11 minute read

Maximise sulfur recovery, minimise carbon intensity

Ganesh Kidambi, Shell Projects & Technology, and Hans Wijnbelt, Shell Catalysts & Technologies,

demonstrate how low-temperature catalyst and solvent technology can help to optimise sulfur recovery and lower the carbon intensity of refining operations.

Demand for energy is set to rise as the global population and standards of living continue to grow. Current energy systems, however, are carbon-intensive and must undergo a rapid transition to lower-carbon alternatives if we are to limit the global average temperature rise to 1.5°C above pre-industrial levels, as set out by the Paris Agreement. This scenario presents multiple opportunities for the hydrocarbon refining industry to showcase its strong innovativity, optimise operations, and offer lower-carbon solutions and products. Not only will this help to reduce industry carbon emissions, but it will also offer significant financial incentives at a time when the cost of carbon dioxide (CO2) emissions is rising, standing at €85/t (US$88/t) in the EU emissions trading scheme at the time of writing. As part of its Powering Progress strategy, Shell has set out to accelerate its transition, in step with society, by becoming a net-zero-emissions energy business by 2050. To achieve this, the organisation will reduce emissions related to its own operations (Scopes 1 and 2) and those that result from the use of all of the energy products that it sells (Scope 3), including products derived from third-party energy feedstocks. Where emissions cannot be avoided,

Shell will capture and store, or offset, any remaining emissions. In addition to curbing carbon emissions, limiting sulfur emissions is imperative for a company’s licence to operate. However, the process of removing sulfur from gas streams can be energy – and therefore carbon – intensive. The SCOT ULTRA process is one of many options

available for decreasing the carbon intensity of refining and gas processing. The Shell Blue Hydrogen Process and Shell Renewable Refining Process are two other refinery decarbonisation options.

The sulfur recovery section of a refinery or gas processing facility is not built to generate revenue, as the sulfur market price is volatile and the cash generation from elemental sulfur is small in comparison to the main revenue streams. Instead, it is built to help a company maintain its social licence to operate. Consequently, the design and success of a sulfur recovery unit (SRU) is measured in terms of its ability to meet the SOx emissions (mostly with a downstream tail gas treatment unit [TGTU]), CAPEX, operating and carbon costs, and reliability and flexibility.

This article demonstrates how SCOT ULTRA technology – the most novel version of the SCOT process with a new, drop-in solvent and a low-temperature catalyst – can enable operating units to reduce the carbon intensity of tail gas SRUs, and increase the amount of sulfur recovered to meet stringent SO x emissions regulations. Additionally, SCOT ULTRA amine solvent, JEFFTREAT ULTRA, secures the SCOT or other TGTU to operate with greater resilience to upsets and extreme hot and cold climatic temperatures. These are important benefits for systems running close to their limits, or in regions where more frequent and intense weather extremes are driven by climate change.

The SCOT ULTRA technology is able to: n Lower OPEX and carbon footprint, and/or increase capacity. n Operate the hydrogenation (SCOT) reactor at a lower temperature, saving steam/fuel costs. n Operate the amine unit at higher solvent temperature, enabling savings in cooling. n Provide increased resilience to upsets. n Offer greater flexibility to handle changing crude slates and upstream gas composition. n Decrease or avoid CAPEX for greenfield developments.

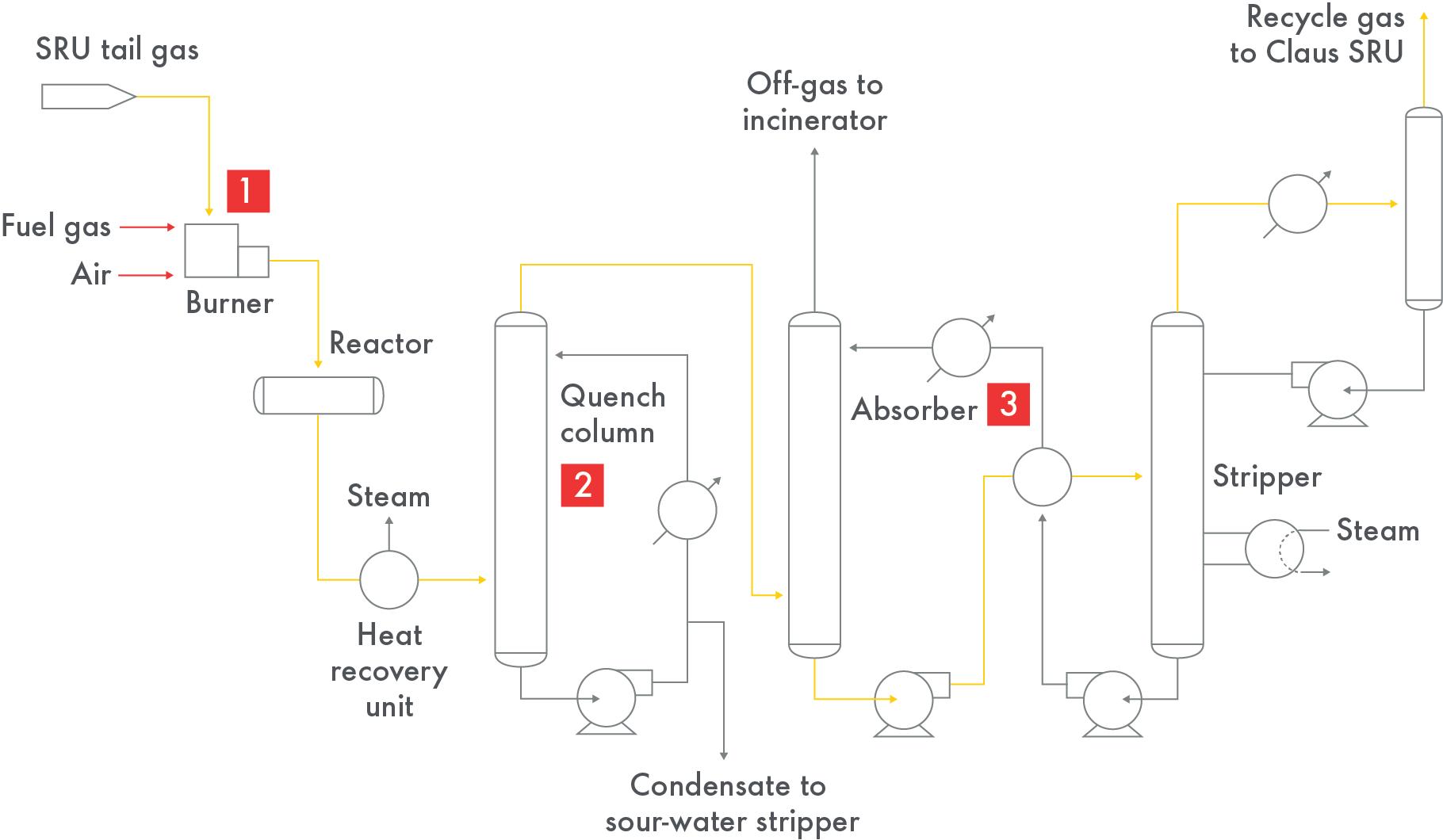

Figure 1. The three-step SCOT ULTRA process. 1 = preheater; 2 = direct-contact quench column; 3 = amine absorber.

Figure 2. Swapping in SCOT ULTRA (834) can help reduce SRU carbon intensity by as much as 50% compared with previous SCOT catalysts.

The process

Due to thermodynamic limits, sulfur recovery from modified Claus SRUs is limited to between 96% and 98%. Therefore, to meet current SOx emission regulations, which require greater than 99.9% sulfur recovery, it is now necessary to install a downstream TGTU.

The SCOT process uses a three-step approach to enable efficient and deep recovery of the residual sulfur species in the tail gas stream (Figure 1). First, the reduction section preheats the SRU tail gas using a line burner (direct reheat) or steam reheater (indirect reheat).

At reactor inlet temperatures of 210 – 260°C (depending on the catalyst used), a catalyst-based reduction reactor section then converts the sulfur components of the tail gas (sulfur dioxide [SO2], sulfur trioxide [SO3], carbonyl sulfide and carbon disulfide) into hydrogen sulfide (H2S).

Second, the gas exiting the reactor is cooled in a two-step process: first, in an (optional) heat recovery exchanger that produces steam; and second, in a direct-contact quench column with water. Claus reactions generate a significant amount of water, which is bled from the quench column to aid the performance of the amine section.

Third, an aqueous amine solvent is used to selectively capture and recycle H2S from the cooled gas. The H2S is stripped in a solvent regenerator (also called a stripper) and recycled to the front end of the SRU. The treated gas from the absorber column is incinerated to convert unrecovered H2S to SO2 before release through the stack.

Like all alternative amine-based TGTUs, SCOT is energy-intensive. This creates an opportunity to develop and deploy novel technologies designed to reduce operating costs and carbon emissions, while maintaining superior performance and sulfur recovery.

Evolving to meet today’s demands

Since its first introduction in the 1970s, the SCOT process has been refined and optimised to keep pace with evolving emissions regulations and the need to reduce the carbon footprints of facilities. The original SCOT design used a conventional secondary amine (DIPA) or a tertiary amine (MDEA) for the amine absorption section. Later, low sulfur, or LS SCOT, was introduced, which used an acid-aided regeneration (formulated MDEA) scheme in the amine regenerator, resulting in reduced energy consumption in the amine reboiler while also meeting a lower SO2 specification in the flue gas.

Additionally, to meet evolving performance standards, Shell Catalysts & Technologies developed a range of catalysts, such as 734, able to operate at lower temperatures (approximately 220°C and lower) for processes such as low-temperature (LT) SCOT. Using these catalysts reduces the amount of fuel gas needed, and enables the use of indirect heating methods.

Lower carbon intensity and reduced OPEX

SCOT ULTRA is the latest evolution of the SCOT catalyst and solvent technologies, and integrates the latest LT SCOT catalysts (834 or 934) with the JEFFTREAT ULTRA amine solvent.

Catalysts

Historically, SCOT catalysts have operated at temperatures greater than 240°C. SCOT ULTRA, however, can operate at much lower temperatures; the latest SCOT 934 catalyst is effective at an inlet temperature of 200°C, and SCOT 834 at an only marginally higher temperature. This low-temperature operation requires less energy while still meeting the demanding performance requirements. This helps to reduce carbon intensity and provides potential operational savings of hundreds of thousands of dollars per year, depending on the temperature delta and unit size.

In a simulation using proprietary Shell models, SCOT ULTRA catalyst 834 has demonstrated a 50% reduction in carbon intensity and an approximately 15% higher organic sulfur yield at a 50°C lower temperature compared with using the conventional high-temperature (HT) SCOT 534 catalyst (see Figure 2).2 The information shared in Figure 2 shows that applying a more active catalyst reduces the carbon intensity as a result of lowering the operating temperature. The highest active catalyst, 934, will allow for a further reduction in carbon intensity of 10 – 20%, depending on the specifics of the unit.

Amine solvent

The choice of amine will significantly impact the overall performance of a SCOT unit. In collaboration with Shell Catalysts & Technologies, Huntsman has developed JEFFTREAT ULTRA, a temperature-resilient, sterically-hindered amine solvent. When used as part of the SCOT ULTRA process, the amine solvent provides deeper H2S removal (lower SO2 emissions), more capacity, the ability to ‘slip’ more CO2, and better upset (H2S spike) resilience.

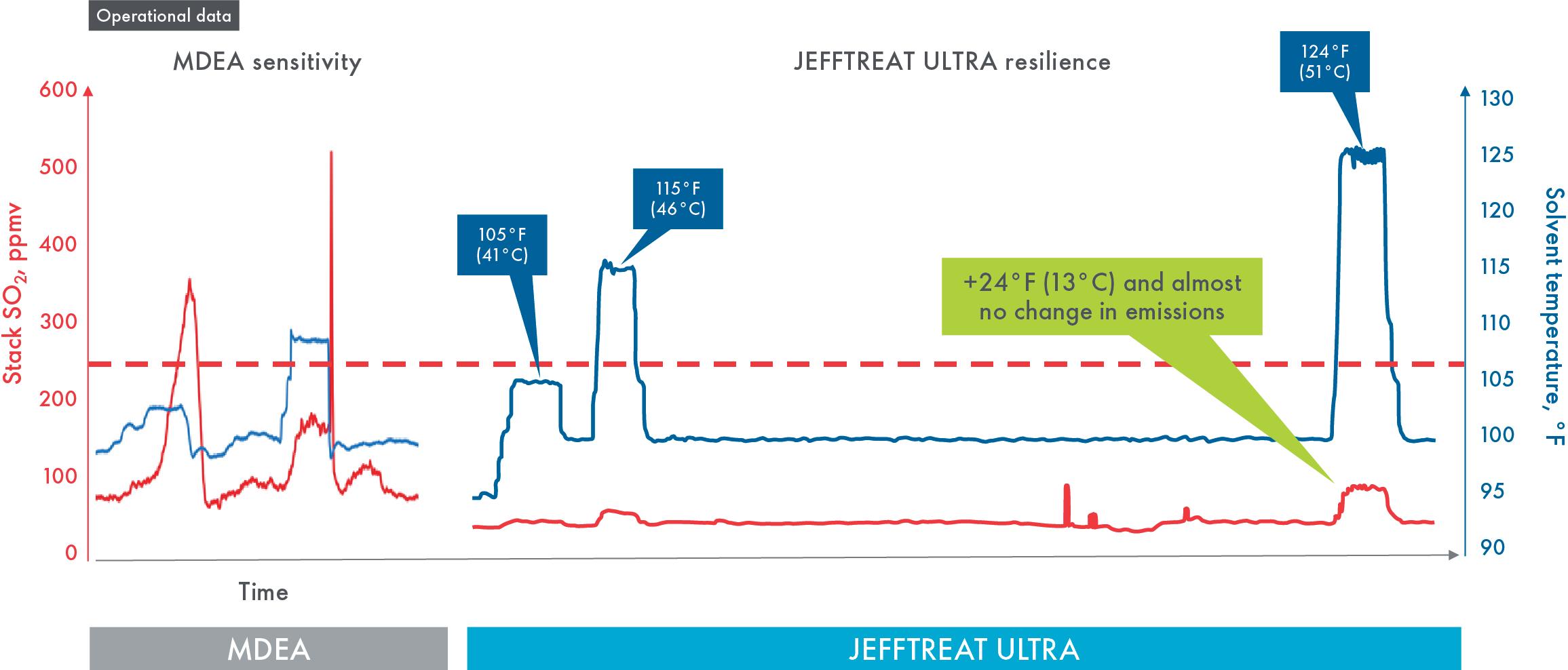

Additionally, compared to a conventional MDEA solvent, the amine solvent enables lower circulation rates for lower energy demand and superior H2S absorption performance. It can also operate at elevated temperatures, thus reducing or eliminating the need for chilling while still meeting strict SOx specifications (see Figure 3).

Catalyst and solvent integration for greater benefits

The key to the SCOT ULTRA process is the integration of a high-performance catalyst and a high-selectivity solvent, both developed through expert knowledge and operational experience. And, although both SCOT ULTRA catalysts and JEFFTREAT ULTRA can be deployed separately, applying them together, with proper integration, brings greater benefits than the sum of each part.

For example, combining SCOT ULTRA’s superior catalyst performance with JEFFTREAT ULTRA’s higher absorption capability can reduce circulation rates by 25 – 50% compared with AAR (formulated) MDEA. The combination can also help decrease the overall carbon footprint by 54% compared with using MDEA (see Figure 4). This comes from lower reboiler duty and reactor operating temperature.

Figure 3. Swapping in JEFFTREAT ULTRA eliminates the need for chilling, thereby reducing circulation rates and overall energy consumption.

Figure 4. SCOT ULTRA technology can help reduce overall carbon footprint by 54% compared with using MDEA.

Lower carbon emissions enable numerous financial benefits, including avoiding carbon levies or attracting emission reduction incentives. At a carbon cost of US$25 – 50/t of CO2, simulations based on a catalyst and solvent swap in a 250 – 500 tpd brownfield facility show a return on investment (ROI) for SCOT ULTRA of just one year. This is solely from lower carbon costs, and does not consider the additional benefits of fewer shutdowns due to greater resilience to upsets.

Case study

SCOT ULTRA technology has now been operating at multiple facilities for several years, which has provided data for the important validation of the technology’s superior performance.

In one example, a US refinery using a conventional MDEA solvent wanted to improve the operational robustness of its SCOT unit against upsets and higher temperatures. The facilities were suffering from several operational challenges, including SRU feed gas with high CO2 concentration (35 vol%) and a Claus unit with lower-than-typical sulfur recovery, resulting in increased load on the SCOT unit. Additionally, the facility was operating with lower steam rates, and emissions were base loaded by the degasser pit vent, which is routed to the incinerator.

By dropping in JEFFTREAT ULTRA as a direct replacement for the MDEA solvent, the overall performance of the SCOT unit was improved, including increased resilience against upsets and high temperatures. Figure 5 shows the unit’s sulfur emissions (red curves) before and after the solvent swap, and the solvent temperature (blue curves). The results show that, with MDEA, a modest 3°C (5°F) increase in solvent temperature caused SO2 limits to be exceeded. Additionally, they indicate that the unit was operating very close to maximum capacity. In contrast, using JEFFTREAT ULTRA, a 13°C (24°F) increase in solvent temperature led to a minimal change in the SO2 concentration. Overall stack SO2 decreased from 60 to 80 ppmv to approximately 40 ppmv.

The carbon intensity of the SCOT unit was also reduced by 54% as a result of 30% lower circulation rates and, with no drop-in absorption capacity, eliminating the need to chill the JEFFTREAT ULTRA solvent.

Moreover, with greater demands now being placed on shared refinery cooling systems, particularly during extreme heatwave events, the fact that deploying SCOT ULTRA technology can remove the SCOT unit from the cooling equation through a simple solvent swap helps to strengthen the resilience of the wider system.

By performing the simple solvent swap, the US refinery was also able to remain within SO2 limits. Figure 6 demonstrates how the same SCOT unit performed before and after swapping the MDEA solvent for JEFFTREAT ULTRA in the cases of similar H2S spikes (yellow lines that go beyond the analyser limit in both cases). In the MDEA case, SO2 (red curve) quickly exceeded the limit, resulting in the operator having to shut down the unit until the upset could be resolved.

After dropping in JEFFTREAT ULTRA, and despite the longer duration of the H2S spike, SO2 emissions remained well inside the limit, thus giving the refiner time to resolve the issue without the need to reduce throughput or shut the unit down.

Figure 5. Swapping in JEFFTREAT ULTRA increases temperature resilience and sulfur recovery compared with conventional MDEA solvents.

Figure 6. Using JEFFTREAT ULTRA enables SO2 emissions to remain well within limits, despite a prolonged H2S spike.

Key takeaways

In a cash-constrained, decarbonising world, it is important to select proven technologies that can help to reduce the carbon intensity of refineries and gas processing units, as well as meet stringent SOx specifications.

SCOT ULTRA technology enables the reactor section of a SCOT unit to operate at lower temperatures (less energy for heating), and the absorber section to operate at higher temperatures and capacity (less energy for cooling and circulation). This enables greater resilience to upset and cooling challenges, and the flexibility to handle turndowns, changing crude slates and upstream gas composition.

Notes

1. SCOT is a Shell trademark. 2. The modelled scenario is a Middle Eastern gas plant with a high ambient temperature, a lean acid gas feed to the SRU (54 mol% H2S, 34 mol% CO2, trace hydrocarbons and the rest water), a 250 tpd sulfur capacity and the need to achieve 99.9% sulfur recovery.