Euromel® Melamine - the leading and most advanced technology for the production of high-quality melamine used in wood-based products, laminates, moulding compounds and fire-extinguishing foams in the last 40 years.

Delivers high purity, high consistency melamine with total zero pollution (TZP) with extremely lower energy consumption using 30% lesser steam import and 20% lower fuel utilisation than the closest competitor.

Euromel® Melamine Process is now used in 28 plants worldwide, accounting for more than 8 million tonnes of melamine produced cumulatively, making it the most traded and widely used melamine worldwide.

03 Comment

05 News

10 North America’s Fertilizer Market: Opportunities To Prosper

Gordon Cope, Contributing Editor, discusses the recent activity in the North American fertilizer market, and examines the prospects for growth in the coming decade.

16 Fuelling The Future

Gary Bennington, UNICAT Catalyst Technologies, LLC, APAC, discusses how breakout catalyst technology can deliver enhanced profitability within the ammonia industry.

21 Embracing Change

Peter Maas, Grandperspective GmbH, explains why a sea-change in emissions monitoring is needed if green ammonia is to become the future of farming.

25 Maximising Hydrogen Electrolyser Capacity

Todd Cartwright, Nel Hydrogen, USA, examines why the capacity for hydrogen electrolysers must be increased.

28 Green Ammonia From A Business Perspective Rochman Goswami, Black & Veatch, USA, discusses the business opportunities that green ammonia presents in the quest to decarbonise across industries.

Maria Acevedo and Brian Clancy, Kimre Inc., USA, examine often overlooked plant design considerations and emphasise the critical role of mist eliminators.

40 A Mist Opportunity

Marilia Davidson, Damion Adams, USA, and Ali Goudarzi, the Netherlands, CECO, explain how droplet collection mechanisms operate and help distinguish different types of mist eliminators.

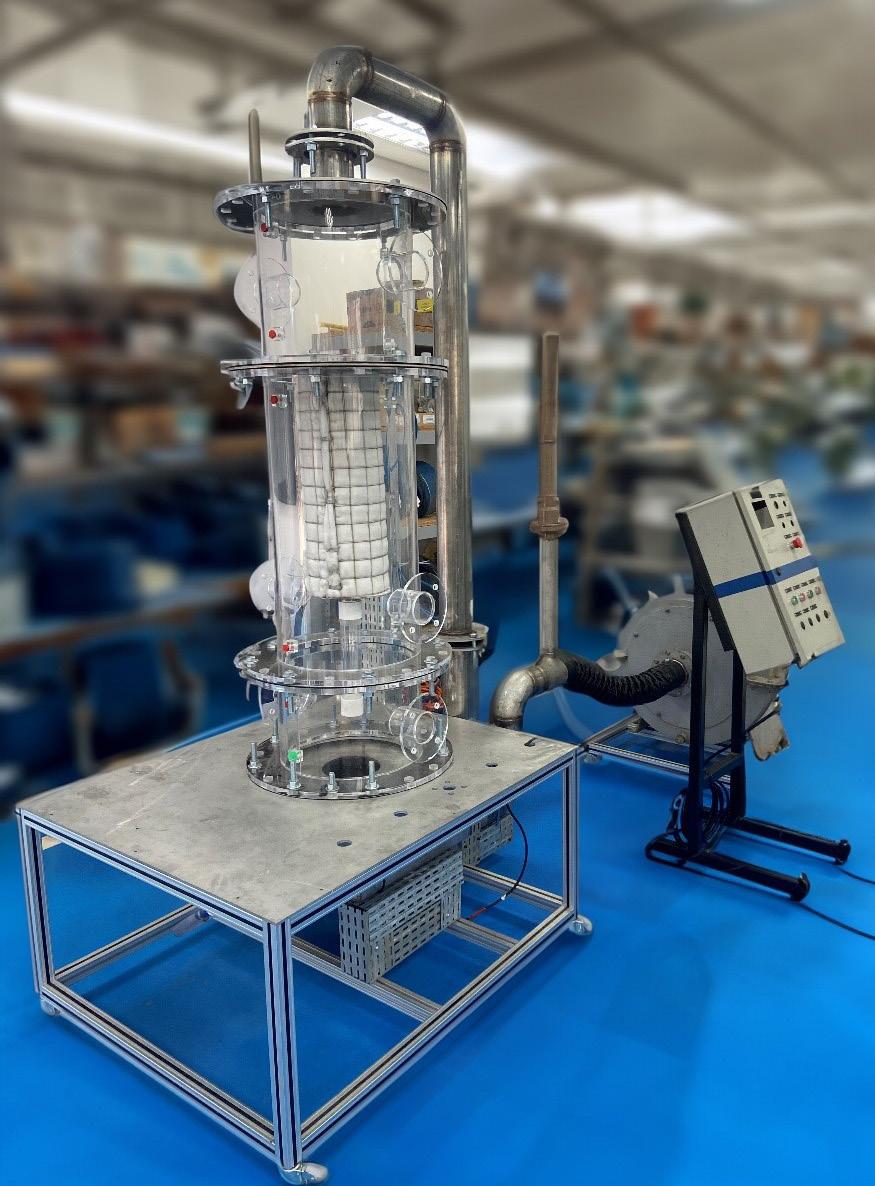

47 Put To The Test

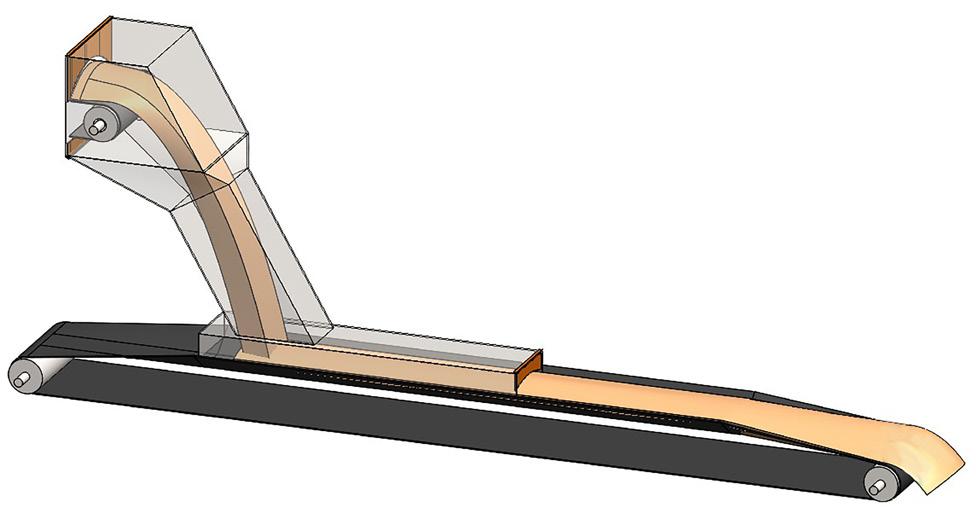

Alexandre Rossi, Breno de Almeida Avancini, Laryssa Lobo, and Vitor Sturm, Clark Solutions, Brazil, discuss the importance of testing systems in validating and updating models, highlighting the example of Brownian diffusion mist eliminators.

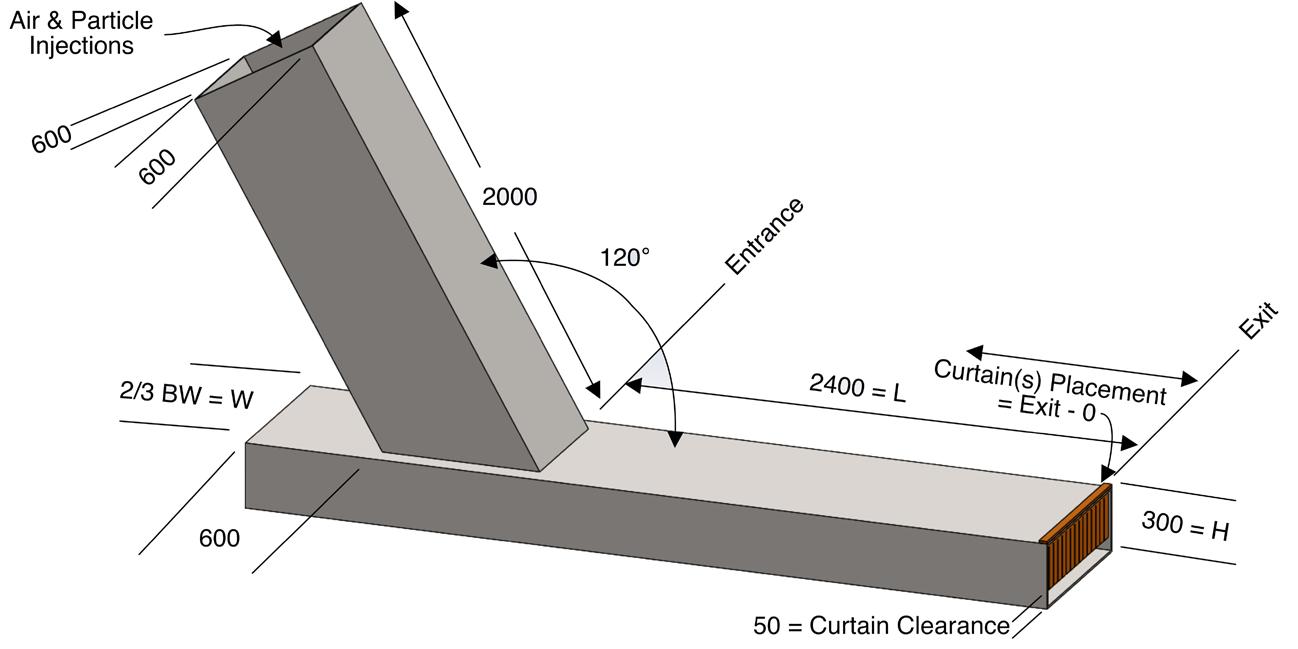

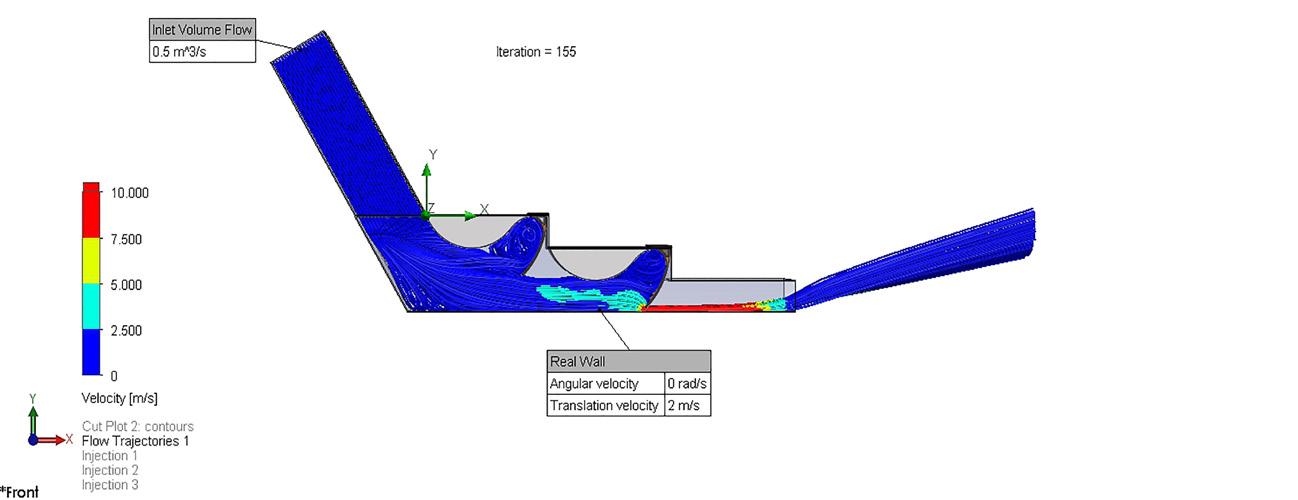

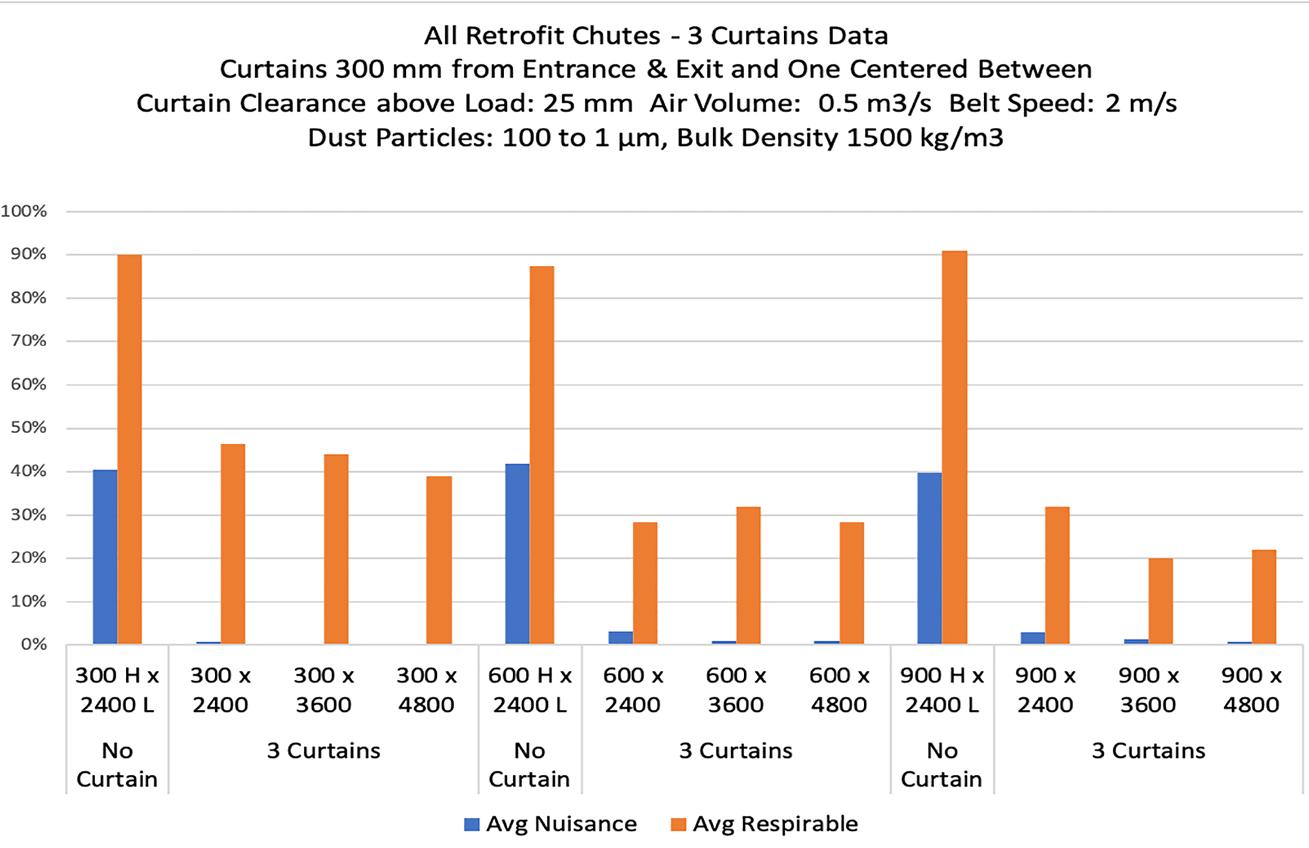

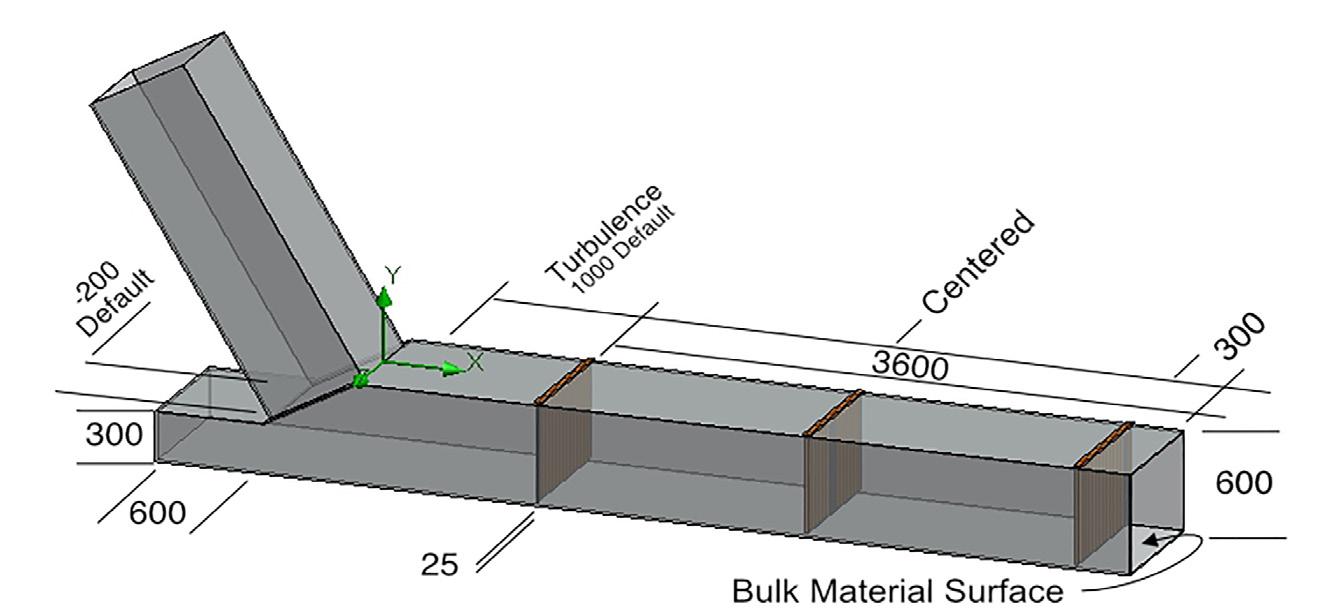

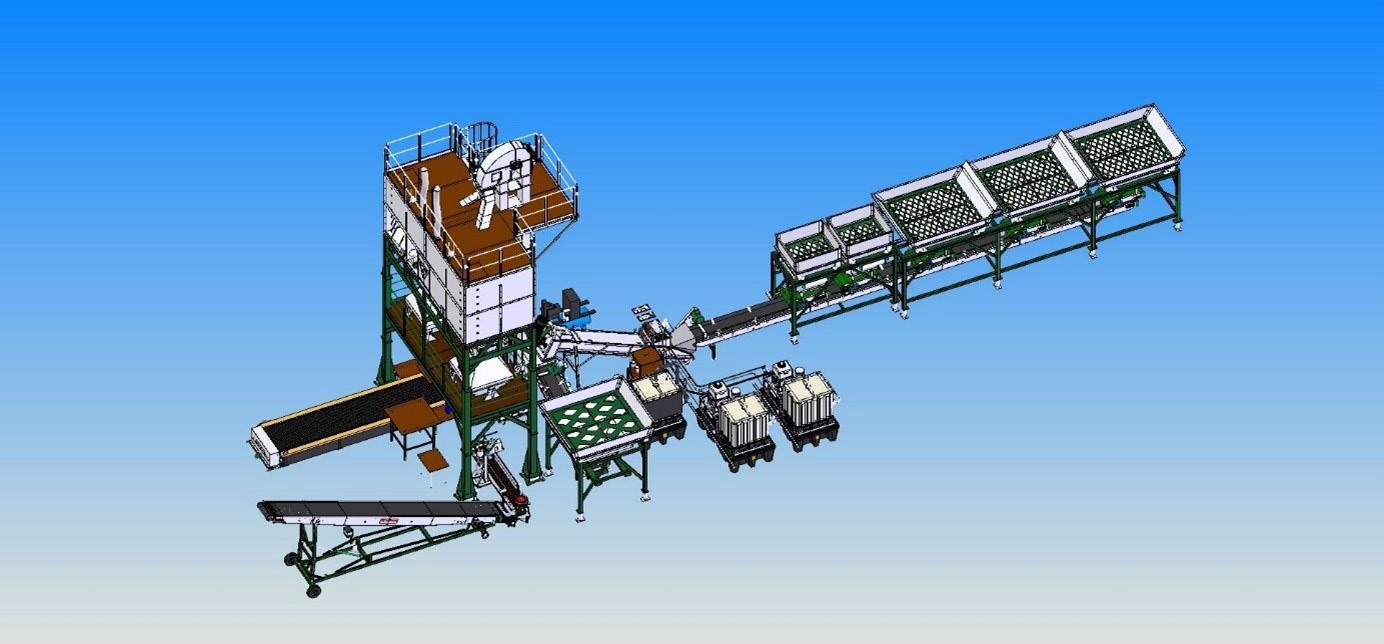

Todd Swinderman, Martin Engineering, USA, discusses how issues with dust control in the fertilizer industry can be addressed through effective conveyor skirtboards and curtain design.

Maxine Schuetz, RHEWUM GmbH, Germany, underlines why the integration of advanced screening machines, along with efficient feeders and under-pressure dedusting systems, represents a leap forward in managing the hygroscopic dust challenge in fertilizer production.

Zico Zeeman, EMT, the Netherlands, showcases how the fertilizer industry is shifting towards customisable, efficient, and technologically advanced production systems.

Phillip E. Prueter, The Equity Engineering Group, Inc. (E2G), USA, shares the company’s insights into common industry practices for understanding, anticipating, detecting, and mitigating ammonia SCC afflicting pressure equipment.

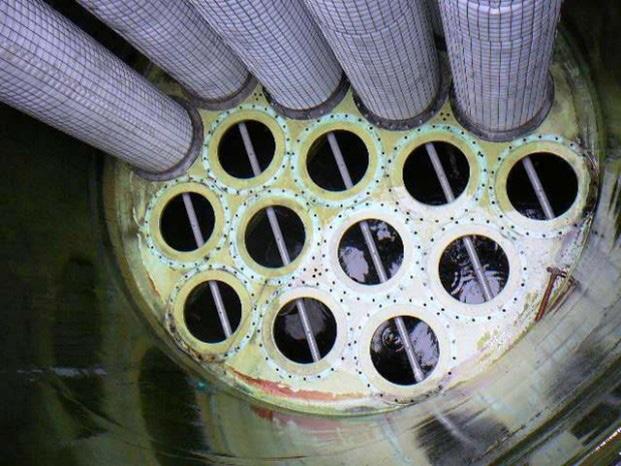

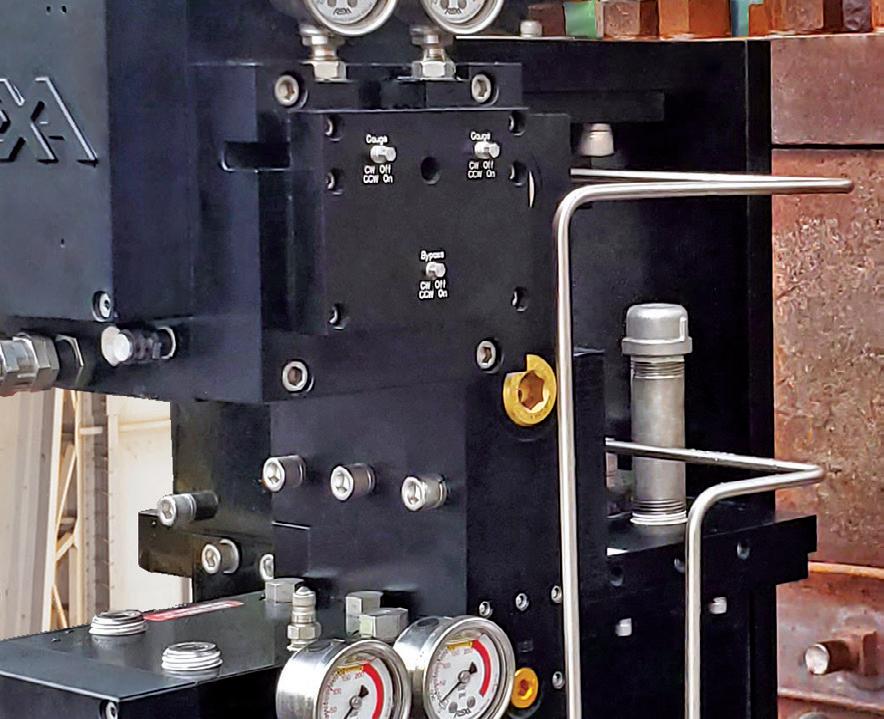

ASME PCC-2 Compliant Heat Exchanger Tube Plugging System

Trusted by fertilizer plants around the world as their go-to solution for heat exchanger tube leaks, Pop-A-Plug Tube Plugs from CurtissWright are engineered for optimal performance throughout the life cycle of equipment. Controlled hydraulic installation eliminates welding and time-consuming pre-/post-weld heat treatments that can cause damage to tubes, tube sheet ligaments, and joints.

• Simple hydraulic installation − no welding

• Helium leak tight seal to 1x10 -10 cc/sec

• 100% Lot tested to ensure unmatched quality

• Pressure ratings Up to 7000 PsiG (483 BarG)

• Wide range of sizes and ASME/ASTM certified materials available

877.383.1029

MANAGING EDITOR

James Little james.little@palladianpublications.com

SENIOR EDITOR

Callum O’Reilly callum.oreilly@palladianpublications.com

DEPUTY EDITOR

Emily Thomas emily.thomas@palladianpublications.com

EDITORIAL ASSISTANT

Jack Roscoe jack.roscoe@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Ryan Freeman ryan.freeman@palladianpublications.com

PRODUCTION

Iona MacLeod iona.macleod@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

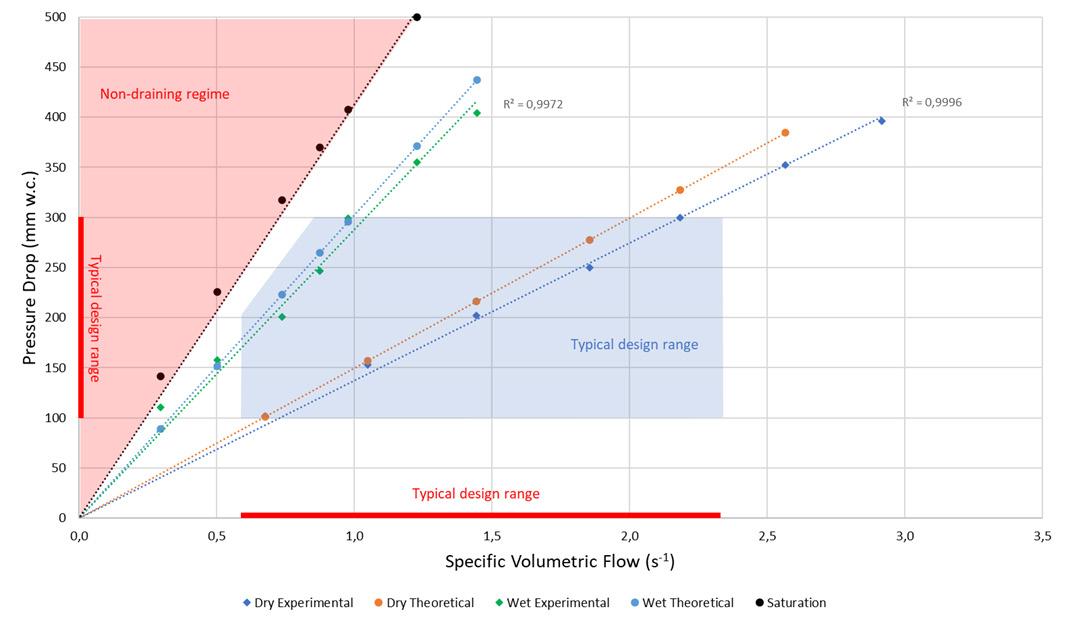

EVENTS MANAGER

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@palladianpublications.com

DIGITAL CONTENT ASSISTANT

Kristian Ilasko kristian.ilasko@palladianpublications.com

DIGITAL ADMINISTRATION

Nicole Harman-Smith nicole.harman-smith@palladianpublications.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey GU9 7QU, UK

Tel: +44 (0) 1252 718 999

Website: www.worldfertilizer.com

While sailing through the Bab el-Mandeb Strait on 18 February, a UK-owned, Belize-flagged ship carrying around 22 000 t of fertilizer was struck by missiles launched by the Houthi movement, as part of a campaign over Israel’s war against Hamas in Gaza. The strikes caused catastrophic damage to the ship, which is said to be the most severely impacted vessel since the rebel group began attacking Western commercial ships in November last year. After taking on water and suffering a fuel leak, the ship eventually sunk, leaving behind the threat of the vessel’s fertilizer load and fuel leaking into the Red Sea, and therefore the possibility of a monumental environmental disaster.1

Julien Jreissati, Programme Director at Greenpeace MENA, has expressed huge concern over the impact a potential fertilizer spill could have on marine life and ocean food chains, as well as the Red Sea’s unique coral reefs.

“This disruption could have far-reaching consequences, affecting various species that depend on these ecosystems and, in turn, potentially impacting the very livelihoods of coastal communities,” Jreissati said. “Immediate access to the shipwreck site is imperative for an expert response team to assess the situation and swiftly devise and implement an emergency plan.”2

Recent weeks have also seen a significant fertilizer spill into the East Nishnabotna River in Iowa, after liquid nitrogen and ammonia leaked from a tank at NEW Cooperative. Contamination is said to extend to Missouri, where small, native species of fish have been killed, likely affecting the wider food chain.3

The uncertain fate of the Red Sea and damage to the ecosystem in Iowa serves as a stark reminder of the potentially detrimental effects of the fertilizer industry on our environment. Farmers have even reported fears that fertilizer has become a ‘dirty word’, having often taken the blame for poor water quality standards – but things may be about to change.4

The BBC recently reported on a flurry of companies looking to make fertilizer production more environmentally friendly. For some time, the sector has excitedly examined the concept of green ammonia, and with a number of start-ups now looking to demonstrate how clean and controllable production can be, a renewable fertilizer future is looking more and more viable.

Starfire Energy, for example, is working towards modular green ammonia production, seeking to reduce transportation emissions and increase efficiency by enabling production closer to the point of use. The technology required will be stored within spaces as small as shipping containers.

Jupiter Ionics has also recently received funding to accelerate its electrolysis technology and scale up a self-contained system that takes in renewable energy, air and water to produce ammonia for fertilizer production.5

While this all sounds promising, there are still barriers to a completely green ammonia economy. McKinsey & Company notes that significant renewables capacity expansion is necessary to ensure green power is both available and economical. Furthermore, producers are facing uncertainty over green ammonia prices – the higher costs of the product must be absorbed throughout the value chain and become more competitive with grey ammonia, in order for new projects to be considered worthwhile.6

Still, the concept of green ammonia is filled with potential and opportunity for the fertilizer industry and beyond. The challenge lies in harnessing this potential in order to transition to a carbon-neutral economy by 2050, a goal which can only be reached with the availability of renewable electricity, and scalable technological and policy solutions.

* References available upon request.

Perfect separations for fertilizers

Screening machines for high product purities at maximum throughput thanks to direct excitation sieving with extreme acceleration.

Atlas Agro has announced that it has awarded a dual competitive engineering contract to two engineering and construction consortiums to perform parallel competitive project engineering development for the company’s first Brazilian green nitrogen fertilizer plant in Uberaba, MG, Brazil.

After this first development phase, Atlas Agro plans to roll the project over into FEED (front-end engineering design). The company expects to start construction in 2025 and enter commercial operation in 2028.

Atlas Agro’s plant will consume 2.5 TWh of renewable energy annually. In an integrated industrial operation, it will produce green hydrogen, green ammonia, and green ammonium nitrate. The final products will serve local Brazilian farmers.

The plant will leverage Atlas Agro’s know-how and experience gained at the company’s first green nitrogen fertilizer project in the Pacific Northwest in the United States.

“We are excited to start engineering for our first plant in Brazil,” says Knut Karlsen, Atlas Agro’s Co-Founder and President of South America. “Today, Brazil imports more than 90% of its nitrogen fertilizer, all produced using fossil fuels like natural gas and coal. By leveraging the country’s natural advantages in green energy, Brazil can substitute its fossil nitrogen fertilizer imports with local, green production. We at Atlas Agro are excited to contribute to the green re-industrialisation of Brazil.”

The Fertilizer Institute has praised the US Senate for introducing bipartisan legislation to include phosphate and potash on the final list of critical minerals of the Department of the Interior.

Introduced by Senators Sherrod Brown (D-OH), Thom Tills (R-NC), Tammy Baldwin (D-WI), Roger Marshall (R-KS), Pete Ricketts (R-NE), and Rick Scott (R-FL), the legislation will recognise the importance of ensuring a strong and sustainable domestic fertilizer supply for American farmers.

“We thank Senators Brown, Tillis, Baldwin, Marshall, Ricketts, and Scott for coming together and introducing this important legislation,” said TFI President and CEO, Corey Rosenbusch. “The majority of the world’s phosphate and potash resources are concentrated in only a few countries, leaving them open to supply chain vulnerabilities and geopolitical instability. The events of the past few years have shown us that food security is national security and now is the time to change how we talk about these vital resources.”

The United States imports roughly 95% of its potash needs, the bulk of which come from Canada. Only 14 countries in the world produce potash, with Belarus and Russia comprising nearly 40% of global production. Regarding phosphate, China accounts for over 40% of global production. “It is vital that we, as a country, take proactive steps to secure our own agricultural future by recognising the role these minerals play in putting food on our tables,” Rosenbusch continued. “Without these two minerals, modern agricultural systems would crumble and the ability to feed our growing population would be nearly impossible.”

The US has both phosphate and potash production, but expanding mines and opening new ones is a costly and time-consuming process measured in years and in the tens of millions of dollars for permitting alone. Being listed as critical minerals would not exclude these projects from environmental reviews, but would assign a single permitting agency to be responsible and streamline the process.

“By adding phosphate and potash to the critical minerals list, we can take a significant stride towards securing our own future and sending the clear message that safeguarding our nation’s food supply is not only an economic imperative, but a strategic priority that ensures our well-being,” Rosenbusch concluded. “We look forward to working with Congress to support this vital legislation.”

Yara Growth Ventures has invested in Dynelectro, a company which develops technologies to unlock the potential of solid oxide electrolysis (SOE). While SOE yields the highest possible efficiencies to produce renewable hydrogen and e-fuels, it has been suffering from system lifetime issues up to now. The investment is part of Yara’s ambition to decarbonise fertilizer production and enable the hydrogen economy.

Dynelectro’s approach increases the lifetime of SOE systems dramatically from typically 2 – 10 years, and it also allows for integration of SOE with intermittent renewable electricity – a key requirement for large scale adoption.

“Electricity is the key driver for the cost of renewable hydrogen. While solid oxide electrolysis has the best potential for low cost, it suffers a niche existence due to system lifetime issues. We believe Dynelectro will overcome these issues and pave the way to make low-cost renewable hydrogen a reality,” says Björn Heinz, Investment Director and part of the Yara Growth Ventures team.

EuroChem has announced the opening of its new phosphate fertilizer production facility in Serra do Salitre, State of Minas Gerais, Brazil.

Topsoe electrolyser manufacturing facility receives environmental permit

Input materials have been received ahead of Cinis Fertilizer’s start of production

Iowa DNR continues to investigate New Cooperative fertilizer spill

NextEra awarded loan for fertilizer facility Visit our website for

With a total project investment of nearly US$1 billion, the new phosphate mine and plant complex will have an annual production capacity of 1 million tpy of advanced phosphate fertilizers, significantly increasing the reliability of domestic phosphate fertilizer supplies to Brazilian farmers.

The facility offers integrated phosphate fertilizer production, with low water consumption, a fully closed water circuit, and a clean energy generation system that re-uses its own steam and generates up to 40% of the entire facility’s energy needs.

“EuroChem has a long-standing and successful history in South America, a key growth market for us, where there is a high demand for our products,” said EuroChem Group President, Oleg Shiryaev. “The launch of our new facility moves us one step closer to our customers and allows us to provide Brazilian farmers with access to the highest quality fertilizers via our well-established distribution network in this important global breadbasket. EuroChem operates on a mine-to-farm basis, ensuring reliability and quality across the entire fertilizer supply chain, from raw material extraction to production and delivery to the end consumer.”

In celebration of its 12th anniversary, PT Pupuk Indonesia (Persero) has reaffirmed its commitment to enhancing agricultural productivity and ensuring food security through various innovations.

In line with this commitment, Pupuk Indonesia has met the government’s 100% target by distributing 6.19 million t of subsidised fertilizer to farmers. This was achieved by the company amidst the complex global challenges of 2023, including the geopolitical conflicts affecting fertilizer commodity prices.

Rahmad Pribadi, President Director of Pupuk Indonesia, stated during an event with the media in Jakarta on 18 March 2024, “Pupuk Indonesia not only survived but also thrived in 2023. This year, we will remain steadfast in our commitment to enhancing agricultural productivity and ensuring food security through innovation and best performance.”

In 2023, the company realised a production output of 18.8 million t, consisting of 11.6 million t of fertilizer and 7.1 million t of non-fertilizer products. Various efforts were made to ensure the smooth and targeted distribution of fertilizer. This included the digitisation of the fertilizer redemption process using the I-Pubers (integrated subsidised fertilizer) application and collaboration with stakeholders.

The I-Pubers application is a result of collaboration between Pupuk Indonesia and the Ministry of Agriculture. This application is aimed at facilitating farmers in the subsidised fertilizer redemption process by implementing integrated data in distributor partners (kiosks) between the e-allocation subsidised recipient list and the fertilizer stock data available at Pupuk Indonesia. As of 01 February 2024 the implementation of I-Pubers has reached 100% nationwide and is available at more than 27 000 kiosks across the country.

Nitrogen + Syngas USA 2024

15 – 17 April 2024

Oklahoma, USA events.crugroup.com/nitrogenusa/ home

Casale has announced a significant milestone as its subsidiary, Casale Project A.S., has secured a turn-key contract with BorsodChem MCHZ, S.R.O., based in the Czech Republic, for the construction of a cutting-edge nitric acid plant.

This strategic collaboration marks the continuation of a long-standing venture between Casale and BorsodChem.

The contract involves the design, engineering, procurement, and construction of a 450 million tpd of weak nitric acid (WNA) plant, showcasing Casale’s knowledge of the nitric acid process as well as the company’s expertise in providing turnkey solutions. The project aims to meet the growing demand for aniline production contributing to the expansion and sustainability of BorsodChem’s operations.

ACHEMA 2024

10 – 14 June 2024 Frankfurt, Germany achema.de/en

Turbomachinery and Pump Symposia 2024

20 – 22 August 2024 Texas, USA tps.tamu.edu

ANNA 2024

29 September – 04 October 2024 Montréal, Canada annawebsite.squarespace.com

A distinctive feature of the project is its ability to generate electrical energy without the use of fuels. Instead, it harnesses surplus steam produced during the nitric acid production process through a carefully optimised approach. This not only enhances the overall energy efficiency of the entire site, but underscores the companies’ commitment to sustainable practices and resource optimisation.

supports Indorama Eleme Fertilizer and Chemicals’ expansion plans

British International Investment (BII) has committed US$65 million to support Indorama Eleme Fertilizer and Chemicals’ expansion plans in Nigeria.

The investment forms part of a US$1.25 billion financing package which will allow Indorama to increase its fertilizer production and build a new port terminal for exports, bolstering global food production and food security.

BII’s investment forms part of a consortium led by IFC and includes commercial banks, impact investors and other DFIs. This is BII’s fourth investment in Indorama since 2013 and signifies the DFI’s longstanding commitment to strengthening value chains in Nigeria’s agricultural sector and increasing the country’s export potential.

YKNOW2024

28 October – 30 October 2024

Texas, USA yokogawa.com

Sulphur + Sulphuric Acid Conference & Exhibition 2024 04 – 06 November 2024 Barcelona, Spain events.crugroup.com/sulphur/ home

Indorama’s two operational urea fertilizer lines currently serve Nigeria’s domestic market, supporting the country’s agricultural sector, which accounts for a quarter of its GDP and employs approximately a third of its labour force. This investment will finance the development of Indorama’s third nitrogenous urea fertilizer production line, which is expected to increase its annual capacity to 1.4 million tpy of urea, one of the most used fertilizers worldwide.

Nigeria’s economy has historically relied heavily upon revenue from the oil and gas sector, making it vulnerable to external shocks and the price volatility of commodities. By supporting Indorama’s expansion, BII aims to accelerate Nigeria’s economic diversification and progress its delivery of the National Development Plan, which outlines ambitions to boost Nigeria’s global competitiveness and build on its strong foundations for industrialisation.

The new production facility will be complemented by a shipping terminal currently under construction at Indorama’s operations in Port Harcourt, Nigeria. Both will help meet the growing global demand for fertilizer and are expected to create up to 8000 direct and indirect jobs.

Manish Mundra, Group Director for Africa, Indorama Corporation said, “The establishment of this fertilizer plant underscores Indorama’s unwavering commitment to Nigeria’s industrial growth, economic diversification, and leveraging its strategic geographic location. This landmark financing represents a pivotal moment in Nigeria’s journey towards becoming a major player in the global fertilizer market. With the addition of Line 3, Nigeria is prepared to significantly ramp up its export capacity, thereby enhancing its position as a key exporter of fertilizers to Africa and the world.”

Innovation is about more than bringing something new to the table. Black & Veatch is built on a foundation of collaboration where your teams work with a true partner in asset development. Between disruptive global challenges and rapidly evolving technologies, the opportunities to continuously improve project development are ever-present. Redefine what’s possible for your asset acquisition programs—all the while staying ahead of the curve. Learn more at bv.com

Gordon Cope, Contributing Editor, discusses the recent activity in the North American fertilizer market, and examines the prospects for growth in the coming decade.

The world fertilizer market has experienced tumultuous times over the last several years, with war, sanctions, export restrictions and wild weather all taking farm commodities, international trade and consumption patterns on a roller coaster ride. Fortunately, North America is a major producer of potash, phosphate and nitrogen products, giving it both flexibility and opportunities to prosper.

The US and Canada produce over 15 million tpy of potash fertilizers, with abundant room for capacity growth. Since 2021, the potash market has been experiencing increased volatility due to international sanctions imposed against Belarus and repercussions against Russia after it invaded Ukraine. Both were major exporters, and the injunctions have had a profound effect; Russia’s output dropped 45% to around 5 million tpy, and output from Belarus dropped over 60%, to around 3 million tpy.

North American producers responded to the market upheaval by increasing production. Nutrien, the world’s largest potash producer, upped 2022 production from an initial 14 million tpy to almost 15 million tpy by the end of 2022. Mosaic announced that it would add 1.5 million tpy of capacity to its Esterhazy K3 mine in Saskatchewan. Both were caught off-base when farmers responded to higher fertilizer prices by cutting back on consumption. Mosaic subsequently temporarily shuttered its Colonsay mine near Saskatoon, Saskatchewan, which reopened in August 2023. The market rebounded in late 2023, and Nutrien now predicts that full-year shipments for 2024 will return to longer-term trend levels of 68 – 71 million t.

Plans for major new mines are still going ahead. BHP recently announced that stage one of the Jensen mine, at a cost of CAN$7.5 billion, is over 30% complete, and is on track to begin production in 2026. In October 2023, BHP gave the green light to the second stage of the project. The CAN$6.4 billion investment will double the mine’s output capacity to 8.5 million tpy when it comes on stream in 2029. At that point, it will be one of the largest potash mines in the world; the company has plans for stage three and stage four, but will await market conditions as the decade progresses before making further investment decisions.

North America produces about 7 million tpy of phosphate fertilizer, but such output is dwarfed by China, which churns out over 17 million tpy. Since 2021, China has taken various steps, including quotas and red tape, to limit its exports of fertilizers in order to protect its domestic market. As a major exporter of phosphate and urea, the interventions have had a significant impact on the international market as buyers have scrambled to meet requirements. Over the latter part of 2023, benchmark prices for di-ammonium phosphate (DAP), have climbed 26%, to over US$600/t.

The search continues for new sources of phosphate in North America. In Quebec, First Phosphate continues to expand its discovery at the Bégin-Lamarche project located in the region of Saguenay-Lac-St-Jean. Recent sampling during the 2023 – 2024 exploration season has extended the strike zone, which measures approximately 1.5 km long and 400 m wide. Testing has indicated levels of P2O5 as high as 39.45%; at this purity, the mineral qualifies as direct shipping ore (DSO). Samples are devoid of high concentrations of harmful elements, facilitating preparation.

Fox River Resources awaits further financing for an integrated phosphate operation at its Martison phosphate discovery in Ontario, Canada. The facility includes an open pit mine capable of producing 4 million tpy of phosphate ore, which will be concentrated into 1.4 million tpy of 37% P2O5. It will then be turned into phosphoric acid feedstock in order to produce up to 730 000 tpy of mono-ammonium phosphate (MAP) and 250 000 tpy of nitrogen phosphate sulfur (NPS) mix, primarily for the western Canadian fertilizer market.

The global ammonia market is currently approaching 170 million tpy, with about two thirds consumed by agriculture. It is expected to grow at a rate exceeding 7% CAGR, reaching 310 million tpy by 2030. North America is a major producer of fertilizer, with approximately 16 million tpy of nitrogen produced.

GlobalData has calculated that new and expansion projects in North America could add over 31 million tpy of capacity by 2028.1 The numbers include Ascension Clean Energy’s Donaldsonville Ammonia Plant, with a capacity of 7.2 million tpy, expected to enter service in 2027.

The health of nitrogen fertilizer in North America is critically dependent on the fortunes of domestic farming. Currently, the sector is being roiled by a series of challenges. After two highly profitable years spurred by market disruptions due to the Ukraine war and drought, prices for corn and soybeans have hit multi-year lows. From a price exceeding US$6/bushel in mid-2023, corn futures had plunged to US$4/bushel by February 2024. Soybean futures dropped under US$12/bushel, their lowest level since November 2021. Several factors have contributed to lower commodity prices:

n When drought and cold conditions threatened crop yields in the spring of 2023, farmers held on to crops awaiting higher prices. When a rebound in weather helped create ideal growing conditions later in the year, corn stockpiles hit a record high of almost 8 billion bushels.

n Thanks to a strong dollar, US grain crops face weak demand internationally.

n Ethanol production, which consumes roughly 30% of US corn production, is stagnating as EV sales bite into the fuel market.

n Costs for production remain high; agriculture economists at the University of Illinois calculate that some farmers may see a US$160 loss per acre of corn, vs a profit of US$340 the year before.

The reduced prices for nitrogen, phosphate and potash fertilizers offer a ray of sunshine. “We saw a continuation of strong fertilizer market fundamentals in North America during the fourth quarter driven by improved affordability, an extended fall application season and low channel inventories,” said Ken Seitz, President and CEO of Nutrien, during a Q423 investor presentation. “As we look ahead to 2024, we expect to deliver higher fertilizer sales volumes and retail earnings, supported by increased crop input market stability and demand.”2

In Canada, the federal government wants to reduce carbon emissions in all sectors by 45% by 2030, primarily through carbon taxes and restrictive legislation. Currently the carbon tax stands at CAN$65/t, and is scheduled to climb by CAN$15/t annually to CAN$170/t by 2030. Grain farmers use large amounts of natural gas to dry and maintain stored grain, however, and greenhouses use natural gas and propane to sustain their operations through the winter months. Both are facing massive increases in energy bills, threatening their livelihoods. In addition, Ottawa is pondering ways to reduce agricultural emissions by 30%, through a combination of tilling methods and fertilizer restrictions. The latter, especially, has the sector concerned; reductions in applications would severely impact productivity.

In the US, federal agriculture policy is at an impasse. The 2018 – 2023 Farm Bill expired on 01 October 2023 and Congress extended the legislation until 30 September 2024. The proposed bill is massive, with an estimated US$1.5 trillion cost over the next 10 years. The majority is targeted to the USDA's main food-aid programme, the Supplemental Nutrition Assistance Program (SNAP). The remainder funds a host of farm-aid programmes, generally referred to as the farm safety net. Republicans favour farm aid, while Democrats prioritise help to the poor. The Biden administration also proposes programmes to entice farmers to adopt greener practices that could create significant revenue streams through conservation and green initiatives. The current dysfunctional climate in Congress has paralysed the passage of bilateral legislation, however, and the 2024 election cycle makes any resolution unlikely until it is determined who controls both houses and the White House.

While net zero legislation is creating challenges for farmers, government incentives to decarbonise major sectors of the economy by producing clean-burning hydrogen fuel is creating immense opportunities for nitrogen manufacturers.

Hydrogen fuel is becoming popular around the world. Not only does the energy-dense element produce nothing but water when burned, it can also be manufactured anywhere using electrolysis powered by wind and sun, reducing geopolitical risk.

Transporting and burning hydrogen itself is rather costly and complex, however; a much easier method is to convert the gas into liquid ammonia, which can then be consumed in ICE engines with minor alterations.

This appeals greatly to the maritime sector. Rystad Energy, a consultancy, predicts that, by 2035, there could be over 170 marine

export terminals focusing on converting hydrogen into clean ammonia, causing total exported volumes to surge from around current levels of 19 million tpy (most of which is used in fertilizer products), to 76 million tpy by 2035 (most of which will be transport and utility fuel related). By 2050, that figure could be over 120 million tpy.3

The US is expected to be the leader in North America, spurred on by incentives in the Biden administration’s Inflation Reduction Act that could provide up to US$3/kg in subsidies for clean hydrogen.

Companies are making plans for major investments. In September 2023, OCI Global reached an agreement with New Fortress Energy to buy all clean hydrogen output from the latter’s ZeroPark 1 project in Texas. The 200 MW plant is expected to produce approximately 17 000 tpy of hydrogen, which OCI will then convert to 80 000 tpy of green ammonia at its Beaumont complex. Plans are underway to double capacity to 160 000 tpy by 2026, as OCI is eyeing exports to Europe, where the EU has established a target of renewable fuels of non-biological origin (RFNBOs) in industrial usage of 42.5% by 2030.

In addition, OCI and Linde are building a new plant in Beaumont capable of producing 1.1 million tpy of blue ammonia, while capturing 1.7 million tpy of CO2 for sequestration. The plant is being designed to convert to green ammonia as economical sources of wind and solar power become available. Production is likely to be consumed in North America and Asia when the plant comes on-stream in 2025.

Yara, based in Norway, is planning on building a blue ammonia plant with Enbridge, a major North American pipeline company, in Texas. The unusual joint venture was announced in 2023 when the two partners realised that their respective assets and goals would optimise the joint project.

Enbridge operates one of the largest pipeline networks in North America, gathering crude and natural gas and delivering them to consumers throughout the US and Canada. Over the last several years, it has been working to expand the Enbridge Ingleside Energy Center (EIEC), a massive terminal located in Corpus Christi, Texas, on the Gulf of Mexico. The company is intent on exporting not only conventional energy commodities, but also low-carbon products, and has plans for carbon capture and solar power generation.

In order to lower its carbon footprint, Yara has been working with Orsted, a Netherlands-based offshore wind-farm developer, to convert a portion of its ammonia output at its existing plant in the Netherlnads to 75 000 tpy of green ammonia using wind-generated electricity and hydrolysis. Green ammonia is still very expensive to produce, however, and Yara has been searching for a greenfield site to produce large amounts of blue hydrogen, (which captures carbon emissions during hydrogen production) for use in both fertilizer and marine transportation purposes. Like Enbridge, Yara is committed to reaching net zero emissions, and the EIEC provided an excellent location to offer carbon capture, solar energy and export potential. If confirmed through front-end engineering and design (FEED), production will start up in 2027/2028. Once operational, the plant will have a capacity of up to 1.4 million tpy of blue ammonia.

German-based RWE, LOTTE Chemical of Korea, and Japan’s Mitsubishi plan to build a clean ammonia production and export facility in the port of Corpus Christi, Texas. The complex will feature a series of units with a final capacity approaching

10 million tpy by 2030. Output will be in the form of both blue and green ammonia, and will be exported to Asia and Europe for use as both fuel and a source of renewable hydrogen.

Not all projects are moving ahead, however. In early 2023, Nutrien announced plans to build the world’s largest clean ammonia facility at its existing complex in Geismar, Louisiana, near tidewater ports in New Orleans. The 1.2 million tpy plant would permanently remove up to 90% of CO2 emissions using carbon capture and sequestration (CCS) technology. But later that year, the Canadian company placed the project on hold, citing increased building costs and uncertainty over the premium market for clean ammonia.

Fertilizer production has a significant impact on the environment. Ammonia producers emit over 500 million tpy of GHG, primarily from the use of coal and natural gas as both feedstock and energy. While blue and green ammonia initiatives are helping to reduce GHG intensity per t, it will be a costly challenge to meet net zero targets by 2050.

Waste from potash and phosphate mines is also a major issue. For instance, there is over 1 billion t of phospho-gypsum, a mining waste product, being sequestered in gypsum stacks throughout Florida. The material releases radon, a toxic radioactive gas, for up to 1600 years. There are few safe uses for the material, but the state legislature recently authorised the Florida Department of Transportation to conduct tests on roads using phospho-gypsum as a construction ingredient. Mosaic has offered to build three 200 ft sections of roadway on its property, but the EPA, which currently bans its use in roadways, must first evaluate the risk to the public prior to approval.

Environmental critics note that even if approved, the amounts required in roadbuilding would be miniscule in relation to the massive amounts needing remediation.

The growth in agricultural demand for nitrogen, potash and phosphate fertilizer is expected to remain healthy due to a growing world population and a shift of diets towards animal protein. Low natural gas prices gives North American nitrogen producers a significant advantage over Europe and Asia. Immense, untapped potash reserves in Canada present large-scale, low-cost expansion opportunities. Tax incentives offer ammonia producers significant new demand opportunities in the transportation and utility sectors. The regulatory push towards net zero emissions in the agricultural sector creates challenges, but also offers new revenue streams.

North America’s fertilizer producers have adapted well to recent challenges. While volatility is unlikely to abate in the near-term, long-term trends in the food commodities market and the opportunities presented by new uses of ammonia will create significant prospects for growth in the coming decade.

1. https://www.globaldata.com/media/oil-gas/north-america-account44-global-ammonia-capacity-additions-2028-reveals-globaldata/

2. https://nutrien-prod-asset.s3.us-east-2.amazonaws.com/s3fspublic/2024-02/024-002%20-%20Nutrien%20Reports%20Fourth%20 Quarter%20and%20Full-Year%202023%20Results.pdf

3. https://www.rystadenergy.com/news/hydrogen-exports-shiftammonia-production-2035

Much has been written of the future needs of ammonia (NH 3 ) to match the global future energy mix; whether it be in the form of fuel itself or hydrogen from ammonia cracking. The use of ammonia as a zero-emission fuel, power source, energy storage solution or feed source leading to fertilizer could provide the world’s growing population sustainable access for these future needs. Producers are continuously working to increase efficiency, become more environmentally friendly, and are often asked to produce even more.

Steam methane reforming (SMR) is currently, for the foreseeable future, the most effective way of producing NH 3 in large quantities. As this process requires hydrocarbons as a feed source, along with supplementary heating, operating an SMR unit efficiently (whether primary or secondary) and being able to increase the output without expensive capital investment, will be key to achieving targets and goals in the future ammonia economy.

Gary Bennington, UNICAT Catalyst Technologies, LLC, APAC, discusses how breakout catalyst technology can deliver enhanced profitability within the ammonia industry.

This article addresses such issues with a case study on an innovative SMR catalyst that is achieving results in efficiency, profitability, and increased NH 3 production capabilities from existing and new-build assets, without the introduction of complex technology, expensive materials of construction, or major changes to typical operating or handling procedures.

The traditional way of significantly increasing output from an existing plant is to add a pre-reformer. Installation of a pre-reformer will typically increase syngas production by 10 – 15% with an expected cost in the range of 20 – 30%

of the cost of the original plant. This feed preparation stage increases the syngas yield from the SMR and allows a wider range of high molecular weight streams to be used as feeds to the ammonia plant, such as LPG and naphtha. However, the costs of installation plus the additional catalyst and running costs of the pre-reformer are prohibitive. Introducing operational complexity adds further unseen or unappreciated costs to the project and does not consider the numerous process complications inherent when installing new equipment. Adding a new process unit requires process operators to learn new procedures and intricacies associated with incoming equipment.

Recently, catalytic solutions have emerged that offer the promise of increasing the output of NH 3 from an existing SMR. This can be advantageous if plot space or capital expenditure limits the ability to install new process units. To fully realise the potential to increase ammonia production, the enhanced catalytic solution proposed should be deployable in the same way as the current catalyst in use to avoid changes in operating installation or removal procedures. Furthermore, the solution should be flexible to handle the wide range of different feed stocks. The optimum future SMR catalyst should also not use complex raw materials in its construction or require made-to-order manufacturing to ensure availability when required, which can, unfortunately, include unplanned change-outs due to a poisoning event, power failure or tube ruptures.

Case study data

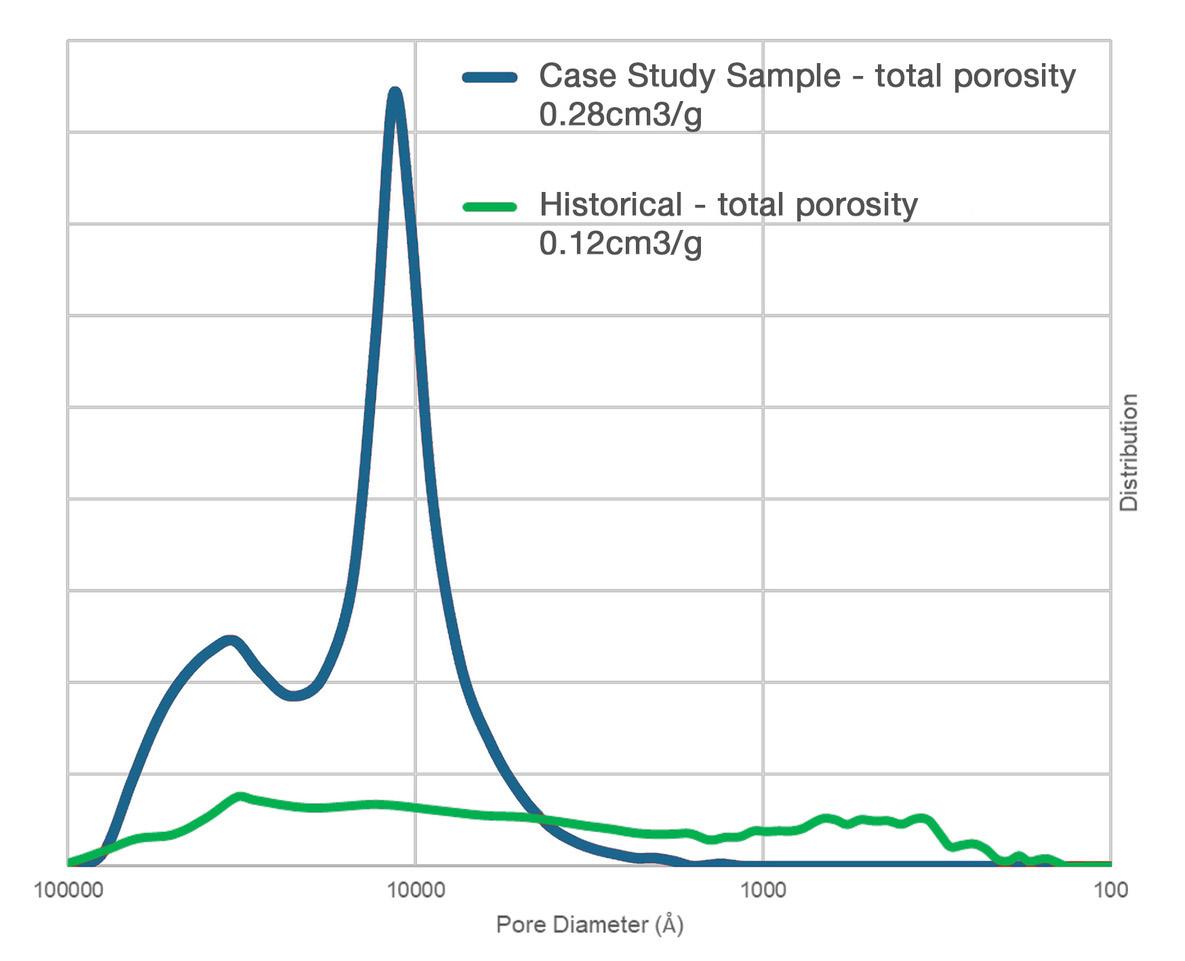

The basic functionality of Magcat by UNICAT is built upon the same catalytic pathways of using nickel as the active ingredient in the steam reforming reaction. The role and functionality of the support is approached in a new way. SMR catalyst pellets have traditionally involved multiple holes, doming, and fluting, in order to achieve a combination of high surface area, low pressure drop, maximum surface contact with reformer tube walls and acceptable crush strength. The design of these pellet shapes is constrained by the manufacturing method used whereby the shape must be regular enough to be produced using a high-frequency pelleting machine. This restricts further innovation and due to reaching a plateau in developments, some companies have been seen to depart from the standard pelleted catalyst and move into various complex and intricate alternative methods, such as structured packing,

to achieve higher syngas yields from the SMR. UNICAT found a way to break the paradigm and achieve increases in ammonia in a way that can be easily implemented without additional costs.

The polymer-matrix-based ceramic used in the formulation aids the carrier strength with crosslinking across the polymer chains. The high temperature calcination sinters the base material to produce a strong ceramic matrix whilst also adding subsurface porosity. Higher strength results in reduced pressure drop evolution over time and this is especially key in units that are expected to experience multiple shutdowns over the cycle length or regular variations in throughput and heat load. The strength of the catayst will not put reformer tubes under stress, as the force in thermally contracting tubes is significantly higher than the strongest catalyst. The preferred spherical shape characteristics of the technology rearrange and push back up to the normal level in the reformer tube. Moreover, the ceramic carrier is designed to snap into larger pieces, when it eventually breaks, in comparison to a cement-based catalyst which will often crumble, resulting in steep pressure drop increases over the cycle length.

SMR catalyst activity is directly proportional to the total surface area of active nickel available to reactants. This SMR catalyst increases nickel availability through two key mechanisms; the first is the external texturing. A significant increase in geometric surface area (GSA) provides additional activity to generate higher amounts of ammonia and also gives the opportunity to scale down, at significant cost savings, new build SMR installations if a higher ammonia production can be achieved from a lower volume of catalyst.

Secondly, activity is increased through subsurface porosity. During calcination of the polymer binding ingredient, a network of interconnected macropores (150-micron diameter) are opened without a negative decrease in strength. Furthermore, in a reformer tube, gases move at high velocity over the catalyst surface so only large pores will

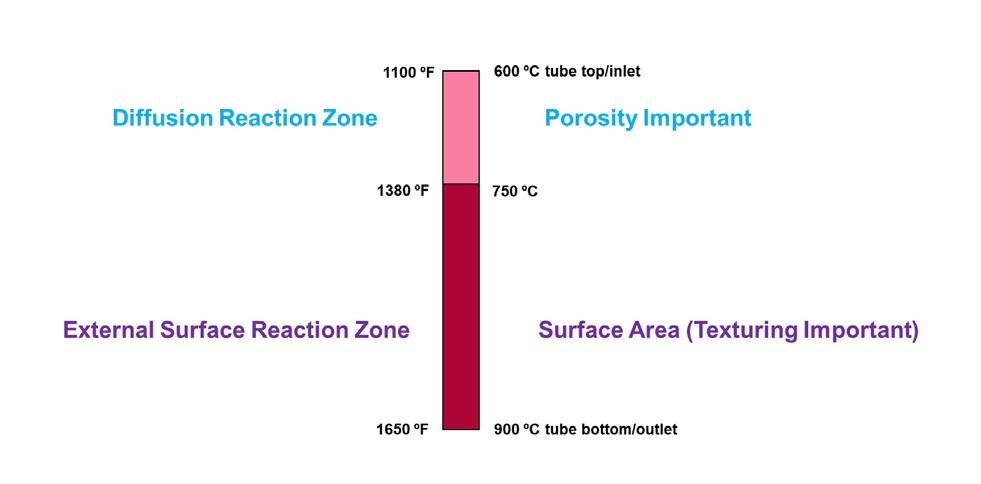

allow the permeation of reactant gases to subsurface catalytic sites (Figure 1.)

The SMR catalyst has a high availability of additional surface area and catalytic sites to complete the reaction through to equilibrium. Good access to catalytic sites throughout the parts of the catalyst that are in contact with feed gases minimises carbon formation and maintains catalyst life.

Regarding the optimisation of reformer loading, UNICAT considers the different flow regimes in play and the relative permeability of reactant gases at increasing temperatures when moving from the inlet to outlet of the reformer tube. When reactants first enter the reformer, the temperature is lower, meaning the kinetic rate of reaction is low. The volumetric flow of the gas is also low and the reaction has not yet moved to completion, meaning fewer molecules of gas. Reactants have the residence time required to permeate into the catalyst structure to contact subsurface nickel, making high porosity critical (Figure 2). As the

volumetric flow of the gas increases, the reactant gases have little opportunity to penetrate into the catalyst structure. Therefore, surface reactions dominate, making maximum external surface area, i.e. surface texturing, the critical variable to ensure methane slip is minimised by the time gases leave the tube.

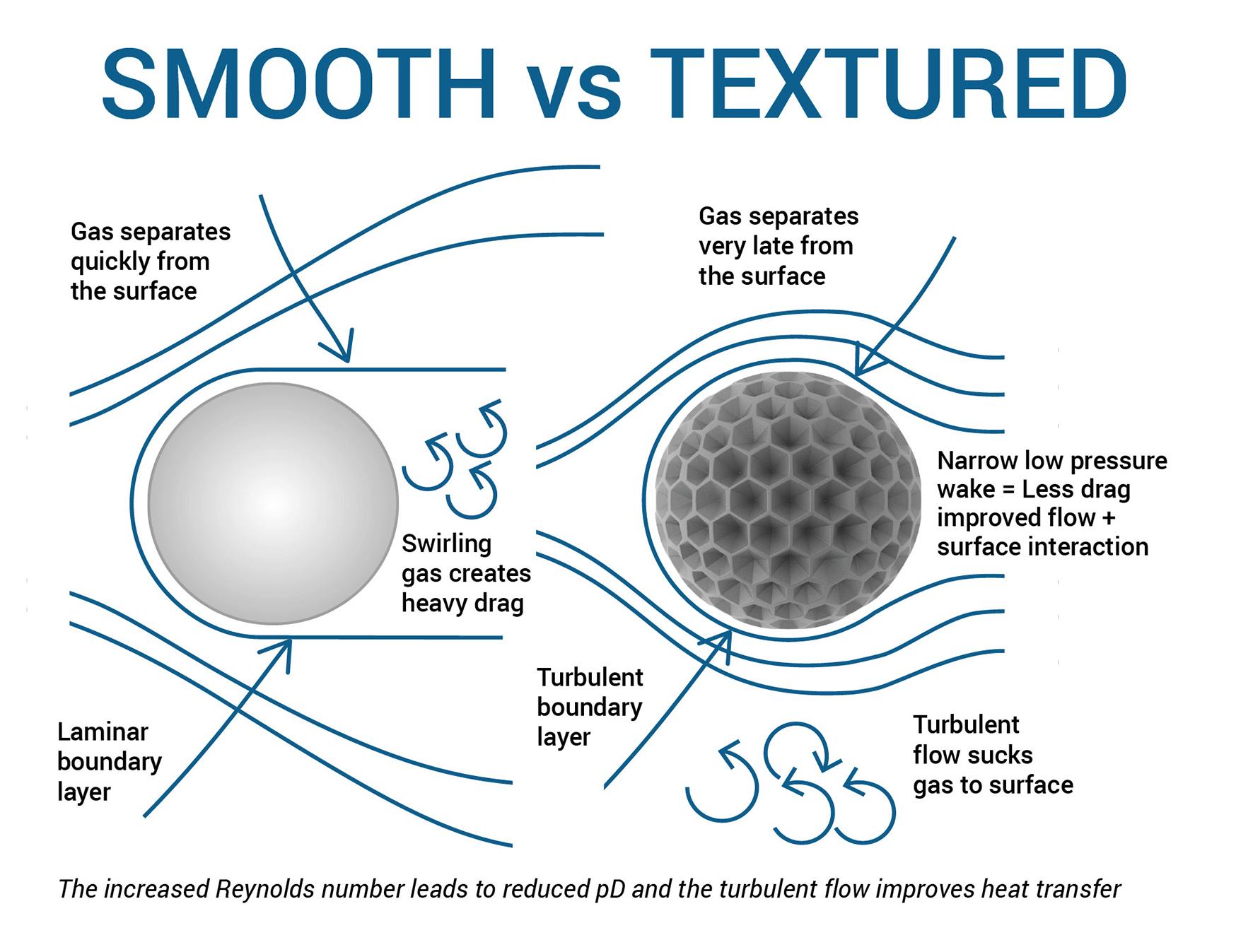

Beside the activity increases, the most advantageous and useful benefit of the catalyst could be the differentiation it provides in heat transfer and pressure drop that allows for full ammonia production increases. Standalone activity benefits will mostly be realised in cases where feed rates can be increased without hydraulic or other bottlenecking limitations. Due to steam reforming being an equilibrium reaction, the amount of syngas produced on a composition basis will be limited by the set of fixed conditions. By adding more feed into an SMR unit, a limit will be reached when pressure drop exceeds the maximum for the plant or methane slip increases without further possibility of increasing the outlet temperature. The textured surface of the catalyst also disturbs the laminar flow of gases over the particle surface. Turbulence over the surface of a body reduces the drag coefficient, which in this context of passing a gas over a fixed body, is realised as a lower pressure differential over the length of the reformer tube. The direct analogy used to explain this is that golf balls are dimpled because when are hit, they travel further; the drag forces are lower due to this increased turbulence.

Gas flowing through the bed of spheres is more uniformly spread, with all exposed surface area being in contact with gases, increasing the effective reaction zone with nickel. Traditionally, pressure drop is reduced in an SMR by moving to a larger catalyst pellet, however, the trade-off is a lower overall surface area, which results in higher methane slip. The catalyst decouples these concerns with additional surface area, porosity, catalyst shape, and surface texture, giving a baseline reduction in pressure drop (Figure 3).

Another limiting factor when attempting to increase ammonia production is heat transfer, specifically, radial heat transfer. Even in low internal diameter steam reformer tubes, a temperature gradient will exist between the heated wall and the centre point of the tube. This temperature gradient increases as feed flowrate increases, due to the reduction in time for heat to travel from the wall to the centre in the gas moving as a plug flow. As temperature is required to drive the overall endothermic reaction, this sets the equilibrium position between reactants and products; the widening temperature gradient at higher flowrates results in an increased methane slip at the exit of the tube. The solution, therefore, is to increase the radial heat transfer to minimise the radial temperature gradient to ensure heat is supplied to the full cross-sectional area of the tube.

Conduction is an important heat transfer mechanism, meaning contacts between the catalyst, the tube wall, and catalyst to catalyst should be maximised. Magcat spheres have an even packing and higher consistent ‘coordination number’ (number of pellets touching other pellets), meaning there is more packing at the tube wall. This decreased voidage and increased tube wall contact will disrupt the flow at the wall, causing turbulence and bringing the heat from the outside into the centre of the tube.

The catalysts’ textured spheres minimise the pressure drop, allowing a smaller size to be selected to maximise heat transfer. This attention to the physical requirements of the system is simultaneously coupled with the activity led inlet and outlet requirements of the catalyst previously mentioned to give the end-user a fully customised and optimised catalyst system.

This promotion acts to minimise carbon deposition through the enhancement of the carbon gasification reaction. A common hazard of potash is that the potassium quickly elutes from the catalyst. In conventional SMR catalysts, potash is added as a post-production step during catalyst manufacture and is easily driven out at reformer temperatures. This means the loss of protection from coking, but potassium will leach downstream, where it combines with other disassociated materials to cause fouling, most commonly on the heat exchange surface of the process gas boiler. Magcat helps to avoid this situation by offering potassium promotion locked within the polymer structure of the unique carrier where it remains active but cannot escape from the carrier structure to cause issues downstream.

Ammonia producers will fall into one of two camps in terms of their primary objective: increased ammonia production or furnace fuel and/or CO2 emissions reduction. Although these two benefits are not necessarily mutually exclusive, and the flexibility of the technology means fuel and CO2 savings can be realised during periods of lower ammonia demand and vice versa without the need to change the catalyst type, further incremental cost-benefits are also apparent.

When combining the advantages of Magcat, two directions can be taken by the end-user to, effectively, reduce costs:

n Lowering the feed and fuel rates but still making the same amount of H2

n Making more H2 which does increase the rate of use of feed and fuel but improves the overall economics per mole of H2 produced.

UNICAT simulated a large ammonia unit for both scenarios to compare the use of Magcat with the previously installed catalyst. When running at the same operating conditions, feed and fuel reduced by 812 665 Nm3 per year with the same quantity of H2 produced.

When running at the same operating conditions, H2 production increased by 267,891 Nm3 per year with the same feed and fuel consumption.

With Magcat, there is no requirement to change loading, start-up, normal operation, upset operation, shutdown or unloading procedures.

UNICAT’s Magcat textured technology offers increased ammonia productivity leading to increased profitability, furnace fuel and/or CO2 emissions reductions. These advances are available without the introduction of complex changes to procedures and with the flexibility to handle a full range of upcoming alternative feedstocks and incoming environmental challenges.

Peter Maas, Grandperspective GmbH, explains why a sea-change in emissions monitoring is needed if green ammonia is to become the future of farming.

Last December, policymakers representing 200 nations struck an historic deal to transition away from fossil fuels at COP28.

Some of these policymakers may have been influenced by the potential of the green ammonia sector. According to Persistence Market Research (PMR), a firm based in New York, it is a sector which is expected to ‘witness explosive growth’ in the coming years.1

The research, which was published in December 2023, forecasts that the market for green ammonia could increase from US$97.8 million to US$4517.6 million by 2030.

One of the largest areas of growth, says PMR, will be the fertilizer production market, which is expected to increase by over 75% between now and 2032.

The Royal Society, the world’s oldest, independent scientific academy, says that between 70 – 80% of ammonia is currently used to make fertilizer.2 However, figures from the Greenpeace Research Laboratories show that ammonia-based fertilizers are responsible for over 2% of the world’s carbon footprint, while agriculture accounts for nearly a quarter of the world’s emissions. Recent research by McKinsey & Company states that if farms switched to

green ammonia, greenhouse gas emissions from agricultural end products could be reduced by about 5%. 3

There are concerns that without more precise emissions monitoring, a significant scaling up of green ammonia production in farming might end prematurely.

Dr Reyes Tirado, a Research Scientist for Greenpeace Research Laboratories, says that if large scale industrial emissions occur, they might have potential impacts on air quality for human health (depending on the range of exposure) and more widely can increase N 2 O emissions as greenhouse gas in the atmosphere. 4

This has not stopped governments ploughing large amounts of resources into developing a green ammonia production capability. With green ammonia now being widely regarded by scientists as a fuel that can help to drastically lower our carbon footprint, nations around the world are setting up specialist research institutes to unlock its rich potential.

In the UK, the Science and Technology Facilities Council is building a small-scale plant to generate ammonia using only renewable energy sources. 5 Dr Tristan Davenne, Principal Engineer at the STFC Energy Research Unit, says that if the prototype is successful, it could prove to be a watershed moment, as it will enable the UK to scale up production, and begin to "build the foundation of a green ammonia economy to decarbonise large swathes of society."

Several nations are one step ahead, however. Saudi Arabia will soon be home to what will be the world’s biggest green ammonia plant. According to the Ammonia Energy Association, by 2026, the facility at Al Muwaileh is expected to produce 1.2 million t of renewable ammonia. 6

If the world is to follow Saudi Arabia’s lead, innovative green policy in the form of carbon taxes and subsidies will be required. Energy plants will also need to invest in ammonia cracking technologies as well as hydrogen separation and purification systems. But, if green ammonia is to replace ammonia in farming, entire ammonia distribution networks equipped with leak detection technology will be needed.

Ammonia, whether it is green, blue or turquoise, presents significant safety challenges. It is toxic, highly poisonous, and extremely difficult to detect with conventional sensor point technology. If it is not identified instantly, it can cause immediate burning of the eyes, nose, throat and respiratory tract. Without the right monitoring systems in place, it can leak uncontrollably in confined spaces, such as a green ammonia plant, and in the worst case scenario, it can result in blindness, lung damage or even death. Needless to say, it is also harmful to the environment and therefore emission-limited.

If plant managers are to protect their staff, and the large population centres who live beyond the perimeter fence, then they need to ensure that the right detection technology is in place.

Many plants have built a world-class safety culture within their operations. Not only do they comply with safety standards, they exceed them. But what about those who do not?

UNLOCK YOUR GOALS WITH

Reduce stack emissions

Decrease CAPEX

IT’S THE SAME, BUT BETTER

Lowest cost construction

Produce CO2free power

Use of green ammonia/ hydrogen O2

Better integrated, more efficient and cleaner production of CO2-free phosphate fertilizers

Leveraging oxygen from water electrolysis / ammonia production, CORE-SO2™ technology decreases acid plants’ environmental footprint and greenhouse gas emissions while recovering clean energy and enhancing plant profitability.

• No fossil fuels required

• 98% lower emissions

• 60% less plot space

• 55% fewer construction materials

• 50% decrease in CAPEX CORE-SO2™

LEARN MORE chemetics.info@worley.com chemetics.equipment@worley.com

Before surveillance technology, AI and open source data became widely available, local communities had no choice but to blindly place their trust in process plants. Now, thanks to sophisticated cameras and drones which are providing greater visibility and have given them a much more powerful voice, they do not have to.

Driven by economies of scale, almost anybody, anywhere can now deploy a drone-mounted camera equipped with sensor technology along the perimeter fence of a green ammonia facility, or sight a fixed camera on a nearby building, to detect, track and monitor emissions. Moreover, open-source data has levelled the playing field. Those with greater resources – such as a government agency, an insurance company or an environmental pressure group, can go even further. They can access satellite imagery to detect leaks, or mount state-of-the-art sensors onto helicopters or fixed-wing aircrafts.

This points to the fact that energy plants have lost control of the emissions narrative. Now, they are wondering who might be watching them and their facilities. However, if green ammonia facilities have rigorous and robust detection systems in place to detect, identify and monitor leaks, then what does it matter if others are also tracking their emissions?

Within the confines of a green ammonia plant, a leak is often impossible to detect using conventional sensor technology. This is because conventional point sensors, which are traditionally used by plants to identify ammonia leaks, have two major weaknesses.

The greatest technological limitation is that conventional points sensors are only capable of providing a local reading. Therefore, to suitably cover a three dimensional production site would require an inordinate number of sensors. One way of doing so, would be to install hundreds of point sensors across the facility, but the installation and maintenance costs would be crippling.

Secondly, for a point sensor to detect ammonia, the chemical needs to be in direct contact with the sensor point in order to trigger an alert. But, even if this were possible, gases rarely behave in the way that we expect. They are unpredictable and can change direction and trajectory very quickly, which means that plants simply cannot always rely on them.

Grandperspective GmbH has developed Fourier-Transform infrared spectroscopy (FTIR) remote sensing technology. With each scanfeld® remote sensor unit covering over 1 km in radius, one, or a few sensors can deliver 3D area coverage to an entire green energy facility.

The technology provides autonomous detection rates of typically 0.05 kg/hr and less. The instrumentation is sensitive, meaning it can identify ammonia and hundreds of other chemicals, whilst at the same time, offering quantification and monitoring capability.

The risk of employing such sensitive detection technology is that it is unable to distinguish technical emissions from an actual incident. This would of course

render the technology unusable. Therefore, it is important to ask how can such precise instrumentation make this critical differentiation? The system recognises normal behaviour of a technical emission which enables remote sensors to spot unconventional behaviour automatically and in real time. It is only then that the system will send an alert to the operator.

The remote sensing technology analyses radiation in the same way finger print detection technology identifies an individual. It allows for forensic detection of ammonia, while accurately pinpointing the source of a leak and the quantity of ammonia in the air.

FTIR technology is not new. It was first developed in the 1940s and the first FTIR spectrum was recorded in 1949. It is an incredibly established method for identifying chemicals in the laboratory, or in space science. What is a development is that the spectrometer is used to analyse omnipresent infrared radiation autonomously 24/7. The technology is highly automated. The light from a kilometre’s distance to find the gas composition in the air is analysed. This is how the precise information is collected, which reveals the exact type and quantity of chemicals in the air. Then, the entire gas cloud is made visible. In doing so, the analytical precision of the laboratory analyser with the overview of camera technology 24/7 is combined.

Additionally, the installations, once set-up, continuously learn more about the normal emission cycles of the plant. Throughout the production cycles, including loading procedures, start-ups, cleaning and maintenance, the system learns to differentiate between technical emissions and potentially dangerous gas leaks.

Furthermore, the system enables plant safety teams to map a gas cloud in real time. This is absolutely key, as in providing facilities with the exact location of a hazardous area, they can take immediate action to stop the leak.

While producers may no longer be in control of the emissions narrative, due to the ubiquitousness of surveillance technology, AI-enhanced remote sensing technologies, which provide low detection rates that conventional sensor technology cannot match, can help them to wrestle it back.

This is why plants who are producing and distributing ammonia are likely to opt for an FTIR spectroscopy-based remote monitoring solution in the near future. It is also the reason why green ammonia facilities will follow in their footsteps. The stakes for them – and the future of green ammonia – are simply too high for them not to.

1. https://finance.yahoo.com/news/green-ammonia-marketexplodes-72-121000094.html

2. https://royalsociety.org/-/media/policy/projects/greenammonia/green-ammonia-policy-briefing.pdf

3. www.mckinsey.com/industries/agriculture/our-insights/fromgreen-ammonia-to-lower-carbon-foods

4. Information obtained via an interview between freelance writer, James Gordon, and Dr Reyes Tirado.

5. www.ukri.org/news/designs-for-green-ammonia-plant-becomereality/

6. www.ammoniaenergy.org/articles/neom-project-reachesfinancial-close-30-year-offtake-secured/

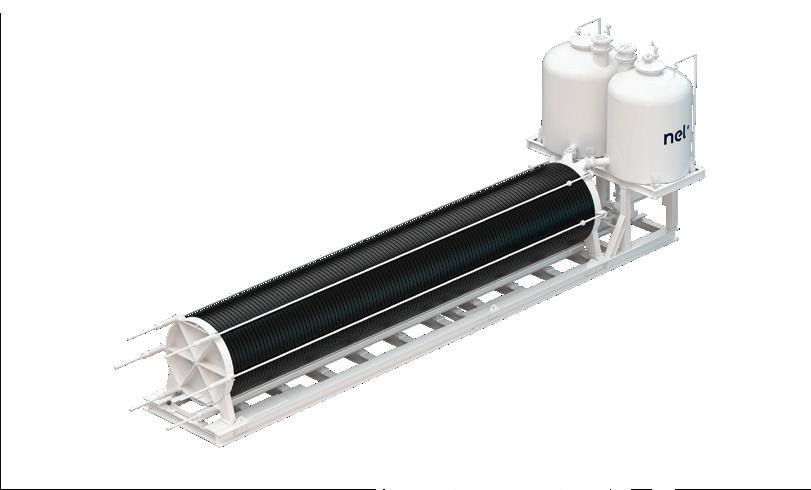

Todd Cartwright, Nel Hydrogen, USA, examines why the capacity for hydrogen electrolysers must be increased.

According to Statista, the global green ammonia market stood at around 5800 t in 2021, an increase of 3700 t from the previous year. Over the next decade, this figure is forecast to increase at a compound growth rate of 90%, reaching approximately 1.6 million t by 2030. 1 As roughly 80 – 85% of all the ammonia produced is used in the fertilizer industry, the pressure is on in virtually every market sector in the world to reduce fossil fuel usage and carbon emissions. To that end, different countries have different policies and incentives to promote the development and use of green ammonia.

In Europe, the EU Renewable Energy Directive will require 42% of ammonia to be green by 2030 – just six years from now. This regulation will also introduce a carbon border adjustment mechanism which will force ammonia and fertilizer importers to report emissions and pay a carbon tax at the border.

In India, the government has announced a new green hydrogen policy which offers a range of incentives to green hydrogen and green ammonia manufacturers, including allocation of land in renewable energy parks, waiving of interstate transmission charges for 25 years, and banking of renewable power for up to 30 days. The policy also aims to

create bulk demand and scale up green hydrogen by specifying a minimum share of consumption by designated consumers as energy or feedstocks. In Canada, the government has launched a hydrogen strategy which includes investing in blue hydrogen projects that use natural gas with carbon capture and storage technology. The strategy also supports the development of green hydrogen projects that use renewable electricity to produce green ammonia. These are just some examples of how governments around the world are trying to encourage the use of green ammonia.

Green hydrogen is the feedstock that enables green ammonia. Hydrogen plays a vital role in ammonia production, as it is the main reactant for the Haber-Bosch process, which converts atmospheric nitrogen and hydrogen into ammonia. Hydrogen can be produced from various sources, including water electrolysis. This process uses electricity to split water into hydrogen and oxygen. The advantages of this method are that it produces pure hydrogen without any carbon emissions or by-products. When the electricity source for the electrolyser is carbon free, then the ammonia production process is carbon free.

There are two types of electrolysis systems that are generally considered commercially mature today. One is alkaline electrolysis, and the other is proton exchange membrane (PEM) electrolysis. There are other types in development which also show promise for the green ammonia industry, such as solid oxide, but for now alkaline and PEM are the field-proven methods. Alkaline technology has historically been used for large capacity hydrogen plants. Alkaline cell stacks costs less on a per kW basis because they do not use precious metal catalysts as PEM does, and alkaline equipment has been commercially deployed for almost a century. PEM electrolysers are compact and can ramp up quickly with variable energy sources. They can also achieve a similar range of hydrogen production, up to thousands of kilograms each day. Contrary to common belief, PEM electrolysis is a long-proven technology, and has been operating in the field commercially for about 50 years. Electrolysis begins with the electrolyser’s cell stack. That is the technology core of the electrolyser, akin to a computer chip or a car’s engine. Each cell stack is made up of many electrolytic cells, each of which is an electrochemical reactor. Add water and a DC power source, and the cell stack creates hydrogen and byproduct oxygen.

There are several advantages of containerised PEM electrolysis. They include predictable availability and limited on site integration risk. The equipment is made in a factory; it is not assembled in the field. There are minimal technology and supply chain risks. There are also minimal infrastructure requirements in the field, in particular the cost of a building. Basically, the needs are deionised water, electricity, the ability to dispose of waste water, and the downstream gas and water processing. Highly skilled tradespeople are not necessary to do field fabrication and integration, and systems can be installed quickly and seamlessly.

Because the systems are highly standardised, companies receive an assured level of support from manufacturers who have made hundreds of such systems. It is believed that PEM electrolysers, at least initially, will play the larger role when coupling to renewable energy sources, because of their ability to respond instantly to electrical supply changes and downstream process needs.

To match the ramp-up of hydrogen needs for the green ammonia market and others, the electrolysis industry is investing to meet these growing needs.

Several projects are underway around the world to ramp up green hydrogen and green ammonia supply. It starts with the foundational infrastructure. As an example, Iberdrola, a multinational electric utility company based in Bilbao, Spain, selected Nel Hydrogen a few years ago to turn Spain into a technological and industrial benchmark in green hydrogen.

Iberdrola and Nel have developed and deployed large-scale electrolyser projects to promote the green hydrogen supply chain in Europe and the United States. Specifically for green ammonia for fertilizer, the Iberdrola-Fertiberia alliance is producing green hydrogen for the Puertollano ammonia plant in Spain. The electrolyser solution is a 20 MW PEM system, the largest electrolysis plant for green ammonia production currently in operation.

According to the Ammonia Energy Association, Fertiberia’s low-carbon fertilizer has been successfully used in pilot programmes by Heineken and PepsiCo.2 This green fertilizer has been used on barley and potato crops in Spain, drastically reducing overall agricultural emissions and paving the way for

future supply chains. Both Heineken and PepsiCo are aiming to reduce agricultural emissions from their product supply chains and intend to scale up the use of green fertilizer based on the success of their 2023 pilot programmes.

Another company making strides in green hydrogen/green ammonia production for fertilizer is Yara International ASA. They have also applied electrolyser technology to help achieve the company's mission to “responsibly feed the world and protect the planet”. According to published press materials on its website, Yara has already removed half of its direct greenhouse gas emissions over the past 30 years and is striving towards carbon-neutrality by 2050.3

According to Recharge, the cost of green hydrogen is expected to fall to US$1.50/kg by 2030 as electrolyser capacity increases; more than 100 GW of electrolysers will be manufactured each year by 2030, up from 2 GW in 2020.4 As one example, Nel is building a new electrolyser equipment manufacturing plant near Detroit, Michigan. When fully developed, the Michigan plant alone will have a production capacity of up to 4 GW/year of alkaline and PEM electrolyser stacks.

1. www.statista.com/statistics/1351122/global-green-ammonia-marketvolume/#statisticContainer

2. https://www.ammoniaenergy.org/articles/fertiberia-low-carbonfertilizer-alliances-with-heineken-pepsico/

3. https://www.yara.com/news-and-media/news/archive/2019/yaraand-nel-carbon-free-hydrogen-for-fertilizer-production/

4. https://www.rechargenews.com/energy-transition/average-cost-ofgreen-hydrogen-to-fall-to-1-50-kg-by-2030-as-electrolyser-capacityramps-up-50-fold-analyst/2-1-1287093.

Rochman Goswami, Black & Veatch, USA, discusses the business opportunities that green ammonia presents in the quest to decarbonise across industries.

The urgency for accelerated decarbonisation has never been better recognised. Green ammonia and low carbon ammonia are critical to decarbonisation efforts across the industrial landscape. This article lays down some key business considerations, as diverse industry players embark on ventures involving green ammonia.

Ammonia has always been a strategic molecule, with strong socio-political and commercial implications, due to its link to food security. Hydrogen-driven decarbonised energy has further amplified ammonia’s strategic profile with the molecule recognised as the leading carrier of hydrogen.

Conventional ammonia production is carbon intensive, with every ton emitting between 1.5 – 3 t of CO 2 , contributing around 1.5% of total global carbon emissions. Green ammonia refers to the production of

renewable and carbon-free ammonia. Other colours include grey ammonia produced from fossil fuels (natural gas or coal) or blue ammonia, which also utilises fossil fuels but with carbon capture and sequestration.

Green or reduced-carbon ammonia is seen as a key solution with tremendous potential for decarbonisation across industries, using:

n Eco-friendly fertilizers to help decarbonise the food chain.

n Decarbonised fuel (transportation, shipping, etc.).

n Green ammonia as a hydrogen carrier for the whole energy supply chain and power generation, in the new hydrogen driven ‘molecules to electron’ economy.

There are many key drivers affecting green ammonia businesses. Analysis of these business drivers aids in setting realistic goals towards developing a successful green ammonia business.

Although the current market is dominated by the fertilizer and food security aspects of ammonia, understanding the ammonia markets provides a good perspective in developing a green ammonia business plan. Over 70% of ammonia production is linked to fertilizers and therefore food security, with its deep socio-political implications. The market is dominated by a sentiment of insecurity that drives every geo-political constituency to seek control over its ammonia supply. After the end of cold war in the 1990s, and with increased global free trade, that sense of insecurity temporarily diminished. However, supply chain disruptions due to the recent global events are triggering these tendencies again. Already, countries like Brazil, with over 85% reliance on imports, are calling for domestic captive production of ammonia. Any business plan that crosses geopolitical boundaries needs to take this into account.

Ammonia’s entanglement with energy, as a carrier of hydrogen, will further exacerbate uncertain situations, and all aspects of the ammonia market will be affected by geo-political occurrences, alliances, manipulations, and tensions.

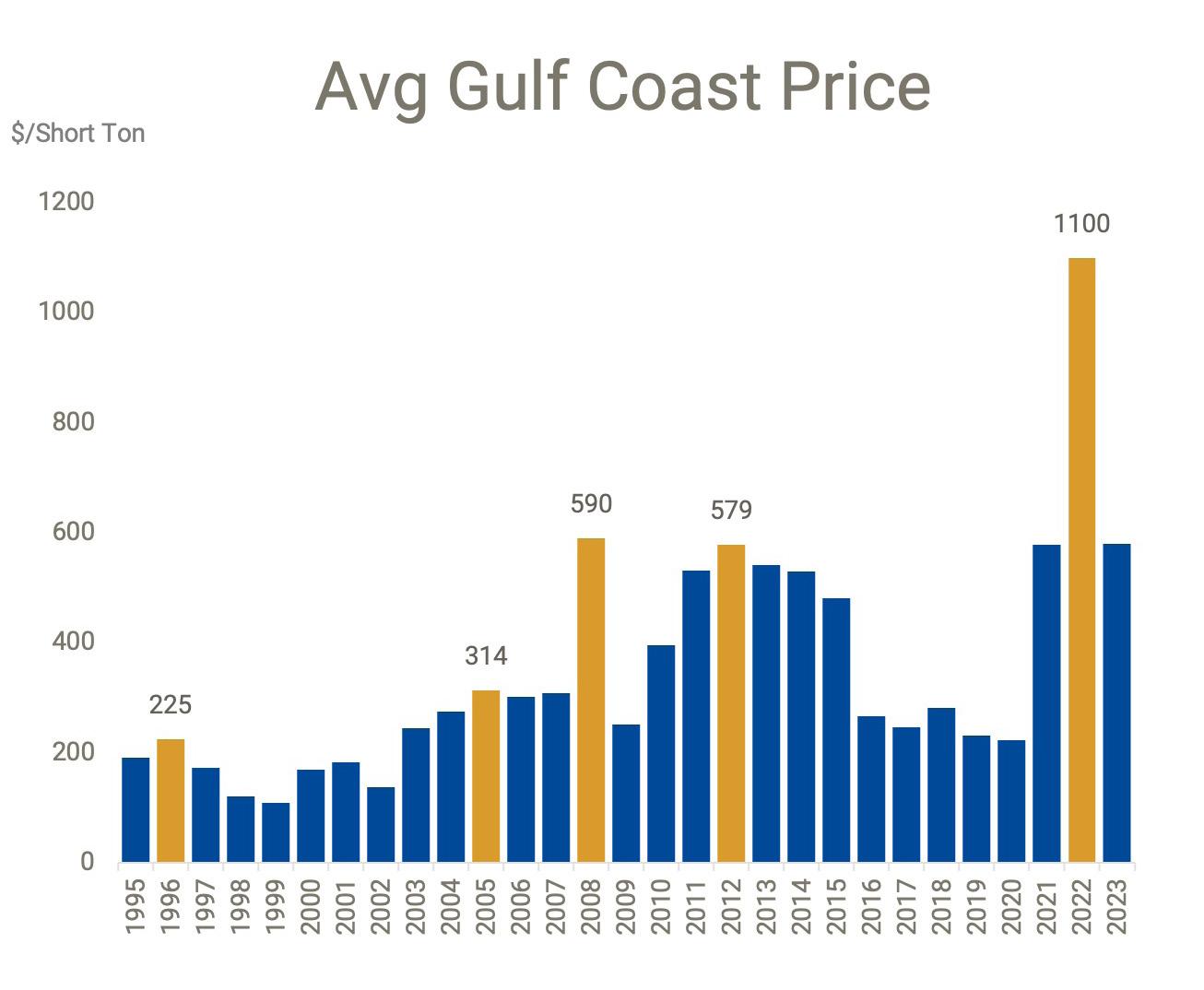

Figure 1 shows that the production of ammonia has grown steadily since 1994 (globally, as well as in major producing countries such as China, USA, Russia, and India). Demand growth is also generally steady, however, the prices of ammonia fluctuate widely (Figure 2). Between 2012 and 2022, production globally has been stable between 140 – 150 million t, but the price has fluctuated from US$600/t in 2012 down to US$220 in 2020, and then skyrocketed to over US$1100 in 2022. Prices are currently down to around US$350 – US$450/t. Sensitivity to economic cycles and geo-political tensions are significant factors in ammonia markets.

Every economic crisis leaves an imprint on the ammonia market (Figure 2). The 1997 Asian currency crisis led to some of the lowest ammonia prices historically due to its effects on the demand side. The 2008 market meltdown caused a temporary spike followed by a steep decline in prices. Global events since 2020, including the pandemic, have led to an unpredictable market situation with unprecedented price levels (while global production is still holding steady).

The ammonia market is affected by natural gas/energy prices, with natural gas being the primary raw material. However, it is much more sensitive to socio-political and economic drivers. For instance, between 2012 and 2020, natural gas prices were fairly stable, between US$2 – 5 per BTU band, while the fluctuations in ammonia prices were much wider.

Farmer affordability is another key driver in ammonia markets, which means crop markets also affect ammonia pricing. Higher crop prices allow

Developing a repeatable, in-service inspection strategy for ammonia storage tanks will help improve operational reliability and minimize the probability of failure from several damage mechanisms, including ammonia stress corrosion cracking (SCC). Fertilizer and renewable hydrogen manufacturers need to identify the optimal balance between the need for an internal inspection versus the potential consequences of performing those inspections.

At E²G | The Equity Engineering Group, Inc., our consulting team helps to navigate the challenges of high-consequence ammonia storage tanks with a multidisciplinary approach to inspection strategies. Our team integrates risk-based inspection (RBI), fitness-for-service (FFS), and materials and corrosion expertise to provide a comprehensive and practical inspection strategy for your ammonia storage tanks.

Your team’s expertise on this topic made completing this project very professional. I appreciate your insight and look forward to working with you again.”

International Fertilizer Manufacturer, August 2023

farmers to afford more use of fertilizers and leads to increased prices. On the other hand, higher ammonia prices mean lower affordability for farmers. The price spike influenced by effects from the war in Ukraine was so steep that it caused fertilizer usage to drop significantly, lowering overall crop yields. Green ammonia is not likely to be directly affected by farmer affordability in the short to medium term, due to pricing levels. However, being in the market for the same commodity, and the strength of the international energy lobby, can weaken a farmer's position in the equation.

The emergence of China as a major supplier of cheap ammonia, sourced from coal gasification, brought down the local production in the US to 8 million t in 2008. Subsequently, China has had to shut down many coal gasification facilities and the continuing rise in global demand has led to current production levels of 13 million t in the US.

US consumption has remained steady, with a slight downward trend, peaking at 18 million t in 1998 and now to current levels of around 13 million t. Some factors driving the trend are:

§ More efficient technology driven fertilizer delivery methods to the roots of the plants.

§ Increased responsible use of fertilizers with soil protection in mind.

§ Growth in bio-fertilizers and organic farming practices.

In the development of a business case for green ammonia, including financial analysis and proforma financial statements, it is recommended to include a sensitivity analysis in relation to the following key drivers:

n Energy markets, oil, natural gas, coal, etc.

Green ammonia is likely to compete in the fuel space until cost levels are brought down to compete with grey and blue ammonia.

n Grey ammonia markets are here to stay for some time due to capacity needs and pricing differentials.

n Farmers are sensitive to pricing. Also, socio-political establishment must keep a sharp eye on food pricing, especially for the vulnerable sections of society. Therefore, natural gas and coal prices as raw material for grey ammonia will have sensitivity for green ammonia as well.

n Major crop markets – farmer affordability is affected, hence the demand side of ammonia is also impacted.

n Geopolitical plays and disruptions – both China and Russia are major players in the space, as is Europe.

n Economic cycles will have a multi-pronged impact on green ammonia markets.

n Financial markets, interest rates, and currency markets have profound impacts on the green ammonia sector. Some recent financial models show interest rates as the most critical driver through sensitivity analysis for green ammonia projects.

n Interplay between grey, blue, and green ammonia markets – an area which is still evolving. Blue ammonia and green ammonia market mechanisms are not yet instituted globally.