9 minute read

Bunker up

Björn van de Weerdhof and Wouter van der Veen, Anthony Veder, the Netherlands, offer some valuable insights for the future of bunkering LNG and alternative fuels.

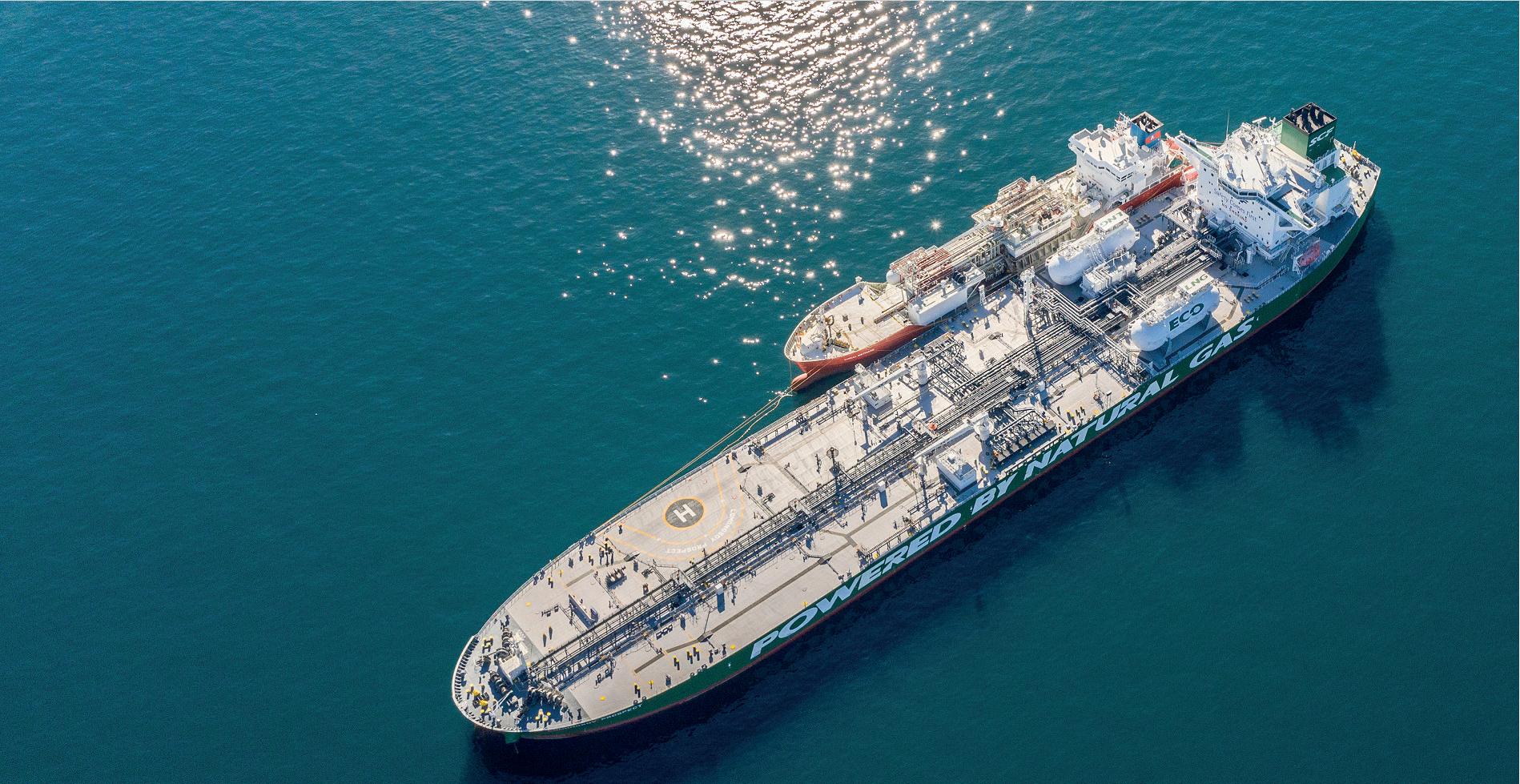

Figure 1. Coral Methane bunkering AIDAnova.

The development of LNG carrier Coral Methane for the Norwegian energy company Gasnor in 2006 marked an innovative first step in small scale LNG. Anthony Veder offered the concept of a combined vessel able to transport LNG, liquid ethylene gas (LEG), and LPG. This combination opened up the opportunity for the company’s partner to grow its presence in the small scale LNG market and the ability to serve the petrochemical market.

After Coral Methane’s delivery in 2009, there were numerous milestones including the first small scale LNG ship-to-ship (STS) operation with Pioneer Knutsen and the opening of LNG trade from Risavika, Norway. During 2018, Coral Methane was modified as a dedicated LNG bunker vessel to serve the maritime industry with today’s most sustainable marine fuel. In 2019, the vessel fuelled the world’s first LNG-powered cruise ship, AIDAnova, in Tenerife.

Progress in LNG bunkering

In 2011, Anthony Veder was awarded a contract to build two ethylene carriers with dual fuel (MGO and LNG) propulsion. This resulted in Coral Star and Coral Sticho being added to the fleet in 2014. A dedicated LNG bunker facility in the Port of Tees was established specifically for these two vessels.

With the gained experience in LNG transport, Anthony Veder performed the world’s first offshore LNG bunker operation in 2016 at the anchorage of Gothenburg, Sweden. Via an STS operation, Coral Energy fuelled the chemical tanker Ternsund with LNG. This operation was the frontrunner for the first dedicated LNG bunker vessel Coralius, launched in 2017 and operational in the Gothenburg area.

Another milestone was performed in the Port of Rotterdam by Coral Fraseri, Anthony Veder’s LNG carrier. In March 2020, the vessel performed the world’s largest LNG bunker operation by fuelling Heerema’s Sleipnir with almost 3300 t of LNG. Although Coral Fraseri is not designed as a bunker vessel, the vessel can deliver LNG by means of an STS operation.

So, what does it take to prepare for an LNG bunkering operation?

Risk assessment approach

Every LNG bunker operation starts with a risk assessment. Herewith the risks to people and the environment should be eliminated or, if not fully possible, mitigated. Also, the parameters and conditions to determine the environmental limits, safety zone, and security zone, and how to monitor this during the bunker operation will be addressed.

Such a risk assessment leads to a full walkthrough of the LNG bunker operation, from preparations before and upon

arrival of the vessel, how to approach and how to moor, and the preparation and testing of bunker equipment when moored. After this has been achieved the actual LNG transfer can take place, with specific care for boil-off gas management. In most cases, the bunkering activity shall be undertaken during cargo operations of the receiving vessel. This is called a simultaneous operation, or SIMOPS, and will have an effect on the identified hazards, thus should be mitigated.

The next phase is completion of the bunker transfer and disconnect of equipment, paperwork, and finally unmooring. This will all be covered in the Joint Plan of Operation (JPO) between both vessels, including the port-specific requirements.

Each port has its requirements and conditions to allow an LNG bunker operation to take place. The LNG industry itself operates on a very high safety standard; this is no different for any LNG bunker operation. The challenge lies with the customer’s vessels, from bulk carriers to platform supply vessels and up to cruise vessels, and its crews having no experience with LNG. As such the risk assessment should be thoroughly carried out to make sure safety is never compromised at any stage of the operation.

Compared to a standard MGO/HFO manifold an LNG bunker manifold will come with restrictions; a hazardous area, spill protection, extra piping, and much more. Therefore, vessel owners typically locate these LNG manifolds where they have the lowest impact on passengers, cargo intake, or cargo operations. This location is not always the ideal place for a bunker operation, and during preparations this requires a thorough check on accessibility, reachability, and fitting of the transfer equipment. A large number of documents and drawings are shared upfront: general ship drawings; bunker manuals including emergency procedures, system drawings, and crew competency certificates, to name a few. Even JPOs for sister vessels out of the same build series cannot be copied as it was experienced that onboard procedures and containment systems could differ.

Quite often these ‘odd’ bunker manifold locations lead to issues with mooring two vessels with regards to limited parallel mid-body contact. In addition, especially in a double banking situation, the availability of strong enough fairleads and bollards are limited as those are either already in use or blocked for mooring with mooring lines to shore. Creative and unconventional mooring layouts could offer a solution, underpinned by mooring analyses, with the same level of safety.

If a SIMOPS is intended during bunker operations this would require special attention. It makes a significant difference whether an iron ore bulk carrier (large changes in draft of the bulk carrier) is loaded or a container vessel is handling boxes (risk of a container falling out of the crane). An even bigger challenge is bunkering a cruise vessel that is simultaneously embarking and disembarking passengers, with balconies in the vicinity of the bunker manifold. In such a case it is hugely important to have good procedures and safety assessments on gas cloud behaviour, related to liquid spills and hazardous area management, so cruise passengers are not aware of the risks.

Another essential part is the transfer equipment combined with the ship-ship linked system. When the vessel separation device detects a movement larger than acceptable, it triggers an ESD1 signal that will stop the pumps and close down the valves. By having a proper ship-ship link this signal will be transferred to the receiving vessel, however, this can also pose a challenge. To get a healthy signal, both systems should be technically aligned, but with several makers and ship equipment integrators there is a risk of non-matching signals that can jeopardise the whole bunker operation. A back-up scenario must always be agreed upon and should be properly documented. When even a larger separation is detected, the system triggers an ESD2 signal which will result in a spill-free disconnection of the hose assembly from the manifold.

Due to the risk-based approach, all aspects of a bunker operation will be taken care of and can be performed at the highest safety standards. These examples make it clear that preparations take much experience and a lot of time. What does this mean for the future of LNG bunkering?

Figure 2. Coral Fraseri bunkering Sleipnir in Rotterdam, the world’s largest LNG bunker operation.

Figure 3. Coral Methane’s first LNG bunkering of AIDAnova in the port of Santa Cruz de Tenerife.

Building competence levels and automation

Informative work has been undertaken by the Society for Gas as a Marine Fuel (SGMF) to accumulate many of the experiences and knowledge detailed in this article, and SGMF has provided for certain standardisation by issuing guidelines. Building the right competence levels within organisations and crew of the vessels is of prime importance, as safety for people and the environment remains the industry’s top

priority. Anthony Veder expects that LNG bunkering will become more custom and that these experience levels will be built onboard the vessel.

Both standardisation and increasing competence levels could lead to shifting responsibilities for preparations of LNG bunkering operations more towards the crew of the bunker and customer vessel, making use of standardised formats for safety zone assessments, mooring, transferring, and purging, leading to shorter preparation time. Also, the transfer systems and transfer itself could become more automated. This will reduce manual handling by the crew, making the overall operations safer and allowing for quicker turnaround times.

What can be learnt from this experience when developing bunkering of alternative fuels such as green ammonia, methanol, or hydrogen?

Figure 4. Aerial view of Coral Methane bunkering Lomonosov Prospect.

Figure 5. Bunkering operation by Coralius in Scandinavian waters.

Figure 6. View from Coral Methane’s bridge during bunkering AIDAnova.

When Anthony Veder started introducing LNG as a fuel for its new-build ethylene carriers Coral Star and Coral Sticho, the company faced fierce opposition. At that time, feedback was received such as ‘you cannot do this’, ‘there are no regulations in place’, ‘LNG is not available’, ‘how do you know what the price is or will be?’ These were all relevant questions but did not hold Anthony Veder back from pursuing its interest in the field, and in 2014 these vessels were the first LEG carriers fuelled with LNG.

What journey was taken? At first, Anthony Veder had to beat the competition in a tender for a charter on a liquid ethylene carrier based on a vessel sailing on MGO/HFO only. Only after the award did the company put the concept of LNG-driven vessels on the table. After intense discussions with the customers, trust was won and dual-fuel propulsion was installed. Where normally the charterer is paying for the fuel, Anthony Veder took the risk on LNG/MGO spread. A courageous and bold attitude. Anthony Veder strongly believes that LNG is the right thing to do, it not only made sense from an environmental point of view, but also economically, over time.

Discussions with many stakeholders took place – including terminals and ports – to sort out and agree on practical and regulatory solutions to get LNG on board. It was important to co-operate with the right partners to help design the LNG bunker tanks and cold box for handling the LNG and vaporising it for use in the vessel’s engines. After being awarded it helped that they were provided with some subsidies to lower the hurdle on the risk taking.

So, what can be learnt from Anthony Veder’s experience in safely and successfully building a supply chain in LNG as bunker fuel for alternative fuels, such as methanol, ammonia, or hydrogen?

First, commitment is needed, and the extra mile should be walked. Secondly, one should not be too easily discouraged by all the things that still need to be done or overcome. It is not important to have all the answers upfront before starting. Focus on the showstoppers and assess what needs to be done to find a solution, not the solution itself. Obviously, there are numerous technical and regulatory challenges, but the experience of Anthony Veder shows that there was no physical or higher law preventing success. Selecting the right partners is key to have an integral approach from the start.

Anthony Veder has had many proud moments along the way, from the delivery of the vessels that bunkered their first LNG to the first LNG bunkering of a cruise vessel after completion of the Coral Methane to a dedicated bunker vessel. Looking backwards and forwards, LNG as a fuel is a huge success overall.

Anthony Veder is ready and ambitious to lead the next step in the transition towards more sustainable shipping by either LNG or alternative fuels that will come.