Volume 25 Number 8 - August 2025

Volume 25 Number 8 - August 2025

Elevate your asset integrity with unmatched data accuracy and unparalleled expertise

Our unique synergy of advanced inspection systems, cutting-edge analytics and human expertise allows us to transform data into knowledge. Knowledge enables smarter decision-making and delivers a comprehensive understanding of asset safety, lifetime, and performance.

25 | NUMBER 08 | AUGUST 2025

03. Guest comment

Antonia Syn, Rystad Energy.

05. Editor's comment

07. Pipeline news

Pipeline news from Argentina, USA, UK, and Egypt.

KEYNOTE: CONSTRUCTION BEST PRACTICES

14. Fuelling the future

Walter Crommelin, Nick Homan, Kalen Jensen, and Sean Keane, four key leaders at the Pipeline Research Council International (PRCI), came together to explore current research priorities, safety standards development, environmental concerns, and workforce development initiatives in order to effectively prepare for the future.

24. Next generation approach to pipeline data management

Vinay Baburao, Director Digital Transformation, CRC Evans, explains how digital technology is delivering next generation pipeline services data management.

ENERGY SECURITY

33. Q&A: a new era of risk and resilience

World Pipelines interviews Raghu Yabaluri, Global Oil and Gas Market Leader, Black & Veatch, on the current state of energy security for pipelines, and the pressure points to which we must pay attention.

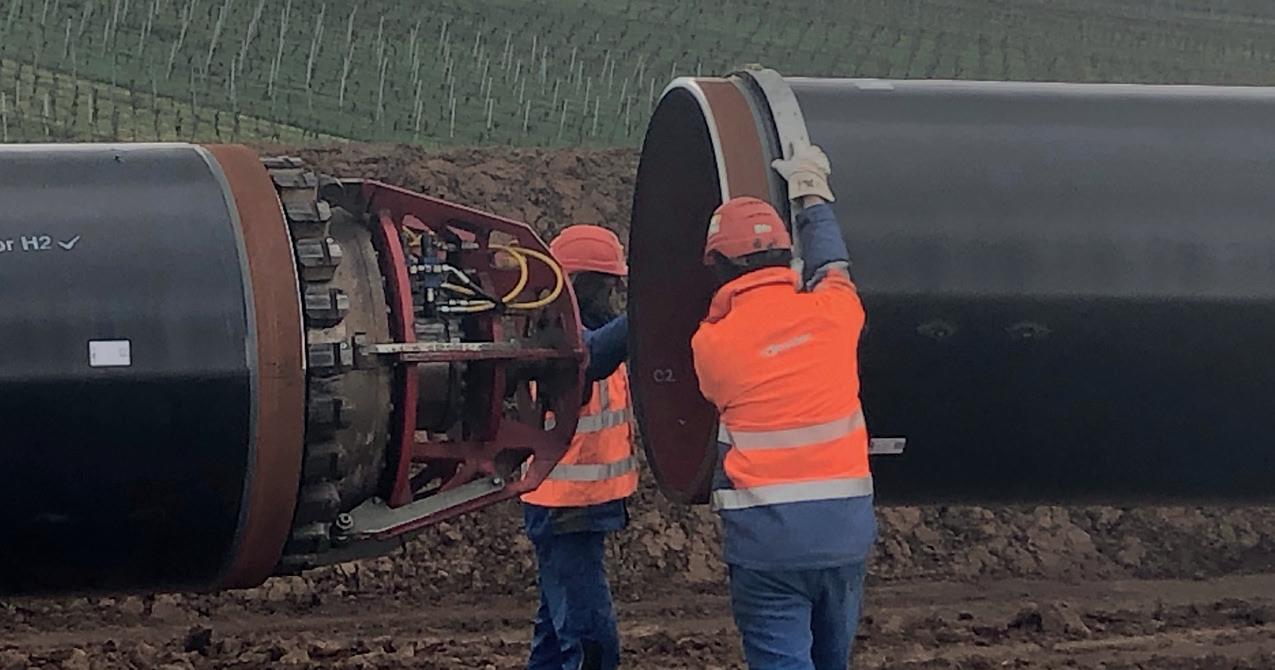

HYDROGEN PIPELINES

39. Repurposing: pass or fail?

Ben Cowell, Integrity Engineer, Luke Fahy, Integrity Engineer, and Nigel Curson, EVP of Technical Excellence, Penspen.

EPC CASE STUDIES

45. High-voltage, high-velocity

Scott Salter, Director of Power and Utilities, Audubon Co.

51. CCS success

Andrea Bombardi, Executive Vice President, RINA.

PIPELINE CONSTRUCTION

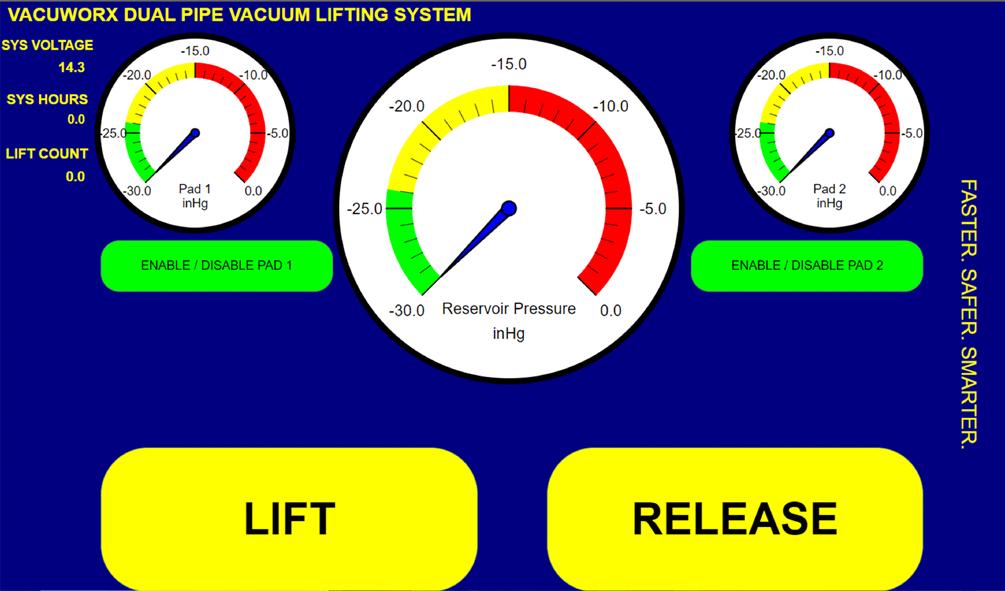

55. The rise of multi-pipe handling systems

Alyson Cram, Vacuworx, USA.

59. Overcoming the impossible

Patrick Koch, General Manager, LCS Cable Cranes.

61. Cutting through complexity

Giacomo Betti and Marco Paris, Tesmec, Italy.

65. Evolving excavators

Margherita Laurini, Chief Financial Officer, Laurini Officine Meccaniche, Italy.

67. Powering the future

Jimmy Herring, Chief Executive Officer, Infra Pipe Solutions.

MANAGING PIPELINES

71. Staying ahead of pipeline thieves

Harry Smith, Sales and Senior Research Engineer, Atmos International.

77. Relieving insurance costs with AI geospatial technology

Sean Donegan, President and CEO, Satelytics.

OFFSHORE AND SUBSEA

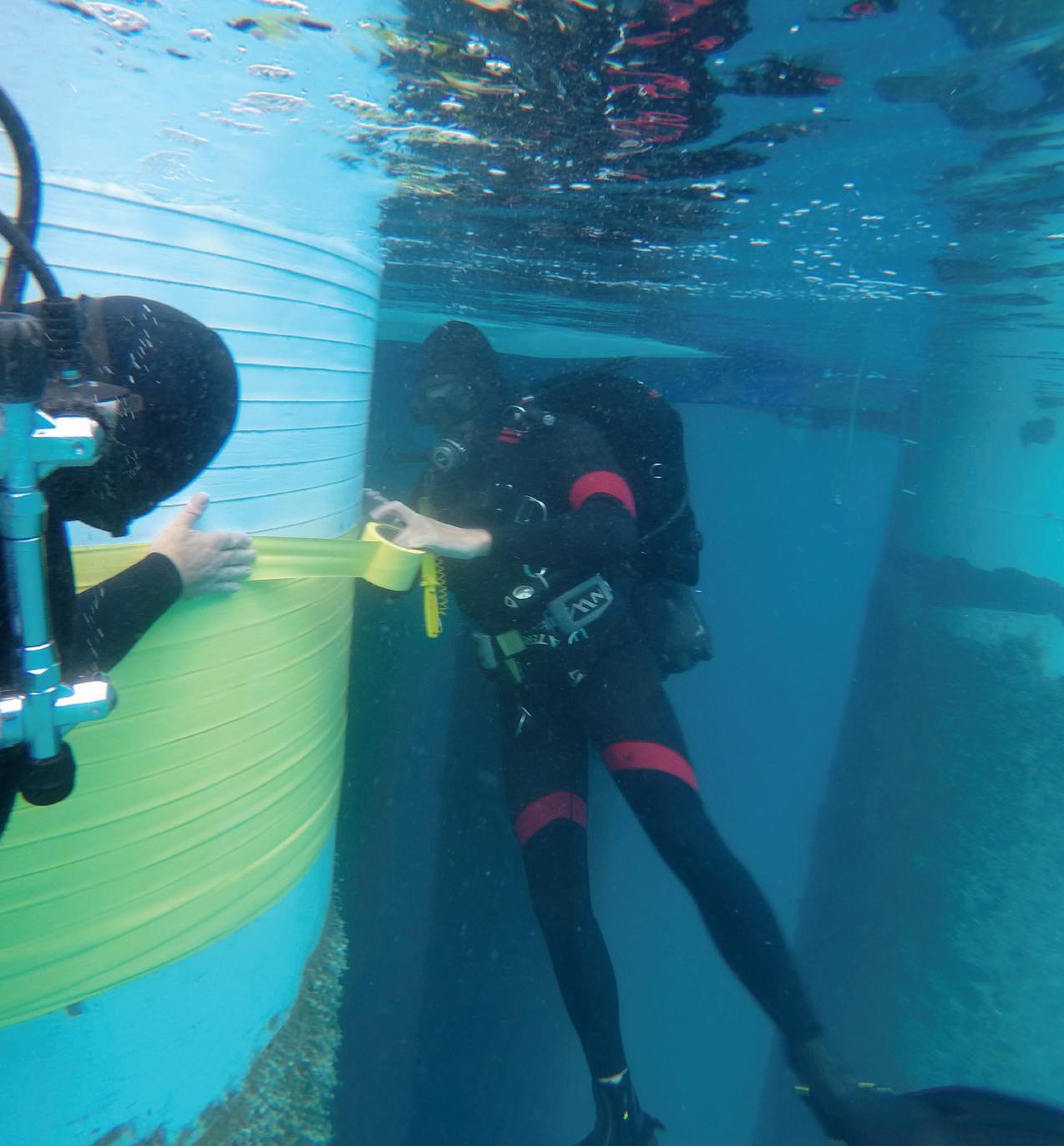

81. Achieving certified accuracy

Patricia Sestari, Voyis.

CORROSION CONTROL & CONDITION ASSESSMENT

87. Extending pipeline longevity Kristopher Kemper, AMPP, USA.

DECOMMISSIONING

93. Managing benzene risks in pipeline decommissioning Mark Burrup, Dräger.

PIPELINE INSPECTION

97. Long-term integrity with baseline inspections

Jim Costain, Craig Hall, Thomas Mrugala, and Ron James, NDT Global.

101. Going above and beyond

Jeff Taylor, Founder and President, Event 38 Unmanned Systems.

107. Transforming oil and gas inspections

Enzo Wälchli, Chief Commercial Officer, ANYbotics.

PIPELINE MONITORING

111. The wireless fight against methane emissions Sandro Esposito, SignalFire Telemetry Inc., USA.

121. A new compass for inspection

Dr. Mario Paniccia, CEO, ANELLO Photonics, USA.

125. Digital control at the edge of the world

Ajitkumar Sreekumar, Vice President of Sales, IMI.

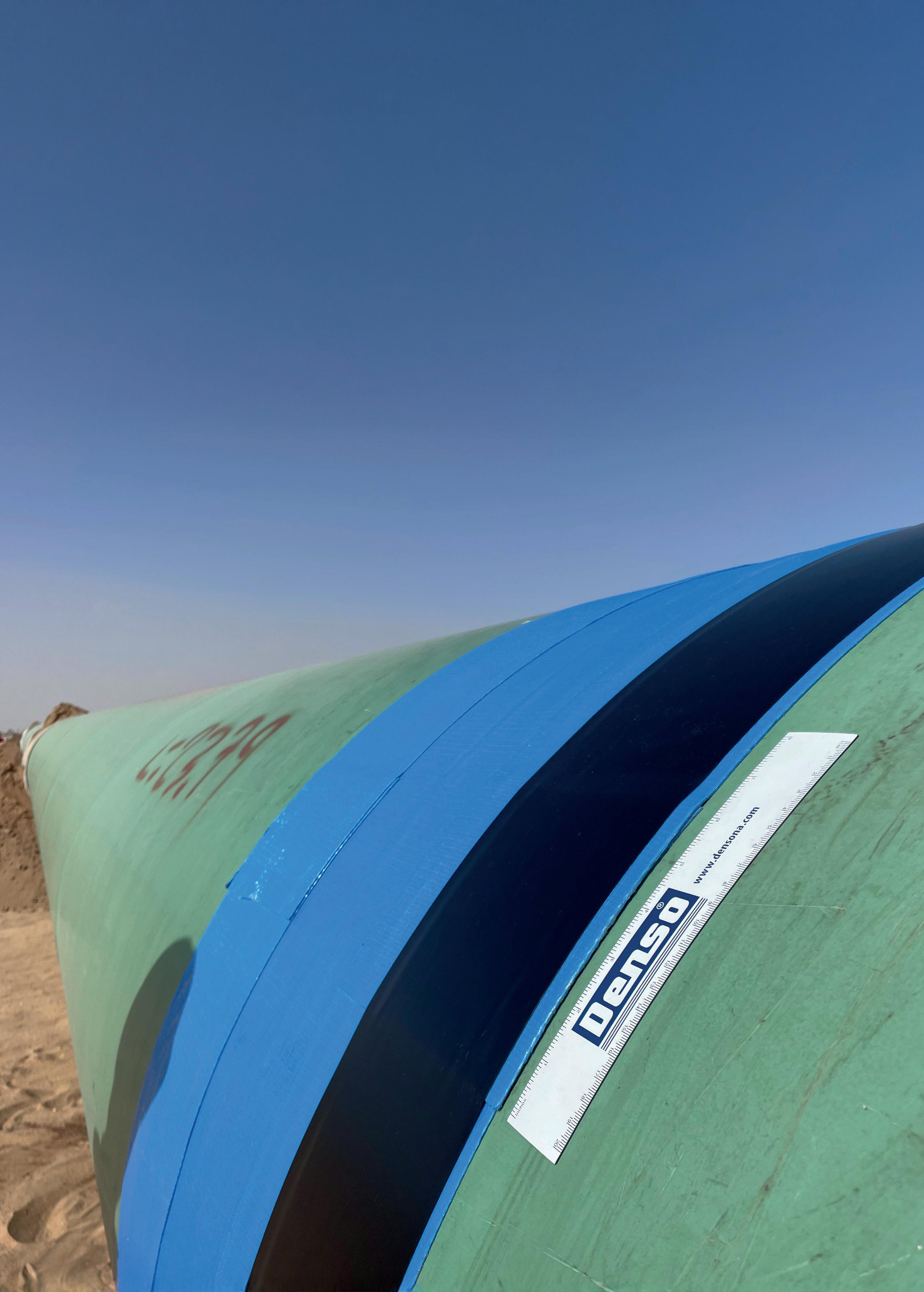

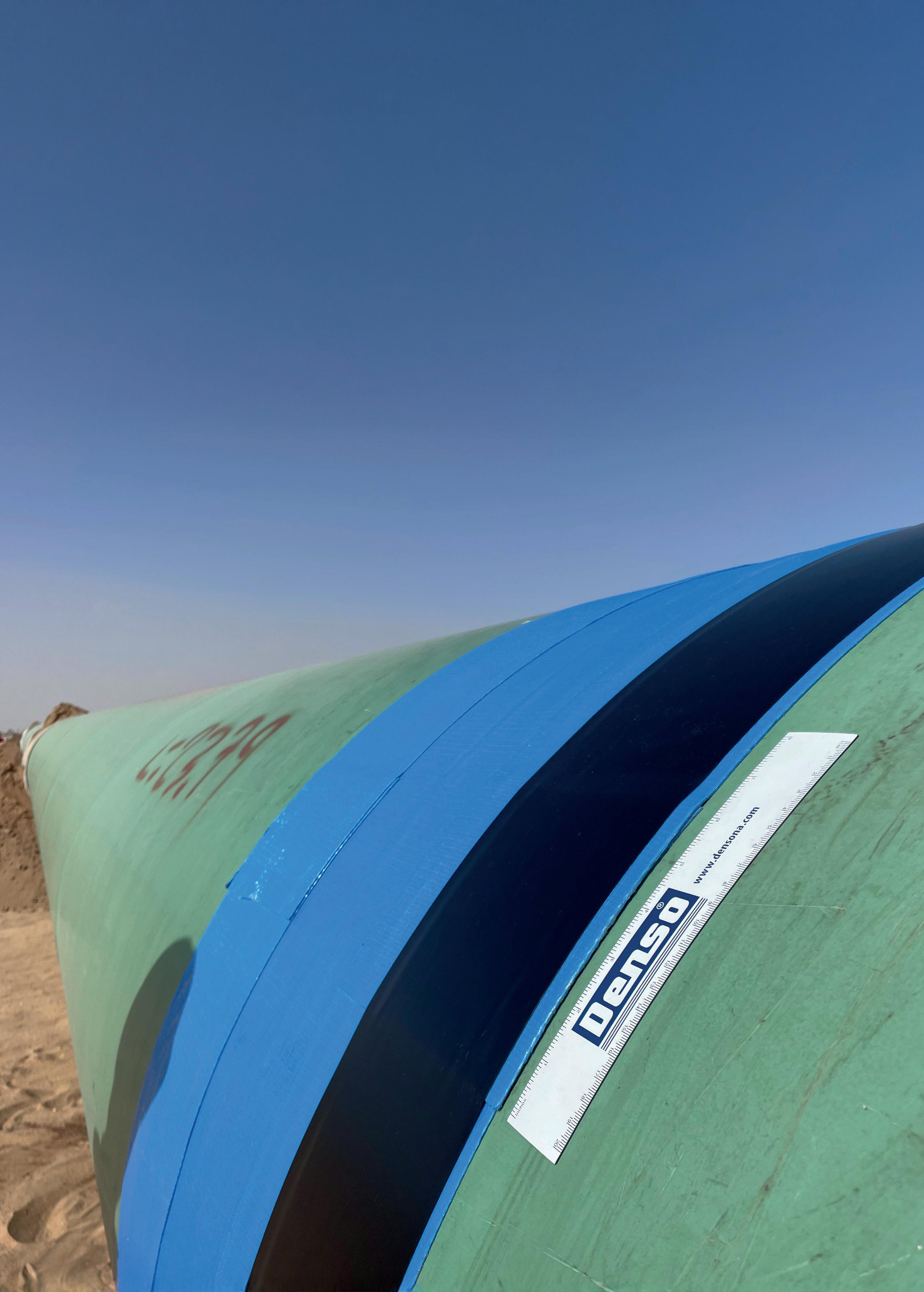

Winn & Coales International Ltd has specialised in the manufacture and supply of corrosion prevention and sealing products for over 90 years. The well-known brands of Denso and Premier offer cost-effective, long-term corrosion prevention solutions. The front cover features their Viscotaq ViscoWrap™ HT system being applied to 350 km of 10 in. and 56 in. diameter field joints on the Master Gas System Expansion Phase III Project in Saudi Arabia.

Antonia Syn Analyst, Commodity Markets Research – Gas & LNG, Rystad Energy

Egypt is rapidly expanding its LNG import capacity – but pipelines will play a critical role in meeting its gas security requirements. The country’s gas balance still hinges on affordable pipeline flows from Israel even amid a flurry of new floating storage and regasification units (FSRUs).

The 12 day shutdown of Israel’s Leviathan field in June 2025 proved the point. When Israel halted exports, 16 million m 3/d – the equivalent of 4 million tpy – stopped flowing through the East Mediterranean Gas (EMG) pipeline. With only one LNG import terminal – the Hoegh Galleon FSRU at Ain Sokhna – already operating at maximum capacity, Egypt could not offset the lost supply. The impact was immediate: fertilizer, petrochemical, and urea plants were cut off within a day, diverting gas toward power generation. Jordan – which relies on Israeli volumes for 60% of its power – rushed to reverse the Arab Gas Pipeline (AGP) to draw emergency flows from Egypt. The disruption exposed how brittle and interdependent the region’s gas grid remains. Even as Egypt races to install more FSRUs, it cannot simply swap the pipelines for LNG.

Falling domestic production since mid 2024 has flipped Egypt from being a net LNG exporter to a net importer. Egypt scrambled to secure new FSRUs to meet peak summer cooling demand. The Hoegh Galleon FSRU arrived in June 2024, followed by the sub chartered Energos Eskimo , which received its first cargo on 15 July 2025. The Energos Power came online on 19 July, with two more – Energos Winter and Energos Force – scheduled for August. With the Hoegh Gandria joining in 4Q26, Egypt’s regasification capacity is set to vastly exceed current pipeline imports. Even so, pipeline flows into Egypt will remain indispensable for two reasons.

Firstly, LNG imports are financially unsustainable for Egypt. Dollar denominated cargoes force Egypt to burn scarce foreign exchange reserves or negotiate deferred payments, deepening its fragile balance of payments. The country remains under a US$8 billion IMF programme, now on its fifth review to unlock another tranche. Yet summer 2025 alone will cost over US$9 billion in LNG imports, plus another US$600 - 700 million for fuel oil. This steep energy bill is expected to strain the country’s foreign exchange reserves further and put downward pressure on the Egyptian pound. New LNG purchases could fuel inflation, increase the cost of other critical imports, and deepen Egypt’s fiscal hole. By contrast, pipeline gas under longer term contracts is cheaper and insulated from volatile LNG spot prices. It is not just affordable – it is financially essential.

Secondly, Israel’s growing gas surplus next door is expected to become ever more accessible to Egypt through planned pipeline upgrades. Leviathan alone already supplies over half of Egypt’s imported gas, at around 14 billion m 3 in 2024. The field’s phased expansion will lift Israeli output from 28 billion m 3 to more than 40 billion m 3 by 2030. Expansion projects at the Tamar field, also exporting to Egypt and Jordan, will further create additional volume Egypt has every incentive to secure. Alternative export options are limited: Israel’s proposed FLNG project was shelved on cost grounds, meaning its surplus gas remains captive to regional pipelines.

Planned pipeline expansions could channel these extra volumes to Egypt. The EMG pipeline connection between Ashkelon and Arish (currently at a capacity of 6 billion m 3) is slated for an additional 2 billion m 3 expansion, while the proposed Nitzana pipeline would add another 6 billion m 3. Meanwhile, the AGP – once designed to export Egyptian gas – can flow in reverse, pulling additional gas from Jordan into Egypt.

when you switch to PipePillo® engineered pipeline supports, the trusted quick and easy replacement for cribbing, foam, sandbags, and pad dirt to keep crews working faster and safer away from the trench.

Whether in or out-of-trench, PipePillos® support your team and your pipe, so your team can stay focused on the job, and not worry about their safety. Contact PipeSak Inc. for engineered pipeline supports, impact protection, saddle bag weights, and all around protection.

Fast, safe & easily stacked

Reliable, versatile, permanent

Won’t float & supports fully loaded pipelines

Proven long-term ovality prevention

Eliminates the need for cribbing, foam, sandbags, and pad dirt

Reduces labor & speeds up your project

MANAGING EDITOR

James Little james.little@worldpipelines.com

EDITORIAL ASSISTANT

Alfred Hamer alfred.hamer@worldpipelines.com

EDITORIAL ASSISTANT

Emilie Grant emilie.grant@worldpipelines.com

SALES DIRECTOR

Rod Hardy rod.hardy@worldpipelines.com

SALES MANAGER

Chris Lethbridge chris.lethbridge@worldpipelines.com

SALES EXECUTIVE

Daniel Farr daniel.farr@worldpipelines.com

PRODUCTION DESIGNER

Siroun Dokmejian siroun.dokmejian@worldpipelines.com

HEAD OF EVENTS

Louise Cameron louise.cameron@worldpipelines.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@palladianpublications.com

EVENTS COORDINATOR

Chloe Lelliott chloe.lelliott@worldpipelines.com

DIGITAL CONTENT COORDINATOR

Kristian Ilasko kristian.ilasko@worldpipelines.com

JUNIOR VIDEO ASSISTANT

Amélie Meury-Cashman amelie.meury-cashman@worldpipelines.com

DIGITAL ADMINISTRATOR

Nicole Harman-Smith nicole.harman-smith@worldpipelines.com

ADMINISTRATION MANAGER

Laura White

laura.white@worldpipelines.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey, GU9 7QU, UK Tel: +44 (0) 1252 718 999 Website: www.worldpipelines.com Email: enquiries@worldpipelines.com

Annual subscription £60 UK including postage/£75 overseas (postage airmail). Special two year discounted rate: £96 UK including postage/£120 overseas (postage airmail). Claims for non receipt of issues must be made within three months of publication of the issue or they will not be honoured without charge.

Applicable only to USA & Canada: World Pipelines (ISSN No: 1472-7390, USPS No: 020-988) is published monthly by Palladian Publications Ltd, GBR and distributed in the USA by Asendia USA, 701C Ashland Avenue, Folcroft, PA 19032. Periodicals postage paid at Philadelphia, PA & additional mailing offices. POSTMASTER: send address changes to World Pipelines, 701C Ashland Avenue, Folcroft, PA 19032.

SENIOR EDITOR Elizabeth Corner elizabeth.corner@worldpipelines.com

Reduced flow has been noted on several US-bound Canadian pipelines following the introduction of US tariffs in March: “Since the announcement, Wood Mackenzie’s real-time pipeline monitoring has detected flow reductions along three major crude systems that deliver Canadian crude to US markets: Southbow’s 590 000 bpd Keystone - Hardisty to Steele City pipeline, TransMountain’s 890 000 bpd TransMountain system, and Enbridge’s 307 000 bpd Express pipeline.”1

Canada is the world’s fourth largest oil exporter, but it sends some 75% of its exports to the US. There is major political momentum towards new pipeline projects and the majority of Canadians support building new oil infrastructure in order to patch this vulnerability, according to a poll conducted by The Globe and Mail.2

Much is happening towards the goal this summer. “Now the real work starts” said Carney as he marked the passage of Bill C-5 on 26 June, which grants powers to the cabinet to fast-track infrastructure projects. At the Calgary Stampede on 5 July, Prime Minister Mark Carney said that a new oil pipeline to Canada’s Pacific coast is set to make it onto the federal government’s list of projects of national interest. “I would think, given the scale of the economic opportunity, the resources we have, the expertise we have, that it is highly, highly likely that we will have an oil pipeline that is a proposal for one of these projects of national interest.”3 Carney added that he also supports a proposed CAN$16.5 billion carbon capture system for Alberta’s oilsands.

The day after Carney’s comments, Alberta and Ontario signed a deal to work together to help fast track investments in energy infrastructure. The two provinces want Ottawa to amend or repeal the Impact Assessment Act, and repeal the Oil Tanker Moratorium Act, Clean Electricity Regulations, the Oil and Gas Sector Greenhouse Gas Emissions Cap, and other federal initiatives that “discriminately impact the energy sector”, said a statement from the Alberta government.

On 22 July, Ontario, Alberta, and Saskatchewan announced a new MoU to construct new pipelines using Ontario steel, and build new rail lines to transport critical minerals from Ontario to Western Canada.

So is a revived Northern Gateway project on the cards? This much debated (and long since cancelled) project remains contentious. Enbridge’s proposed pipeline would have transported oil from Alberta to Kitimat, B.C., for export via tanker. In 2016, the Federal Court of Appeal overturned the Canadian government’s approval of the project, citing inadequate consultation with Indigenous peoples. The new Bill has caused concern among Indigenous communities, who are worried that the government could speed up approvals for infrastructure and energy projects and override legitimate protest.

Reflecting on the cancelled Northern Gateway and Energy East pipeline projects, an article in The Conversation about the case for building new pipelines argues: “On the one hand, any progress that mitigates the significant cost of US tariffs are likely dollars well spent. Building new pipelines strengthens the bargaining power of Canadian producers [...] On the other hand, if the US never follows through on tariffs on energy exports – or if future administrations do not share Trump’s affinity for chaotic trade policy – Canada could end up right back where it started when these projects were cancelled”.4

In this issue of World Pipelines, we focus on construction best practice. Canada almost certainly needs to lay new pipe as part of its quest to lay down its future direction. As the nation seeks its own form of energy independence, it should make a deliberate effort to value legal due process, Indigenous sovereignty, economic foresight, and global climate alignment. Good infrastructure is sometimes built fast, but it is always fair, future-proof, and built well.

1. https://www.woodmac.com/news/opinion/reduced-flow-on-several-us-bound-canadian-pipelines-following-introduction-of-tariffs/

2. https://www.theglobeandmail.com/business/article-canadians-support-building-new-oil-pipeline-poll/

3. https://www.reuters.com/sustainability/climate-energy/carney-says-new-oil-pipeline-proposal-canada-is-highly-likely-2025-07-06/

4. https://theconversation.com/could-new-pipelines-shield-canada-from-u-s-tariffs-the-answer-is-complicated-259660

Across energy and critical infrastructure, we bring expertise where complexity is highest, partnering with globally local teams and leveraging unrivalled proprietary technologies. Like the M-500 Single Torch External Welding System, seamlessly integrated with Data 360 our cloud-based digital platform that analyses, and visualises your project performance data in real time. We move projects forward, no matter the challenge.

We’re here to partner on how our specialist welding and coating solutions can help you power tomorrow.

Sulzer expands operations in Argentina with third facility opening

As part of its ongoing strategy to grow across Latin America and enhance its service offerings, Sulzer has expanded its footprint in Argentina with the opening of a third facility. In addition to a field service hub in La Plata and a main office in the heart of Buenos Aires, Sulzer has recently opened a new rotating equipment service centre in Ezeiza to serve its clients in key industries including oil and gas, pulp and paper, power generation, and food and beverage. This milestone strengthens the company’s local presence and underscores its commitment to supporting customers across the region with greater reach and capabilities.

Sulzer’s new facilities will support essential industries in the region, such as oil and gas, pulp and paper, power generation and food and beverage. The expansion underlines Sulzer’s global

strategy of establishing full-service, in-region capabilities to meet the needs of its industrial customers.

The facility provides a more advanced setup by creating a safer and higher-capacity production facility for customers. In addition, Sulzer is expanding its engineering capabilities to offer pump operators innovative energy efficiency upgrades that reduce emissions by lowering their assets’ power consumption.

Gabriel Skazon, General Manager of Sulzer Argentina said: “The opening of three new facilities in Argentina is a testament to our ongoing commitment to providing our customers in the region with critical manufacturing and industrial solutions and unparalleled service offerings. We are excited about this progress and our growth in Argentina and the broader Latin America region.”

CF Industries announces start-up of Donaldsonville complex CO2 dehydration and compression unit, permanent CO2 sequestration

CF Industries Holdings, Inc. has announced the start-up of the CO2 dehydration and compression facility at its Donaldsonville Complex in Louisiana. The facility will enable the transportation and permanent geological sequestration of up to 2 million tpy of CO2 that would otherwise have been emitted into the atmosphere. ExxonMobil, the company’s carbon capture and sequestration (CCS) partner for this project, will be transporting and permanently storing the CO2

On an interim basis, ExxonMobil is storing CO2 from the Donaldsonville Complex in permanent geologic sites through enhanced oil recovery. Upon receiving its applicable permits, ExxonMobil plans to transition to dedicated permanent storage, starting with its Rose CCS project. Rose is one of many

dedicated permanent storage sites ExxonMobil is developing along the Gulf Coast to expand its integrated CCS network. The US Environmental Protection Agency issued a draft Class VI permit for Rose in July, and final permits are expected later this year.

“The start-up of the Donaldsonville carbon dioxide dehydration and compression facility and initiation of sequestration by ExxonMobil is a historic milestone in our Company’s decarbonisation journey,” said Tony Will, President and Chief Executive Officer, CF Industries Holdings, Inc. “By starting permanent sequestration now, we reduce our emissions, accelerate the availability of low-carbon ammonia for our customers and begin generating valuable 45Q tax credits.”

Sumitomo announces investment in CO2 transportation pipeline project

Sumitomo Corp., through its wholly-owned subsidiary in the UK, Summit Energy Evolution Ltd. (SEEL), has agreed new funding for the development of a CO2 transport pipeline, to support Peak Cluster Carbon Capture project (Peak Cluster). Peak Cluster will capture CO2 from four plants in and around the Peak District, which currently produce 40% of the UK’s domestic cement and lime production, vital for key sectors of the economy including construction, manufacturing and environmental protection. CO2 transported by new-build pipeline will contribute to the industry’s decarbonisation as part of the CCS value chain. Through this investment, Sumitomo Corp. will further promote Energy Transformation, one of the growth areas in its current Medium-Term Management Plan.

SEEL, through its joint venture vehicle Progressive Energy Peak Ltd. (PEPL), has agreed to make equity investment into Peak Cluster Ltd. (PCL), the project company for the CO2 transport pipeline development. National Wealth Fund, the UK government’s principal investor and policy bank, is also making a new investment in PCL.

The planned total investment of £59.6 million will be used to further develop the CO2 transport pipeline project through to a

final investment decision (FID) as early as 2028. This includes the successful completion of FEED and other studies that underpin the regulatory approval and consenting process. Cement and lime are two of the hardest industrial sectors to decarbonise due to the high levels of process emissions which cannot be mitigated through a transition to low carbon fuels. CCS is therefore essential to the decarbonisation of the sector.

The UK is a leading country in the global CCS sector, with the government aiming to capture 50 million tpy of CO2 by 2035. Peak Cluster will decarbonise the UK’s largest group of cement and lime plants, and transport 3 million tpy of CO2, contributing to the realisation of UK Government’s target.

The new build buried onshore pipeline will become part of a full value chain CCS network, which will transport the CO2 emissions captured on industry sites to the coast, to be stored permanently deep under the seabed of the East Irish Sea within Morecambe Net Zero (MNZ) project being developed by Spirit Energy, a UK energy company. Peak Cluster CCS network will help decarbonise hard-to-abate industries and secure the future of this critical industry and safeguard and create 13 000 jobs including the Spirit Energy’s storage.

Strohm has completed successful field trials with Petrobras for its TCP pipe design offshore Brazil, at water depths of approximately 1500 m.

Fugro has announced a partnership with DTACT, a high-tech software company, and Ubotica, a leader in AI-powered satellite intelligence, to develop a unique data fusion and intelligence platform.

NDT Group Inc., a provider of pipeline inspection and integrity services, has adopted the PLXPortable from mechanical testing provider Plastometrex, becoming the first company in Canada to deploy this in-field material verification system.

The Serbian Minister of Mining and Energy attended the signing of a document defining the technical specifications of the Serbia-Hungary oil pipeline.

Intensity Infrastructure Partners, LLC and Rainbow Energy Center, LLC have announced they will jointly develop a natural gas pipeline in North Dakota.

TC Energy has announced that it has commenced the collection of tolls from the Comisión Federal de Electricidad (CFE) for the Southeast Gateway pipeline.

ANYbotics, provider of AI-driven robotic inspection solutions, has launched a new gas leak and presence detection solution for its ANYmal robot, aimed at changing how industrial sites identify and manage costly and hazardous gas leaks.

Tallgrass announces commencement of open season for new natural gas pipeline from the Permian Basin to multiple markets

Tallgrass has announced the launch of a binding open season, commencing 21 July 2025, to solicit commitments for firm transportation service on its previously announced pipeline project from multiple points of receipt in the Permian Basin to Rockies Express Pipeline markets and points of delivery specified in accordance with the

open season terms.

The new pipeline project is unique in that it will enable natural gas to access markets broadly across the US, including multiple major markets that are key hubs of activity for industrial, agricultural, and data centre development.

France’s NaTran and Teréga and Spain’s Enagás launch hydrogen pipeline joint venture for H2med project

Spain’s Enagás – through its affiliate Enagás Infraestructuras de Hidrógeno (EIH) –alongside France’s NaTran and Teréga have announced the signing of a Shareholders’ Agreement, which establishes the creation of a joint venture dedicated to the development of the BarMar, Project of Common Interest (PCI), the renewable hydrogen pipeline that will connect Barcelona, Spain, to Marseille, France - a key part of the H2med project, alongside the CelZa project. This major new step, coming one year after the signing of a Joint Development Agreement in June 2024, provides a clear structure and accelerates the implementation of this essential component of the EU’s first clean hydrogen corridor, which aims to cover 10% of Europe’s hydrogen consumption by approximately 2030.

The new company, which will be based in the South of France, in Région

Provence-Alpes-Côte d’Azur, defines the project’s governance structure. The shareholding is distributed as follows: EIHEnagás with 50%, NaTran with 33.3%, and Teréga with 16.7%. This split reflects the overall balance of the H2med project, which is shared 50% by Spain and 50% by France. Mr. Francisco Pablo de la Flor, from Enagás, has been appointed as the new entity’s Chief Executive Officer (CEO). This was announced eight days after European support was reconfirmed during a high-level meeting between the leaders of the five companies involved in the H2med project and the Executive Vice-President of the European Commission, Ms. Teresa Ribera, who oversees the Green, Just, and Competitive Transition.

The project’s momentum is further solidified by the recent signing of Grant Agreements with the European Climate,

Infrastructure and Environment Executive Agency (CINEA) for the BarMar and CelZa (Celorico–Zamora) projects. The funding secured represents 100% of the funds requested under the Connecting Europe Facility (CEF) and covers 50% of the development costs.

Arturo Gonzalo, CEO of Enagás, commented: “The creation of this joint company embodies our collective commitment and determination to deliver this vital energy infrastructure for Europe. This marks the beginning of a new operational phase that will allow us to tackle the technical and regulatory challenges with an integrated team and a common goal: making H2med a reality.”

Sandrine Meunier, CEO of NaTran, said: “This new joint company provides the necessary framework for the longterm development of the BarMar hydrogen pipeline, a key component of the H2med project. It also gives concrete form to cross-border cooperation in developing strategic energy infrastructure to decarbonise our industries. Based in France, the BarMar company is now a place where all partners’ expertise in hydrogen transport will converge to foster a new phase of Europe’s energy.”

Carolle Foissaud, CEO of Teréga, commented: “The announcement of the BarMar company anchors H2med at the heart of Europe’s energy sovereignty and enables the achievement of carbon neutrality goals. The European funding testifies to the confidence placed in our joint expertise. Along its partners, Teréga is fully mobilised to make this European clean hydrogen corridor a success for the decarbonisation of our industries and regions.”

Induction Heating Generators & Coils

STOPAQ®: Visco-elastic systems

COVALENCE®: Heat shrinkable multi-layer sleeves

BORE-WRAPTM: sacrificial Abrasion Resistant Outerwrap (ARO)

9 - 13 September 2025

McDermott awarded offshore contract by Brazil’s BRAVA Energia

Gastech Exhibition & Conference

Milan, Italy

https://gastechevent.com/

23 - 24 September 2025

Subsea Pipeline Technology Congress

London, UK

https://sptcongress.com/

8 - 10 October 2025

Carbon Capture, Utilization and Storage (CCUS) Conference

Houston, USA

https://www.woodmac.com/events/carboncapture-utilization-storage-conference/

21 - 23 October 2025

Carbon Capture Technology Expo

Europe

Hamburg, Germany

https://www.carboncapture-expo.com/

3 - 6 November 2025

ADIPEC

Abu Dhabi, UAE

https://www.adipec.com/

19 - 23 January 2026

PPIM 2026

Houston, USA

https://ppimconference.com/

15 - 19 March 2026

AMPP Annual Conference + Expo

Houston, USA

https://ace.ampp.org/home

27 - 30 April 2026

Pipeline Technology Conference (PTC)

Berlin, Germany

https://www.pipeline-conference.com/

4 - 7 May 2026

Offshore Technology Conference

Houston, USA

https://2026.otcnet.org/

McDermott has been awarded an offshore transportation and installation contract by Brazil’s BRAVA Energia for the Papa-Terra field in the Campos Basin and the Atlanta field in Block BS-4 within the Santos Basin, both offshore Brazil.

Under the contract scope, McDermott will execute the transportation and installation of flexible pipelines, umbilicals, and associated subsea equipment for two new wells at the Papa-Terra field and two new wells for the Atlanta Phase 2 development. The scope also includes

pre-commissioning and onshore base support services.

“This award highlights the vital role of subsea infrastructure in enabling long-term production and asset value for deepwater developments,” said Mahesh Swaminathan, McDermott’s Senior Vice President, Subsea and Floating Facilities. “We will leverage our proven integrated delivery model, marine capabilities and expertise in delivering brownfield deepwater solutions to support Brazil and the broader South American offshore market.”

Bridger Photonics announces methane leak detection contract with Pacific Gas & Electric

Bridger Photonics Inc. has announced it is working with Pacific Gas and Electric Company (PG&E). Bridger’s technology will help PG&E to detect and repair system leaks and reduce methane emissions across its natural gas distribution pipeline system.

“PG&E’s utilisation of Bridger’s advanced aerial leak detection technology represents a significant step forward in reducing risk on

our natural gas system and in lowering methane emissions,” said Jeff Janvier, Lead of Gas Distribution Operations at PG&E.

“This sensor enables us to accurately pinpoint leaks on our system from an aerial platform, including precise measurement of flow rates, thus mitigating safety risk and reducing methane emissions in a prioritised manner.”

Tekmar Group plc has announced the award of a contract to supply bespoke subsea infrastructure technology for a pipeline project via a major offshore EPC contractor operating in the Middle East. The base case scope is valued at approximately £2 million, the full amount of which will be recognised in the current financial year. This covers the design and manufacture of specialist reinforced concrete support structures for a large-diameter gas pipeline. There is also potential for additional scope supporting

the broader requirements of the project. Delivery is scheduled to be completed by September 2025.

Richard Turner, CEO of Tekmar Group, commented: “We are delighted to have been selected for this significant project in the Middle East, which remains a key market for the Group. As an existing customer of Tekmar, it underscores the trust our customers have in our technical expertise and our ability to deliver high-value infrastructure solutions worldwide.”

Subsea7 has announced the award of sizeable contract offshore Egypt. Subsea7 will be responsible for the engineering, procurement, commissioning, and installation of flexible pipelines, umbilicals, and associated subsea components for a tie back to existing infrastructures. Project management and engineering work will begin immediately at Subsea7’s offices in France, Portugal, and Egypt. Offshore activity is expected to start in 2026.

David Bertin, Subsea7’s Senior Vice President GPC East, said: “Our early engagement has been instrumental in shaping a shared vision and delivering innovative, efficient solutions. This award is a testament to the strength of our collaboration, our proven track record, and our commitment to safe, high-quality execution. We are pleased to be able to support our client in enabling and executing such a strategically important project in Egypt.”

• Two-thirds of pumps run inefficiently, Sulzer reveals – with millions in energy savings left untapped by industrial operators

• Wabtec finalises acquisition of Evident’s Inspection Technologies division

• DNV advances JIP to enable safe CO2 pipelines for CCS

• Connected by pipeline: Marathon and Osage Nation find success

• FET to provide UAE-based offshore construction firm with two work class remotely operated vehicles

• Qapqa has signed a contract for the supply of automatic welding equipment and services

• John Crane launches new dry gas sealing solution

• Joseph Gallagher to deliver trenchless crossings on Liverpool Bay CCS project

Ntorya to Madimba pipeline contract awarded

Aminex has announced that the Tanzania Petroleum Development Corp. (TPDC) has awarded an EPC contract for the construction of the gas pipeline from the Ntorya gas field to the Madimba gas processing plant to China Petroleum Pipeline and China Petroleum Technology & Development Corp.

Charles Santos, Executive Chairman of Aminex commented: “We are delighted to receive confirmation of the award of the EPC contract for the construction of the Ntorya to Madimba Pipeline. This is a major milestone, reflecting the commitment of the Tanzanian government to progress the project, and follows the signing of a Gas Sales Agreement, the award of the

Development Licence that locks the project in for 25 years, and the update of a Field Development Plan with upgraded production figures – all in the past 18 months.

“The signing of the contract demonstrates the Tanzanian government’s conviction of Ntorya’s enormous value to Tanzania as a world class gas resource that will help alleviate energy poverty, boost industrial development and improve the lives of ordinary people. A conviction that we share at Aminex.

“We thank the TPDC and all Tanzanian agencies for working together to reach this major milestone and look forward to providing a more detailed update to the market as soon as we can.”

SLB OneSubsea secures EPC contract for Northern Lights CO2 transport and storage project expansion

SLB has announced the award of an engineering, procurement and construction (EPC) contract by Equinor (Technical Service Provider) to its OneSubsea™ joint venture for a CO2 subsea injection system for the Northern Lights phase two project offshore Norway.

The final investment decision for phase two was made by the Northern Lights’ owners TotalEnergies, Shell and Equinor following a commercial agreement with an end-use customer, marking a decisive milestone for the adoption of carbon capture and storage (CCS) at scale. The SLB OneSubsea scope includes two new satellite subsea CO2 injection systems with associated tie-in equipment. Work

has already commenced, with first deliveries expected in 2026.

“Equinor’s enduring commitment to subsea standardisation is now yielding substantial benefits across new offshore value chains, including CO2 storage. By utilising standardised components, we achieve reduced risk and economies of scale, which enhance both traditional and innovative subsea projects,” said Mads Hjelmeland, CEO, SLB OneSubsea. “The Northern Lights project is pivotal for Europe’s path toward net-zero emissions, and it is well aligned with our own strategy to expand the frontiers of subsea for a sustainable energy future.”

ROSEN (UK) Ltd has secured a major contract to provide design verification and subsea engineering support for one of the UK’s most significant carbon capture projects.

As part of this contract, ROSEN will conduct comprehensive design verification of the project’s CO2 transportation pipelines, ensuring they meet the highest safety, reliability, and performance standards. ROSEN’s engineering expertise will support the client to reengineer and repurpose pipelines for carbon storage. This collaboration, which began in

early 2025, marks the start of a two-year partnership, with potential for further projects as the UK accelerates its transition to net-zero emissions.

Gordon Blair, Business Development Manager, commented: “We are proud to be part of a project that is shaping the future of the UK’s energy sector. Our deep expertise in pipeline verification and subsea engineering ensures the infrastructure supporting carbon capture is both safe and efficient.”

Walter Crommelin, Nick Homan, Kalen Jensen, and Sean Keane, four key leaders at the Pipeline Research Council International (PRCI), came together to explore current research priorities, safety standards development, environmental concerns, and workforce development initiatives in order to effectively prepare for the future.

With ageing infrastructure requiring enhanced safety management and new energy commodities demanding innovative transport solutions, the need for coordinated research and knowledge transfer has never been greater. The Pipeline Research Council International (PRCI) has emerged as a collaborative platform, bringing together operators, service providers, and technical experts to address these complex challenges through seven decades of practical, science-based research.

The collective perspectives of PRCI’s current Executive Board illuminate how it is driving innovation while maintaining its commitment to safety, reliability, and environmental stewardship. This roundtable discussion features insights from Walter Crommelin, PRCI Chair (Gasunie); Nick Homan, PRCI Vice Chair (Marathon Pipeline); Kalen Jensen, PRCI Research Steering Committee Chair (ATCO); and Sean Keane, PRCI Research Steering Committee Vice Chair (Enbridge).

With evolving technologies, changing regulatory landscapes, and increasing environmental concerns, organisations like PRCI are at the forefront of addressing these challenges to help shape the future of the pipeline industry – what are the current priorities for pipeline research at PRCI?

Walter Crommelin (Gasunie)

The pipeline industry is navigating a range of complex challenges, which directly shape PRCI’s research priorities. Operators must deal with aging pipelines and ancillary systems under increased public scrutiny while considering their role in the energy transition toward a carbon neutral society. These challenges are interconnected – pipeline operators can only participate in the energy transition if they demonstrate capability in managing current infrastructure safely and reliably.

enhances problem-solving, and

leading to more creative and effective solutions. Working together allows teams to combine strengths and tackle challenges more effectively. Ultimately, it is a powerful tool for achieving goals that would be difficult to attain alone.

Figure 2. Researchers and graduate students work together on an experimental setup to enhance natural gas soil aeration systems, improving safety and reducing methane emissions. This hands-on collaboration supports PRCI’s mission to develop the next generation of skilled pipeline professionals.

Walter raises an excellent point about that interconnection. What we’re seeing at PRCI is research portfolios increasingly targeted at addressing gaps that will have the largest impact across member jurisdictions. We focus on practical research that furthers knowledge, reliability, safety, and operating efficiency precisely because we can’t separate current operations from future needs.

That’s right, Kalen. The research within PRCI is diverse, spanning the full pipeline lifecycle, but it’s all focused on closing gaps related to safe, reliable, environmentally sound, and cost-effective pipeline transportation of energy. Our current priority areas – emerging fuels, efficient and effective crack management, greenhouse gas (GHG) emissions reduction, and optimising the detection and mitigation of mechanical damage – reflect that dual focus Walter mentioned.

Building on what Sean outlined, PRCI’s mission centres on producing research to promote safe, reliable, sustainable pipeline systems. What is particularly exciting is how those research priorities now encompass both traditional hydrocarbon energy-based pipeline transmission and future energy commodities like hydrogen and CO2 through the Emerging Fuels Institute (EFI). Our technical committees execute research projects that evaluate technology and techniques to address asset integrity threats, reduce emissions, and improve equipment performance – addressing both sides of Walter’s equation.

Ensuring the safe and reliable transportation of energy resources depends on maintaining pipeline safety and integrity. What role does PRCI play in advancing standards and best practices to uphold these critical priorities?

PRCI represents a collaboration of many different companies, both operators and service providers. Our research results are validated by these groups, ensuring high quality and reliability – exactly what standardisation needs to be effective. The results aren’t based on the opinions of a few but on the substantiated results supported by many.

That collaborative validation is crucial. PRCI focuses on practical, scientifically robust solutions to tangible industry problems. What makes this approach unique is that the projects and solutions are vetted by operators, service providers, and industry associations – the same parties that develop consensus-based standards supporting safe and reliable pipeline operation worldwide.

Installation in less than an hour.

PETROSLEEVE® is a steel compression repair sleeve that neutralizes threats faster, safer and more cost-effective than traditional methods.

Keane

Kalen’s point about practical solutions really resonates with our experience. As an operating company, much of our PRCI-funded research relates to improving safety and integrity practices across design, construction, operation, and abandonment. The research engages industry experts to set scope and provide feedback through completion, but crucially, independent experts design and conduct the research to protect against biased outcomes.

Sean touches on something important about independence leading to credible outcomes. PRCI research has become the basis for numerous American Petroleum Institute Recommended Practices (API RP). For example, our research on mechanical damage contributed to API RP 1183: Assessment and Management of Pipeline Dents. What Walter said about the council’s structure is key – any member can seek reevaluation or enhancement of results, which continuously improves industry standards. Our research also forms the basis for pipeline engineering software solutions and the PRCI Pipeline Repair manual, making the knowledge practically accessible.

With the global shift toward cleaner, more sustainable energy solutions, organisations in the energy sector are under growing pressure to tackle critical environmental and safety challenges. How is PRCI rising to meet these demands, particularly in reducing GHG emissions and improving pipeline safety as part of the energy transition?

Keane

The energy transition has focused attention on reducing GHG emissions and risks associated with potential leaks. What’s encouraging is that this focus aligns well with ongoing and planned research portfolio.

Jensen

Sean’s right about that alignment, and I think it also demonstrates PRCI’s adaptability. We’ve shown flexibility in responding to changing industry needs through establishing Strategic Research Priorities (SRP) and the EFI. This pivot in research execution mechanisms and targeted research portfolio creation has enabled rapid, holistic execution of project portfolios addressing challenges facing our members and the industry.

Crommelin

The EFI has been transformative over the past four years by initiating substantial projects that address major issues with emerging fuels. PRCI research now examines existing oil and gas pipeline systems along with hydrogen, biogas, and CO2 systems associated with the energy transition. For existing systems, there’s ongoing research into preventing and detecting GHG emissions, helping operators reduce environmental impact while keeping more commodity in the pipeline.

Homan

Walter’s point about the dual focus is exactly what we’ve implemented. PRCI recently completed an SRP focused on GHG emission reduction, providing options for natural gas transmission pipeline operators to identify and reduce emissions from compressor stations and pipeline maintenance activities. Simultaneously, the EFI has completed research on asset integrity improvements required to introduce hydrogen and CO2 into existing pipeline transmission systems. It’s that comprehensive approach Kalen described in action.

With growing emphasis on renewable energy sources, carbon capture technologies, and reducing environmental impact, organisations must adapt to remain relevant. How is PRCI preparing for the future energy transition, including the shift towards renewable energy sources and carbon capture technologies?

Jensen

The EFI’s creation and successful promotion has enabled systematic execution of alternative fuels projects at an unmatched pace. Its thoughtful structure and governance has enabled rapid transitions from shifting to alternative fuels to the transport and storage of captured carbon, helping the pipeline industry meet energy transition demands across all member organisation jurisdictions.

Keane

Kalen’s right about the pace. To tackle the challenges from the shifts toward ammonia, biofuels, carbon capture and sequestration, hydrogen, and renewable natural gas, PRCI created the EFI specifically because no single organisation could address these challenges alone. It brings together global expertise to strengthen research collaborations, transfer knowledge, and enable partnerships to fund and prioritise research, leading to key knowledge updates, standards development, and training creation.

Crommelin

That is exactly why the EFI model works so well. It allows members interested in energy transition to pool resources and collaboratively push research in areas where they see greatest value while the existing PRCI structure provides all members the optionality to continue improving upon existing systems. This dual approach allows PRCI to flexibly respond to industry changes while bringing like-minded operators together and preventing unnecessary research duplication.

The consortium approach Walter and Sean describe is essential. PRCI created the EFI as a research consortium allowing interested pipeline operators to pool resources and complete research projects needed to ensure safe pipeline operations when transporting new energy sources in pipeline infrastructure. What Kalen mentioned about the systematic execution – that’s only possible because of the collaborative structure and shared investment model.

catgroup.net

As the energy industry evolves, pipeline infrastructure faces increasing demands to adapt to new technologies, stricter environmental regulations, and shifts in energy sources. With renewable energy and hydrogen gaining traction alongside traditional oil and gas, what are the anticipated challenges and opportunities for pipeline infrastructure over the next 25 years?

Jensen

Repurposing existing aged infrastructure to meet decarbonising economy needs while meeting growing population energy demands presents a generational challenge. This requires creative, robust technical solutions that uphold the reliability customers depend on, all while maintaining an unwavering commitment to safety.

Keane

Kalen touches on the infrastructure challenge, but I’d add that digital innovation opportunities are evolving just as quickly. Artificial intelligence (AI) for interrogating massive, complex data is already reshaping the toolset for managing infrastructure through all lifecycle phases. With these opportunities come new challenges in cybersecurity, data privacy, and workforce training needed for digital adoption.

Crommelin

Both Kalen and Sean bring attention to key challenges in the evolving fuel landscape. Significant progress is still needed to develop efficient transportation methods for various energy carriers. The future envisions a diverse mix of energy sources –both molecular and electrical – tailored for different applications. Achieving this vision will require substantial infrastructure development to ensure users have access to the most suitable energy options for their needs. This task becomes even more complex in densely urbanised areas, where safety and practicality are of utmost importance.

Homan

Walter’s description of a mosaic perfectly illustrates the complexity we’re navigating. Achieving zero pipeline safety incidents remains our ultimate goal, but research must keep advancing to address emerging threats and anticipate the unknown. As asset integrity challenges evolve – whether from external factors like geohazards or the integration of new energy sources such as hydrogen –pipeline research must adapt accordingly. Sean’s emphasis on digital tools highlights their critical role, but as Kalen pointed out, we also need innovative, resilient technical solutions that uphold reliability while tackling the decarbonisation challenges.

The pipeline industry requires a skilled workforce to ensure safety, efficiency, and innovation. As the industry evolves with new technologies and regulations, what initiatives are in place to support workforce development and training in the pipeline industry?

Cultivating new talent and preserving domain expertise throughout the careers of pipeline professionals are essential to the industry’s long-term success. Recognising this, organisations like PRCI have

introduced comprehensive engagement initiatives designed to support the growth and development of as many operators as possible.

Crommelin

Kalen’s point about career-long development is especially critical now. The workforce is changing because many of the talented individuals who ‘grew up’ alongside developing pipeline systems have retired. A younger generation must now maintain existing and build future pipeline systems with fewer opportunities to learn from experience and mistakes. PRCI is uniquely positioned to support workforce development through applied research by providing guidelines, best practices, and technical evaluations that are applicable to dayto-day pipeline system operations.

With the development of the PRCI Academy, we’re making research more accessible as part of a larger framework for helping individuals understand prerequisites and follow-ups needed to become subject matter experts. This leverages years of research for anyone entering the industry and contributing to keeping society running smoothly, safely, and sustainably.

Walter’s mention of the PRCI Academy is an exciting development that builds on our existing achievements. At PRCI, knowledge transfer is a strategic priority. We’ve established in-person and online training programs covering a range of pipeline research topics such as pipeline repair fundamentals, managing geotechnical hazards, and nondestructive examination training for long seam evaluation, providing foundational knowledge for engineers and technicians.

The Academy framework takes this effort to the next level, offering a more systematic and comprehensive approach to training. It directly addresses the need for career-long professional development, as highlighted by Kalen, ensuring industry professionals have access to the tools and knowledge they need to succeed at every stage of their careers.

The insights shared by PRCI’s leadership highlight its role as a driving force in transforming the pipeline industry. PRCI’s Emerging Fuels Institute (EFI) reflects its commitment to strategic research, workforce development, and industry standards during a transformative era in energy. Aligned with its Strategic Resource Priorities (SRP), PRCI focuses on sustainability, efficiency, safety, and innovation. Through initiatives like the PRCI Academy and specialised training programmes, PRCI drives research and equips the next generation of pipeline professionals to meet the industry’s evolving needs.

Striking a balance between addressing the immediate challenges of aging infrastructure and fulfilling the longterm demands of the energy transition, PRCI continues to solidify its reputation as the pipeline sector’s leading research collaborative. The future of pipeline infrastructure hinges on the kind of coordinated, science-driven approach PRCI has championed throughout its history.

The S SETTANTA PIPELINER combines Laurini’s legacy of equipment innovation with a modular boom and stick design for unmatched versatility across multiple industries. Featuring a compact footprint with massive lifting power, a hydraulic high-rise cab, and full integration with the D DECKHAND® pipe handling system by LaValley Industries, the S SETTANTA is purpose-built to handle pipe with precision.

• H Hydraulically actuated variable gauge undercarriage gives you 360° full reach for superior maneuverability and stability

• H Hydraulic high-rise cab enhances visibility for stockpiling, loading/unloading trucks and rail cars

• I Integrated DECKHAND® pipe handling system increases safety, control and productivity in any condition

• H Heavy lifting on a smaller chassis allows for 2 25% more lift capacity than a similarly-sized excavator

• M Modular front-end design features quick disconnect boom and stick system with fully automatic electronic and hydraulic connections for any application

In the left pictures: 2 PIECES DIGGING BOOM

3 PIECES DIGGING BOOM

Vinay Baburao, Director Digital Transformation, CRC Evans, explains how digital technology is delivering next generation pipeline services data management.

Digital technologies are set to play a transformative role in the sectors in which we operate. While historically slower to adopt new technologies, the industry is now undergoing a rapid shift – driven by the growing influence of cloud computing, artificial intelligence, Internet of Things (IoT), and automation. These advancements are empowering organisations to predict, adapt, and optimise in ways that were unimaginable just a decade ago.

One of the key benefits being achieved across all areas of activity is the greatly enhanced access to data – how it is collected, collated, the way in which it can deliver realtime information and results, and how this in turn is bringing significant benefits to the industry.

In the pipeline welding, technology, and coating services field for example, data management across the pipeline lifecycle has tended to be fragmented and reactive. Critical information from stakeholders such as pipe mills, welding crews, coating teams, and non-destructive testing (NDT) providers are often siloed – if collected at all. In many cases, data is only compiled after project completion, severely limiting its value for real-time decision-making or quality assurance.

Field teams typically have had to rely on spreadsheets, paper logs, and lengthy email chains, creating a patchwork of disconnected records. These traditional methods led to significant inefficiencies, data loss, and reporting delays, especially across geographically distributed projects. The absence of integrated, real-time data not only hindered operational transparency, it also made it difficult to anticipate issues or drive continuous improvement.

While partial digital solutions are available on the market, they have not yet achieved cutting edge advancement. Typically, they focus on digitising inspection data through manual entry or document uploads at various stages of production. In most cases, users input information into mobile or web platforms after the fact, which still introduces delays, inconsistencies, and missed opportunities for real-time insights.

Taking the various shortcomings into account, it was clear there was a need for a system of data management that would make a transformative shift from retrospective data gathering to a system that would engender proactive, connected decision-making.

Initially conceived in response to meet a specific project requirement off the coast of Guyana during 2023 - 2024, where the need to capture weld data from our equipment became a critical operational priority, CRC Evans developed the DATA 360 data management platform.

Engaging in deeper conversations with clients and industry stakeholders confirmed this was not an isolated need. There was a significant gap in the market for a truly integrated, domain-specific platform capable of digitising and connecting every stage of the production lifecycle – from welding to NDT.

A next generation solution, the platform is fundamentally different from the partially digital solutions available on the market, delivering true end-to-end integration, consolidating

material traceability, welding, coating, and NDT into one unified platform.

Rather than relying on fragmented tools, it provides a purpose-built digital ecosystem tailored to the complex demands of pipeline and fabrication projects, automatically capturing data directly from welding and coating machines as production occurs.

This real-time data flow replaces manual logging and ensures immediate visibility, accuracy, and operational intelligence. In comparison to other systems that digitise after the fact, DATA 360 digitises in the moment – transforming how data is collected, connected, and used to drive smarter, faster project execution.

It leverages a suite of cutting-edge digital technologies designed to transform how energy infrastructure is planned, executed, and analysed. These technologies don’t just digitise data, they enable a more intelligent, connected, and predictive approach to project execution:

) Cloud computing ensures secure, scalable access to project data from anywhere in the world, enabling collaboration across global teams.

) AI and optimisation algorithms power PipeFitter, a solution for pipe stalk configuration, dramatically improving fitment efficiency and material usage.

) AI-based geospatial clustering is used to intelligently assign unique joint IDs by analysing GPS data, reducing errors, and enabling automatic traceability.

) IoT integrations connect directly to welding and coating machines, capturing production data in real time, eliminating manual entry and unlocking live operational insights.

) A mobile-first architecture empowers field teams to report and access critical information instantly, streamlining workflows and improving responsiveness

At the heart of the platform is a vision to create a digital twin of the energy infrastructure as it’s being built – a living, evolving model that mirrors the physical asset and unlocks powerful capabilities in traceability, quality assurance, and lifecycle management. In short, it doesn’t just collect data, it builds intelligence into the infrastructure itself.

It is now being deployed across multiple global on- and offshore projects, with feedback confirming it is delivering a wide range of benefits, helping clients improve operational efficiency, ensure compliance, and reduce project risk.

Its application is relevant across various sectors where production complexity and traceability are critical to success, particularly for industries that operate under strict regulatory standards and demand end-to-end visibility across the asset lifecycle. This includes oil and gas pipeline construction, offshore wind and renewable energy projects, and process plants and fabrication yards – places where high-volume, high-precision welding and material tracking are essential, and infrastructure projects involving pressure piping or regulated welds.

Some of the core advantages include:

) Improved productivity through faster data reporting and reduced rework.

) Complete material and weld traceability to meet stringent regulatory standards.

) Real-time monitoring of production and asset performance.

) Elimination of delays caused by manual paperwork or miscommunication.

) Data-driven decision-making for better planning and resource allocation.

) Increased transparency across all project stakeholders.

No difficult-to-inspect pipeline should be left behind.

Whether you're dealing with short or extremely long pipelines, or you require ultra-high resolution, or high inspection speed.

Our Surveyor UT ILI family is designed to handle it all.

Explore what our ILI technologies can do for you.

In a welding project, the ability to swiftly identify the root cause of defects and minimise downtime is of utmost importance. The vast amount of data generated during welding poses a challenge, as it requires significant time to collect and analyse data from every station and welding system.

This process becomes even more complex when welds are not tagged, making problem identification more difficult. Therefore, a solution that can streamline this data analysis process is crucial for reducing downtime and improving efficiency in welding projects.

DATA 360 revolutionises how welding data is handled. By wirelessly collecting and hierarchically collating data it presents a comprehensive overview to the user. This system’s ability to indicate if data falls within the set limits of welding parameters could be a game changer in identifying and resolving issues in a few minutes.

Identifying the issues during production is only one of the benefits; the data collected is helpful in the extracting operational insights about the project. Furthermore, the welding data and defect data can be fed into a machine learning model, which can predict the defect before it happens and control the parameters with which we weld.

Incorporating cutting-edge digital technologies provides expedited access to production data, improved analytical capabilities, and precise data tagging.

This reduces downtime and minimises the number of inspection personnel required to extract, transform, and analyse data. Additionally, the platform serves as a data repository of as-built documentation for customer infrastructure, with data curated and ready to use for compliance needs.

The DATA 360 platform enables real-time monitoring of production activities during welding, coating, and inspection. It utilises long-range Wi-Fi communication, which allows for the wireless downloading of logs from all stations and evaluates the status of joints based on the parameters established during the qualification process.

At a time when clients are under growing pressure to improve compliance, efficiency, traceability, and sustainability, platforms such as DATA 360 respond to those needs – not just as a product, but as a transformation tool for how projects are executed and managed in the digital age.

Some real-world examples include:

) Reducing downtime through real-time weld verification: in a recent offshore project, compliance required validating weld parameters after each pass before moving to the next station. Traditionally, this would have meant a technician had to manually download data from each welding machine, analyse it on-site, and confirm compliance – a process that could take 15 - 20 minutes per joint. The welding module in DATA 360 provides automatic verification in under 30 seconds, eliminating delays and human error.

) Accelerating regulatory compliance reporting: compiling final documentation can be a significant burden for projects with strict regulatory oversight. The platform can reduce the timescale from months to weeks.

) Reducing manpower and exposure on the firing line – traditionally, field teams would need to physically monitor the production line, manually collecting data on each joint. Integrated IoT-enabled systems capture this information automatically in real time, reducing the number of personnel required, minimising exposure to hazardous environments.

The advent of digital transformation is not just crucial for end-users, it is increasingly imperative for businesses to reinvent how they work to ensure they remain relevant, current and fit for the purpose of servicing modern day requirements.

As we look to the future as an industry, there is immense potential to build intelligent tools that can provide real-time guidance, automate analysis, and support decision-making in the field.

CRC Evans is also exploring how Physical AI can be embedded into core equipment, making machines not just connected, but context-aware and self-optimising.

This convergence of operational data and intelligent systems will mark a new era for the industry – one where digital technology doesn’t just support the work, but actively enhance it. The future is not about replacing human expertise, it is about amplifying it with the right data, at the right time, in the right way as, we lay the foundation for that future today.

Vinay Baburao, Director of Digital Transformation, CRC Evans, leads enterprise-wide innovation initiatives through the development and deployment of transformative digital platforms. He has more than 17 years of cross-industry experience spanning industrial products, elevators, and medical devices. His work focuses on harnessing data-driven tools, automation, and connected technologies to modernise field operations, enhance traceability, and deliver measurable efficiency gains.

When your pipeline shares a right of way with high-voltage power lines, the electromagnetic field on the power lines can induce unwanted voltage onto the pipeline, creating a safety hazard for personnel and contributing to AC corrosion problems. Dairyland decouplers provide an effective grounding path that mitigates induced AC, while simultaneously maintaining DC isolation to optimize your CP system. With a Dairyland decoupler, your CP system will continue to work efficiently, and the pipeline and personnel will be safe from AC interference.

Let us help you find the right solution for your AC Mitigation problems.

Mainline Pipeline

Direct Pipe®

Horizontal

Directional Drilling

Gas Distribution

Facilities Construction

Pipe Fabrication

Maintenance & Emergency Repairs

World Pipelines interviews Raghu Yabaluri, Global Oil and Gas Market Leader, Black & Veatch, on the current state of energy security for pipelines, and the pressure points to which we must pay attention.

How do we best approach protecting complex oil and gas pipeline infrastructure? What do we need to take into account as we survey the magnitude of the task at hand?

Raghu Yabaluri: We need to take a more holistic approach and evaluate various threats from a physical, digital, legal, and societal lens.

Let’s start by looking at physical operational threats that can lead to significant safety and environmental issues. Leaks, for instance, can create major issues – financial and reputational – for companies. There are also physical threats: bad actors scheming to interfere with pipelines and their systems, as well as natural disasters that create major disturbances to the infrastructure itself.

Another dimension to consider is how we protect both existing and new infrastructure in a digital world. Many companies are modernising their systems via AI, automation, and other technologies. As they do, they must make sure that they modernise in terms

of both value and security. If I can easily operate my machine remotely, then a bad actor can easily operate my machine remotely, too.

Cybersecurity threats have increased recently, and will only increase further. When we were all offline, we didn’t have as many risks. As we started integrating online, we saw hacks, such as the Colonial Pipeline issue, where bad actors broke into an IT system. Colonial had to shut down the entire pipeline, the lifeline for the Northeastern US. As we continue integrating OT with IT systems, threats will increase even more.

Thirdly, the concept of right-of-way (ROW) is critical. Virtually everywhere we build pipelines, we get a ROW, or lease, for a particular amount of time from the landowners or the government. There is always a possibility that they revoke a lease and cease our ability to operate. So we must be mindful of several factors, including how to interact with communities, to maintain these privileges.

We recommend a ‘big tent’ approach: engage the communities and landowners at the earliest stages of development. Consider how those communities are going to react to having a pipeline on or near their land, not just today but in 10 - 20 years. For instance, the community may require a financial stake in the pipeline. In Canada, 23 First Nations communities brokered such an arrangement with the Enbridge West Coast Pipeline project.

Given the complexity of global energy supply chains, how can pipeline infrastructure be more resilient to disruptions (natural and manmade)?

RY: Resilience starts with comprehensive, accurate, and continuous evaluation of the man-made and natural risks to the infrastructure and overall markets, as well as the creation of dynamic risk management. Many projects fail because operators conduct a risk management exercise that is static, not dynamic, in nature. When you don’t know the unknowns, or don’t plan for them, they eventually will reveal themselves with disastrous consequences. Keep your evaluation process dynamic by actively looking for signals that make you better informed about future risks.

Consider the Russia to Europe pipeline [Nord Stream I and II], an asset taken for granted worldwide for decades. In reality, there were plenty of risk signals for years. With dynamic evaluation, mitigating actions could have been implemented a few years ago and saved untold consequences.

With cybersecurity, new and different types of attacks emerge virtually every day. You might not always be able to predict a particular attack. But one should continuously learn from the developments and attacks in other industries, too –and adapt quickly. If you are breached, it’s important to react quickly to minimise any impact. Change your risk management accordingly. For this, you may need to make your infrastructure resilient to new cyber threats and make necessary investments.

What are the most pressing vulnerabilities in energy supply chains?

RY: We have witnessed several pressing vulnerabilities in the past decade. First, we’ve seen a shift in global political environments and markets (e.g. Russian gas to Europe).

We’ve also seen a shift in energy demand from fossil fuels to cleaner energy and now back to gas in some parts of the world. Cyberterrorism has shut down critical international infrastructure operations and forced some to pay significant ransoms. Ignoring asset integrity and ineffective network control have resulted in high-consequence incidents, such as a spill some years ago that led to 1 million gal. of bitumen leaking into an American river.

Expanding on a couple of issues, the shift in energy demand was widely misread. Five years back when people started talking about energy transition, some said “let’s not invest in any more oil and gas infrastructure”. That led to a misconception that oil and gas demand was going to disappear or drop massively within 10 - 15 years. Many investments were paused.

Today, gas is an important transition fuel, as well as a means for providing energy security. Gas is one of the cleanest ways to meet some of our key energy requirements, especially base load, while we transition. In other words, conventional wisdom swung from demand dying down to demand increasing. That kind of avoidable volatility puts pressure on prices.

To combat ineffective network control, asset integrity is more critical than ever. Continuous monitoring is essential. While uncommon in the US and EU, in some regions, bad actors will punch a hole into a pipeline to steal the oil, which starts a leak. It’s critical to quickly identify when that happens. Now, rather than depending on human monitoring, AI and other technologies can be used to remotely monitor what’s coming in, what’s going out, and where changes are happening in near-real time.

What strategies can pipeline operators use to mitigate the risks of geopolitical instability and ensure continuity of energy supply?

RY: We already covered dynamic portfolio management and scenario modelling that enable you to react quickly to emerging situations. There are a few other strategies.

First, diversify suppliers. Create multiple supply sources to secure oil, gas, or product in order to mitigate disruption from any one player. Second, create redundancies – multiple transportation routes through additional pipelines and other modes. If you add an FLNG to your network or build another pipeline, then, if you get blocked on one end, you can still get supply from another place.

Third, adjust your operations in high-risk areas. If it’s dangerous to do physical monitoring, implement automated monitoring. Or build new pipelines that are not easily accessible, such as underground lines. In addition, implement greater security.

Finally, utilisation of longer-term contracts, financial hedging and other economic instruments can help mitigate financial losses.

What role do pipelines play in supporting a sustainable and diversified energy portfolio in the long term?

RY: Pipelines remain the safest, lowest-carbon and most cost-effective mode for the transport of molecules. They are

essential to the reduction of environmental and operational risks to the supply of energy, domestically and internationally.

Natural gas is now widely recognised as the dominant energy transition fuel, and gas pipeline infrastructure is key for companies, states, and nations to manage energy demand, especially the base load. Further, pipeline infrastructure will be critical to ensuring the commerciality and scalability of hydrogen and carbon capture, utilisation, and storage (CCUS). Existing rights of way can help accelerate these pipelines, as will the increase in incentives for CO2-enhanced oil recovery (EOR) that were passed in the recent US budget act.

Can you discuss any specific cybersecurity measures that are being implemented to protect pipeline systems from cyberattacks?

RY: As internationally important critical infrastructure, pipelines will be points of attack, whether in a political conflict or a cyber conflict. It’s not about when they get attacked, it is about how many times they are attacked – and whether operators will be able to keep the attackers from achieving their goals. That is why we need to have multiple cyber programmes set up to defend pipeline systems.

Operators need to know three things. What assets do they have end-to-end (every single asset, because any asset can be attacked)? Second, if the system is breached, how can it be exploited? Third, once you know the answers to the first and second questions, how do you monitor, defend and respond in case of attack?

Regulators are increasingly mandating cyber requirements – which is where the TSA (Transportation Security Administration) comes into play in the US.

But operators also need to have the right architecture and technology. For instance, companies are adopting cyber frameworks such as Zero Trust Architecture to combat and minimise impacts of any disruptions. These architectures segment the networks that operate pipeline assets (OT) from information systems that monitor those assets (IT). This separation reduces a bad actor’s access to critical systems.

Finally, companies need to implement access control and train their workforce. Only the right people should have access to some of these very critical systems and people with access must be thoroughly trained on security processes.

How do you assess the risk of sabotage or other malicious activities that could target pipeline infrastructure?

RY: Let’s talk about the two types of sabotages – cyber and physical. The hard truth is that cyber risks are always expanding and changing. Pipelines are becoming more connected, remote controlled and automated, all of which makes them more vulnerable to new kinds of attacks. Attackers are taking advantage of the same new techniques and technologies, including AI, to disrupt and sabotage operations. That means you can’t simply look at past old attack techniques when assessing risk. If you do, you’ll get blindsided by the next new attack type. You have to plan for the unknown, and that means going back to basics.

Companies can decrease the probability of a successful attack by strengthening their defences via asset management, training and segmentation as well as deploying robust monitoring and response programmes. When possible, build those defenses in while building or modifying new assets. Don’t bolt in on, build it in.

Physical risks – typically correlated to the geopolitical environment, societal impact, and physical location, terrain and right-of-way of the asset – are also still a major hazard. Assets in high-risk environments have to be actively monitored and protected for sabotage and physical damage. Similarly, assets in urban/suburban contexts may warrant higher consequence ratings than those in exurban/rural contexts.

It’s also critical to gauge and actively manage changing societal sentiment, whether it opposition to CO2 pipelines or disagreements regarding First Nation access.

What are the main risks associated with operating ageing pipeline assets, and how can they be addressed?

RY: Most pipelines are 50 plus years old. That presents a lot more risk to operations and integrity. What’s more, investing in upgrades to old equipment doesn’t always make sense financially. So those upgrades get deferred, which can lead to issues such as physical leaks, unplanned downtime or non-compliance. Regulations change over time. And you need to comply with them, even if you have older equipment.

Finally, stakeholder groups are changing, too. When we built pipelines 50 years ago, we didn’t typically have stakeholders from the activist and environmental community.

In light of increasing demands for energy security, how can pipeline systems be designed to provide long-term reliability without compromising on sustainability or environmental goals?

RY: For new projects and the modernisation of existing assets, operators should account for five things. First, consider lifecycle assessment – including economics, operations, and carbon intensity. Understand the impact of your assets from initial construction (materials, transportation) to operation and end-of-life (disposal, recycling). Complement that understanding with relevant environmental impact analyses. And be sure to conduct these assessments prior to making any investment decisions on whether to build or replace an asset.