Boosting Efficiency and Sustainability in Fertilizer Production with

Sealing Solutions

Boosting Efficiency and Sustainability in Fertilizer Production with

22 Optimising water sustainability in ammonia production

08 Regional report: North America

Gordon Cope, Contributing Editor, discusses the challenges and opportunities facing North America’s fertilizer sector, including the impacts of geopolitical issues, environmental regulations, and new technologies.

13 Navigating the low-carbon ammonia journey

Deepak Shetty, Rolf Postma, and Nikolay Ketov, Stamicarbon, the Netherlands, explore how ammonia and fertilizer technologies, when integrated within an efficient low-carbon complex, can play a crucial role in supporting global efforts to reduce the nitrogen industry’s greenhouse gas (GHG) footprint.

17 The road to decarbonised ammonia

Matt Cousins, Johnson Matthey (JM), UK, and Klaus Nölker, thyssenkrupp Uhde, Germany, discuss the role that blue hydrogen can play in the decarbonisation of ammonia.

Giulia Sporchia and Elisa Brocca, Cannon Artes S.P.A., Italy, analyse solutions and technologies to effectively reduce the water footprint in ammonia production, through water recovery and reuse.

30 Advanced welding technology

Stefano Alberini, Belleli Energy CPE, Tosto Group, discusses the fabrication of a high-pressure ammonia synthesis converter with enhanced 2.25cr-1mo low alloy steel and advanced welding technology.

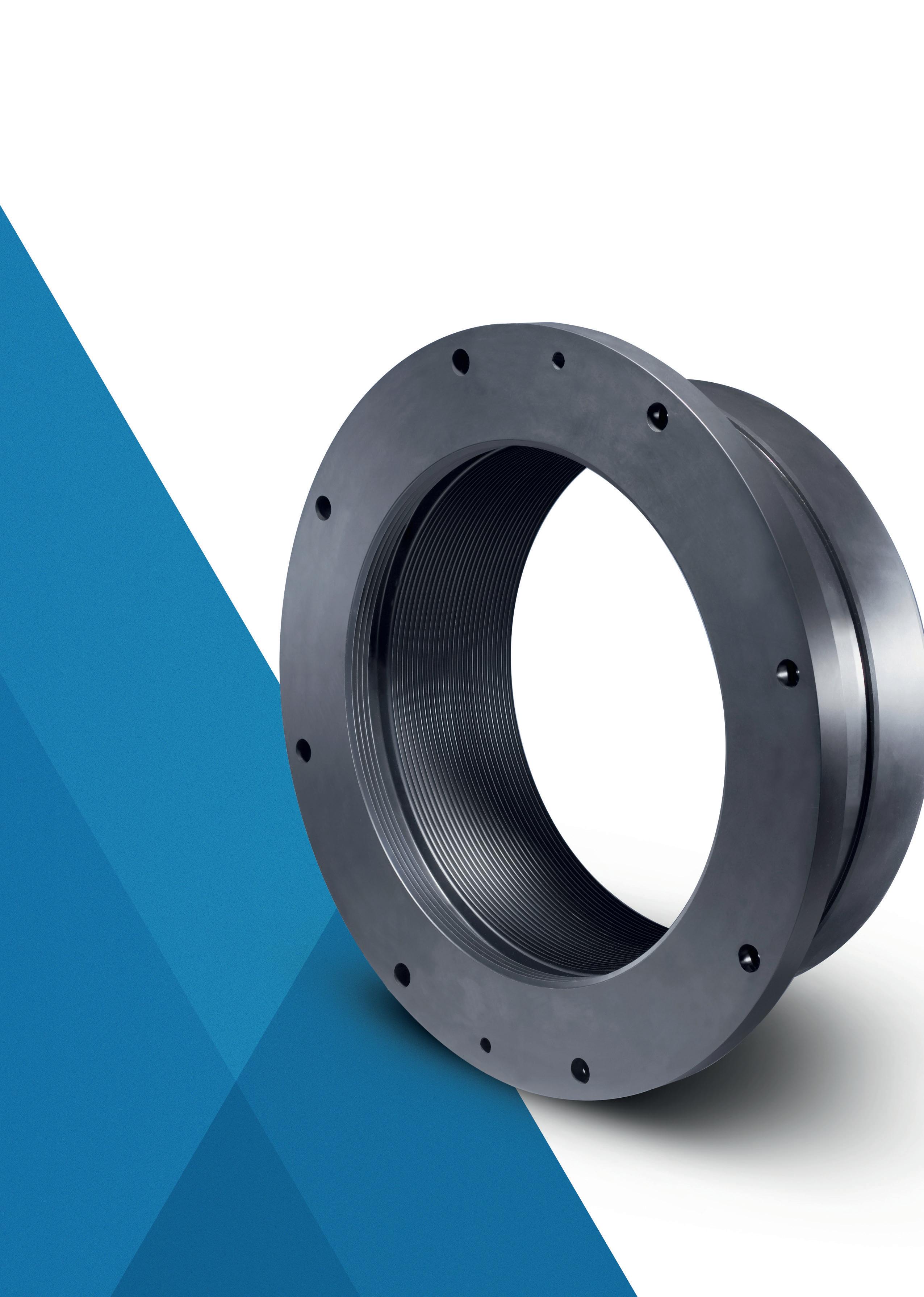

36 Q&A with Greene Tweed

Greg Gedney, Greene Tweed, considers how sealing solutions help to improve efficiency in the fertilizer industry.

38 Performance, purity, and phosphate processing

Kevin De Bois, Prayon, Belgium, explores advanced chemical benefication techniques within the phosphate processing industry.

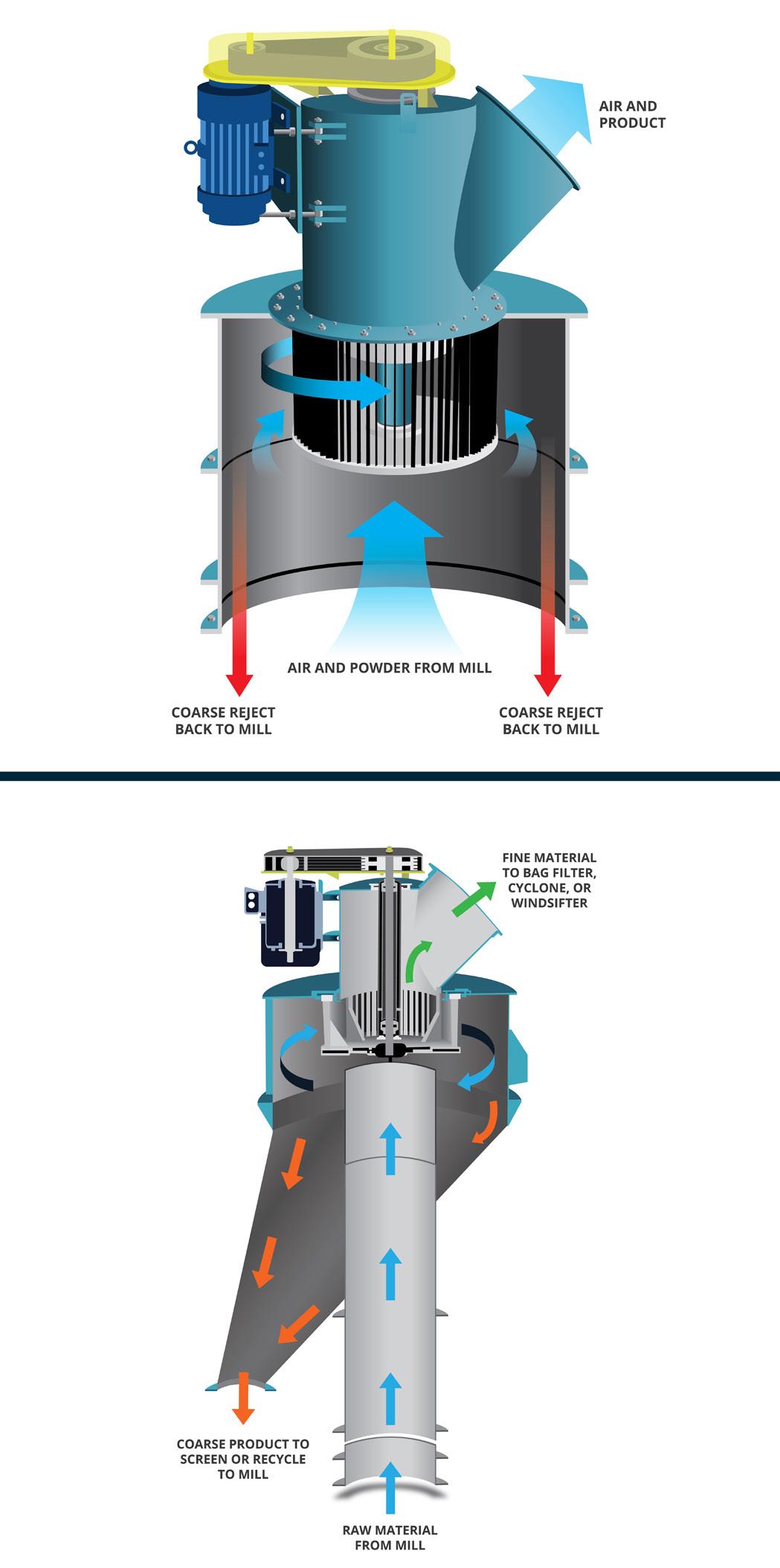

43 Options for improvement

Ian K. Hancock, Bradley Pulverizer, UK, discusses classifier options for improved fertilizer milling.

49 Granulation in action

Alberto Militare, LB Technology, Italy, examines the benefits of fertilizer granulation within the agri-food, crop nutrition, and animal feed sectors.

53 Weighing up corrosion protection

Brad Hudson, Mettler Toledo, USA, outlines key considerations when designing vehicle scales to ensure adequate corrosion protection.

57 Advancing efficiency with AI

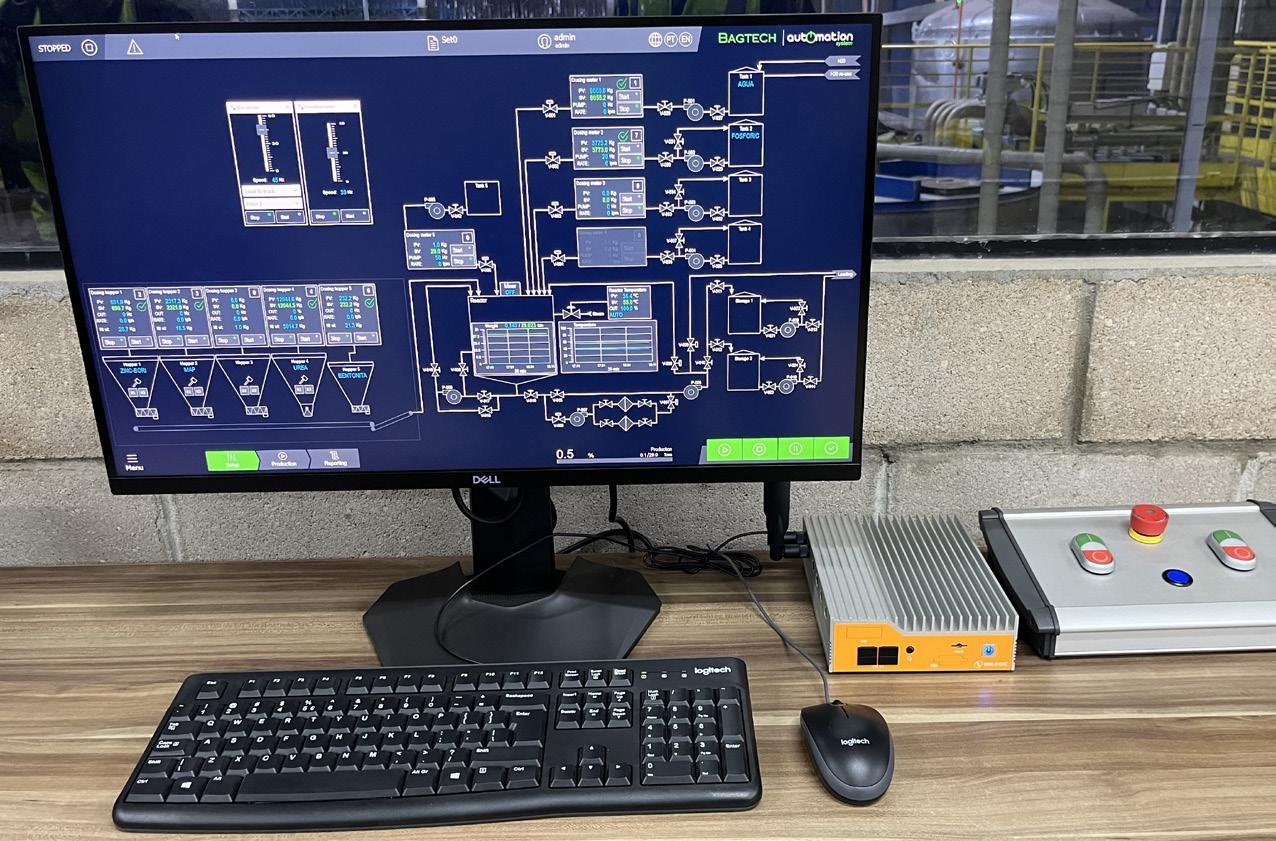

Brett Binnekade, Bagtech International, South Africa, discusses predictive maintenance with artificial intelligence (AI) in fertilizer blending and bagging plants, and how to make modern fertilizer plants more efficient and reliable.

61 Minimising the risk of dust-related explosions

Kyle Langley, Vortex Global, UK, considers methods to mitigate against the risks posed by dust accumulation.

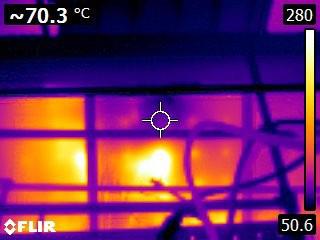

65 Hot spot management

Johannes Poth, Integrated Global Services (IGS), Germany, explains how to manage the occurrence of hot spots in primary reformers at fertilizer plants.

69 The critical role of cooling

Igor Makarenko, Solex Thermal Science, Canada, explores the impact of thermal management on production and product quality.

Reduce stack emissions Decrease CAPEX Lowest cost construction Produce CO2free power Use of green ammonia/ hydrogen O2

IT’S THE SAME, BUT BETTER

Leveraging oxygen from water electrolysis / ammonia production, CORE-SO2™ technology decreases acid plants’ environmental footprint and greenhouse gas emissions while recovering clean energy and enhancing plant profitability.

• No fossil fuels required

• 98% lower emissions

• 60% less plot space

• 55% fewer contruction materials

• 50% decrease in CAPEX

MANAGING EDITOR

James Little james.little@palladianpublications.com

SENIOR EDITOR

Callum O’Reilly callum.oreilly@palladianpublications.com

ASSISTANT EDITOR Oliver Kleinschmidt oliver.kleinschmidt@palladianpublications.com

EDITORIAL ASSISTANT

Emilie Grant emilie.grant@palladianpublications.com

EDITORIAL ASSISTANT

Ellie Brosnan ellie.brosnan@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Ryan Freeman ryan.freeman@palladianpublications.com

PRODUCTION

Iona MacLeod iona.macleod@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

HEAD OF EVENTS

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@palladianpublications.com

EVENTS COORDINATOR

Chloe Lelliott chloe.lelliott@palladianpublications.com

DIGITAL CONTENT ASSISTANT

Kristian Ilasko kristian.ilasko@palladianpublications.com

DIGITAL ADMINISTRATION

Nicole Harman-Smith nicole.harman-smith@palladianpublications.com

JUNIOR VIDEO ASSISTANT

Amelie Meury-Cashman amelie.meury-cashman@palladianpublications.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey GU9 7QU, UK Tel: +44 (0) 1252 718 999 Website: www.worldfertilizer.com

World Fertilizer Subscription rates: Annual subscription: £50 UK including postage £60 overseas (postage airmail) Two year discounted rate: £80 UK including postage £96 (postage airmail).

Subscription claims: Claims for non receipt of issues must be made within 3 months of publication of the issue or they will not be honoured without charge.

Applicable only to the USA & Canada: World Fertilizer (ISSN No: 2398-4384, USPS No: PENDING) is published 8 times a year by Palladian Publications Ltd GBR and distributed in the USA by Asendia USA, 701 Ashland Ave, Folcroft PA. Application to Mail at Periodicals Postage Prices is pending at Philadelphia, PA and additional mailing offices. POSTMASTER: send address changes to World Fertilizer, 701 Ashland Ave, Folcroft, PA. 19032.

The hot topic on everyone’s mind at the moment is tariffs. And this is no different for the global fertilizer industry, with market turmoil being perpetuated by the uncertainty regarding what lies ahead when it comes to new import taxes.1

The question is: how do we weather this storm?

The re-election of President Trump has caused a certain amount of volatility in many aspects of life, with impacts rippling out across the globe. These very ripples are now catalysing major changes, from pledging to help cease conflicts in regions such as the Middle East and Europe; to dramatic fluctuations in crypto-currency values after the announcement of the US crypto-currency reserve. It is clear to see that the impact is profound, and the fertilizer industry will also be impacted.

Import tariffs placed on Canada, Mexico, and China have culminated in uncertainty within the agricultural sector, primarily raising concerns over supply and demand issues – especially as the US relies on Canada for approximately 85% of its potash imports.2 But with the Trump Administration’s aim being to ‘make America rich again’, there is no surprise that tariffs have become an important pawn in this game of chess. The aim here is clearly to promote US industry whilst encouraging domestic agricultural activity.3 Not only this, but also to provide a greater standard of living for the American people, ensuring affordable food prices, access to fertilizers, and an overall strengthening of the country’s agricultural sector.

Proponents of autarky have advocated for national self-sufficiency in order to reduce the reliance on external factors for decades. This emphasised reliance on self-sufficiency is a theme gaining greater traction and prominence throughout the world, in an age where global tensions are running high and patience is running thin. COVID-19 exposed the weaknesses within the global supply chain, and, whether it is a ‘knee-jerk’ reaction or not, governments have ever since been re-evaluating their reliance on imports to sustain their demands economically, socially, and politically. This has therefore opened the door for the EU’s Open Strategic Autonomy policy – a policy placing emphasis on self-sufficiency without completely ruling out collaboration and cooperation where possible.4 A policy designed for the modern world.

Over the coming decade, it would be naïve to assume that the future of fertilizer imports, exports, production, and consumption will be plain sailing. The heightened buzz around trade barriers and restrictions has placed an ever-growing uncertainty within the sector; an uncertainty fuelled by market volatility. Not to mention the great strain being placed on the agriculture sector to provide the food to sustain the ever-growing population of the world. Despite this, however, it is important to remember that you can’t have a rainbow without a little rain.

This month’s issue of World Fertilizer Magazine features a North American regional report from contributing editor Gordon Cope, where he discusses the challenges and opportunities facing North America’s fertilizer sector, including the impacts of geopolitical issues, environmental regulations, and new technologies.

1. https://www.bbc.co.uk/news/articles/cgr21jjwg4wo

2. https://www.reuters.com/markets/us/us-farmers-face-higher-costs-fewer-markets-tariffs-farm-groupswarn-2025-03-04/

3. https://www.fertilizerdaily.com/20250306-trump-announces-tariffs-on-u-s-agricultural-imports-set-for-april-2/

4. https://www.europarl.europa.eu/thinktank/en/events/details/the-future-of-eu-s-open-strategicautono/20230215WKS04981

Agricultural producers on the Canadian Prairies stand to benefit from a collaboration between Arctic Gateway Group (AGG) and Genesis Fertilizers Ltd Partnership (Genesis Fertilizers), which is focussed on cutting fertilizer import and export costs, improving supply chain reliability, and expanding market reach.

The parties have entered into a letter of intent to establish a framework for cooperation between AGG and Genesis Fertilizers to enhance business opportunities and facilitate the development of efficient logistical and supply chain solutions. The parties seek mutually beneficial new import and export shipments in 2025 and beyond.

Genesis Fertilizers and AGG will cooperate to source and import phosphate and ammonium sulfate supply from international vendors as feedstock for the products to be produced at Genesis Fertilizers’ proposed nitrogen fertilizers facility to be built at Belle Plaine, Saskatchewan. The parties seek to distribute such supply domestically through facilities at the Port of Churchill and the planned SuperCenter distribution network of Genesis Fertilizers. Currently, this feedstock is brought into Canada from the US by other importers.

In addition, AGG aims to utilise Genesis Fertilizers’ transportation and storage needs to expand its logistical capabilities and grow their operations. By collaborating on best practices for storage, shipping, distribution, and supply chain management, AGG aims to create operational efficiencies that will benefit both organisations. This collaboration is expected to increase shipping and rail traffic, optimise the use of AGG’s rebuilt infrastructure, and establish a strong new relationship with a key player in the Canadian fertilizer industry. Both companies are also committed to increasing jobs and training for Indigenous and northern communities through this increased economic activity.

Genesis Fertilizers seeks to leverage AGG’s port and rail infrastructure to efficiently link its fertilizer products to key markets, reducing lead times and costs. By tapping into new and emerging markets that AGG’s network provides access to, Genesis Fertilizers aims to enhance the growth potential for the plant’s production. The collaboration with AGG will also foster timely delivery and optimised supply chains for fertilizer distribution to both domestic and international markets. This collaboration underscores the benefits of farm producers partnering with northern communities and Indigenous groups to strengthen Canada’s agricultural resilience. By fostering these relationships, producers can contribute to a more stable and sustainable food supply chain, ensuring long-term benefits for all Canadians.

IRELAND OMEX opens Ireland’s largest liquid fertilizer facility

OMEX Ireland has officially opened the country’s first and largest dedicated liquid fertilizer distribution hub at the Port of Cork. This landmark facility marks a major milestone for Irish agriculture, ensuring farmers across the country have reliable access to high-quality liquid fertilizer.

With a significant storage capacity, the Cork terminal is the largest of its kind in Ireland and is strategically positioned to serve all key agricultural regions. The facility utilises fertilizer technology, operating 24/7 to supply high-performance liquid N+S fertilizers. OMEX’s investment into liquid fertilizer infrastructure offers Irish farmers a dependable and efficient nutrient management solution

The facility was officially inaugurated on 5 March 2025, with key representatives from OMEX, including Chairman Max Winkler and Managing Director Sam Bell. Leading figures from the Irish farming community also attended, recognising the significance of this investment for the sector.

Sulphur World Symposium 2025 08 - 10 April 2025 Florence, Italy www.sulphurinstitute.org/ symposium-2025/

The Fertilizer Show 08 - 10 April 2025 Orlando, Florida, USA www.fertilizershow.com

IFA Annual Conference 12 - 14 May 2025 Monaco www.IFA2025.org

48th Annual International Phosphate Fertilizer & Sulfuric Acid Technology Conference 06 - 07 June 2025

St. Petersburg Beach, Florida, USA aiche-cf.org/annual-conference

99th Annual Southwestern Fertilizer Conference 13 - 17 July 2025 Nashville, Tennessee, USA www.swfertilizer.org

69th Annual Safety in Ammonia Plants and Related Facilities Symposium 7 - 11 September 2025 Atlanta, Georgia, USA www.aiche.org/conferences/ annual-safety-ammonia-plants-andrelated-facilities-symposium/2025

ANNA 2025

12 - 17 October 2025

Omaha, Nebraska, USA www.annawebsite.squarespace. com/2025-conference

Wood Mackenzie Hydrogen Conference 12 - 13 November 2025

London, UK www.woodmac.com/events/ hydrogen-conference

POLAND Grupa Azoty comments on the current situation in the fertilizer market

For several weeks now, fertilizer prices have been on an upward trend in the main global markets. This is the result of several factors – demand, fertilizer availability, and supply logistics. Fertilizers are becoming moderately more expensive both in countries with low and stable production costs and in countries where costs are high and subject to rapid changes. In light of the trend observed over several quarters of postponing fertilizer purchases until just before the seasonal peak, Grupa Azoty consistently recommends spreading purchases over several batches to reduce the risk of buying products at high prices.

Since the beginning of the year, urea prices in the Baltic have increased by US$85/t (approximately 340 PLN/t). Prices of nitrate fertilizers (AN, CAN) at major European producers have also risen by about €60/t (around 250 PLN/t) during the same period.

Although natural gas prices at around €45/MWh are slightly lower than at the beginning of March 2025, they remain high in the context of fertilizer production costs. It should be noted that compared to prices a year ago, they are as much as 50% higher – before the war in Ukraine, they were between €15 - 20/MWh. The rapid fluctuations in gas prices cause producers to continuously adjust fertilizer prices according to the current raw material situation.

3Degrees has launched the Low Carbon Fertilizer Alliance, a collaborative initiative designed to help reduce emissions in agricultural supply chains.

Managed by 3Degrees, the alliance leverages decades of expertise in greenhouse gas (GHG) strategy and agricultural emissions reductions by bringing together organisations in the food, beverage, and apparel industries. The alliance is supported by founding member Mars Inc., alongside three additional Fortune 200 food companies, with CF Industries joining as the founding manufacturing member.

The alliance provides a scalable approach to decarbonising fertilizer manufacturing by funding emissions reduction initiatives within the agriculture value chain. With funding to be secured through the alliance, CF Industries has committed to complete a new nitric acid plant emissions abatement project at its Verdigri manufacturing facility in Oklahoma, US, which is expected to reduce CO2 emissions from the facility by 600 000 tpy, beginning in 2025.

ANGOLA Minbos receives second tranche of funds from FSDEA for 2025 field

Minbos Resources Ltd (Minbos) has announced that it has received the second tranche of funding, totalling US$2.43 million, from the Fundo Soberano de Angola (FSDEA).

The final tranche of funding, totalling US$1.17 million, will be completed upon the company finalising the renewal of project insurances and presenting supplier quotations for project long lead items to FSDEA.

The company’s early trials in Angola in 2025 continue to perform strongly. Take aways from the trials include: improved crop yields with PRIMEIRO, particularly in areas with low soil phosphorus and low pH (acidic) soils; PRIMEIRO has demonstrated yield increases by up to 80% when applied as the only source of phosphorus; and that local trials have shown that without phosphorus, other nutrients are not effective.

Gordon Cope, Contributing Editor, discusses the challenges and opportunities facing North America's fertilizer sector, including the impacts of geopolitical issues, environmental regulations, and new technologies.

North America is a leading producer of food and fertilizer for both domestic consumption and export. However, a variety of challenges within the US and Canada, as well as around the world, have the capacity to whipsaw the sector in dramatic fashion; drought, wars, environmental goals, trade disputes and geopolitics, to name a few.

Since May 2024, phosphate Gulf spot prices have surged 10%, to above US$575/t. The primary reason is China, which churns out over 17 million tpy. Once the world’s leading exporter of phosphate fertilizer, the country has taken various steps since 2021 to limit fertilizer exports in order to protect its domestic market and encourage food production. In June 2024, it extended export bans on urea and phosphate, slowing the former and virtually eliminating the latter.

North America produces approximately 7 million tpy of phosphate fertilizer and imports over 2.7 million tpy, primarily from Morocco, to meet its agricultural needs. Florida accounted for over half of all phosphate ore production, but producers in the tourism-reliant 'sunshine state' are facing increasing regulations and fines associated with groundwater contamination, wastewater spillage, waste piles, and red tide blooms spoiling pristine beaches.

North American producers are seeking new sources of phosphates. In Quebec, First Phosphate continues to advance its discovery at the Bégin-Lamarche project located in the region of Saguenay-Lac-St-Jean. In June 2024, it announced that drilling had delineated 41 million t of recoverable ore using open pit mining. Testing has indicated levels of phosphorus pentoxide (P2O5) as high as 39.45%; at this purity, the mineral qualifies as direct shipping ore (DSO). Samples are devoid of high concentrations of harmful elements such as cadmium, facilitating preparation.

Vancouver-based Fertoz Ltd has staked some of the largest sedimentary deposits of phosphate in Canada.

The Wapiti project in northeast British Columbia contains approximately 1.4 million t of +20% P2O5 phosphate rock at a depth of less than 30 m. The company is currently seeking industrial minerals mining permits to conduct up to 250 000 t of sampling in order to determine its viability in both fertilizer and lithium-iron-phosphate battery applications.

The US and Canada produce over 15 million t of potash fertilizers annually, with abundant room for capacity growth. International sanctions imposed against Belarus and repercussions against Russia after its invasion of Ukraine have significantly impacted potash exports from the two countries;

Russia’s output dropped 45%, to approximately 5 million tpy, and Belarus over 60%, to approximately 3 million tpy.

North American producers responded to the shortfall. Nutrien, based in Calgary, Canada, and the world’s largest potash producer, upped production from an initial 14 million tpy to almost 15 million tpy by the end of 2022. Rising prices reduced applications, however, leading to unsold inventory. Lower prices induced a rebound, however, and Nutrien now forecasts that full-year shipments for 2025 will reach 71 - 74 million t, up from the 2024 estimate of 70 - 72 million t, as growers around the world replenish soil nutrients.1

In April 2024, BHP reported that stage one of its new Jansen mine in Saskatchewan, Canada, is 44% complete, and is on track to begin production in 2026. The CA$5.4 billion underground mine will have a capacity of 4.5 million tpy. They have also approved CA$4.9 billion for stage two, which will double output capacity to 8.5 million tpy when it comes on stream in 2029. Further stages could see production eventually rise to 16 - 17 million t.

North America is a major producer of nitrogen fertilizer, with approximately 16 million t of various liquid and solid products produced annually.

The health of the North American nitrogen fertilizer sector is closely linked to the fortunes of domestic farming. Over the last several years, droughts have caused regional crop failures, high prices have deterred applications, and cereal prices have experienced volatility. In its 3Q24 report, Nutrien noted that, while crop prices have reduced margins to farmers, near record yields in corn and soybeans have bolstered incomes and the majority of growers in the US Midwest are in sound financial standing to replenish soil nutrients.

The strength of the farm sector is encouraging producers to expand capacity. According to a GlobalData report, North America is expected to dominate global ammonia capacity additions for the next five years.2 Currently, world capacity stands at slightly over 240 million tpy, with 71 million tpy expected to be added by 2028. North America is the leading region for new capacity, with 29 million tpy planned. The list includes:

n Ascension US$7.5 billion Clean Energy Donaldsonville, (Louisiana, US) ammonia plant, with an ultimate capacity of 7.2 million tpy of blue ammonia, expected to enter service in 2029.

n St Charles Clean Fuels US$4.6 billion St. James Parish (Louisiana, US) plant, which will have a capacity of 2.9 million tpy, is expected to enter production in 2027.

n CF and Mitsui’s US$2 billion Ascension Paris (Louisiana, US) plant, expected to produce 1.5 million short tpy of blue ammonia when it opens in 2027.

The predominance of new ammonia capacity being built in North America has several causes. Prices for natural gas, used as both feedstock and processing energy, are lower than most other jurisdictions in Asia and Europe for instance, but the US is also on a crusade to shift to low-carbon hydrogen. Not only does the energy-dense element produce nothing but water when burned, it can also be manufactured anywhere using electrolysis powered by wind and sun, reducing geopolitical risk.

Producing clean-burning hydrogen fuel is creating immense opportunities for nitrogen manufacturers. Because transporting and burning hydrogen itself is rather costly and complex, a much easier method is to convert the gas into liquid ammonia, which can then be consumed in internal combustion engines (ICEs) with minor alterations.

The maritime sector is expected to lead the conversion to ammonia fuel. Rystad Energy, a consultancy, predicts that total exported volumes to surge from around current levels of 19 million tpy (most of which is used in fertilizer products), to 76 million tpy by 2035 (most of which will be transport and utility fuel related). By 2050, that figure could be over 120 million tpy.3

North America is expected to play a key role. Under the Biden Administration’s Inflation Reduction Act, the federal government could provide up to US$3/kg in subsidies for clean hydrogen.

In September 2024, Netherlands-based OCI announced the sale of its blue ammonia production facility in Beaumont, Texas, US, to Australia’s Woodside Energy, for US$2.35 billion. OCI and Linde are currently building the 1.1 million tpy plant; when it enters production in 2025, Linde will use carbon capture and sequestration to supply blue hydrogen and nitrogen feedstock. A second train of equal capacity is seeking regulatory approval.

German-based RWE, LOTTE Chemical of Korea, and Japan’s Mitsubishi continue to develop plans to build a clean ammonia production and export facility in the port of Corpus Christi, Texas, US. The complex would be built in phases, with a final capacity approaching 10 million tpy by 2030. Blue and green ammonia would be exported to Asia and Europe for use as both fuel and a source of renewable hydrogen.

Not all projects are facing smooth sailing, however. Yara, based in Norway, is planning to build a blue ammonia plant with Enbridge, a major North American pipeline company, in Ingleside, Texas, US. The unusual joint venture was announced in 2023 when the two partners realised that their respective assets and goals would optimise the joint project. Over the last several years, Enbridge has been expanding the Enbridge Ingleside Energy Center (EIEC), a massive terminal located in Corpus Christi, Texas, US, on the Gulf of Mexico. Project YaREN would include two trains with a total capacity of 2.8 million tpy of output, starting in 2028. The project faces strenuous objections from the communities in Ingleside, however; residents are concerned about potential ammonia leaks and the lack of emergency planning.

Several projects have also hit financial roadblocks. In November 2024, Air Products announced that it was cancelling its proposed US$4.5 billion green hydrogen plant with partner AES Corp. The 1.4 GW plant, to be built in Wilbarger County, Texas, US, was to be the largest green hydrogen plant in the US, producing 200 tpd. Air Products, which is building the immense green hydrogen plant at Saudi Arabia’s NEOM project, decided to back out of the deal due to poor demand.

Air Products is following in the footsteps of Nutrien. In early 2023, the company announced plans to build the world’s largest blue ammonia facility at its existing complex in Geismar, Louisiana, US. The 1.2 million tpy plant would permanently remove up to 90% of CO2 emissions using

carbon capture and sequestration (CCS) technology. Later that year, Nutrien placed the project on hold, citing increased building costs and uncertainty over the premium market for clean ammonia.

The Canadian federal government wants to reduce carbon emissions in all sectors by 45% by 2030, primarily through carbon taxes and restrictive legislation. Currently the carbon tax stands at CA$80/t of CO2e, and is scheduled to climb by CA$15/tpy to CA$170 by 2030. Grain farmers use large amounts of natural gas to dry and maintain stored grain, however, and greenhouses use natural gas and propane to maintain operations through the winter months. In addition, Ottawa, Canada, is pondering fertilizer restrictions. The latter, especially, has the sector concerned.

In the US, the election of President Donald Trump will have significant impact on the agricultural sector for three primary reasons. First, environmental legislation – a foundation of the Biden Administration – is expected to take a back seat for the next four years. While this may supply relief to farmers wrestling with higher energy bills, others could experience significant drops in income. The Conservation Reserve Program (CRP) was created by the United States Department of Agriculture (USDA) in 1985 to encourage land owners to set aside environmentally sensitive land, primarily near waterways and marshes. The intent was to create buffers that would encourage wildlife and pollinators to thrive. Today, the programme delivers US$2 billion to farmers to conserve over 25 million acres of land. According to Project 25, a political playbook written by conservative supporters of President Trump, the CRP would be eliminated.

Secondly, the first Trump Administration generated a trade war with China that had far-reaching impacts on farming; a 20% tariff caused a loss of US$23 billion in sales of soy and corn to China. During his recent campaign, President Trump threatened a 60% blanket tariff that could have a far greater impact. In order to placate producers during the first trade war, President Trump allocated over US$20 billion to the farming sector, but there are no guarantees that any future losses would be covered. In addition, China has made significant strides to increase domestic food consumption and deepen trade relations with Brazil, which now delivers US$60 billion of food to China annually. The Asian country could also impose its own 60% tariff on US goods, crippling corn and soy exports.

Finally, the 2018 - 2023 Farm Bill, which expired on 1 October 2023 (and has been extended through several temporary measures), must be formally renewed by Congress in 2025. The massive omnibus bill directs US$1.5 trillion per decade to food and agriculture. The majority is targeted to the USDA's main food-aid programme, the Supplemental Nutrition Assistance Program (SNAP). The remainder funds a host of farm-aid programmes, generally referred to as the farm safety net. Republicans favour farm aid, while Democrats prioritise help to the poor. Project 25 proposes eliminating major portions of the bill, but Republicans are fully aware that the small number of agribusinesses that control the immense land, meat processing, and cereal exports benefit immensely from the bill. And farmers vote.

Fertilizer production has a significant impact on the environment. Ammonia producers emit an estimated 1.3% of all greenhouse gases (GHGs) per year, primarily from the use of coal and natural gas as both feedstock and energy. While blue and green ammonia initiatives are helping to reduce GHG intensity per t, it will be a costly challenge to meet net zero targets by 2050.

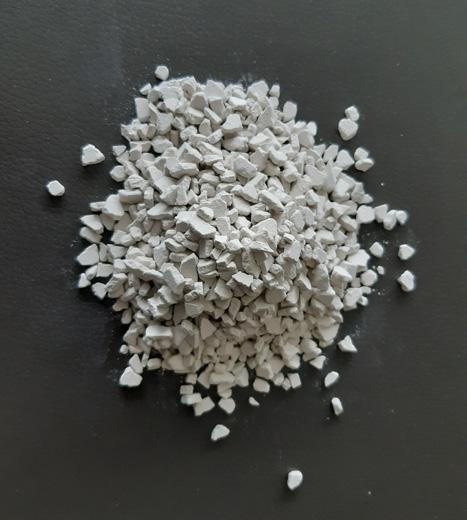

A recent study shows that runoff of phosphorous fertilizer from farms has increased over the last four decades. Researchers at Pennsylvania State University analysed data from 430 rivers across the US from 1980 to 2019. The loss leads to pollution in drinking water and algal blooms that deprive fish of oxygen. Although efforts have been made to reduce urban sources of phosphorous, such as waste treatment plants, extreme weather events dumping large amounts of rain on agricultural lands increase runoff losses. In response, Pennsylvania State University alumni have developed a phosphate granule that is activated by plant roots, increasing uptake efficiency by 50% and reducing runoff while maintaining yields.

In order to reduce emissions, BHP has opted to use underground battery-electric loaders for its Jansen Potash Project in Saskatchewan, Canada. Sandvik will provide ten vehicles for the first phase of the project. BHP touts that the mine will have the lowest carbon footprint of any potash mine operating in Saskatchewan.

In February 2025, President Trump imposed a 25% tariff on a wide range of Canadian goods. US farmers rely on Canada for almost 90% of their potash needs, and fear that the tariffs could add up to US$75 per short t, reducing profit margins and potential yields.

In the coming decade, demand for nitrogen, potash and phosphate fertilizer is expected to remain healthy due to a growing world population and a shift of diets toward animal protein. Net zero environmental regulations are also expected to create demand for millions of tonnes of green ammonia for use in marine transport. The trade barriers restricting Belarusian and Russian potash exports will act as an incentive to develop the immense potash reserves in Canada that present large-scale, low-cost expansion opportunities. New sources of phosphorous throughout North America will gradually displace Moroccan imports.

North America’s fertilizer producers have adapted well to recent challenges; being isolated from the regional turmoil in Eastern Europe and the Middle East, for instance, has encouraged investment in the low-risk continent. While volatility in international trade of fertilizer is unlikely to abate in the near-term, long-term trends in the food commodities market and the opportunities presented by new uses of ammonia will create significant prospects for growth in the coming decade.

1. https://www.nutrien.com/news/press-releases/nutrien-reports-thirdquarter-2024-results-1713.

2. https://www.globaldata.com/store/report/ammonia-marketanalysis/?_gl=1*iri4vo*_ga*MTAzOTgwMDI2Ni4xNzMyMjE1MTE1*_ga_ TDKVNS5N2K*MTczMjIxNTExNS4xLjEuMTczMjIxNTE4NC42MC4wLjA.

3. https://www.rystadenergy.com/news/hydrogen-exports-shiftammonia-production-2035.

Deepak Shetty, Rolf Postma, and Nikolay Ketov, Stamicarbon, the Netherlands, explore how ammonia and fertilizer technologies, when integrated within an efficient low-carbon complex, can play a crucial role in supporting global efforts to reduce the nitrogen industry’s greenhouse gas (GHG) footprint.

The global nitrogen industry is a cornerstone of food production through fertilizers. It is also expected to play an increasingly important role in other applications, from energy to industrial processes. However, it is also a major contributor to greenhouse gas (GHG) emissions, making the reduction of its carbon footprint a critical priority.

This challenge can be tackled by adopting highly efficient industrial processes, maximising efficiency through the integration of industry-leading technologies, and minimising emissions with advanced solutions to create value chains rooted in circularity, stewardship, and responsible resource use. A reduced-carbon emissions ammonia plant has the potential to revolutionise the industry, reshaping how global food security and energy demands are met.

Companies, such as Stamicarbon, the nitrogen technology licensor of NEXTCHEM (MAIRE Group), are assisting in this transition, creating ammonia and fertilizer technologies for a more sustainable future.

Developed over a century ago, the Haber-Bosch process remains the cornerstone of the ammonia industry. While this method can use hydrogen from any source, today's dominant production method uses hydrogen coming from fossil fuels. This is typically done through steam reforming of natural gas or coal gasification, leading to significant carbon emissions, resulting in the product ammonia referred to as ‘grey’.

Efforts to make this conventional ammonia production process more sustainable led to the development of ‘blue’ ammonia. In this method, the carbon dioxide, previously emitted into the atmosphere, is captured and stored, or utilised in other processes.

Green ammonia is produced by using renewable electricity to power electrolysers, which split water to create hydrogen and oxygen. The nitrogen needed for ammonia synthesis is obtained from the air using a nitrogen generation unit. This method enables the production of ammonia with minimal GHG emissions, positioning it as one of the most promising approaches for a low-carbon future.

While there are other ‘colours’ of ammonia, recent industry discussions have primarily focused on the actual carbon reduction rather than the source of feedstock.

While the availability of electrolysers and the cost of renewable electricity remain key challenges for gigawatt-scale projects, smaller ammonia plants offer a viable pathway for early adopters to achieve their decarbonisation goals. Modular and scalable green ammonia production, suitable for local production of urea, nitrates, diesel exhaust fluid (DEF), or ammonia to be used as fuel, offers a promising pathway.

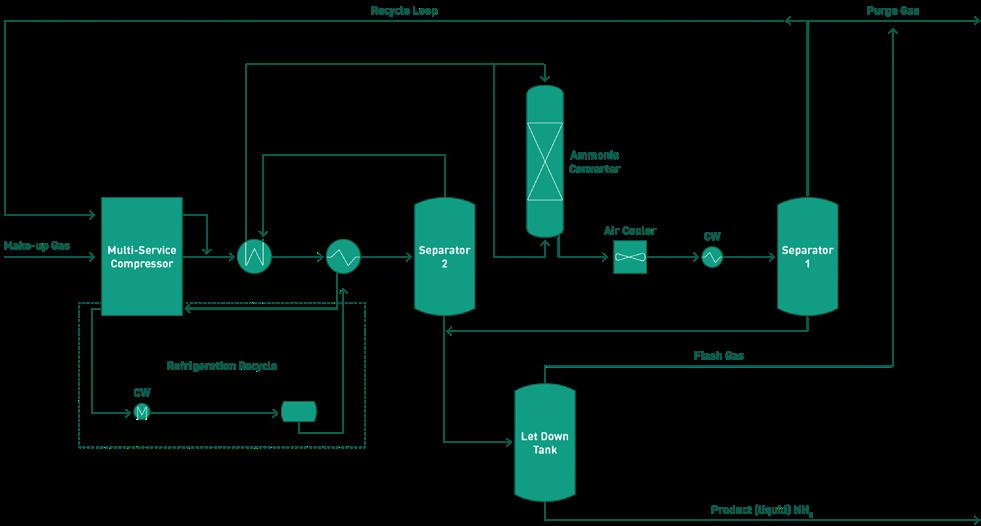

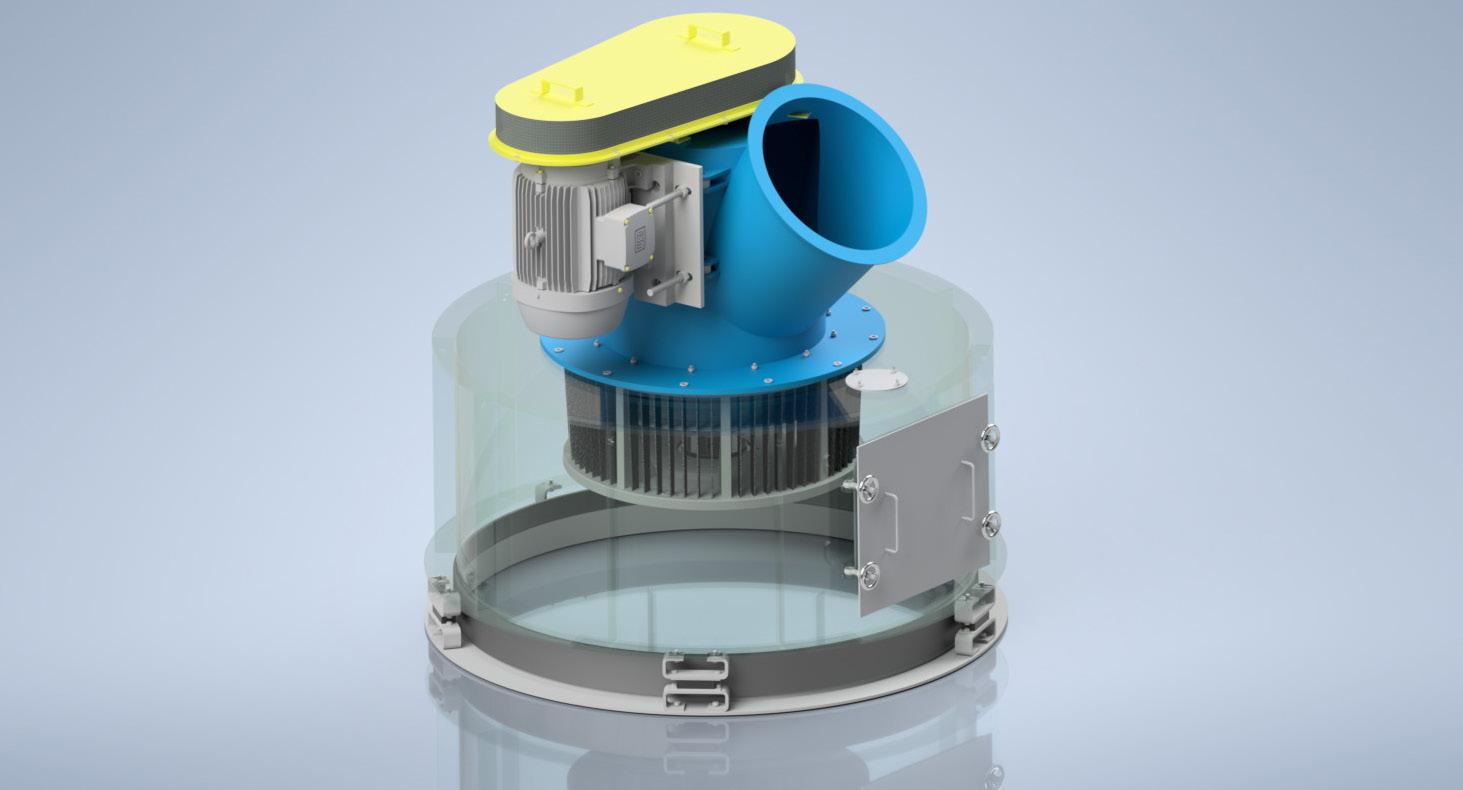

Stamicarbon’s NX STAMI AmmoniaTM technology (Figure 1), designed for small- to medium-sized plants (50 - 500 tpd), enables ammonia production from renewable energy with minimal environmental impact. This high-pressure technology optimises efficiency of a conventional process while maintaining a compact and cost-effective design.

The ammonia synthesis loop operates at a high pressure (~300 bar), increasing conversion efficiency while reducing the need for costly refrigeration systems. The process flow (Figure 2) begins with make-up gas, a mixture of hydrogen and nitrogen from an upstream electrolyser and nitrogen generation unit. This gas is compressed in an electrical-driven reciprocating compressor to over 300 bar, with the recycle stream also recompressed to the same pressure.

The ammonia converter used in this process features a single axial flow catalyst bed design. Heat exchange tubes submerged in the catalyst bed allow for better temperature control, preventing adverse effects such as catalyst sintering. Simultaneously, the converter feed is preheated using the exothermic reaction heat. An integrated start-up heater is also included within the converter.

The high-pressure synthesis loop allows for single-stage ammonia condensation using cooling water, eliminating the need for a refrigeration compressor. This reduces equipment count and achieves 25 - 30% capital expenditure (CAPEX) savings. Over 85% of ammonia is recovered in separator 1, while additional uncondensed ammonia is captured in separator 2.

Ammonia can be produced at a pressurised condition (i.e., 16 - 18 bar) and ambient temperature to be stored in bullets or used in downstream plants, or any intermediate pressure level as required, such as 8 bar required for shipping. Alternatively, the final product can be at ambient pressure and -33°C to be stored in atmospheric ammonia storage.

While the high-pressure ammonia loop offers advantages for small- to medium-scale production, the demand for

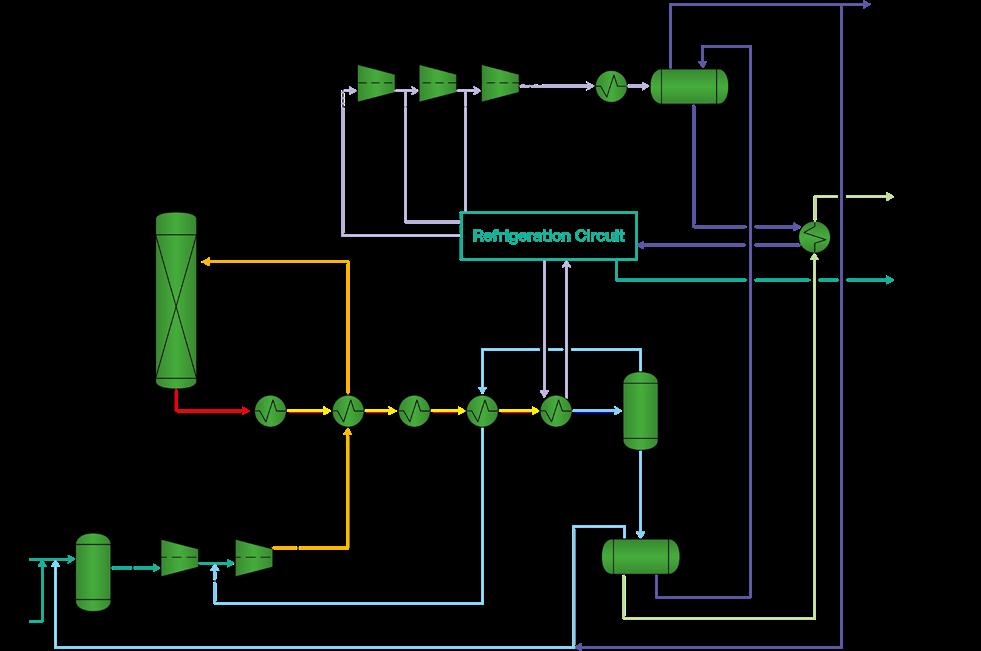

low-cost and high-efficiency ammonia production is leading to the development of conventional larger-scale ammonia plants. Stamicarbon offers the medium-pressure technology, designed for capacities from 50 to 3500 tpd, with potential for even larger capacities, depending on customer’s needs.

This medium-pressure ammonia technology (Figure 3) features a multi-bed, radial-flow reactor with a low-pressure drop configuration. This has been optimised to allow high per pass conversion with the minimum possible catalyst volume and can be customised based on operating variables.

The system is notable for its superior temperature control in the first bed, allowing for a more efficient converter operation and a longer expected catalyst lifespan.

With over 45 industrial references, this process offers a cost-effective and proven ammonia production solution.

As the demand for low-carbon ammonia increases, fertilizer producers must adopt advanced technologies to achieve significant emission reductions. While conventional ammonia production allows for only incremental CO2 reductions, significant cuts can only be achieved through carbon capture, utilisation, and storage (CCUS).

Fortunately, auto-thermal reforming (ATR) provides a solution for large-scale blue ammonia production, as it generates a highly concentrated CO2 stream that makes CCUS both technically feasible and, under the right conditions, economically attractive.

ATR is a highly efficient process that maximises ammonia production while minimising external energy requirements. ATR is particularly advantageous for production of blue ammonia (and, equally, blue hydrogen and low-carbon methanol) as it provides a highly concentrated CO2 stream, enabling carbon capture rates of up to 95%. ATR presents a viable alternative for world-scale low-carbon ammonia production. NEXTCHEM’s ATR process operates at high pressure (70 bar), which reduces compressor duty in the ammonia plant, lowering operational expenditure (OPEX). Robust, proven equipment, a flexible feedstock intake, and higher energy efficiency due to a simplified process scheme result in lower CAPEX and OPEX.

By making carbon capture more feasible, ATR enables the production of low-carbon ammonia, which can be

integrated into a world-scale fertilizer complex or supplied as a low-carbon fuel or energy carrier.

Using low-carbon ammonia directly in urea production can significantly reduce the carbon emissions associated with nitrogen-based fertilizers. Alternatively, nitrate-based fertilizers can offer even greater GHG reduction potential, making them an attractive solution for sustainable agriculture in the right conditions.

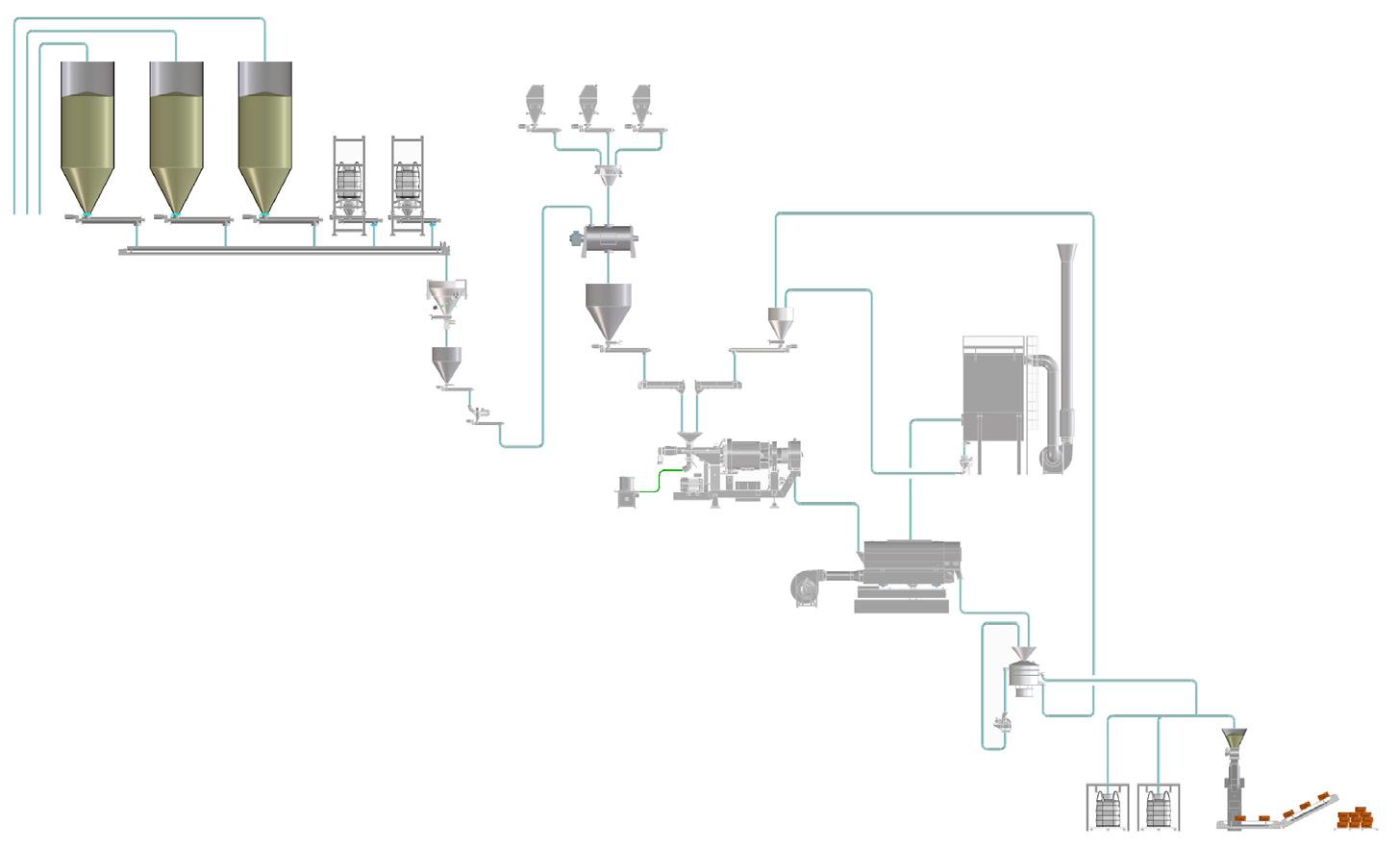

A low-carbon fertilizer plant, as shown in Figure 4, can integrate multiple units, including ammonia, urea melt, nitric acid, ammonium nitrate solution, DEF, and urea ammonium nitrate (UAN). An integrated complex, incorporating ammonia loop, can be delivered by a single licensor.

An example of integrating the company’s technologies is the Meadowlark Project in Gothenburg, Nebraska, US. This facility will be the first to combine the technologies in ammonia, urea, ammonium nitrate, UAN, nitric acid, and DEF.

Powered entirely by renewable energy, this plant will produce 450 tpd of green ammonia. Down the line, the nitric acid plant will have a nameplate capacity of 330 tpd and will be integrated with a urea melt plant, ammonium nitrate neutralisation section, and UAN mixing section. The facility is projected to produce impressive outputs: 365 000 t of UAN, 146 000 t of ammonium thiosulphate (ATS), and 20 million gal./yr of DEF. This project represents a fully integrated green fertilizer plant that will supply fertilizers for the local farmers while utilising waste CO 2.

Another example of the integration of the technologies is the FertigHy project in France. NEXTCHEM has been awarded a feasibility study and pre-FEED contract for FertigHy’s first low-carbon fertilizer plant. The plant, expected to start construction in 2027, will produce 500 000 t of low-carbon nitrogen-based fertilizers annually, using hydrogen from renewable and low-carbon electricity. The company’s technologies will enable environmentally friendly ammonia production and highly efficient nitric acid processing with minimal GHG emissions.

The availability of various process designs tailored for different feedstock and scales is enabling economically viable, low-carbon integrated plants. Stamicarbon’s technology enables ammonia production using renewable energy or fossil fuels with minimal environmental impact, while the NEXTCHEM’s ATR process maximises ammonia production and efficiently integrates with CCUS. These technologies provide a comprehensive approach to low-carbon fertilizer and fuel production in a lean, highly efficient plant.

Matt Cousins, Johnson Matthey (JM), UK, and Klaus Nölker, thyssenkrupp Uhde, Germany, discuss the role that blue hydrogen can play in the decarbonisation of ammonia.

There is an urgent need to limit the rise in global temperatures to avoid severe environmental and societal impact. Many countries across the world have committed to zero emission targets being met by 2050, this timeframe is now only one typical syngas plant lifetime away. The provision of decarbonised hydrogen at scale is an essential step to achieve this. It is forecasted that ammonia production will increase threefold by 2050. At present, around 85% of ammonia production is used to manufacture nitrogen fertilizers, with the remainder used in applications such as refrigeration, mining, pharmaceuticals, water treatment, plastics, fibres, and the abatement of nitrogen oxides (NO x).

New applications including the use of ammonia as a low carbon fuel in the maritime sector, for stationary power generation or as a hydrogen carrier are emerging, and fast-growing markets require decarbonised ammonia.

Ammonia production is a highly energy-intensive process, which currently accounts for about 2% of global energy consumption. Global production was nearly 180 million t in 2022, with associated CO 2 emissions of 420 million t CO 2 1 The challenge facing the ammonia industry is twofold – how to achieve a step change increase to overall ammonia production without increasing overall CO 2 emissions; and how to decrease the CO 2 intensity of existing ammonia manufacturing assets.

Low carbon ammonia can be either produced via:

n Renewable energy with electrolytic hydrogen.

n By combining conventional fossil-fuels processes with carbon capture.

To achieve climate targets and lower carbon emissions that occur through ammonia production, we need both methods to produce affordable and efficient low carbon ammonia. This article discusses the role of blue hydrogen in decarbonising ammonia.

Blue ammonia production projects can be executed today using well proven technology. These will provide a chemical feedstock that is already transported and used extensively around the world, offering a carbon-free molecule, with a low carbon intensity for use as an energy vector. Current ammonia and fertilizer producers, with decades of experience in ammonia production, can support meeting this need, through applying their know-how and ammonia infrastructure to operate future low carbon ammonia flowsheets.

By reforming natural gas with carbon capture and storage (CCS) to produce low carbon (blue) hydrogen, one can efficiently convert this into low carbon ammonia (NH 3) via the Haber Bosch process, with significantly reduced carbon emissions. The announcement of the JM and uhde® decarbonised ammonia – where the companies integrate JM’s LCH TM technology with uhde® ammonia process –offers a way to do this at scale today.

Low carbon hydrogen can be produced via two primary routes:

n Electrolytic splitting of water using renewable electricity.

n Reforming of fossil resources with CCS.

Hydrogen produced from renewable resources is commonly referred to as ‘green hydrogen’, from fossil resources with CCS as ‘blue hydrogen’, and from fossil resources without CCS as ‘grey hydrogen’.

Arguably the best way to achieve the scale up of hydrogen production is to be technology agnostic –embracing both blue hydrogen and green hydrogen production to ensure growing demand can be met quickly and sustainably.

Greening the production of electricity will play a crucial role in decarbonising our energy mix. Using this resource, we should continue to increase green hydrogen production. We should also recognise that the greener power can support production of lower carbon intensity blue hydrogen and ammonia. As greener power is imported into a blue ammonia process, it also has a positive effect. It is encouraging to see ongoing investment and more renewable electricity capacity added to our energy system, as this will help bring the overall cost of clean hydrogen down.

To put the scale of the energy transition into context on a global basis, replacing all fossil fuel derived hydrogen with green hydrogen would require all the solar and wind power generation capacity currently in operation and developing. As already set out, much more hydrogen will be required to meet demand as new uses for hydrogen come online. This is where blue hydrogen should complement green hydrogen. It is ready to scale up now

and can meet our immediate needs to reduce CO 2 emissions, while green hydrogen will take longer to scale.

Steam methane reforming and advanced gas reforming are the two principal technologies used for blue hydrogen production. Advanced gas reforming consists of either an autothermal reformer (ATR), or an ATR coupled with a gas heated reformer (GHR). Where there is a requirement to capture CO 2, it is recognised that advanced gas reforming is a more appropriate technology for generation of blue hydrogen, due to its provision of a more suitable stream for CO 2 capture. JM's LCH technology enables decarbonised hydrogen to be produced at scale now, in a sustainable manner.

The ATR flowsheet combines two processes that take place in a primary reformer:

n Heating of the process gas.

n Reforming of the feedstock.

The ATR flowsheet carries out both these functions on the process side of the flowsheet, meaning there is no low-pressure atmospheric CO 2 release (Figure 1).

It does this by introducing oxygen through a burner, which entrains the oxygen flow with the process gas.

This happens in the area directly below the burner. Simultaneously the gas stream ignites due to the flammability of the gas mixture, and it is partially oxidised (burnt) creating heat, resulting in the formation of CO x and water (H 2 O).

The adiabatic ATR reactor is energy balanced, considering energy from combustion, and energy consumed by the endothermic reforming reaction and energy loss from the vessel. The net difference is the sensible heat energy. The process gas exits the ATR and then passes through a reformed gas boiler where a portion of sensible heat can be used to raise steam. This energy balance is illustrated in Figure 2.

Steam raising from the ATR is necessary (and as such involuntary) for its operation. However, it has a positive effect on the energy balance of the overall flow sheet, providing energy to drive machines. However, raising additional steam requires burning more feedstock in oxygen (O 2 ). So, the focus should be to optimise where the operating conditions allow for long stable operating cycles of at least 4 years.

The hot, well mixed gas stream now passes through a catalyst bed. It is through this bed that the reforming reactions take place, producing hydrogen by reacting process gas with steam as shown by the general reaction equations below. While the CO also reacts with H 2 O in the process, to produce hydrogen (H 2 ), and CO 2 via the water gas shift process.

General steam methane reforming reaction:

Water gas shift (WGS) reaction:

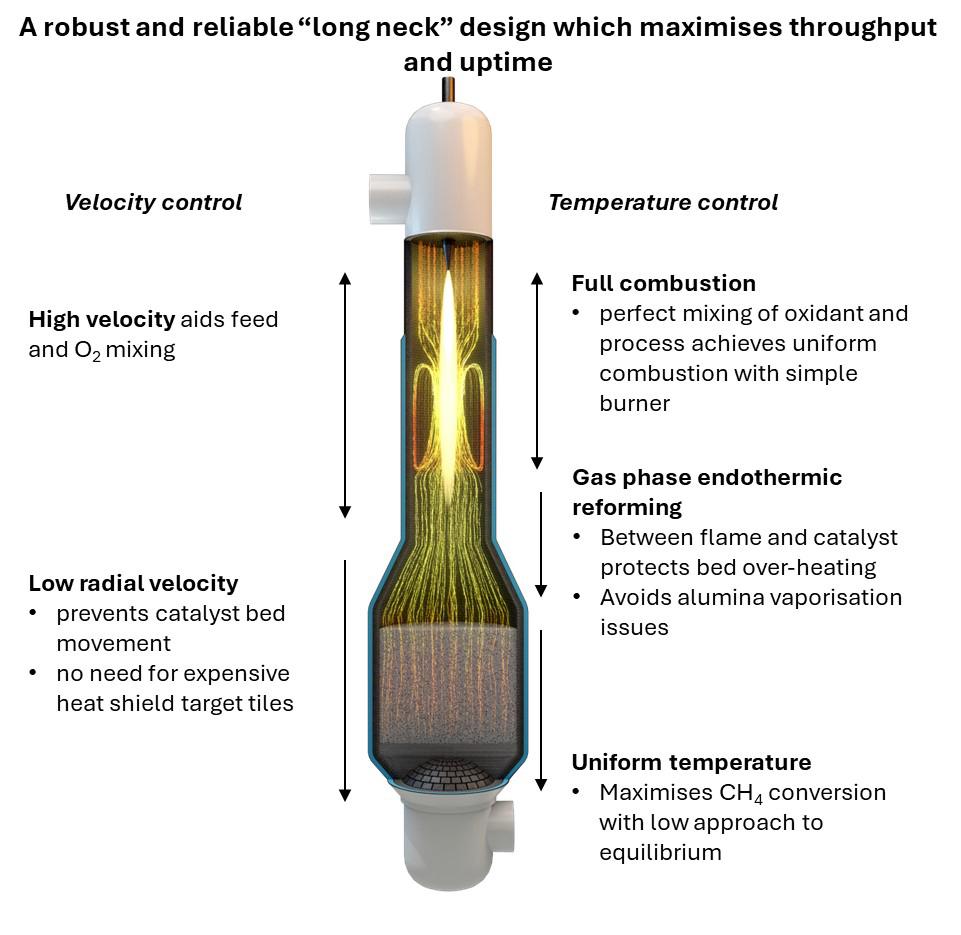

The equilibrium position and kinetics favour high methane conversion at the typical ATR exit temperature (950°C - 1050°C). The ‘long-neck design’ can enable long runs and high effectiveness from relatively small volumes of catalysts.

The ATR operation should be considered in the context of the hydrogen (or ammonia) flowsheet it is part of. In either case the target product contains no carbon. Part of the optimisation for a process that does not benefit from CO as a downstream reactant should maximise hydrogen production from reforming and WGS. By doing this, we maximise the amount of hydrogen generated from splitting water in the process. So, the choice of operating conditions; (i) temperature, effected by level of combustion, and (ii) the ratio of steam to carbon (S:C), should reflect this target.

O 2 level defined by x in the equation below, sets a target achieved exit temperature.

Combustion reaction:

4 +

Higher S:C drives the reforming reaction. A requirement when optimising this is to minimise the unconverted CH 4 in reaction 1. Noting the global steam addition can be adjusted downstream of the ATR, with steam addition into the WGS section to convert CO to CO 2 and produce further H 2, from water splitting. Allowing the S:C inlet of the ATR to be adjusted independently.

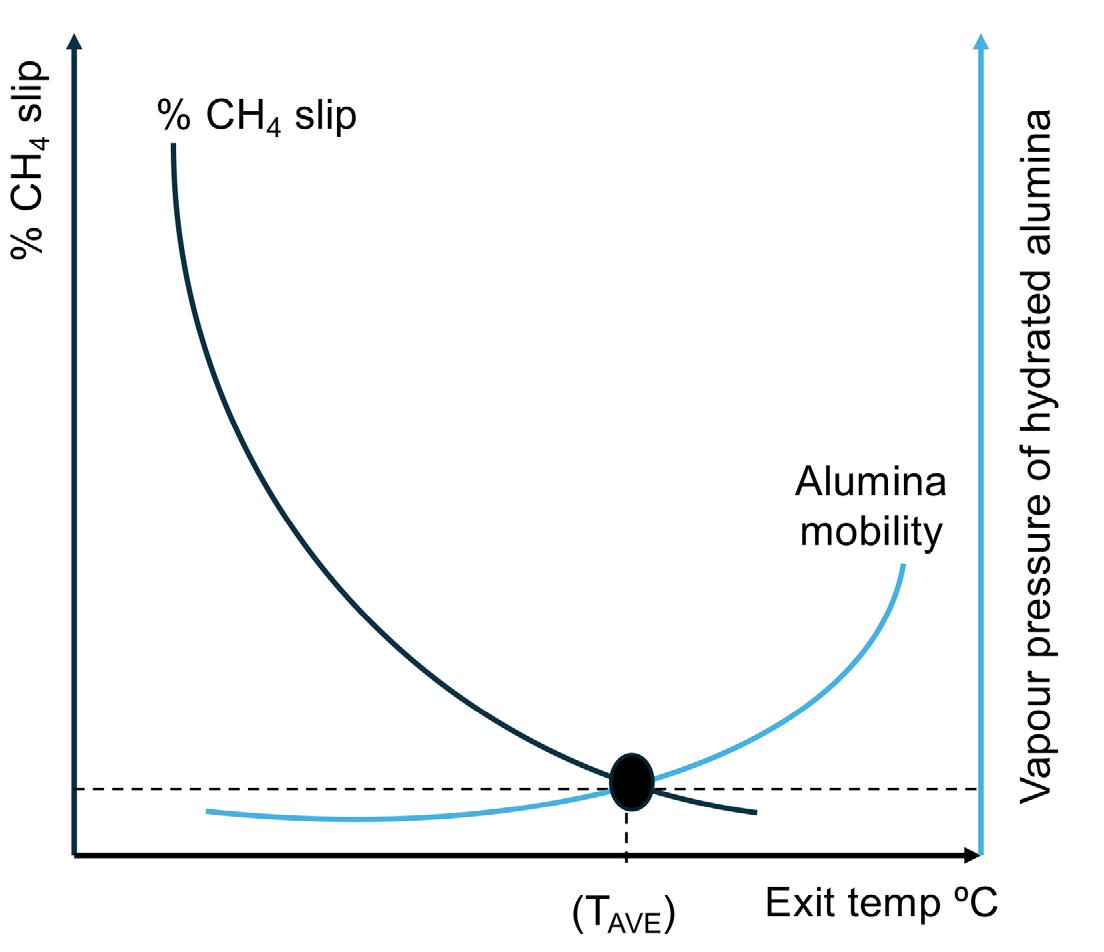

Figure 3 compares the equilibrium methane (CH 4) slip for a S:C of 0.6 and 1.3 at the inlet of the ATR when the exit temperature and feed to oxygen ratio remains the same. The lower S:C affects the performance as follows:

n Increases the methane slip, which means the purge (tail gas) is more carbon rich.

n Makes the operating conditions more aggressive within the ATR.

n Reduces steam raising capability.

3. Plot of equilibrium methane slip at S:C 0.6 and 1.3 inlet the ATR.

To minimise CH4, a higher exit temperature provides a favourable equilibrium position with respect to reaction 1. However, Figure 4 shows the risk of increasing the exit temperature to be alumina mobility. This is known to adversely impact performance to access the benefit after the plant is commissioned without modification.

So, when thinking of the S:C at the ATR to make blue hydrogen or ammonia, it is important to consider conditions that:

n Minimise CH4 slip, while not unduly stressing the ATR.

n Provide long and efficient operating cycles between plant shutdowns.

In doing this the ATR operation will:

n Minimise CH4 (feed): product.

n Minimise carbon intensity: product.

Where the hydrogen is further processed, the ATR flowsheet should be integrated, for example, with an ammonia synthesis loop in an analogous way to what we know today, that uses high grade steam exiting the secondary reformer. The ATR flowsheet uses the involuntary steam raised from the reformed gas boiler(s), exiting the ATR, to provide motive steam that powers the syngas and refrigeration compressors.

GHR-ATR based flowsheets can be integrated to provide zero steam export from the hydrogen production process. This enables the increased use of external renewable electrical power. This can lower the carbon intensity of the product, and/or lower the cost of the production as less natural gas is needed per unit of ammonia production.

This configuration uses the heat exiting the ATR to directly drive more reforming in a GHR.

Where the GHR replaces the reformed gas boiler, it utilises the high grade heat on the shell side of the GHR. This heat drives approximately 30% of the reforming, through reaction on the tube-side of the GHR, before the gas enters the ATR (Figure 5).

The ATR then completes the remaining 70% of the reforming reaction, through the processes already described in this article. In this case, the size of the ATR, for the same hydrogen production, can be smaller. It follows that the air separation unit (ASU) can also be smaller, as less oxygen is required. This has two effects: n It lowers operational costs, as less power is needed for the ASU.

n It is capital expenditure (CAPEX) neutral, as while the GHR adds a unit-operation, the reformed gas boiler is removed and the ASU is smaller, and so lower in cost.

The transition from grey ammonia to blue ammonia offers the most efficient decarbonisation route for the chemical industry, with proven at-scale technologies. Blue ammonia production offers a pathway to decarbonise fertilizer production, as well as meeting future energy requirements, by using ammonia as an energy vector. Crucially, this will build on existing infrastructure and supply chains. Fully integrated blue ammonia technology can decarbonise the fertilizer production and be one of the solutions to meet the energy transition targets, being aimed at globally.

Reference

1. World Hydrogen Review’, Internqtional Energy Agency (IEA), (2024).

Note

LCH is a trademark of Johnson Matthey PLC. uhde® ammonia process is a trademark of thyssenkrupp Uhde.

Giulia Sporchia and Elisa Brocca, Cannon Artes S.P.A., Italy, analyse solutions and technologies to effectively reduce the water footprint in ammonia production, through water recovery and reuse.

The conventional grey ammonia production process is highly water-intensive, with even higher consumption for blue and green ammonia. Advanced water and wastewater treatment technologies are crucial for enhancing the sustainability of ammonia production. This article analyses solutions and technologies for effectively reducing the water footprint through water recovery and reuse.

Ammonia is one of the most crucial chemicals in the modern world. It is a key component in producing nitrogen-based fertilizers, which are essential for global food production. As the world’s population continues to grow, so does the demand for fertilizers. However, ammonia production presents significant environmental challenges, one which is the large amount of water required for the process.

The Haber-Bosch process has been the cornerstone of industrial ammonia production since the early 20 th century, and remains the dominant method today: ammonia synthesis comes from the reaction between nitrogen and hydrogen at a high temperature and pressure in the presence of iron-based catalysers.

While nitrogen is distilled from air, the hydrogen is produced through steam methane reforming (SMR), in

Conductivity

which natural gas together with steam water produces synthesis gas, which contains hydrogen and carbon oxides.

CH 4 + 2H 2O → CO 2 + 4H 2

Considering only the stoichiometric reactions, almost 1 t of steam water is required to produce 1 t of ammonia (0.8 t of H 2O per t of NH 3).

The stoichiometric consumption further increases when considering blue and green ammonia. For instance, the amount of steam water required doubles when considering green ammonia, arriving at 1.8 t of H 2O per t of NH 3

However, water is not just entering the chemical reaction as a feedstock, but is involved in various stages of ammonia production, making the overall process highly water-intensive.

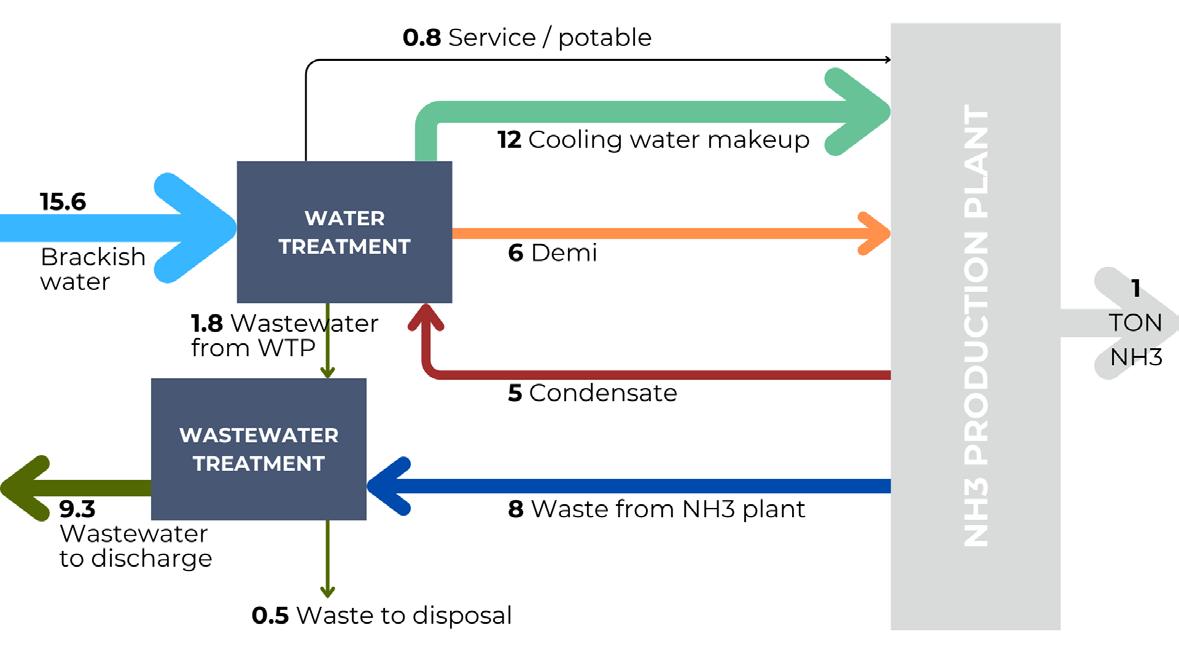

To determine the quantity and usage of the required water, a number of ammonia production plants – where Cannon Artes has either collaborated or supplied water treatment plants – were studied. In particular, several plants with capacities varying from 400 to 4400 tpd of ammonia produced, located in different parts of the world were analysed. Figure 1 summarises the location of the considered plants.

The first part of the analysis carried out consisted in normalising the water consumed for the ammonia produced to determine the typical consumption.

This study allowed us to calculate the amount of water required for the following uses:

n Water for steam production.

n Water for cooling systems.

n Water for other uses.

One initial finding from this analysis is highlighted in Figure 2, where it is seen how the demineralised water produced as a function of the ammonia capacity of the different plants demonstrates a clear linear relationship.

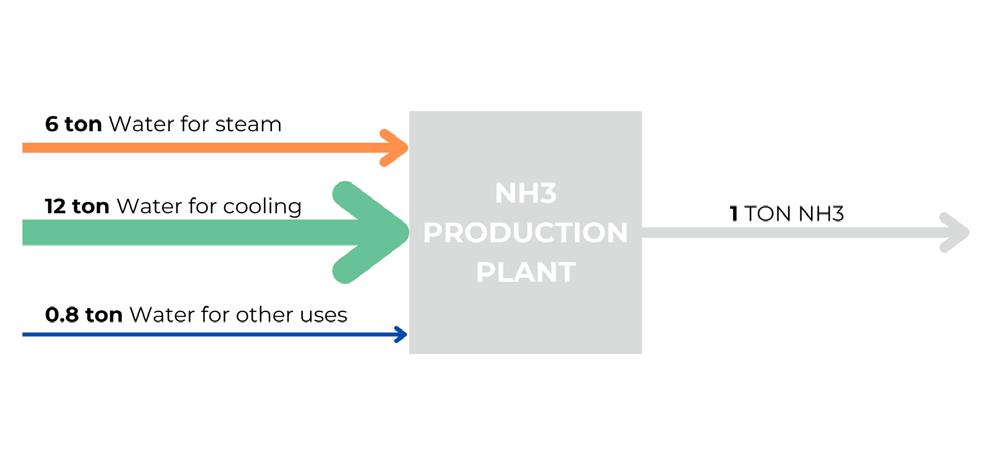

Demineralised water is used in steam production in different parts of the plant such as process steam, steam for the ammonia synthesis compressor, steam for the electricity generator, and steam for the CO 2 compressor. These streams require a total amount of approximately 5 - 7 t of demi water per t of NH 3, as seen in the graph in Figure 3.

In particular, water for steam production is required for: n Process steam.

n Steam for the ammonia synthesis compressor.

n Steam for the electricity generator (power turbine).

n Steam for the CO 2 compressor.

The total demi water required is 6 t of demi water per t of NH 3

Water is used as a cooling medium to remove heat produced by exothermic reactions and to condense steam. Cooling water feeds the following equipment, mainly: the blow down cooler, critical oil coolers, seal water coolers, the flushing condensate cooler, the auxiliary boiler blow

Fully automatic packaging machines

Fully automatic high-quality packaging machines for bagging up to 2000 pillow and/or gusset bags per hour.

Fully automatic FFS packaging machines

Fully automatic form-fill-seal packaging machines for the production and packaging of up to 2800 bags

High-performance robot palletizer

High-performance robot palletizer for palletizing up to 3000 bags or cartons per hour.

down cooler, the ammonia storage refrigeration unit, and the instrument air compressor. Different cooling systems are suggested depending on the plant’s location. Using seawater as a cooling medium usually involves closed-loop cooling towers (CT) or once-through cooling systems due to the stream’s high salinity. On the other hand, brackish water (rivers, lakes) can be used in open-loop cooling towers. Different water amounts are consumed depending on the cooling system’s typology. The analysis carried out highlighted how for open-loop cooling towers, considering a concentration factor of 4 - 5, the make-up water contribution is around 12 - 13 t per t of NH 3.

Water is also used for firefighting, drinking water, service water, and in the plant's domestic facilities. The estimation is approximately 0.8 t per t of NH 3

When considering the water that the plant will produce, it is not only important to consider the amount of water produced, but also its required quality, to determine the optimal water treatment.

Table 2. General guidelines for cooling water quality

water quality

Strongly dependent on location and weather conditions

Steam production requires using demineralised water. Depending on the final use of the steam, the demi water quality slightly changes (refer to Table 1).

The required treatments and the consequent achievable recoveries can vary widely depending on the feed water type.

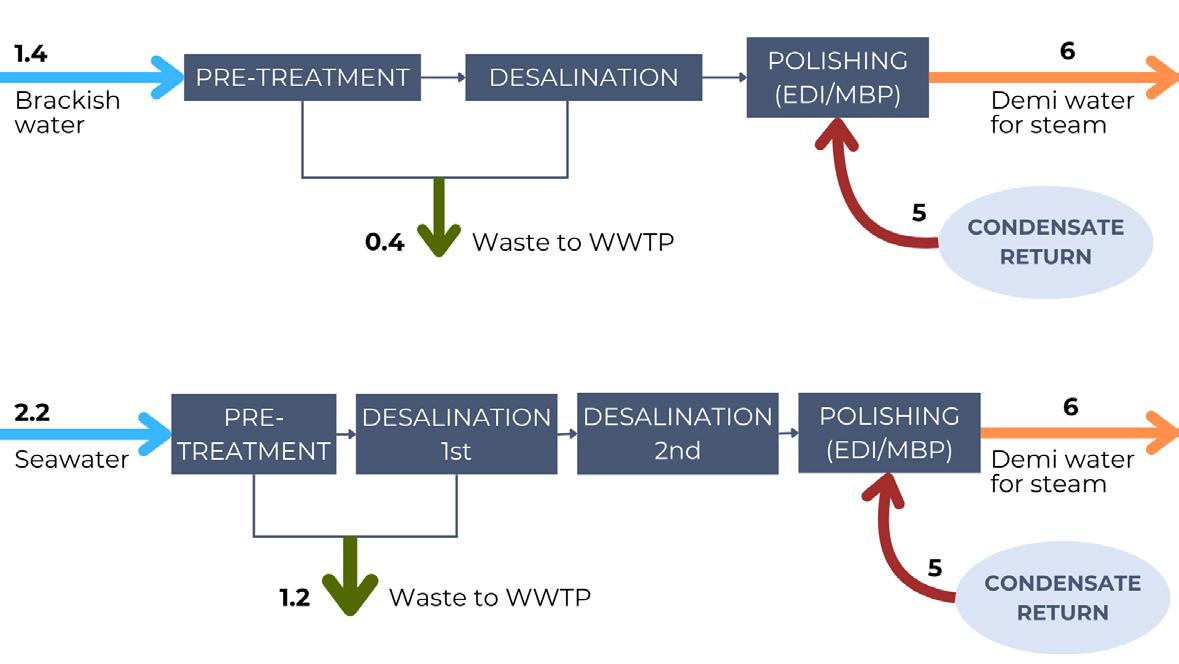

Brackish water is usually associated with a recovery rate of 80% and requires a pre-treatment for solids removal, filtration (on sand and/or ultrafiltration membranes) followed by a demineralisation treatment with IEX (ion exchange, cationic + anionic + MB mixing bed) or with RO (reverse osmosis) + EDI (electrodeionisation).

On the other hand, seawater is associated with a significantly decreased recovery, due to the requirement for a further desalination step. In this case, pre-treatment is followed by a double-pass RO and polishing system, EDI or MBP (mixed bed polisher).

The study carried out took into account plants sourcing from both brackish and seawater. The differences in the water intake and the waste generated for demi water production is highlighted in Figure 4.

In the case of green ammonia, where H 2 is produced through hydrolysis, the required quality depends on the chosen technology. In general, alkaline and anion exchange membrane cells require a maximum conductivity of 5 µ S/cm, proton exchange membrane cells require 0.1 µ S/cm and plants producing more than 100 MW generally require a maximum of 0.056 µ S/cm.

The technologies available to reach these values are the same presented for demineralised water for grey ammonia production (RO followed by EDI or IEX).

Cooling

The make-up water in cooling towers is characterised by a limited salinity and the absence of total suspended solids (TSS). Some general indications on cooling towers’ make-up quality can be found in Table 2.

Depending on the water employed in demineralised and make up water production, different treatment trains may be required. If the water characteristics are comparable to those of river water, achieving these characteristics is possible thanks to a pre-treatment, ensuring that the TSS limitation is met. Furthermore, if the total dissolved solids (TDS) are particularly elevated, an RO treatment is also required.

Pre-treatment usually consists in TSS elimination with a physical separator, followed by multimedia filters and/or ultrafiltration. Once the desired suspended solids level is achieved, the stream can undergo a partial TDS removal. The goal is that of achieving a dissolved solids concentration around 50 - 500 ppm, to avoid salt accumulation and guarantee a suitable number of concentration cycles. The salinity limitation may vary depending on the minimum number of concentration cycles.

In the production plant, water for other uses is also required: fire water, service water and potable water. Removal of suspended solids, organic matter, and

eventually TDS is required. Some further adjustments may be required for producing drinking water. In this case, additional remineralisation and disinfection might be needed. The resulting stream follows the regulations of the country where the plant is located. As a general reference, it is necessary to follow World Health Organization (WHO) parameters.

Once the amount of raw water and the quality requirement have been identified, it is necessary to maximise water reuse. Water reuse involves capturing and recycling water used in the production process rather than releasing it as wastewater. This not only reduces the need for fresh water but also minimises the amount of wastewater discharged into the environment.

A further step in the present study consisted of evaluating the main waste streams coming from an ammonia production plant. Table 3 highlights the main contaminants found in these waste streams, together with the average amount of water associated with the production of 1 t of ammonia.

Condensated streams can be reused entirely. Condensates have different origins and are mostly characterised by the same pollutants. These streams are generally clean and,

after a polishing treatment, can be reused as boiler feed water. The main contaminants present are ammonia, urea, CO 2 , and formic acid, which are usually removed with IEX. Depending on the cases, it may be necessary to use only mixed bed polishing or a more complete treatment including cationic and anionic exchangers.

It was estimated that the condensates reused are approximately 5 t of condensate per t of NH 3 produced, which can be entirely recycled. Their reuse makes up for approximately 80% of the demi water required to produce steam.

Figure 5 highlights how condensates reuse introduction in the considered plants modified the raw water intake with respect to Figure 4, both in the case of brackish and seawater.

The treatment and reuse of return condensates allows for decreasing the request of raw water from 8.2 to 1.4 t of condensate per t of NH 3 for brackish water and from 13.3 to 2.2 t of condensate per t of NH 3 in the case of seawater.

Polished condensate streams are not the only by-products from an ammonia production plant that can be recycled. Several other waste streams, typically directed to a wastewater treatment plant for disposal, are potentially reusable (Table 3). Each stream has different contaminants and can be treated and reused in different ways.

The stream with the highest flow rate is for cooling tower blowdown. In the case where brackish water is used as raw water, the CT blowdown salinity will be 3 - 5 times more than that of raw water, depending on the number of concentration cycles. A desalination treatment for this stream will eliminate the demand of raw water for demi make up water.

The contribution of rainwater depends upon the location and weather conditions, but its treatment and recovery can be very helpful for further decreasing raw water intake.

A specific study on wastewater reuse allowed the calculation of an estimation of the water flows involved per 1 t of ammonia production in the case where only condensates are reused, and wastewater is treated and discharged. The result is shown in Figure 6, which was then compared with the case of wastewater recirculation.

In areas with limited water availability, it becomes necessary to decrease raw water intake, reusing wastewater from ammonia production as much as possible. Considering wastewater recovery, discharge to the environment is eliminated and, as a consequence, water make up is reduced by more than 50%, from 15.6 t of H 2 O per t of NH 3 to 6.8 t of H 2 O per t of NH 3 . Different water needs can be seen in Figure 7.

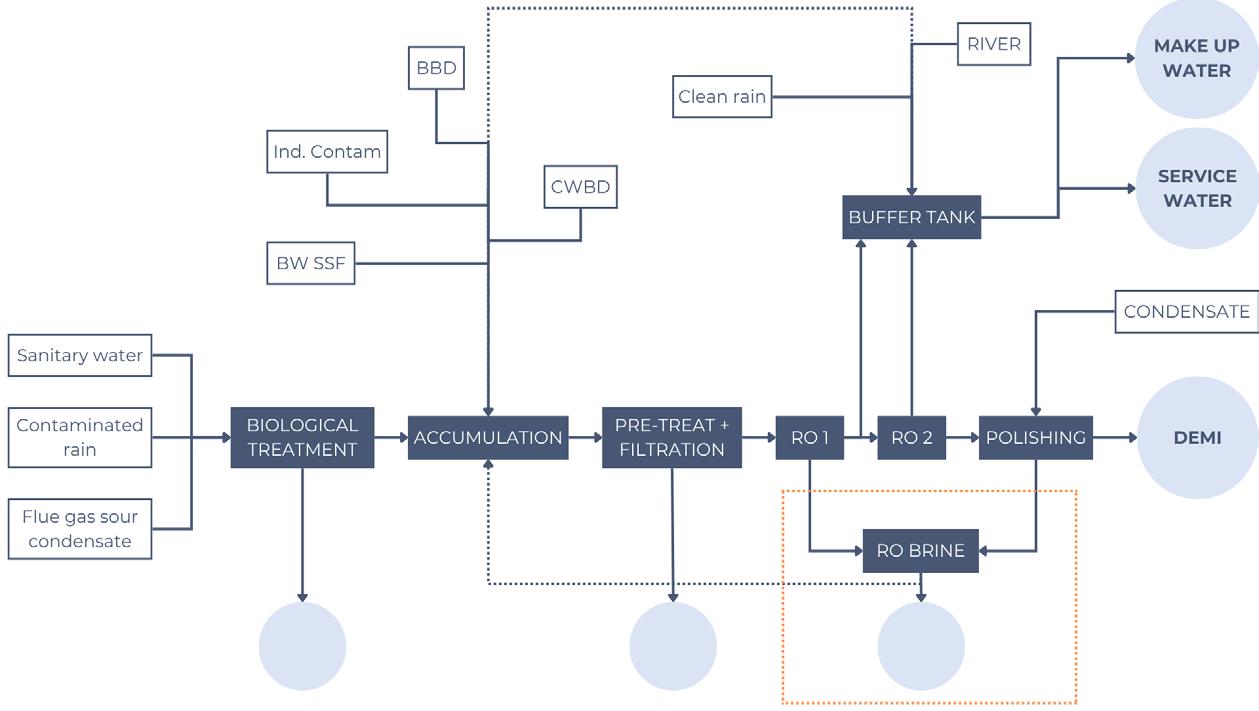

An example of an integrated water treatment scheme for ammonia production is reported in Figure 8, highlighting a possible treatment and wastewater reuse strategy.

In the example, the following treatment streams are considered:

n Sanitary water, contaminated drain water and fuel gas sour condensate are mixed and treated in a biological system with membrane bioreactor (MBR).

n An accumulation section mixes other waste streams, such as industrial contaminated, cooling towers blowdown and blowdown from boilers, with a portion of river water.

n A chemical-physical treatment is introduced to remove TSS, heavy metals (whenever present), and hardness, with the goal of increasing the recovery of the following sections. This step usually requires dosing of a flocculant and a coagulant.

n A membrane filtration system with ultrafiltration is predicted to achieve negligible TSS content.

n The first reverse osmosis treatment allows for achieving a salinity comparable to that of river water. In this step, antiscalants and acids are dosed to avoid scaling. A portion of the permeate water from first pass RO is then separated and mixed with clean rainwater and make up water from the river. These streams contribute to producing 12 t for cooling tower make up and 0.8 t for other services.

n To produce 6 t of demi water, the remaining fraction from first pass permeate is headed to the second pass of RO, mixed with condensates and sent to the final polishing treatment, with mixed beds ion exchange.

n All waste streams are recirculated in this treatment, including sludge supernatants, filter backwash, RO low salinity concentrates. This strategy allows for as much recovery as possible.

The streams with higher salinity, like first RO concentrate and eluates, are treated with a further RO treatment, maximising the concentration of this stream, reducing the volume that will be sent to final disposal and achieving near zero liquid discharge. Finally, only 1 t, composed of a rejected salty stream and dewatered sludge, is disposed of.

ZLD can be achieved by sending the reject stream to an evaporator, which allows water recirculation (with a previous pre-treatment). This will result in discharging only solid waste: the dried sludge from chemical-physical treatment and salt slurry from evaporator crystalliser.

The analysis carried out on several fertilizer plants highlighted the important water requirement for

nitrogen-based products. As a first step, it was possible to determine the amount of water needed for demi and cooling tower make up water, both substantial for the operation of the fertilizer facility. The raw water requirement for the desired streams was then calculated depending on the source, since brackish water and seawater are associated with different recoveries. The impact of water reuse was then examined, highlighting how condensates and wastewater recycle can contribute to decreasing raw water intake. The main results are collected in Table 4, summarising the water requirements associated with the different cases.

Stefano Alberini, Belleli Energy CPE, Tosto Group, discusses the fabrication of a high-pressure ammonia synthesis converter with enhanced 2.25cr-1mo low alloy steel and advanced welding technology.

The production of ammonia, a critical component of fertilizers and various industrial chemicals, relies heavily on high-pressure synthesis converters. These vessels operate under extreme conditions, demanding exceptional structural integrity and reliability. The fabrication of such converters presents significant challenges, particularly in the welding of thick-walled components, where traditional welding methods can lead to increased weld material volume, residual stresses, and potential defect risks. This article will provide a comprehensive overview of a successful application of enhanced 2.25Cr-1Mo low alloy steel

to fabricate high-pressure ammonia synthesis converters with enhanced overall mechanical properties obtained through the adoption of an advanced welding technolog y.

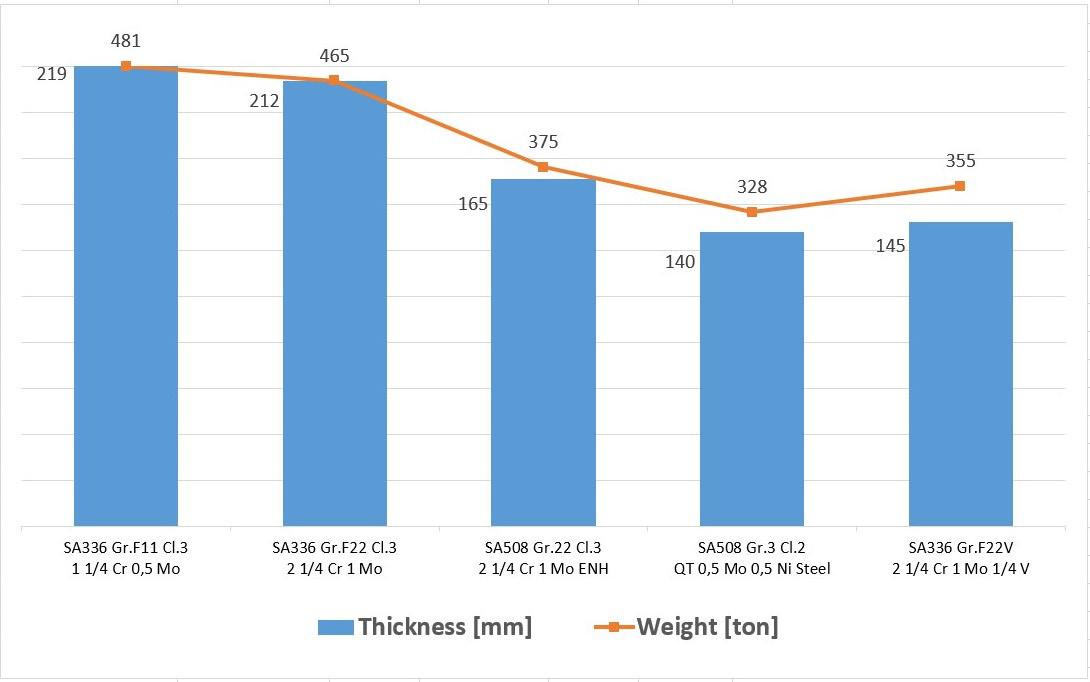

Enhanced 2.25Cr-1Mo low alloy steel offers a compelling combination of properties that make it well-suited for demanding applications:

n Enhanced mechanical properties: compared to conventional 2.25Cr-1Mo steel, the enhanced version exhibits superior strength and creep resistance due to a specifically designed heat treatment process involving lower tempering temperatures. This allows for reduced wall thicknesses and weight savings without compromising structural integrity.

n Suitability for high-temperature hydrogen service: while the development of 2.25Cr-1Mo-0.25V steel with its enhanced resistance to high-temperature hydrogen attack led to a temporary decline in the use of enhanced 2.25Cr-1Mo, it has experienced a resurgence in applications where operating temperatures are below its ASME Code allowance (e.g., 454°C), such as ammonia synthesis.

Figure 2. Weld macro-section ‘one-bead-per-layer’ welding sequence.

SA

SA 336 Gr.F22

(2 ¼ Cr 1 Mo low alloy steel)

SA 336 Gr.F22V (2 ¼ Cr 1 Mo

Sa

(2 ¼ Cr 1Mo Enhanced steel)

Notes: * 300°C ASME BPV code Section VIII Div. 2 ** Toughness reference values can vary based upon the involved thickness

n Cost-effectiveness: enhanced 2.25Cr-1Mo steel offers a cost-effective alternative to more expensive high-strength fine-grained steels, which may not be necessary for all ammonia synthesis converter applications. Table 1 shows typical base materials adopted for ammonia synthesis converter and their mechanical characteristics.

The enhanced mechanical properties of 2.25Cr-1Mo steel are achieved by reducing the tempering and post weld heat treatment (PWHT) temperatures compared to the standard grade. While this enhances strength, it necessitates careful control of the heat treatment process to ensure adequate toughness, particularly in the weld zone. Lower PWHT temperatures can make it challenging to achieve the required impact toughness, especially at low temperatures (e.g., -29°C). However, the advanced MONOWELD® technology, with its ability to promote uniform microstructures, can help mitigate this challenge.

High-pressure vessels, such as ammonia synthesis converters, are typically constructed from thick steel plates to withstand the high

internal pressures and temperatures involved in the process. Welding these thick sections poses several challenges:

n Increased weld volume: traditional multi-pass welding techniques require substantial weld material, increasing the risk of defects and distortion.

n Residual stresses: the heat input during welding can induce significant residual stresses in the joint, potentially compromising its integrity.

n Hydrogen embrittlement: ammonia synthesis involves high-pressure hydrogen environments, which can lead to hydrogen embrittlement in susceptible materials, particularly in the weld zone.

n Toughness requirements: maintaining adequate toughness, especially at low temperatures, is crucial for preventing brittle fracture in high-pressure vessels.

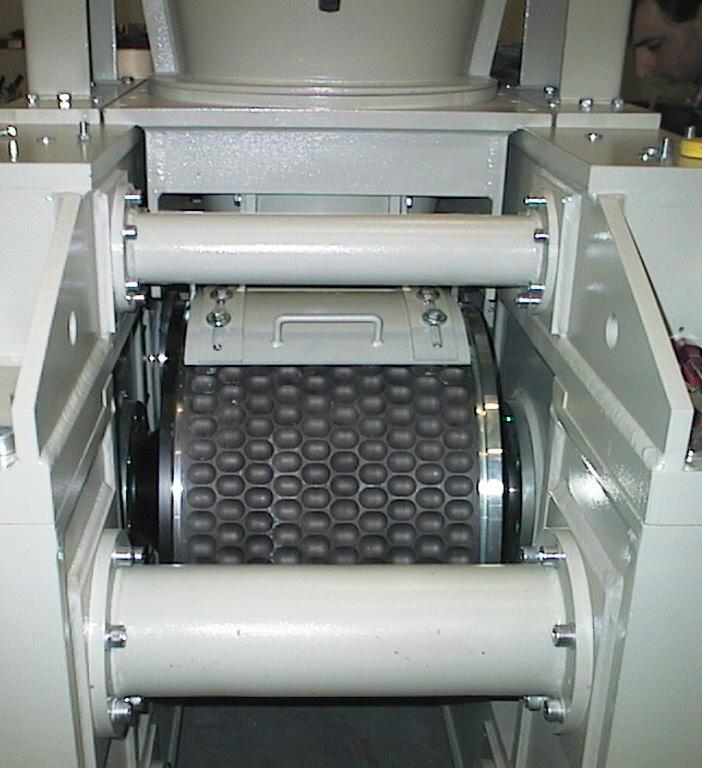

To address these challenges, conventional welding practices for high-pressure vessels often employ narrow gap welding techniques. This approach utilises a specialised joint preparation with a narrow groove, minimising the volume of weld metal required. Typically, a two-bead-per-layer welding sequence is employed with submerged arc welding (SAW), a process known for its high deposition rates and ability to produce high-quality welds.

While effective, this method still involves multiple passes and can be time-consuming.

The advanced MONOWELD technology represents a significant departure from conventional narrow gap

Wondering what other machines we offer and how we can assist in your situation?

Scan the QR-Code and take a look at our website.

For more than 35 years EMT has proven to be the right partner for all mixing, bagging and conveying machines.

• Capacities from 25 to 75 tons per hour

• Machine sizes of 4.5-5.4-7-9-11.5-14 tons

• Simple and subtle mixing process

• For big bags/Jumbo bags

• Capacity of 50 to 70 tons per hour

• 500 kg to 1250 kg bags

• Also systems of 120/180 tons per hour available

• Custom made

• Unlimited number of weighing bunkers

• Capacity from 20 to 300 tons per hour

• Fully automatic computer controlled mixing process

The successful implementation of the technology required extensive development and optimisation efforts, focusing on three key aspects:

n Weld bevel design: the bevel design was carefully engineered to facilitate proper fusion and penetration with a single-bead-per-layer sequence.

n Welding parameter selection: extensive experimentation was conducted to determine the optimal welding parameters, including current, voltage, travel speed, and wire feed rate, to ensure consistent weld quality and performance.

n Welding torch design: a specialised welding torch was developed to accommodate the single-bead-per-layer technique and provide precise control over wire positioning within the joint.

The chosen welding process, tandem submerged arc welding with two wires, offers high deposition rates and excellent weld quality. The custom-designed torch further enhances control and precision, crucial for the success of the advanced welding technology.

Macro-sections of welds produced (Figure 2) reveal uniform and regularly distributed weld bead shapes and dimensions.

welding practices. It introduces a single-bead-per-layer welding sequence, effectively reducing the number of passes required to complete the weld joint (Figure 1).

This innovative approach offers several advantages:

n Reduced weld volume: by minimising the number of passes, the advanced technology significantly reduces the volume of weld metal, leading to lower distortion and a decreased risk of defects.

n Improved weld quality: the single-bead-per-layer technique promotes better fusion and reduces the likelihood of slag inclusions and other imperfections.

n Reduced residual stresses: fewer welding passes translate to lower overall heat input, minimising residual stresses in the joint.

n Enhanced toughness: the technology, when properly optimised, can contribute to more uniform and consistent toughness properties in the weld zone.

Comparing these to traditional narrow gap welds based on a two-beads-per-layer technique highlights the ability of the technology to eliminate significant variations in the weld microstructure, contributing to improved mechanical properties and reduced susceptibility to localised weaknesses.

Toughness, a critical property for pressure vessels operating in demanding environments, was rigorously evaluated through Charpy V-notch impact testing. To assess the impact of weld bead placement on toughness, impact test specimens were extracted from standard narrow gap welds with notches located at the weld centre and the bead centre.

Impact tests were conducted at various temperatures to compare the performance of the different welding sequences and notch locations. The results (Figure 3) demonstrate that while the standard narrow gap technique also performed well, the MONOWELD technology exhibited more uniform and consistent toughness across the weld

joint, minimising the potential for localised brittle fracture.