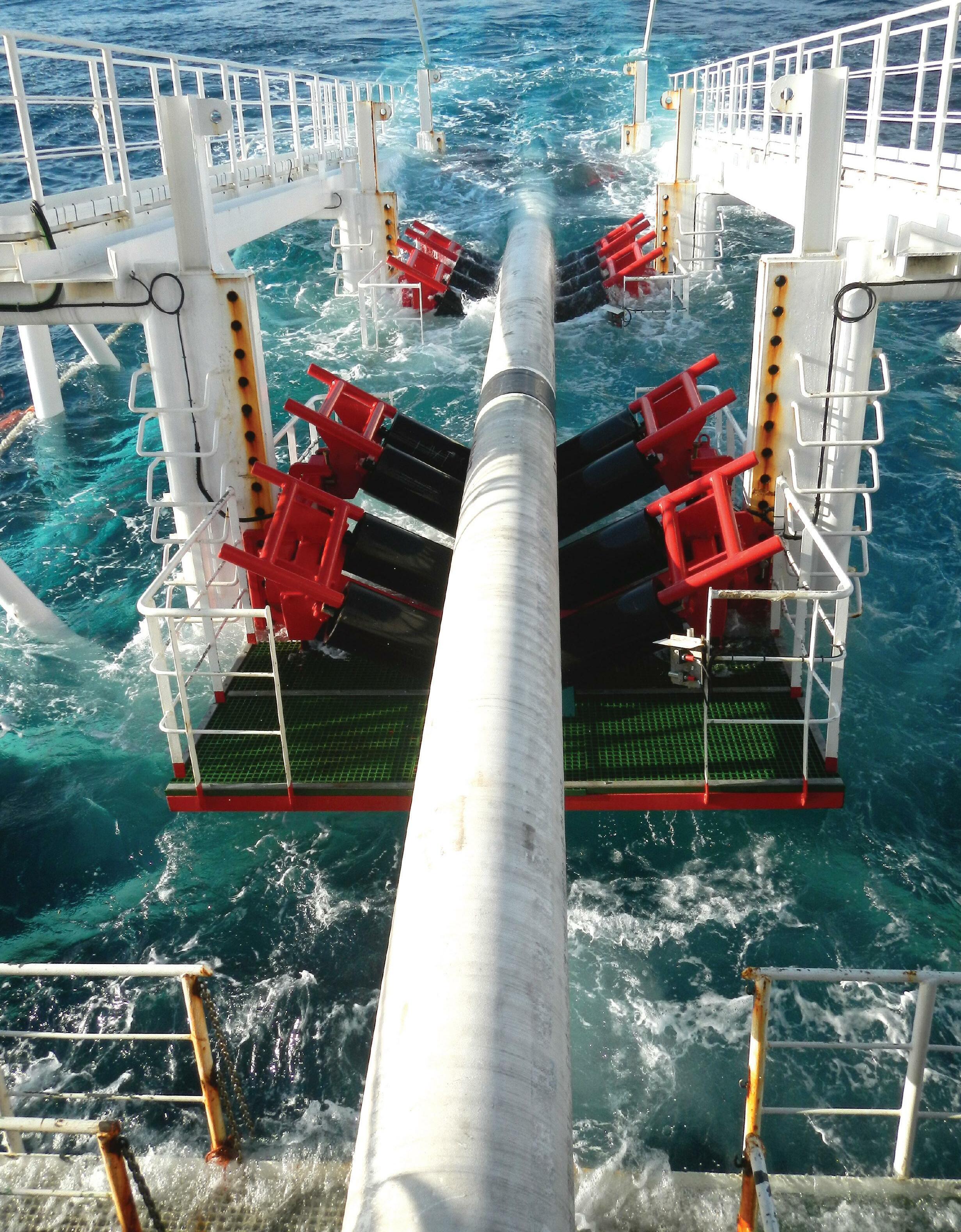

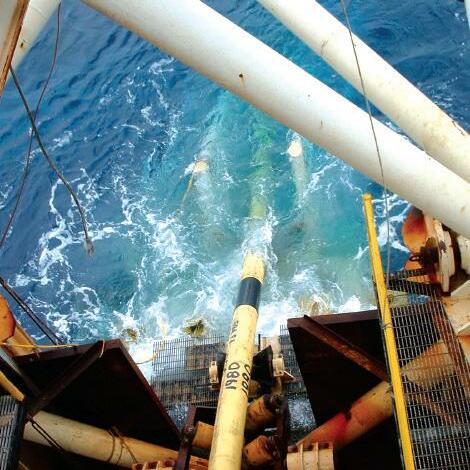

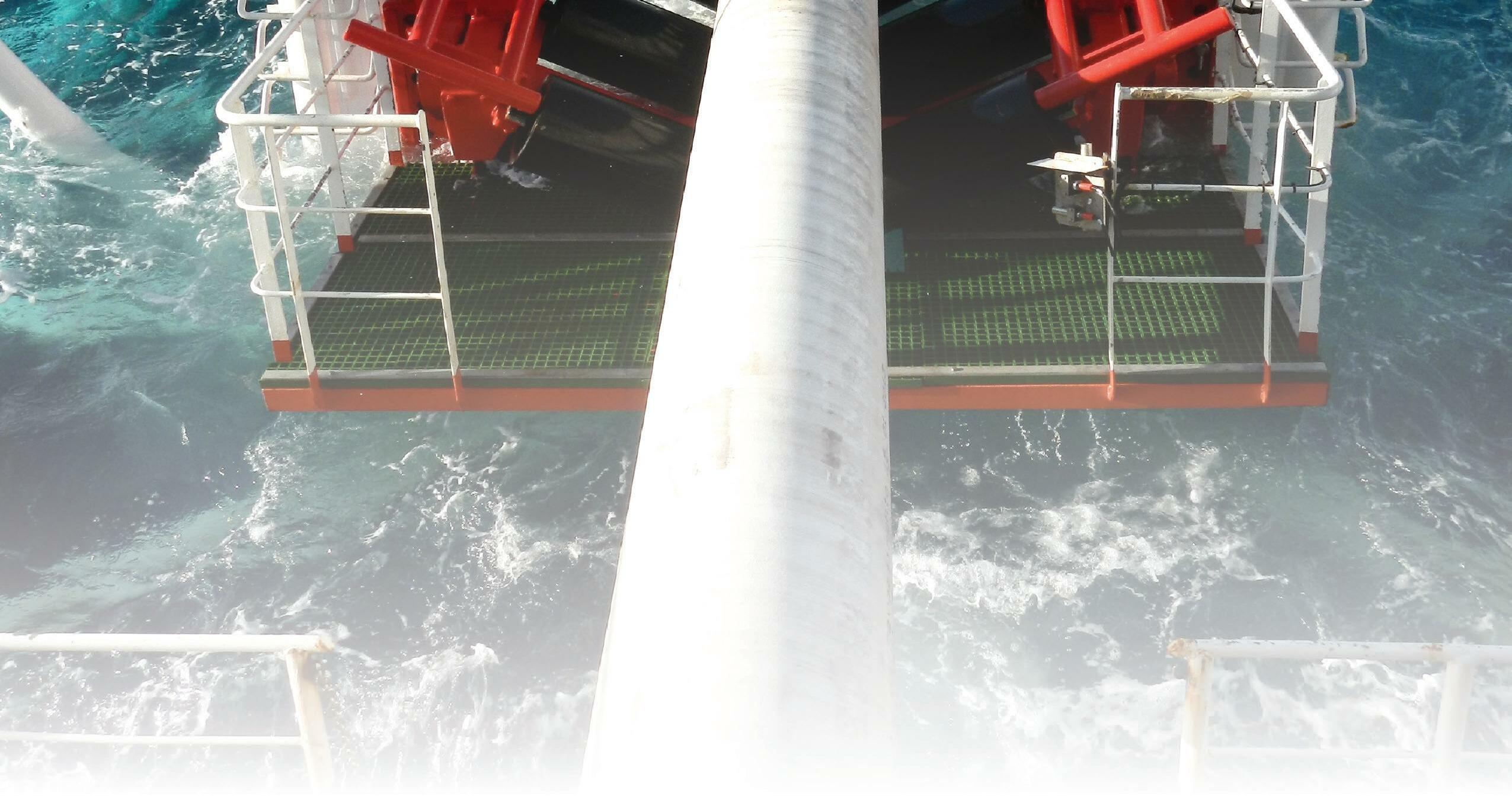

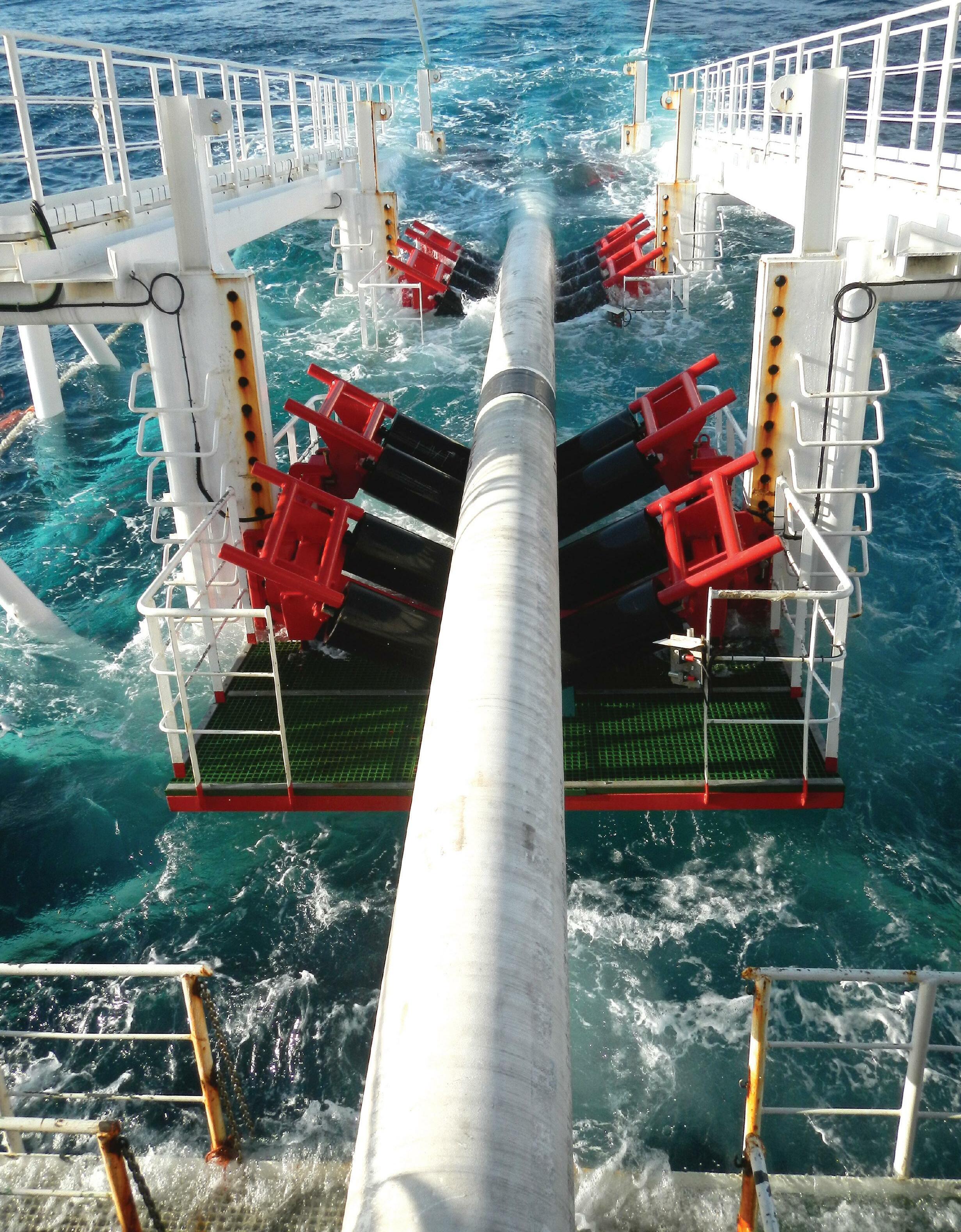

Pipeline Induction Heat (PIH) provide specialist field joint coating services at spool base locations, offshore pipe lay barges and onshore pipeline construction projects around the world, involving the use of stateof-the-art equipment and processes for the application of a wide range of field joint coating materials.

PIH also provide Custom Coating services for the application of the latest Thermal Insulation solutions (IMPP and IMPU) to bends and spools.

Field Joint Coating and Custom Coating Services

Innovation Integrity Offshore Onshore Spoolbase Custom Coating Pipeline Induction Heat Ltd, Burnley, UK Tel: +44 (0) 1282 415 323 Fax: +44 (0) 1282 415 326 E-mail: sales@pih.co.uk Web: www.pipelineinductionheat.com

Dedication

E.ON cuts value of its Nord Stream 1 stake

E.ON, Europe’s biggest operator of energy networks, on 9 November said it had almost fully cut the value of its stake in Nord Stream 1, reflecting damage to the pipeline that has made the asset inoperable and whose cause is yet to be determined.

E.ON, in its nine-month report, said the value of the 15.5% stake, which is sitting in its pension fund, was cut by another € 400 million (US$403 million) to € 0.1 billion, down from € 0.5 billion at the end of June.

“Among the reasons for this are greater uncertainty amid the current situation and, since 26 September, damage to both of Nord Stream 1’s pipelines whose cause is as yet unclarified,” the company said.

Nord Stream 1 and Nord Stream 2 were damaged in September, and the gas transport infrastructure has been a focal point in the wider row between the West and Moscow. NATO Secretary-General, Jens Stoltenberg has called the damage an act of sabotage.

News about the value adjustment came alongside E.ON’s results for the first nine months of 2022, which showed a 3% decrease in adjusted core profit (EBITDA) to € 6.1 billion. Adjusted net profit was also down 3% at € 2.1 billion.

The company still stuck to its 2022 outlook, expecting adjusted EBITDA of € 7.6 billion to € 7.8 billion and an adjusted net income of € 2.3 billion to € 2.5 billion.

Ukraine to raise Druzhba oil transit fee after Russian strikes

Bloomberg reports that Ukraine will raise transit fees for Russian oil through the Druzhba pipeline to eastern Europe next year, following Moscow’s attacks on the nation’s power supplies.

Ukrtransnafta JSC, the operator of Ukraine’s oil pipeline network, informed its Russian counterpart Transneft PJSC that “continued destruction of the Ukrainian energy infrastructure has led to a significant shortage of electricity, an increase in its costs, a shortage of fuel, spare parts,” according to a letter from the company seen by Bloomberg.

The cost of organising safe work conditions for its personnel and protecting its facilities has also increased, according to the letter, which was signed by Volodymyr Tsependa, General Director of Ukrtransnafta.

The company said it will raise tariffs for transporting

crude toward Hungary and Slovakia by € 2.10 to € 13.60/t (US$13.90/t) from 1 January 2023. The fee was also hiked in April, bringing the total increase on an annualised basis to 51%.

On 15 November, Russian crude flows to eastern Europe were halted for a day after a power station serving the pipeline in Ukraine was hit by artillery fire. That day, Russia launched around 100 rockets into Ukraine, according to the country’s air force in Kyiv.

Ukrainian President, Volodymyr Zelenskiy has urged his citizens to limit energy consumption, accusing Russia of trying to “kill” power and heating for millions at the onset of winter.

Russian state oil pipeline monopoly Transneft is reportedly reviewing Ukraine’s proposal to raise its oil transit fee.

DNV partners with energy companies on software for ammonia, hydrogen and CCUS

The energy transition depends on several technologies with potential hazardous characteristics, such as carbon capture and storage (CCS), and utilisation of hydrogen and ammonia. When deploying these solutions at a larger scale, safety is essential. DNV is working with energy companies to address this in three research projects.

DNV is leading three parallel joint industry projects (JIPs) to develop the existing KFX software, which simulates gas dispersion, fire and explosions, to increase safety in the deployment of energy transition solutions. The KFX computational fluid dynamics (CFD) software simulates what actually happens to liquids, vapour clouds and potential dry ice formation in the event of accidents. The simulations are used as the basis for design of installations and to mitigate consequences.

“DNV has in recent years been involved in CFD simulation software development projects. The JIPs for CCS, hydrogen and ammonia safety strengthen our commitment to the energy transition,” says Kenneth Vareide, CEO of Digital Solutions at DNV.

In the event of an accidental release, there are widely varying scenarios depending on the properties of the gases

or liquids involved.

The first JIP is a partnership between Equinor, TotalEnergies and DNV, and focuses on CO 2. The research concentrates on the consequences of accidental release, depending on surrounding environmental conditions such as terrain and wind, combined with dry-ice formation and its impact on dispersion.

The second JIP includes Equinor and DNV, focusing on hydrogen and the consequences of low storage temperatures, dispersion, fires and explosivity.

The third JIP, with Equinor, Vår Energi, Horisont Energi and DNV, is developing solutions for ammonia safety, analysing alternative strategies to mitigate consequences of toxicity.

“DNV is committed to close collaboration with customers in the areas of hydrogen safety, CO2, ammonia and LNG, enabling the accelerated energy transition journey,” says Trond Evanger, Head of Section of CFD Solutions at DNV.

KFX CFD software has been developed for more than 25 years by DNV in collaboration with Equinor, TotalEnergies, ConocoPhillips, Eni, Gassco, GRT GAZ and other energy companies, as well as the Research Council of Norway.

DECEMBER 2022 / World Pipelines 5

WORLD NEWS

CONTRACT NEWS

Pipeline Technique enters agreement with Subsea7

6 - 10 February 2023

Pipeline Pigging and Integrity Management Conference and Exhibition Houston, USA www.ppimconference.com

7 - 11 February 2023

PLCA Annual Convention Hawaii, USA www.plca.org/annual-convention-events

13 - 15 February 2023

Pipeline Coating 2023 Vienna, Austria www.ami-events.com

20 - 21 February 2023

Transportation Oil and Gas Congress 2023 Istanbul, Türkiye www.togc.events

20 - 25 February 2023

DCA Annual Convention 2023 Miami, USA www.dcaweb.org/page/Convention

19 - 23 March 2023

AMPP Annual Conference + Expo Denver, USA www.ace.ampp.org

27 - 29 March 2023

European Gas Conference 2023 Vienna, Austria www.energycouncil.com/event-events/ european-gas-conference

1 - 4 May 2023

Offshore Technology Conference 2023 Houston, USA 2023.otcnet.org

Pipeline Technique (PTL), provider of welding and coating solutions to the global onshore and offshore energy sectors, has entered into a long-term agreement with Subsea7 for the provision of welding and coating services.

Under the terms of the agreement, PTL will provide Subsea7 with access to a team of experienced specialists and cutting-edge equipment, building upon the pre-existing and long-standing relationship between the two companies.

PTL supports customers’ projects through the consistent and progressive delivery of global rigid pipeline systems, locally tailored solutions, automation and strategic supply chain partnerships.

PTL recently acquired the Oil and Gas division from Stanley Black & Decker, a major international pipeline services and equipment provider, bringing together two

CF Industries and ExxonMobil sign major deal on CCUS in Louisiana

CF Industries, a global manufacturer of hydrogen and nitrogen products, has entered into the largest-of-its-kind commercial agreement with ExxonMobil to capture and permanently store up to 2 million t of CO2 emissions annually from its manufacturing complex in Louisiana. Start-up for the project is scheduled for early 2025.

CF Industries is investing US$200 million to build a CO2 dehydration and compression unit at its Donaldsonville, Louisiana, facility to enable captured CO2 to be transported and stored. ExxonMobil will then transport and permanently store the captured CO2 in secure geologic storage it owns in Vermilion Parish.

As part of the project, ExxonMobil has signed an agreement with EnLink Midstream to use EnLink’s transportation network to deliver CO2 to permanent geologic storage. The 2 million t of emissions captured annually will be equivalent to replacing approximately 700 000 gasoline-powered cars with electric vehicles.

“EnLink has a system of over 4000 miles of pipeline already in the ground in Louisiana,” said Jesse Arenivas, CEO of EnLink. “Utilising this extensive network enables us to provide the most timely and cost-effective solution to CO2 transportation, with a significantly lower environmental impact. Because of this, EnLink is uniquely positioned to be the CO2 transportation provider of choice in Louisiana’s Mississippi River corridor.”

long-term suppliers of Subsea7 and further strengthening this collaboration agreement.

The acquisition of CRC-Evans, Pipeline Induction Heat (PIH), and Stanley Inspection (including MicroAlloying, part of Stanley Inspection) created a global leader in PTL, with expected revenues in excess of US$200 million.

Ben Mackay, COO for PTL, said: “By offering predictability, we can provide Subsea7 with a robust foundation for longterm planning and enhanced project performance. We look forward to contributing to more efficient operations benefitting both parties.”

PTL CEO, Frederic Castrec said: “PTL’s close working relationship with Subsea7 spans several years, and this collaboration agreement forms the basis for its long-term continuation.”

THE MIDSTREAM UPDATE

• Penspen announces launch of Energy Transition Consultancy

• Shell partners with Kongsberg Ferrotech

• Novarc to partner with Lincoln Electric

• AIS acquires subsea specialist CRP Subsea

• TC Energy reports strong 3Q22 results

• Natural gas imports from Canada provide winter reliability

Follow us on LinkedIn to read more about the articles linkedin.com/showcase/worldpipelines

6 World Pipelines / DECEMBER 2022

EVENTS DIARY

PROTECTIVE OUTERWRAPS SOIL-TO-AIR INTERFACE SYSTEMS BITUMEN & BUTYL TAPES PETROLATUM TAPE SYSTEMS PROTAL 7200™ SPRAY/ROLLER/BRUSH APPLIED LIQUID EPOXY COATING DENSO VISCOTAQ™ FOR CORROSION PREVENTION DENSO™ are leaders in corrosion prevention and sealing technology. With over 135 year’s service to industry, our mainline and field joint coating solutions offer reliable and cost effective protection for buried pipelines worldwide. United Kingdom, UAE & India USA & Canada Australia & New Zealand Republic of South Africa www.denso.net www.densona.com www.densoaustralia.com.au www.denso.co.za A MEMBER OF WINN & COALES INTERNATIONAL A range of viscoelastic tapes used for corrosion prevention on pipelines, field joints, fittings & valves. The unique, self-healing technology of Viscotaq offers asset owners outstanding, long-term protection against corrosion. > >

ipeline cybersecurity is more important now than it’s ever been before. As demand surges, the technology landscape morphs, the threats exasperate, and risks become realities, it’s more apparent than ever that keeping the backbone of energy security secure, is crucial to our survival.

In most developed nations, pipelines are considered critical infrastructure; in some, they are even more critical, being a key component in a national energy security strategy. As governments attempt to tackle the problem, they are faced with the challenge of not overburdening infrastructure operators with redundant or unnecessary regulations, while continuing to raise the bar on a minimum-level to operate safely and securely. For example, US government 49 CFR part 192 and 195 sets the bar for minimum physical, design, and operational safety characteristics for pipelines, but others, like the TSA SD02 Series recent update ‘C’, are focused on cybersecurity for the pipelines. Both had the best interests of public safety in mind when they were drafted. At the time of drafting, there were cases of overlap, contention, and industry/government back and forth. As we discover new data, collaborate on issues, and new risks emerge and old risks evolve, the recommended minimum for safe operations is updated, thereby ‘raising the bar’ on what the minimum is, in order to safely operate the regulated asset.

There will also be a multitude of applicable, interconnecting, and overlapping regulations, standards, and best practices that reside-between the aforementioned rules and directives. In some cases, they may even have competing requirements.

There’s no doubt that regulatory overhead adds to the complexities of sustaining vast pipeline operations. Creating regulations without input from those that will be regulated rarely works out well; collaboration and flexibility are crucial in order to accommodate the nuances that pipeline operations can bring. As an example, attempting to forklift electricity grid regulations over to pipelines, or other copy and paste type rule setting, is challenging and ambitious in general, but when industrial control systems are introduced into the equation, the impact from a mistake can be larger than what many are willing to accept.

At the time that many of today’s regulations were drafted, the physical world and cyberspace was quite a different place. Common risks were low-level cyber criminals, or disorganised one-off saboteurs. But the changing landscape due to the Russian invasion of Ukraine has resulted in turning the internet into a hot warzone, with multiple threat actor groups, ranging from state-sponsored, to hacktivists, to quasistate cyber-militia viciously and relentlessly attacking critical infrastructure around the world. Their goal is to create mass destruction by any means necessary. Another facet is the energy war being waged, with pipelines front and centre. After the Colonial Pipeline incident, it’s clear, nation-state actors will commit the same types of attacks when the time comes. Defending pipelines against cyberattack is more than just protecting profit, it’s fighting in the trenches in a new frontier of war. Government regulators know this, and are working

8

Chris Grove,

of Cybersecurity Strategy,

Networks, USA, shares some advice for moving the cybersecurity ball forward, with the goal of being better positioned to accommodate changing regulations.

9

Director

Nozomi

expeditiously to mitigate this risk, as quick as possible, with the best information on hand.

Based on the existing cyber threat level, the potential for a full-blown cyberwar, and the realisation that the next frontier of warfare could be our pipelines, we don’t want to find ourselves in the position of looking back, wishing we had done more, or questioning why our institutions didn’t act sooner. Regardless of where regulations land, the ball has to move forward. Most technologies and systems aren’t designed to withstand a directed, nation-state level attack. The Russian government has weaponised it’s cybercrime gangs, like TrickBot Gang, and are targeting critical infrastructure in Ukraine to further the advance of the war efforts. In this case their aim is destruction, not the pursuit of profit. To put that development in context, imagine if the motive behind the Colonial Pipeline attack was mass destruction and chaos rather than profit.

The challenges that face information technology (IT) systems are generally solved differently than the types of issues facing operational technology (OT) systems. If even those high-level differences are not accounted for when rulemaking, the result may not be the one we are working toward. Take for example password changes: in an IT system, it makes sense and is a good practice to change the password often. But, when it’s applied as a prescriptive regulation to follow, without consideration for the design of the system being regulated, particularly when it comes to industrial control systems, the resulting efforts required to become compliant can be a lot more labour-intensive and intrusive to operations than expected. To further that, pipeline operators have larger public safety and economic criticality than a typical manufacturer running a typical OT system, and the vast geography that pipeline operations could span requires a much larger effort to physically visit for a password change. Unfortunately, the next step could be for pipeline operators to find a way to reduce costs and simultaneously obtain compliance, which can lead to installing high-risk remote access to the assets, simply to execute a password change from the central office. Exposing risky assets by installing remote-access for the sole purpose of pursuing an IT-centric best practice, or checking a box in a regulatory checklist, is not the most cost-effective or recommended approach. Letting checkboxes and a changing regulatory landscape steer the direction of an organisations risk management can drive up operational costs, as well as make compliance difficult to manage.

Good design, great operations

Compliance to best practices and regulations should be a byproduct of good design and great operations. This can be particularly true when it comes to cybersecurity. In the cybersecurity trade, we generally design security using a layered approach. This is primarily driven by the notion that eventually, one day, the attacker will bypass the security, so we need another layer of security on top of another layer, upon layer, like an onion. Essentially, it’s the realisation that all great things will fail one day, eventually. It is therefore not entirely about the prevention of failures; sometimes we also need to plan on being resilient to failure.

Resistance is about building and managing those security layers, but resilience is being able to withstand a failure of those layers as a whole, with minimal impact to operations or safety. For example, although we have many design specifications for the piping used in the transport of products, we also have various consequence reduction mechanisms in place for unplanned incidents (like damage from an earthquake, farm equipment, etc.), even though that may have complied with those specifications or regulations.

When an incident happens, a resistance mindset would result in a shutoff valve being installed to stop operations, halting the flow, in the event of failure in all of the layers. A resiliency mindset would be to install a way to re-route the product to ensure continued operations during an incident.

So how do we leverage a resiliency-based mindset when tackling pipeline cybersecurity, in the midst of changing federal regulations, while keeping modern cyber threat adversaries in mind?

First, we plan for static findings and facts to eventually fail and expect subsequent changes to happen. Today, we can say that using ‘X method’ against ‘adversary Y’ is a valid approach, but by the time the ink dries, ‘adversary Y’ has evolved. Therefore, embracing recommendations as a prescription makes adapting to change harder. If operators need a prescriptive approach, there are many that exist, such as ISA 62443. Instead, aim to have great cybersecurity, overall, which as a natural consequence will be agile enough to effortlessly adapt to change. Having a solid foundation of tools and technologies, based on some well-known tenants of cybersecurity can go a long way in obtaining easy compliance while raising the cybersecurity posture of pipeline operations. If one spends enough time studying many of the common cybersecurity best practices, guidelines, and regulations, some common themes start to emerge. Many are expecting some basics, some push for more advanced capabilities; but they all rely on having intimate knowledge of the assets within the environment, combined with monitoring for threats, and having a measurable way to track, report, and reduce risk.

Moving the ball forward

With all of this in mind, here’s some advice for moving the cybersecurity ball forward, with the goal of being better positioned to accommodate changing regulations.

) Develop a comprehensive asset inventory of everything that’s critical, connected to anything that’s critical, or connected to anything that’s connected to anything that’s critical. In other words, expand your vision and scope to include non-traditional technologies as assets, they’ll probably be the first to get hacked if you don’t. Make sure you know everything about the asset, the make, model, product number, serial numbers, who put the last configuration on it, who is interacting with it, for what purpose, how, and what’s considered ‘normal’ for that asset. Consider what operations would look like if that asset were impacted or unavailable.

) Monitor the asset for changes to anything, in particular, the firmware, running code, configuration settings, and

10 World Pipelines / DECEMBER 2022

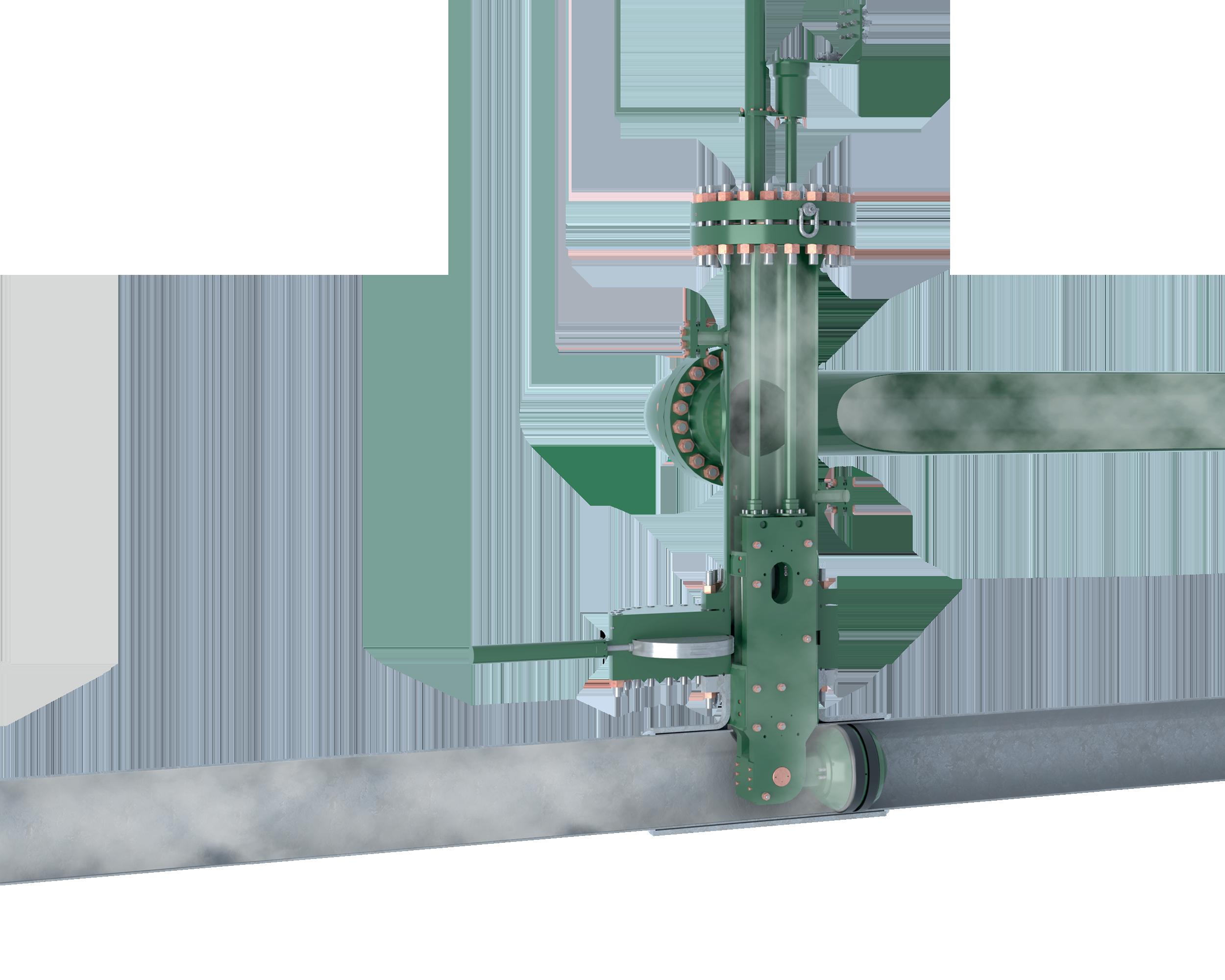

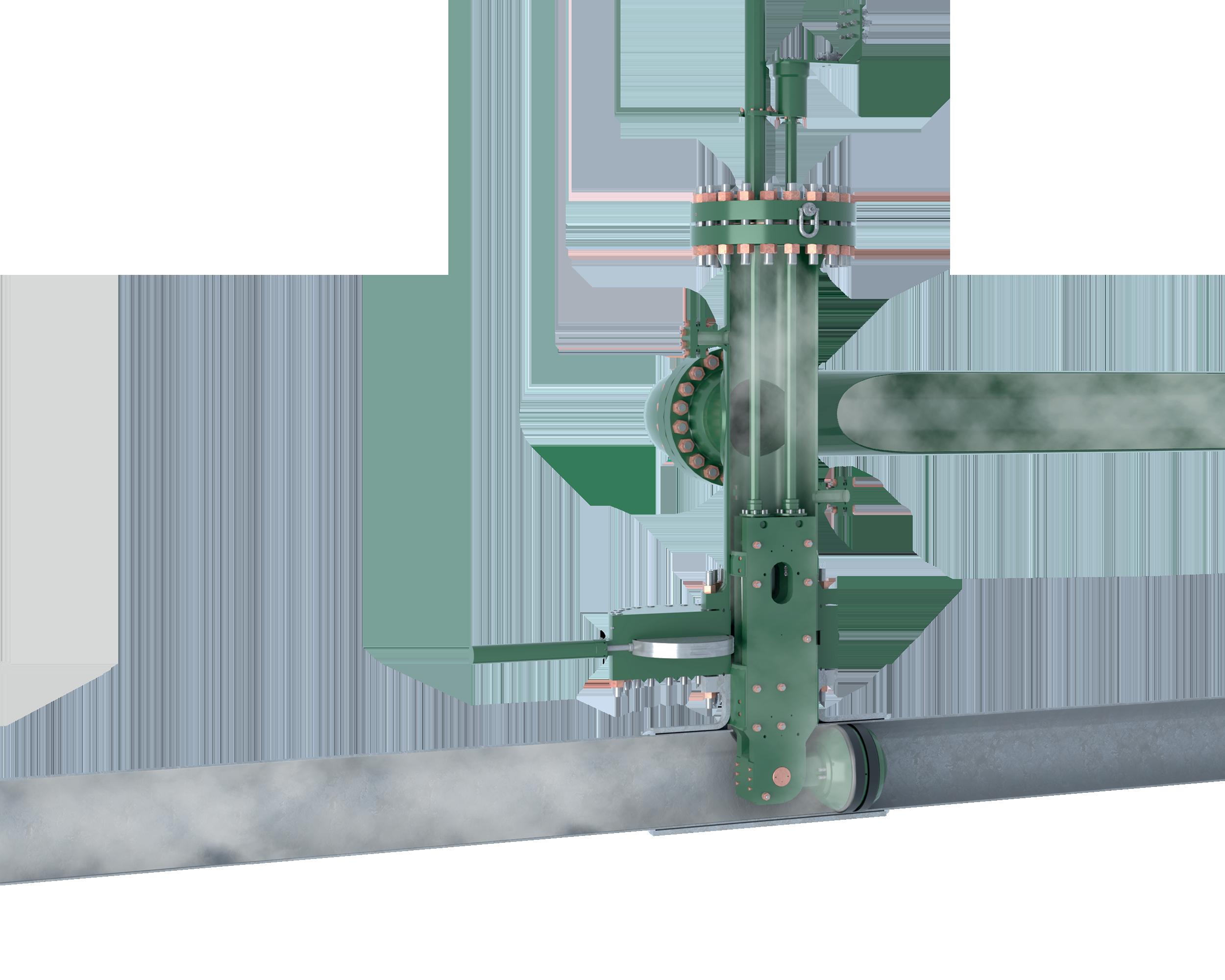

The BISEP® with extensive track record provides industry first double block and bleed isolation while maintaining production. Hydraulically activated dual seals provide fully monitored leak-tight isolation, every time, any pressure. ZERO-ENERGY ZONE SINGLE HOT TAP POINT DUAL Leak-Tight Seals double block & bleed isolation PRODUCTION MAINTAINED BISEP® Hot Tapping & Plugging ISOLATED PIPELINE

administrative-level controls like stop/start, Go Online, key positions, remote connections, etc.

) Monitor the network at all levels. At a generic high-level network, signature matching can be used to identify known attacks. A layer deeper, industrial control system protocols can be inspected for signs of reconnaissance activity like parameter scanning or requesting non-existent variables. Another layer deeper into the protocols, the actual ICS payloads can be monitored for anomalous values being set, or values being set at anomalous frequencies. Leveraging anomaly detection technologies to monitor the network will identify novel attacks that don’t yet have signatures.

) Develop people and processes on the receiving end of the monitoring, track their progress, and operationalise the security and set goals for improvement.

) Have a strategy for tracking and reducing risk, and hardening the assets. This includes knowing where the vulnerabilities are, having a plan to remediate them, and an active compensating control if they can’t be patched (as is common in industrial control systems).

) Develop and test incident response playbooks, ensuring the staff is able to respond when an event happens. Having an up-to-date communications plan with multiple

) Ensure there are multiple levels or backups of data and systems, but also that there is a restoration procedure that includes restoring operations, not just restoring data or a system.

) Execute tabletop exercises to test resilience to ransomware outbreaks, nation-state attacks, and other advanced threat actors.

) Engage with your partners. When under attack, sometimes your vendors and partners can make a huge difference in time to recovery. Find ways to enable and empower them before an event happens. It could range from working with cloud technologies, to safely working with external partners, to looping them into the playbooks and communications plans.

Summary

If we’re not planning on failures, we’re failing to plan. By having deep visibility and detailed knowledge of assets, and multiple layers of monitoring, we’re anticipating a failure in a security layer, like a firewall, virus protection, or other resistance technologies. By building a security programme driven by operational resiliency, when an incident or event happens, regulations change, or directives are written, organisations are better equipped for agility and lower recovery costs. Whether the task at hand is a nation-state attacker, a ransomware group, or new rules to follow, having complete visibility into

visit www.iploca.com to find out more

IPLOCA - supporting the reduction of carbon footprints in the pipeline industry

or midstream oil and gas companies, leaks and fugitive emissions from gas pipelines have long been a scourge. They are a source of wasted product and revenue loss, they pose safety risks, and cause damage to the environment that can adversely affect company finances through hefty fines or compensation.

Only now is the extent of the damage caused by methane leaks from pipelines being understood. Research from the Laboratory of Climate and Environmental Sciences found that during 2019 and 2020, over 1800 large bursts of methane occurred, often releasing many tons of methane each hour. It’s estimated that these large releases of methane are responsible for 8 12% of global methane emissions from oil and gas infrastructure.

Finding a solution that seals this problem for midstream operators might not just be a logical next step, but soon a mandatory one. In the US, the Pipeline and Hazardous Materials Safety Administration (PHMSA) is preparing to issue proposed standards that will require operators to use commercially available advanced leak detection technology to detect and fix leaks, and other countries are likely to follow.

This is not only the right thing to do both for the environment and companies’ bottom line, but an easier thing to do now than even a few years ago. Modern technology advancements have resulted in a step change occurring in leak detection methods. Legacy methods were imprecise, time consuming, outdated, impractical and resource intensive, such as inspecting pipeline right of ways for visual signs of disturbance, walking lines with portable gas sensors, and monitoring for changes in pipeline pressure.

Pauline Morrice, Senior Communications Advisor, UK and Steve Kemp, Senior Director of Customer Success, Project Canary, USA, consider why the measurement economy is changing the methane emissions game.

13

Today’s marketplace is embracing the measurement economy – measuring environmental performance and identifying verifiable climate attributes using real-time data and analytics – that is now being used by companies to minimise waste, cut costs, reach climate targets, and protect the public.

Harnessing climate-tech with the measurement economy

Last winter, Kellas Midstream entered a partnership with Project Canary®, a US-based climate and emissions data firm, to install 12 high-fidelity continuous methane monitoring sensors at its Teesside Central Area Transmission System (CATS) terminal in northeast England. The sensor array relies on technology that can detect methane down to <0.1 g/sec.

and report this data to a cloud-based dashboard every 60 sec. for advanced continuous monitoring and insights. This level of fidelity is unparalleled and consequently provides precise accuracy and granularity of data in real-time that has never been seen before in molecule tracking. The ‘measurement economy’ means that technology is advancing; and as the technology advances, so has Kellas Midstream’s ability to advance methane emission detection, monitoring, and measurement to become even more accurate than its competitors and take immediate action on any methane leaks. This capability to detect and make rapid interventions on any leaks ensures that gas moving through its pipelines is transported with the highest level of reliably accurate accounting of methane and now, Verified Climate AttributesTM, while helping to fortify its standing as an ESG leader in the sector. Ultimately, utilisation of this pioneering technology is raising the bar for midstream operators, and sending a message to the market that the new gold standard is now measurement of emission profiles minute by minute for immediate action. Quarterly or monthly emission profiles are not an assessment of methane leaks but merely a guess that in many cases can be off by up to 40%, which is sure to catch the eye of shareholders and environmental groups.

Oil and gas companies operate in a fast-changing landscape, and companies that can identify emerging legislation that is waiting on the horizon hold a competitive advantage over their competitors. In the UK, the country’s ‘Net Zero Strategy: Build Back Greener’ indicates that midstream operators are expected to minimise pipeline gas leakage and associated emissions. This means that as the UK enacts further regulatory and legislative policies to reduce its emissions in its push to reach its climate commitments under the Paris Agreement, forward-looking companies such as Kellas that have stayed ahead of the curve have future-proofed themselves against any potential disruptive emerging legislation.

Today, companies have a duty to be good neighbours to the communities they operate in, and for companies in heavy-emitting sectors such as oil and gas, this responsibility is even more pertinent. Methane leaks are not only a potent source of climate pollution, but they are also a health and safety hazard, and nuisance to nearby communities. Although rare, explosions that are dangerous to both people and property can result from gas leaks. Likewise, leaking methane can create a foul odour and harm nearby vegetation. Kellas has long demonstrated a commitment to being socially responsible in the communities it operates in and, by prioritising advanced leak detection through its partnership with

Figure 2. A Kellas Midstream employee demonstrating continuous emissions monitoring in real-time.

14 World Pipelines / DECEMBER 2022

Figure 1. Kellas Midstream installs Project Canary continuous emissions monitoring at Teesside CATS Terminal.

Project Canary, Kellas has reaffirmed its dedication to being a good neighbour. Additionally, by putting environmental stewardship first, Kellas has protected its strong relationship with the community in Teesside while also leading the way to a lower-carbon future.

Indeed, much has been made about the rapid uptake of responsible, low emission production in the upstream natural gas market, with estimates projecting that supply of producer-certified responsibly sourced gas (RSG) will soar from 8.7 billion ft3/d last year to surpass 20 billion ft3/d by the end of the 2022. But as the RSG market continues its tremendous growth with sustainability top of mind in the business arena, and ESG continuing to gain prominence in financial markets, there will be more and more value placed on low emission transportation of natural gas. This means midstream companies have an opportunity knocking on their door to seize this growing market by demonstrating their commitment to environmental stewardship with auditable third-party data.

Top of the agenda: managing methane emissions

There’s no denying it, the oil and gas industry has a methane problem. The sector is responsible for 82 million t, which

is roughly 15% of global methane emissions. And given that methane is over 80 times more potent than carbon dioxide, this is a problem we cannot afford to run away from.

But there is no need for the oil and gas sector to run away from this issue or bury its head in the sand. We have the tools and technology available to measure and manage methane leaks right now, and an increasing number of companies in the sector are realising this, as witnessed by RSG’s phenomenal growth.

It’s not too much of a stretch either to acknowledge that oil and gas companies’ long-term viability depends on addressing methane leaks. Last year, more than 100 countries signed the Global Methane Pledge at COP26, promising to reduce methane emissions by 30% by 2030, compared with 2020 levels, with the initiative emphasising making cuts by tackling methane leaking from oil and gas wells.

While net-zero by 2050 is the final destination, natural gas can serve as a ‘bridge fuel’ to transport us along the journey in the energy transition if we can guarantee that its production, gathering, processing, and transmission have been carried out with the highest level of sustainability standards. Indeed, signs point to a day in the not-too-distant future where certified natural gas is the industry standard.

Natural gas companies will continue to play a crucial role in the energy mix for decades to come, but only ones that place value on sustainability are likely to thrive long-term, considering that a generation of millennials and Gen-Z have turned their back on fossil fuels. With oil and gas companies experiencing a cash windfall from record oil prices, the time is right to invest some of that free cash flow into a more future-looking business model that allocates greater importance to ESG while reducing exposure to climate risk.

Ultimately, it is gas buyers that establish the standards. But as pressure mounts on utilities to prove their ESG credentials, midstream operators can improve the attractiveness of their product by demonstrating their ability to transport gas safely with the highest environmental standards used. Project Canary’s continuous methane monitoring sensors provide the data that allows ESG-leading midstream operators such as Kellas to deliver credentialed gas to buyers and validate their commitment to sustainability.

Governments have shown that they are not afraid to block energy deals if there are concerns around the environmental impact. In 2020, the French government stepped in to annul a US$7 billion deal between NextDecade and French utility Engie over concerns regarding methane emissions and other environmental impacts. However, following NextDecade’s decision to source 100% certified RSG for its planned Rio Grande Texas LNG export facility, Engie secured a 15 year contract.

Certainly, pressure is mounting from politicians, regulators, the public and investors for oil and gas companies to better manage methane leaks. Pakistan’s devastating floods this summer show that the consequences of failing to act on climate change can have catastrophic consequences. Advances in continuous monitoring technology means RSG has the ability to be the cleanest carbon on the planet, and tackle natural gas’ brand problem. The oil and gas sector has the tools at its disposal to be part of the solution in solving the climate conundrum by curbing methane emissions, and with strong balance sheets now the onus is on companies to demonstrate that they have the will.

16 World Pipelines / DECEMBER 2022

Figure 3. Kellas Midstream installs Project Canary’s sensors at multiple points throughout the terminal to precisely detect, monitor, and measure methane emissions in real-time.

IT IS MY ENDURING PLEDGE

to always deliver on my commitments, never underestimating the critical role that pipelines play as energy lifelines in fueling everyday life and unforgettable experiences.

It is who I am. I am a pipeliner.

We are pipeliners too.

Keeping product in the pipe is a big job that’s critical to protecting the environment, requiring specific expertise and technology to ensure success.

TDW brings industry-leading application engineering teams, innovative solutions and world-class technicians to help you deliver on your goals. We remain committed to supporting you and the industry in moving toward a more sustainable energy future.

The world counts on you. You can count on us.

For the life of your pipeline.

tdwilliamson.com

©2022 T.D. Williamson

20

Every day, massive volumes of data are created across a variety of industries.

Without the use of proper advanced modelling techniques such as machine learning (ML) models, however, the value and benefits from data cannot be extracted. This includes information such as the condition of instruments, fault detection, and diagnosis. Future performance forecasting can also be obtained, which will ultimately minimise unexpected downtime and provide an early warning when meters are approaching the end of their remaining useful life. As a result, it has become increasingly important to utilise predictive models and ML algorithms to unlock this valuable information and obtain new insights.

TÜV SÜD National Engineering Laboratory’s data acquisition systems have logged and archived 20 years’ worth of data, detailing various flowmeters’ performance, test facility configuration and operating conditions. Multiple research projects have been conducted, with the use of ML models and advanced modelling techniques showing that, despite operating under the same conditions, the performance of flowmeters belonging to the same technology

subgroup (e.g., Coriolis, electromagnetic, ultrasonic) can vary.

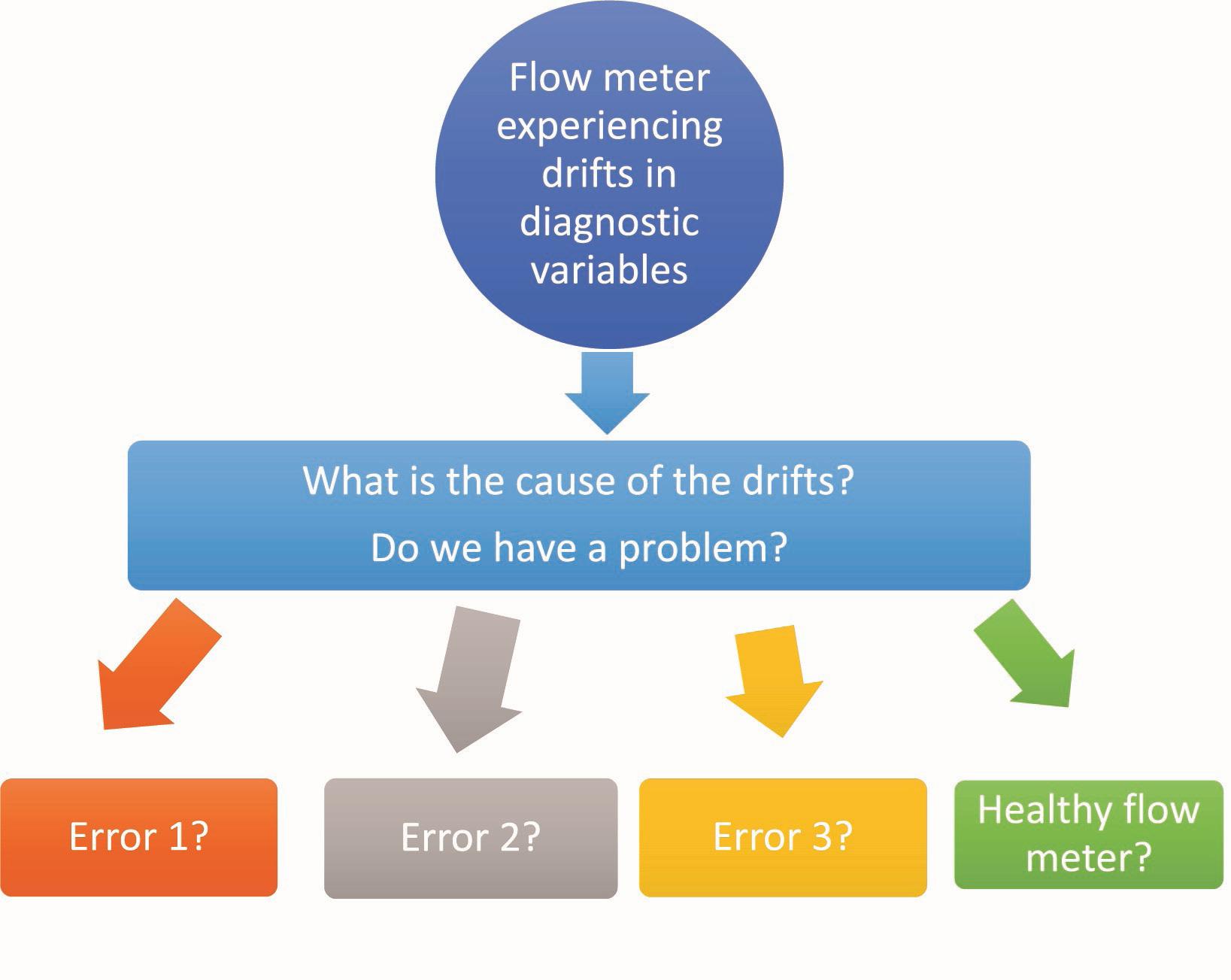

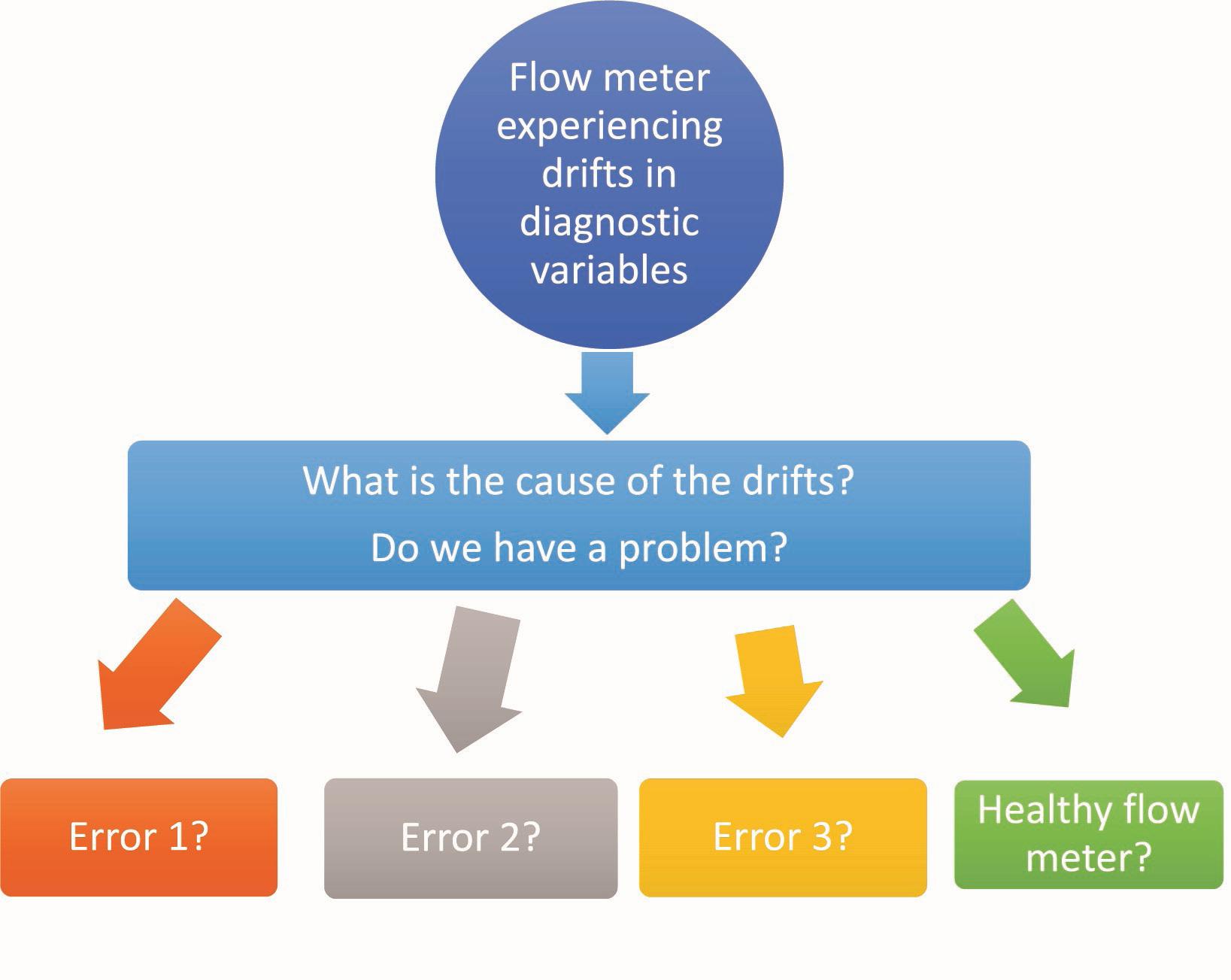

This is mostly due to differences in build and manufacturing materials, making it difficult to pinpoint the causes of sub-optimal performance. The performance of flowmeters is also dependent on operating conditions such as flow profile and pipe configuration. Typically, when a flowmeter is exposed to undesirable conditions, these are manifested as drifts from baseline values in multiple variables, thus giving the false impression that the error responsible for the drifts can be easily identified. Although drifts in variables can be an indication of potential underlying problems, our studies found that there is an inherent challenge in being able to distinguish and pinpoint the exact root cause of drifts in variables. In many examples it was found that different errors could induce the same drift patterns in the same variables. This challenge is described in Figure 1.

Such ambiguity and uncertainty in the fault diagnosis process could result in more time and effort performing additional inspections to pinpoint the exact root cause of drift. With the use of ML models and the appropriate datasets,

Dr Yanfeng Liang, TÜV SÜD National Engineering Laboratory, explores optimising flowmeter data for operational and strategic decision-making.

21

the challenge described in Figure 1 can be overcome and consequently improve end users’ fault detection and diagnosis process.

Experiments

To offer insight into the reasons for sub-optimal performance, we conducted experiments on meters with different sizes within two technology subgroups, where they were deliberately set up differently and exposed to various conditions and disturbances. A comparison on the performance of meters under each operating condition was made to determine which meter performed the best under a particular set up.

Our study revisited the historical data gathered from Meter Category A (Meter A) and Meter Category B (Meter B), which had been intentionally set up with different configurations, as a means of investigating the effect of each configuration on the performance of flowmeters. Simple plots were initially produced when the experiment was first conducted to compare the performance of these meters. From the basic ‘observational’ diagnostic assessments presented in previous research, it was apparent that the meters behaved differently depending on the configurations they were operated in. However, no further analysis was conducted on the data, and therefore only a limited insight was obtained.

Comparing data

Based on the simple plots produced initially, it was challenging to interpret the degree of impact when

changing operating conditions, as multiple results were obtained under various conditions. To deepen our understanding of the collected data, and to better visualise the impact of different setups on the performance of each meter, our new study revisited the data, whereby a series of statistical visualisation tools and advanced data-driven models were used to extract new insights. ML models were also built to detect the presence of a specific faulty condition within the system, where, if left undetected, it would have had a significant impact on the accuracy and reliability of the measurement outputs. These advanced modelling techniques allowed for more comprehensive insights to be extracted from the data, and provided a more conclusive representation of the performance of each meter.

When working with data that contains results from multiple factors, it is sometimes difficult to interpret and extract the most crucial findings. Therefore, having a good visualisation tool can aid end users to quickly identify similarities and differences in varying factors on the performance of flowmeters.

In this study, we used two different visualisation tools – box plots and interaction plots. A box plot is good for visualising and comparing the distribution of data under different setups, as well as displaying the critical statistical properties in data, such as the minimum, maximum, lower quartile, upper quartile, and the median values of the data. Any outliers (which could be an indication of potential underlying anomalies) are also illustrated in a box plot. While an interaction plot provides less information than a box plot, it does have the inherent advantage of allowing end users to quickly compare the effect of changing one factor on the overall performance of flowmeters by focusing on the mean value of the data. In other words, the interaction plot focuses on the degree of change when exposed to a different factor.

From these plots, it was found that Meter A outperformed Meter B by showing the least degree of drift from the baseline value measured by the percentage error in volume flow. It was also observed that the full-bore Meter A and Meter B that were studied had a similar drift pattern when changing from one operating condition to another. The effects of changing

22 World Pipelines / DECEMBER 2022

Figure 1. The challenge of determining the cause of drifts in diagnostic variables.

READY-TO-USE (EPRS) ONSHORE /OFFSHORE OIL & GAS

pipeline configurations and having a disturbance in the system were more predominant in full-bore meters.

Acheiving high prediction accuracy

The presence of a faulty condition will have a negative impact on the reliability and accuracy of outputs from flowmeters. Therefore, having the ability to detect such disturbance will ensure any issues are rectified promptly, and minimise the risk of errors propagating and affecting other related measurement outputs. Consequently, seven ML models under three scenarios were built and trained, where a mixture of data coming from different meters was used to detect a specific problem within the system, based entirely on the underlying patterns and trends in data.

In our previous studies, ML models were typically trained and validated using data generated from a single flowmeter. Although the models usually performed well with high prediction accuracy, it was challenging to apply the trained models to other meters because they were trained on variables that were unique to a particular flowmeter. In other words, the training sample space was restricted. As the meter diagnostic data was not logged during the original experiments, it provided an opportunity to explore the potential of building a more generic model that is trained based on a wider sample space involving data coming from multiple meter types.

Despite having no diagnostic data available, high prediction accuracy (97 - 99 %) and high sensitivity rates (0.96 - 1), accompanied with low false positive rates (0 - 0.07), were still obtained by successfully detecting when a set of data was gathered under normal operating conditions vs the faulty conditions. These results highlight the potential of making better use of data coming from different meters to expand the sample space to allow for a more generalised model to be trained and built, which would be capable of predicting specific operating conditions.

Conclusion

From the results and insights obtained from revisiting the historical data, it is evident that data-driven models and advanced modelling techniques have demonstrated the capability to help end users better understand a large amount of digital data output by flowmeters, as well as having the ability to detect the presence of undesirable operating conditions. This will improve end users’ fault detection and diagnosis process, and ensure any underlying problems are rectified promptly.

Certain data can be expensive to collect (for example, erosive flow data) but a reliable ML model often requires a large sample data for it to capture all hidden patterns and correlations in multiple variables. However, it is sometimes not cost-effective to collect a large amount of expensive data for the sole purpose of training a model. Therefore, if a model can be trained using a variety of data from different sources, it would maximise the potential value in the data, as well as make better use of smaller batches of expensive data from different sources. This would prevent smaller batches of expensive data from being wasted due to their unsuitability in training a ML model because of their small sample sizes, if used independently.

It seems that a common requirement from end users is ‘plug and play’. However, this is extremely challenging as models are typically bespoke to specific customer requirements/devices. By having generalisable models, we can offer faster deployment and enable automation with less requirement for fine tuning to specific meter type/manufacturer/model numbers, as well as improving the fault diagnosis process, enabling condition-based monitoring, and minimising any unexpected downtime. Future research within TÜV SÜD National Engineering Laboratory will continue to explore the potential and capability of generalising data-driven models to be applied in wider applications.

OUR BALL VALVES GO BEYOND THIS DISPLAY AND YOUR EXPECTATIONS! www.boehmer.de OIL, GAS, HYDROGEN, DISTRICT ENERGY & VARIOUS APPLICATIONS 1/8’’ - 56 ‘‘ CLASS 2500 AND HIGHER

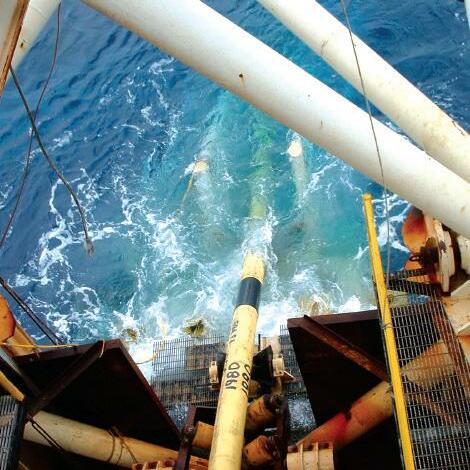

he demand for oil and gas is extremely high across the world, at present mainly due to the war between the Ukraine and Russia. As governments look for solutions closer to home, the oil and gas industry as a whole is going through a significant period of reviewing how it can become more efficient through reducing costs and improving efficiencies.

The inspection of an oil and gas pipeline costs as much as US$5000 - 10 000 per mile, according to statistics quoted in the Oil and Gas Journal. The traditional way of maintaining oil rigs is through the engagement of a highly trained crew of engineers. While this is a proven method of pipeline supervision, there are limitations based on human capabilities and financial constraints. A manned crew can only go so far, while unmanned aircraft systems (UAS) can provide a quick overview and evaluation of difficult-toreach areas.

As the industry moves towards non-conventional sources and more challenging environments, UAS, also

known as unmanned aerial vehicles (UAV) or drones, will be instrumental to ensuring uninterrupted oil supply chains. However, when considering UAS technology, cost-effectiveness usually comes to the fore in terms of the concerns felt by oil and gas companies. This is a valid concern because companies around the world are having to cut costs, especially after the COVID-19 pandemic.

Pain points in pipeline maintenance and surveillance

Finances are one of the primary areas of concern. For example, detecting and fixing problems is an essential, but costly, step towards increasing production and operations. However, this is a very difficult task due to the resources and time required to inspect or monitor the entire infrastructure. Oil and gas organisations spend a substantial amount of money running into millions of dollars to monitor pipelines every year that often includes the maintenance of a manned fleet to do the job.

Richard Hjelmberg, UMS SKELDAR, Sweden, considers if unmanned aircraft systems could replace manned maintenance in the oil and gas industry.

25

Figure 1. SKELDAR V-200 in flight to offshore oilfield.

There is a heightened need for preventive maintenance planning and optimised production while keeping costs on the low side. UAS provides an alternative to sending fully manned crews on missions. Unmanned aircraft capable of performing the task of inspecting infrastructure are often far more fuel efficient than their manned counterparts, and in the case of rotary-wing platforms do not require hard largescale infrastructure to deploy. In addition to this, spare parts packages are often lower in cost when compared to manned aircraft.

The oil and gas industry faces a variety of safety risks arising from accidents, fires, falls, difficult terrains, hostile communities, and more. Damages and leaks may occur on critical infrastructure such as pipelines, which are difficult to assess as they often cover many miles and sometimes travel through hostile or difficult terrains. This may go unnoticed for some time and expose the community and environment to harmful gases. Light detection and ranging (LiDAR) is one example of an advanced sensor that can detect methane leaks.

Current hinderances to UAS take-up

One of the main issues for the oil and gas industry is keeping costs down. This is why when it comes to assessing the use of UAS, a thorough cost/benefit analysis is required.

In establishing cost-effective practices for the oil and gas industry, not many UAS manufacturers have gone to the trouble of assessing every aspect of a UAS purchase. Global prices for petroleum products can encounter volatile phases, therefore, any investments made must be justified. Europe’s leading provider of rotary UAS, UMS SKELDAR, has made this a focal point when assessing what benefits its platforms can deliver. The company is reviewing every aspect of the development to deployment process to isolate potential areas for cost savings for users. This process incorporates the regulatory requirements.

Over the last decade and more, regional civil aviation authorities have been charged with formulating UAS polices and regulations to keep pace with the needs and requirements of global businesses. Unfortunately, the regulations set have sometimes acted as a barrier to widespread take-up. For example, in many countries, it is still very difficult to fly over populated areas due to heavy regulation, making it hard to undertake missions where there is a vast area to monitor. Although legislation is evolving rapidly as regional restrictions

are eased, and more is understood about UAS from an operational safety perspective, there is still a long way to go.

There are projects that have happened or are ongoing that are assessing how UAS platforms can be safely integrated into controlled manned airspace, such as the ECARO project. ECARO is a multidisciplinary project whose main objective is the adoption of European satellite navigation systems global navigation satellite systems (GNSS), EGNOS and Galileo, for all civil aviation applications including fixed-wing and UAS operations, as well as rotorcraft emergency operations.

As UAS capabilities and usage rates increase, it is pertinent that legislation continues to evolve to allow UAS in UMS SKELDAR’s weight category to be deployed for such tasks as oil and gas pipeline monitoring. Current aviation legislation frameworks are designed with visual line of sight (VLOS) regulations in mind, which means that an operator of a UAS must always be capable of maintaining VLOS of the UAS they are piloting. Beyond visual line of sight (BVLOS) regulations are also in place, which allow UAS to be operated at a distance outside the normal visible range of the pilot. This is the area that is currently being evaluated through a number of tests and demonstrations. The expectation is that BVLOS flights will begin for specific missions, such as oil and gas pipeline monitoring and maintenance. Working together with the oil and gas industry, alongside regulators, is therefore the best route forwards.

Without a doubt, UAS have the advantage of enabling oil and gas operatives to monitor any suspicious activities, as well as check the status of the condition of hard-to-reach oilfields or cross-border pipelines, at a minimal cost. However, government regulations must be progressive enough to provide an enabling environment for the changes needed to thrive while the industry doubles down on improving current technology.

Solutions

The use of UAS in the oil and gas industry is only going to increase in the future. Being able to monitor suspicious activities as well as check the condition of hard-to-reach oilfields or cross border pipelines without putting any person at risk is a significant advantage worth pursuing. Inspecting and maintaining oil pipelines and platforms is a perilous task: many are remote and in extremely harsh environments. Rig inspections carried out by rope-access technicians are not only extremely dangerous operations but can take up to eight weeks, and involve shutting down production (Airborne Drones, 2019).

By capitalising on their endurance, using UAS in these environments means it is possible to access these areas with relative ease, and without exposing crew to the associated hazards. This removes risk to employee safety and consequently reduces medical expenses and lost work hours due to injury.

As well as the associated dangers, the remote location of oil and gas work also presents a challenge in gathering and sharing data. Having manned crews run inspections and repairs means a delay between data recording and analysis. In contrast, using UAS means data can be shared via the cloud in

26 World Pipelines / DECEMBER 2022

Figure 2. SKELDAR V-150 in flight.

real-time to crews in another location, totally separate from the inspection itself.

Not only do UAS gather information more efficiently than humans, digital data enables operatives to make better decisions based on more accurate data. Once a potential hazard has been identified, it can be addressed in a far shorter time. This helps to identify issues earlier and reduce downtime, which is vital for organisations in charge of safeguarding critical infrastructure.

Today, oil and gas organisations are assessing UAS as they look to move towards non-conventional sources and more challenging environments. This is due to the requirement to ensure round the clock vigilance, a priority in any strategic asset protection plan.

Overall, the key benefits include:

) Providing a quick overview and evaluation of difficult to reach areas.

) Preventive maintenance planning and optimised production keeping costs on the low side.

) Access to locations that pose health, safety, and environmental risk to personnel.

) Real-time data transmission.

) Fast onsite deployment of UAS platforms.

) Authorised and qualified UAS-inspection personnel.

) Reduced downtime increases overall efficiency.

The way forward

After years of advocacy by UAS manufacturers, there is greater awareness in general around what these innovative technologies can provide to an ever-broadening variety of sectors and organisations. However, people in civilian sectors like the oil and gas industry need to be made more aware of the roles and therefore purposes of a UAS. Education is key to the integration across the sector and crucially how we can further employ it as an intelligence asset. That intelligence is gold dust and getting hold of the data a UAS can gather is one thing, but that is only part of the equation.

To really move things forward, the regulations behind the scenes rightly controlling what is possible also need to adjust to the technology advancements that have been made in recent times. Being able to fly BVLOS over land, and not just at sea, is pivotal to what is possible in the future. Many pipelines are not only vast in terms of length, but also across borders. Therefore, regulations should adapt to allow oil and gas organisations to perform monitoring operations. Although significant work is being done in this area, advancements as well as studies are still required to form a legislative framework that allows for operations with unmanned aircraft to take place, where companies not only understand what they have to do, but also the implementation is relatively simple to undertake –without this, UAS system uptake may well continue to be slow.

28

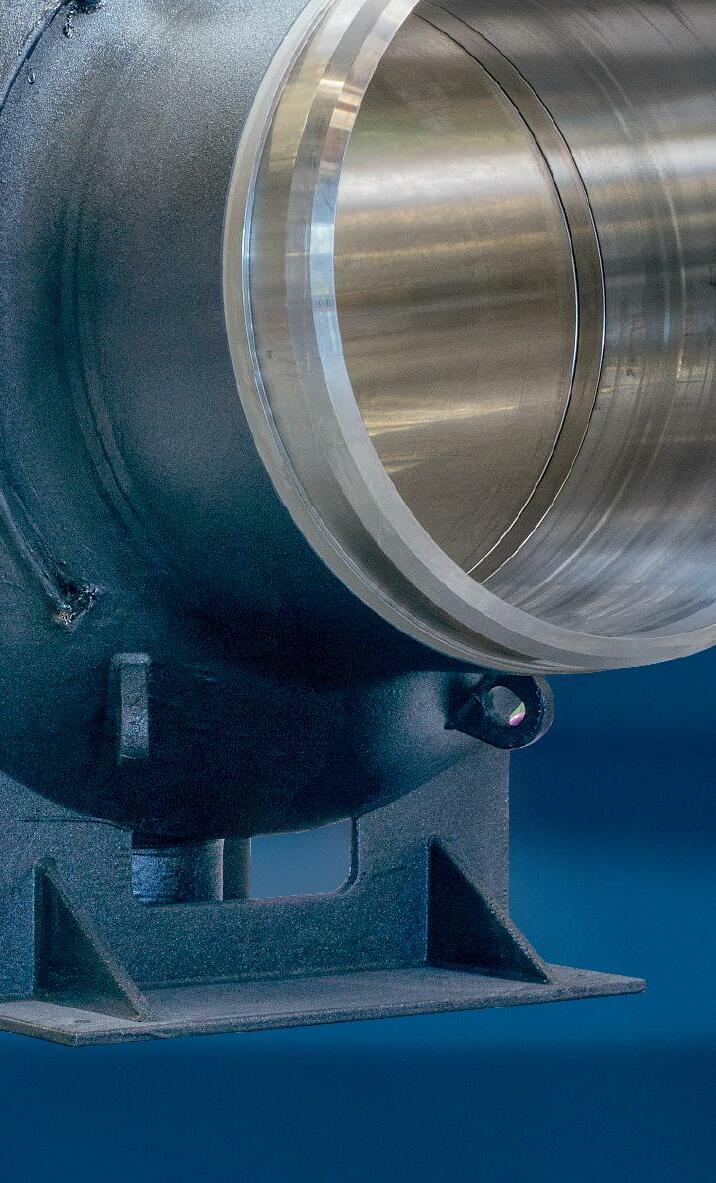

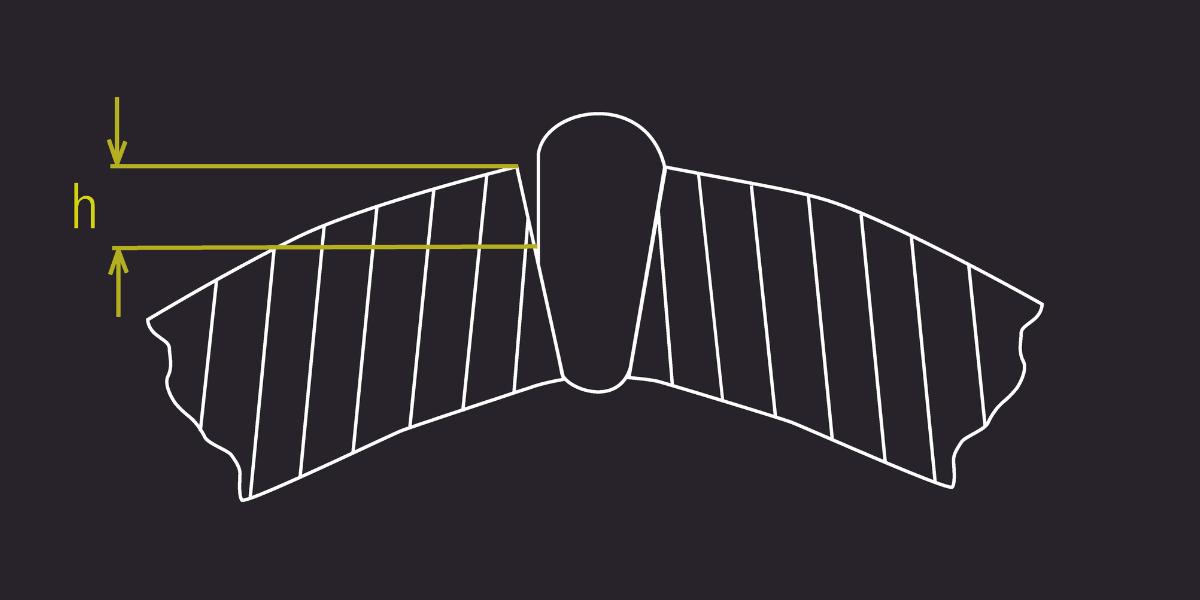

Flow control specialists Tommi Bergman, Manager of Engineering Analysis and Taija Hämäläinen, Director of Butterfly Valves, Valmet, Finland, consider improving process performance in demanding control valve applications.

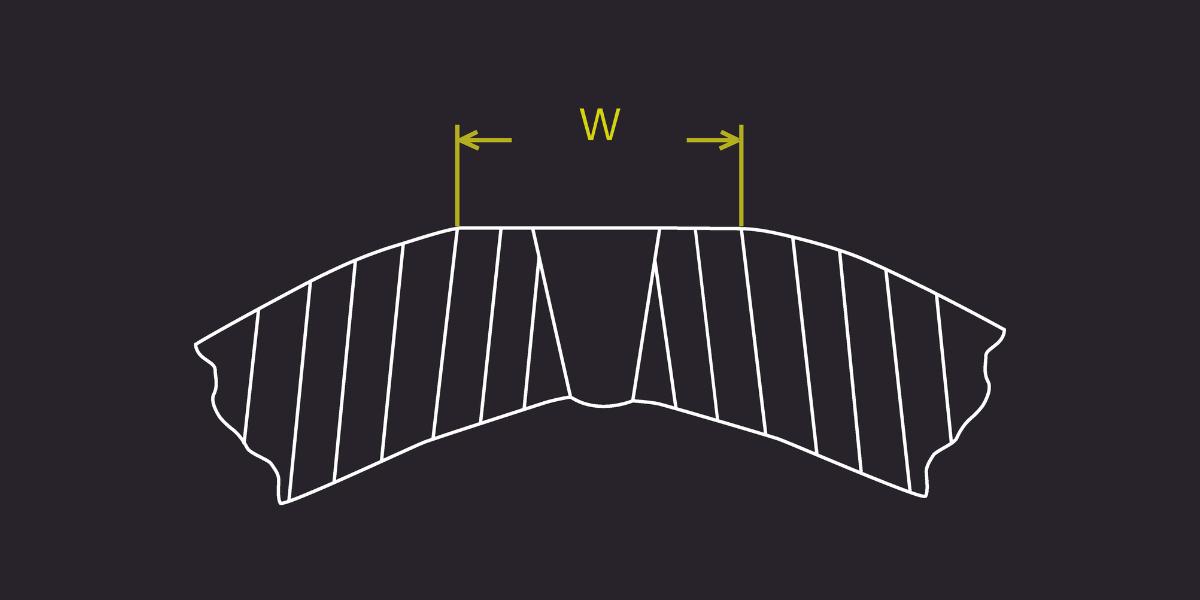

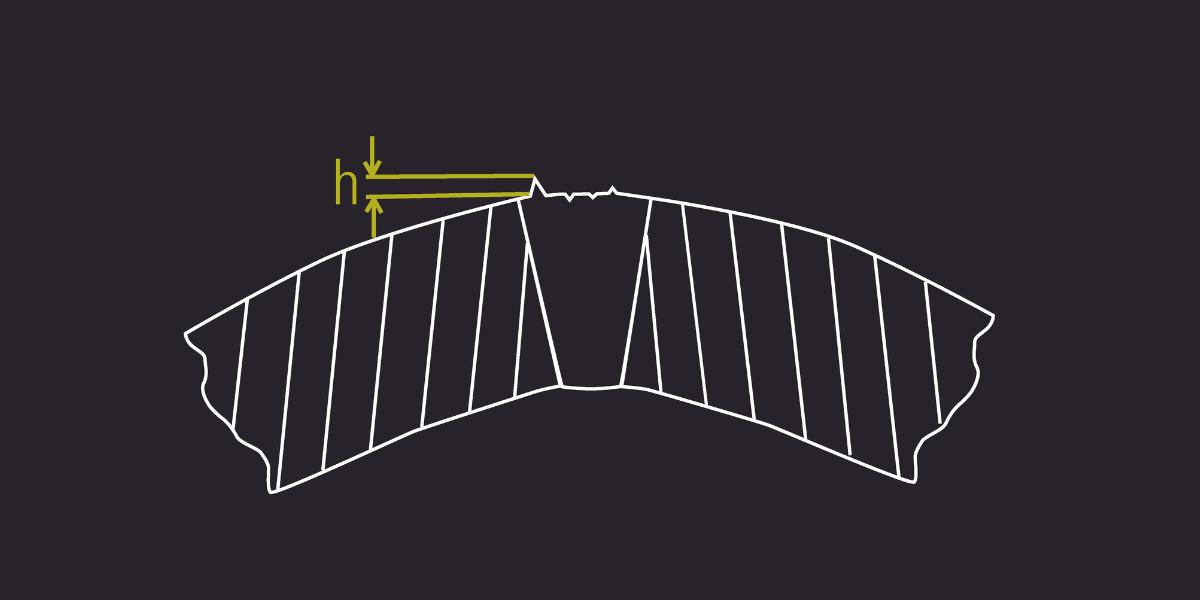

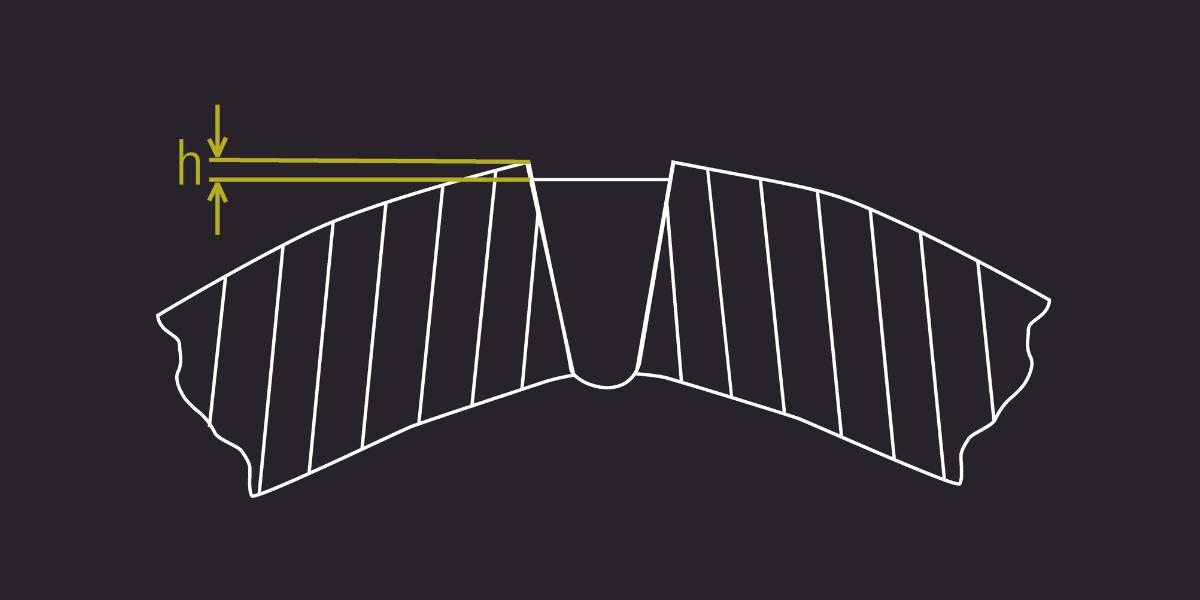

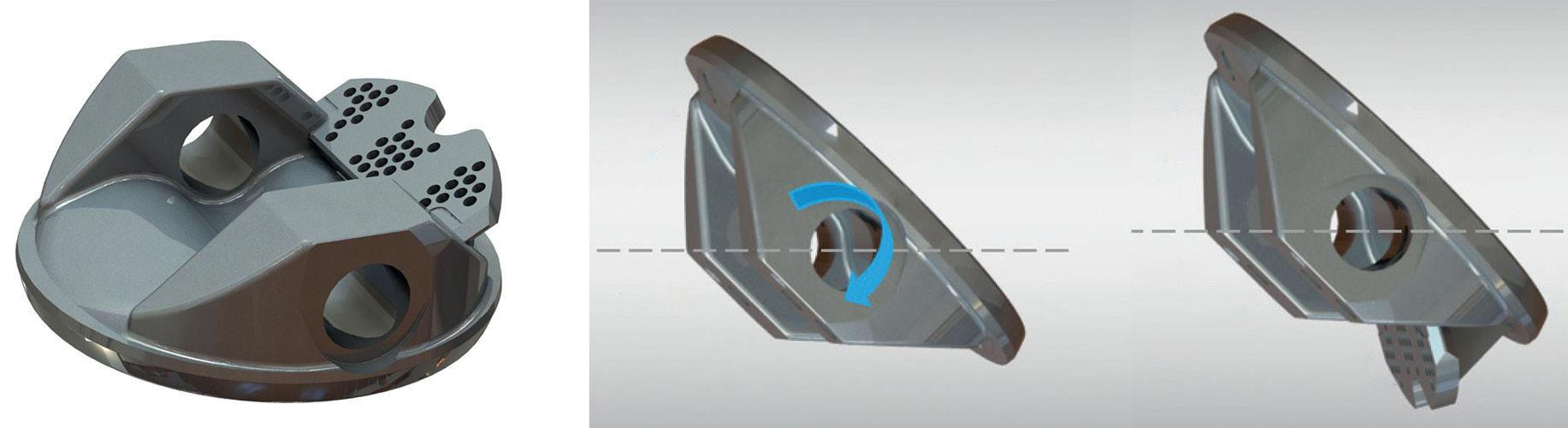

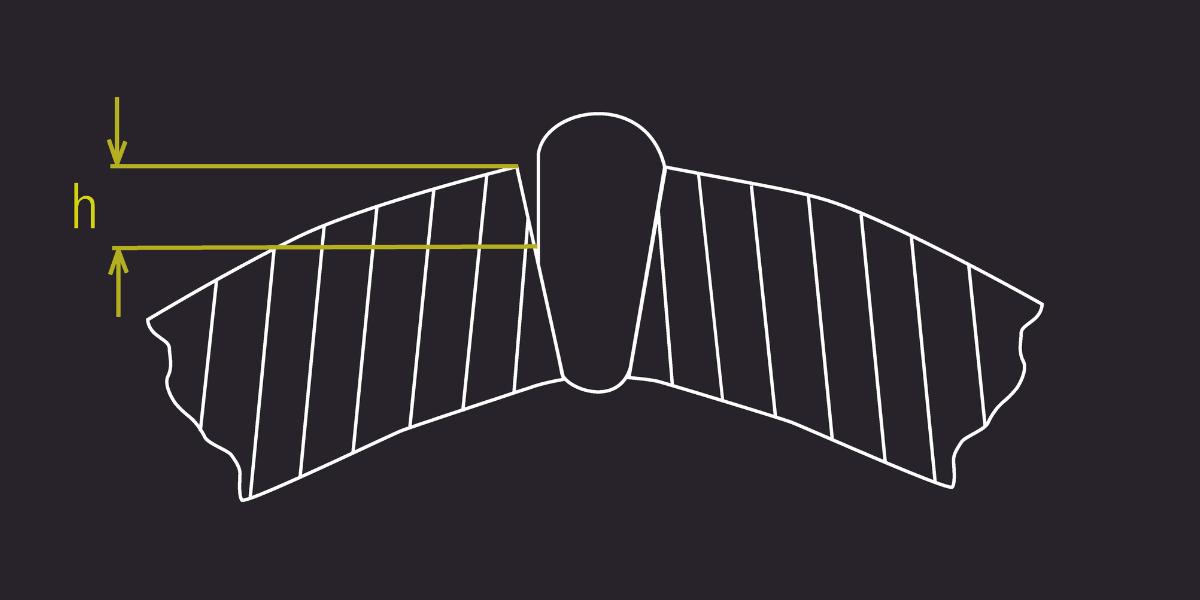

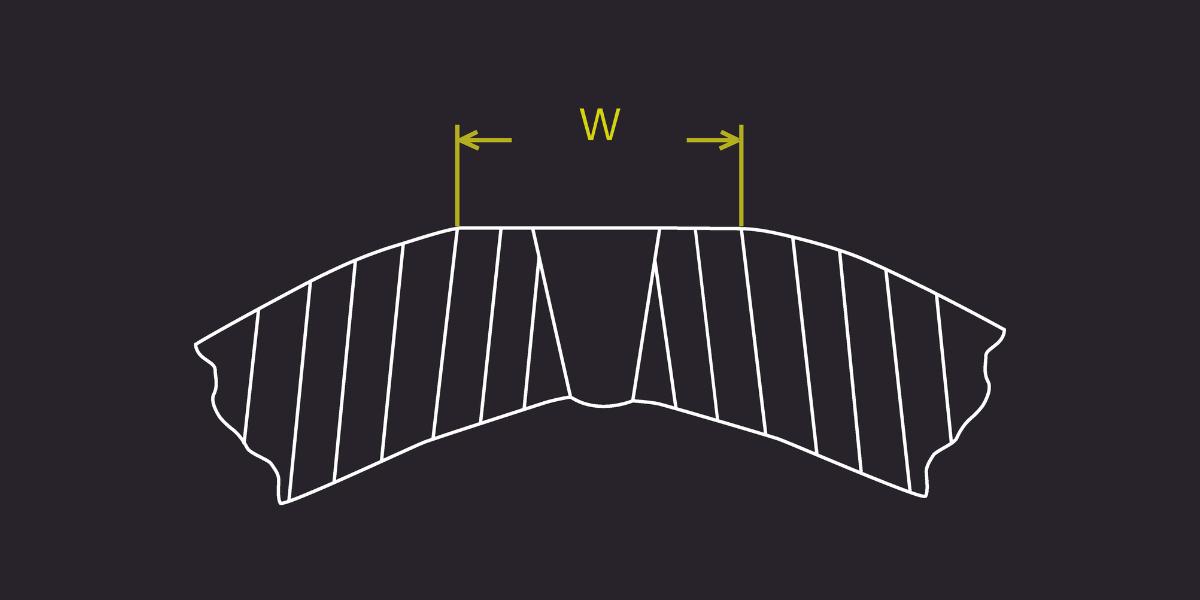

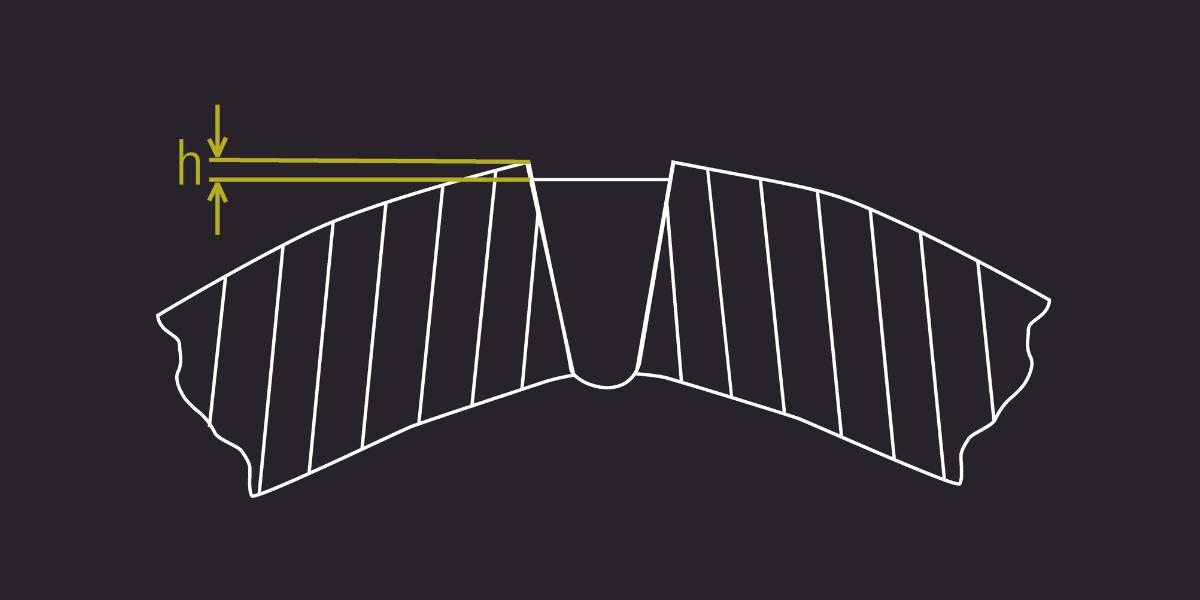

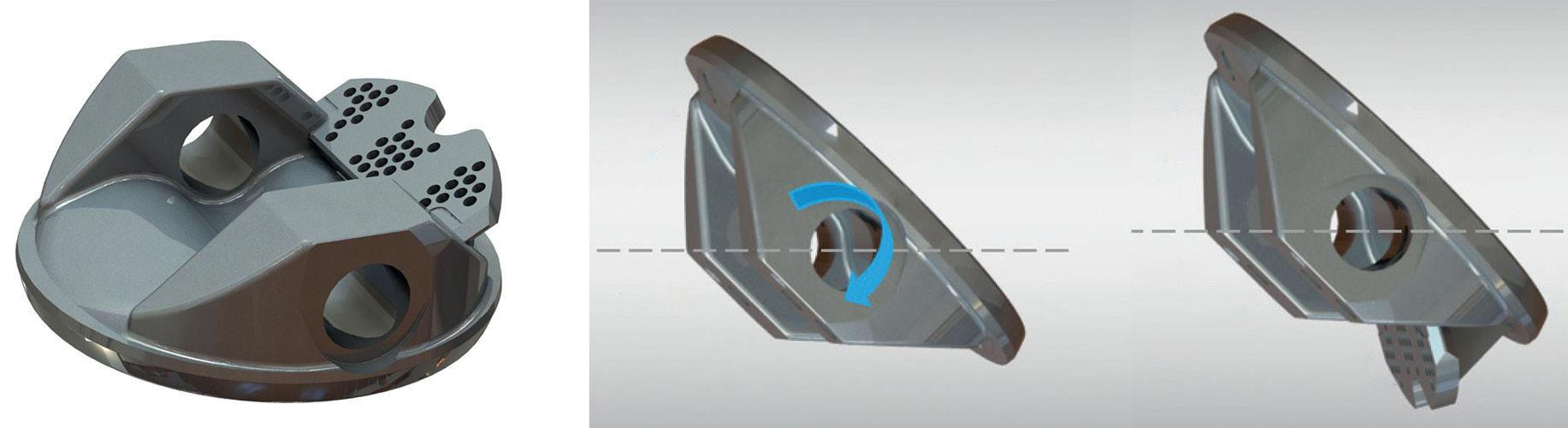

Valmet expanded its offering with flow control solutions in April 2022, when the industrial flow control company Neles was merged into Valmet. In June, the company broadened its new generation versatile butterfly valve product range with the NelesTM Q-DiscTM, a new high-performance feature to help flow balancing in control valve applications. But what makes the new Q-Disc a game-changer? Let’s take a closer look at the Q-Disc design journey to find out.

The Q-Disc flow balancing trim addresses dynamic torque-related challenges in butterfly valve applications. The perforated trim plate is seamlessly integrated with the disc, making it durable, efficient and easy to incorporate into your valve assembly. Q-Disc has been designed to be easy to install, service and maintain as a part of

versatile Neles NeldiscTM and JamesburyTM Wafer-SphereTM butterfly valves. It also provides market leading noise reduction even up to 12 dB.

Neles, now Valmet’s Flow Control Business Line, has a long history in bringing reliable and innovative flow control solutions to the market. In addition to decades of engineering know-how, our design process is based on continuous dialogue with customers, combining experience from tens of thousands of customer installations and translating them into solutions that answer to specific needs of specific industry and process. In the case of Q-Disc, one of the key drivers was to improve process performance in demanding control valve applications that involve challenging media or process conditions, for instance. We also build on and get inspiration from existing innovations: the Q-Disc, for example, helps reduce noise and cavitation like all the other Neles trims under the Q-moniker.

Tackling the dynamic torque

Dynamic torque is a challenge that all rotary valves, especially butterfly valves, face when in active flow control service. However, it is an aspect that is not as often taken into consideration when designing valve solutions and selecting the right configurations. While the requirements brought along by static torque are well addressed, we find that design considerations addressing dynamic torque are often an afterthought. For Valmet’s flow control business line, it was a consideration that was at the core of the design process.

29

Dynamic torque is the flow-induced pressure torque placed on the valve in service. It is a direct result of the operating environment in which a valve is placed. Depending on the flow direction, valve travel, and valve design, dynamic torque may even cause the valve to open or close. Rotary valves in throttling service may experience high torques, especially on larger valve openings. Valmet is seeking patent protection for the innovations that the new Q-Disc is bringing to the table when it comes to tackling the effects of dynamic torque in butterfly valve applications.

Easy selection and sizing for optimal performance

Dynamic torque is also a key factor that has an effect on actuator sizing as a part of the valve assembly. Actuators may easily end up being undersized if only taking static

torque into consideration. Also, when playing with high safety margins, actuators may end up oversized. The Neles NelprofTM sizing software takes dynamic torque into consideration and recommends the correct actuator automatically. Nelprof has all the different actuator characteristics inside, so sizing is accurate for all actuator types.

By taking dynamic torque into careful consideration and making the correct valve-actuator configuration choices, process efficiency and performance can be optimised. The Q-Disc as a part of the valve assembly can deliver potential cost reductions and improvements in efficiency. A stable flow with minimised restrictions to capacity means even output and quality, as well as reduced mechanical stress on valves. In other words, Q-Disc also helps in optimising the entire valveactuator package by making it possible to reduce the impact of dynamic torque caused by the flow, providing improved reliability and efficiency for the overall process the valve is part of.

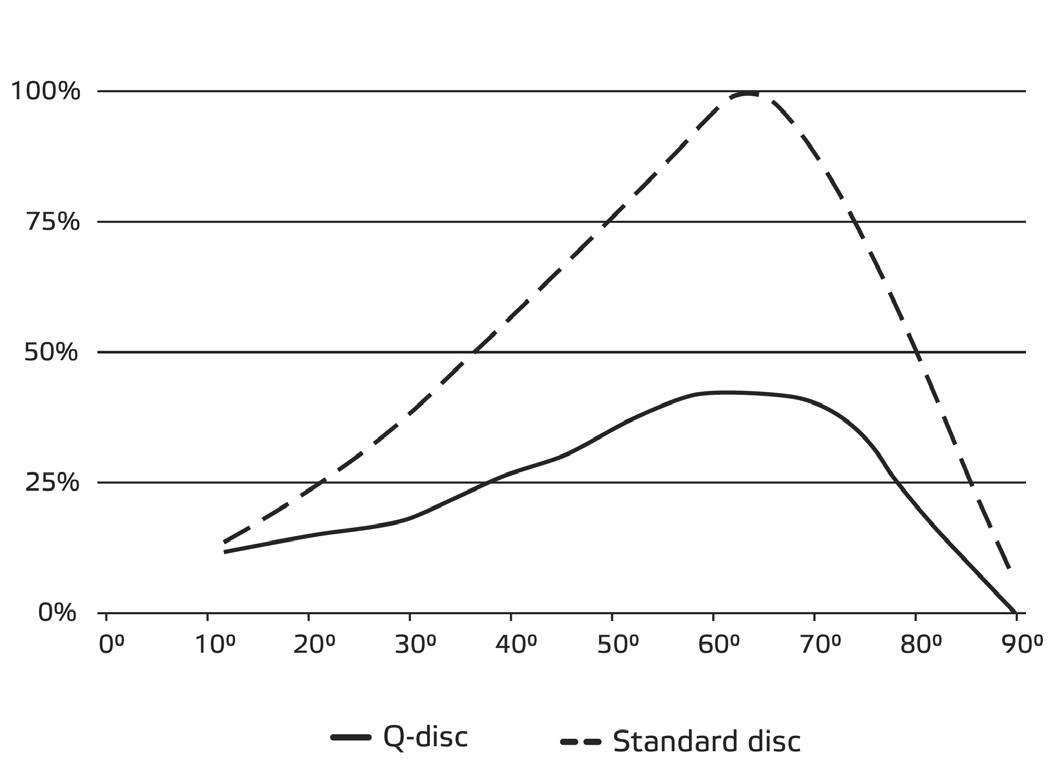

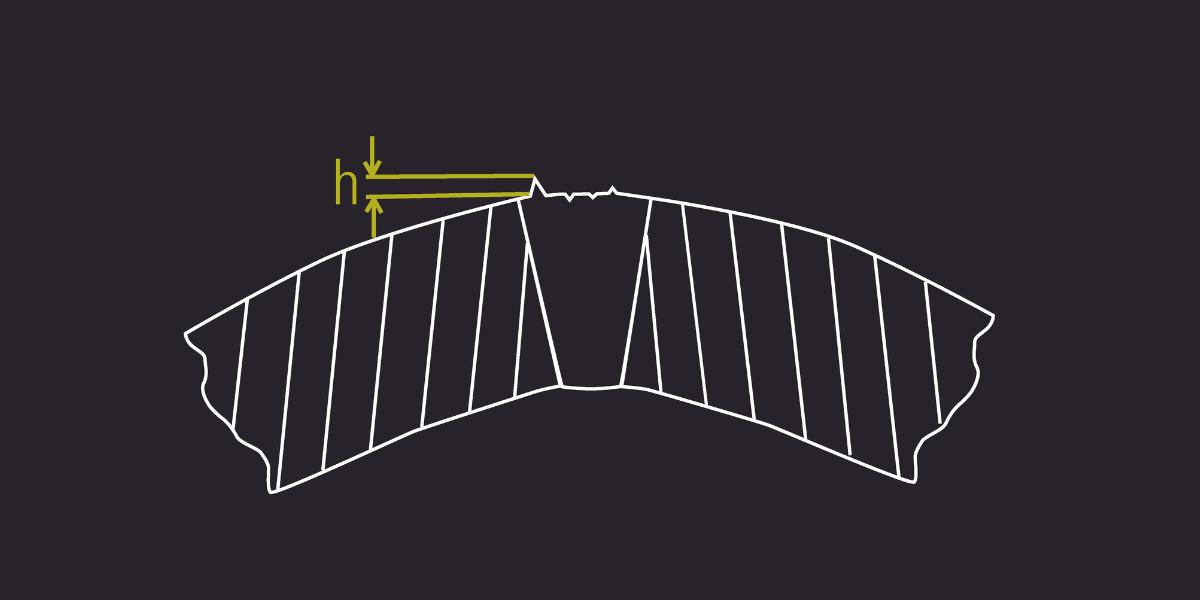

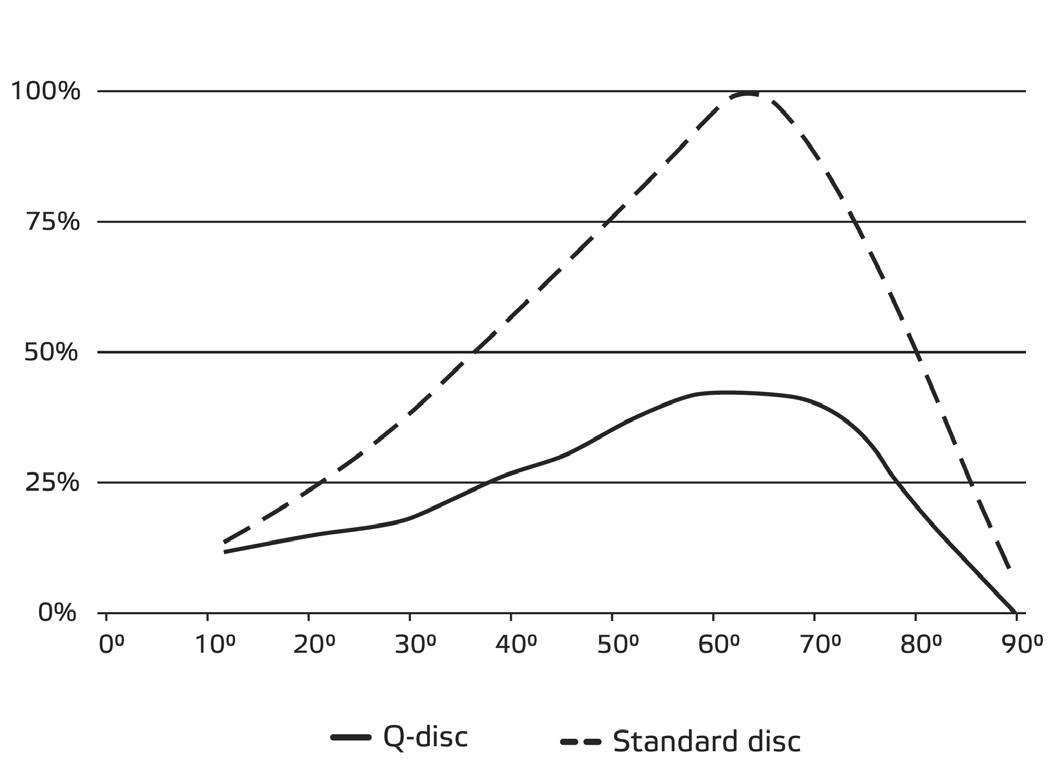

Improved performance in any and all valve configurations

The Q-disc can have a positive effect on the dynamic torque coefficient of a butterfly valve. When looking at and measuring dynamic torque, we need to look at differential pressure and the valve size, or in the case of butterfly valves, the size of the valve disc in particular. As dynamic torque is a result of the pressures created by the flow of media through the valves, things like disc geometry and shaft offsets come into play. The effects of the Q-disc’s integrated flow balancing trim on a triple offset butterfly valve can clearly be seen in the curve shown in Figure 3.

The modular design of our latest range of versatile butterfly valves means that the Q-disc can easily be incorporated into any and all valve configurations. They have been designed by pressure class and valve size to ensure you always find the perfect fit. Speaking of fit, the Q-disc fits neatly inside the valve, requiring no deviations in terms of regular installation or maintenance procedures.

Excellent relative flow capacity with an integrated trim solution

There is no separate external trim plate and no fasteners between the trim and disc. The disc and trim form an

Definition: Dynamic torque and dynamic torque coefficient

Valve dynamic torque (Md), which tends to close or open the valve depending on the type of valve, is caused by asymmetric pressure distribution on the surface of the throttling element, in this case the disc. The dimensionless dynamic torque coefficient (Cd) is a value determined experimentally using laboratory measurements.

30 World Pipelines / DECEMBER 2022

Figure 1. NelesTM Q-DiscTM flow balancing trim for butterfly valves.

Only one call away...

You’re looking for a partner that provides the best service in sales & rental in pipeline equipment. One that deals in all the big brands and offers worldwide delivery. A company you can rely on, one that keeps its promises, thinks ahead and always delivers...

You can build on BAUMA!

BAUMA-PIPELINE.COM

Vermiet- und Handels GmbH

integrated piece with a rigid connection. There is a patent pending on this innovation. This solution has been found to work particularly well with bigger opening ranges. The Q-disc has excellent relative flow capacity compared to traditional flow balancing trims, and flow characteristics that are very similar to standard discs.

And much like the other perforated integrated trims that carry the Q-moniker in the Neles product brand range, the Q-disc also acts to lower noise and cavitation. It has a positive effect on the valve choking factor (FL) and can be particularly helpful in reducing aerodynamic noise to some extent. All in all, the Q-disc is an innovation that was born out of the need and desire to improve process stability and ensure long-lasting performance and reliability. It is literally helping take some of the pressure off the shoulders of the butterfly valve’s disc and shaft.

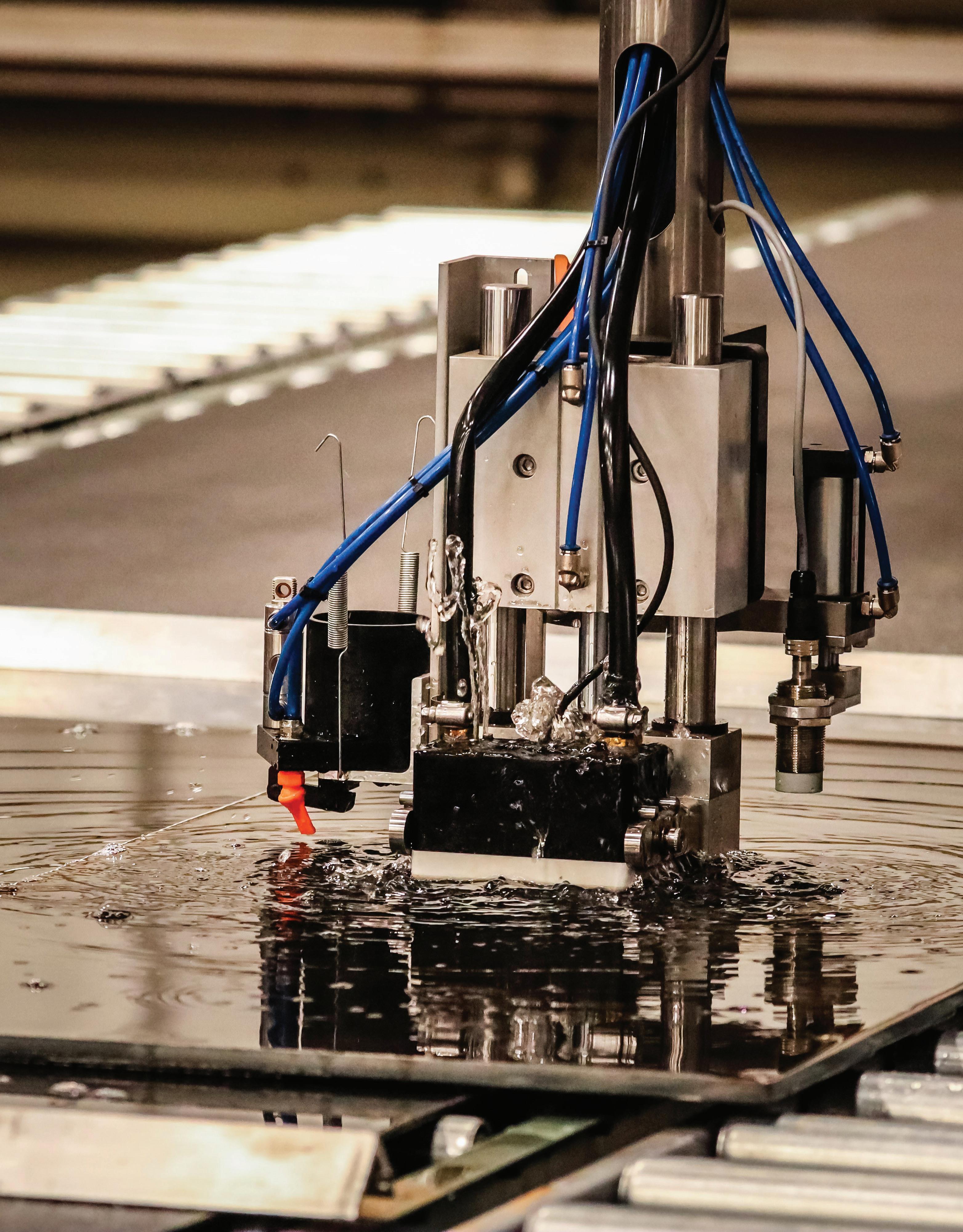

Simulation-driven development process